A2 S Mini Master

A2 S G Master

A2 SFE1 / A2 SGE1

101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

0456 552 981111001

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Valid from Serial NO 740 XXX--XXXX

SVENSKA 3..............................................

DANSK 17................................................

NORSK 31................................................

SUOMI 45................................................

ENGLISH 59..............................................

DEUTSCH 73.............................................

FRANÇAIS 88.............................................

NEDERLANDS 103.........................................

ESPAÑOL 118..............................................

ITALIANO 133..............................................

PORTUGUÊS 148..........................................

ЕЛЛЗНЙКБ 163.............................................

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

-- 2 --

ENGLISH

1 DIRECTIVE 60........................................................

2SAFETY 60...........................................................

3 INTRODUCTION 61...................................................

3.1 General 61..................................................................

3.2 Definitions 61................................................................

3.3 Technical data 62............................................................

3.4 Welding method 62...........................................................

3.5 Equipment 63................................................................

4 INSTALLATION 64....................................................

4.1 General 64..................................................................

4.2 Mounting 64.................................................................

4.3 Connections 64..............................................................

5 OPERATION 66.......................................................

5.1 General 66..................................................................

5.2 Starting work 66..............................................................

5.3 Conversion of A2 SFE1 (Submerged arc welding) to MIG/MAG welding 70...........

5.4 Conversion of A2 SFE1 (Submerged arc welding) to Twin--arc 70...................

6 MAINTENANCE 70....................................................

6.1 General 70..................................................................

6.2 Daily 70.....................................................................

6.3 Regularly 71.................................................................

7 FAULT TRACING 71...................................................

8 ACCESSORIES 72....................................................

9 ORDERING OF SPARE PARTS 72......................................

WEAR COMPONENTS 178.................................................

SPARE PARTS LIST 179...................................................

TOCe

-- 5 9 --

GB

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, 695 81 Laxå, Sweden, gives its unreserved guarantee

that automatic welding machine A2 SFE1 / A2 SGE1 from serial number 740 complies with standard EN 60292, in accordance with the requirements of directive

(89/392/EEA) and addendum.

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Laxå 97--09--29

Paul Karlsson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584

12336

2SAFETY

Users of ESAB automatic welding machines have ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions.

The following recommendations should be observed in addition to the standard regulations that apply

to the work place.

All work must be carried out according to the specified instructions by personnel who are thoroughly

familiar with the operation of the welding machine.

Incorrect or unintentional operation of the equipment may lead to a hazardous situation which can

result in injury to the operator and damage to the equipment.

1. Anyone who uses the automatic welding machine must be familiar with:

S its operation

S the location of emergency stops

S its function

S relevant safety precautions

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the machine when it is started

up.

S that no--one is in a hazardous position when the carriage or slide mechanisms are operated.

3. The work place must:

S be clear of mechanical components, tools, or other obstructions that could prevent the oper-

ator from moving freely within the working area.

S be organized so that there is free access to the emergency stop.

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, etc., which could become

trapped.

5. General precautions

Live electrical components are normally shielded from accidental contact.

S Make sure the return cable is connected securely.

S Work on high voltage components may only be carried out by a qualified electrician.

S Appropriate fire extinguishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during its operation.

dha5d1ea

-- 6 0 --

GB

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

3 INTRODUCTION

3.1 General

All the automatic welding machines included in this instruction manual are designed

for SAW and MIG/MAG welding of butt and fillet joints.

ESAB’s welding heads are of the A2 S type and are intended for use in combination

with A2--A6 Process Controller and ESAB’s welding power sources LAF and TAF.

The welding head can be positioned horizontally and vertically with the linear slides.

The angular position is adjusted with the angular slide.

3.2 Definitions

SAW welding The weld bead is protected by a cover of flux during the

welding.

SAW Light duty Permits welding with lower current load and thinner wire.

MIG/MAG welding The weld bead is protected by shielding gas during wel-

ding.

Tandem welding Welding with two welding heads.

Twinarc weldin g Welding with two wires in the same welding head.

dha5d1ea

-- 6 1 --

GB

3.3 Technical data

A2 SFE1 A2 SGE1

Submerged--arc MIG/MAG

LD D20

Rated load 100% 800 AAC/DC 600 A AC/DC

Wire dimensions:

solid single wire 1.6--4.0 mm 0.8--2.5 mm

flux--cored wire 1.6--4.0 mm 1.2--3.2 mm

twin wire 2x1.2--2.0 mm --

Wire feed speed 0.2--9.0 m/min 0.2--16 m/min

Brake drum braking torque 1.5 Nm 1.5 Nm

Max weight, wire 2x30 kg 2x30 kg

Flux hopper capacity

(Must not be filled with preheated flux)

Weight (flux and wire excluded) 50 kg 15 kg

Sideways tilt, max. 25_ 25_

6l --

Setting length of slide *

manual drive

*) NB! Other lengths on request.

90 mm 90 mm

3.4 Welding method

Submerged arc welding (SAW)

For submerged arc welding, the A2 SF welding head is always to be used.

S Submerged arc Light duty

Submerged arc light duty, with a 20 mm connector, which permits a load of up

to 800 A (100%).

This version can be equipped with feed rollers for single or twin wire welding

(twin--arc). A special knurled feed roller is available for flux--cored wire, which

guarantees even wire feed without the risk of deformation due to high feed pressure.

MIG/MAG welding

For MIG/MAG welding the A2 SG welding head is always used, permitting a max.

load of 600 A. The welding head is water--cooled, with the cooling water supplied by

hoses from connections intended for the purpose.

dha5d1ea

-- 6 2 --

GB

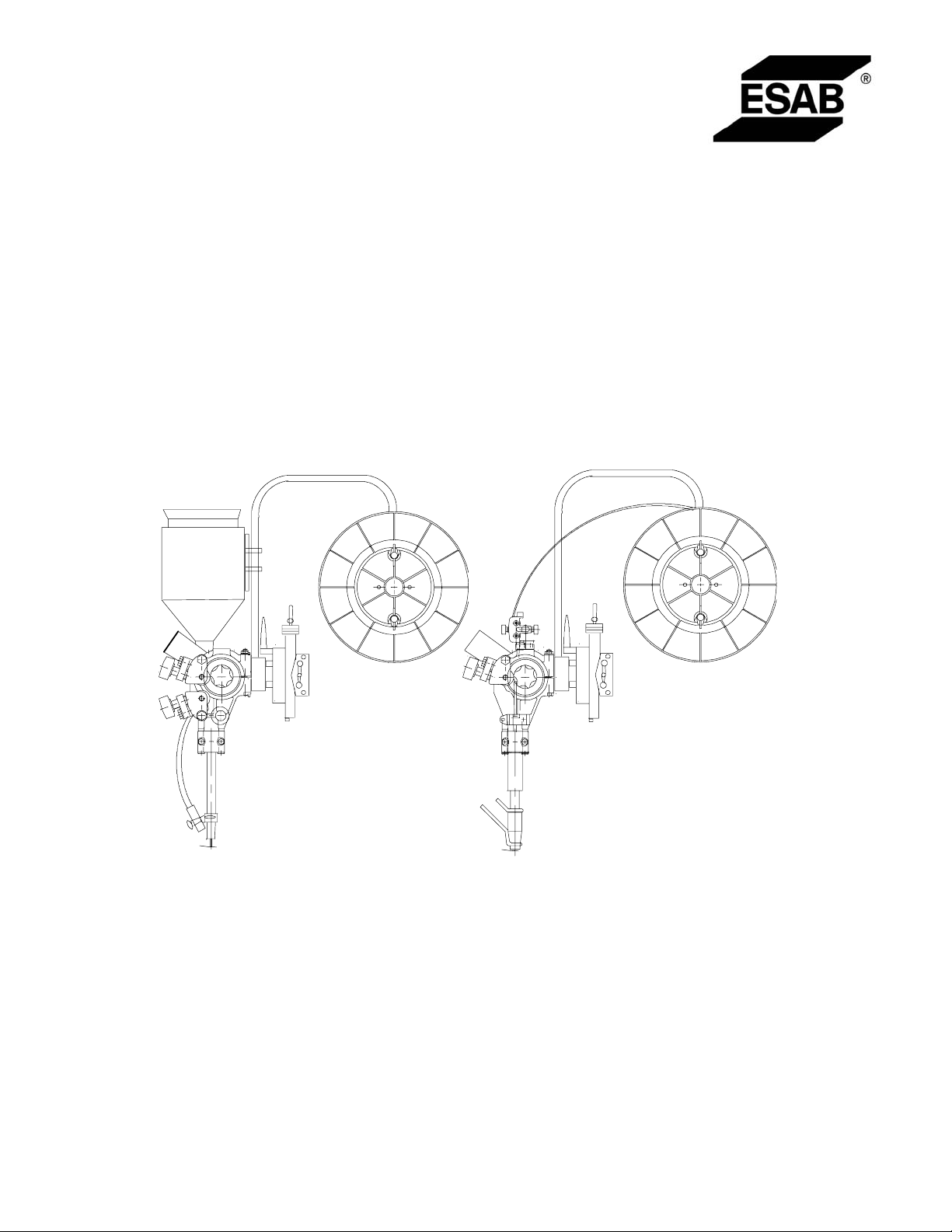

3.5 Equipment

The complete welding head includes a feed motor for the wire feed and contact

equipment supplying current to the wire and ensuring good contact.

The contact equipment is available in different versions.

S A2 SF is used for Submerged arc welding.

S A2 SG is used for MIG/MAG welding.

Example -- A2 SFE1

1. Wire straightener

2. Contact equipment consisting of

contact tip, connector and flux tube

3. Angular slide

4. Slide

5. Feed motor

6. Wire drum

7. Flux hopper (may be fitted with a cyclone)

Example -- A2 SGE1

1. Wire straightener

2. Contact equipment consisting of

connector, gas nozzle and water

hoses.

3. Angular slide

4. Slide

5. Feed motor

6. Wire drum.

7. Fine--wire straightener

8. Wire guide

Connection instructions for SAW and MIG/MAG welding appear from the system

diagram on page 64.

dha5d1ea

-- 6 3 --

GB

4 INSTALLATION

4.1 General

Installation shall only be performed by qualified personnel.

WARNING!

Rotating parts can cause injury, take great care.

4.2 Mounting

The automatic welding machines can easily be fitted on a rail--borne carriage or on a

column and boom unit with 4 screws.

4.3 Connections

1. The connection of the A2--A6 Process Controller (PEH) to the welding machine

shall be done according to the connection instructions in the A2--A6 Process

Controller (PEH) service manual.

For further information, see instruction manual for the A2--A6 Process Controller

(PEH).

2. Connect the A2 welding heads as follows:

SUBMERGED ARC WELDING (SAW)

S Connect the control cable (7) between the welding power source (8) and the

A2--A6 Process Controller (PEH) (2).

S Connect the return cable (11) between the welding power source (8) and the

work piece (9).

S Connect the welding cable (10) between the welding power source (8) and

the automatic welding machine (1).

S Connect the measuring cable (12) between the welding power source (8)

and the work piece (9).

dha5d1ea

-- 6 4 --

GB

GAS METAL ARC WELDING (MIG/MAG)

S Connect the control cable (7) between the welding power source (8) and the

A2--A6 Process Controller (PEH) (2).

S Connect the return cable (11) between the welding power source (8) and the

work piece (9).

S Connect the welding cable (10) between the welding power source (8) and

the automatic welding machine (1).

S Connect the gas hose (5) between the reduction valve (6) and the gas valve

on the automatic welding machine (13).

S Connect the hoses for cooling water (3) between the cooling unit (4) and the

automatic welding machine (1).

S Connect the measuring cable (12) between the welding power source (8)

and the work piece (9).

dha5d1ea

-- 6 5 --

GB

5 OPERATION

5.1 General

General safety regulations for the handling of the equipment appear from

page 60. Read through before you start using the equipment!

S Select wire type and flux powder or shielding gas so that the weld material is as

close as possible to the analysis of the base metal. Select wire size and welding

data in accordance with the values recommended by the welding materials

supplier.

S Thorough preparation of the weld surfaces is necessary to achieve a good weld.

NOTE! The width of the weld joint gap must be uniform.

S To minimise the risk of heat crack formation, the width of the weld must be

greater than the penetration depth.

S Always carry out a test weld with the same joint type and sheet thickness as the

production work piece.

S For control and adjustment of the automatic welding machine and welding power

supply, see the instruction manual for the A2--A6 Process Controller (PEH).

S When changing consumables, see table on page 178.

5.2 Starting work

Loading the welding wire

S Remove the wire drum (1) from the brake hub (2)

and take off the side plate (3).

S Locate the wire reel on the wire drum (1).

S Cut off the binding wires from around the

wire reel.

S Replace the side plate (3).

S Replace the wire drum (1) on the brake hub (2).

Check that the carrier (4) is in the correct position.

NOTE! The maximum angle for the wire bobbin is 25q.

At extreme angles, wear will occur on the brake hub locking

mechanism and the wire bobbin will slide off the brake hub.

IMPORTANT!

To prevent the reel sliding off the hub: Lock the reel in place

by turning the red knob as shown on the warning label attached next to the

hub.

dha5d1ea

-- 6 6 --

GB

SAW MIG/MAG

S Check that the feed roller (1) and contact jaw or contact tip (3) are of the correct

dimension for the selected wire size.

S Pull the end of the wire through the straightener (2). For a wire diameter greater

than 2 mm; straighten out 0.5 m of wire and feed it by hand down through the

straightener.

S Locate the end of the wire in the feed roller (1) groove.

S Set the wire tension on the feed roller with the knob (7). Note! Do not tension

more than is required to achieve an even feed.

S Feed the wire forward 30 mm by pressing

on the control box A2--A6

Process Controller.

S Direct the wire by adjusting the knob (6).

For fine wire, the special fine--wire straightener (4) is used for both single and

twin wire.

Ensure that the straightener is correctly adjusted so that the wire emerges

straight out through the contact jaws or contact tip.

Always use a guide tube (5) to ensure even feed of fine wire (1.6 -- 2.5 mm).

For MIG/MAG welding with wire sizes < 1.6 mm , use a guide spiral, which is

inserted in the guide tube (5).

dha5d1ea

-- 6 7 --

GB

Changing the feed roller

S Single wire

S Release the knobs (3) and (4).

S Release the hand wheel (2).

S Change the feed roller (1). They are marked with their

respective wire sizes.

S Twin wire (Twin--arc)

S Change the feed roller (1) with twin grooves in the same way as for single

wire.

S NOTE! T he pressure roller (5) must also be changed. A special curved

pressure roller for twin wire replaces the standard pressure roller for single

wire.

S Assemble the pressure ro ller with special stub shaft

(order no. 0146 253 001).

S Flux--cored wire (for knurled rollers)

S Change the feed roller (1) and pressure roller (5) as a pair for the wire size

to be used. NOTE! A special stub shaft is required for the pressure roller

(order no. 0212 901 101).

S Tighten the pressure screw (4) with moderate pressure to ensure that the

flux--cored wire does not deform.

Contact equipment for Submerged arc welding

S For single wire 3.0 -- 4.0 mm. Light duty (D20)

Use the straightener (3), connector (1) D20 with

contact tip (2) (M12 thread).

S Tighten the contact tip (2) with a key in order to ensure

that a good contact is achieved.

S For single wire 1.6 -- 2.5 mm Submerged--arc

Light duty (D20)

Use the straightener (3), connector (1) D20 with contact

tip (2) (M12 thread) and separate fine--wire straightener (4)

with guide tube (6).

S Assemble the clamp (7) with guide tube (6) in the M12

hole on the straightener (3). The guide tube (6) should

bottom on the contact tip (2).

S If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

S Assemble the fine--wire straightener (4) on the upper

side of the clamp for the straightener (3).

dha5d1ea

-- 6 8 --

GB

S Fortwinwires2x1.2--2.0mm,LightTwin(D35)(Accessories)

Use the straightener (3), connector (1) D35 with

twin adapter (9) and 2 contact tips (2) (M6 threads)

and separate fine--wire straightener (4) with two guide

tubes (6). For twin wires <1.6 mm, a guide spiral,

inserted into each guide tube, is used.

S Assemble the twin adapter (9) for M6 contact tips (2)

with the M5 bolts in the fixed half of the two--piece

connector (1).

S Assemble the clamp (7) with guide tube (6) in the M12 hole

on the standard straightener (3). The guide tube should

bottom on the twin adapter (9) for the contact tip (2).

S Tighten the contact tip (2) with a key to ensure that good

contact is achieved.

S If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

S Adjustment o f the wires for Twin--arc weld in g :

S Position the wires in the joint so as to achieve optimal weld quality by

rotating the connector. The two wires can be rotated so that they are

positioned one after the other along the line of the joint, or in any position

up to 90q across the joint, i.e. one wire on each side of the joint.

Contact equipment for MIG/MAG welding

S For single wire 1.6 -- 2.5 mm (D35)

Use the straightener (3), connector (1) D35 with contact

tip (2) (M10 thread).

S Tighten the contact tip (2) with a key to ensure that good

contact is achieved.

S Assemble the clamp (7) with guide tube (6) in the M12

hole on the standard straightener (3). The guide tube (6)

should bottom on the contact tip (2).

S If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

S For single wire < 1.6 mm (D35)

Use the straightener (3), connector (1) D35 with contact tip (2)

(M12 thread), fine--wire straightener (4) with guide tube (6)

and guide spiral, which is inserted in the guide tube (6).

S Assemble the clamp (7) with guide tube (6) in the M12

hole on the standard straightener (3). The guide tube (6)

should bottom on the contact tip (2).

S If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

S Assemble the fine--wire straightener (4) on the upper

side of the clamp for the straightener (3).

S Connect the cooling water and gas (MIG/MAG welding).

dha5d1ea

-- 6 9 --

GB

Refilling with flux powder (Submerged arc welding)

S Close the flux valve on the flux hopper.

S Remove the cyclone on the flux recovery unit, if fitted.

S Fill with flux powder. NOTE! The flux powder must be dry. Where possible avoid

using agglomerating flux powder outdoors and in damp environments.

S Position the flux tube so that it does not become kinked.

S Adjust the height of the flux nozzle above the weld so that the correct amount of

flux is delivered.

Flux coverage should be sufficient so that penetration of the arc does not occur.

5.3 Conversion of A2 SFE1 (Submerged arc welding) to MIG/MAG

welding

S Assemble in accordance with the instructions accompanying the conversion kit.

5.4 Conversion of A2 SFE1 (Submerged arc welding) to Twin--arc

S Assemble in accordance with the instructions accompanying the conversion kit.

6 MAINTENANCE

6.1 General

NB! Before doing any kind of maintenance work, make sure the mains is

disconnected.

For the maintenance of the A2--A6 Process Controller (PEH), see the instruction

manual.

6.2 Daily

S Clean flux and dirt off moving parts of the welding machine.

S Check that the contact tip and all electrical cables are connected.

S Check that all bolted joints are tight and that guides and drive rollers are not

worn or damaged.

S Check the brake hub braking torque. It should not be so low, that the wire reel

continues to rotate when wire feed is stopped and it should not be so great that

the feed rollers slip. As a guide, the braking torque for a 30 kg wire reel should

be 1.5 Nm.

Adjusting the braking torque:

S Set the locking button (2) to the

locked position.

S Insert a screwdriver into the hub

springs.

S Turning the springs (1) clockwise

reduces the braking torque.

S Turning the springs anticlockwise increases the torque.

NOTE! Turn the springs by the same amount.

dha5d1ea

-- 7 0 --

GB

6.3 Regularly

S Check the wire feed motor brushes once every three months. Replace when

they are worn down to 6 mm.

S Examine the slides and lubricate if they bind.

S Inspect the wire guides, drive rollers and contact tip on the wire feed unit.

Replace any worn or damaged components, (see spare parts list on page 179).

7 FAULT TRACING

Equipment S Instruction manual for A2--A6 Process Controller.

Check S that the power supply is connected for the correct mains supply

S that all three phases are supplying the correct voltage

(phase sequence is not important)

S that welding cables and connections are not damaged

S that the controls are correctly set

S that the mains supply is disconnected before starting repairs

POSSIBLE FAULTS

1. Symptom Current and voltage readings show large fluctuations

Cause 1.1 Contact jaws or nozzle are worn or wrong size.

Action Replace contact jaws or nozzle.

Cause 1.2 Feed roller pressure is inadequate.

Action Increase pressure on feed rollers.

2. Symptom Wire feed is irregular

Cause 2.1 Pressure on feed rollers incorrectly set.

Action Pressure on feed rollers incorrectly set.

Cause 2.2 Feed rollers wrong size.

Action Replace feed rollers.

Cause 2.3 Grooves in feed rollers are worn.

Action Replace feed rollers.

3. Symptom Welding cables o verheating

Cause 3.1 Poor electrical connection.

Action Clean and tighten all electrical connections.

Cause 3.2 Cross--sectional area of welding cables too small.

Action Use cables with a larger cross--section or use parallel cables.

dha5d1ea

-- 7 1 --

GB

8 ACCESSORIES

Slide 0413 518 880................................................................

Angular slide 0413 506 880........................................................

Contact equipment for twin wire 2x1.2 -- 2x2.0 Light duty 0333 852 881.................

Fine--wire straightener 0332 565 880................................................

Conversion kit A2 SFE1 to MIG/MAG welding 0413 526 881...........................

Conversion kit A2 SFE1 to Twin with fine--wire straightener (LD) 0413 541 882...........

Pilot lamp (D20) 0153 143 886......................................................

Adapter M6/M10 0147 333 001.....................................................

9 ORDERING OF SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list on page 179.

This will simplify dispatch and ensure you get the right part.

dha5d1ea

-- 7 2 --

Slitdelar Sliddele Slitedeler Kulutusosat Wear components Verschleissteile Pièces d’usure Slijtageonderdelen Piezas de desgaste Parti di usura Peças expostas a desgaste Бнблюуймб бнфбллбкфйкЬ

D (mm) D (mm)

2185 102--81 1,6 2185 224--80 2,5

2185 102--82 2,0 2185 224--84 2,0

2185 102--83 2,5 2185 224--86 1,2

2185 102--86 4,0 2185 224--88 1,6

2185 102--98 3,0--3,2

146 024--880 0,8--1,6 146 025--880 0,8--1,6

146 024--881 2,0--4,0 146 025--881 2,0--4,0

БнблЩуймб бнфбл лбкфйкБ

154 623--003 4,0 153 501--002 0,8

154 623--004 3,2 153 501--004 1,0

154 623--005 3,0 153 501--005 1,2

154 623--006 2,5 153 501--007 1,6

154 623--007 2,0 153 501--009 2,0

154 623--008 1,6 153 501--010 2,4--2,5

145 538--880 0,6 2129 011--01

145 538--881 0,8

145 538--882 1,0 146 253--001

145 538--883 1,2

148 772--880 2,0--3,0

dha4s11a

-- 1 7 8 --

Reservdelsförteckning Reservedelsfortegnelse Reservedelsliste Varaosaluettelo Spare parts list Ersatzteilliste Liste de pièces détachées

Reserveonderdelenlijst Lista de repuestos Elenco ricambi Lista de peças

sobressalentes РЯнбкбт бнфбллбкфйкюн месюн

РЙнбКБУ бнфблл бкфйкЩн месЩн

Edition 981023

A2 SFE1 A2 SGE1

Ordering no. Denomination Notes

0456 550 880 ! 0456 550 882 A2 SFE1 Without controll box PEH

0456 550 883 ! 0456 550 885 A2 SFE1 With controll box PEH

0456 555 880 ! 0456 555 882 A2 SGE1 Without controll box PEH

0456 555 883 ! 0456 555 885 A2 SGE1 With controll box PEH

dha5r11a

-- 1 7 9 --

Qty Orderingno. Denomination Notes

Item

0456 550 880

#

0456 550 882

0456 550 883

#

0456 550 885

1 1 0456 495 882 Feed unit (right) 36 rpm

2 1 0413 510 001 Contact tube

4 1 413 506 880 Rotary slide

6 4 0215 100 018 Washer

9 2 0413 518 880 Slide

10 1 0413 956 001 Attachment

11 6 0212 601 107 Nut

13 4 0192 471 104 Pipe clamp

14 1 0413 853 001 Mounting boom

17 1 0413 318 001 Holder

18 1 0332 837 001 Flux hopper

19 1 0332 948 001 Fluz tube

20 1 0333 094 880 Clamp

22 2 0154 734 001 Clamphalf

23 2 0192 238 382 Screw

25 1 0146 967 880 Brake hub

26 1 0153 872 880 Wire reel

27 1 0211 102 952 Pin

28 1 0443 741 880 Control box PEH

35 4 0278 300 180 Insulator

36 4 0192 238 530 Screw

37 4 0190 452 178 Washer

38 1 0153 347 881 Flux valve

39 1 0020 301 780 Flux strainer

40 1 0443 383 002 Flux hose L = 500

Automatic welding machine without

control box PEH

Automatic welding machine with control

box PEH (Item 28)

A2 SFE1, UP

A2 SFE1, UP

dha5r11a

-- 1 8 0 --

dha5r11a

-- 1 8 1 --

Qty Orderingno. Denomination Notes

Item

0456 555 880

#

0456 555 882

Automatic welding machin without

control box PEH

A2 SGE1, MIG/MAG

0456 555 883

#

0456 555 885

1 1 0456 495 883 Feed unit (right) 68 rpm

2 1 0030 465 389 Connector

4 1 0413 506 880 Rotary slide

6 4 0215 100 018 Washer

9 2 0413 518 880 Slide

10 1 0413 956 001 Attachment

11 6 0212 601 107 Nut

13 2 0192 471 104 Pipe clamp

14 1 0413 853 001 Mounting boom

16 2 0154 734 001 Clamp half

17 2 0192 238 382 Screw

18 1 0146 967 880 Brake hub

19 1 0211 102 952 Pin

20 1 0456 494 884 Solenoid valve

21 2 0192 238 287 Screw

22 3 0333 754 001 Hose L=750

23 6 0193 761 002 Hose clamp

24 2 0147 336 880 Hose coupling

26 1 0443 741 880 Control box PEH

33 4 0278 300 180 Insulator

34 4 0192 238 530 Screw

35 4 0190 452 178 Washer

Automatic welding machine with control

box PEH (Item28)

A2 SGE1, MIG/MAG

dha5r11a

-- 1 8 2 --

dha5r11a

-- 1 8 3 --

Qty. Ordering no. Denomination Notes

Item

no.

0456 495 888

0456 495 889

4 0334 339 001 Cable fixture

6 0334 678 001

0334 678 002

8 0456 493 881 Control cable L=1,5

19 0413 517 001 Bracket Motor Attachment

21 0413 072 881 Bearing housing

22 0147 639 882 Straightener right D=20

24 0218 810 183 Insulated hand wheel

25 0456 504 882 Arc voltage cable

Wire feeder unit

Wire feeder unit

Motor 24 V

Motor gear

36 rpm

68 rpm

36 rpm

68 rpm

dha5r11a

-- 1 8 4 --

Qty Orderingno. Denomination Notes

Item

413 072--881 Bearing housing with stub shaft

1 1 413 073--002 Searing housing

2 2 190 726--003 Ball bearing

3 1 334 575--001 Stub shaft

4 1 2157 010--14 Betaining ring D17

5 3 334 576--001 Spacer

dha5r11a

-- 1 8 5 --

Qty Orderingno. Denomination Notes

Item

147 639--882 Straightener (right)

01 1 156 449--001 Clamp

02 1 Screw M10x100

03 1 Washer D22/10.5x2

04 1 2155 036--01 Insulating sleeve

06 2 2129 000--01 Spacer screw

07 4 2152 012--09 O--ring D11.3x2.4

08 2 2184 008--01 Pressure roller arm

09 1 2188 101--81 Handwheel

10 1 2188 101--82 Handwheel

11 3 332 408--001 Stub shaft

13 3 153 148--880 Roller

14 1 415 498--001 Thrust roller carrier

15 2 2129 026--01 Spacer screw

16 1 415 499--001 Thrust roller carrier

19 2 Spring washer D18.1/10.2

20 1 Screw M16x50

21 1 Washer

23 1 334 571--880 Contact clamp

30 1 Nut M10

31 9 Washer D22/13x2

33 2 Screw M10x30

dha5r11a

-- 1 8 6 --

Qty Orderingno. Denomination Notes

Item

0413 518 880 Slide

1 1 0413 519 001 Slide profile

2 1 0413 524 001 Bearing bushing

3 1 0413 521 001 Flunner

4 1 0145 862 001 Nut

5 1 0413 522 001 lead screw

6 1 0190 452 165 Washer

7 1 0334 537 002 Crank

8 1 0211 102 938 Boll pin D3x20

9 2 0413 523 001 Axis

10 4 0193 104 003 Rivet washer

12 1 0215 100 013 Washer

17 4 0190 240 107 Bearing

dha5r11a

-- 1 8 7 --

Qty Orderingno. Denomination Notes

Item

0030 465 389 Connector

02 1 0145 226 001 Insulating sleeve

03 1 0190 680 313 Oring OR 15.3x2.4

04 1 0190 680 303 Oring OR 5.3x2.4

05 1 0190 680 405 Oring OR 22.2x3

08 1 0334 278 880 Insert tube

09 1 0334 279 001 Spiral

22 1 0146 099 001 Plug

23 1 0145 534 882 Contact tube

24 1 0145 227 882 Gas nozzle

25 1 0144 998 882 Water hose L = 180

39 1 0040 979 804 Extension L = 108

dha5r11a

-- 1 8 8 --

Qty Orderingno. Denomination Notes

Item

0456 494 884 Solenoid valve with cable

2 1 0157 259 002 Contact

7 3 0262 613 401 Cable

8 1 0456 489 001 PCB Connector, plug

12 1 0193 054 002 Solenoid valve 42 V

20 1 0192 645 002 Bushing

dha5r11a

-- 1 8 9 --

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 726 80 05

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Prague

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Copenhagen--Valby

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 204

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NETHERLANDS

ESAB Nederland B.V.

Utrecht

Tel: +31 30 248 59 22

Fax: +31 30 248 52 60

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.z.o.o

Warszaw

Tel: +48 22 813 99 63

Fax: +48 22 813 98 81

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 1 837 1527

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcobendas (Madrid)

Tel: +34 91 623 11 00

Fax: +34 91 661 51 83

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB International AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 333 43 33

Fax: +55 31 361 31 51

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 44 58

Asia/Pacific

AUSTRALIA

ESAB Australia Pty Ltd

Ermington

Tel: +61 2 9647 1232

Fax: +61 2 9748 1685

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 6539 7124

Fax: +86 21 6543 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. Esabindo Pratama

Jakarta

Tel: +62 21 460 01 88

Fax: +62 21 461 29 29

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 703 36 15

Fax: +60 3 703 35 52

SINGAPORE

ESAB Singapore Pte Ltd

Singapore

Tel: +65 861 43 22

Fax: +65 861 31 95

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 861 74 42

Fax: +65 863 08 39

SOUTH KOREA

ESAB SeAH Corporation

Kyung--Nam

Tel: +82 551 289 81 11

Fax: +82 551 289 88 63

THAILAND

ESAB (Thailand) Ltd

Samutprakarn

Tel: +66 2 393 60 62

Fax: +66 2 748 71 11

UNITED ARAB EMIRATES

ESAB Middle East

Dubai

Tel: +971 4 338 88 29

Fax: +971 4 338 87 29

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA--CIS

ESAB Representative Office

Moscow

Tel: +7 095 937 98 20

Fax: +7 095 937 95 80

ESAB Representative Office

St Petersburg

Tel: +7 812 325 43 62

Fax: +7 812 325 66 85

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

ESAB Welding Equipment AB

SE--695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

Fax +46 584 123 08

www.esab.com

001004

Loading...

Loading...