Page 1

A2- A6

Process Controller

PEH

101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

0443 745 001 000615

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

ПдзгЯет чсЮуещт

Valid for machine no 724 XXX--XXXX

Valid for program version PEH 1.00A, PEH1.1, PEH1.2, PEH2.0

Page 2

SVENSKA 3..............................................

DANSK 22................................................

NORSK 41................................................

SUOMI 60................................................

ENGLISH 79..............................................

DEUTSCH 98.............................................

FRANÇAIS 117.............................................

NEDERLANDS 137.........................................

ESPAÑOL 156..............................................

ITALIANO 176..............................................

PORTUGUÊS 195..........................................

ЕЛЛЗНЙКБ 214.............................................

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

ДйбфзсеЯфбй фп дйкбЯщмб фспрпрпЯзузт рспдйбгсбцюн ЧщсЯт рспейдпрпЯзуз.

-- 2 --

Page 3

ENGLISH

1 DIRECTIVE 80........................................................

2SAFETY 80...........................................................

3 INTRODUCTION 82...................................................

3.1 General 82..................................................................

3.2 Welding power sources 82.....................................................

3.3 Technical data 82............................................................

4 INSTALLATION 83....................................................

4.1 General 83..................................................................

4.2 Motor connections for the wire feed motor, M1 83.................................

4.3 Motor connections for travel motion (travel motor M2) 83..........................

4.4 Connection of flux or gas valve 84..............................................

4.5 Connection of welding power source 84.........................................

4.6 Connection of the welding head 84.............................................

5 OPERATIONAL DESCRIPTION 85......................................

5.1 General 85..................................................................

5.2 Control panel 85.............................................................

6 MANUAL OPERATION 86..............................................

6.1 Travel and wire feed 86.......................................................

6.2 Controlling valves 86..........................................................

7 MENUS 87...........................................................

7.1 Menu overview 87............................................................

8MAINMENU 88.......................................................

8.1 Entering welding parameters 89................................................

8.2 Adjusting parameter values (during welding) 90..................................

8.3 Choosing a new set of parameters during welding 91..............................

9 WELDING SETUP 92..................................................

9.1 General 92..................................................................

9.2 Available settings 93..........................................................

9.3 Definitions 94................................................................

9.4 Preset indicators 96..........................................................

10 ERROR LIST 97.......................................................

10.1 Error codes 97...............................................................

11 ORDERING SPARE PARTS 97..........................................

DIAGRAM 234............................................................

ACCESSORIES 236.......................................................

SPARE P ARTS LIST 237...................................................

TOCe

-- 7 9 --

Page 4

GB

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, 695 81 Laxå, Sweden, gives its unreserved guarantee

that control unit A2--A6 Process Controller from serial number 724 complies with

standard EN 60974--1, in accordance with the requirements of directive (73/23/EEA)

and addendum (93/68/EEA).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Laxå 97--05--30

Paul Karlsson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 12336

2SAFETY

Users of ESAB welding equipment have the ultimate responsibility for ensuring that anyone who

works on or near the equipment observes all the relevant safety precautions.

Safety precautions must meet the requirements that apply to this type of welding equipment.

The following recommendations should be observed in addition to the standard regulations that apply

to the work place.

All work must be carried out by trained personnel well familiar with the operation of the welding equipment.

Incorrect operation of the equipment may lead to hazardous situations which can result in injury to the

operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S location of emergency stops

S its function

S relevant safety precautions

S welding

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment when it is

started up.

S that no--one is unprotected when the arc is struck

3. The work place must:

S be suitable for the purpose

S be free from draughts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety glasses, flame--proof

clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which could become

trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment shall only be carried out by a qualified electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close at hand.

S Lubrication and maintenance must not be carried out on the equipment during operation.

fgb7safe

-- 8 0 --

Page 5

GB

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERATING.

PROTECT YOURSELF AND OTHERS!

WARNING

This product is intended for industrial use. In a domestic environment this

product may cause radio interference. It is the user’s responsibility to take

adequate precautions.

fgb7safe

-- 8 1 --

Page 6

GB

3 INTRODUCTION

3.1 General

ESAB’s A2--A6 Process Controller (PEH) is a control unit which, when combined with

A2--A6 automatic welding equipment can be used for submerged--arc or MIG/MAG

welding.

The process controlle r is designed for use with ESAB’s LAF and TAF welding power

sources. Close integration of the control system with the welding power source

makes it possible to ensure very precise process reliability.

All the controls that are needed to control welding travel and the entire welding

process are situated on the control panel.

Incoming cables from various system components are connected to sockets at the

rear of the process controller or to the circuit board terminals inside the controller.

3.2 Welding power sources

The welding power sources are specially adapted to work with the A2--A6 Process

Controller. T he welding power source and process controller are connected by a twin

wire bus that allows the welding process to be controlled and monitored much more

precisely than previously possible. T he power source settings can be adjusted from

the control panel on the process controller.

ESAB’s earlier generation of welding power sources, such as the LAH, LAE and TAE

can be adapted for use with the new process controller with the aid of a conversion

kit. The new welding power sources are already prepared for straightforward

connection to the A2--A6 Process Controller (PEH). The welding power sources also

supply the correct current to the process controller, thus eliminating the need for any

external power supply.

3.3 Technical data

A2--A6 Process Controller (PEH)

Nominal voltage from power source: 42V AC 50/60 Hz

Nominal load: Max. 900 V A

Motor connections adapted for ESAB’s

A2-- or A6-- motors:

Wire speed regulation: Internal EMK control or with AC tacho,

Welding speed: 0.1--2 m/min (depending on travel unit))

Max. manual travel speed: 2.0 m/min

Filler wire, wire feed speed: 0.3--25 m/min (depending on wire feed unit)

Ambient temperature: Max. 45_ C, Min. --15_ C

Relative humidity: Max. 98 %

Weight: 5.5 kg

Dimensions L x B x H: 355 x 210 x 164 mm

Enclosure class: IP 23

Motor current 5 A continuous, max. 10 A

6 pulses per rev

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water. Equipment marked IP 23 is designed for indoor and outdoor use.

fgb7d1ea

-- 8 2 --

Page 7

GB

4 INSTALLATION

4.1 General

The installation shall b e executed by a professional.

4.2 Motor connections for the wire feed motor, M1

A2 motor

S Motor cable, two conductors and screen, connected to connectors K10.1 and

K10.2.

S AC--Tachometer cable (accessory), two conductors and screen, connected to

connectors K10.5 and K10.6.

A6 motor

S Motor cable, four conductors and screen, connected to connectors K10.1 and

K10.2, with the field connections made to K10.3 and K10.4.

S The AC tachometer cable (accessory), is connected to connectors K10.5 and

K10.6.

4.3 Motor connections for travel motion (travel motor M2)

S Motor cable, two conductors with screen, connected to connectors K11.1 and

K11.2.

S The motor field winding is connected to K11.3 and K11.4 (with screen).

S The AC tachometer cable (accessory): two conductors and screen, connected to

K11.5 and K11.6.

Motor connections for the wire feed motor, M1

Motor connections for travel motion (travel motor M2)

fgb7i1ea

-- 8 3 --

Page 8

GB

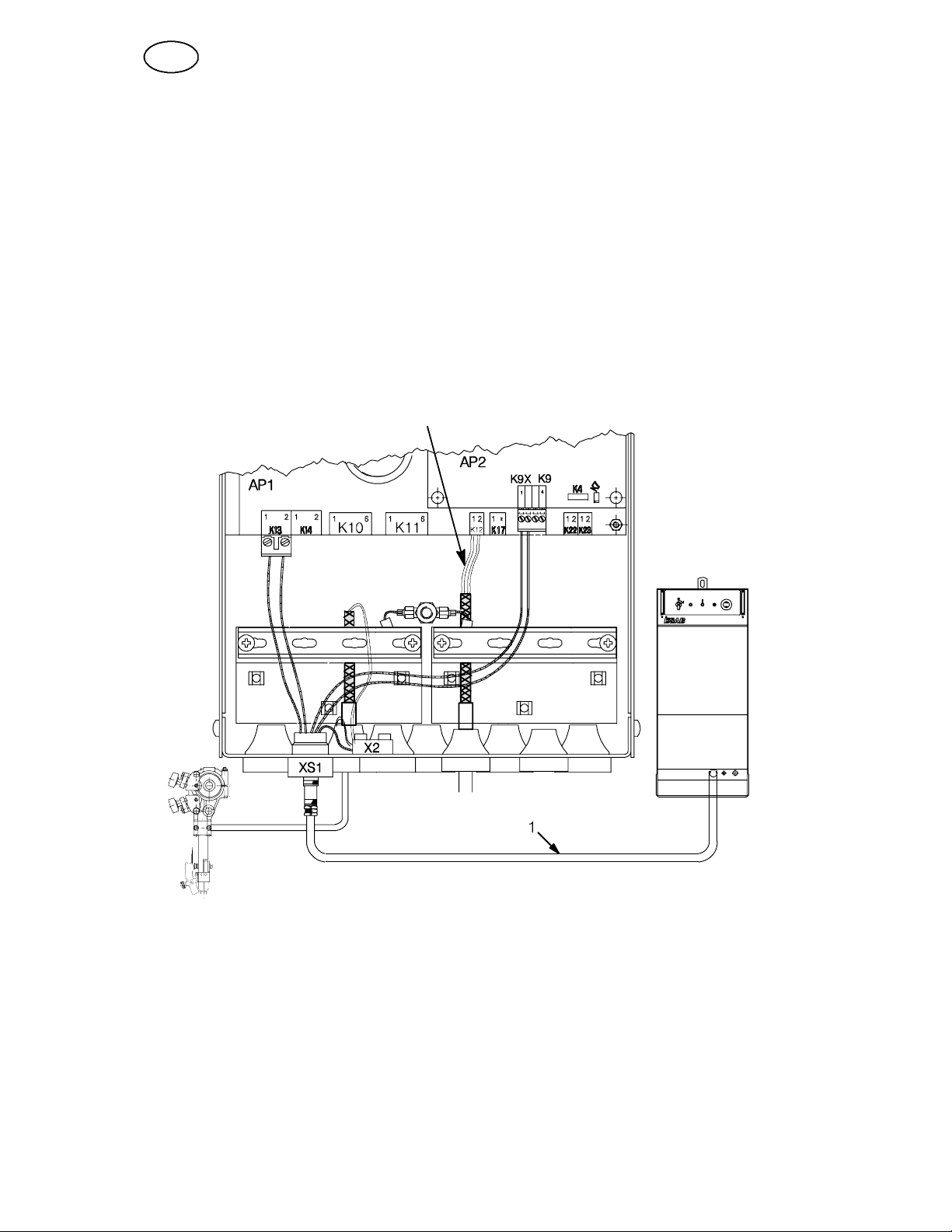

4.4 Connection of flux or gas valve

S Output for connecting a flux or gas valve, 42 V AC max. 0,5 A

2

S Screened 2--wire 2 x 0,75 mm

4.5 Connection of welding power source

S Connect control cable (1) from the welding power source to connector XS1.

4.6 Connection of the welding head

S Arc voltage to terminal X2.1

Connection of flux or gas valve

, connected to K12.1 and K12.2.

Connection of the

welding head

Connection of welding

power source

fgb7i1ea

-- 8 4 --

Page 9

GB

5 OPERATIONAL DESCRIPTION

5.1 General

Switch on welding power source

The process controller can be used in manual or automatic mode.

In manual mode the wire feed speed and travel speed are controlled manually and

you can preset all other essential welding parameters for the current weld.

In automatic mode you can choose a preset group of welding parameters and

fine--tune the actual welding parameters. Other settings made previously in manual

mode cannot be adjusted in automatic mode.

The process controller is ready for manual operation as soon as the mains power is

switched on. When welding begins the controller switches to automatic mode. When

welding stops, or if there is a fault, the controller switches back to manual mode.

5.2 Control panel

1. Emergency stop

2. Retract wire

3. Travel

4. Travel, opposite direction

5. Advance wire

6. Change menu

7. Numerical key, number entry

8. ENTER key, Change row

9. SHIFT key

10. Stop welding.

Return to manual mode

11. Start welding. Switch to automatic mode

12. F a st, wire feed or travel

13. Scroll page (welding setup menu) or close valve (main menu)

The arrowed keys are used during welding to increase or

decrease the current, voltage and speed.

By pressing either

fgb7fb1e

, ,

+

or

-- 8 5 --

+

it is possible to browse.

Page 10

GB

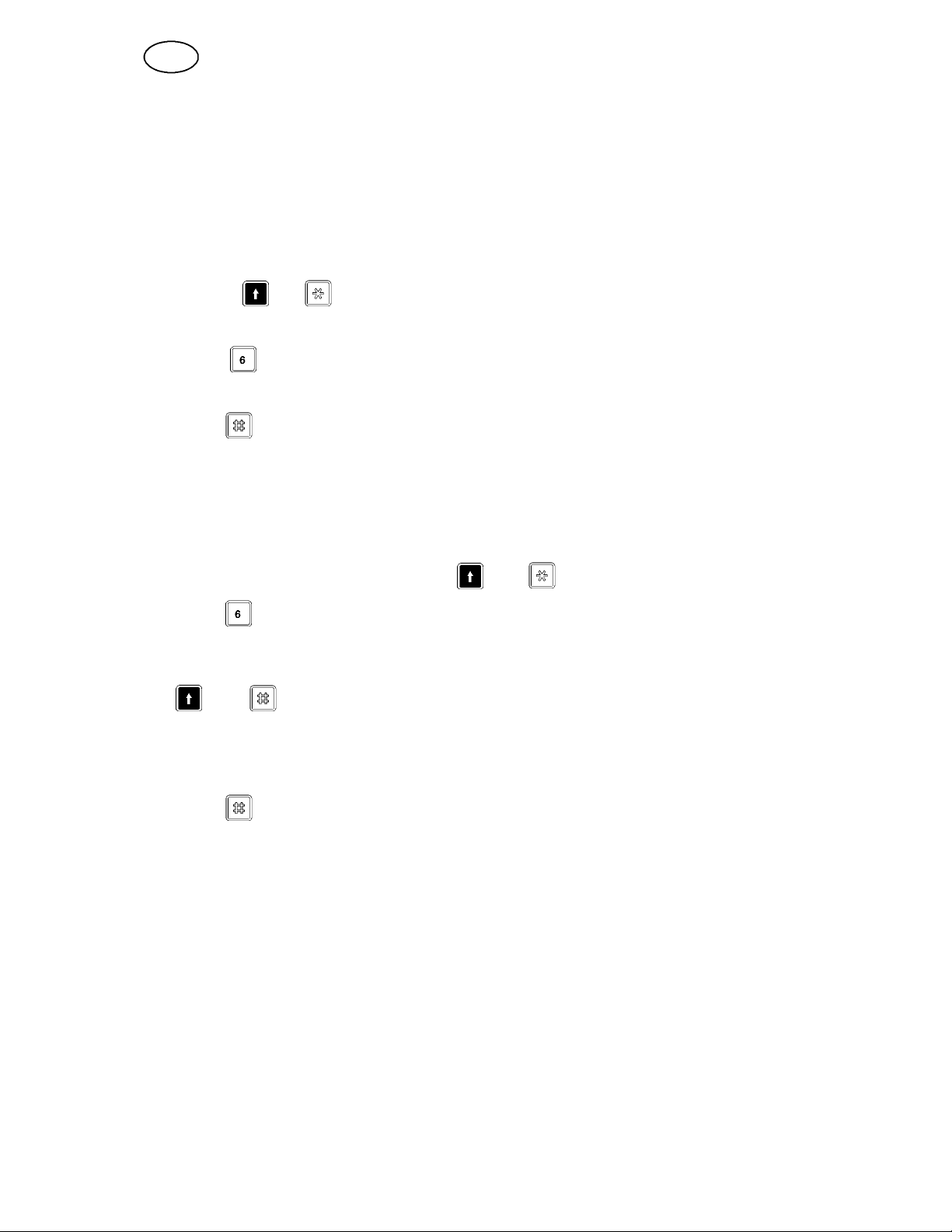

6 MANUAL OPERATION

6.1 Travel and wire feed

Travel and wire feed commands can be given when not welding, as follows:

Switch on welding power source

S The direction of travel is as shown by the square symbol on the power

source.

Normal speed

S The direction of travel is as shown by the triangular symbol on the power

source.

Normal speed

To stop travel described above, press the same key again.

S Retract wire. Normal speed

Wire continues to retract until you release the key.

S Advance wire. Normal speed

Wire continues to advance until you release the key.

S After switching on, you can select maximum speed by pressing the fast key

.

The LED in the key lights up.

S To return to normal speed press the fast key again

To stop immediately, press

Normal speed and max. speed can be adjusted under “PRESET SYSTEM MENU”.

.

.

.

.

.

, or even at max. speed.

6.2 Controlling valves

To operate a valve you must be in the “MAIN MENU”.

S Open the valve for flux or gas by pressing

S Close an open valve by pressing the same key

-- 8 6 --

fgb7o1ea

.

.

Page 11

GB

7 MENUS

7.1 Menu overview

The A2--A6 Process Controller (PEH) software

is divided into several menus. The program

structure is described in the overview below.

MAIN MENU

MAIN MENU

Direction Y

Start Direct

STOP WELDING

WIRE DATA

Regulation CA

PRESET SYSTEM MENU

WELDING SETUP

S SET S Heat input per cm S Welding current

S Wire feed speed S Arc voltage S Travel speed

S Preset indicators

+

WELDING SETUP

S Arc start method S Type of weld finish

S Welding direction S Regulation method

S Wire type S Wire material S Wire size

PRESET SYSTEM MENU / DISPLAY MENU /

ERROR LIST

Menus that are not accessible by the user

fgb7me1e

-- 8 7 --

Page 12

GB

8MAINMENU

In the main menu you choose the welding current, arc voltage and travel speed you

want to use for welding. During welding you can adjust the welding parameters or

choose a complete new set of parameters.

Switch on the power source

.

The main menu will appear as follows:

Example of display if constant current (CA) has been chosen.

A

350

Chosen welding current in amperes.

Example of display if welding with constant wire feed speed (CW) is chosen.

cm/min

110

Indicates chosen wire feed speed.

Example of display during welding at constant wire feed speed (CW).

350 A

Resulting welding current after the

welding start.

For the selection of (CA) or (CW), see the menu WELDING SETUP on page 92.

SET 1 Indicates that parameter set 1 of 10 available has been selected (can be hidden).

30 kJ/cm Indicates the heat input in kJ/cm that will result from the chosen values of welding

current, arc voltage and travel speed (can be hidden).

V

33.0

cm/min

23

Chosen arc voltage in volts.

Chosen travel speed in centimetres per minute.

Indicates the type of start

J Indicates the travel direction

Indicates if the valve output is open or closed.

Example of display in the event of a fault.

Error code appears in bottom left section of display .

Error message is cancelled by pressing

Max. 20 messages saved in chronological order.

S Start welding by pressing . The LED in the key lights up.

S Stop welding by pressing

fgb7hm1e

-- 8 8 --

Page 13

GB

8.1 Entering welding parameters

When the power source is switched on, the main menu appears on the display.

In the “Display menu” you can choose how many sets of parameters you want to

work with. If more than one set of parameters is used then the SET number appears

in the top left corner.

1. Welding current or wire feed speed

2. SET no.

3. Arc voltage

4. Travel speed

If you choose to work with just one set of parameters then start at step 3.

S Press

S Type in the desired SET number and press

S Select the field for welding current or wire feed speed by pressing

S Type in the desired welding current or wire feed speed. Max. 4 numbers, press

.

S Select the field for arc voltage by pressing

S Type in the desired arc voltage, max. 3 numbers, press

S Select the field for travel speed by pressing

S Type in the desired travel speed, max. 3 numbers and press

Now the whole set has been marked and is ready to use. A further 9 additional sets

can be stored. (Total 10 SETs).

+ to mark the “parameter set field “.

.

.

.

.

.

.

fgb7hm1e

-- 8 9 --

Page 14

GB

8.2 Adjusting parameter values (during welding)

Once welding has started the welding parameters can be fine--tuned using the

arrowed numerical keys (over--ride function).

Increase Decrease

Welding current or wire feed speed

Arc voltage

Travel speed

Save the values as follows:

S Stop welding with

S Save the changed values with

.

.

S To revert to the original values, press

+

.

fgb7hm1e

-- 9 0 --

Page 15

GB

8.3 Choosing a new set of parameters during welding

(Only possible when you have chosen to work with several sets of parameters by

programming the “Display” menu)

Immediate selection

Suppose that while welding with parameter set 1 (“SET 1”) you decide to change to

parameter set 6 (“SET 6”) without checking the parameters first.

S Press

The field “SET 1” is marked and parameter set 1 is active

S Press

The field “SET 6” flashes.

S Press

The field “SET 6” is marked and parameter set 6 is active

Check before choosing

Suppose that while welding with parameter set 1 (“SET 1”) you decide to change to

parameter set 6 (“SET 6”) after first checking the parameters.

S Mark the field “SET 1 “ by pressing

S Press .

The field “SET 6” flashes.

S The new parameter set can be checked before being chosen by pressing

+

The complete row displaying the welding parameters flashes and displays the values

for parameter set 6 (“SET 6”), although parameter set 1 (“SET1”) remains in use

during the cur r ent welding cycle.

+

.

.

.

.

+

.

S Press

The field “SET 6” is marked and parameter set 6 is active.

fgb7hm1e

.

-- 9 1 --

Page 16

GB

9 WELDING SETUP

9.1 General

In WELDING SETUP you can choose a variety of settings including start method,

welding direction, wire diameter and similar variables in order to carry out a specific

welding task. These settings cannot be changed during welding.

You can cancel any error message in the main menu by pressing

S Switch from the MAIN MENU to WELDING SETUP by pressing

The display will now show a number of variables in column A (see page 93) and the

relevant options in columns B and C. Other options can be scrolled forward one at a

time. You can change row in column A.

S To change a setting, move from column A to columns B and C by pressing

S Scroll forward to the chosen option by pressing

your own values for rows 3 and 4 (”Number of wires”).

S Return to column A to change row by pressing

S Jump to the next row by pressing .

After the last row you will return to row 1.

S Return to the previous row by pressing

This combination will also take you straight to row 6 from row 1

Explanations of terms:

+

or

+

.

.

.

.

+

or type in

.

When

hold it down while pressing the second key.

fgb7fs1e

is indicated in combination with another key you should press first and

-- 9 2 --

Page 17

GB

9.2 Available settings

A B C

1 Direction

2 Start

3 STOP WELDING

4 WIRE DATA

5 Regulation CA, CW

6 PRESET SYSTEM MENU

Y (TRIANGLE),

J (SQUARE)

Crater fill (ms) 10--3000

Burnback time (ms) 10--3000

Wire type Solid wire, Flux cored, Strip

Wire diameter

if “Solid wire” is chosen

if “Flux cored” is chosen

if “Strip” is chosen

Wire material Fe, Al, SS

Number of wires 1, 2

WELDING SETUP

ScratchDirect

0.8 1.0 1.2 1.6 2.0 2.4 3.0 3.2

4.0 5.0 6.0

0.8 1.0 1.2 1.6 2.0 2.4 3.0 3.2

4.0

30 x 0.5 60 x 0.5 100 x 0.5

Switches to sub--menus in rows 3 and 4:

S Mark menu and press

.

S Return to “WELDING SETUP” by pressing

S Return to “MAIN MENU” by pressing

+

+

.

.

fgb7fs1e

-- 9 3 --

Page 18

GB

9.3 Definitions

1. Direction

Two alternatives can be chosen Y (triangle) and J (square) (these symbols are

repeated on all units)

SY(triangle) indicates travel in one direction.

SJ(square) indicate

2. Start

Two alternatives can be chosen: Direct start or Scratch start.

S

S

3. STOP WELDING

Crater fill and Burnback time canbeset.

Crater fill times between 10 and 3000 ms (0.01 -- 3 sec.) can be selected.

The crater fill function is used to finish the weld without leaving a crater. Crater fill

starts when the welding stop key

fill time. This function is most useful when MIG/MAG welding.

Burnback times between 10 and 3000 ms (0.01 -- 3 sec.) can be selected.

The burnback time starts after the crater fill sequence has ended.

Correct choice of the burnback time prevents:

S the wire sticking to the work piece

S the wire sticking to the nozzle

Direct start means that travel starts when the arc ignites.

Scratch start means that travel starts at the same time as wire feed. Scrape

start is used when welding rusty or dirty material.

is pressed, and continues for the preset crater

fgb7fs1e

-- 9 4 --

Page 19

GB

4. WIRE DATA

type

Wire

The equipment can be preset for the wire you intend to weld with. The control

system must be given information about the wire shape in order to achieve optimum

start/stop characteristics.

S solid wire

S cored wire

S strip

Wire

diameter

The chosen wire diameter has a big effect on the start cycle and crater filling. When

welding with a wire diameter that is not given in the options table, choose the nearest

diameter from the menu.

Note! For certain wire materials a better welding result can be achieved, if a value

deviating from the real wire dimension by 1 step is set (normally 1 step from the real

value).

When metric units are used the following alternatives are available:

S solid wire 0.8 / 1.0 / 1.2 / 1.6 / 2.0 / 2,4 / 3.0 / 3.2 / 4.0 / 5.0 / 6.0 mm

S cored wire 0.8 / 1.0 / 1.2 / 1.6 / 2.0 / 2,4 / 3.0 / 3.2 / 4.0 mm

S strip 30 x 0.5 / 60 x 0.5 / 100 x 0.5 mm

When inch units are used the following alternatives are available

S solid wire 0.030, 0.040, 0.047, 1/16, 5/64, 3/32, 7/64, 1/8, 3/32,

7/64, 1/8, 5/32, 3/16, 1/4

S cored wire 0.030, 0.040, 0.047, 1/16, 5/64, 3/32, 7/64, 1/8, 3/32,

7/64, 1/8, 5/32

S strip 30 x 0,5 / 60 x 0,5 / 100 x 0,5

Wire

composition

When welding with different filler materials the start and stop method is affected by

the choice of materials. It is therefore important that the settings show whether you

are welding with steel--based or aluminium--based filler wires.

S Fe Steel filler wire

S Al Aluminium filler wire

S SS Stainless steel filler wire

Number of

wires

Values between 1 -- 2 can be entered.

For example, if welding with two wires (Twin Arc) enter the value 2.

fgb7fs1e

-- 9 5 --

Page 20

GB

5. Regulation

Two different operating modes can be used for welding, either constant current, CA,

or constant wire feed speed, CW.

S CA, constant current. Normally used for submerged arc welding, which involves

working with large welds, large currents and large weld pools. The wire feed

speed is controlled by the power source to maintain a constant current.

S CW, constant wire feed speed. Normally used for MIG/MAG welding, for small

weld pools, thin sheet metal and thin filler wire. It is easier to achieve a constant

throat thickness when welding with this method. Welding is controlled by

selecting a fixed wire feed speed and the current is adjusted to achieve this

speed. The resulting current is displayed above the selected wire feed speed

(see display shot on page 96).

9.4 Preset indicators

The numbers and symbols on the display show the chosen preset values, see table

below.

Shown in display

MAIN MENU as

Y

J

Shown in plain English

(e.g. 3.0)

WELDING SETUP

options

Start Direct

Scratch

Direction TRIANGLE

SQUARE

Wire diameter:

Solid wire

Flux cored

Strip

OUTPUT

ON/OFF

0.8 1.0 1.2 1.6 2.0 2.5 3.0 3.2 4.0 5.0 6.0

0.8 1.0 1.2 1.6 2.0 2,4 3.0 3.2 4.0

30 x 0.5 60 x 0.5 100 x 0.5

Valve

fgb7fs1e

-- 9 6 --

Page 21

GB

10 ERROR LIST

10.1 Error codes

M1.3 Overheating Stop Wait until temperature has fallen

Wire feed motor (Motor 1)

M1.1 Tacho fault Stop Check wire feed unit / gearbox / tacho

M1.2 Current too high Stop Check wire feed

Travel motor (Motor 2)

M2.1 Tacho fault Stop Check travel motor / gearbox / tacho

M2.2 Current too high Stop Check travel motor / gearbox

Welding power source (T1)

T1.01 Communication error Stop Check cables and connections

T1.51 Incorrect welding voltage Stop Check joint preparation

T1.52 Incorrect current Stop Check joint preparation

T1.53 Unsuccessful start Stop Check stick--out and welding parameters

T1.54 Current limit Stop Welding short--circuited / Cure short--circuit

T1.55 Thermostat / overheating Stop Wait until temperature has fallen

T1.57 Arc extinguished Stop Check wire feed

Inputs / outputs

Display

(Flashing)

(Flashing)

No cooling water

(inlet K22 open) *

No gas flow

(inlet K23 open) *

Stop Check if the water is flowing or if the limit switch

is open.

Stop Check gas pressure

* Inputs are activated by using settings in menu “PRESET SYSTEM MENU”.

11 ORDERING SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as designation and spare part number as shown in the spare parts list on page 237.

This will simplify dispatch and ensure you get the right part.

fgb7f1ea

-- 9 7 --

Page 22

Schema Skema Skjema Johdotuskaavio Diagram Schaltplan Schéma

Schema Esquema Schema Esquema

Ó÷Þìб уэндеузт УЧЗМБ УХ НДЕУЗУ

dgb7e12a

-- 2 3 4 --

Page 23

dgb7e12a

-- 2 3 5 --

Page 24

Tillbehör Tilbehør Tilbehør Lisävarusteet Accessories Zubehör

Accessoires Accessoires Accesorios Accessori Acessórios Aоеупхбс

БОЕУПХБС

Remote control PHH1, incl. cable (5m)

Ordering no: 0449 040 880

Tillb

-- 2 3 6 --

Page 25

Reservdelsförteckning Reservedelsfortegnelse Reservedelsliste

Varaosaluettelo Spare parts list Ersatzteilliste L iste de pièces détachées

Reserveonderdelenlijst Lista de repuestos Elenco ricambi Lista de peças

sobressalentes РЯнбкбт бнфбллбкфйкюн месюн

РЙнбКБУ бнфблл бкфйкЩн мес Щн

A2- A6 Process Controller (PEH)

Edition 000615

Ordering no. Denomination Notes

0443 741 880 Control box A2--A6 Process Controller (PEH)

Abbreviations used in the spare parts list:

C = Component designation in the circuit diagram

pehspare

-- 2 3 7 --

Page 26

Item

no.

3 1 0443 638 880 Control panel KB1

4 1 0443 740 001 Emergency stop ST1

8 2 0457 278 001 Rail

9 1 0443 748 880 Cable, complete XS1

10 0443 730 880 Circuit board AP1 + AP2

14 1 0443 849 001 Insulation

20 1 0443 726 001 Display DY1

21 0192 526 003 Sealing strip 530 mm

23 10 0192 645 002 Bushing

26 2 0467 911 883 Capacitor Valid from programversion PEH1.2

40 0262 612 714 Cable 330 mm

41 0193 045 001 Connection block 2--pole X2

Ordering no.

Qty

0443 741 880 Control box

Denomination Notes C

s443741r

-- 2 3 8 --

Page 27

Item

no.

2 0456 489 002 Connection terminal 6 poles K10, K11

3 0456 489 001 Connection terminal 2 poles K12, K17, K22, K23

4 0456 489 004 Connection terminal 2 poles K13, K14

5 1 0486 471 880 Flash memory IC15

6 1 0486 473 880 EPROM Capsule IC304

7 0456 489 005 Connection terminal 4 poles K9, K9X

Ordering no.

Qty

0443 730 880 Circuit board AP1 + AP2

Denomination Notes C

s443730r

-- 2 3 9 --

Page 28

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 726 80 05

THE CZECH REPUBLIC

ESAB VAMBERK s.r.o.

Prague

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Copenhagen--Valby

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 204

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NETHERLANDS

ESAB Nederland B.V.

Utrecht

Tel: +31 30 248 59 22

Fax: +31 30 248 52 60

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.z.o.o

Warszaw

Tel: +48 22 813 99 63

Fax: +48 22 813 98 81

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 1 837 1527

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcobendas (Madrid)

Tel: +34 91 623 11 00

Fax: +34 91 661 51 83

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB International AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 333 43 33

Fax: +55 31 361 31 51

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 44 58

Asia/Pacific

AUSTRALIA

ESAB Australia Pty Ltd

Ermington

Tel: +61 2 9647 1232

Fax: +61 2 9748 1685

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 6539 7124

Fax: +86 21 6543 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. Esabindo Pratama

Jakarta

Tel: +62 21 460 01 88

Fax: +62 21 461 29 29

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 703 36 15

Fax: +60 3 703 35 52

SINGAPORE

ESAB Singapore Pte Ltd

Singapore

Tel: +65 861 43 22

Fax: +65 861 31 95

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 861 74 42

Fax: +65 863 08 39

SOUTH KOREA

ESAB SeAH Corporation

Kyung--Nam

Tel: +82 551 289 81 11

Fax: +82 551 289 88 63

THAILAND

ESAB (Thailand) Ltd

Samutprakarn

Tel: +66 2 393 60 62

Fax: +66 2 748 71 11

UNITED ARAB EMIRATES

ESAB Middle East

Dubai

Tel: +971 4 338 88 29

Fax: +971 4 338 87 29

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA--CIS

ESAB Representative Office

Moscow

Tel: +7 095 937 98 20

Fax: +7 095 937 95 80

ESAB Representative Office

St Petersburg

Tel: +7 812 325 43 62

Fax: +7 812 325 66 85

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

ESAB Welding Equipment AB

SE--695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

Fax +46 584 123 08

www.esab.com

001004

Loading...

Loading...