ESAB A22 POB Simplified Service Manual

A22 POB

Tubeplate welding tools

Simplified service manual

334 771--001 9611

LIST OF CONTENTS Page

SAFETY 4...........................................................

TECHNICAL DESCRIPTON 5..........................................

INSTALLATION 6.....................................................

OPERATION 10.......................................................

MAINTENANCE 10....................................................

SELECTION TABLE 11.................................................

ACCESSORY SET FOR INTERNAL WELDING 12.........................

ACCESSORY SET FOR EXTERNAL FILLET WELDING 13.................

ACCESSORY SET FOR WELDING TITANIUM 14.........................

WORKING RANGE 15.................................................

DIMENSION DRAWING 16.............................................

DIAGRAM 17.........................................................

CONNECTION DIAGRAM 18...........................................

SPARE PARTS LIST A22 POB 21.......................................

Rights reserved to alter specifications without notice

WARNING

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS.

TAKE PRECAUTIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY

PRACTICES WHICH SHOULD BE BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or

wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from

your breathing zone and the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens

and wear protective clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no

inflammable materials nearby.

MALFUNCTION

S Call for expert assistance in the event of malfunction.

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE

INST ALLING OR OPERATING THE EQUIPMENT

PROTECT YOURSELF AND OTHERS!

-- 3 --mvarnen1

SAFETY

SAFETY

Users of ESAB welding equipment have ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions.

Safety precautions must meet the requirements that apply to this type of welding

equipment.

The following recommendations should be observed in addition to the standard regulations that apply to the work place.

All work must be carried out by trained personnel who are familiar with the operation

of the welding equipment.

Incorrect operation of the equipment may lead to a hazardous situation which can

result in injury to the operator and damage to the equipment.

1. Anyone who uses the welding equipment must be familiar with:

S its operation

S the location of e mergency stops

S its function

S relevant safety precautions

S welding

To make this easier each switch, pushbutton or potentiometer is marked with a

symbol or text that indicates its function when activated.

2. The operator must ensure that:

S no unauthorized person is stationed within the working area of the equipment

when it is started up.

S that no--one is unprotected when the arc is struck

3. The work place must:

S be suitable for the purpose

S be free from draughts

4. Personal safety equipment

S Always wear recommended personal safety equipment, such as safety

glasses, flame--proof clothing, safety gloves.

S Do not wear loose--fitting items, such as scarves, bracelets, rings, etc., which

could become trapped or cause burns.

5. General precautions

S Make sure the return cable is connected securely.

S Work on high voltage equipment may only be carried out by a qualified

electrician.

S Appropriate fire extinquishing equipment must be clearly marked and close

at hand.

S Lubrication and maintenance must not be carried out on the equipment dur-

ing its operation.

df00f2ea

-- 4 --

TECHNICAL DESCRIPTION

The POB tube plate welding tool is intended for TIG--welding of tubes into flat tube plates.

It is suitable f or all types of weld joints, in certain cases using extra equipment.

The POB 12--60 welding tool is intended for use together with a spindle and a centering mandrel

according to the selection table on page 11.

POB 12--60 is intended for use with the power sources MECHTIG 315 INVERTER,

PROTIG 315 INVERTER, PROTIG 250 and PROWELDER 250

TECHNICAL DATA

Max. continuous welding current 180 A/60 %

Max. pulsed welding current 200 A/60 %

Working range:

base specification

with titanium welding kit

with external fillet welding kit

with internal welding kit

Electrode angle for:

butt welding

internal fillet welding

external fillet welding

internal welding

Electrode diameter 1.6 and 2.4 mm

Speed of rotation 0.3--4.5 r.p.m

Wire feed speed 0.15-- 1.5 m/min

Wire diameter 0.8 and 0.91 mm

Length of welding cable 8m

Weight

tool

cable and hose bundle

A22 POB

12--60 mm

12--60 mm

12--60 mm

according to designation

(See page 15)

parallel with tube axis

30_ to tube axis

15_ to tube axis

90_ to tube axis

4.5 kg

4.5 kg

Order no.

POB 12--60, base version with wire feed unit 333 893--881

Base version can be fitted with accessory kits for

-- external fillet welding

-- titanium welding

-- internal welding diameter:

9.5--15 mm

15--20 mm

20--30 mm

dra1b003

333 897--880

441 000--880

441 131--880

441 132--880

441 133--880

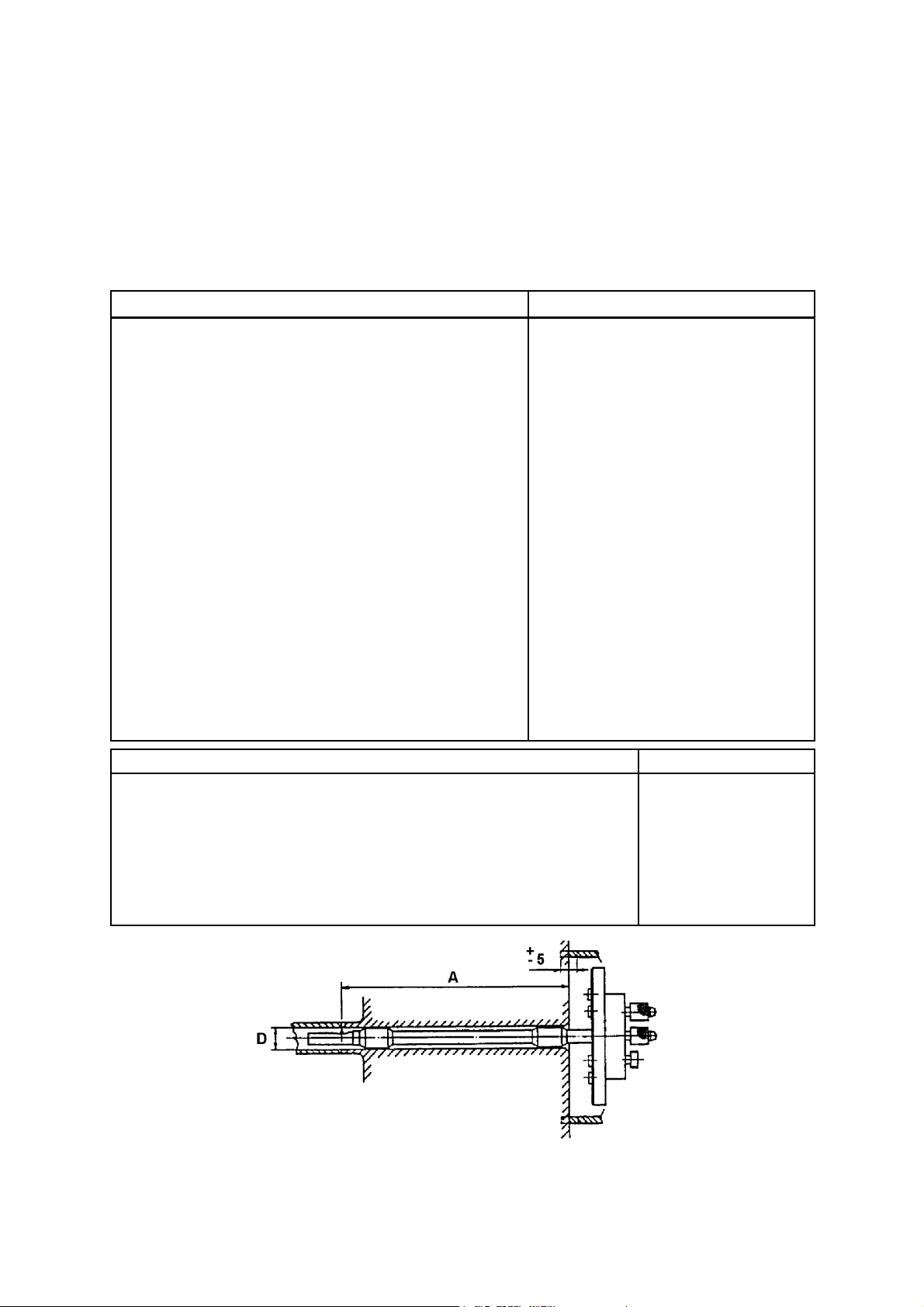

When ordering an accessory set for internal welding, please indicate both the inner diameter

(D) of the tube and the distance of the welding joint to the outside (A) of the plate.

-- 5 --cra1d1ea

Loading...

Loading...