ES FCW 12.1, FCW 18.1 Operation & Installation Manual

Wall mounted Fan Coil

Operation&Installation manual

◎ Before operating this product,please read the instruction

carefully and keep this manual for future use.

1.

3. Working principle

4. Specification

5. Installation

5.1 Location

5.2 Mounting plate installation

5.3 Installing the unit onto the mounting plate

5.4 Piping and drainage

5.5 Air purging

6. Remote controller operation

7. Functions & operation modes

8. Trouble shooting

8.1 Display

8.2 Failure Code

8.3 Causes&Action

9. Maintenance

10. Exploded view

11. Wiring diagram

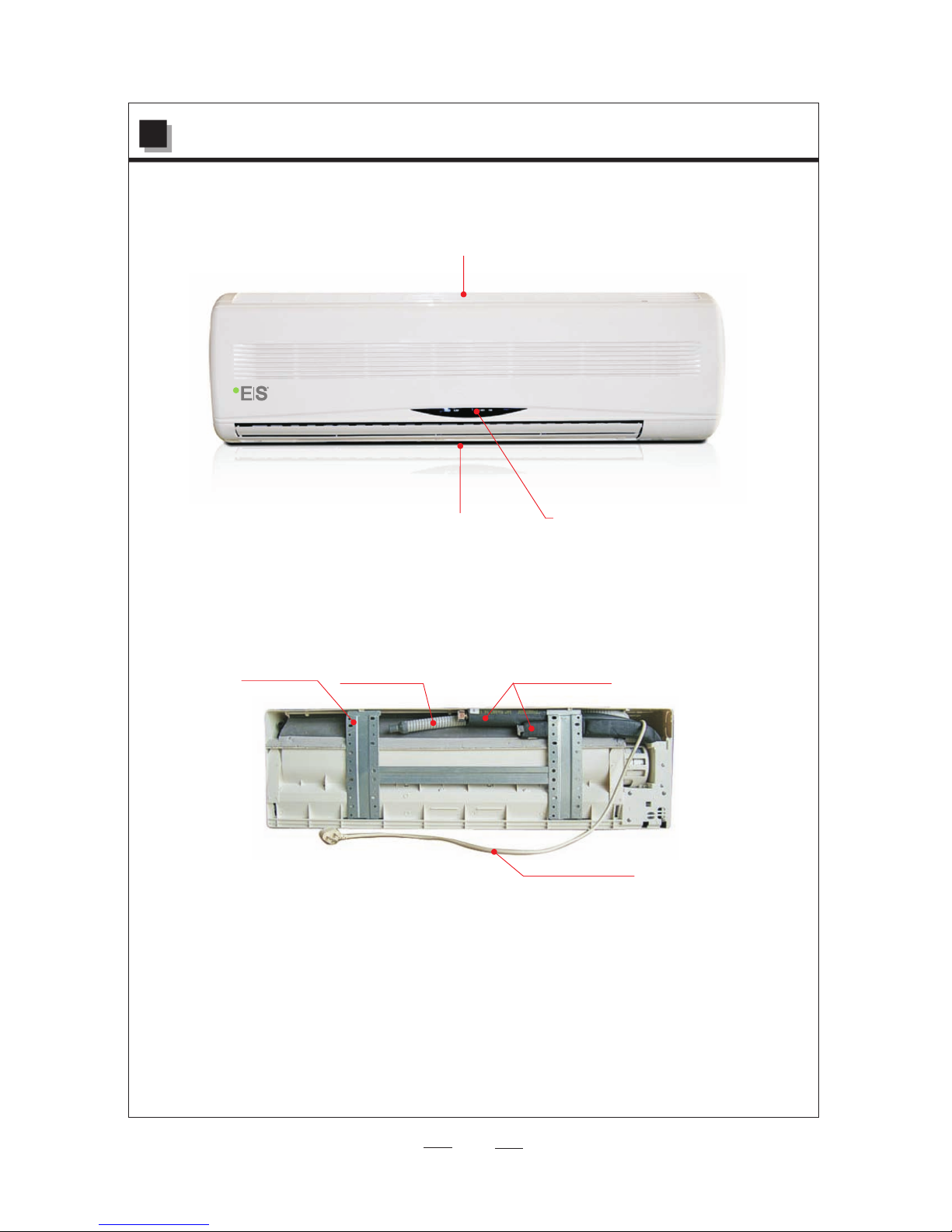

Names of Components

2. Notice

1

2

2

3

4

5

5

5

6

7

8

10

11

14

14

14

15

16

17

CONTENT

Display

Air outlet

Air inlet

Wate r Pipe

Drain hose

Mounting

plate

Power plug

1. Names of Components

1

● The unit is wid ely used together with centr al HVAC s ystem in hotel, h ospital, me dicine

factory, theater, commer cial building , office bu ilding, ent erprises, che mical industry, exhibit ion

room, resea rch institutes and so on.

● The install ation, commissioning and m aintenance of t hese machin es should be perf ormed by

qualified p ersonnel having a good knowl edge of standar ds and local regulations, as w ell as

experienc e of this type of equipment.

● Make sure tha t the rated voltage of the unit co rresponds to th at of the name plate before

commencin g wiring work according to the w iring diagram .

● The unit must b e GROUNDED to pre vent possib le hazard due to in sulation failure.

● Make sure tha t the unit has been switched OFF b efore install ing or servicing the unit.

● Keep the unit a way from any combustible or co rrosive envir onment.

● Disconnec t the power plug wh en the fan coil i s not going to be use d for a long time.

Otherwise d irt may gather and cause low efficiency .

● Make sure the a ir inlets and outlets of the uni t are not blocked .

2. Notice

Air inlet

Air outlet

Heat Exchan ger

Fan Coil

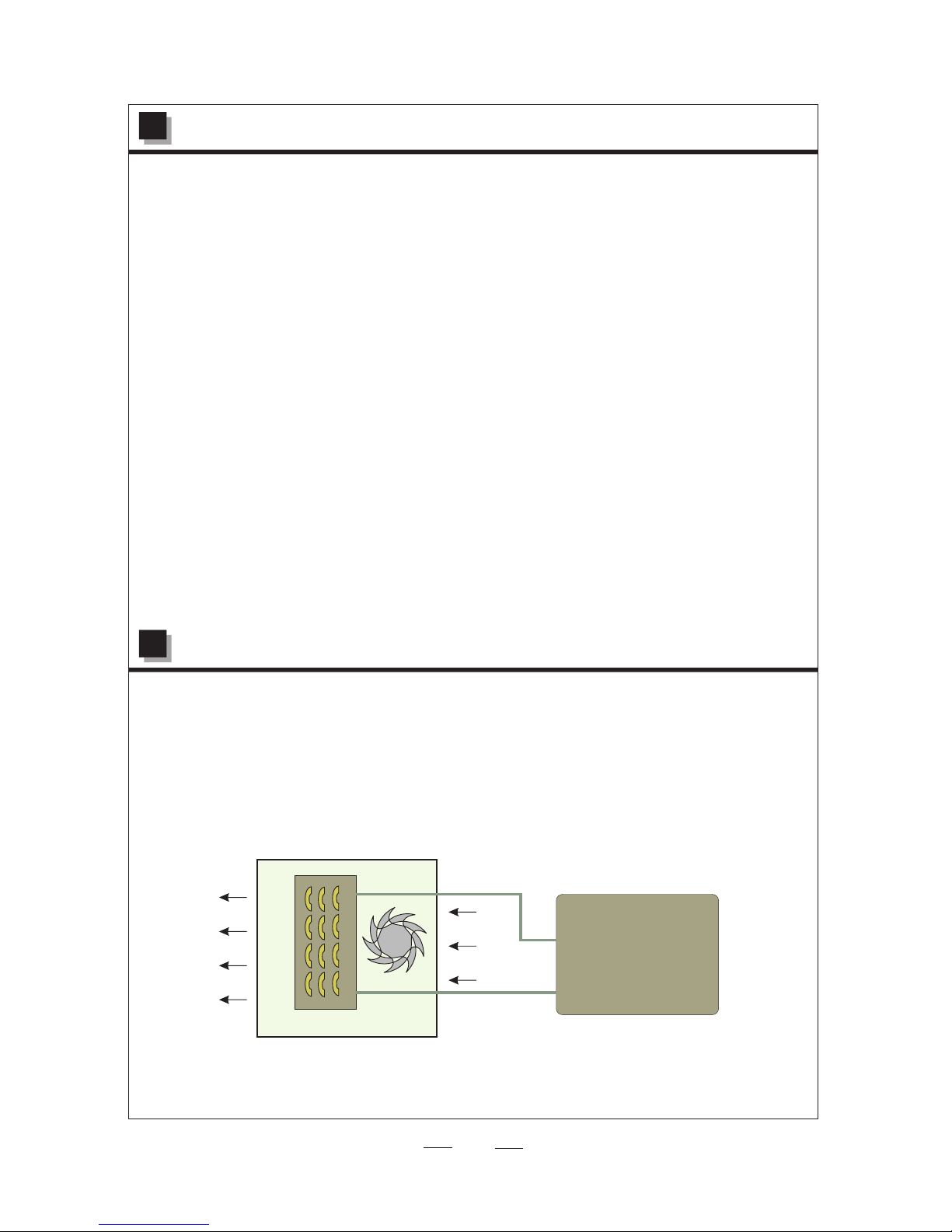

The fan c oil unit has no ene rgy by itse lf but provides heating or coo ling with hot or ch illed water from

central wat er supply syste m(heat pump o r chiller etc) .The fan of the unit blows throug h the heat

exchanger t o cool or heat the air in the room.

If inlet wate r is cool, set the unit to cooling m ode, the air outl et is cool air.

If inlet wate r is hot, set the unit to heating mo de, the air outle t is hot air.

The uni t is characteri zed with energy-saving, high efficiency, lo w noise, reliab le and

convenien t to select and install.

Fan

Central wat er

supply syst em

3. Working principle

2

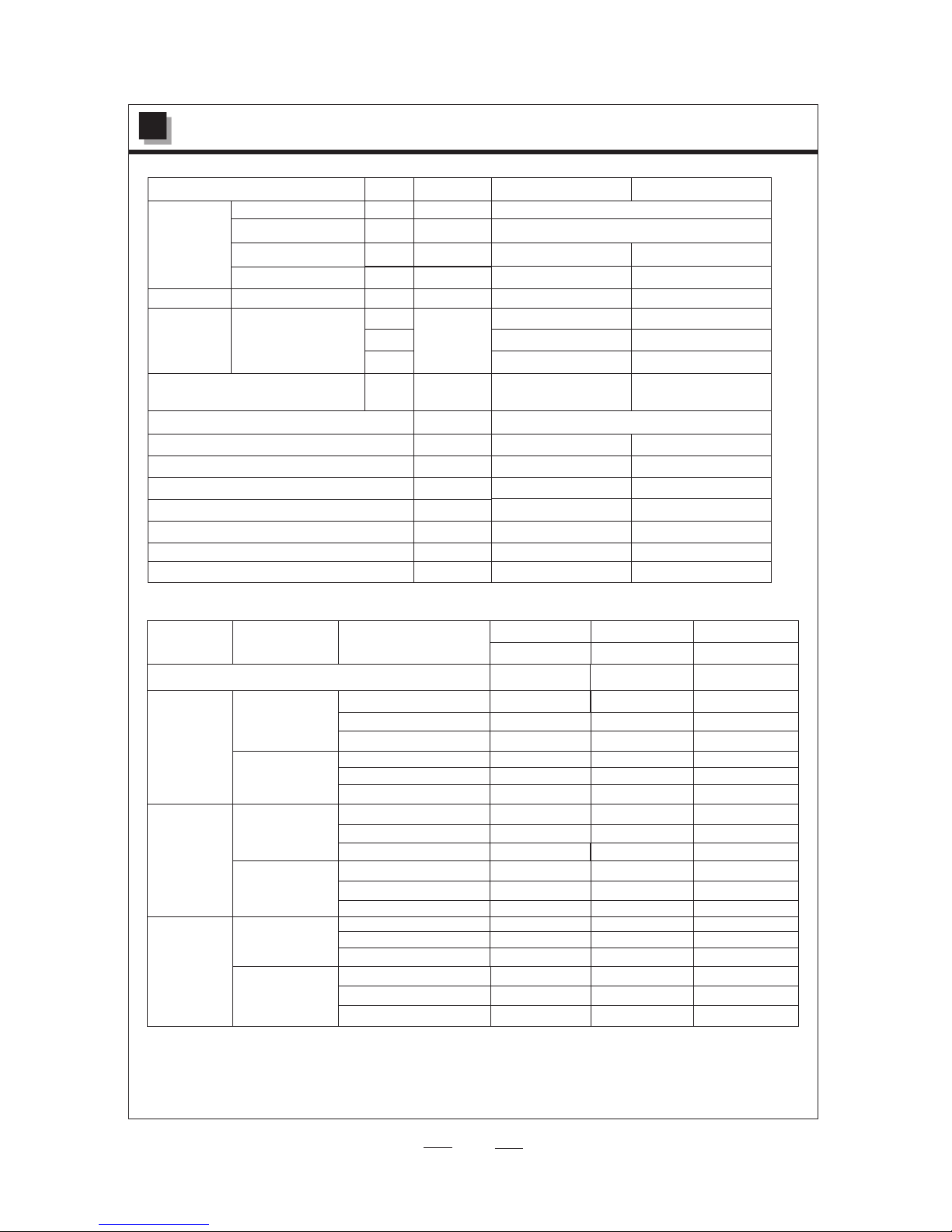

3. Specification

3

Model

Coil data

Tub e diameter

Rows/fins

Fin height/ length

Face area

mm

mm

W

m2

RPM

m3/h

W

dB(A)

mm

mm

mm

Kg

Net Weight

Packaging D imension (L×D ×H)

Net Dimensi on (L×D×H)

Drain Conne ction--(O.D )

Pipe Connec tor Size

Noise Level a t high speed

Power Input

Power Suppl y

Air Flow at Hig h Speed

Fan data

Motor data

Fan Speed

Power Outpu t

L

M

H

1100 (cooling)

1150 (heating)

15

1070×377×262

1020×315×210

16

G1/2

37

72

35

35

G3/8

13

890×280×210

950×345×260

12

650 (coolin g)

750 (heatin g)

220~ 20/5 0,60Hz/1PH

1000

1100

1300

35

0.25

310×796

0.092

15

1150

1000

800

2R/17fin

7

FCW 18. 1

FCW 12. 1

31×561

Output Under Different Water Temperature

FCW 12. 1

Fan Speed

Work ing Mode

Wate r Inlet Temp (℃)

FCW 18. 1

FCW 12. 1

Capacity(W)

Capacity(W)

Capacity(W)

Wate r Flow Rate(L/S )/Water Pressure Dr op(Kpa)

Low Speed

Medium

Speed

High Speed

Cooling

Heating

Cooling

Heating

Cooling

Heating

Note: (1) Cap acity Test Conditio n for cooling : room temperat ure is DB/WB 27/19℃ .

Capacity Test Con dition for heat ing: room tem perature is DB/ WB 20/-℃ .

(2) specifica tions are subject to change wi thout prior not ice. For actual pecificati ons

of unit, plea se refer to the stickers on the un it.

The

5

7

9

60

50

45

5

7

9

60

50

45

5

7

9

60

50

45

3100

3540

4490

1112

1365

1530

3160

3660

4600

1120

1375

1545

3260

3710

4640

1130

1390

1670

0.062/30

0.076/40

0.13/40

2025

1785

1510

5160

4000

3440

2010

1730

1470

5020

3920

3340

1990

1685

1460

4890

3870

3100

3660

3375

2685

7365

5775

4830

3455

3225

2530

7220

5625

4575

3420

3035

2510

6710

5225

4390

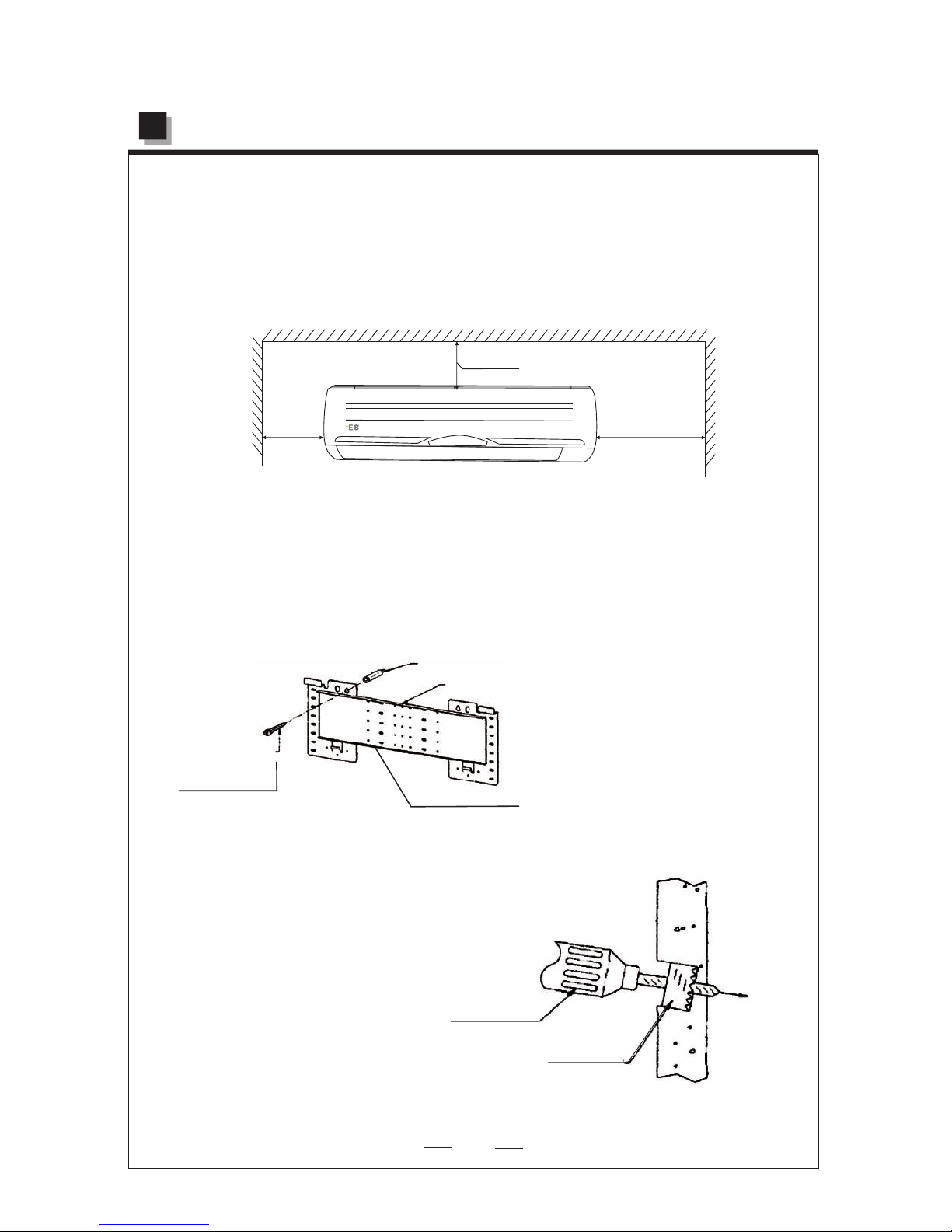

Select installation location with following considerations;

1. The re turn and supply a ir should be free f rom any obstr uction.

2. The wa ll which the unit i s to be mounted on should be stiff enough not t o resonate and

produce muc h noise.

3. Ensure the c learance on every side of the un it conforms to fi gures as shown be low.

5.1 Location

>2 00 mm

>2 00 mm

>4 00 mm

5.2 Mounting plate installation

5. Installation

1. After selecting a proper l ocation, plac e the mountin g plate horizon tally onto the wa ll.

Use a plumb lin e if necessary.

2. Drill the ho les for the type of mounting scr ew to be used. Chec k local building regulatio n for

correct mou nting screw.

3. Secure the m ounting plate and check for if i t is stable.

Mounting pl ate

▲Figure 1

Long screw

In door

Slightly sl ant

Outdoor

Drilling

machine

Hole saw

Wall

Indoor

▲Figure 2

4. Drill a hole of 70.0 mm in

Diameter for piping either at

the right or left side of the unit

and make sure that the hole is

slightly slant downward.

4

Wall p lug

Loading...

Loading...