ES AWH6-V6-SW, AWH13-V6-SW, AWH9-V6-SW, AWH11-V6-SW User Manual

Heat Pump

DC Inverter Air to Water

Before operating this product, please read the

instructions carefully and keep this manual for future use.

User’s manual

User’s manual

AWH6-V6-SW

AWH9-V6-SW

AWH11-V6-SW

AWH13-V6-SW

2

5

Catalogue

1.Introduction

1.1.Preliminary Information

1.2.Safety Precautions

1.3.Functioning Principles

1.4.Product Component Diagram

1.5.Technical Specifications

2.Overview of the Units

2.1.Functional Diagrams

2.2.Outlines and Dimensions

2.3.Exploded Views

3.Assembly Configurations

Assembly Configuration Selection Flowchart

Assembly Drawings, Wiring, and Software

4.Installation Walkthrough

4.1.Sanitary Hot Water Applications

4.2.Heating and Cooling Circuits

4.3.Indoor Unit Installation

4.4.Outdoor Unit Installation

4.5.Wiring

4.6.Refrigerant Pipework

4.7.Water Pipework

4.8.Test Run

5.Appendix

A. Wiring

5

3

6

8

9

10

11

11

13

15

19

19

20

49

49

53

56

58

60

70

73

74

75

75

B. Wiring Diagrams

77

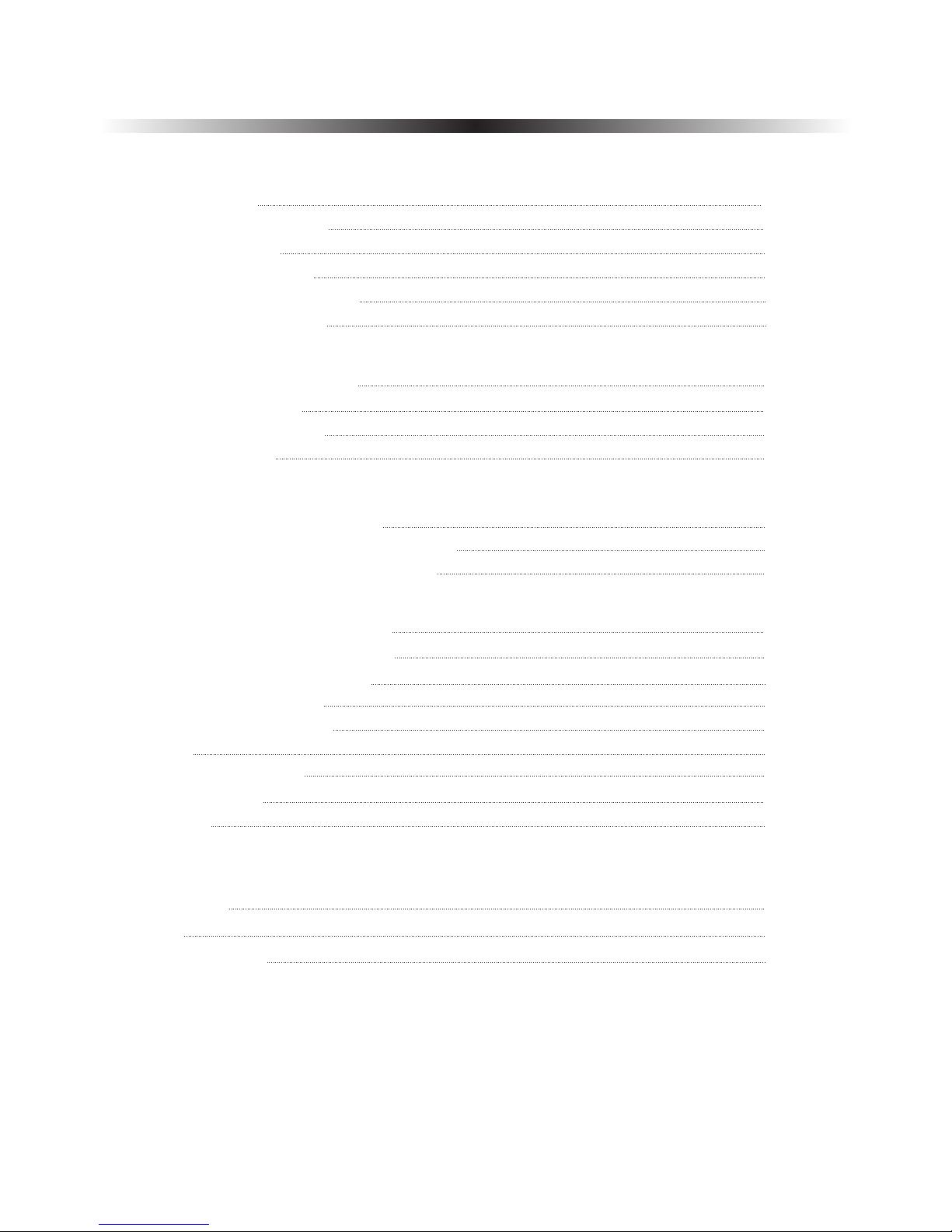

Installation

Manual

User’s

Manual

Indoor

Unit

Bracket

Expansion

Bolts

Below are the accessories that are included with your purchase.

Please check to ensure that none are missing or damaged.

If so,please contact your local distributor.

Included Accessories

Screws

1 2

3

4

5

X1 X1 X1 X2

X10

4

Temperature

TC-Water

Sensor

Temperature

Sensor

(for cooling

and heating)

TR-Room

Temperature

Sensor

(for sanitary

hot water)

TV(1+2)- Water

Temperature

Sensors for

Mixture Valves

Sensor

Communication

Cable

Communication

Cable between

Indoor and

Outdoor Unit

TR - Room

(1+2)

6

7

8

9 10

11

X1 X1 X1 X2 X4 X1

1. Introduction

1.1 Preliminary Information

Thank you for your purchase of our quality heat pump.

This manual is intended to provide detaile d instructions for the successful installation o f your newly

purchased heat pump product. Please ensure that this manual, along w ith the User ’s and Service

manuals, are kept in an easy-to-access location for your reference later on.

DISCLAIMER

Proper adherence to the directions provided herein is vital for both t he smooth operation of this

system, as well as for your safety and the safety of those around you. Amitime Electric Co., Ltd. is not

responsible or liable for any losses incurred due to misuse or mishandling of this product, which

includes, but is not limited to:

• Purchasing, installing, and/or operating this product with the intention of using it outside of

its established, technical purpose.

• Carrying out improper work upon the unit, or any of its components, that has not been given

explicit, prior consent in the form of writing.

• Installation attempts of this system by anyone other than a properly trained and licensed

professional.

• Negligence of properly-worn personal protection (safety glasses, gloves, etc.) while performing

installation, maintenance, or servic ing of this product.

SAFETY

• The operation of this system during ambient temperatures which are b elow or beyond the

temperature range intended (-25°C to 43°C)

If unsure of what installation procedures to use, please contact your local distributor for information

and/or advisement. Any accessories used with this pr oduct must be official only. Any electrical work

must be carried out by certified electricians only. The manufacturer is not responsible for any alterations or modifications that are made with out explicit, written approval. The design of thi s unit complies and conforms to all necessary and relevant safety regulation s, and is otherwise safe to op erate for

its intended use.

Please pay attention to the following pages, which detail importan t precautions that should be closely

followed, to ensure safe installation and operation .

5

1. Introduction

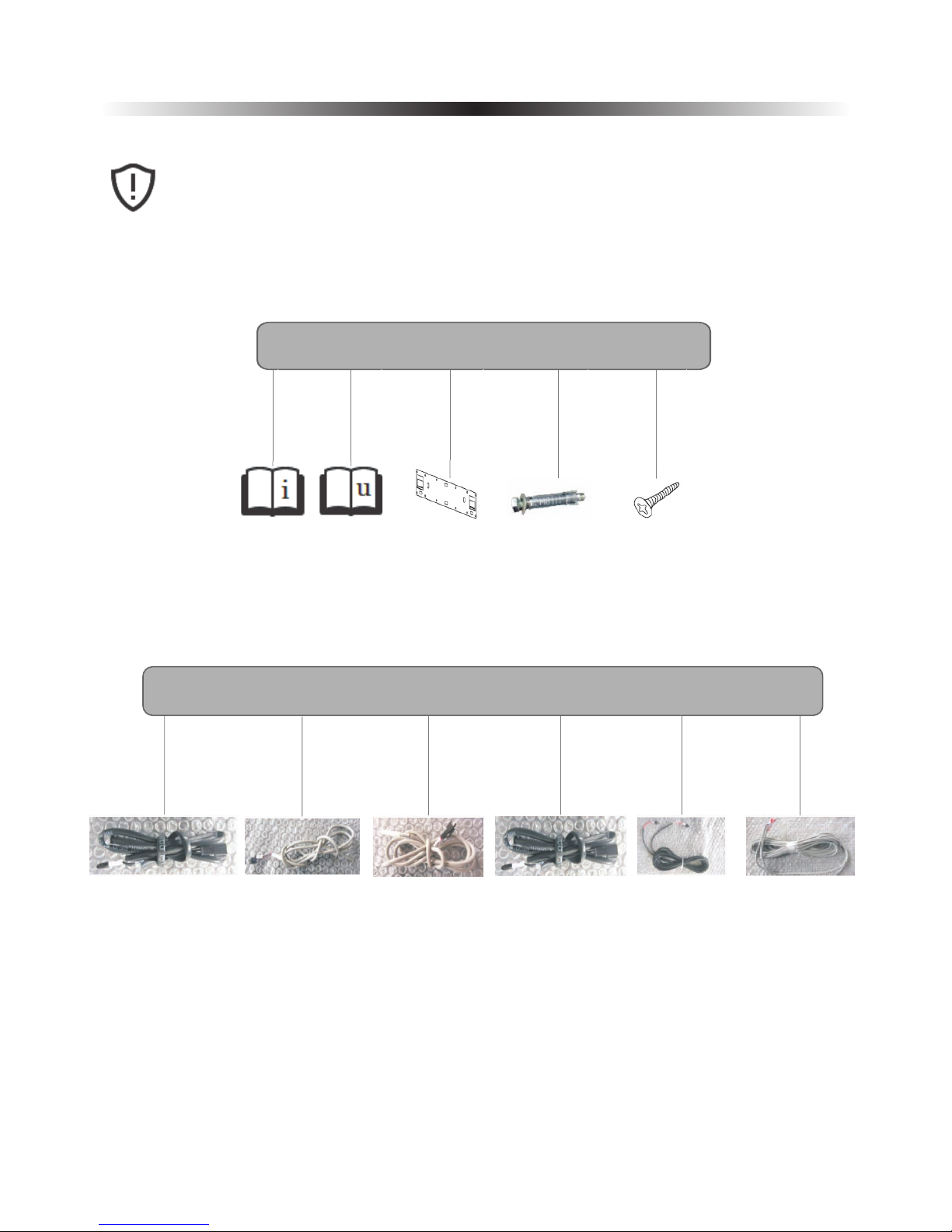

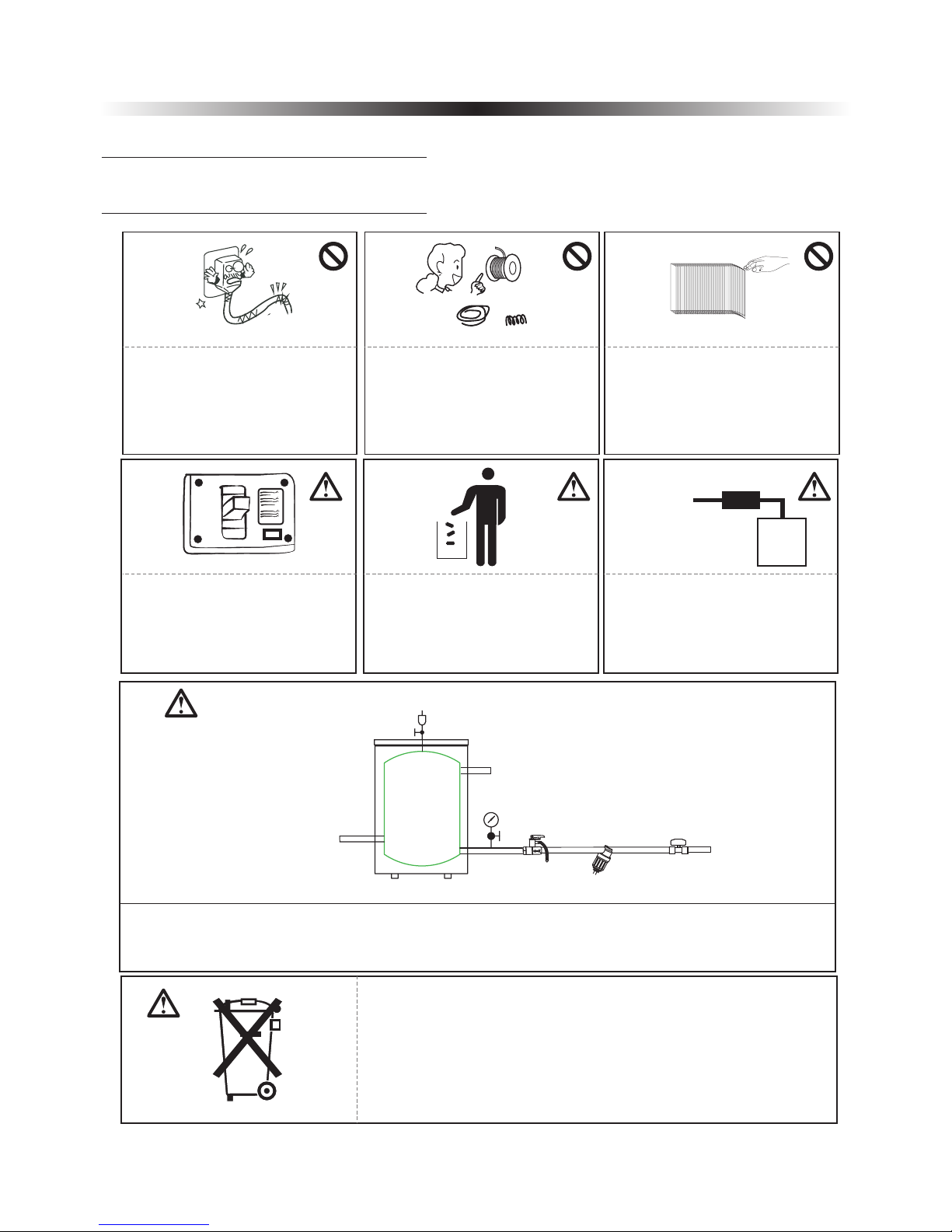

1.2.Safety Precautions

To ensure both your personal safety, as well as the safety of the product, note the symbols below and

be sure to understand their correlation to each of the precautions depicted.

CautionWarning

Prohibition

The installation, dismantlement

and maintenance of the unit must

be performed by qualified

personnel. It is forbidden to do any

changes to the structure of the unit.

Otherwise injury of person or unit

damage might happen.

To avoid electrical shock, make

sure to disconnect the power

supply 1 minute or more before

servicing the electrical parts. Even

after 1 minute, always measure the

voltage at the terminals of main

circuit capacitors or electrical parts

and, before touching, make sure

that those voltages are lower

than the safety voltage.

User Ma nual

Be sure to read this manual before

use.

For sanitary hot water, please

always add a mixture valve before

water tap and set it to proper

temperature.

Ground wire

Use a dedicated socket for this

unit, otherwise malfunction may

occur.

The power supply to the unit must

be grounded.

Do not touch the air outlet grill

when fan motor is running.

Do not touch the power plug with

wet hands. Never pull out the plug

by pulling the power cable.

Water or any kind of liquid is

strictly forbidden to be poured into

the product, or may cause electric

creepage or breakdown of the

product.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

6

Copper

Steel

Fuse

Main

Power Cable

RCD

Indoor

unit

When the power cord gets loose

or damaged, always get a qualified

person to fix it.

It is mandatory to use a suitable

circuit breaker for the heat pump

and make sure the power supply to

the unit corresponds to the

specifications. Otherwise the unit

might be damaged.

Disposal of Scrap Batteries(if

there is).Please discard the

batteries as sorted municipal waste

at the accessible collection point.

Installation of a residual current

device (RCD) having a rated

residual operating current not

exceeding 30 mA is advisable.

ON

OFF

Please select the correct fuse or

breaker as per recommended. Steel

wire or copper wire cannot be

taken as substitute for fuse or

breaker. Otherwise, damages

maybe caused.

Be aware fingers might be hurt by

the fin of the coil.

7

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote the sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

System water filling

T/P valve

Connect to heating/cooling system

Buffer tank

Connect to heat pump

One way valve

Filter

City water inlet

1. It's suggested to use pure water for filling the system.

2. If use city water for filling, please soften the water and add a filter.

Note: After filling, the system of water system should be 0.15~0.6MPa.

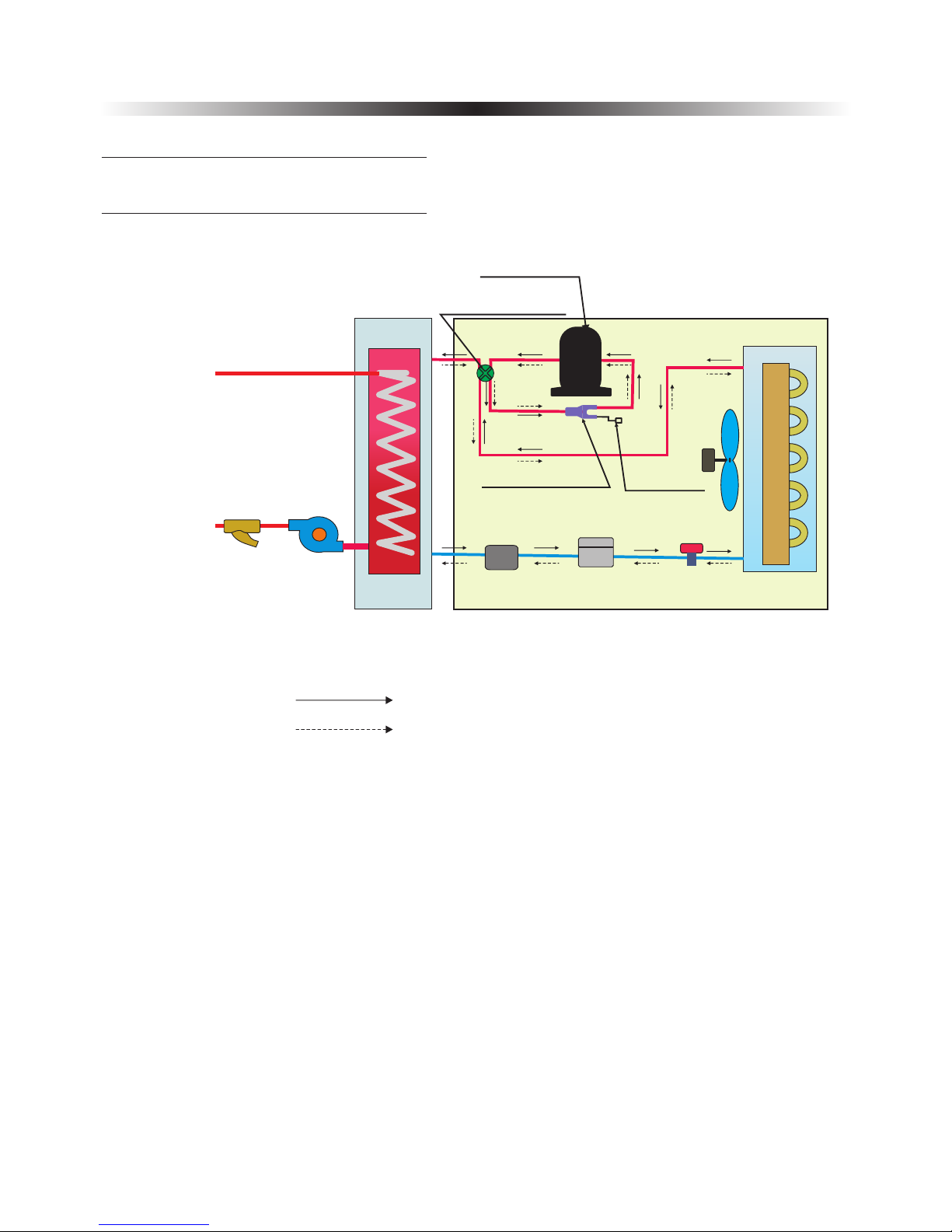

1. Introduction

1.2.Safety Precautions

Water inlet

Water Outlet

Outdoor unitIndoor unit

Filter

Water pump

Heat

exchanger

Power supply

Four-way vavle

Compressor

Three-way valve

Refrigerant Filter

T-connector

Fan motor

Pressure

check valve

Evaporator

Heating

Cooling

8

1. Introduction

1.3.Functioning Principles

9

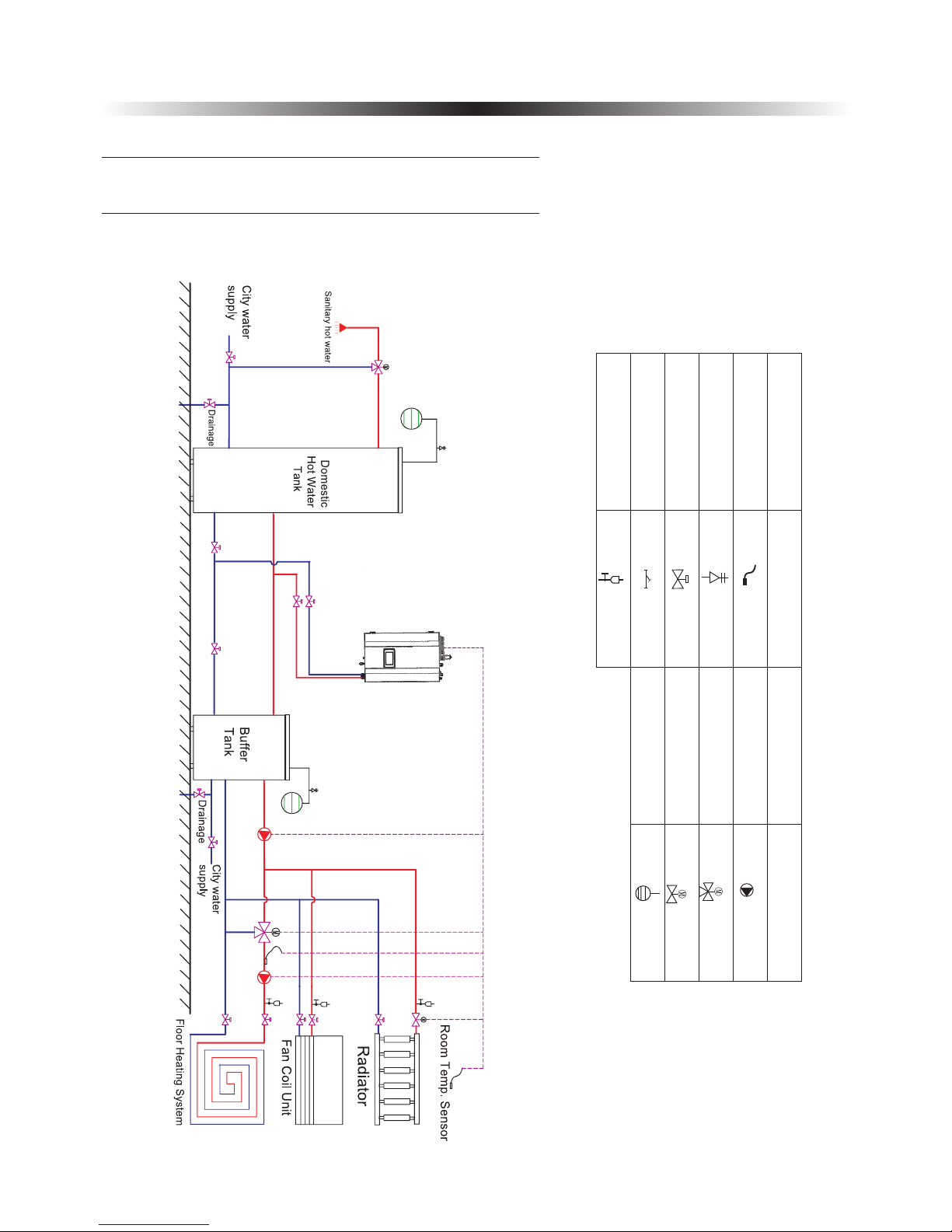

1. Introduction

1.4.Product Components Diagram

Below is a general system application of the heat pump. Any specific configurations should be a

variation of this “master” system drawing. All suggested assembly variations are given in Chapter 3.

Name

Symbol

Name

Symbol

Temp.S en sor

Safe ty v alv e Ki t

Ball valv e

Wat er filt er

Air pu rg ing v al ve

Wat er pump

Mixi ng v alv e

Moto ri zed valv e

Expa ns ion t an k

Note:Dot te d li ne s me an〝a ble to be control le d by t he H ea t Pump〞.

10

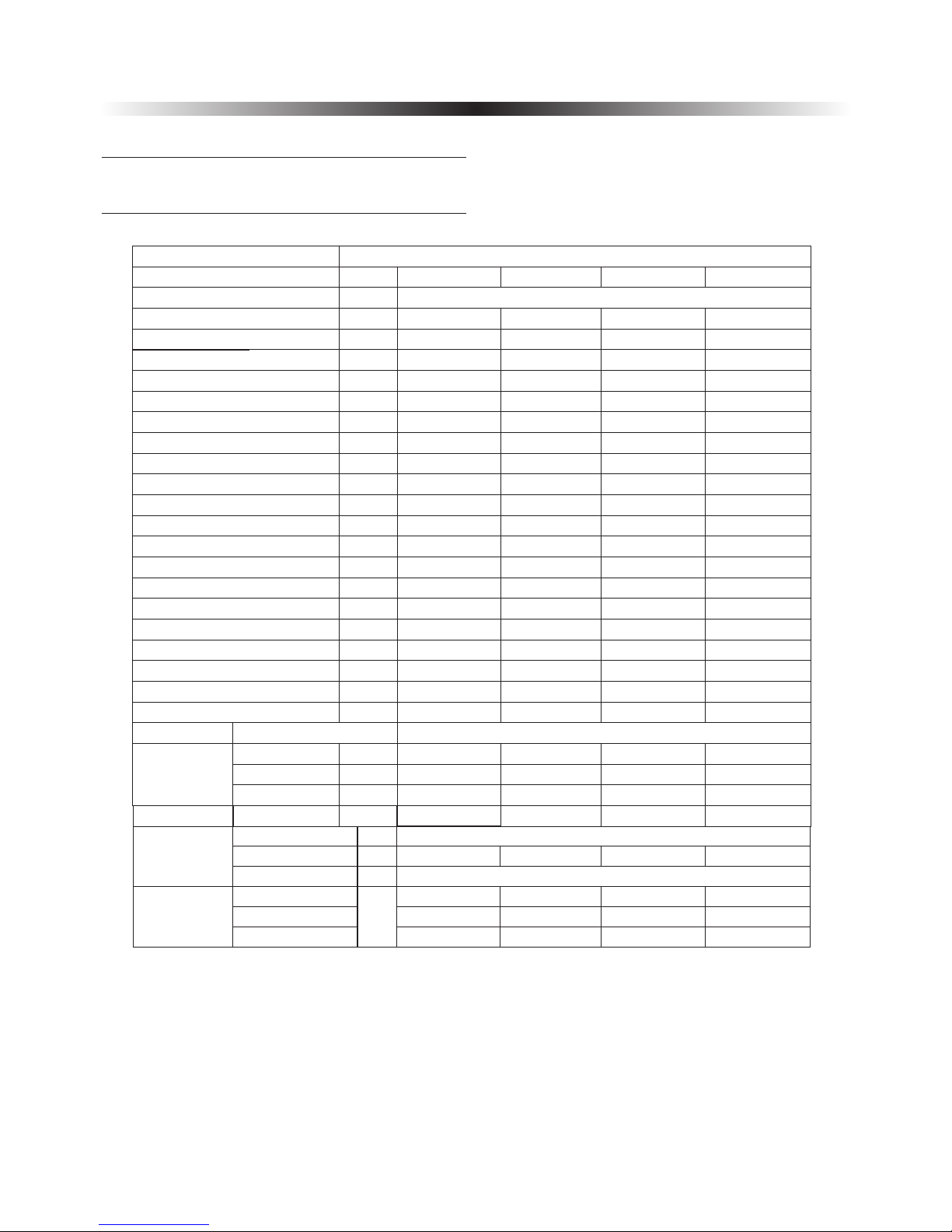

Model

Power Supply-Refrigerant

V/Hz/Ph

AWH11-V6-SW

AWH9-V6-SW

220-240/50/1-R410A

Max. Heating Capacity (1)

C.O.P (1)

Heating Capacity Min./Max.(1)

Heating Power Input Min./Max.(1)

C.O.P Min./Max.(1)

Max. Heating Capacity(2)

C.O.P (2)

Heating Capacity Min./Max.(2)

Heating power input Min./Max.(2)

C.O.P Min./Max.(2)

Max. Cooling Capacity(3)

E.E.R (3)

Cooling Capacity Min./Max.(3)

Cooling Power Input Min./Max.(3)

E.E.R Min./Max.(3)

Max. Cooling Capacity(4)

E.E.R(4)

Cooling Capacity Min./Max.(4)

Cooling Power Input Min./Max.(4)

E.E.R Min./Max.(4)

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

11.5

10.10

3.82

4.03

4.67/11.5

4.33/10.10

915/3029

975/2153

3.82/5.054.02/4.65

10.7

9.53

2.95

3.17

4.14/10.74.19/9.53

1218/3624

1230/2990

2.95/3.56

3.12/3.55

9.2

6.84

2.68

2.09

4.33/9.2

4.10/6.84

993/3465

1230/3280

2.685/4.11

2.09/3.32

6.74

5.05

2.15

1.58

2.17/6.74

2.34/5.05

924/3132

1080/3200

2.15/3.0

1.58/2.40

Compressor

Type-Quantity/System

Twin Rotary/1

Fan

Quantity

Airflow

Rated Power

m³/h

W

3100

3000

76

1

1

Type of Product

DC Inverter Air to Water Heat Pump Unit

Noise Level

Indoor/Outdoor

35/56

dB(A)

AWH13-V6-SW

12.6

3.89

4.2/12.6

926/3072

3.89/4.77

11.5

3.08

3.76/11.5

1267/3723

2.97/3.28

10.3

3.29

4.29/10.37

957/3156

3.29/4.63

7.9

2.63

2.34/7.91

1000/3012

2.33/3.12

4200

150

2

30/59

AWH6-V6-SW

6.21

4.05

2.19/6.21

540/1530

4.05/5.87

5.8

3.22

2.05/5.8

640/1810

3.22/4.12

5.81

3.51

2.05/5.81

768/2105

3.15/4.71

4.5

2.52

1.59/4.5

614/1740

2.52/4.32

2700

1

7665

1. Introduction

1.5.Technical Specifications

30/5635/52

Water Side Heat

Exchanger

Allowable Water

Flow

Type

Water Pressure Drop

Piping Connection

Min. Water Flow

Rated Water Flow

Max. Water Flow

23

G1”

0.520.395

0.310.24

0.620.48

Kpa

Inch

L/S

0.61

0.37

0.73

Plate Heat Exchanger

23

26

0.29

0.19

0.33

20

NOTE:

(1) Heating condition: water inlet/outlet temperature:30℃/35℃, ambient temperature:DB/WB 7/6℃;

(2) Heating condition: water temperature:40℃/45℃, ambient temperature:DB/WB 7/6℃;

(3) Cooling condition: water temperature:23℃/18℃, ambient temperature:35℃;

(4) Cooling condition: water temperature:12℃/7℃, ambient temperature:35℃.

inlet/outlet

inlet/outlet

inlet/outlet

(5) The specifications are subject to change without prior notice.

For actual specifications of the unit, please refer to the specification stickers on the unit.

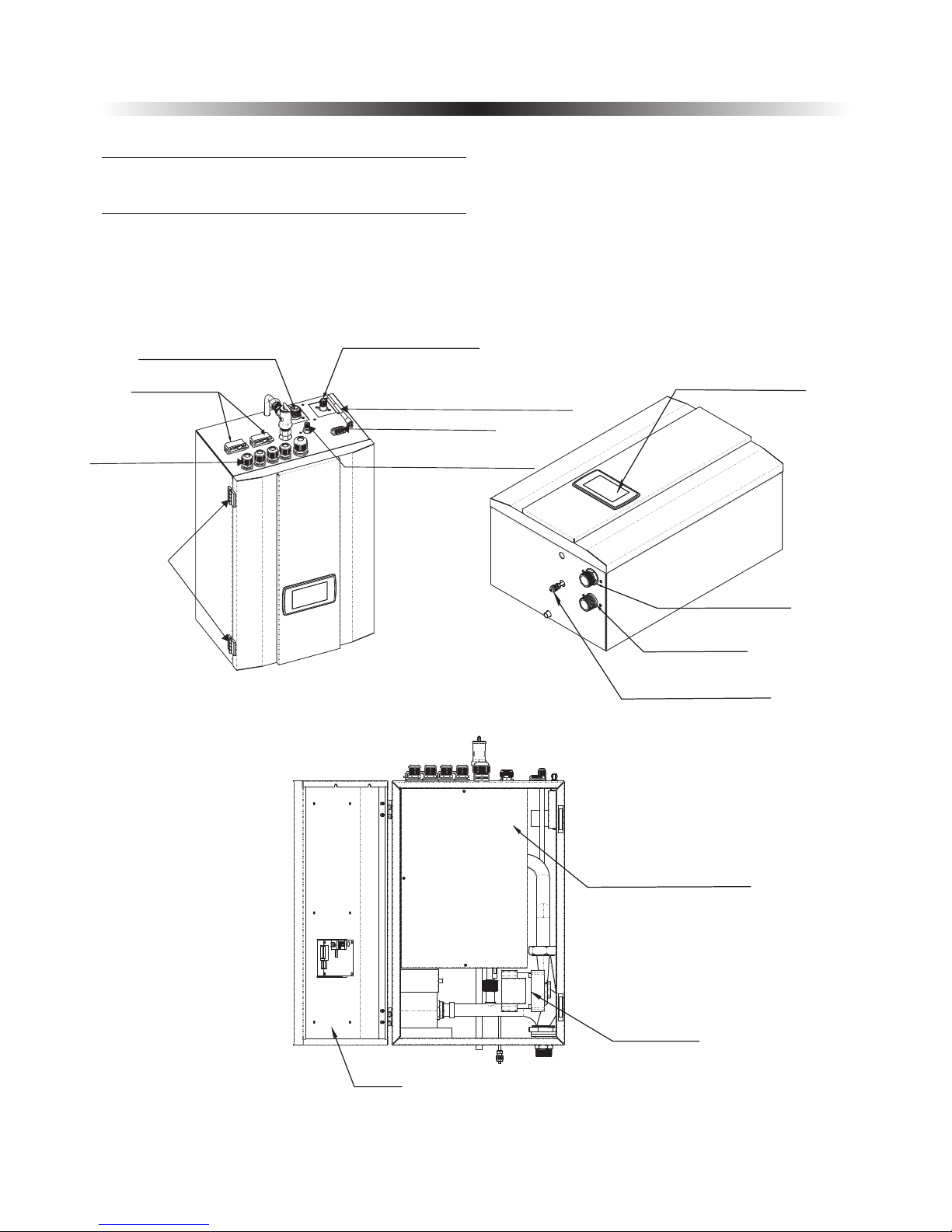

2. Overview of the Units

Indoor unit

11

2.1.Functional Diagrams

Electric Box Cover

Water Pump

Door

Wate r inlet

Wate r outle t

Air pu rgin g valve

Oper ation pan el

Refrigerant Connector

: 1 / 2"

: 5 / 8"

AWH6-V6-SW

AWH9/11/13-V6-SW

Refrigerant Connector

: 3 / 8"

: 3 / 8

"

AWH6-V6-SW

AWH9/11/13-V6-SW

Cabl e clip

Cabl e gland

Hing e

Rece iving sig nal ant enna

Sens or fixtur e

Need le valve fo r servi ce

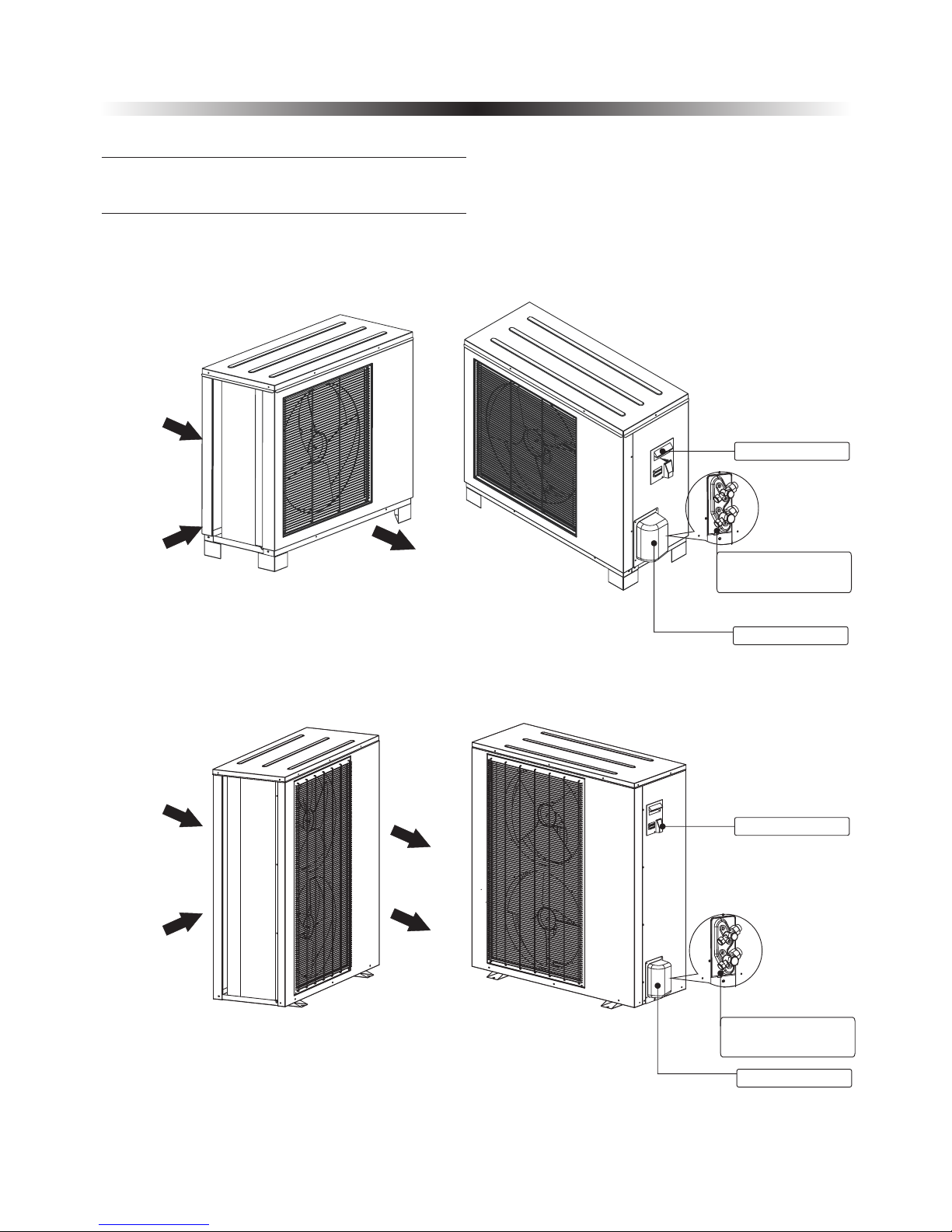

Outdoor unit

2. Overview of the Units

12

Air inlet

Air inlet

Air outlet

Valve cover

Refrigerant connector

1/2”

AW6-V6-SG

AW9-V6-SG

AW11-V6-SG

Handle

Valve cover

Refrigerant connector

5/8”

Air inlet

Air inlet Air outlet

Air outlet

Handle

2.1.Functional Diagrams

AW13-V6-SG

718.8

580.3

388.8

380

272.6

380

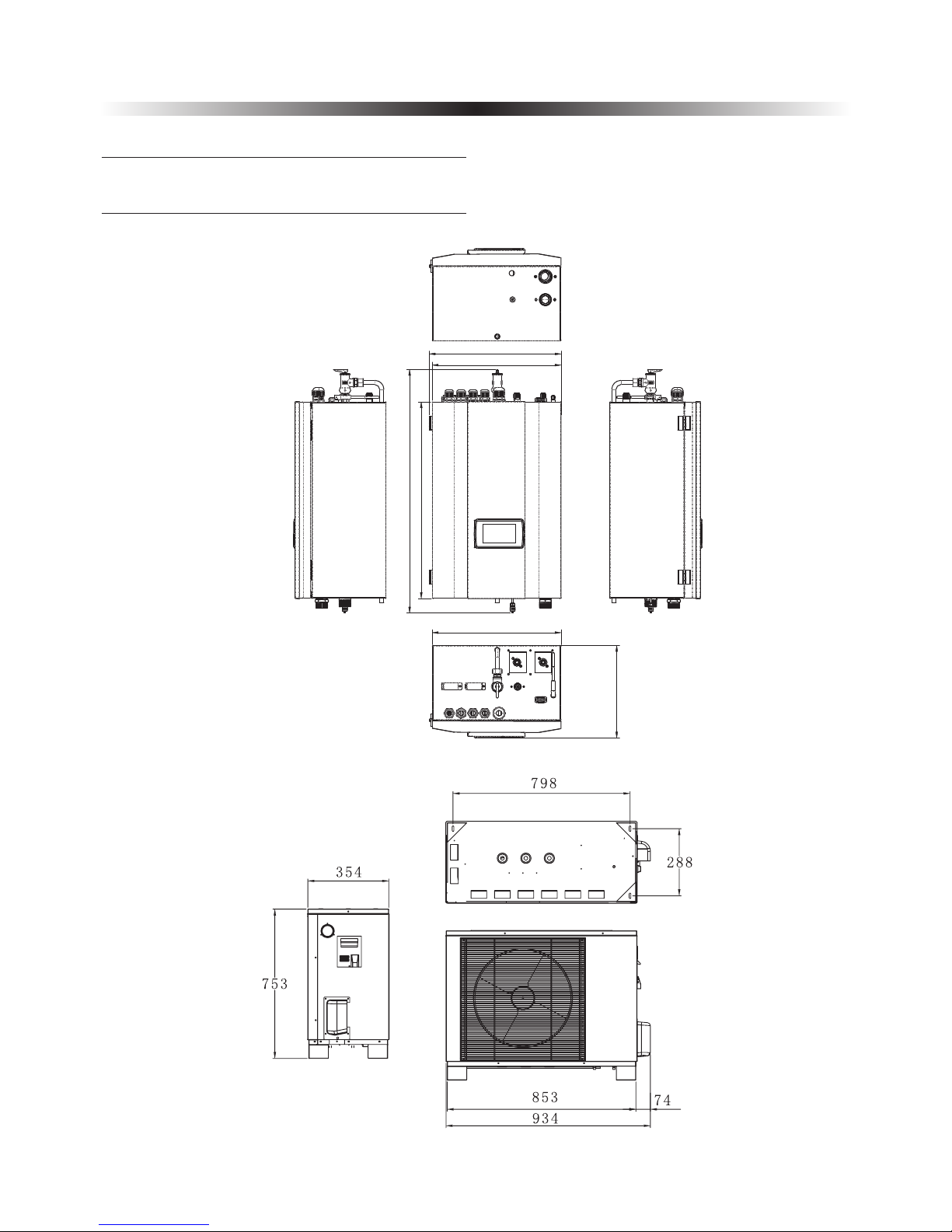

13

2. Overview of the Units

2.2.Outlines and Dimensions

Outlines and dimensions

Unit:mm

Indoo r ——

Outdo or ——

AW6-V6-SG

AW9-V6-SG

Unit:mm

Refrigerant connector

dimension: 1/4” and 1/

2”

AWH6-V6-SW:

AWH9-V6-SW:3/8” and 1/

2”

AWH6-V6-SW

AWH9-V6-SW

AWH11-V6-SW

AWH13-V6-SW

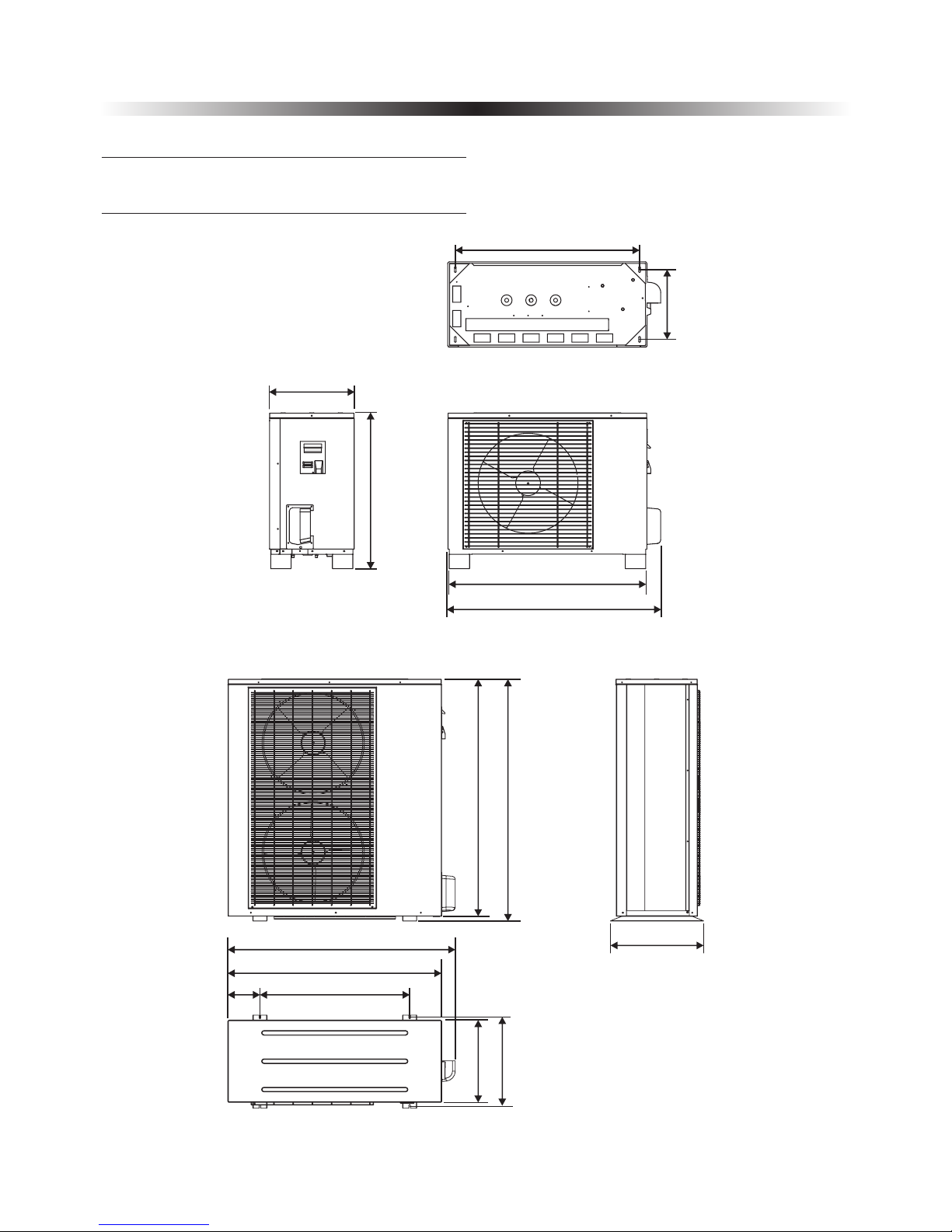

14

Refrigerant connector

dimension:3/8” and 5/8”

Unit:mm

1195

1171407

740159

1058

1124

460

Refrigerant connector

dimension:3/8” and 1/

2”

904

343

414

763

964

1044

Unit:mm

Outdo or ——

AW11-V6-SG

Outdo or ——

AW13-V6-SG

430

2. Overview of the Units

2.2.Outlines and Dimensions

15

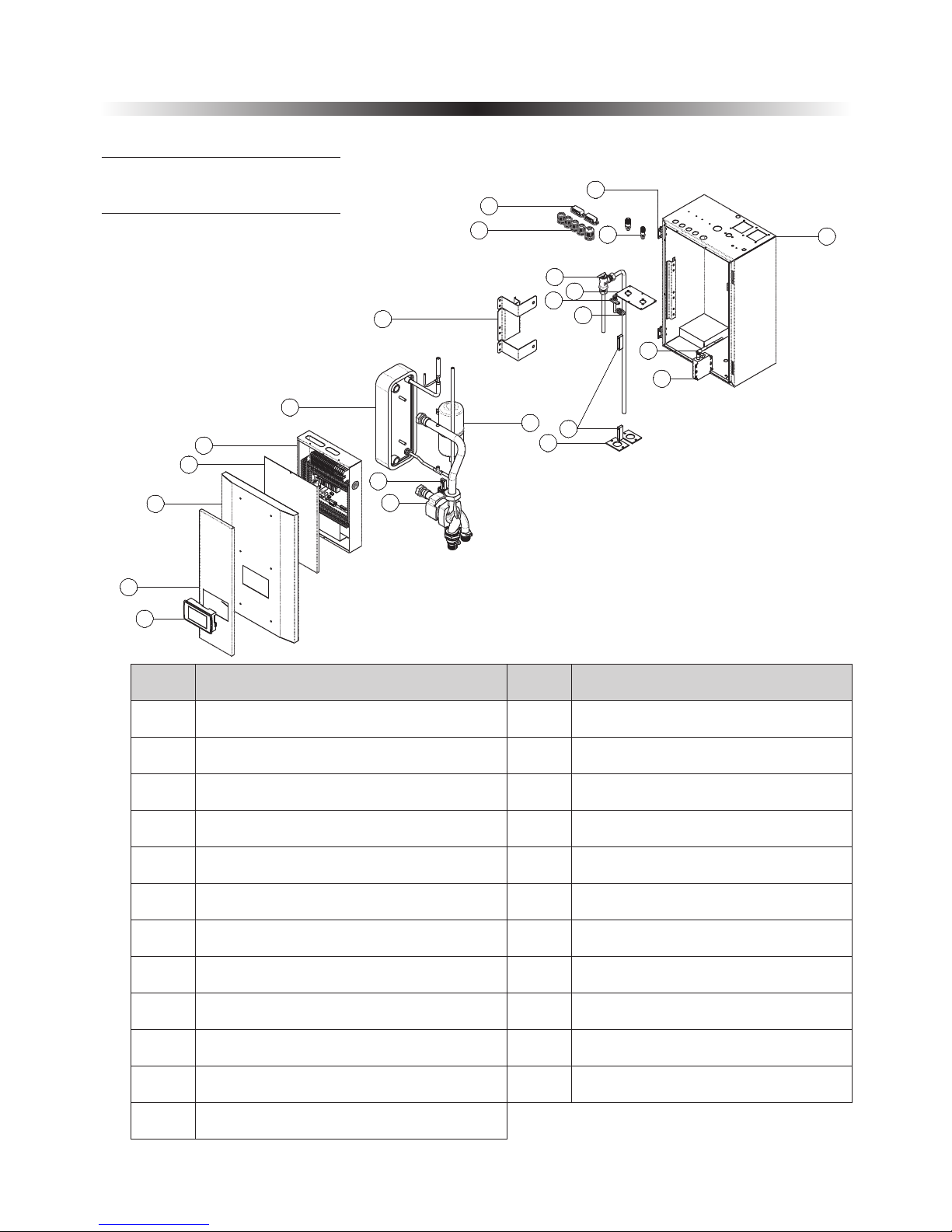

Indoo r ——AWH6-V6-SW

AWH9 -V6 -SW

AWH11 -V6-SW

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

22

Operation panel

Decorative panel

Door

Electric box cover

Electric box

Plate heat exchanger

Water pump

Water flow switch

Refrigerant expansion tank

Fixture of plate heat exchanger

Insulation panel

Sensor fixture

Cable gland

Refrigerant connector

Hinge

WIFI module

Receiving signal antenna

Casing

NO

Name

NO

Name

2.3. Exploded view

2. Overview of the Units

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1 2

Magnet

23

Needle valve for service

Plate for refrigerant connector

Cable clip

Air purging valve

16

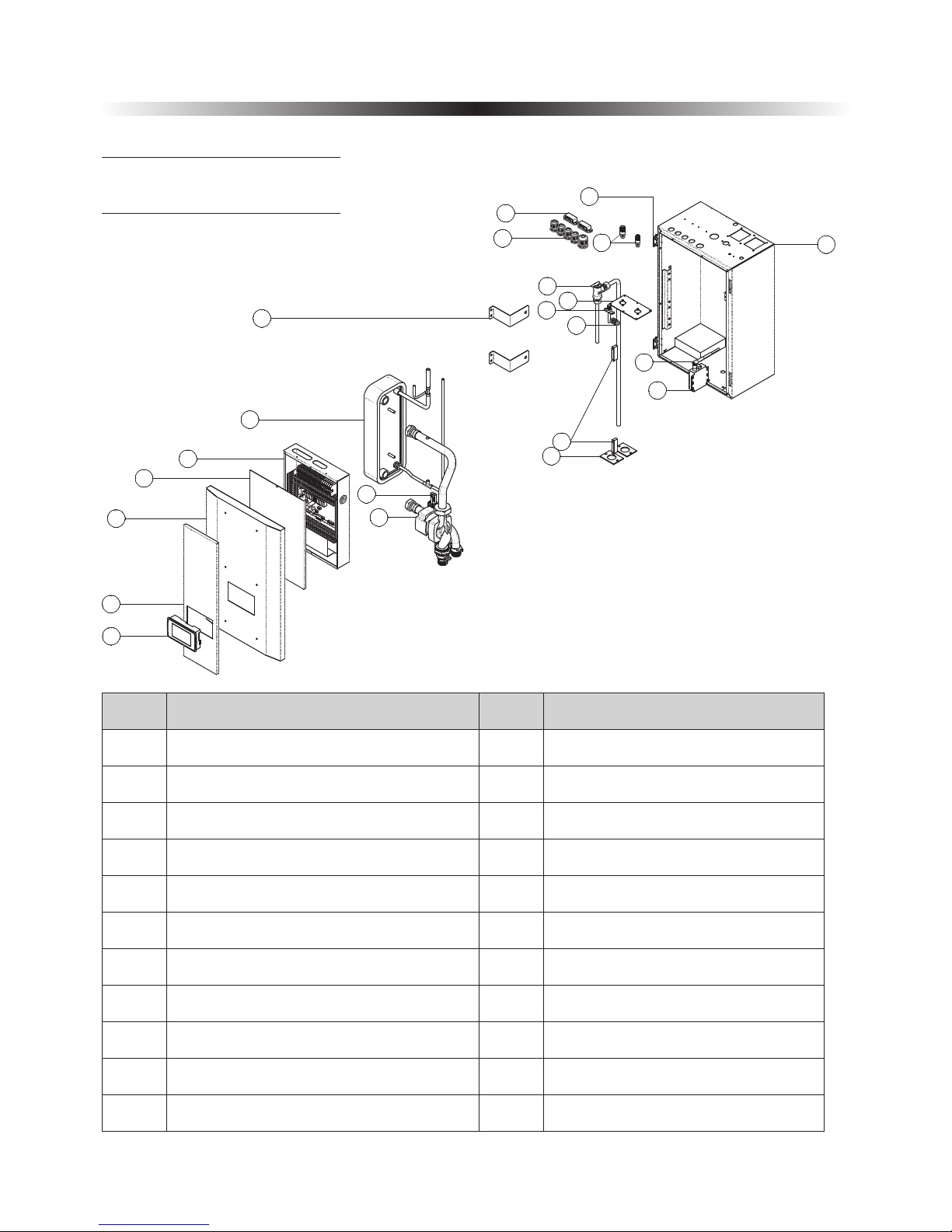

Indoo r ——AWH13-V6-SW

2.3. Exploded view

2. Overview of the Units

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

22

Operation panel

Decorative panel

Door

Electric box cover

Electric box

Plate heat exchanger

Water pump

Water flow switch

Fixture of plate heat exchanger

Insulation panel

Sensor fixture

Cable gland

Refrigerant connector

Hinge

WIFI module

Receiving signal antenna

Casing

NO

Name

NO

Name

1 2

Magnet

Needle valve for service

Plate for refrigerant connector

Cable clip

Air purging valve

17

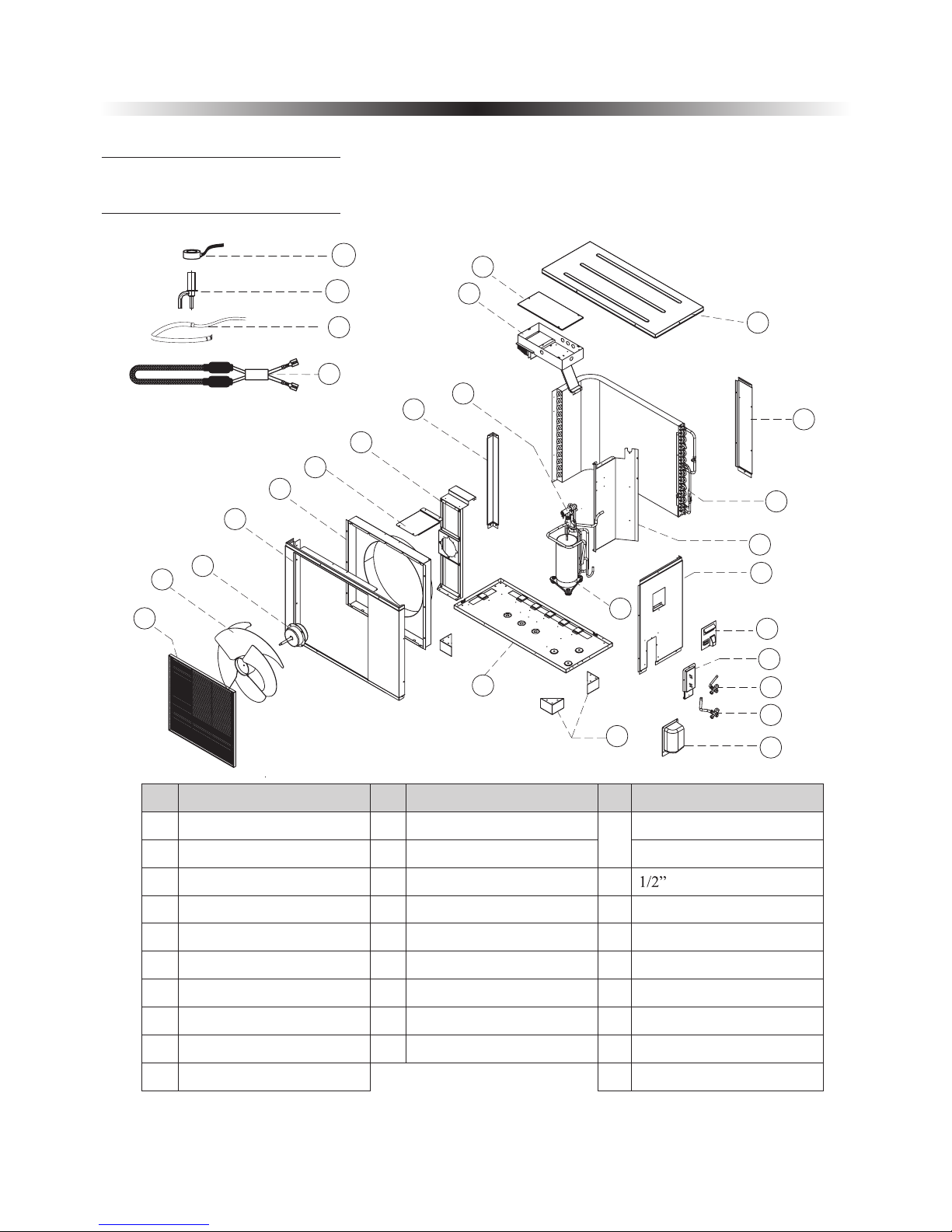

Outdo or —— AW6-V6-SG

AW9- V6- SG

AW11- V6-SG

26

27

28

8

9

5

6

7

1

2

3

4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

12

NO

Name

NO

Name

Decorative panel

Name

NO

13

14

15

17

18

19

20

23

24

25

26

27

28

NO NO

Fixture

Outdoor fan

Front panel

Motor bracket

Column support

Four-way valve

Air guide

Outdoor motor

1

2

3

4

5

6

7

8

9

Electrical box

Electric box cover

10

11

Top panel

Big handle

Back panel

Bulkhead

Bulkhead

3/8” -AW9/11-V6-SGValve

Condenser

Compressor

Compressor heater

Feet

Eev coil

Condebser heater

Electrical expansion valve

Bottom plate

21

22

Valve cover

Right plate

16

Valve

1/4” Valve-AW6-V6 -SG

2.3. Exploded view

2. Overview of the Units

18

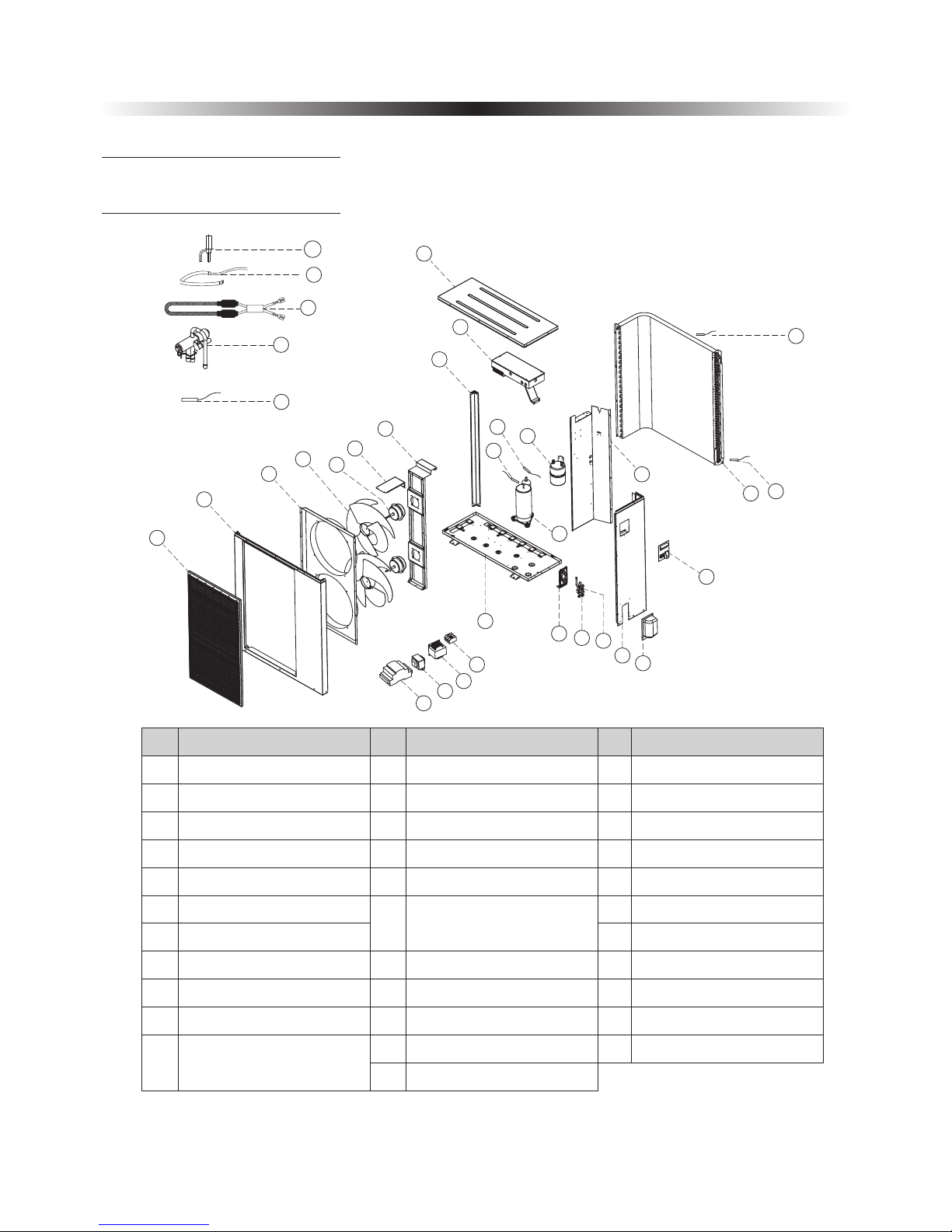

Outdo or —— AW13-V6-SG

1

2

3

4

6

7

8

9

10

5

12

13

14

15

18

11

16

17

19

20

21

22

23

24

11

29

30

32

31

33

25

26

27

28

13

NO

Name

NO

Name

Decorative panel

Name

NO

14

15

16

17

18

19

20

21

25

26

27

28

29

30

NO NO

Fixture

Front panel

Outdoor fan

Motor bracket

Column support

Controller

Outdoor motor

Air guide

31

32

1

2

3

4

5

6

7

8

9

Top panel

Coil and ambient

temperature sensor

Condenser

10

11

12

22

33

Bulkhead

Compressor

Handle

Suction temperature sensor

Bottom plate

Valve plate

5/8” Valve

Compressor discharge

temperature sensor

Sperator

3/8” Valve

Terminal block

Crankcase heater

PFC transducer

EEV controller

Condenser heater

4-Way valve

Electronic expansion valve

Transformer

EEV temperature sensor

23

24

Side panel

Valve cover

2.3. Exploded view

2. Overview of the Units

19

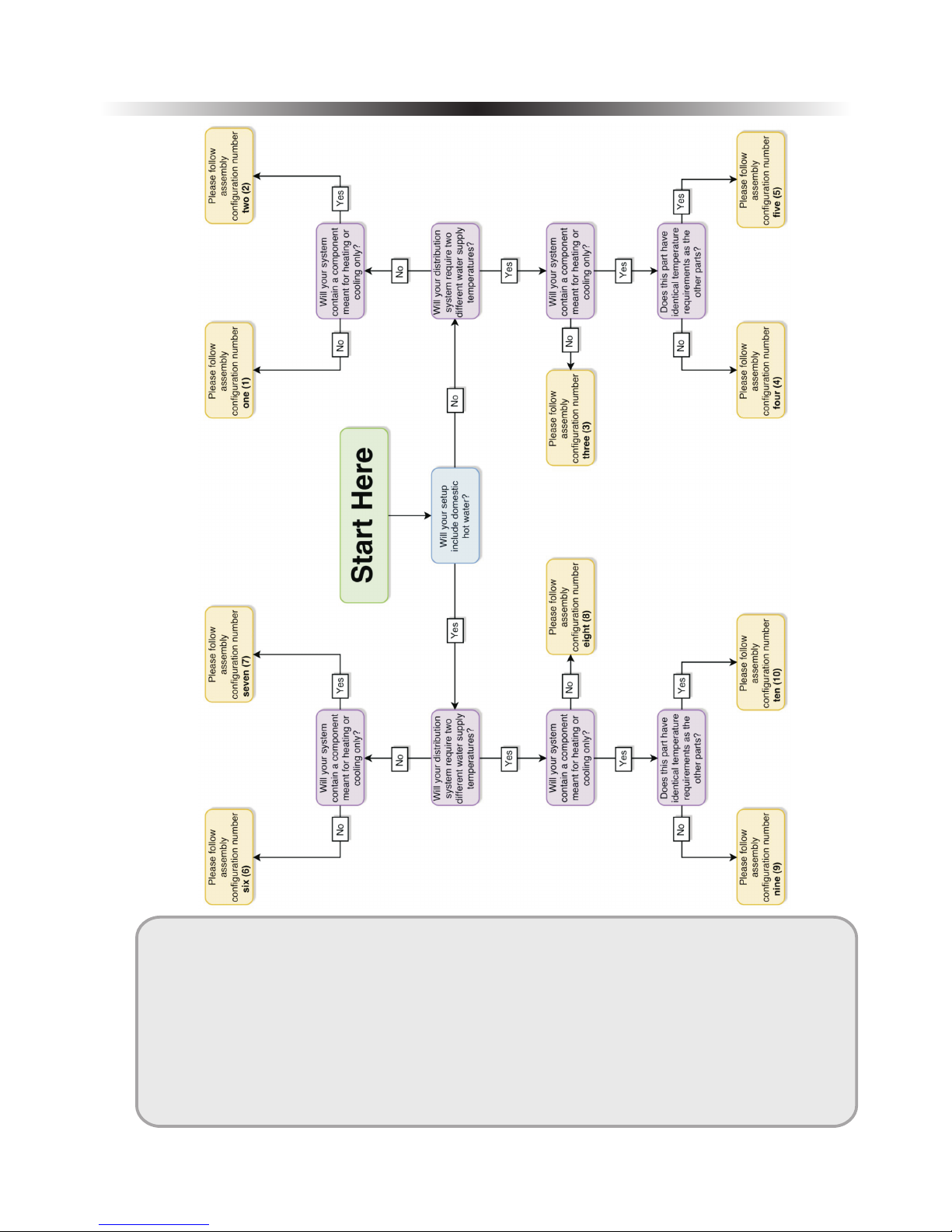

3. Assembly Configurations - Flowchart

Locate the Configuration that Meets Your Needs

Follow the flowchart on

the right in order to locate

which of the assembly

configuration matches the

needs of the end user,

each of which contains

specific assembly and

wiring diagrams, with

software instructions.

Beginning from the green

“Start Here” bubble,

follow the appropriate

arrows to each question,

which are dependent on

the needs of the user.

The corresponding

assembly instructions will

be found by turning to the

page number in the end

bubble.

Note: The instructions in this

section are meant to achieve

the minimum requirements for

successful system operation

only.

For more in-depth settings

explanations, please refer to

the user′s manual.

20

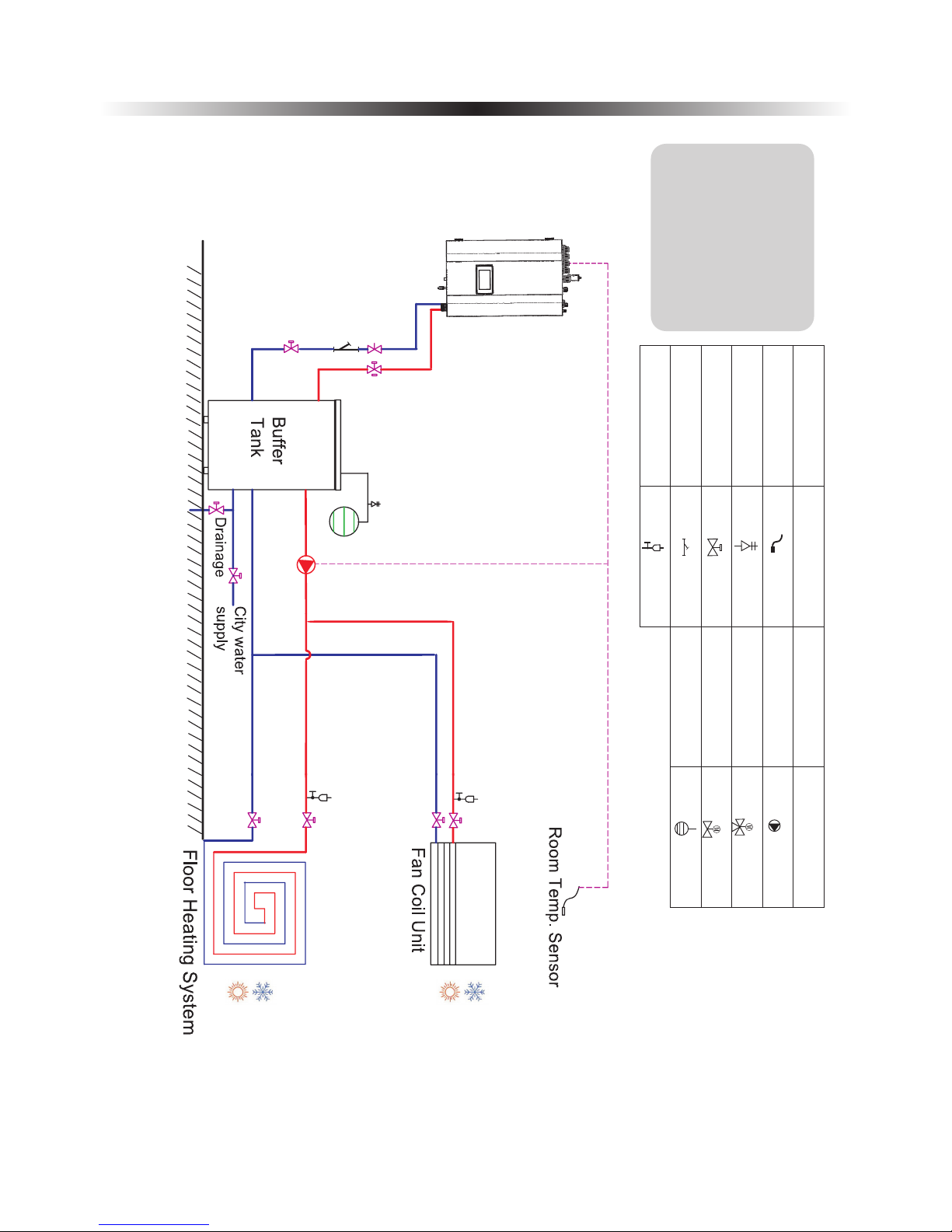

3. Assembly Configurations - Drawing 1

Notice: The Fan Coil Unit,

Floor Heating System, and

Radiator are placeholder

distribution systems only

and can be substituted by

any other appropriate

distribution systems.

Please ensure that the

configuration matches the

assembly drawing depicted

on the right for a one

temperature zone without

domestic hot water setup.

Note: Refer to the next page for

wiring and software

operation instructions.

Nam e

Sym bol

Nam e

Sym bol

Temp.Sen so r

Safety v al ve K it

Ball valve

Wat er f il te r

Air purg in g va lv e

Wat er p um p

Mixing v al ve

Motori ze d val ve

Expans io n ta nk

Note: Do tt ed l in es mean〝abl e to b e co nt ro ll ed by the Hea t Pu mp〞.

One Temperature Zone ,without DHW

21

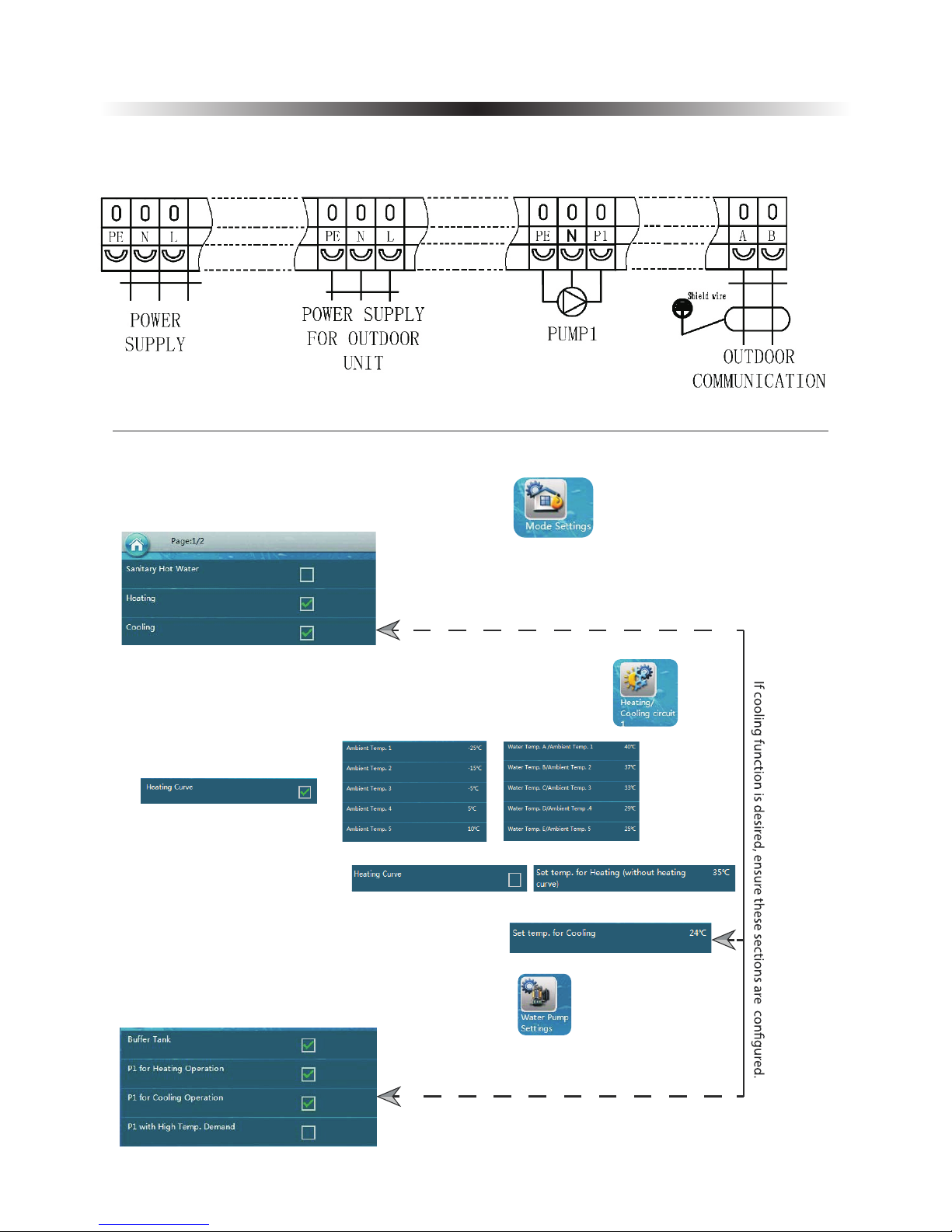

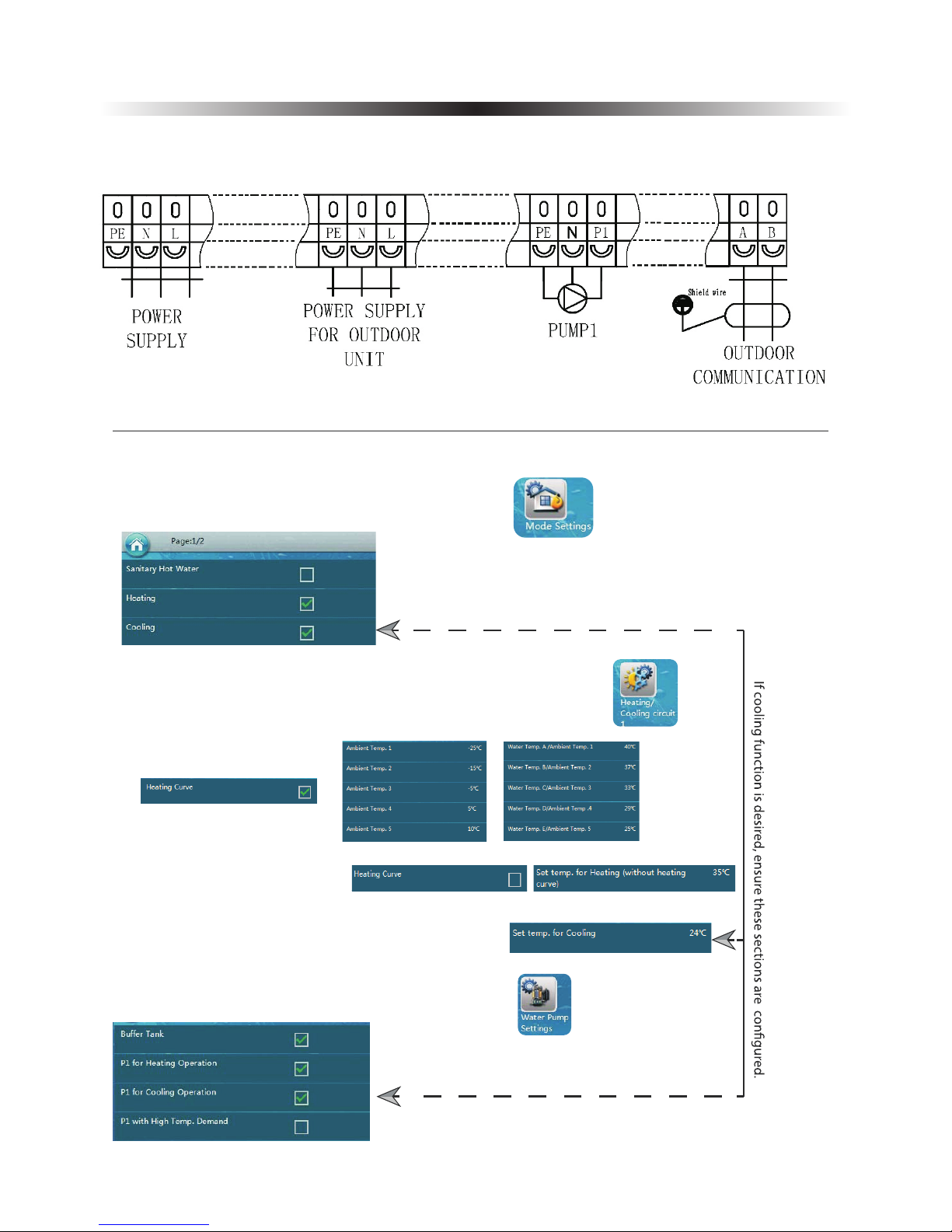

3. Assembly Configurations - Drawing 1

Assembly 1: Wiring Diagram

To achieve successful operation at a minimum, ensure the ports below are properly connected.

Software: Basic Settings

1.Se t the nee ded wor king mo des of th e unit vi a the men u

H.2. If no heating curve is desired:

3.Locate and activate the buffer tank and appropriate pumps under

H.1.Setting a heating curve:

H.Configuring the set water heating temperatures:

2.Temperatur e confi gurat ion opt ions fo r Heati ng/Co oling c ircui t 1 are found under

C.Co nfigu ring th e set wat er cool ing tem perat ure (if a pplicable):

22

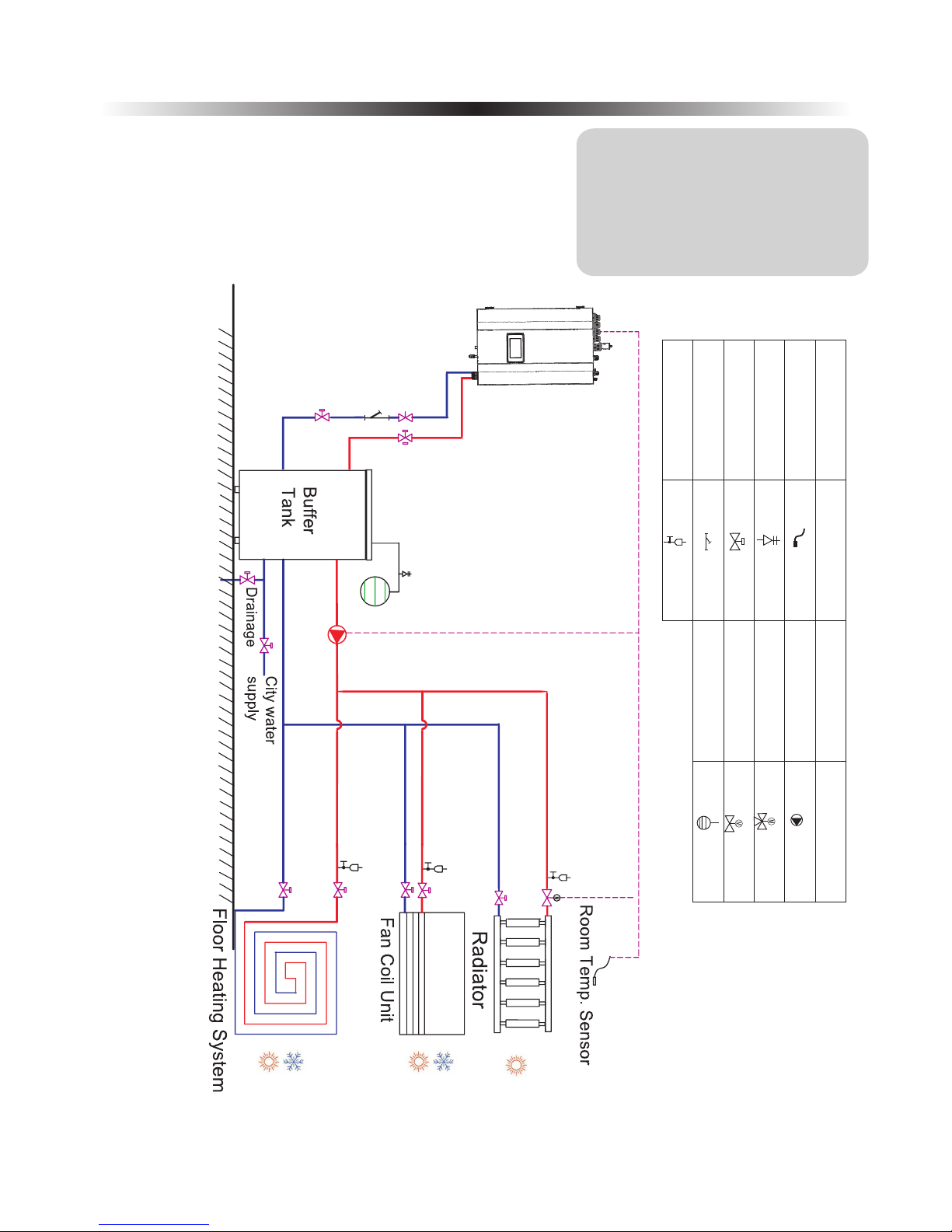

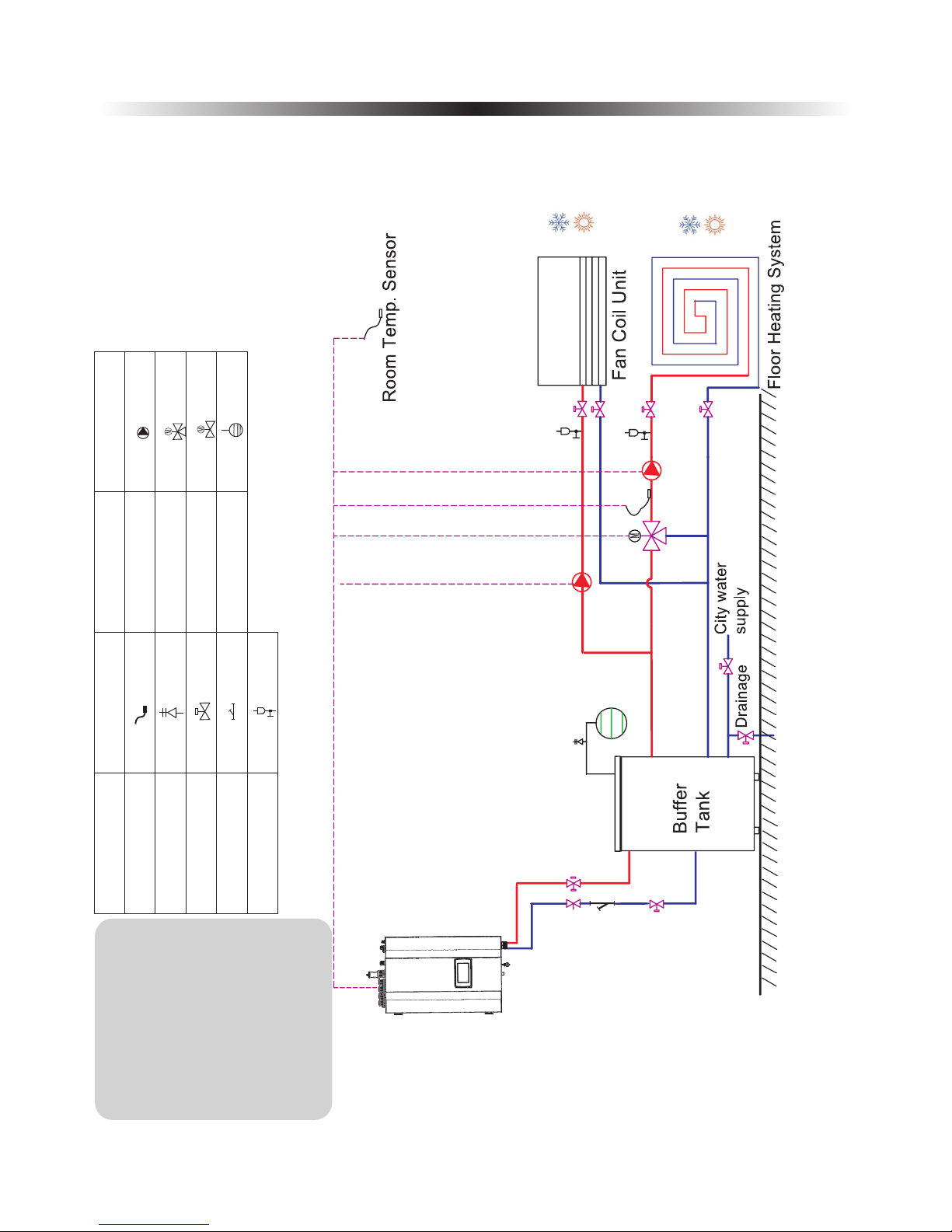

3. Assembly Configurations - Drawing 2

Notice: The Fan Coil Unit,

Floor Heating System, and

Radiator are placeholder

distribution systems only

and can be substituted by

any other appropriate

distribution systems.

Please ensure that the

configuration matches the

assembly drawing depicted

on the right for a one

temperature zone without

domestic hot water setup,

that includes a component

circuit capable of heating or

cooling only,through the use

of a two-way motorized

valve.

Note: For the cooling-only or

heating-only circuit, a

motorized two-way valve

can be connected to the

unit, to cut the water

supply during heating or

cooling operation.

Refer to the next page for

wiring and software

operation instructions.

Nam e

Sym bol

Nam e

Sym bol

Temp.Sen so r

Safety v al ve K it

Ball valve

Wat er f il te r

Air purg in g va lv e

Wat er p um p

Mixing v al ve

Motori ze d val ve

Expans io n ta nk

Note: Do tt ed l in es mean〝abl e to b e co nt ro ll ed by the Hea t Pu mp〞.

One Temperature Zone ,without DHW,with a heating-only

(or cooling-only) circuit,by usage of a motorized 2-way valve

23

3. Assembly Configurations - Drawing 2

Assembly 2: Wiring Diagram

To achieve successful operation at a minimum, ensure the ports below are properly connected.

Software: Basic Settings

1.Se t the nee ded wor king mo des of th e unit vi a the men u

H.2. If no heating curve is desired:

3.Locate and activate the buffer tank and appropriate pumps under

H.1.Setting a heating curve:

H.Configuring the set water heating temperatures:

2.Temperatur e confi gurat ion opt ions fo r Heati ng/Co oling c ircui t 1 are found under

C.Co nfigu ring th e set wat er cool ing tem perat ure (if a pplicable):

24

3. Assembly Configurations - Drawing 2

Software: Basic Settings (continued)

4.The location of the configuration for heating-only or cooling-only system is under

25

3. Assembly Configurations - Drawing 3

Nam e

Sym bol

Nam e

Sym bol

Temp.Sen so r

Safety v al ve K it

Ball valve

Wat er f il te r

Air purg in g va lv e

Wat er p um p

Mixing v al ve

Motori ze d val ve

Expans io n ta nk

Note: Do tt ed l in es mean〝abl e to b e co nt ro ll ed by the Hea t Pu mp〞.

Notice: The Fan Coil Unit,

Floor Heating System,and

Radiator are placeholder

distribution systems only

and can be substituted by

any other appropriate

distribution systems.

Please ensure that the

configuration matches

the assembly drawing

depicted on the right for

a two temperature zone

without domestic hot

water setup.

Note: Refer to the next page

for wiring and

software operation

instructions.

Two Temperature Zones ,without DHW

Loading...

Loading...