Heat Pump

DC Inverter Air to Water

Before operating this product, please read the

instructions carefully and keep this manual for future use.

User’s manual

User’s manual

AWH9/11-V5+

MBG series

2

1. Before use

1.1 Safety precautions

1.2 Working principle

1.3 Main components

1.4 Specifications

2. Installation

2.2 Tools needed

2.3 Installation of the indoor control unit

2.4 Installation of the monoblock unit

2.5 Accessories

2.6 Wiring

2.7

2.8

2.9

3. Usage

3.1 Introduction of wired controller

3.2 Parameter setting overview

3.6

4. Maintenance

4.1 Attention

4.5

4.6

4.7

4.8 Trouble-shooting

5.

5.1 Outlines and dimensions

5.2 Exploded view

5.3 Wiring diagram

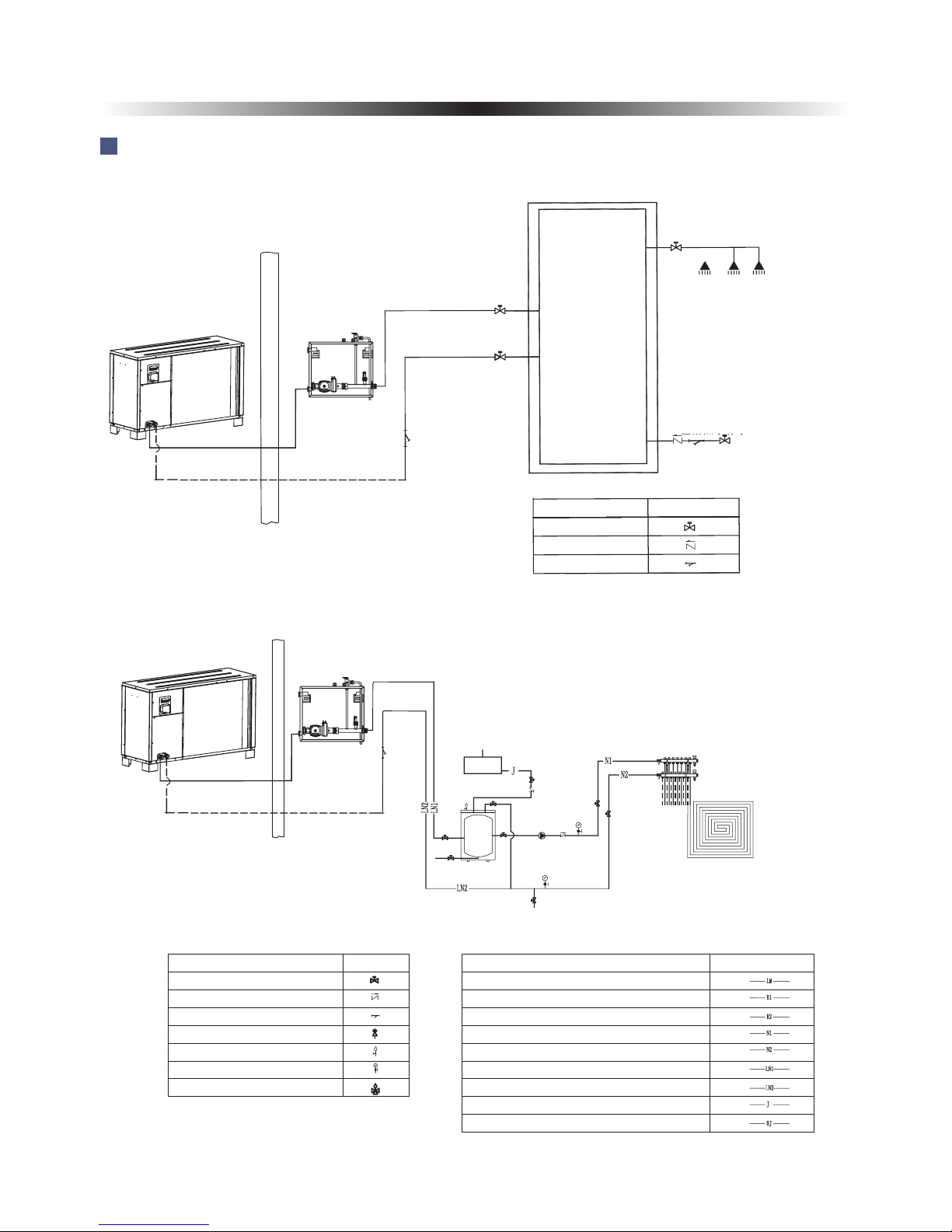

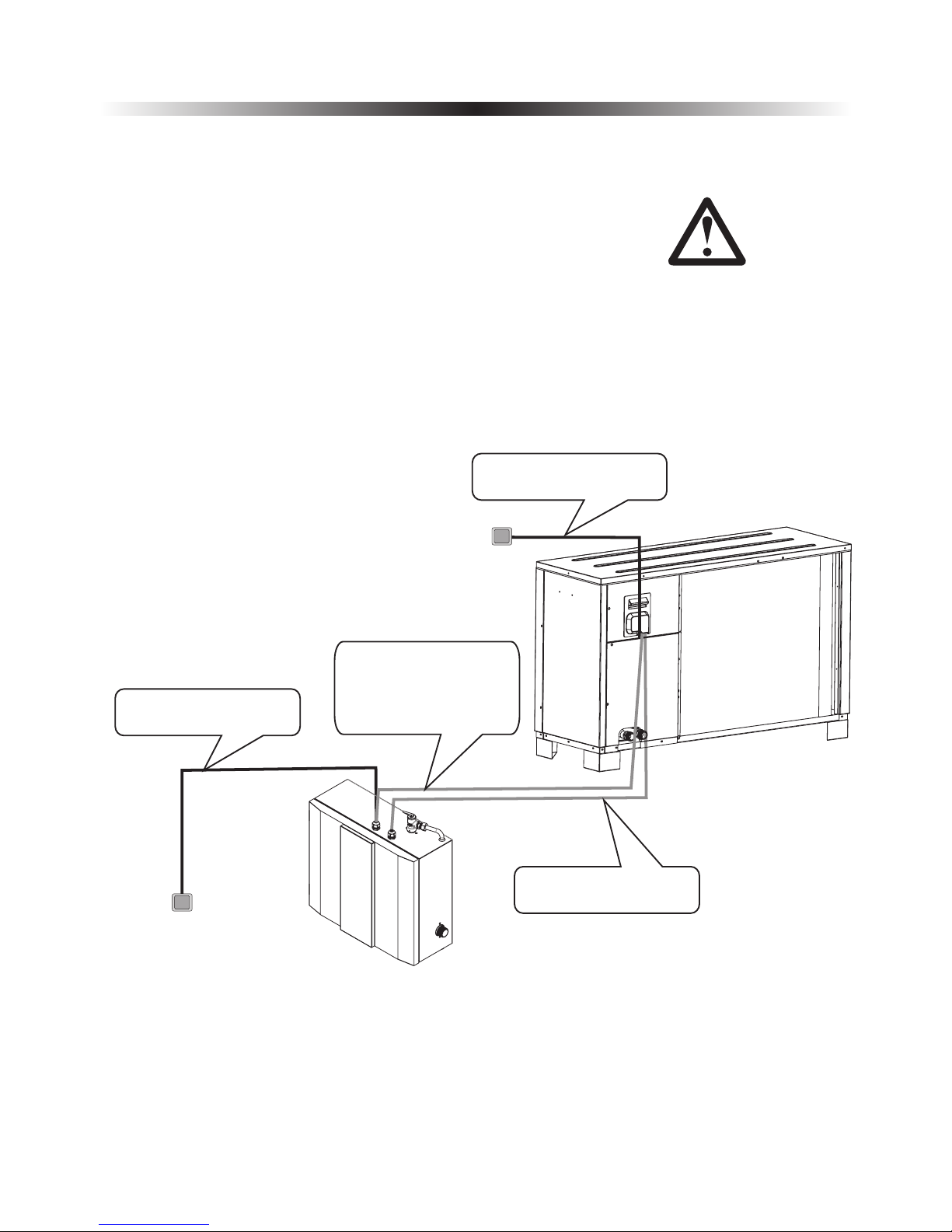

2.1 General application system introduction

Installation of safety valve kit

3.3 Basic operation

4.2 Cleaning of water filter

4.3 Cleaning of plate heat exchanger

4.4 Gas charging

Condenser coil

Service of indoor control unit

Service of monoblock unit

Water pipe connection

Test run

3.4 Advanced setting

3.5 Failure code

Error code

Attached drawing

4

4

6

7

8

11

11

13

13

15

17

18

25

26

27

28

28

30

35

47

58

59

68

68

68

68

68

69

69

72

76

78

78

81

83

Catalogue

3

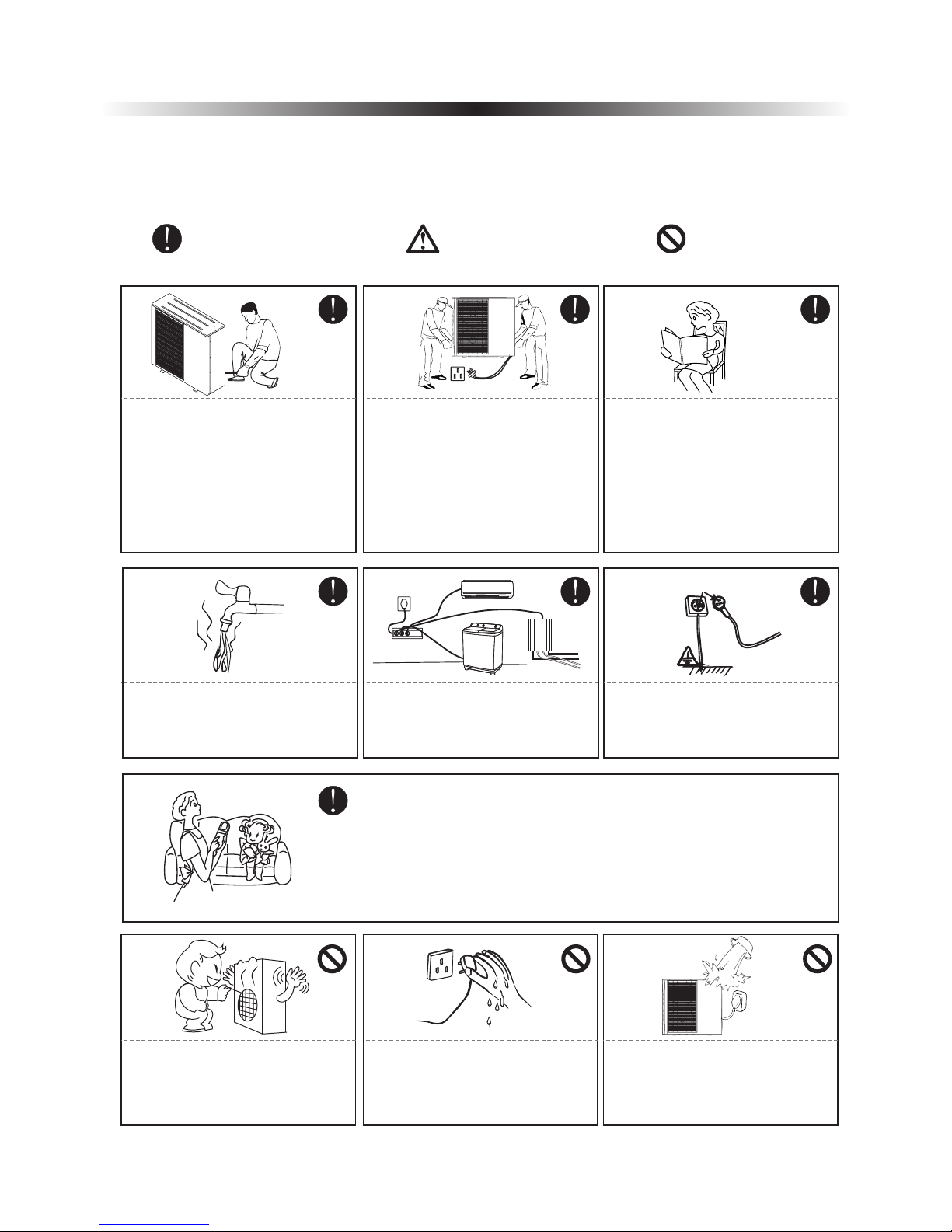

1. Before use

CautionWarning

Prohibition

1.1 Safety precautions

The following symbols are very important. Please be sure to understand their meaning, which concerns

the product and your personal safety.

The installation, dismantlement

and maintenance of the unit must

be performed by qualified

personnel. It is forbidden to do any

changes to the structure of the unit.

Otherwise injury of person or unit

damage might happen.

To avoid electrical shock, make

sure to disconnect the power

supply 1 minute or more before

servicing the electrical parts. Even

after 1 minute, always measure the

voltage at the terminals of main

circuit capacitors or electrical parts

and, before touching, make sure

that those voltages are lower

than the safety voltage.

User Ma nual

Be sure to read this manual before

use.

For sanitary hot water, please

always add a mixture valve before

water tap and set it to proper

temperature.

Ground wire

Use a dedicated socket for this

unit, otherwise malfunction may

occur.

The power supply to the unit must

be grounded.

Do not touch the air outlet grill

when fan motor is running.

Do not touch the power plug with

wet hands. Never pull out the plug

by pulling the power cable.

Water or any kind of liquid is

strictly forbidden to be poured into

the product, or may cause electric

creepage or breakdown of the

product.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

4

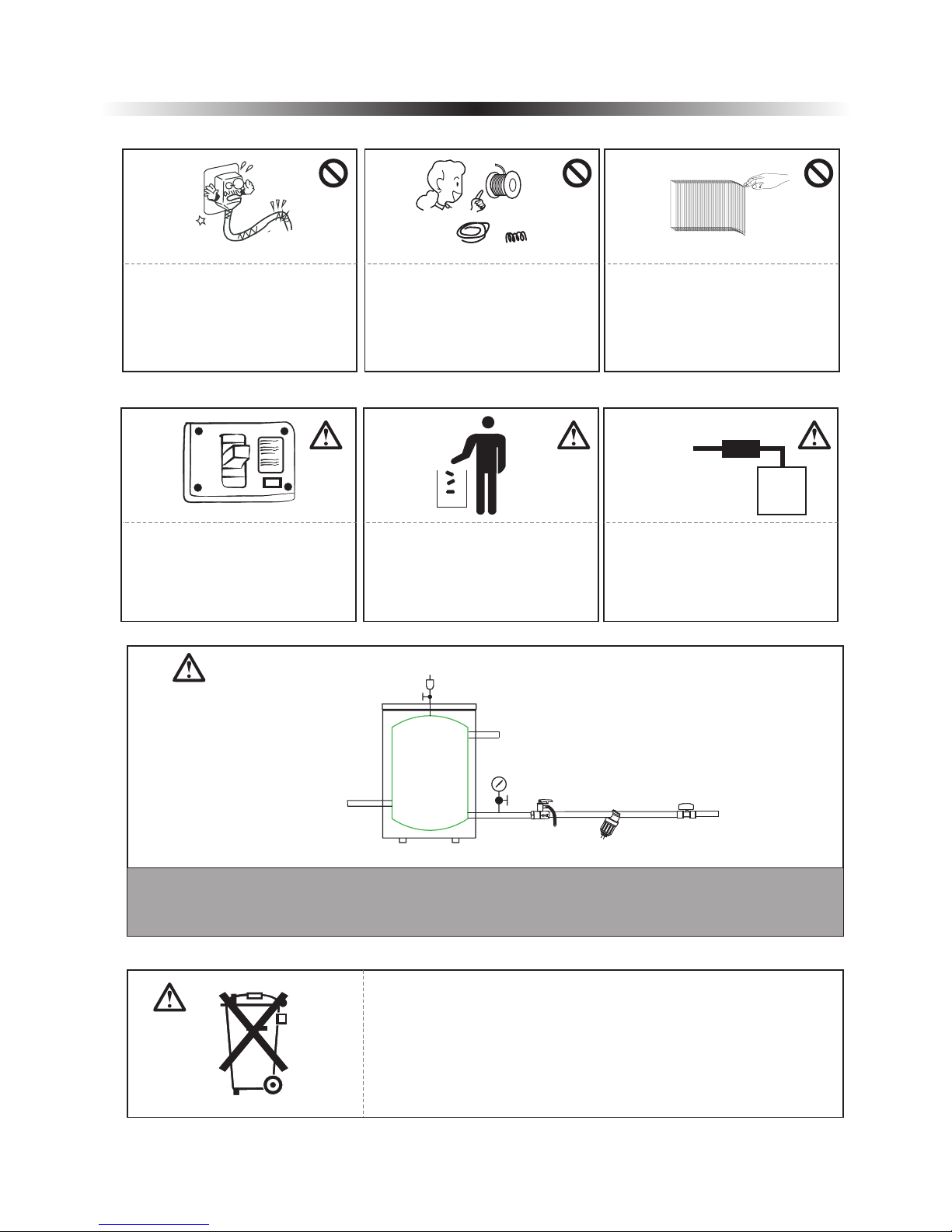

1. Before use

Copper

Steel

Fuse

Main

Power Cable

RCD

Indoor

control

unit

When the power cord gets loose

or damaged, always get a qualified

person to fix it.

It is mandatory to use a suitable

circuit breaker for the heat pump

and make sure the power supply to

the unit corresponds to the

specifications. Otherwise the unit

might be damaged.

Disposal of Scrap Batteries(if

there is).Please discard the

batteries as sorted municipal waste

at the accessible collection point.

Installation of a residual current

device (RCD) having a rated

residual operating current not

exceeding 30 mA is advisable.

ON

OFF

Please select the correct fuse or

breaker as per recommended. Steel

wire or copper wire cannot be

taken as substitute for fuse or

breaker. Otherwise, damages

maybe caused.

Be aware fingers might be hurt by

the fin of the coil.

5

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote the sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

System water filling

T/P valve

Connect to heating/cooling system

Buffer tank

Connect to heat pump

One way valve

Filter

City water inlet

1. It's suggested to use pure water for filling the system.

2. If use city water for filling, please soften the water and add a filter.

Note: After filling, the system of water system should be 0.15~0.6MPa.

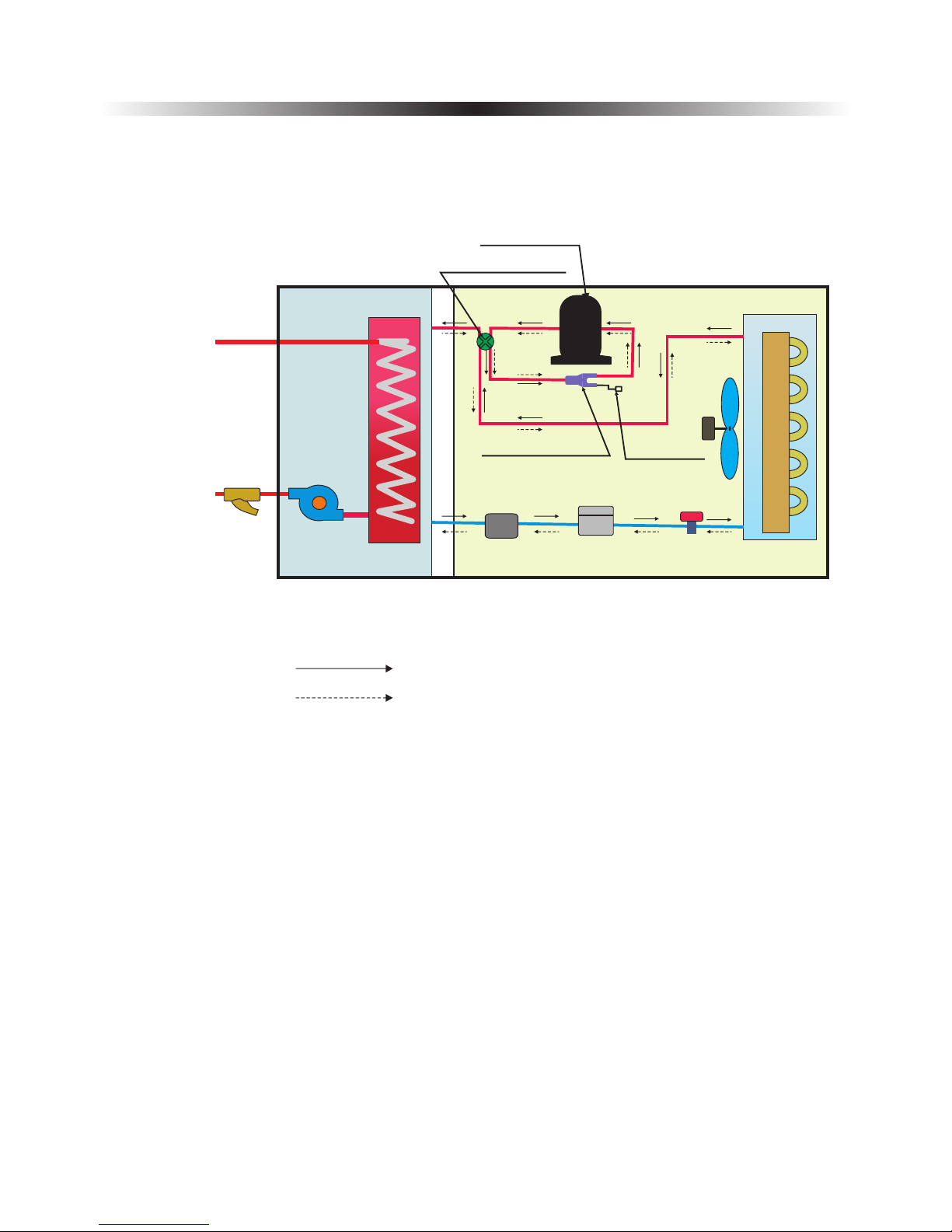

1.2 Working principle

1. Before use

Water inlet

Water Outlet

Filter

Water pump

Heat

exchanger

Power supply

Four-way vavle

Compressor

Three-way valve

Refrigerant Filter

T-connector

Fan motor

Pressure

check valve

Evaporator

Heating

Cooling

6

Operation panel

Cable gland

Water outlet

Water inlet

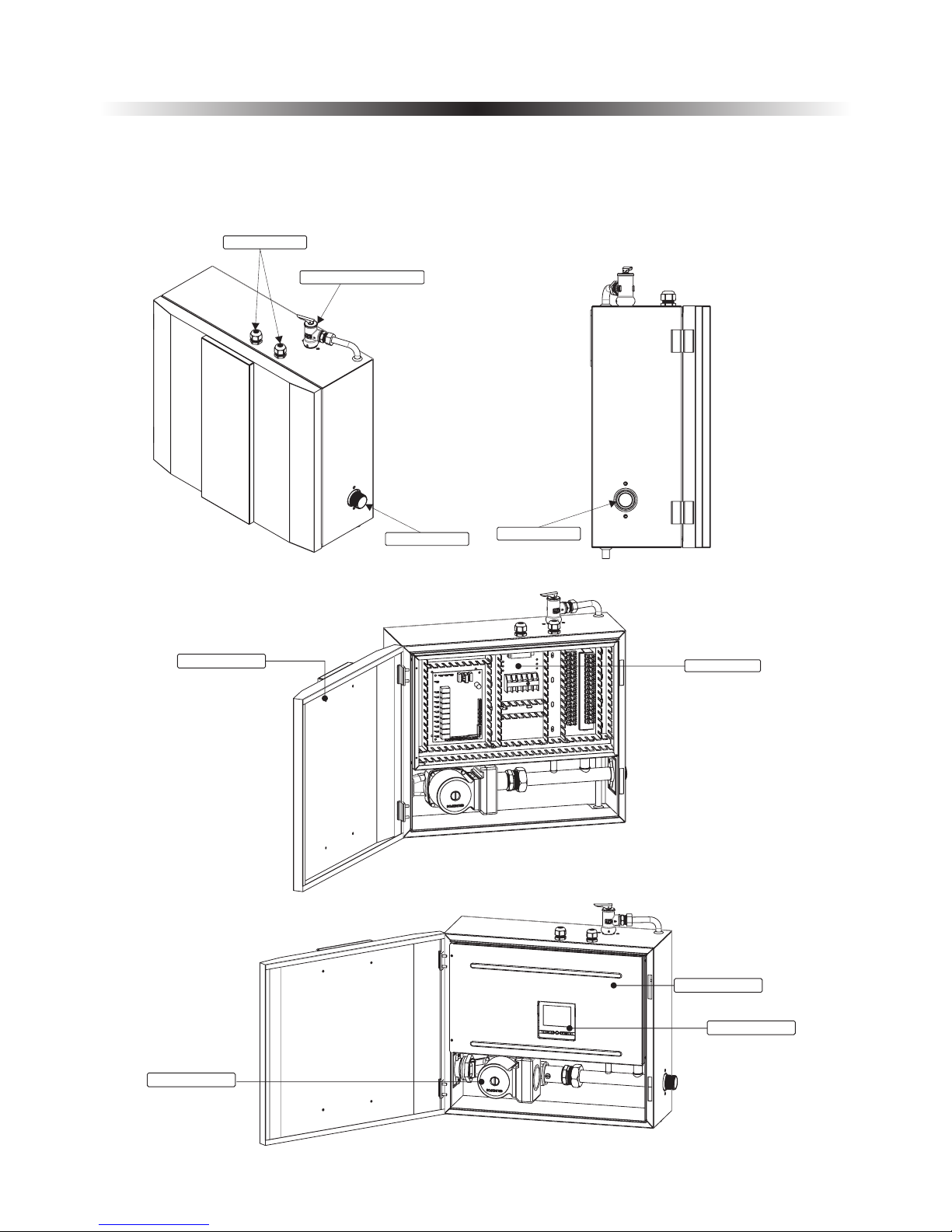

1.3 Main components

1. Before use

1.3.1 Indoor control unit

7

Press ur e Re li ef Valves

Electric box

Door

Electric box cover

Water pump

1.3.2 Monoblock unit

1. Before use

8

AW9-V5+

AW11-V5+

1. Before use

1.4 Specifications

9

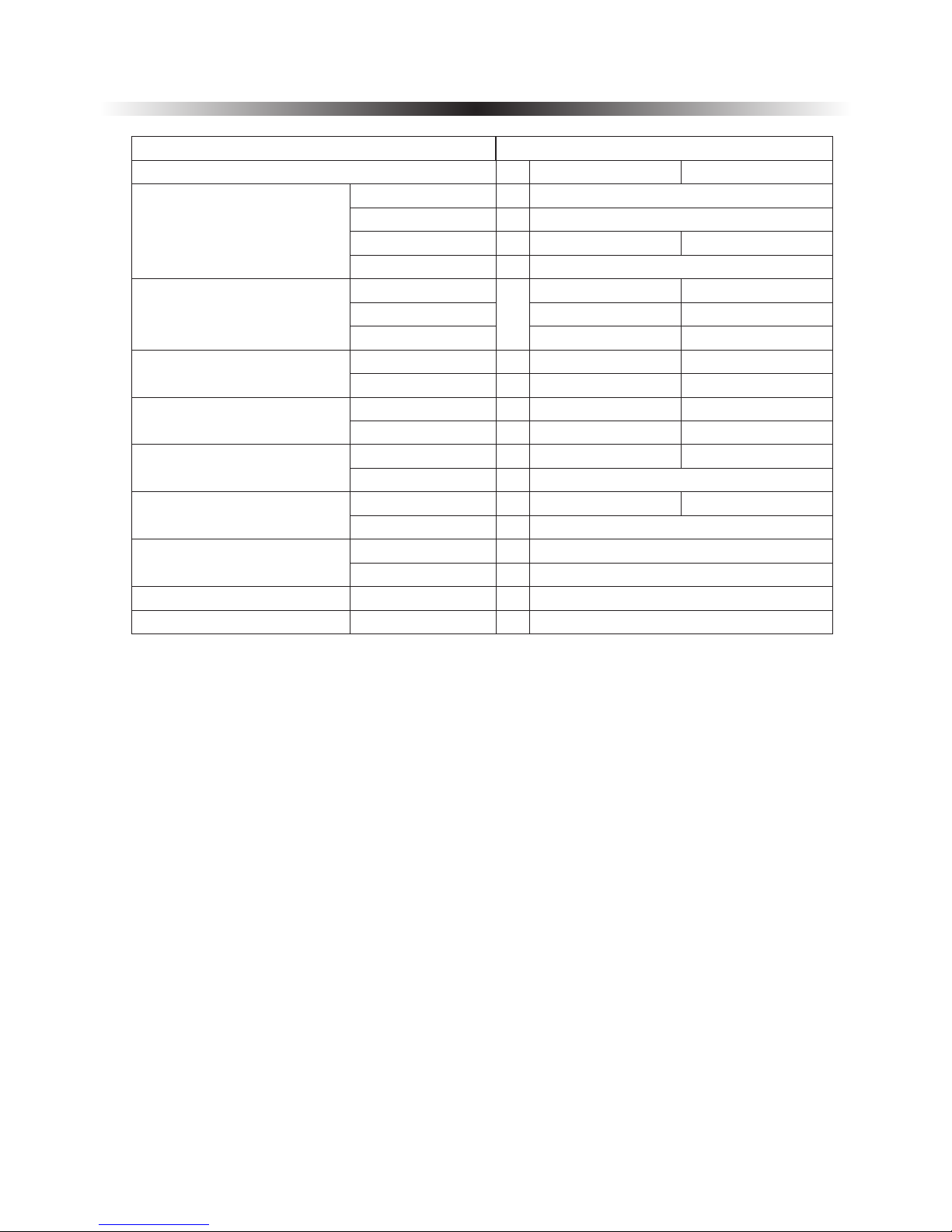

Model

Power Supply

V/Hz/Ph

AWH11-V5+

AWH9-V5+

220-240/50/1

Refrigerant

Max. Heating Capacity (1)

C.O.P (1)

Heating Capacity Min./Max.(1)

Heating Power Input Min./Max.(1)

C.O.P Min./Max.(1)

Max. Heating Capacity(2)

C.O.P (2)

Heating Capacity Min./Max.(2)

Heating power input Min./Max.(2)

C.O.P Min./Max.(2)

Max. Cooling Capacity(3)

E.E.R (3)

Cooling Capacity Min./Max.(3)

Cooling Power Input Min./Max.(3)

E.E.R Min./Max.(3)

Max. Cooling Capacity(4)

E.E.R(4)

Cooling Capacity Min./Max.(4)

Cooling Power Input Min./Max.(4)

E.E.R Min./Max.(4)

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

11.510.10

3.824.03

4.67/11.5

4.33/10.10

915/3029

975/2153

3.82/5.05

4.02/4.65

10.7

9.53

2.95

3.17

4.14/10.74.19/9.53

1218/36241230/2990

2.95/3.563.12/3.55

9.2

6.84

2.682.09

4.33/9.24.10/6.84

993/3465

1230/3280

2.685/4.11

2.09/3.32

6.745.05

2.15

1.58

2.17/6.742.34/5.05

924/31321080/3200

2.15/3.01.58/2.40

R410A/1.9

R410A/2.45

Circuit Max. Pressure

bar

42

Rated Power Water Pump

W

Compressor

Type

Quantity/System

Twin Rotary

1

Oil

Fan

Quantity

Airflow

Rated Power

m³/h

W

31003000

60

1

1

Allowable

Fan Flow

Face Area

Row-Fins/Inch

Tube.Dia

m²

Inch

0.8710.542

Kg

Type of Product

DC Inverter Air to Water Heat Pump Unit

Noise Level

Indoor/Outdoor

30/56

dB(A)

87

FV50S

3/8 O.D

2 Rows-14

30/56

1. Before use

10

NOTE:

(1) Heating condition: water in/out temperature:30℃/35℃, ambient temperature:DB/WB 7/6℃;

(2) Heating condition: water in/out temperature:40℃/45℃, ambient temperature:DB/WB 7/6℃;

(3) Cooling condition: water in/out temperature:23℃/18℃, ambient temperature:35℃;

(4) Cooling condition: water in/out temperature:12℃/7℃, ambient temperature:35℃.

(5) The specifications are subject to change without prior notice.

For actual specifications of the unit, please refer to the specification stickers on the unit.

Net Dimension (L×D×H)

Packing Dimension (L×D×H)

Net Weight

Packing Weight

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

1215×415×7601064×353×754

500 495 210× ×

1310× ×830520

1130 460 904× ×

94

20

81

98

86

Water Side Heat Exchanger

Allowable Water Flow

Type

Water Pressure Drop

Piping Connection

Min. Water Flow

Rated Water Flow

Max. Water Flow

23

G1”

0.520.43

0.310.26

0.620.51

Material

Heating

Cooling

Operating Ambient Temp. range

Operating Inlet Water Temp. range

Water Volume

mm

mm

mm

mm

Kg

Kg

Kg

Kg

Kpa

Inch

L/S

℃

℃

℃

Kg

18

-25~46

0~55

7~75

4.5

Plate Heat Exchanger

Stainless Steel+Copper

Model

Type of Product

DC Inverter Air to Water Heat Pump Unit

23

600×520×260

AWH9-V5+ AWH11-V5+

500 495 210× ×

600×520×260

2. Installation

11

2.1 Application system introduction

To city water

Wate r disch arge outlet

De 25

De 3 2

De 3 2

De 40

De 4 0

De 2 5

De 2 5

De 3 2

De 3 2

UP S 2 5 / 8 0

热水 出 水

口G1

"

生活热

水补 水

口

G1

"

G1

"

G1

"

AH

-

2

00

L

40

~

5

0℃

Application 1: Sanitary hot water

Hot wa ter outle t

City water inlet

Application 2: Floor heating system

Name

Drawing

Ball valve

One way valve

Filter

Drain outlet

30L buff er t ank

Floor heatin g

distributi on sy ste m

Name

Drawing

Ball valve

One way valve

Filter

Safe valve

Air discharge valve

Water pressure gauge

Motor three way valve

Refrigerant pipe

Hot water outlet pipe

Hot water inlet

Heating water outlet pipe

Heating water inlet pipe

Cooling/heating water outlet pipe

Cooling/heating water inlet pipe

City water inlet pipe

Sanitary hot water outlet pipe

Name

Drawing

2. Installation

12

De 3 2

De 3 2

De 4 0

De 4 0

De 2 5

De 2 5

De 3 2

De 3 2

UP S 2 5 / 8 0

12

11

9

10

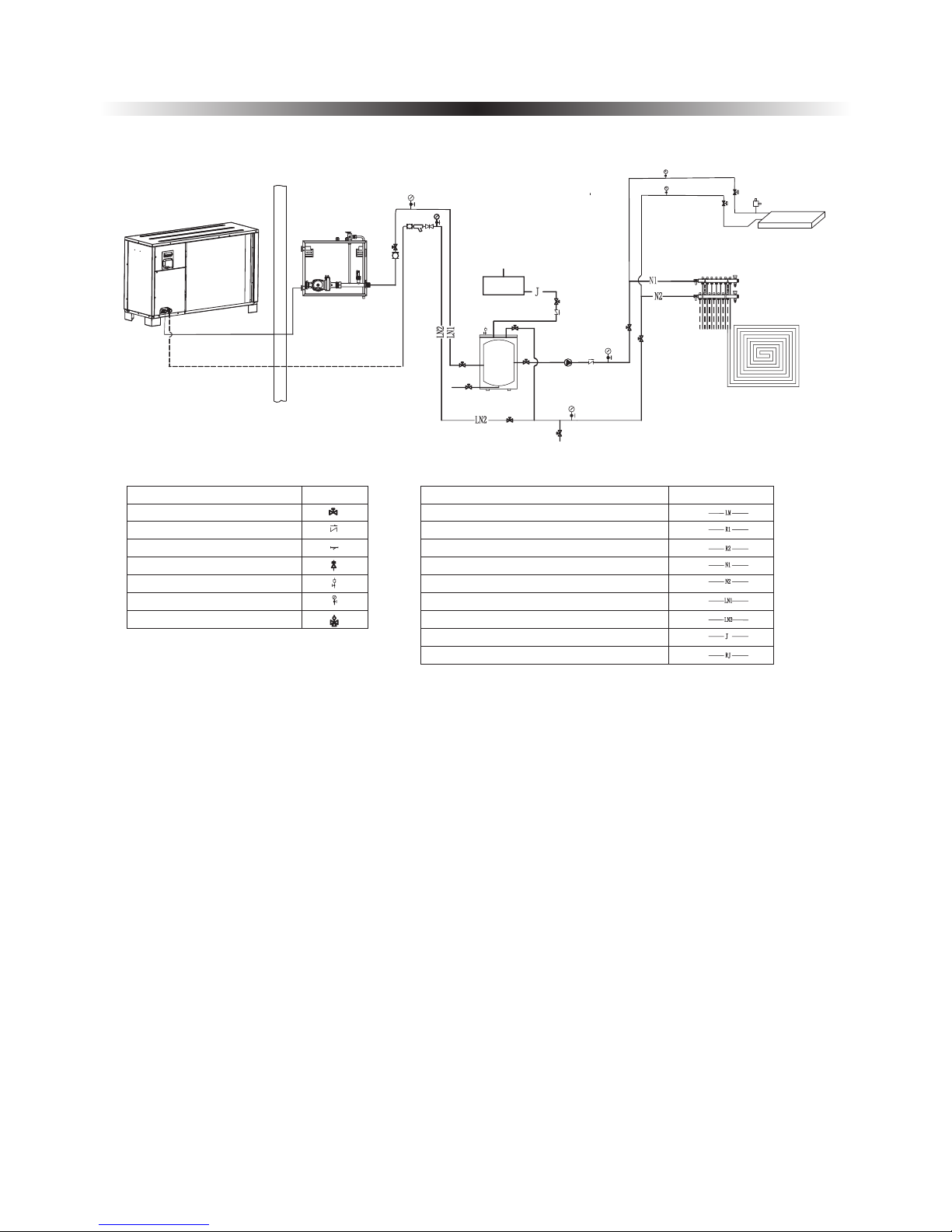

Application 3: Heating and cooling system

Fan coil unit

Floor heatin g

distributi on sy ste m

To city water

Drain outlet

30L buff er t ank

Wate r disch arge outlet

De 25

Name

Drawing

Ball valve

One way valve

Filter

Safe valve

Air discharge valve

Water pressure gauge

Motor three way valve

Refrigerant pipe

Hot water outlet pipe

Hot water inlet

Heating water outlet pipe

Heating water inlet pipe

Cooling/heating water outlet pipe

Cooling/heating water inlet pipe

City water inlet pipe

Sanitary hot water outlet pipe

Name

Drawing

The installation of the product should be handled by professional installers or under their

instructions.

>500mm

>100mm >100mm

>500mm

2. Installation

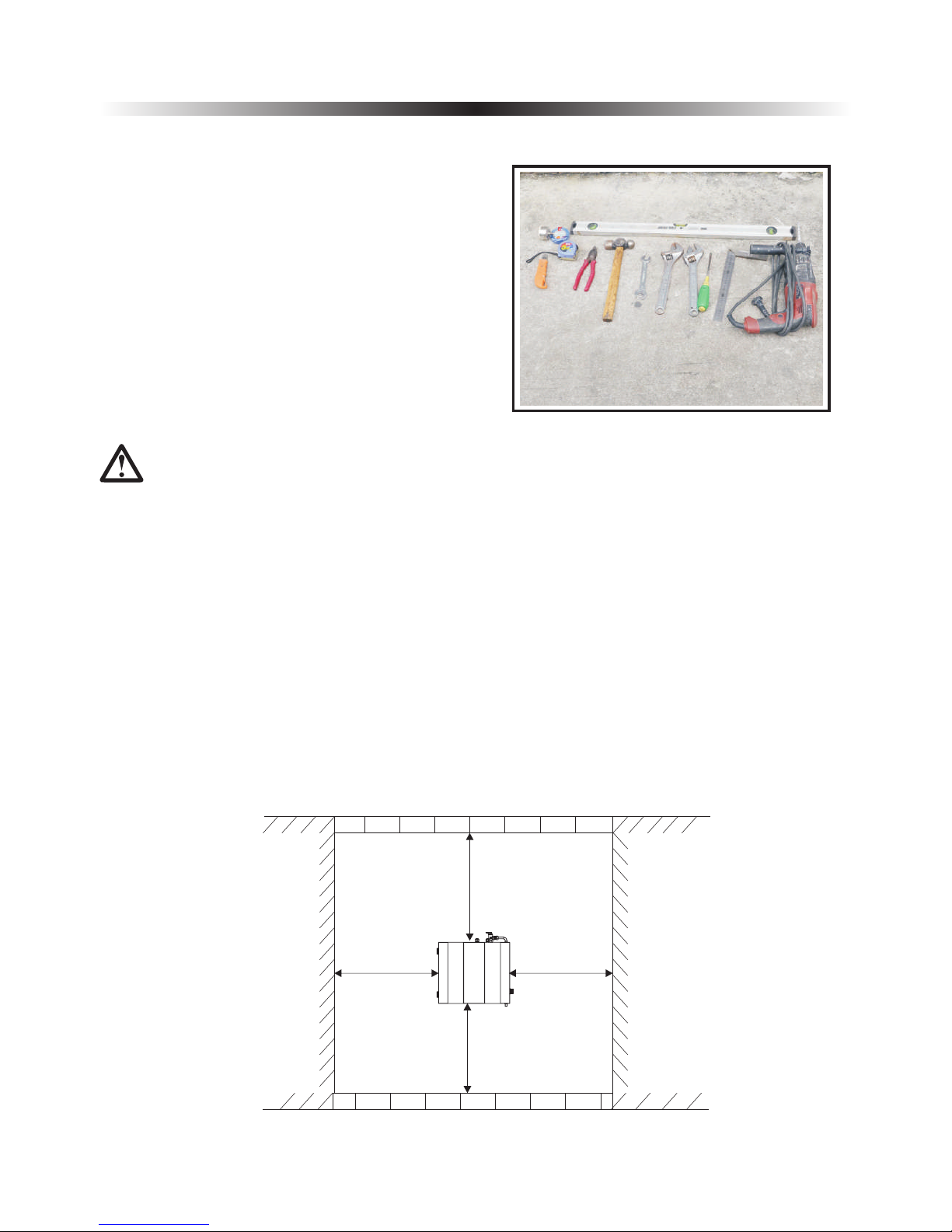

2.2 Tools needed

2.3 Installation of the indoor control unit

Most people already have the tools needed for

installation: spirit level, pencil, crosshead

screwdriver, drill, 8 mm. concrete drill bit, detection

drill, square, tape measure or ruler, tape width 65

mm, hole saw about 80 mm (deviation in size may

occur), knife and two adjustable spanners or pliers

(and possibly torque wrench).

2.3.1 Installation notes

1)

2) The indoor unit shall be placed in dry and well-ventilated environment.

3) Indoor unit mustn't be installed in an environment where volatile, corrosive or flammable liquid

or gas exists.

4)

The indoor control unit should be installed indoors and mounted on the wall, with water outlet

downwards.

control

control

control

Please choose a suitable position to install the indoor control unit as follows:

Enough space should be left around the indoor unit for futher maintenance.

13

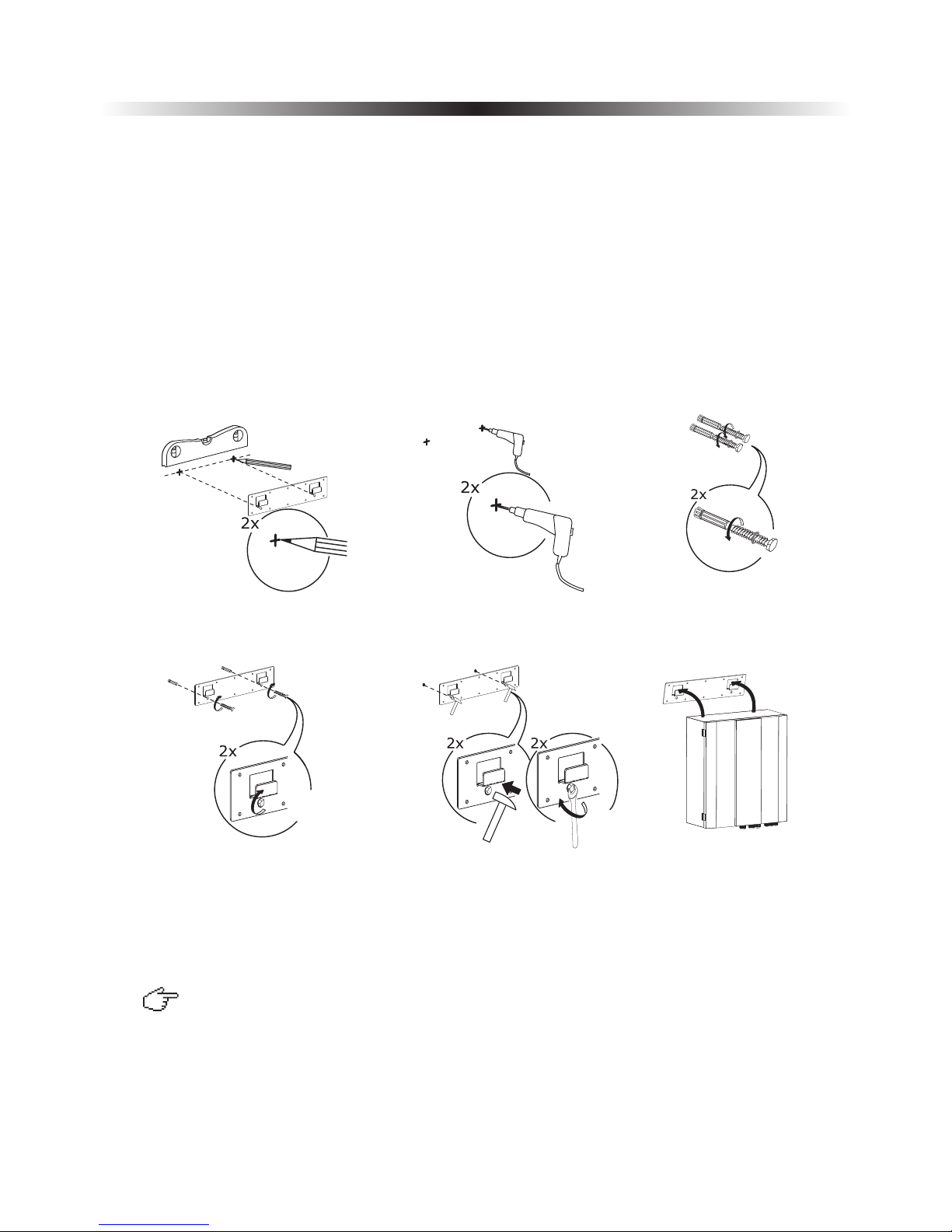

2.3.2 Installation

Indoor unit should be mounted on the wall as per procedures below:

1) Take out the expansion bolts and mounting board from accessory and put the mounting board on the

wall horizontally; Mark on the wall the location for bolts through the holes on mounting board.

2) Drill holes with proper diameter for expansion bolts.

3)

4)

5)

6) Hang the indoor unit onto the mounting board and make sure it's placed well before you let go

your hands. The installation is finished.

control

Unscrew the nuts out from the expansion bolts.

Fix the mounting board on the expansion bolts a little bit, but don't be too tight.

Use a hammer to pound the expansion bolts into the drilled holes. Fasten the nuts by turning the wrench

to fix the mounting board on the wall.

control

2. Installation

1

2 3

4

5 6

Note:

You must choose very firm wall for installation otherwise the bolts may get loose and unit be damaged!

If it's wood wall, please use self-tapping screws in accessory instead of bolts. Please hang

the mounting board directly onto the wood wall without drilling holes. The wood wall must be firm

enough. Wood walls that are too thin, too brittle or humid are not adequate for installation.

expansion

14

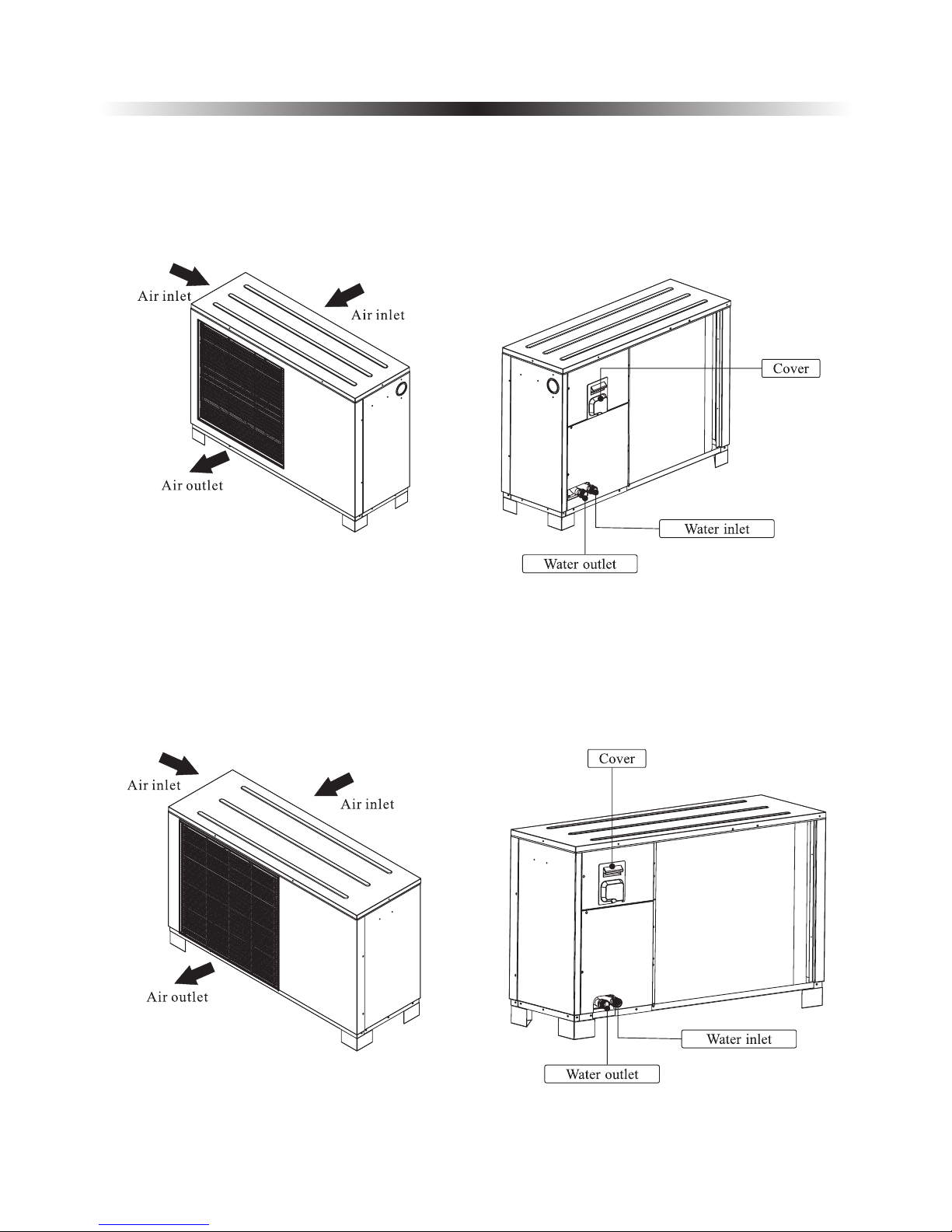

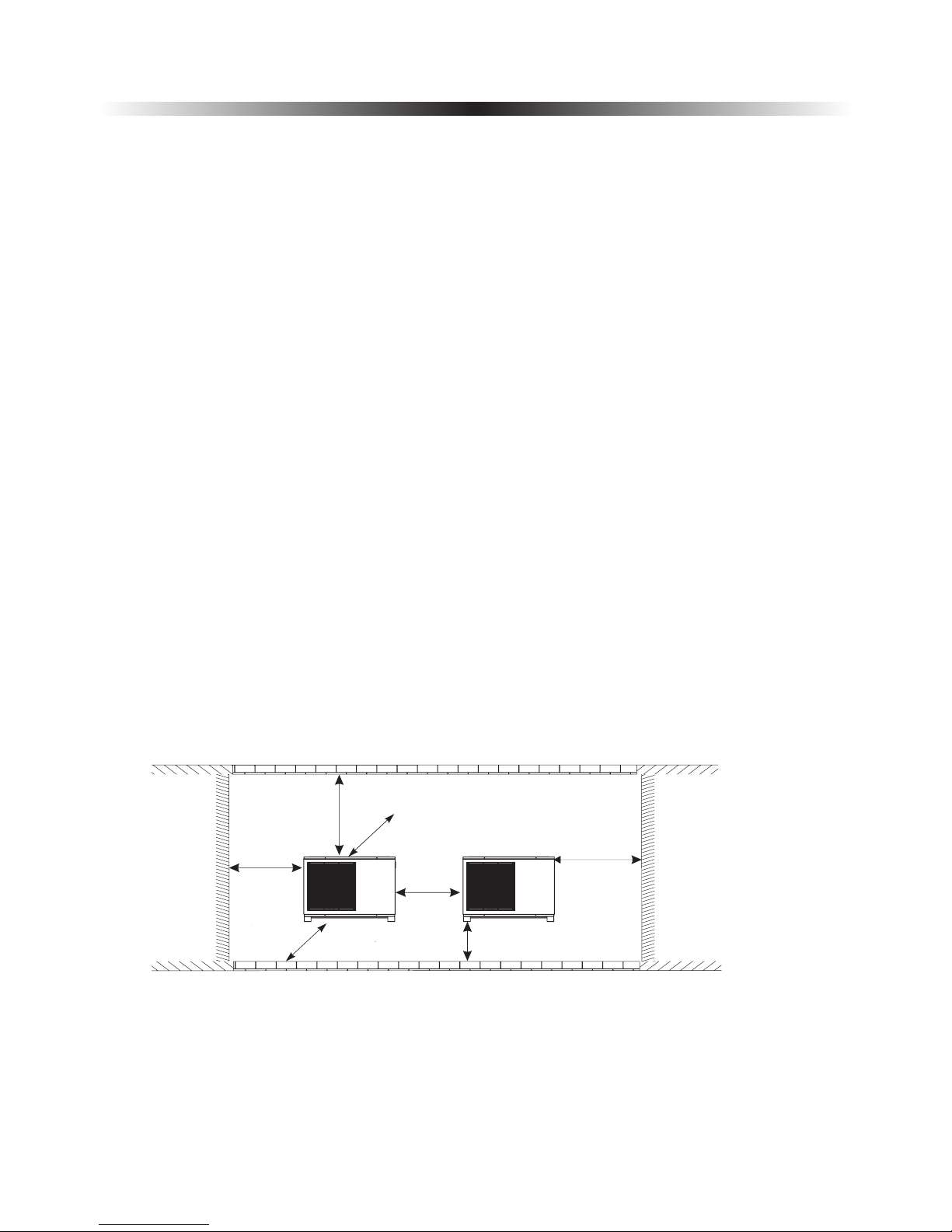

2.4 Installation of the monoblock unit

2.4.1 Installation notes

1) The monoblock unit can be located in a open space, corridor, balcony, and roof.

2) The unit shall be placed in dry and well-ventilated environment;

3) unit mustn't be installed in an environment where volatile, corrosive or flammable liquid or

gas exists.

4) Please don't install unit close to bedroom or living room, because there is some noise when

it's running.

5) When installing the unit in harsh climatic conditions, sub-zero temperatures, snow, humidity..., please

raise the unit above the ground by about 50cm.

6) Please ensure there is drainage system around the location, to drain the condensate water under

defrosting mode.

7) When installing the unit, tilt it by lcm/m for rain water evacuation.

8)

9) Please don't install the indoor control unit and unit in damp locations, otherwise it may

cause short-circuit or corrosion of some components. The unit should be free from corrosive and

moisture surrounding. Otherwise the lifetime of the unit might be shortened.

10) Please ensure enough space around the unit, for better ventilation and maintenance.

Please refer to the illustration below.

monoblock monoblock

Monoblock

monoblock

monoblock

monoblock

monoblock

monoblock

monoblock

If the unit is

installed in humid environment, electronic components may get corroded, or short-circuited because of

heavy humidity.

It's recommended to install an awning above the unit, to protect the snow from clogging in

the air inlet and outlet and ensure the normal running.

Install unit far away from the exhaust port of kitchen, to avoid oil smoke entering

into unit and adhering to heat exchanger. It's hard to clean up.

2. Installation

15

≥650mm

≥400mm

≥150mm( )Back space

≥1500mm

()Front

space

≥500mm

≥500mm

≥500mm

( )Above ground

2. Installation

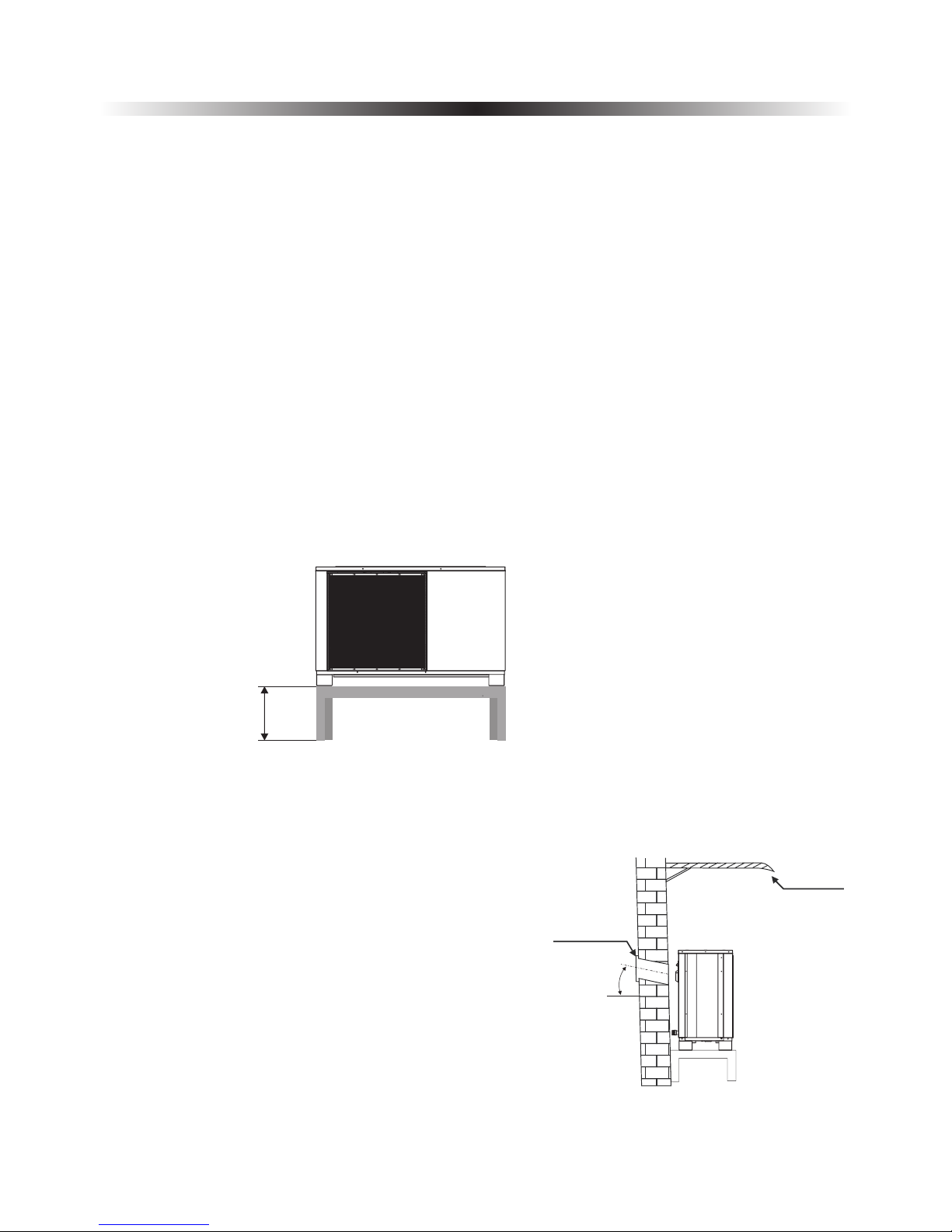

2.4.2 Installation

User can either use the dedicated mounting bracket from the supplier, or prepare a suitable bracket for the

unit installation. Make sure the installation meets following requirements:

1) The unit must be installed on flat concrete blocks, or a dedicated mounting bracket. The bracket should

be able to support at least 5 times of unit’s weight.

2) All nuts must be tightened after the bracket is fixed; otherwise, it may cause damage to the equipment.

3) User should double check and make sure the installation of unit is firm enough.

4) The bracket can be of stainless steel, galvanized steel, aluminum and other materials as required by the

user.

5) Besides the mounting bracket, the user can also install the monoblock unit on two concrete blocks, or a

raised concrete platform. Please make sure that the unit is securely fastened after installation.

6) Please see the dimensions of unit when choose a suitable wall bracket. monoblock

≥500mm

◆ Hole for piping kits should lean to outside a little bit

(≥8 degrees), to keep rain water or condensate water

from flowing back indoors.

≥8°

Sleeve

Shield

16

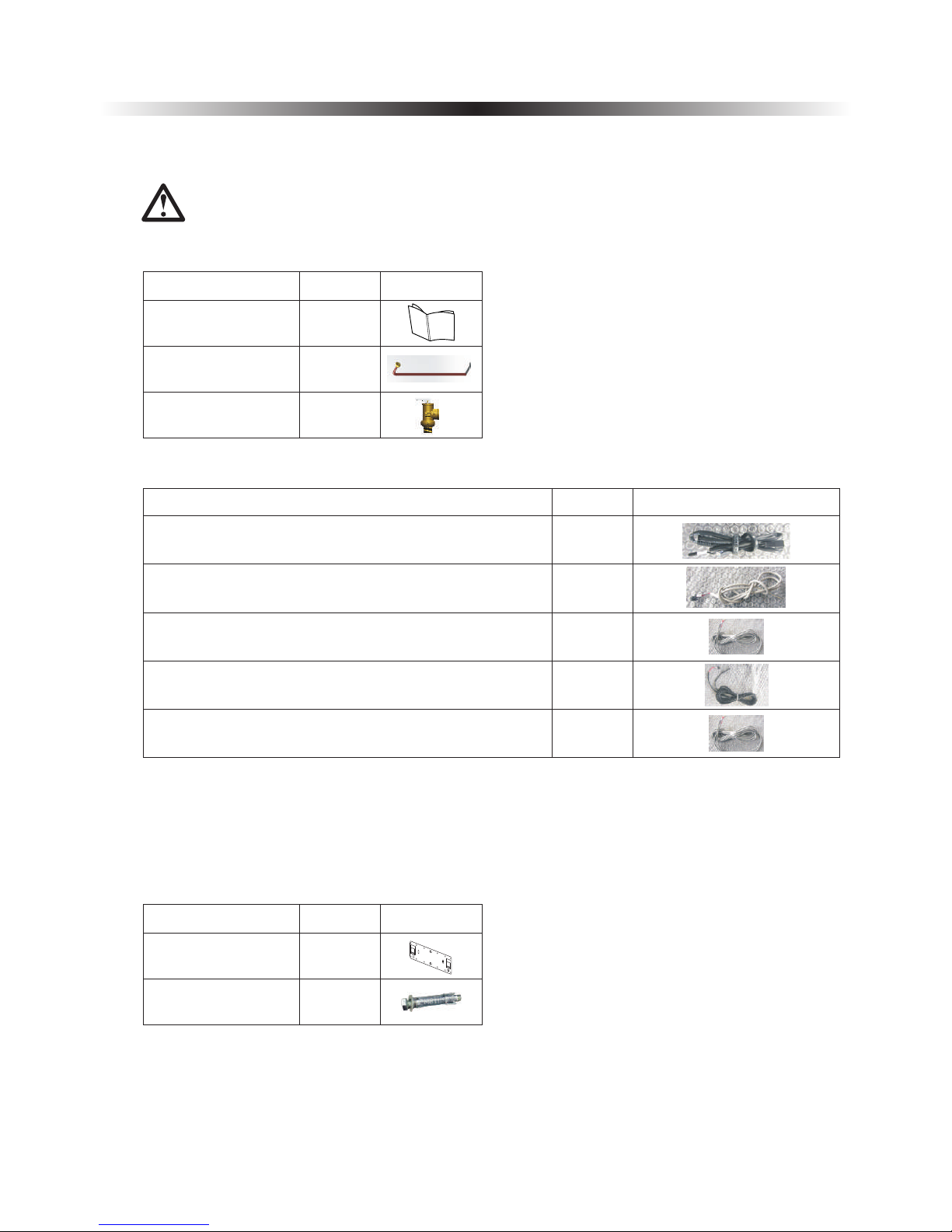

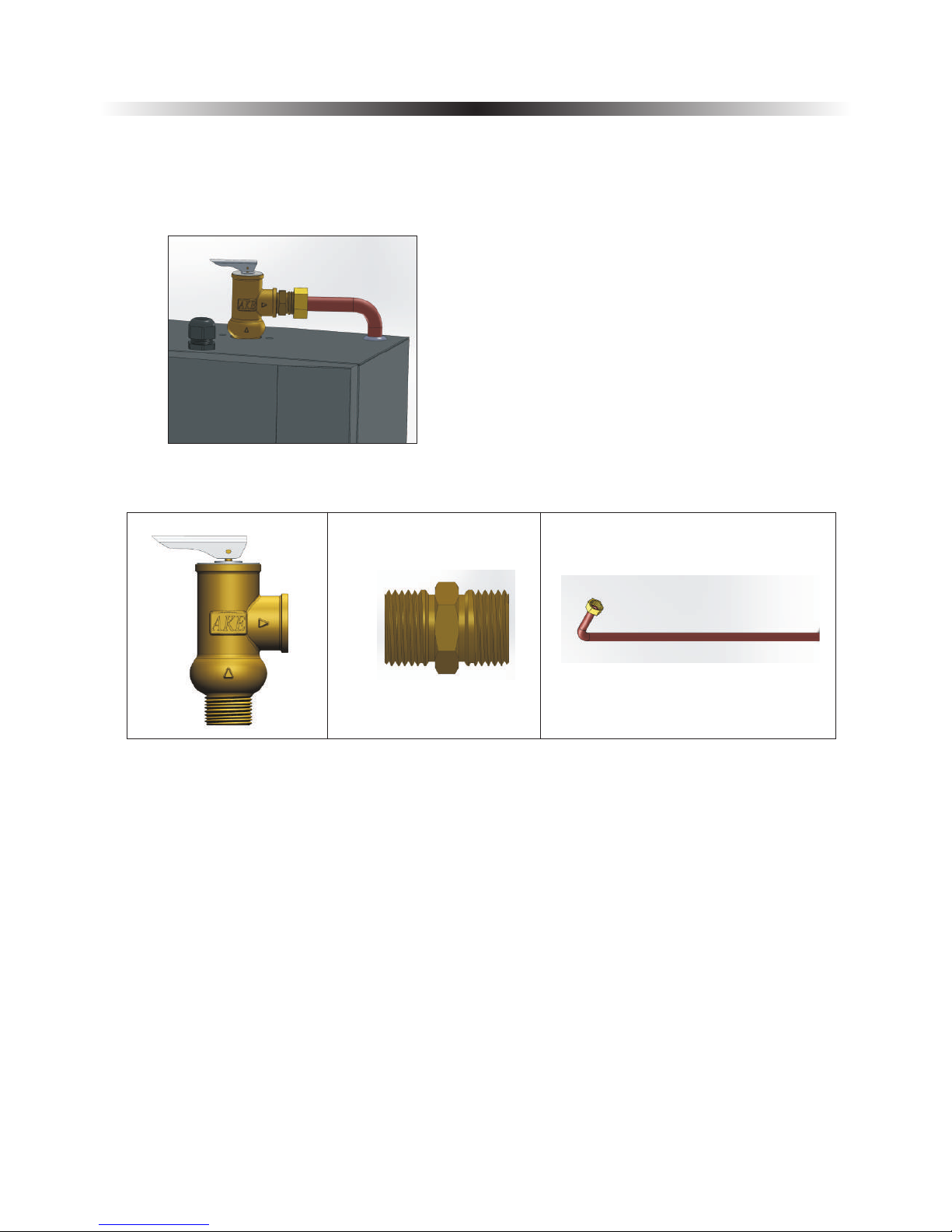

2.5 Accessories

Accessories below are delivered together with the product .

Please check in time. If there is any shortage or damage, please contact local distributor.

Name

Quantity

Picture

User’s manual

Drain pipe

1

Safety valve kit

1

1

User Ma nual

2. Installation

Indoor control unit

bracket

1

Expansion bolts

2

Name

Quantity

Picture

17

Name

Quantity

Picture

1

1

TR-Room temperature sensor

TC-water temperature sensor for cooling

TH-water temperature sensor for heating

1

Communication cable between indoor control unit and

monoblock unit

Communication cable

Signal cable between indoor control unit and monoblock

unit

1

1

TW-Water temperature sensor for hot water

◆

◆

◆

◆

◆

◆

◆

◆

◆

It is recommended to use a suitable circuit breaker for the heat pump;

The power supply to the heat pump unit must be grounded.

The wiring should be done by professional person.

The wiring should be comply with the local industry regulation.

The wiring should be done after the unit is powered off.

Cable should be fixed tightly, to ensure it won’t get loose.

Don't connect several parts of cables together to use.

Make sure the power supply in the local coincide with the power supply marked in rating label.

Make sure power supply, cable and socket can meet the requirement of the input power of the unit.

2.6 Wiring

2. Installation

Installation sketch

18

Signal cable between

indoor and outdoor unit

Main power

in user side

Heat pump unit power

supply

Aluminum foil electric

heating piece power cable

between indoor control

unit and monoblock unit

Heat pump monoblock unit

power supply

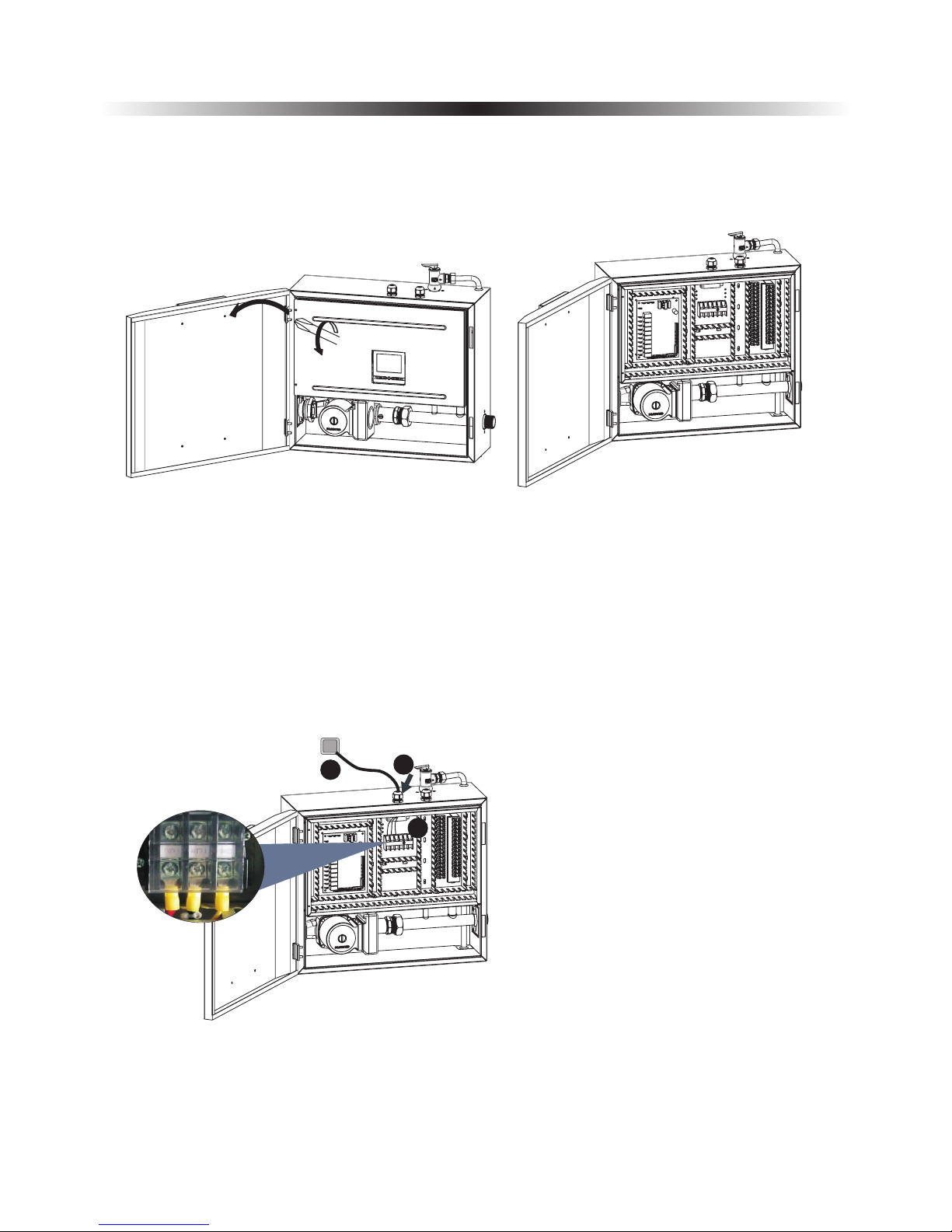

1) Heat pump unit power supply

Get a power cable in suitable length that complies to the local safety regulations.

Before wiring, open the indoor control unit front panel and take off the electronic box cover.

A. Insert one end of this cable through the

cable gland on bottom of the indoor control

unit, and connect it with heat pump power

supply terminals (G, N, L).

B. Fasten the cable gland to ensure the cable

won't get loosen.

C. Connect the other end to the city power

supply.

2. Installation

19

A

B

C

G N

L

2. Installation

20

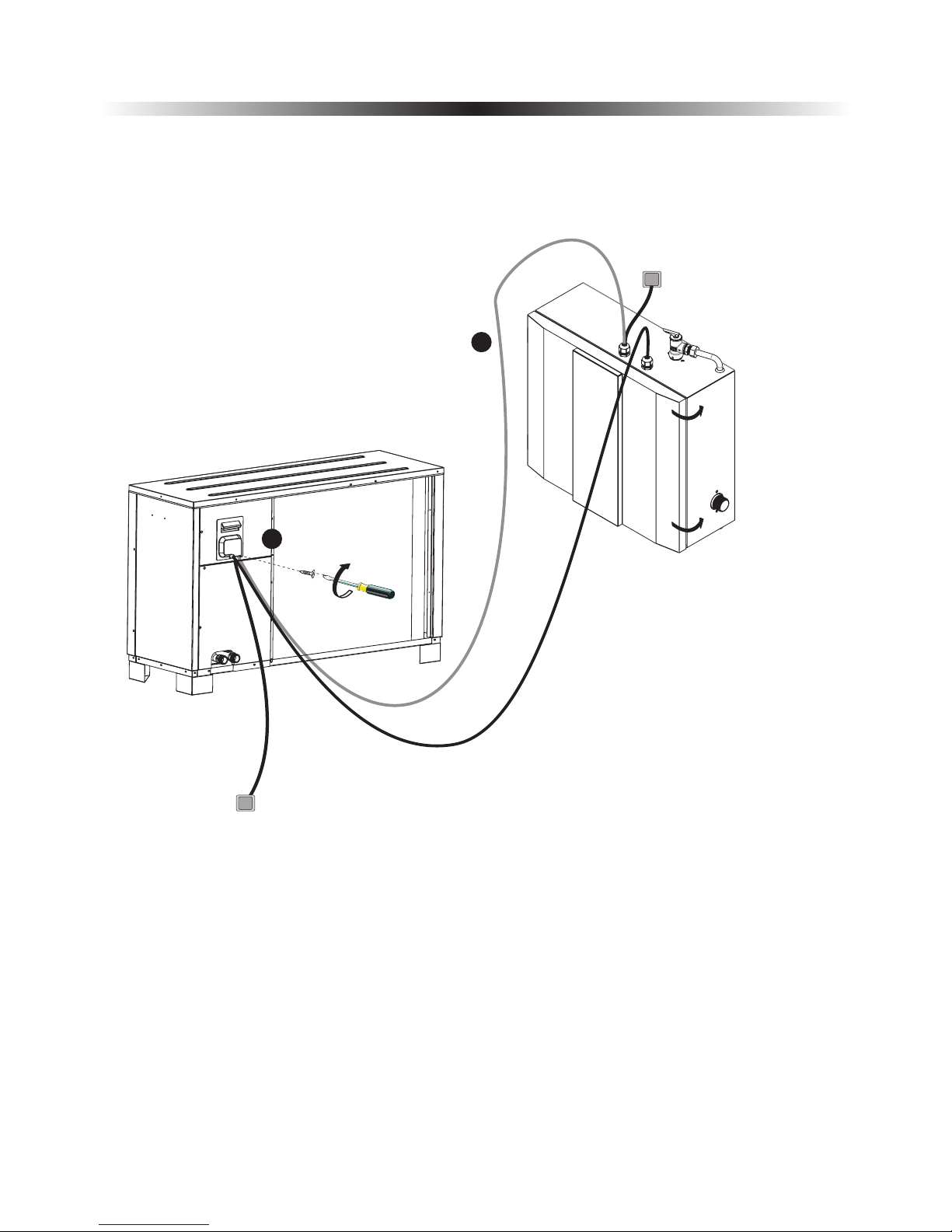

2) Monoblock unit power supply.

C

B

A

Get a power cable in suitable length that complies to the local safety regulations.

A. Insert one end of this cable through the cable gland on back of the outdoor control unit,

and connect it with heat pump power supply terminals (G, N, L).

B. Fasten the cable gland to ensure the cable won't get loosen.

C. Connect the other end to the city power supply.

2. Installation

21

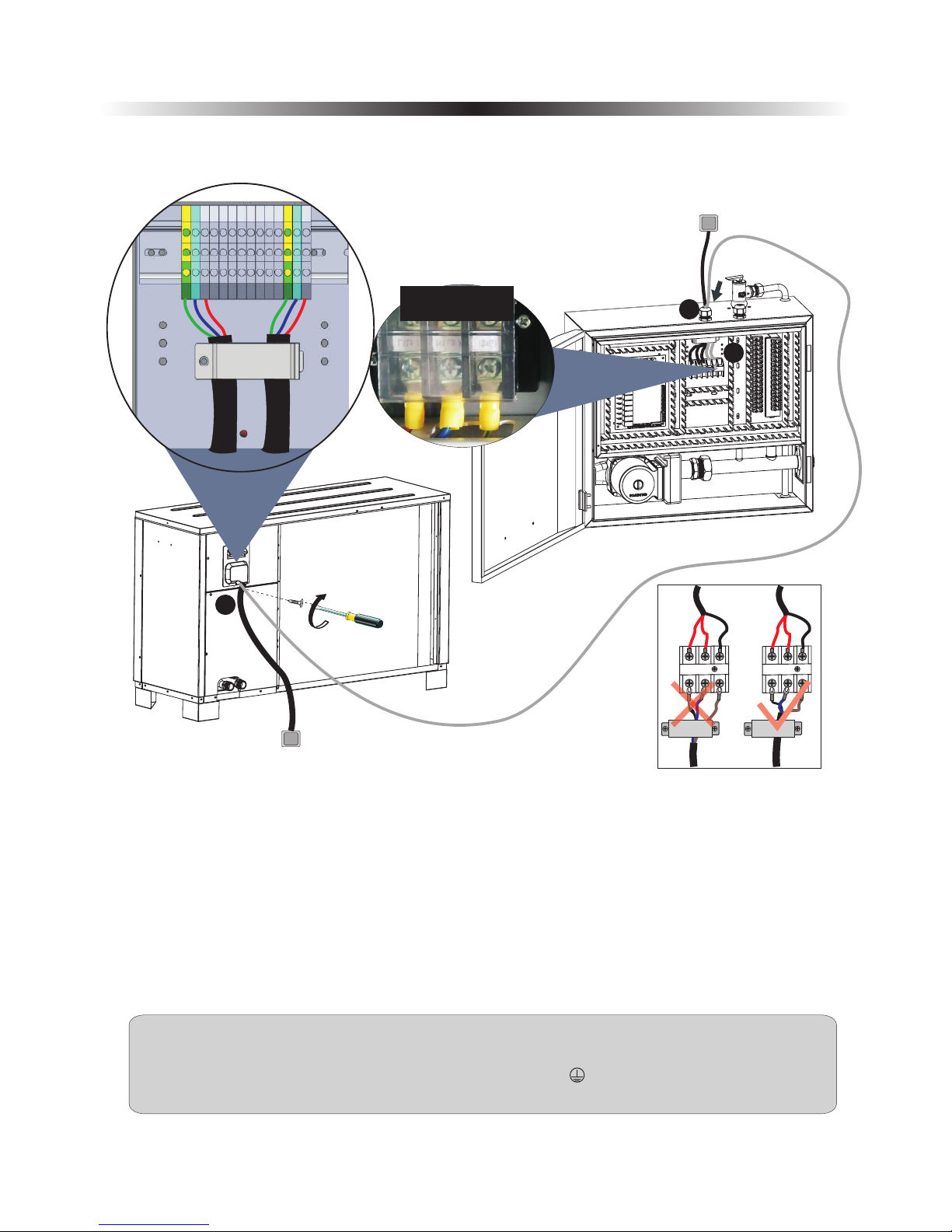

When connecting the power cable between the monoblock unit and indoor control unit, cables

connected to the terminal block in indoor control unit must match these in monoblock unit.

For example, if the terminals and power cables are connected as →gree/yellow cable, L→red cable,

N→blue cable, the connections in the monoblock unit should be in the same way.

3) Aluminum foil electric heating piece power cable between indoor control unit and monoblock unit

Prepare a 3 cores power cable with suitable length that complies the local safety regulations,

A. Insert one end of this cable through the cable gland on top of the indoor control unit, and connect

this power cable to "Outdoor unit” on indoor control unit terminal block.

B. Fasten the cable gland to ensure the cable won't get loosen.

Connect cable between indoor control unit and monoblock unit to correspondent terminal block

according to the wiring diagram. Fasten the cable gland to ensure the cable won't get loosen.

C.

C

B

Sho wn as "Ou tdoor u nit

" on wi ring di agram

G

HN

HL

For more solid connection, for that cables that need to be connected with terminals:.

1.Please try to use solid ware instead of strand wire.

2.If stranded wire is used, please make a pin terminal on the end.

3.The stripped length of the wire should be no shorter than 10mm.

A

Warning.

Electric heater for water lines inside outdoor cabinet must be attached. Pipe insulation must be able

to hold 120℃. Separate power supply to heater.

Water pipe connected between monoblock unit and house (water pipe in between should not longer

than 50cm.)

2. Installation

22

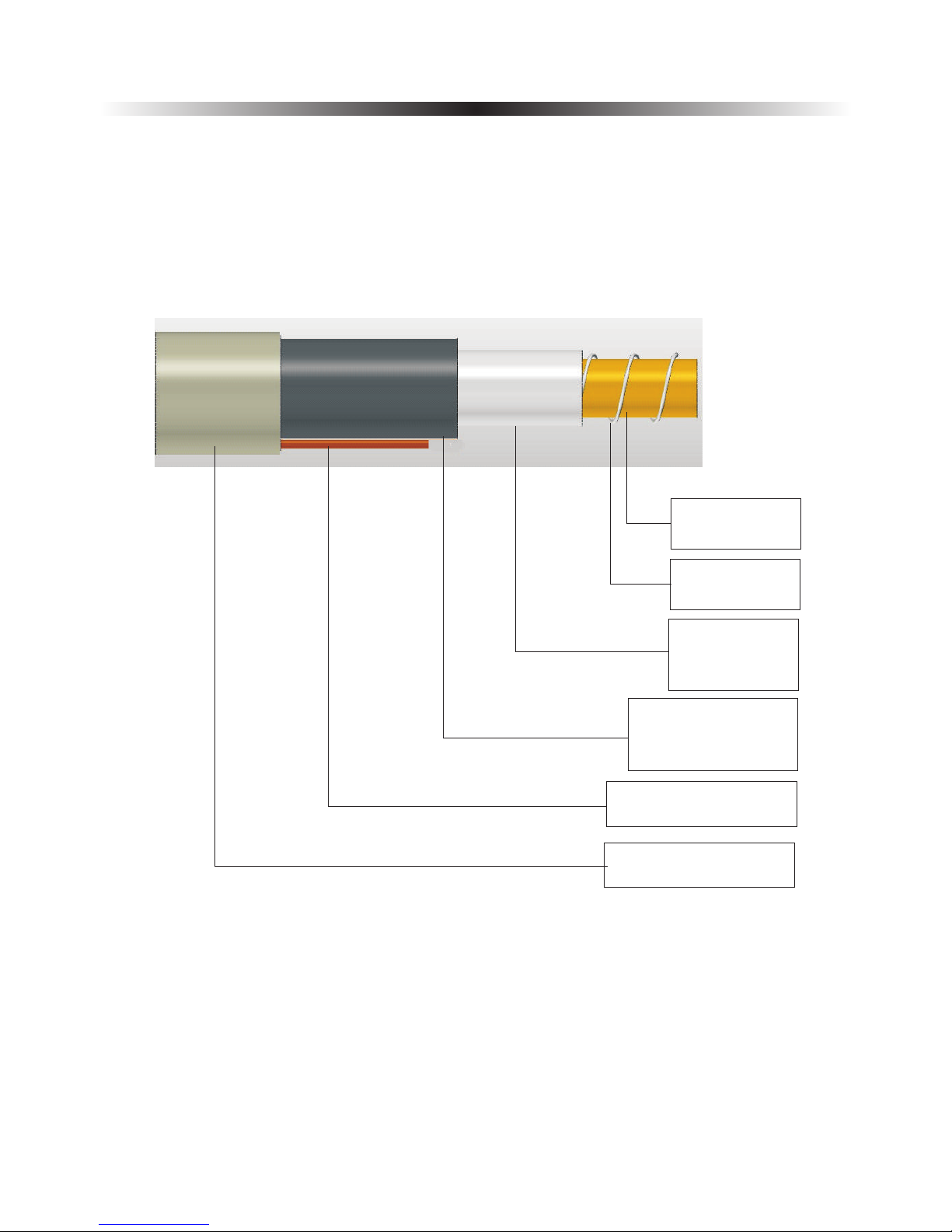

Copper or Steel

water pipe,28mm

Electric heating

cable.

Aluminum foil,

reflex heat back

to water pipe.

Insulation, that

can hold temperature

over 120℃

Power and signal cables

Wrapping material.

2. Installation

23

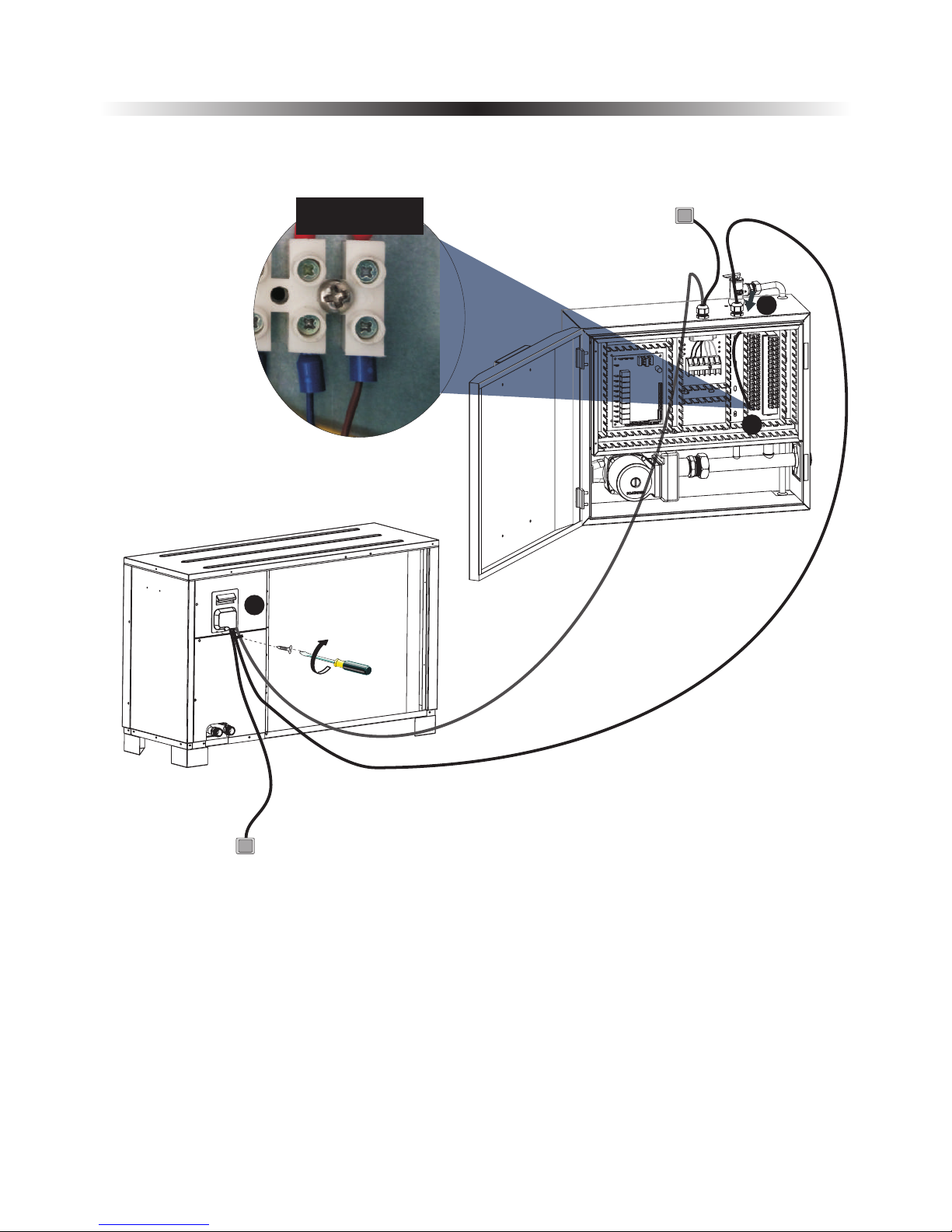

4) Signal cable between indoor control unit and monoblock unit

10M communication cable is packed in accessories bag.

A. Insert one end of this cable through the cable gland on top of the indoor control unit, and connect

this cable to A, B, on terminal block.

B. Fasten the cable gland to ensure the cable won't get loosen.

Take off the electric box cover, and connect the other end of communication cable to correspondent

terminal block through cable gland. Fix the cable with cable gland after cable is well connected. A, B,

on monoblock unit should be connected with A, B on indoor control unit, otherwise unit will show

communication failure.

C.

C

B

A

B

corresponding

with each other

A

2. Installation

24

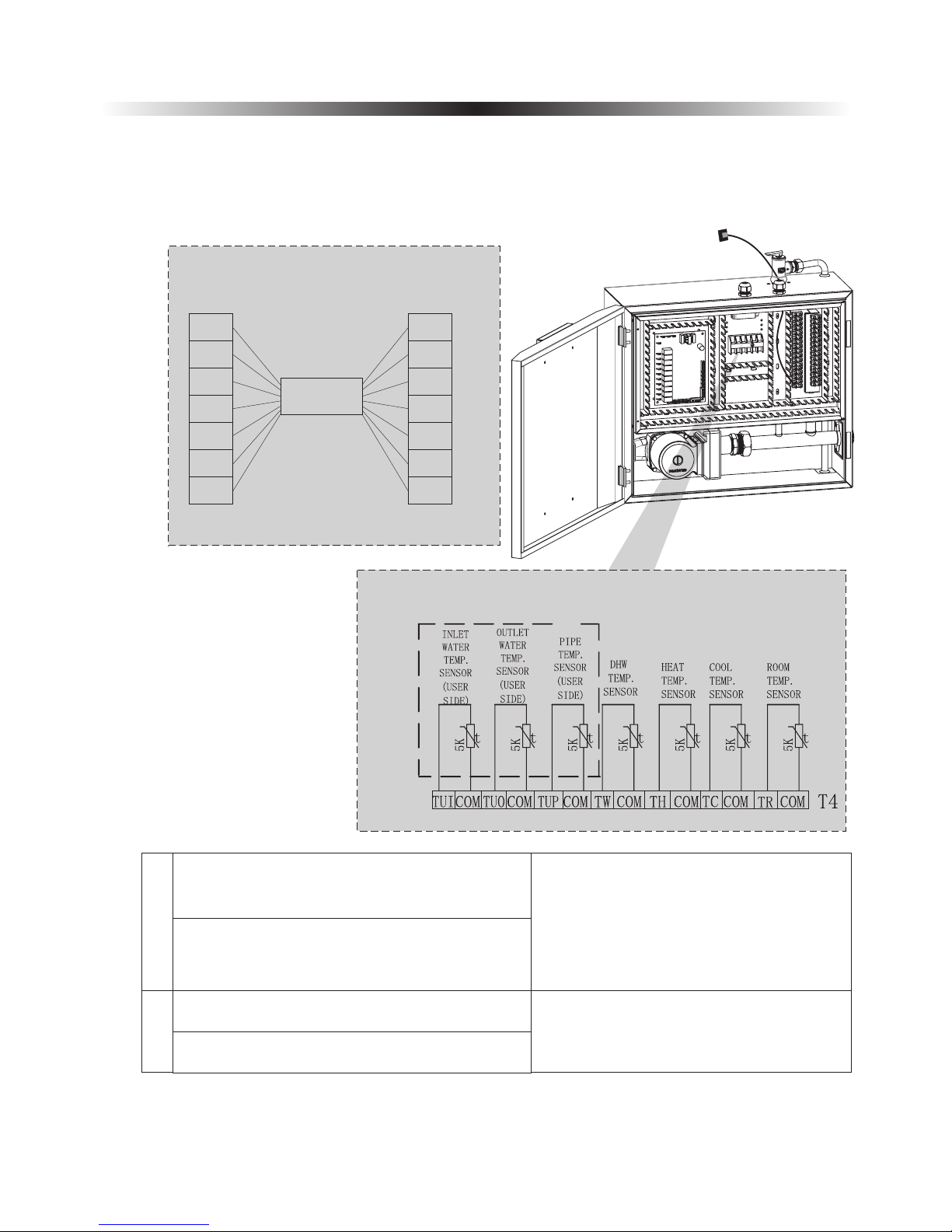

5) Sensor cables

Take all sensors and communication cables out from the accessories bag. Connect the sensors together with

the quick connectors on communication cables. After done, insert communication cables (the end without

quick connector) that have no quick connector through cable gland, and connect them to the correspondent

terminals on terminal block.

A

TR-Room temperature sensor

B

TUP-Coil temperature sensor

TUI-Water inlet temperature sensor

Connect these sensors with communication

cables by quick connector, and then connect

communication cable (the end without quick

connector) with terminal block. (These

sensors are packed inside the accessories

bag).

TUP/TUI/TUO(terminal of indoor PCB

and outdoor sensor) are connected to the

terminal board, connect via cushion cable.

Place all sensors in right positions

Sensor cable connection

Indoor control

Communication cable

CO M

TU I

CO M

TU O

CO M

TU P

CO M

CO M

TU I

CO M

TU O

CO M

TU P

CO M

TC-water temperature sensor for cooling

TH-water temperature sensor for heating

TW-Water temperature sensor for hot water

2. Installation

Install the electric box cover on indoor control unit and electric box cover on monoblock unit

back, and close the door of indoor control unit.

25

C

C

2.7 Installation of safety valve kit

1) Install the safety valve kit to the connector on top of indoor control unit.

2) Connect the drainage pipe to safety valve outlet.

2. Installation

26

2.8 Water pipe connection

After installing the unit, please connect the water inlet and outlet pipe according to the local .

Please carefully select and operate the water pipe.

After connection, the water piping should be pressure tested, cleaned before use.

1) Filter

A mesh filter must be installed in front of the water inlet of the unit and water tank, to keep the water

quality and collect impurity contained in the water. Take care to keep the water filter mesh towards the

bottom. Check valve is recommended to be installed at both sides of the filter, so as to clean or change the

filter in a easier way.

regulations

2) Insulation

All pipes running hot water should be well insulated. The insulation

must be tied up tightly without gap (But please don't wrap up the

check valve for future maintenance).

3) Requirements of water quality

A. Chloridion element in the water should be less than 300ppm(temperature is less than 60℃).

B. PH value of water should be from 6 to 8.

C. The water with ammonia can't be used for the unit.

If the water quality is bad, or water flow too little, scale formation or clogging may happen after unit

running for a long time, then the efficiency of cooling or heating will be low or the unit will work

abnormally.

Please clean water before use, or use purified water. Make sure the water quality is good enough to keep the

unit long-term running in high efficiency.

One way valve

Drain pipe

Filter

Ball valve

City water inlet

Connect to unit

water inlet

Please ensure enough water pressure to send the water to the required height.

If the water pressure is not enough to maintain proper water flow rate for the system,

please add a water pump to increase the pumping head.

2. Installation

27

1)

Before the unit starts up, a certain number of verifications must be performed on the installation to ensure

that the unit will operate under the best possible conditions. The check list below is not exhaustive and

should only be used as a minimum reference basis:

A. Make sure fan rotates freely;

B. Inspect all water piping for flow direction;

C. Verify all system piping is correct for operation as per installation requirements;

D. Check voltage of the unit power supply and make certain voltage is within authorized limitations;

E. Make sure the unit is properly grounded;

F. Check the presence of protective and breaking devices;

G. Check all electric connections for tightness.

H. Check all piping for leaks and air is well ventilated.

Before start-up

2) Pre-start up

A. When the installation of unit is completed, water system pipes are well connected and air purging is

done, no leakage or other problems, the unit can be powered to start up.

B. Turn on the unit, press the on-off button on the operation panel to start the unit. Please check carefully

if there is some abnormal noise or vibration, or the display of wired controller is normal or not.

C. After the unit is working properly for 10 minutes, without any problem, then the pre-start up is

completed; If not, please refer to the Service and Maintenance chapter in this manual to solve the

problems.

If everything above is OK, the unit can start up.

If any of them fails, please fix it.

It is suggested not to run "heating" or "hot water" mode, when ambient temperature is

over 32 ℃,otherwise unit may go into protection mode easily.

2.9 Test run

After installation finished, please fulfill the water system with water and purge out air

in the system before start-up.

2. Installation

28

3. Usage

29

3.1 Introduction of wired controller

1

2

ON/OFF

MODE

Up-Regulation

Timer

Confirm

Down-Regulation

Symbol

Function

Explanation

Heating mode

Cooling mode

Shower

Water mode

Heat recovery

function

Actual set

temperature

Actual water

temperature

Quiet operation

Defrosting

Degrees in Celsius

of Fahreneit

Operation values

Auxillary heater

step 1 and step 2

Anti legionella

function

Working mode

When heating mode is selected, symbol is

shown in the display

When cooling mode is selected, symbol is

shown in the display

When shower water mode is selected,

symbol is shown in the display

When auxillary heater is connected and

activated, symbol is shown in the display

Increases the shower water temperature wirth

electric heater weekly to kill bacterias

Shows the actual water temperatdure in

according to units operation mode

Shows the actual set temperatdure in

according to units operation mode

Not available for this model

Lower the working speed of compressor

and fan motors in selected time periode

Deicing the outdoor unit evaporator when ice

is build up. (Self learning, not adjustable)

Shown when digits is correspondent with

temperatures

Shows selected temperature values when unit

is on or parameter setting values

Symbol display when selected,

flickers when activated

shown in

Symbol display when selected,

flickers when activated

shown in

Symbol display when selected,

flickers when activated

shown in

Symbol flickers when step 1,

2 or both are "ON"

Symbol starts flickering when function

is "ON"

Always "ON" when unit is "Water Control"

Always "OFF" when unit is "Room Control"

Always "ON" when unit is "ON"

When activated this symbol is "ON"

When defrosting is activated this sumbol is

"ON". For dual compressor system: left

symbol = system 2, right symol = system 1.

When parameter setting is selected, values

are shown in accordance to the parameter

setting menu

Anti feezing

protection

Self function to avoid freezing

when ambient temperature drops and unit is

in "OFF" mode. (Not adjustable)

protection

Constantly lights for primary anti-freezing

protection.

Flickers for secondary anti-freezing

protection.

3. Usage

30

Symbol

Function

Explanation

Compressor

indicator

Clock or parameter

indicator

Timer

Down value

Set button/Clock

UP value

Operation mode

selector

Timer button

Timer Shower

water

Timer

heating/cooling

ON/OFF

Working mode

1

2

Indicates the current working level,

“low range30-46”, "middle range47-65",

"high range66-100”

If symbol is "ON" compressor is working

Clock and parameter menu and group

indicator

Shows time when unit is "ON", Shows

parameter groupe or -number when unit

is "OFF" and parameter setting is selscted

Indicates that one or more operation timer

parameters is selected

When "ON" means unit is "OFF" until the

selected time where unit is set to be "ON"

Indicates that shower water is set to "Timer"

operation, and weather it is in "ON" periode

and if unit actually is working in this mode.

“1" shows that "Timer" for shower water

mode is selscted and that unit is within its

"ON" periode. "ON" indicates that unit is

actually working in shower water mode

Indicates that heating/cooling mode is set to

"Timer" operation, and weather it is in "ON"

periode and if unit actually is working in this

mode.

"2"shows that "Timer" for heating/

cooling mode is selscted and that unit is

within its "ON" periode. "OFF" indicates

that unit is not working in heating/cooling

mode at the moment

Button switch the entire unit on and off

Button a so have some parameter setting

functions

l

Button switch between basic operation

modes, Heating/cooling/shower/water, and

different combinations of these

Button have some parameter setting

functions

also

Button increases set temperature, switch

between parameters or adjust set value in

parameter setting menu

Button have some parameter setting

functions

also

Button deacreases set temperature, switch

between parameters or adjust set value in

parameter setting menu

Button have some parameter setting

functions

also

Button activates the unit for changing in set

values in temperatures or parameters and

button enters clock setting when the unit “OFF”

Button have some parameter setting

functions

also

timer settings

Button have some parameter setting

functions

also

3. Usage

31

3.2 Parameter Setting Overview

Item

Item

Sub-menu

Sub-menu

Unit Statue

Under

Unit Statue

Operation

Level

Operation

Level

Default factory

settings

Default factory

settings

Clock Time

Temp. Setting

Working Mode

Room Temp.

Control

None

Hot water/Heating/Cooling

Hot water, heating, cooling, hot

water+heating, hot water+cooling,

heating+cooling, hot water+heating

+cooling

OFF

ON

ON

ON

User

User

User

User

No matter the unit is ON or OFF, press button to check or actiave "Timer" parameter setting. Use or

button to view all parameters in sequence. When the value of a parameter needs to be adjusted, press "SET" when

this parameter is shown to activate the setting of this parameter. The value start flickering.

Use button to adjust the value, or button to adjust setting in "hours", button to adjust the setting in

“minutes", if this parameter is a time parameter.

Timer function ON/OFF

0 (OFF)

Hot Water Timer ON-1

00:00

Hot Water Timer OFF-1

00:00

Hot Water Timer ON-2

00:00

Hot Water Timer OFF-2

00:00

Heating/Cooling Timer ON-1

00:00

Heating/Cooling Timer OFF-1

00:00

Heating/Cooling Timer ON-2

00:00

Heating/Cooling Timer OFF-2

00:00

Normal Shower Time (for unit with

heat recovery function only)

00:00

Anti-legionella function

00:00

Anti-legionella function starting

time

00:00

Pump anti-block running time

00:00

Quiet operation starting time

00:00

Quiet operation ending time

00:00

ON/OFF

Timer

Parameter

User

00:00

20°

Page in

the menu

Page in

the menu

36

38

36

37

39

39

40

40~41

41

3. Usage

32

All the units sensor values (temperatures) and information of current running statue (compressor speed, voltage

and current) can be red and checked via operation panel in both ON/OFF statue. Press and buttons for 5

seconds in main interface, to activate the menu of current running statue. Press or buttons to check all working

status in sequence in accordance to below list. The current number is displayed where the clock is displayed in main

interface. See operation panel symbols in page...

Item

Meaning

1

19

2

20

3

21

4

22

5

23

6

24

7

25

8

26

9

27

10

28

11

29

12

30

13

31

14

32

15

33

Item

Meaning

User level Parameter under basic operation level can be set in "OFF" mode only. Press "SET"+"M" for 5 seconds,

Parameter will shown on the display. Press or to check parameter values for each paramter in sequence.

Item

Sub-menu

Unit Statue

Operation

Level

Default factory

settings

Hot Water restart based on water ∆T

Heating restarts based on water ∆T

Cooling restarts based on water ∆T

Cooling and heating switch judgment

User level

Parameter

Check in

ON/OFF, Set

in OFF

User

5

°

2°

2°

0 (OFF)

Page in

the menu

44

44

DHW Set Temp

16

34

17

35

18

36

Heating Set Temp

Cooling Set Temp

Room Set Temp

Ambient temperature

Hot water temperature

Heating water temperature

Cooling water temperature

Room temperature

Unit outlet temperature

Unit inlet temperature

System 2

temperature

indoor coil

System 2 voltage (V)

System 2 current (A)

System 2

(Hz)

compressor speed

System 2 comp.

discharge temp.

System 2

temperature

outdoor coil

System 2 suction temperature

System 2 evaporating pressure

System 2 condensing pressure

System 2 EEV position

System 1 indoor coil temperature

System 1 voltage (V)

System 1 current (A)

System 1 compressor speed (Hz)

System 1 outdoor coil temperature

System 1 comp. discharge temp.

System 1 suction temperature

System 1 evaporating pressure

System 1 condensing pressure

System 1 EEV position

Indoor Unit Software Version

System

Versio n

2 Outdoor Unit Software

System

Versio n

1 Outdoor Unit Software

Water outlet Temp.

Too Low Protection

Water outlet Temp.

Too High Protection

3. Usage

33

Item

Sub-menu

Unit Statue

Operation

Level

Default factory

settings

Ambient temp. to start heating

20

Ambient temp. to start cooling

25°

°

Shifting priority

100

°

Set room temperature

20°

Check in

ON/OFF, Set

in OFF

User

Temperature

Parameter

1.Code input: When unit is in "OFF" mode, press for 5 seconds, "----" will be shown. Press to swfit

between 4 positions, and press to adjust the value of the blinking value. Press "SET" to confirm the input

password. If the password is correct, "Advanced Setting" mode is activated.

2.Complete Advanced Setting menu is divided into 6 groups (Group 0~Group E). When Advanced Setting menu

is activated, press to switch between each group(Group 0, A, B, C, D,E) .

3.Press or to switch different parameters in the same group. Press "SET" to activate setting of current

parameter, with its value blinks, and adjust its value by or . Press "SET" to confirm the setting.

Item

Sub-menu

Unit Statue

Operation

Level

Default factory

settings

Advanced

Setting Group

0

Test working mode indoor controller

External ON/OFF switch

Water flow switch

Heating buffer tank

Cooling buffer tank

Priority switch between hot water

and heating operation

Refrigerant collecting function

Lock Function

Installer

OFF

0 (Normal

operation)

0 (Invalid)

60 sec

0 (No)

0 (No)

0 (hot water)

0 (OFF)

00 (OFF)

Advanced

Setting Group

A

Unit Circulation Pump Control

Type

Heating Circulation Pump Control

Type

Cooling Circulation Pump Control

Type

Heating Circulation Pump Start

Temperature

Heating Cirulation Pump Stop

Temperature

Cooling Circulation Pump Start

Temperature

Cooling Cirulation Pump Stop

Temperature

Installer

OFF

0 (unit controlled)

0 (unit controlled)

0 (unit controlled)

20

°

18°

18

°

20

°

Page in

the menu

Page in

the menu

44

44

49~50

51

53

53

Available working modes

2(all func tions)

Stop/Speed down ΔT based on

set temperature in heating/cooling

2℃

30 min

Max Allowed Duration For Min

Compress or Speed

46~47

52

3. Usage

34

Item

Sub-menu

Unit Statue

Operation

Level

Default factory

settings

Advanced

Setting Group

Advanced

Setting Group

Installer

Installer

OFF

OFF

Advanced

Setting Group

Advanced

Setting Group

A

D

Unit Motorized 3-way valve

Switching Time

Heating Operation Motorized

3-way valve Direction

Installer

Installer

OFF

OFF

1 same as cooling

operation

120 sec

B

C

Anti-Legionella Set Temperature

Anti-Legionella Duration

Anti-Legionella Maximum

Allowable Working Duration

Anti-freezing Function

Anti-freezing Starting Ambient

Temperature--Primary

Anti-freezing Starting Ambient

Temperature--Secondary

Anti-freezing Ending Ambient

Temperature--Secondary

Anti-freezing Starting Water

Temperature--Secondary

Anti-freezing Ending Water

Temperature--Secondary

60

120 min.

1 (ON)

5°

2°

5°

2°

15°

Manual ON/OFF of Heater in Hot

Water Mode

Backup Heating Source For Hot

Water Mode

Priority Of Backup Heating Sources

For Hot Water Mode (Compared

With Unit Auxiliary

Heater)

Temperature Increasement

Checking Duration in Hot Water

Mode

Maximum Allowable Set Water

Temperature in Heating Mode

Manual ON/OFF of Heater in

Heating Mode

Backup Heating Source For Heating

Mode

Priority Of Backup Heating Sources

For Heating Mode (Compared With

Unit Auxiliary

Heater)

Accumulated Value between

operation time VS set temp.

for Heating Mode

0 (OFF)

0 (No)

0 (lower)

40

42

0 (OFF)

1 (Yes)

1 (Higher)

45

Heating Curve Function

Room Temp. Effect On Heating

Curve

1 (ON)

0 (OFF)

Page in

the menu

54

54

55

56

57

46

46

30 min.

3. Usage

35

Item

Sub-menu

Unit Statue

Under

Operation

Level

Default factory

settings

Advanced

Setting Group

Advanced

Setting Group

Installer

Installer

OFF

OFF

D

E

Ambient Temp. 1

Ambienttemp 1 Vs Water Temp. 1

Ambient Temp. 2

Ambienttemp 2 Vs Water Temp. 2

Ambient Temp. 3

Ambienttemp 3 Vs Water Temp. 3

Ambient Temp. 4

Ambienttemp 4 Vs Water Temp. 4

Ambient Temp. 5

Ambienttemp 5 Vs Water Temp. 5

12

25

7

28

2

31

-7

35

-20

42

Heat Recovery Function

Hot Water Restart Based On ∆T in

Heat Recovery Operation

Hot Water Stop Based On ∆T in

Heat Recovery Operation

Allowable Temp Drift In Heating

in Shifting Priority Operation

Hot Water Min. Working Hours in

Shifting Priority Operation

Heating Max. Working Hours in

Shifting Priority Operation

Working of Extra Heating Source

for Hot Water in Shifting Priority

Operation

0 (Invalid)

5

°

5

°

5

30

50

0 (No)

Page in

the menu

46

57~58

58

3. Usage

36

3.3 Basic Operation

When the unit is O FF, press to tu rn on t he un it. The un it wi ll wo rk in its last working mode.

Press again to t urn o ff the un it.

Press for 5 seco nds

Value flickers

Press to adjus t

time by hours

Press to adjus t tim e

by minutes.

When the unit is i n OFF m ode , press "SET" for 5 seconds, to activate clo ck ti me se tting, with the

value flicke rs. P res s to adjust time by hours; press to adjust time b y min ute s.

Chose workin g mod e set tings in accordance to your heating/hot w ate r/c ooling system.

When the unit is O N, pr ess " M" to s et the unit working mode. For each time “M” is p res sed w ork ing mode

is changed by th e bel ow se quence. When a working mode is selected, it s sym bol (s) will be shown on the

screen. The cu rre nt wo rking mode of the unit, is shown by a flickerin g wor kin g mode symbol.

Picture show s tha t

heating and ho t wat er

mode is select ed

Worki ng Mo des

Hot water+He ati ng

Symbols

Hot water

Hot water+Co oli ng

Heating only

Auto

Cooling only

Hot water+Au to

OFF: The unit is

OFF when it is

fed with power.

【 】

ON/OFF

【 】

Clock time setting

【 】

Woking modes setting

3. Usage

37

When unit is ON, k eep o n pre ssing "M" to switch the control of cooling an d hea tin g operation between room

temperatur e con tro l and water temperature control mode .

When in water te mpe rat ure control mode, "Water Temp." will be shown on the screen;

When in room tem per atu re control mode, "Water Temp." will not be shown on the screen .

Note:

If unit is set to Ho t Water mode only, or unit is set to c omb ine d wor kin g mode but unit is working in hot

water mode, this operation is i nva lid .

Room tempera tur e

control mode

Wate r tem per ature

control mode

Single worki ng mo de

Keep on

pressing "M”

When unit is on and working mode is selected, press “set”

to activate the temperature setting. Working mode symbol

flickers.

Adjust the set temperature by:

Press to increase the set temperature by 1℃.

Press to decrease the set temperature by 1℃.

Note:1. If heating curve function is activated, set temperature for heating will be calculated according to the set

curve automatically. Its set temperature can't be adjusted by this operation.

2. If room temperature control mode is activated, temperature set here for heating and cooling

is based on room temperature.

【 】

Room Temperature Control

【 】

Temperature setting

Combined working mode

When combined working mode is selected, unit will switch between selected working modes. For example heating + hot

water, unit will switch between space heating and hot water operation. Press “set” to activate the temperature

settings. The working mode symbol that is being adjusted, flickers. Adjust the temperature setting by using the

/ arrows.

Press “set” to confirm the setting, and activate following

working modes temperature setting, with its working mode

symbol flickers. Adjust the temperature setting by using the

/ arrows.

Press "SET" to switch the temperature setting between selected working modes in sequence.

3. Usage

38

Timer function allows you to control different working modes at spesific hours during a 24 hour periode, for even more

energy savings. For example you can turn off hot water production in the daily hours you don’t use this. In the selected

periode unit will not produce hot water even hot water is selcted as working mode in your application. The setting is

repeted every 24 hours until it is disactivated.

Parameter list

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Parameter No.

Meaning

Range

Default Value

0

0

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

00 00

0(off), 1(on)

0(off), 1(on)

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

Timer function ON/OFF

Hot Water Timer ON-1

Hot Water Timer OFF-1

Hot Water Timer ON-2

Hot Water Timer OFF-2

Heating/Cooling Timer ON-1

Heating/Cooling Timer OFF-1

Heating/Cooling Timer ON-2

Heating/Cooling Timer OFF-2

Normal Shower Time (for unit with

heat recovery function only)

Anti-legionella function

Anti-legionella function starting time

Pump anti-block running time

Quiet operation starting time

Quiet operation ending time

No matter the unit is ON or OFF, press to check or actiave "Timer" parameter setting, which looks as shown below:

Value of parameter

Number of parameter

Parameter 00, value=0000

Use or to view all parameters in sequence. When the value of a parameter needs to be adjusted, press "SET"

when this parameter is shown to activate the setting of this parameter. The value start flickering.

Use to adjust setting in hours, to adjust the setting in minutes" if this parameter is a time parameter

【 】

Time&Timer Setting

3. Usage

39

For example, parameter 00 is to set the ON/OFF of complete timer function (if it is set

to OFF, following parameters 01~08 will be invalid). When setting for this parameter is

activated, use to adjust the value.

For example, parameter 01 is the ON time for hot water function. When setting for

this parameter is activated, press to adjust the setting in hours; press to

adjust the setting in minutes" for parameter that relates to time

Timer setting parameter 0 to 8.

To be able to activate timer setting for parameter 1 to 7, parameter 0 needs to be activated first.

0

Parameter No.

Meaning

Range

Default Value

0

0(off), 1(on)

Timer function ON/OFF

Meaning of each parameter

Hot Water Timer:

1

1

2

2

3

3

4

4

Parameter No.

Parameter No.

Meaning

Meaning

Range

Default Value

Value

00 00

04 00

00 00

09 00

00 00

14 00

00 00

21 00

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

Hot Water Timer ON-1

Hot Water Timer ON-1

Hot Water Timer OFF-1

Hot Water Timer OFF-1

Hot Water Timer ON-2

Hot Water Timer ON-2

Hot Water Timer OFF-2

Hot Water Timer OFF-2

For example, if the below setting is set; domestic hot water will only be heated up during the period 04:00~09:00, and

14:00~21:00 every day.

These parameters are used for setting the ON/OFF timer for hot water operation. After setting, unit will only activate hot

water operation in the selected period(s).

For how to make the setting, please refer to previous page.

3. Usage

40

5

5

6

6

7

7

8

8

Parameter No.

Parameter No.

Meaning

Meaning

Range

Default Value

Value

00 00

00 00

00 00

08 00

00 00

17 00

00 00

23 59

00 00-23 59

00 00-23 59

00 00-23 59

00 00-23 59

Heating/Cooling Timer ON-1

Heating/Cooling Timer ON-1

Heating/Cooling Timer OFF-1

Heating/Cooling Timer OFF-1

Heating/Cooling Timer ON-2

Heating/Cooling Timer ON-2

Heating/Cooling Timer OFF-2

Heating/Cooling Timer OFF-2

Then heat pump will only heat or cool the house during the period 00:00~08:00, and 17:00~23:59 every day.

1

2

When timer function is activated, following symbols might be shown on the screen:

This symbol means the unit

is in sanitary hot water Timer

ON period. Unit will work in

hot water mode when needed.

This symbol means the unit is

in cooling/heating Timer ON

period. Unit will work in

cooling/heating mode when

needed.

1

This symbol means the unit is

in sanitary hot water and

cooling/heating Timer ON

period. Unit will work for both

hot water and cooling/heating

mode (not in same time) when

needed.

This symbol means the unit is

neither in hot water nor

cooling/heating Timer ON period.

Unit will work not work for both

hot water and cooling/heating

mode even needed.

Normal Shower Time:

Parameter No.

Meaning

Range

Default Value

9

00 00

00 00-23 59

Normal Shower Time (for unit with

heat recovery function only)

Heating/Cooling Timer:

These parameters are used for setting the ON/OFF timer for heating or cooling operation. After setting, unit will only

activate heating or cooling operation, when needed, in the set timer period. For example, below setting is made

This parameter is designed for the unit with heat recovery function only. When using recovered heat to heat up sanitary

hot water, it is not always enough to heat up the shower water. If 1 hour before this "Normal Shower Time" set time is

reached, hot water temperature has still not reached the set value, unit will activate standard hot water operation to ensure

you can enjoy enough hot shower water at/after this time.

2

3. Usage

41

【 】

Temperature Info

For example, if the setting is made like below:

Parameter No.

Meaning

Value

9

20 00

Normal Shower Time (for unit with

heat recovery function only)

Anti-legionella function

10

11

Parameter No.

Meaning

Range

Default Value

0

00 00

0(off), 1(on)

00 00-23 59

Anti-legionella function

Anti-legionella function starting time

Pump anti-block running time

12

Parameter No.

Meaning

Range

Default Value

00 00

00 00-23 59

Pump anti-block running time

Quiet operation

13

14

Parameter No.

Meaning

Range

Default Value

00 00

00 00

00 00-23 59

00 00-23 59

Quiet operation starting time

Quiet operation ending time

All temperature information of current running statue can be checked via operation panel in both ON/OFF status.

Press and for 5 seconds

in main interface, to activate

inquiry of current running status.

Press or to check

all working status in sequence.

Number of

parameter

Value of

parameter

If at time 19:00 in the day, shower water is still not enough for shower, unit will activate standard hot water operation,

instead of using recovered heat to heat up the shower water.

Parameter 10 is used to activated or deactivate Anti-legionella function.

Parameter 11 is used to set the starting time of Anti-legionella function.

During the hot water operation, unit will record the highest hot water temperature it produced. If in 7*24 hours time

period, unit has not reached the set water temperature for "anti-legionella function" (set in Advanced Menu) even

once, then unit will activate anti-legionella operation at "Anti--legionella function starting time".

For details for "anti-legionella" function, please contact your installer or read chapter "Advanced Opeartion" in our manual.

Circulation water pump may easily get blocked if it has not working for long time. In order to avoide this from happening,

circulation water pump will be activated for 1 minute, if it is not working at this set clock time every day.

Thanks for the DC technology applied in this system, unit can lower both its compressor speed and fan rotating speed,

to get a ultra low noise operation in this set time period.

3. Usage

42

Meaning of all readings:

Parameter under basic operation level can be checked in both ON and OFF mode.User level

Press "SET"+"M" for 5

seconds, Parameter will

shown on the display.

Press or to check

parameter values for

each paramter in

sequence. Total 8

parameters can be

checked.

Value of the

parameter

Sequence of the

parameter

【 】

User level Parameter

Item

Meaning

1

19

2

20

3

21

4

22

5

23

6

24

7

25

8

26

9

27

10

28

11

29

12

30

13

31

14

32

15

33

Item

Meaning

DHW Set Temp

16

34

17

35

18

36

Heatin g Set Tem p

Cool in g Set Tem p

Room S et Temp

Ambi en t tempe rature

Hot wa te r tempe rature

Heatin g water t emperat ure

Cool in g water t emperat ure

Room tem perat ure

Unit out let tem peratur e

Unit inl et temp erature

Syst em 2

temper ature

indo or c oil

Syst em 2 v oltag e (V)

Syst em 2 c urren t (A)

Syst em 2

(Hz)

compre ssor sp eed

Syst em 2 c omp.

disc ha rg e temp.

Syst em 2

temper ature

outdoo r coil

Syst em 2 suctio n tempe rature

Syst em 2 e vapor ating pre ssure

Syst em 2 c onden sing pres sure

Syst em 2 E EV positi on

Syst em 1 i ndoor c oil tempe ratur e

Syst em 1 v oltag e (V)

Syst em 1 c urren t (A)

Syst em 1 c ompre ssor spee d (Hz)

Syst em 1 o utdoo r coil temp eratu re

Syst em 1 c omp. di scharge tem p.

Syst em 1 s uctio n tempera ture

Syst em 1 e vapor ating pre ssure

Syst em 1 c onden sing pres sure

Syst em 1 E EV positi on

Indo or U nit Sof tware Version

Syst em

Version

2 Outd oo r Unit So ftware

Syst em

Version

1 Outd oo r Unit So ftware

Wate r outlet Temp.

Too Hi gh Prot ection

Wate r outlet Temp.

Too Lo w Prote ction

3. Usage

43

Temperature Parameter under basic operation level can be set in "OFF" mode only.

Press "SET"+"M" for

5 seconds, Parameter

will shown on the display

Press or to check

parameter values for each

paramter in sequence.

Value of the

parameter

Sequence of the

parameter

Press "SET" to activate setting of current parameter, with its value blinks.

Value of

the parameter blinks

Press or to adjust

the value, and confirm

the setting by pressing

"SET" again. If no

operation for 5 seconds,

it exit to Off mode.

In OFF mode, default paramter settings of factory can be recovered by pressing "M"+" ".

3. Usage

44

Parameter No.

Meaning

Range

Default Value

Cooling and Heating Switch Judgment

Cooling and Heating Switch Judgment

3

3

0

0

4

4

20

Ambient Temp. To Start Heating

Ambient Temp. To Start Heating

5

5

25

25

Ambient Temp. To Start Cooling

Ambient Temp. To Start Cooling

100

-20 -20, stands

for invalid

100 (

)

Shifting Priority

6

7

20

10-31 (in ℃)

Set Room Temperature

0(via. Ambient Temp.), 1

(via. External Signal)

0(via. Ambient Temp.), 1

(via. External Signal)

-1 43 )0 - (in ℃

-1 43 )0 - (in ℃

5 - 35 (in ℃)

5 - 35 (in ℃)

Meaning of each parameter

List of adjustable parameters in Temperature Parameter Setting menu:

0

1

2

Parameter No.

Meaning

Range

Default Value

5

2

2

0 - 10 (in ℃)

0 - 10 (in ℃)

0 - 10 (in ℃)

Domestic Hot Water Restart Based

On Water ∆T

Heating Restarts Based On Water ∆T

Cooling Restarts Based On ∆T

If "Auto" mode (unit opeartion mode, set by press "M" button) is set, unit needs to switch between cooling and heating

automatically, either according to "ambient temperature" (parameter 3=0) or "external signal" (parameter 3=1).

If setting=“via. Ambient Temp.”, the system will automatically switch between cooling and heating functions,

based on the outdoor ambient temperature:When Ambient temperature is lower than value set in parameter 4, unit

activate heating operation.When Ambient temperature is higher than value set in parameter 5, unit activate cooling

operation.

If setting="via. External Signal", an external room thermostat or central control system in the building can control the.

cooling or heating requirements by connecting it to the respective signal ports. The signals are simple 1-0 (on-off) signals

List of parameters

Parameter No.

Meaning

Range

Default Value

Domestic Hot Water Restart Based

On Water ∆T

0

5

0 - 10 (in ℃)

2

0 - 10 (in ℃)

Heating Restarts Based On Water ∆T

1

2

2

0 - 10 (in ℃)

Cooling Restarts Based On ∆T

Domestic Hot Water Restart Based On ∆T:

After sanitary hot water is heated up to the set temperature, unit will stop sanitary hot water operation. It will activate

sanitary hot water operation after temperature drops "Hot Water Restart Based On Water ∆T" below set temperature.

Heating Restart Based On ∆T:

After house heating temperature is heated up to the set temperature, unit will stop heating operation. It will activate

heating operation after temperature drops "Hot Water Restart Based On ∆T" below set temperature.

Cool Restart Based On ∆T:

After house cooling temperature is cooled down to the set temperature, unit will stop cooling operation. It will activate

cooling operation after temperature increases "Hot Water Restart Based On ∆T" above set temperature.

20

3. Usage

45

Parameter No.

Meaning

Range

Default Value

100

- - , (stands

for invalid)

20 20 100

Shifting Priority

6

Air to water heat pump is an equipment that absorbs heat from surrounding air, and transfers it to water.

The lower the ambient temperature is, the less heat the unit absorbs. This makes the unit heating capacity and efficiency

drop when ambient temperature drops. The unit takes longer time to heat up the sanitary hot water. However, the lower

the ambient temperature is, the more heat the house demands. If the unit does not provide enough heat while it is working

for hot water, the temperature inside the house may drop too much, and people in it feels uncomfortable.

So when this function is activated, unit tries to divide the working time for sanitary hot water into several cycles, after

ambient temperature drops below this set value.

In Advanced Setting, there has more parametes related to the working of this function. For more details, please contact

your installer or read chapter "Advanced Opeartion" in our manual.

Note: If this parameter is set to 100, it means this function is invalid. If it is set to any value other than 100, that

means this function is activated and start to shifting priority after ambient temperature drops below this set value.

Parameter No.

Meaning

Range

Default Value

7

20

10-31 (in ℃)

Set Room Temperature

Heating or cooling function has “Water Temperature Control” as default. However when a room temperature

sensor is connected to the unit and a more precise control of room temperature where the sensor is placed is

preferred, “Room Temperature Control” mode can be selected. And the ideal room temperature can be set

via this parameter.

Note:When “Room Temperature Control” mode is selected, system will not operate under the heating curve

function and actual water temperature may swing significantly.

If cooling port receives the signal, the system switches to cooling; If heating port receives the signal, the system

switches to heating. When neither port receives the signal, the system stays in standby mode.

Note: If system has a very big buffer tank for both cooling and heating operation, please pay special attention to

set "Auto" to "via. Ambient Temperature". Otherwise it may waste lots of energy in Spring or Autumn, as unit

may need to switch between cooling and heating operation quite often.

【Heating Curve】

Group D

List of parameters

0(invalid), 10 - 60(time

period for every adjustment,

in minutes)

Room Temp. Effect On Heating

Curve

D2

0

Heating Curve Function

D1

1

0(invalid), 1(valid)

Parameter No.

Meaning

Range

Default Value

D3

D4

D5

D6

D7

D8

D9

DA

DB

DC

Ambient Temp. 1

Ambienttemp 1 Vs Water Temp. 1

Ambient Temp. 2

Ambienttemp 2 Vs Water Temp. 2

Ambient Temp. 3

Ambienttemp 3 Vs Water Temp. 3

Ambient Temp. 4

Ambienttemp 4 Vs Water Temp. 4

Ambient Temp. 5

Ambienttemp 5 Vs Water Temp. 5

-20 - 45 (in ℃)

20 - 65 (in ℃)

-20 - 45 (in ℃)

20 - 65 (in ℃)

-20 - 45 (in ℃)

20 - 65 (in ℃)

-20 - 45 (in ℃)

20 - 65 (in ℃)

-20 - 45 (in ℃)

20 - 65 (in ℃)

12

25

7

28

2

31

-7

35

-20

42

3. Usage

46

Heating Curve means let the system adjust the outlet water temperature based on the ambient temperature by continually

monitoring and adjusting in opposite direction with the current ambient temperature levels according to a pre-set curve,

to optimum comfort levels based on the changing heat demand,insulation levels,etc.

In a way, when it is colder (warmer) outside, house will need a higher (lower) temperature water to keep the same air

temperature in the house. Thus we can set a curve for the unit to follow, to let the unit adjust its set temperature for

heating operation according to the set curve and actual ambient temperature.

This function can be turned ON/OFF by adjusting the value of this parameter.

Heating Curve Function

D1

1

0(invalid), 1(valid)

Parameter No.

Meaning

Range

Default Value

Unit will create a heating curve according to these setting.

Parameter D3, D5, D7, D9 and DB are used to set 5 different ambient temperatures; Parameter D4, D6, D8, DA

and DC are used to set 5 corresponding set water temperatures VS the set 5 ambient temperatures. Then a heating

curve will be generated automatically.

Note: Value of parameter D3, D5, D7, D9 and DB should be in negative direction, or say in other way,

D3>D5>D7>D9>DB, otherwise the setting of the value may not saved.

Parameter No.

Meaning

Range

Default Value

D3

D4

D5

D6

D7

D8

D9

DA

DB

DC

Ambient Temp. 1

Ambienttemp 1 Vs Water Temp. 1

Ambient Temp. 2

Ambienttemp 2 Vs Water Temp. 2

Ambient Temp. 3

Ambienttemp 3 Vs Water Temp. 3

Ambient Temp. 4

Ambienttemp 4 Vs Water Temp. 4

Ambient Temp. 5

Ambienttemp 5 Vs Water Temp. 5

-20 - 45 in ℃

20 - 65 (in ℃

-20 - 45 in ℃

20 - 65 (in ℃

-20 - 45 (in ℃)

20 - 65 (in ℃

-20 - 45 (in ℃)

20 - 65 (in ℃

-20 - 45 (in ℃)

20 - 65 (in ℃

( )

)

( )

)

)

)

)

12

25

7

28

2

31

-7

35

-20

42

0(invalid), 10 - 60(time

period for every adjustment,

in minutes)

Room Temp. Effect On Heating

Curve

D2

0

Parameter No.

Meaning

Range

Default Value

If room temperature sensor is connected, "Set Room Temperature" in "Temperature Parameter" under "Basic Operation"

is set, and this "Room Temp. Effect On Heating Curve" is ON, unit will adjust the set water temperature (a set value or

calculated value via heating curve), according to the difference between actual room temperature and ideal room

temperature.

For example, if current water set temperature calculated according to the heating curve is 35℃:

If actual room temperature is 27℃, while "Set Room Temperature" is set to 22 ℃, then the unit will deduct

(27 ℃-22 ℃)=5 ℃ from water set temperature, which means unit will take 30 ℃ as the final set temperature.

3. Usage

47

As shown here, actual set water temperature (TSha) is calculated according to actual ambient temperature (Ta), according

to this created curve.

A

C

B

D

E

DC

DA

D8

D6

D4

DB

D9

D7

D5

D3

(Tsha)

(TSh)

T(Ta)

(Ta)

3. Usage

3.4 Advanced setting

48

Advanced setting is opened to installer or professional customer. It contains more functions and setting that can maximum

the comfort and efficiency of the system.You need to enter the correct password to activate "Advanced Setting":

4.Press to swift

between 4 positions

2.Press for

5 seconds

3."----" will be

shown.

1.When unit is in "OFF"

mode

1.Press to

adjust the value

of the blinking

value.

Press "SET" to

confirm the input

password. If the

password is correct,

"Advanced Setting"

mode is activated.

If the password is incorrect, it exits to OFF mode

Operation in Advanced Setting menu:

Complete Advanced Setting menu is divided into 6 groups (Group 0~Group E).

When Advanced Setting menu is activated, press to switch between each group(Group 0, A, B, C, D,E) .

press

Press or to switch different

parameters in the same group, for

example from A1 to A9 in group A.

Press "SET" to activate setting of current parameter, with its value blinks.

Value of the parameter blinks

3. Usage

49

Press or to adjust

the blinking value

Press "SET" to confirm the setting. If no operation for 6 seconds, it exits to main interface without saving the setting.

Group 0

List of parameters

0

1

2

Parameter No.

Meaning

Range

Default Value

0

0

60

0 (normal), 1(testing)

0 (invalid), 1(valid)

0 (invalid), 1 - 60 (checking

time, in seconds)

Indoor Control System Working Mode

External ON OFF Switch

Water Flow Switch

Heating Buffer Tank

3

0

0(no), 1(yes)

4

0

Cooling Buffer Tank

5

0

0 (hot Water), 1(heating)

Priority Switch Between Hot Water

and Heating Operation

0

0(off), 1(compressor System

1ON), 2(compressor System

2 ON)

Refrigerant collecting function

6

7

00

00 - 99 (in weeks)

Lock Function

0(no), 1(yes)

This function is designed for letting the installer test the output signals of the indoor control system.When this function

is activated,indoor control system will activate the relay on the PCB when correspondent port on PCB is short-connected:

0

Parameter No.

Meaning

Range

Default Value

0

0 (normal), 1(testing)

Indoor Control System Working Mode

Port On PCB Relay Output

Funtion

ES

FS

HS

CS

IRES

ES+FS

ES+HS

ES+CS

ES+IRES

CS+HS

W

W

EVC

EVW

SH

AS

HW

PUMPH

PUMPC

PO

RHS

YL

3-way valve (Cooling/Heating Port)

3-way valve (Hot Water Port)

Auxiliary Heater

Heating Back-up Heater

Domestic Hot Water Back-up Heater

Heating Distribution System Pump

Cooling Distribution System Pump

Unit Circulation Pump

Preserved-1

Preserved-2

【System Setting】

8

Available wor king modes

2(all functions)

0-DHW-1.Cooling+Heating

-2.Cooling+Heating+DHW-3.

Heating Only-4.Heating+DHW

9

Stop/Speed down ΔT based on

set temperature in heating/cooling

2-10

2℃

0a

Max Allowed Duration For Min

Compressor Speed

30 min

10-6 0(in minutes)

3. Usage

50

An external Close/Open signal from other control devices can be connected to the ES and GND port shown on the below

picture on indoor PCB, to switch ON/OFF the working of complete heat pump unit, if this parameter is set to 1:

When the input external signal is "close" type, unit works;

When the input external signal is "open" type, unit stops.

Meaning

Range

Default Value

Parameter No.

1

0

0 (invalid), 1(valid)

External ON OFF Switch

For example, when the parameter 0=1, the unit

works in testing mode. If port ES and GND are

short-connected, the relay EVW output 230V,

and the LED lamp near the relay will light.

Meaning

Range

Default Value

Parameter No.

0 (invalid), 1 - 60 (checking

time, in seconds)

2

60

Water Flow Switch

This parameter is used to set whether the system has a water flow switch or not, and if yes, how many seconds after unit

circulation pump starts, unit starts to check the statue of the water flow switch.

If it is set to "0", unit will not check the statue of the flow switch.

If it is set to any value except "0", unit starts to check the statue of flow switch after unit circulation pump starts for this

set time. If flow switch is in "open" statue at this time, unit will show failure code 00 P7, which means "not enough water

flow rate".

Note:

If unit circulation pump is OFF, flow switch should in "open" statue as there should has no flow in the system. If

not, unit will take it as the failure of flow switch itself, and give out correspondent failure code 00 Eb.

Parameter No.

Meaning

Range

Default Value

Heating Buffer Tank

3

0

0(no), 1(yes)

This parameter is used to set whether the system has a buffer tank for heating operation. It is more related to the control

of "circulation pump for heating system".

If there has no buffer tank included in the heating system, circulation pump for heating system”will work only when the

unit works in heating mode. And the circulation pump works for 1 minute after stops for every 6 minutes to read the

temperature in the distribution system.

If there has a buffer tank included in the heating system, "circulation pump for heating system" will work whenever the

unit has the demand for heating operation.

ESHS

CS

HW

SH

CS

HS

ES

HW

SH

3. Usage

51