Erricson GH688, GA628 Service Manual

GH688,GA628, Standard Electrical Repairs

Approved according to 1776-2/FEA 209 544

Trouble-shooting

instruction

GH 688/GA 628

Service Manual by Toko

4/00021-2/FEA 209 544/1.G

GH688,GA628, Standard Electrical Repairs

Table of contents

1 Conditions .......................................................................................... 3

1.1 Component classes. ......................................................................... 3

1.2 Abbreviations. ................................................................................. 4

1.3 Pin placements ................................................................................ 6

2 No serv or can´t place a call. ............................................................ 8

3 Doesn’t start. ................................................................................... 13

4 Audio. ............................................................................................... 22

5 Display. ............................................................................................ 30

6 Charging. ......................................................................................... 38

7 SIM fault (“Insert card”). .............................................................. 43

8 Keyboard. ........................................................................................ 48

9 Illumination and buzzer. ................................................................ 55

10 RTC .................................................................................................. 63

11 Component lists ............................................................................... 65

11.1 Explanation ................................................................................... 65

11.2 Mounting drawing tables ............................................................. 66

GH688 .............................................................................................. 66

GA628 .............................................................................................. 66

11.3 Component list GH688 ................................................................. 67

11.3.1 Revision change tables GH688 ......................................................... 80

Revision change table for

2/ROA 117 3307/1 and 2/ROA 117 3307/5, 2/ROA 117 3307/3 80

Revision change table for

2/ROA 117 3307/4 2/ROA 11 73307/6 ............. 84

11.4 Component list GA628 ................................................................. 88

11.4.1 Revision change tables GA628 ....................................................... 100

Revision change table for

2/ROA 117 3308/1, 2/ROA 117 3308/2 .......... 100

Revision change table for

2/ROA 117 3308/3, 2/ROA 117 3308/4 .......... 104

Revision change table for

2/ROA 117 3308/5, 2/ROA 117 3308/7 .......... 109

4/00021-2/FEA 209 544/1.G 2 (112)

GH688,GA628, Standard Electrical Repairs

1 Conditions

1.1 Component classes.

All the components in thephone are divided into classes and after every component

in the troubleshooting guide you have a class written. The components are divided

into four classes: A, B, C and D.The class of the component depends on how much

of the phone’s performance is affected when replacing it.

Class A and B:A test call towards the “real” net (not only towards a GSM test

Class C: Since the tolerances of the component are so great it can substantially

instrument) and run it through the normal tests is enough to verify the

functionality since the performance of the phone is only slightly

affected.

affect the performance of the phone you need to calibrate it at station

level after replacing the component.

Class D: Class D components need to be calibrated at board level using very

advanced equipment and may therefore not be replaced.

4/00021-2/FEA 209 544/1.G 3 (112)

GH688,GA628, Standard Electrical Repairs

1.2 Abbreviations.

A: The power module at some phones.

B: Crystal.

C: Capacitor.

D: Digital circuit.

F: Over voltage protection.

G: VCO.

H: Buzzer, LED, pads for display.

J: Connector.

L: Coil.

N: Analogue circuit.

R: Resistor.

S: Keyboard pads.

U: BALUN. A circuit that converts a signal from balanced to unbalanced or the

opposite.

V: Transistor or diode.

X: Contact surface at the circuit board.

Z: Filter.

AGND: Ground for analogue signals.

DCIO: DC voltage used for charging the battery through the system connector.

DCON: Logical signal from the processor that keeps the phone running after

you’ve released the On/Off key.

EXTAUD: Input signal at the system connector that the processor uses to deter-

mine if there’s any external audio equipment attached.

EXTAUDI: The same signal as the EXTAUD signal but at the processor side.

GND: Ground.

LED3K: Logical signal used to activate the background illumination.

ONSRQ: Voltage from the On/Off key that starts the phone.

PORTHF: Input signal at the system connector that the processor uses to deter-

mine if there’s any handsfree equipment attached.

PHF1: The same signal as PORTHF but at the processor side.

REGON: Logical signal that activates the voltage regulators.

RTC: Real time clock. The clock that keeps track of time and date.

4/00021-2/FEA 209 544/1.G 4 (112)

GH688,GA628, Standard Electrical Repairs

SIMCLK: Clock signal from the processor used for communications with the

SIM.

SIMDAT: Data signal from the processor used for communications with the SIM.

SIMRST: Reset signal from the processor used for communications with the

SIM.

SIMVCC: Feed voltage for the SIM.

SWDC: Switched VBATT.

VANA: DC voltage for the analogue part of the logic (N800).

VBATT: Battery voltage.

VDIG: DC voltage for the processor and memory.

VDSP: DC voltage for the DSP (Digital Signal Processor).

VLCD: DC voltage for the display that controls the contrast.

VRAD: DC voltage for the radio part except the synthesizer.

VRPAD: DC voltage for the radio part in D600 (also used for the top diode and

the buzzer).

VRTC: DC voltage for the real time clock.

VSIMPAD: VDIG voltage that has been switched up to 5V used for SIM.

VVCO: DC voltage for the synthesizer.

I2C: Two line serial communications standard using one clock and one data

line.

LO: Local oscillator.

PWM: Pulse width modulation.

4/00021-2/FEA 209 544/1.G 5 (112)

GH688,GA628, Standard Electrical Repairs

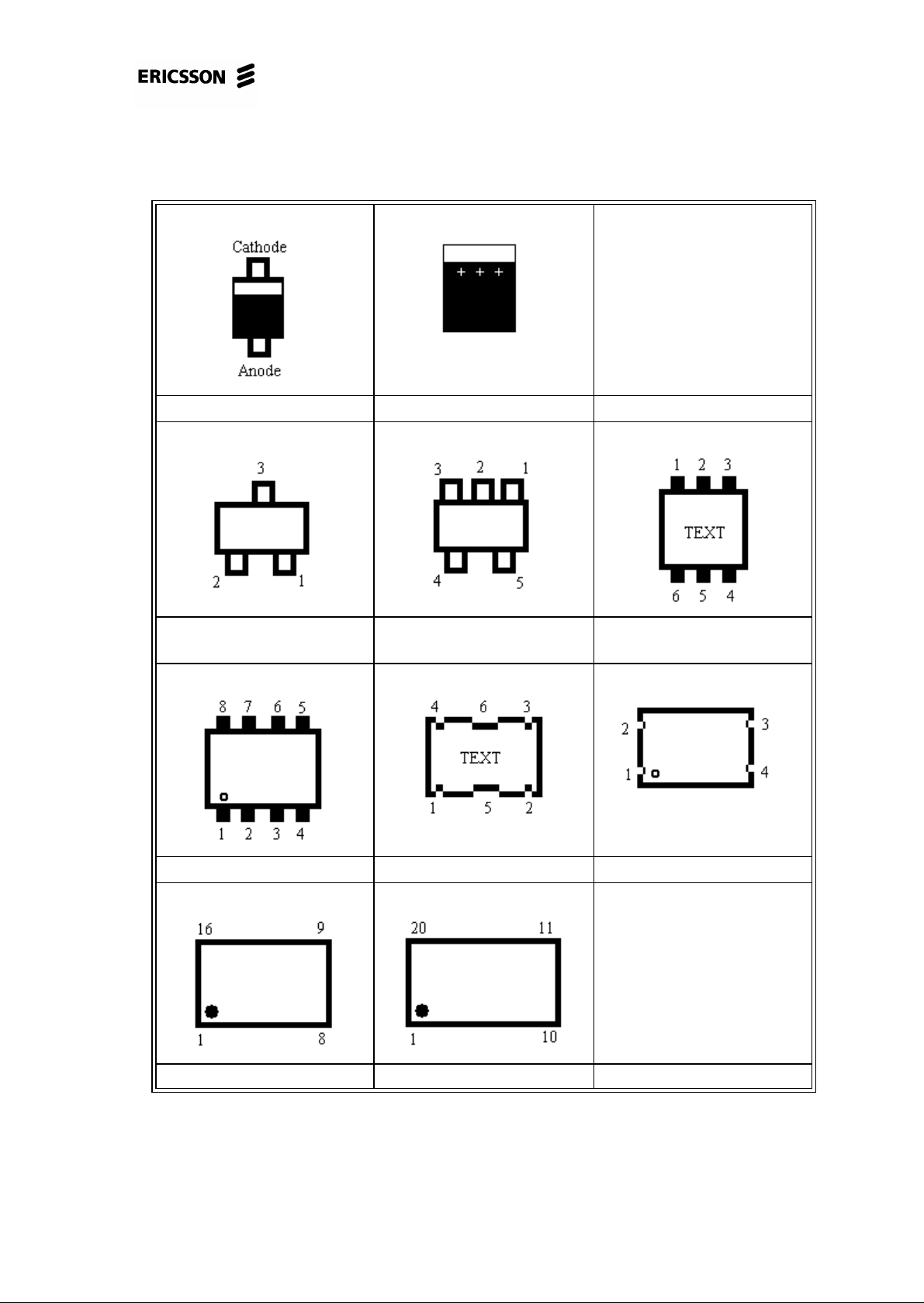

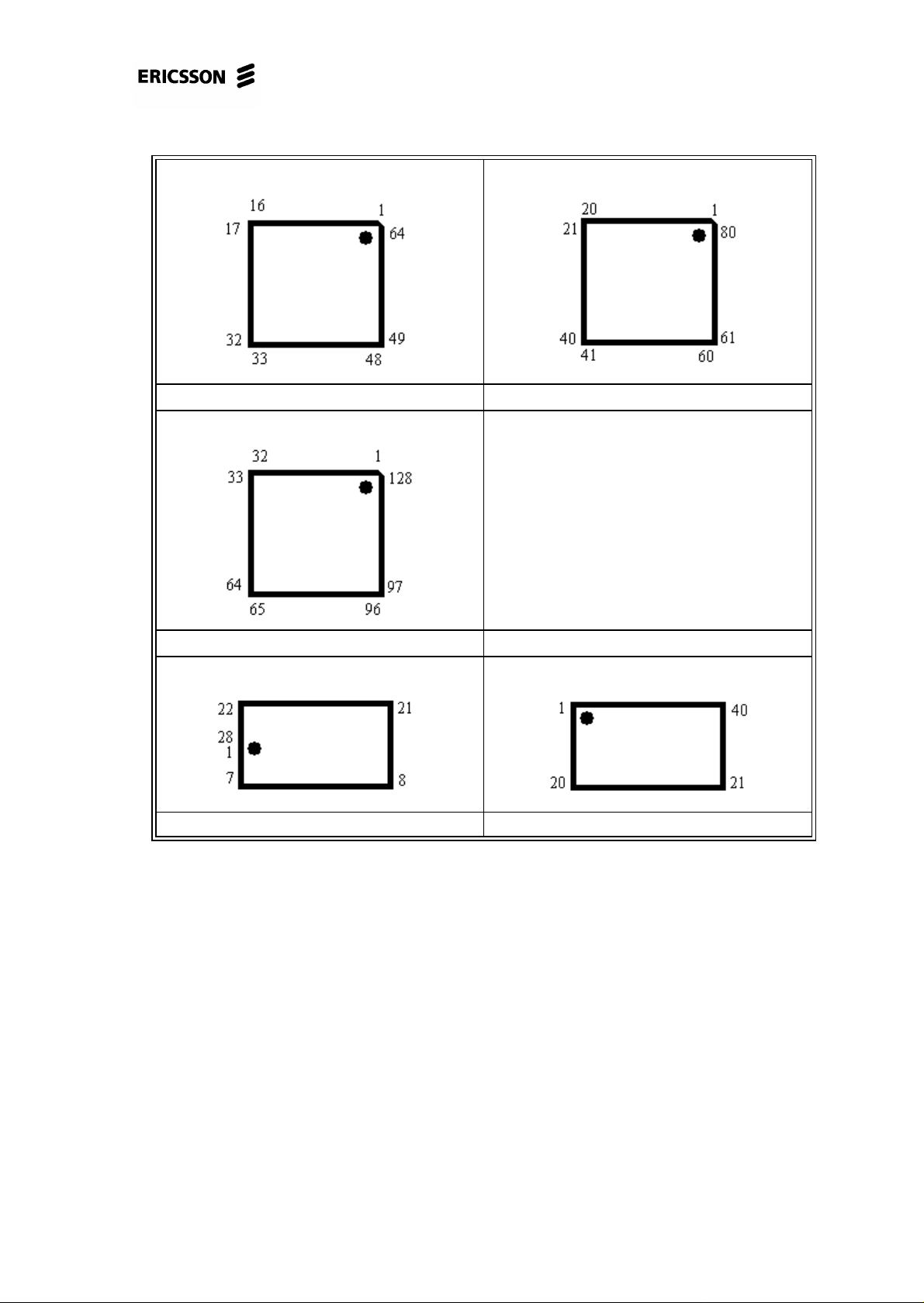

1.3 Pin placements

Single diode (PIN diode). Electrolytic capacitor.

Double diode or single trans-

stor.

Eight pin circuit. VCO circuit Crystal

Sixteen pin circuit Twenty pin circuit

Five pin circuit (usually volt-

age regulator).

Double transistor.

4/00021-2/FEA 209 544/1.G 6 (112)

GH688,GA628, Standard Electrical Repairs

N800 D900

D600

D620 D610

4/00021-2/FEA 209 544/1.G 7 (112)

GH688,GA628, Standard Electrical Repairs

2 No serv or can´t place a call.

2.1 Find out if the problem is Tx- or Rx-related.

Connect the phone (with signaling program) to a GSM instrument and try to get

serv at –68.5dBm signal strength.

• If the phone gets serv proceed to section 2.2.

• If it doesn’t get serv it’s probably a problem located in the LO-part or the losses

in the signal path are too great.

Open the phone and check for liquid damage.

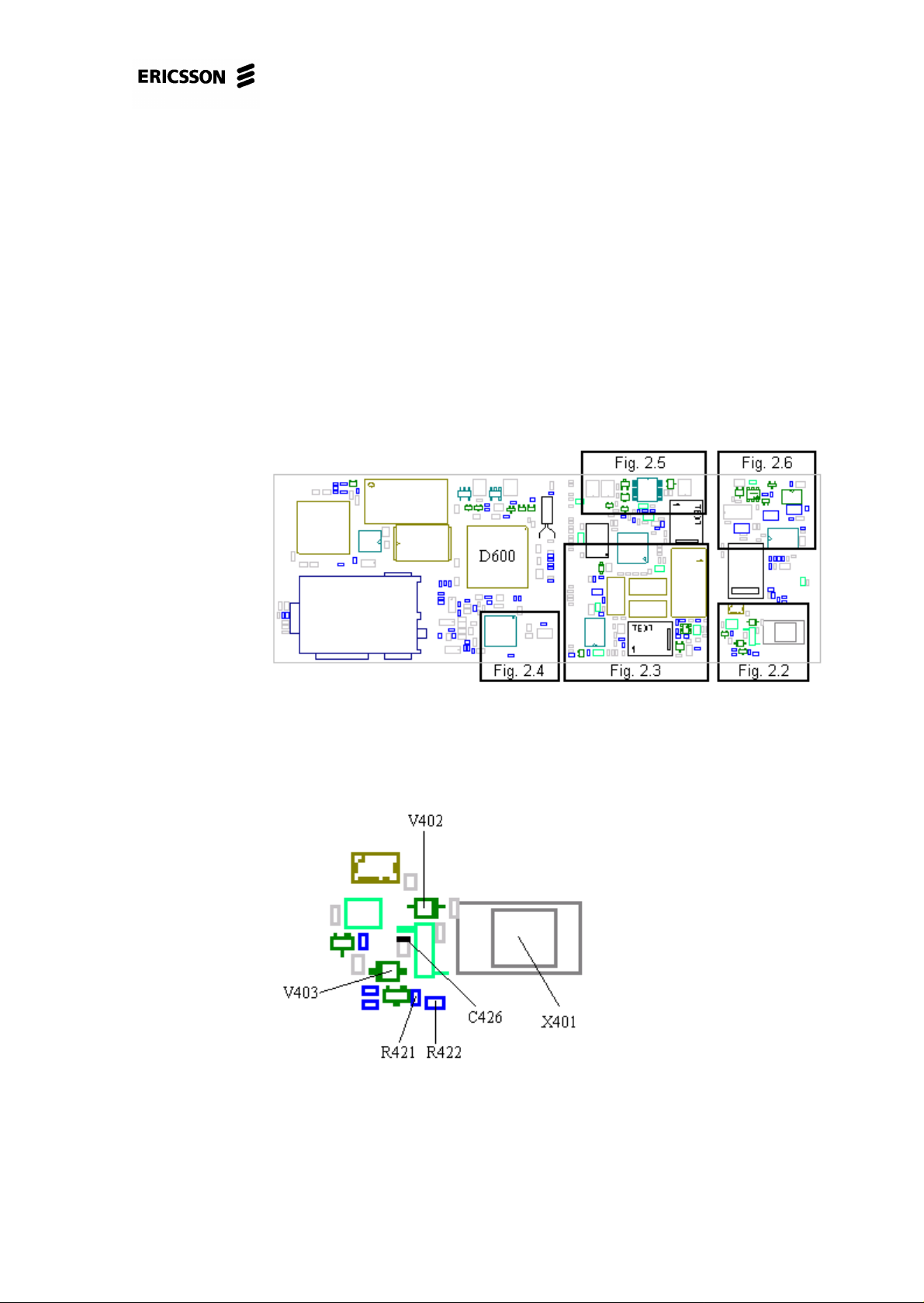

The component side of the board is shown in fig. 2.1.

Fig. 2.1

Check the antenna connector, X401 (class A, fig. 2.2), and make sure that it isn’t

damaged or dirty (glue, varnish, oxide…) and that the solderings aren’t faulty.

Fig. 2.2

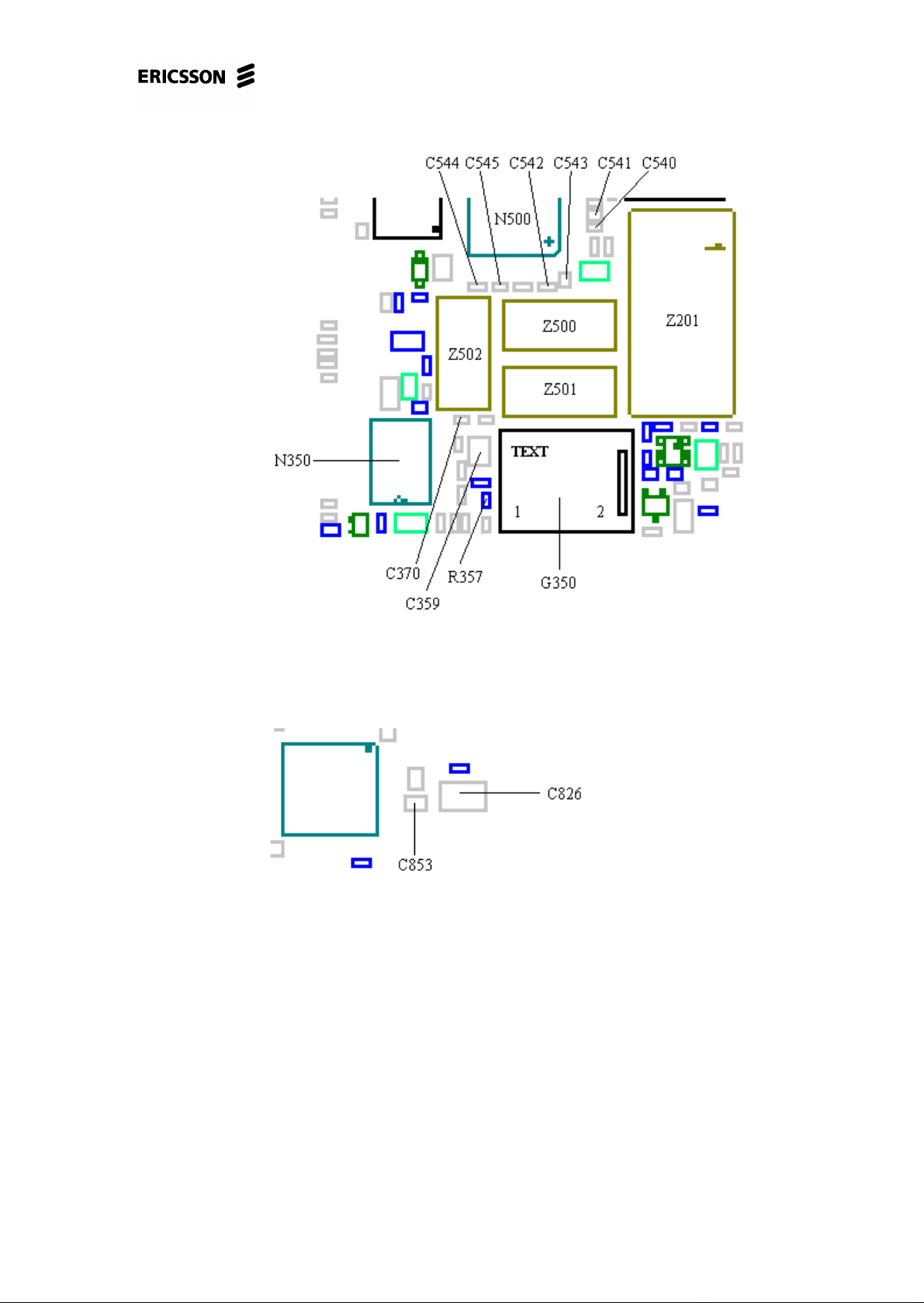

Look for faulty solderings at G350 and C359 (fig. 2.3).

4/00021-2/FEA 209 544/1.G 8 (112)

GH688,GA628, Standard Electrical Repairs

Fig. 2.3

Measure the resistance of C853 (class B, >100 kohms, fig. 2.4).

Fig. 2.4

Give the board power and start it up.

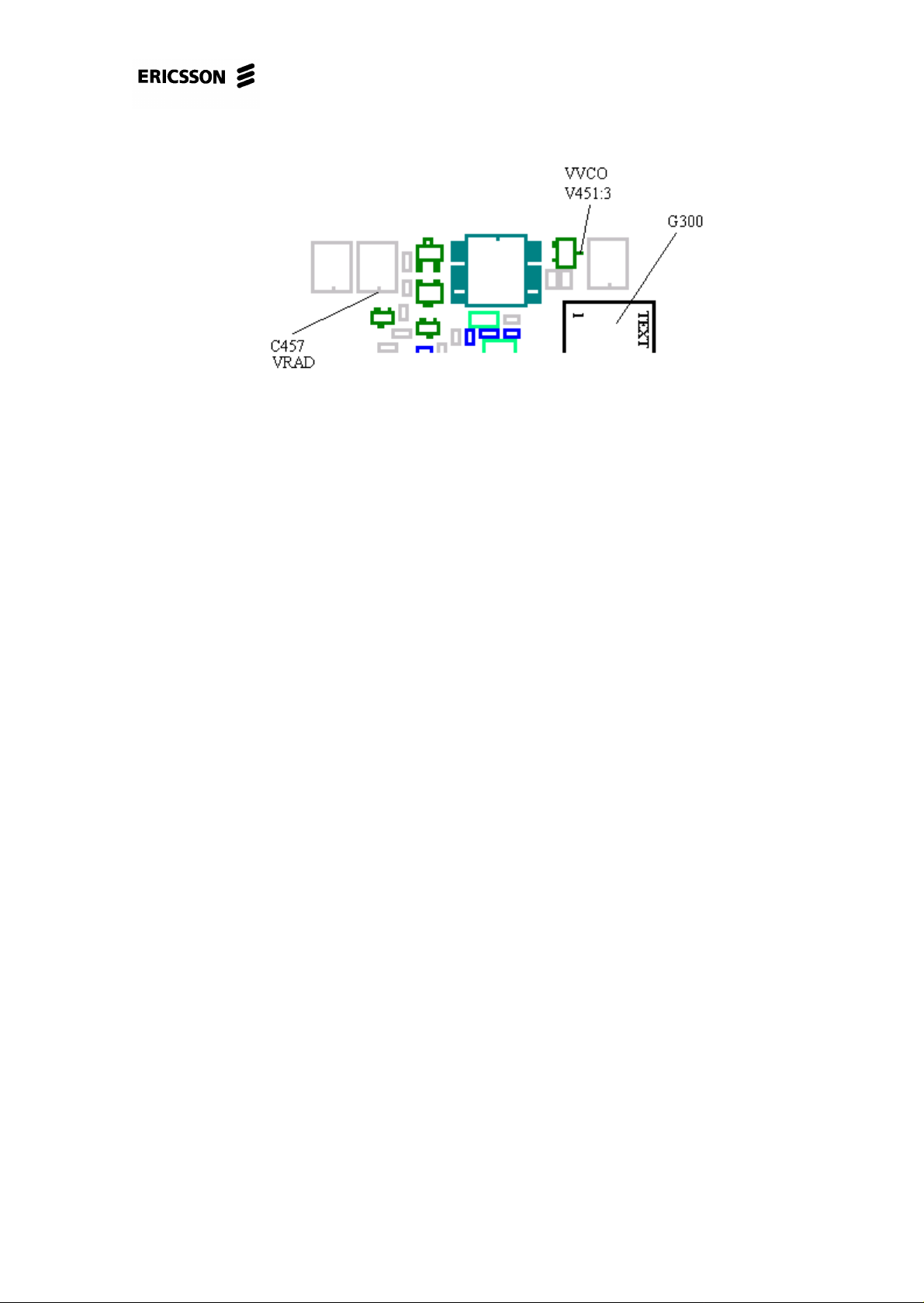

Measure VVCO (~3.8V) at V451 pad 3 and VRAD (~3.8V) at C457 (fig. 2.5).

• If any of the voltages are incorrect, proceed to chapter 3 (“Doesn´t start”-fault).

4/00021-2/FEA 209 544/1.G 9 (112)

GH688,GA628, Standard Electrical Repairs

Fig. 2.5

Measure the DC voltage at pin 1 and 2 of G350. The voltage at pin 1 (control voltage) should always vary between ~0.8V - ~2.8V (usually starts at ~1.7V). The voltage at pin 2 (feed voltage) also varies but usually starts at ~3.3V (fig. 2.3).

• If the feed voltage is incorrect (usually no voltage at all), check the soldering at

D600 pin 102 (fig. 2.1).

* If the soldering isn’t faulty, send the phone to the next level.

• If the control voltage is incorrect (usually ~0V or ~3.6V), check if C370 (class

B) and R357 (class B) are mounted (both of them in fig. 2.3).

* If that is the case, replace N350 (class B, fig. 2.3).

* If that doesn’t help, replace G350 (class B, fig. 2.3).

Measure the resistance of C540, C541, C542, C543, C544 and C545 (all of them

class B, >200 kohms, fig. 2.3)

Check the solderings at C826 (fig. 2.4), Z201, Z500, Z501 and Z502 (fig. 2.3).

If the problem isn’t solved, send the phone to the next level.

2.2 Connect a call at powerlevel 5 using an

instrument with –68.5dBm signal strength.

• If it works, proceed to section 2.3.

• If it doesn’t work, open the phone and check for liquid damage. Make sure the

ground foil around the antenna connector isn’t dirty.

Check the antenna connector, X401 (class A, fig. 2.2), and make sure that it isn’t

damaged or dirty (glue, varnish, oxide…) and that the solderings aren’t faulty.

Replace the back cover and try again.

• If it doesn’t work it most likely means that the problem is Tx-related.

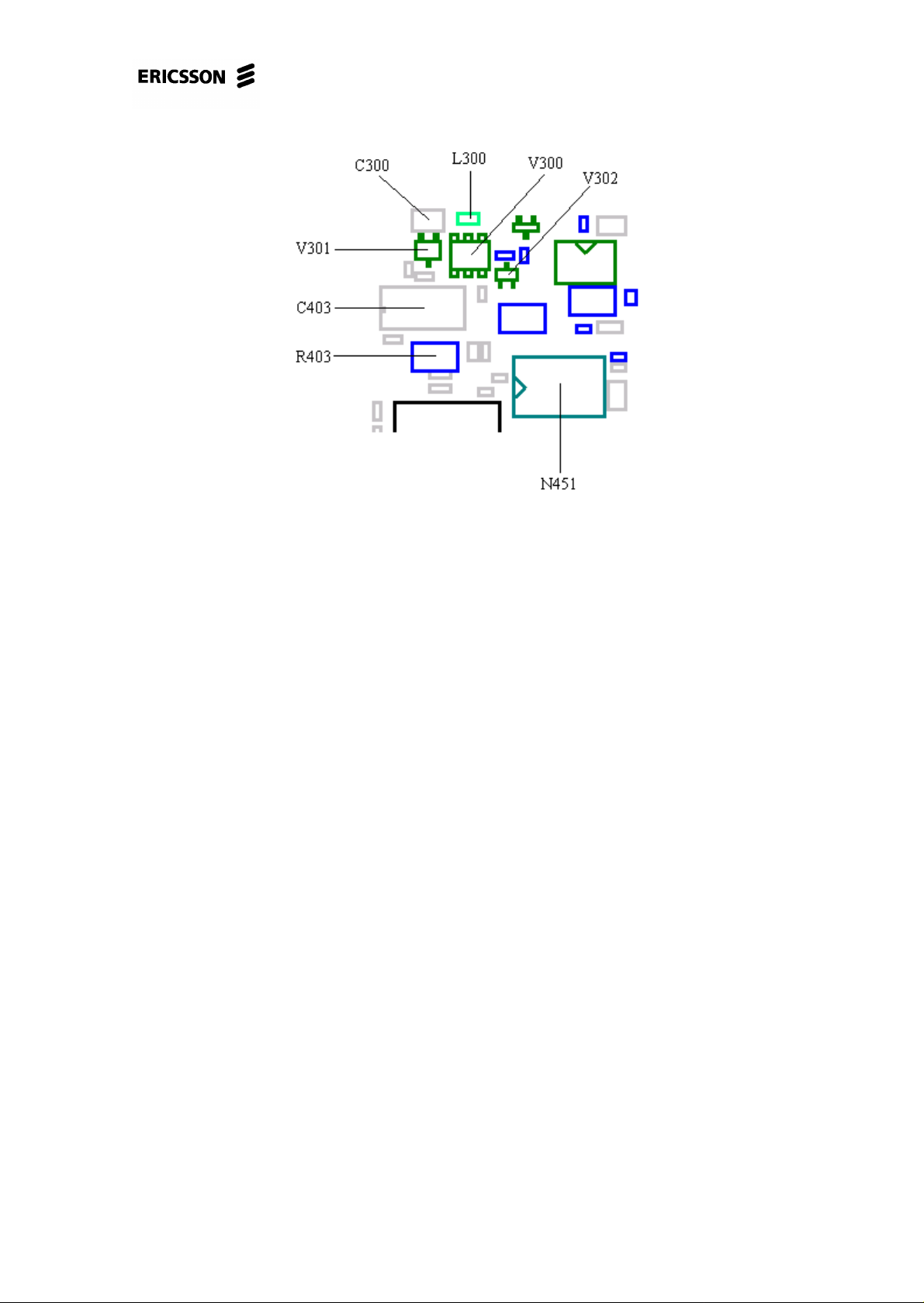

Check if C300, C403, L300, V300, V301 or V302 (all class A, fig. 2.6) are burnt.

4/00021-2/FEA 209 544/1.G 10 (112)

GH688,GA628, Standard Electrical Repairs

Fig. 2.6

Check soldering at G300 (fig. 2.5).

Measure the resistance of C853 (class B, >100 kohms, fig. 2.4).

Measure the resistance of R403 (class B, <1 ohms, fig. 2.6).

Measure the resistance of L300 (class A, <1 ohms, fig. 2.6).

If the problem isn’t solved, send the phone to the next level.

2.3 Read the Rx-level and output power values

from the instrument while the call is still

connected.

• If the Rx-level value is at 40 - 46 steps, check that the output power is 31-

35dBm.

* If it is correct it means that the phone probably isn’t faulty.Lowerthe signal

strength at the instrument to –102dBm and make sure that the Rx-level value

is 6-12 steps and that the Rx-quality value is 0-2 steps.

* Try running the phone through the test again.

* If the phone passes the test but doesn’t manage to connect a call at

the “real” net, make sure that it isn’t because it is stolen. If it isn’t,

replace D600 (class B, fig. 2.1).

* If you get one of these error messages; “phase and frequency

error”, “burst timing”, “power level 5-19”, ”Rx-quality” or “Rx-

level” that differs slightly from the default values, try replacing the

4/00021-2/FEA 209 544/1.G 11 (112)

GH688,GA628, Standard Electrical Repairs

back cover and run the phone through the test again. This applies espe-

cially for the GA 628.

• If the output power is too low or the Rx-quality value is too high, send the phone

to the next level.

• If the Rx-level value is too high, the phone has to be calibrated and therefore you

have to send the phone to the next level.

• If the Rx-level value is below 40 steps at –68.5dBm signal strength or below 6

steps at –102dBm signal strength, the problem is Rx-related.

Open the phone and check for liquid damage.

Check the antenna connector, X401 (class A, fig. 2.2), and make sure that it isn’t

damaged or dirty (glue, varnish, oxide…) and that the solderings aren’t faulty.

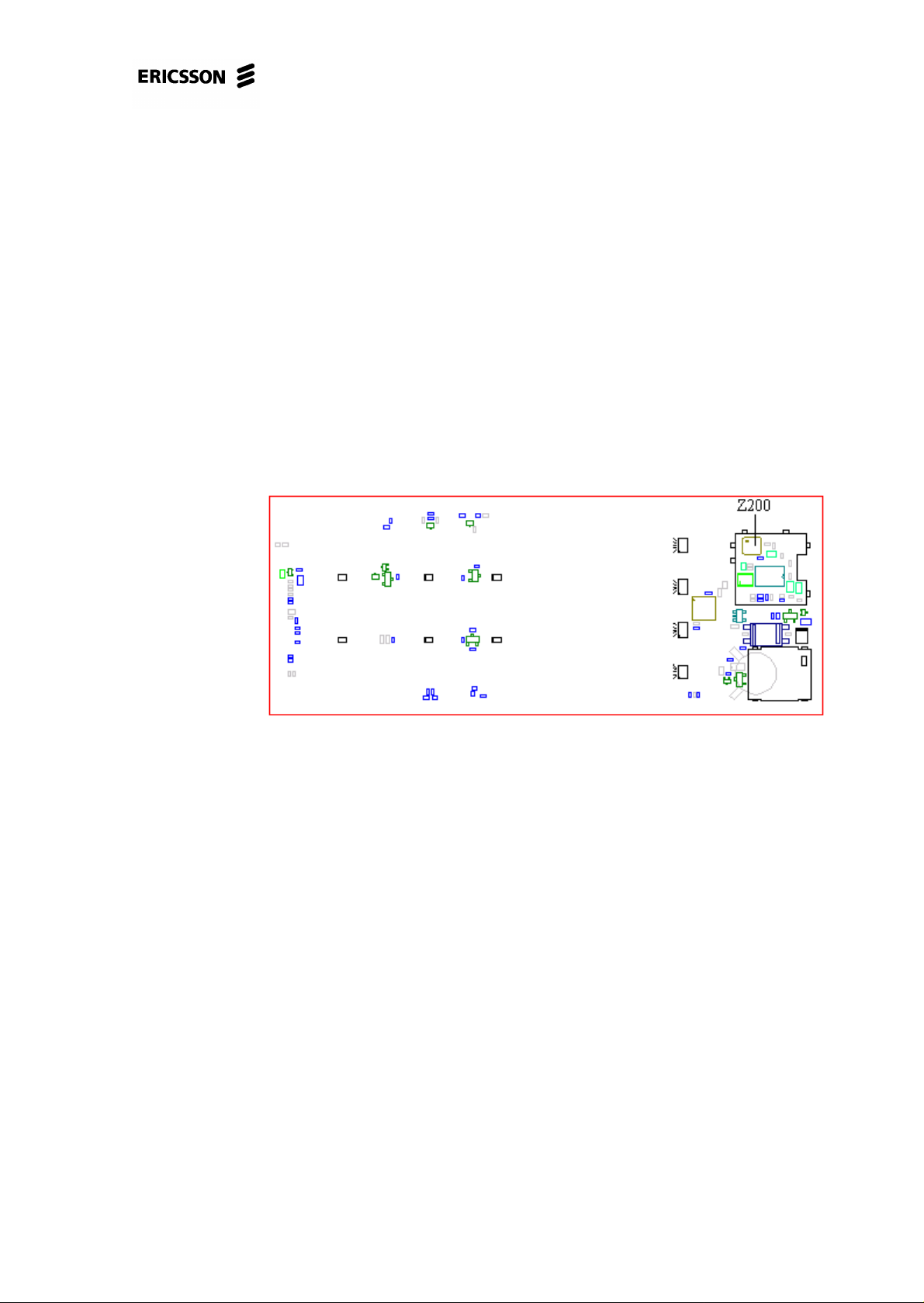

Measure the resistance from C426 (fig. 2.2, measure from the marked side) to

ground (>1 Mohms). The resistance is usually only a few ohms when Z200 (class B,

fig. 2.7) is broken.

Fig. 2.7

Measure the resistance from the anode of V403 (class B, fig. 2.2) to ground (~60

kohms).

• If it’s less (a few kohms), lift one of the V402 pins from the pad and measure

again at the same place.

If it’s correct (~60 kohms), replace V402.

• If the resistance is still too low, replace both diodes.

Measure again after replacing the component(s).

• If the resistance is still too low, measure the resistance of R421 and R422 (both

of class B, 100 kohms, fig. 2.2). Both the resistors are 100 kohms but when you

measure them the instrument will show ~60 kohms.

Check the solderings at C826 (fig. 2.4), Z201, Z500, Z501 and Z502 (fig. 2.3).

Measure the resistance of C540, C541, C542, C543, C544 and C545 (all of them

class B, >200 kohms, fig. 2.3)

If the problem isn’t solved, send the phone to the next level.

4/00021-2/FEA 209 544/1.G 12 (112)

GH688,GA628, Standard Electrical Repairs

3 Doesn’t start.

3.1 Find out if the phone will start by using the

On/Off-button.

Insert a fully charged battery and press the On/Off-button.

• If the phone doesn’t start, proceed to section 3.2

• If the phone starts, check the charging function by connecting a charger at the

system connector.

If the phone doesn’t charge, proceed to chapter 6 (“Charging”-fault).

If the phone starts (lights the background illumination, asks for SIM/PIN,

seeks the net…) and charges it’s probably not faulty or the problem is inter-

mittent.

Open the phone and make a visual examination of the circuit board.

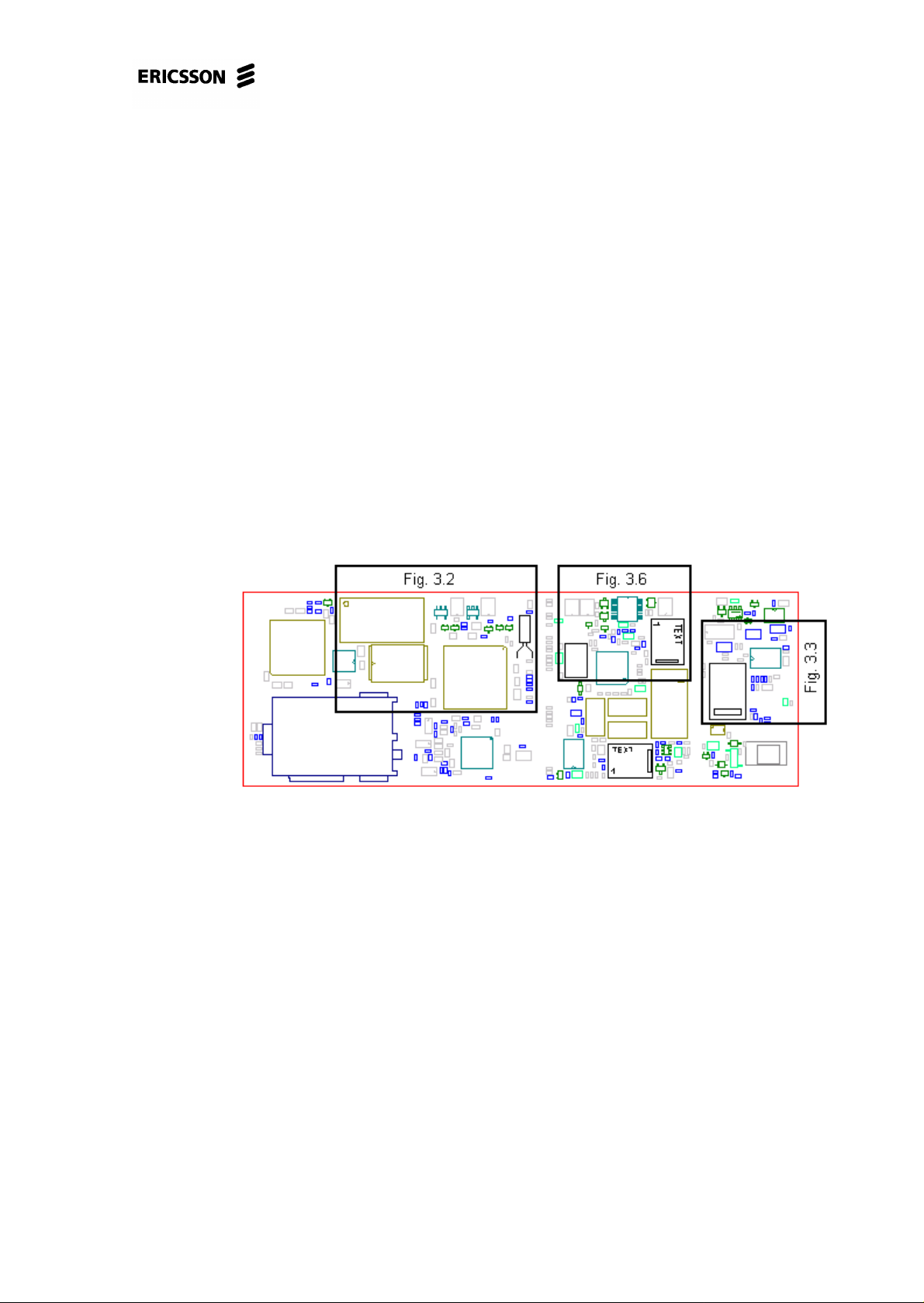

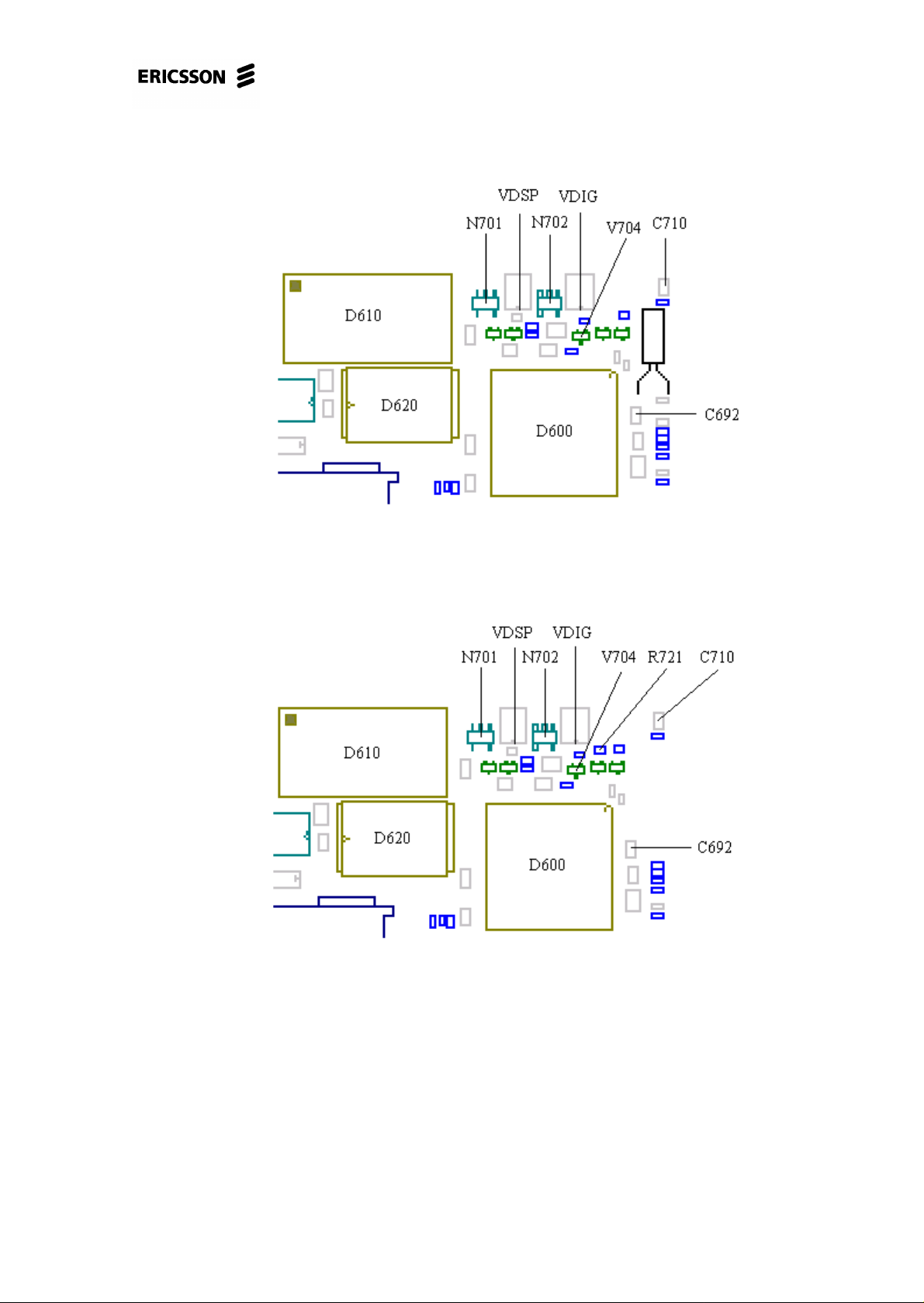

The component side of the board is shown in fig. 3.1.

Fig. 3.1

Check for liquid damages anywhere at the board. Also check for burnt or damaged

pads at the system connector and faulty soldering at, for instance, D600, D610 and

D620 (fig. 3.2).

4/00021-2/FEA 209 544/1.G 13 (112)

GH688,GA628, Standard Electrical Repairs

GH688

GA 628

Fig. 3.2

As soon as the problem is solved, send the phone through the flow as usual.

4/00021-2/FEA 209 544/1.G 14 (112)

GH688,GA628, Standard Electrical Repairs

3.2 Visual check.

Make a visual check. Make sure that the battery screws are intact and properly

mounted, that the isolator sleeve (GH 688) is properly mounted, that the volume

keys aren’t stuck and that the system connector isn’t dirty or liquid damaged. Continue at 3.3.

3.3 Current consumption with On/off-key

pressed.

Insert a dummy battery.

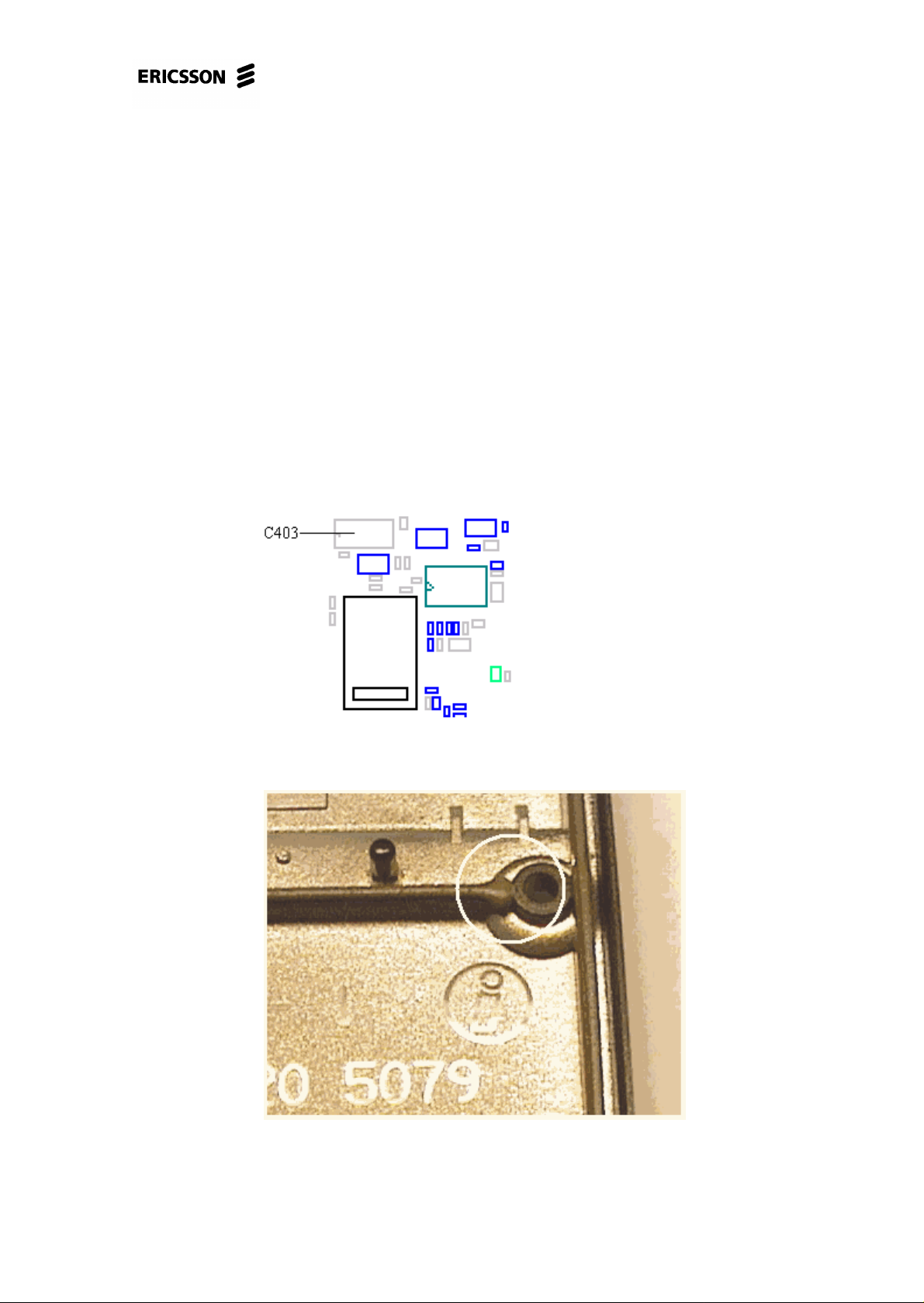

• If the phone consumes current immediately it usually means that C403 (class A,

fig. 3.3) is faulty but first you should make sure that the frame gasket isn’t in contact with the positive battery connector pad at the circuit board (fig. 3.4).

Fig. 3.3

Fig. 3.4

4/00021-2/FEA 209 544/1.G 15 (112)

GH688,GA628, Standard Electrical Repairs

Start the phone using the On/Off-key and check the current consumption.

• If the phone doesn’t consume any current at all when the On/Off-key is

pressed it is most likely liquid damaged. Open the phone and check this. Also

check that the keyboard and the keyboard pads are functional and clean.

• If the phone consumes more than 200mA, remove the display elastomer and try

again.

* If the consumption is reduced it was probably the elastomer or the display.

* If the consumption is just as high as before, proceed to section 3.4.3.

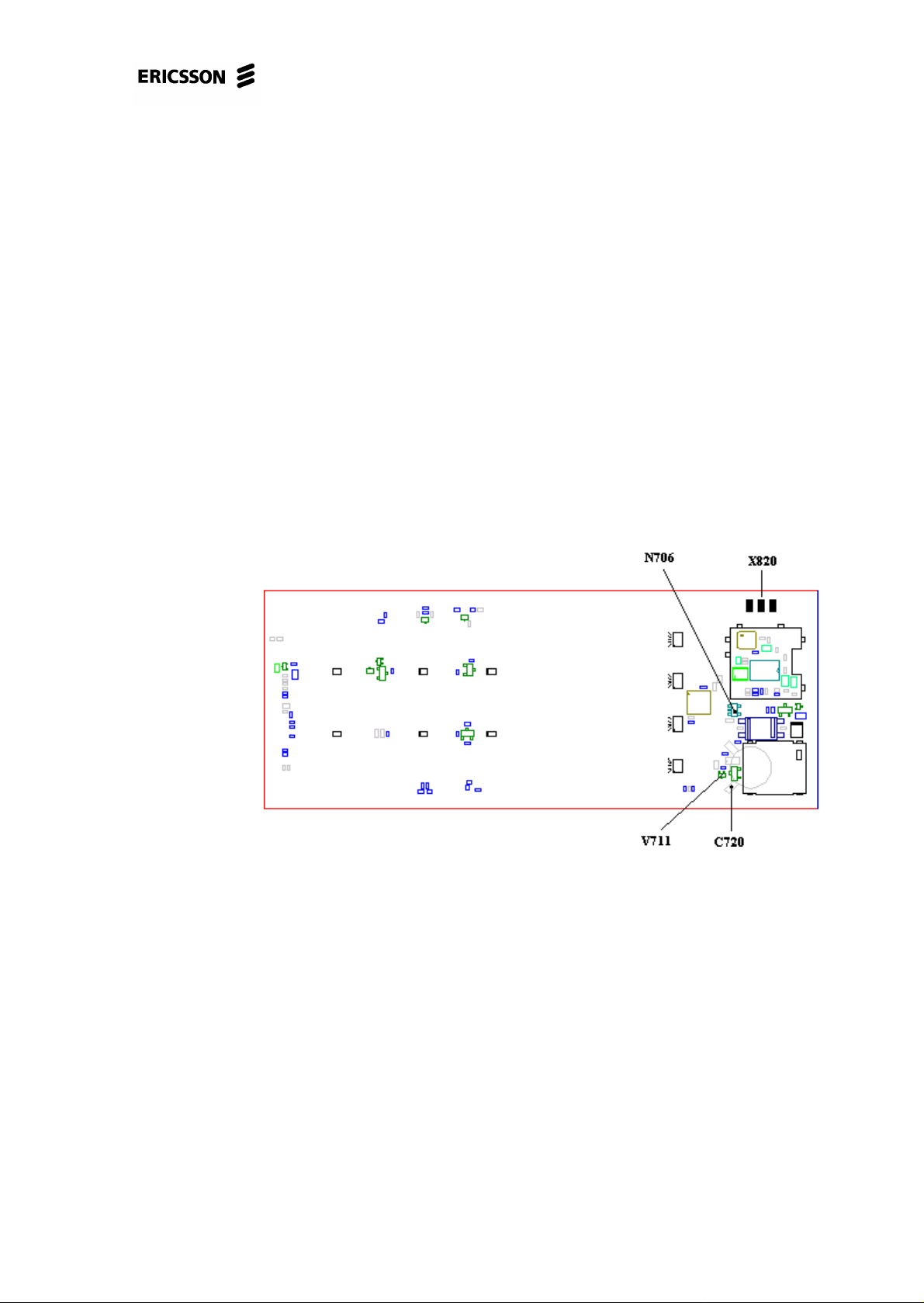

• If the phone consumes ~60mA (average, varies), the battery indicator blinks

once or twice and then the phone turns itself off, then it’s probably X820 (the

pads to the volume flex film, fig. 3.5) or the volume flex film (J820) that is

shorted out. Replace the flex film and if that doesn’t work, proceed to section

3.2.

* If the same phenomena arises without the On/Off-key being pressed it

means that V704 is broken (fig. 3.2).

Fig. 3.5

• If the phone consumes 1-200mA, starts (asks for SIM/searches for the

net…etc…) and works as long as you keep the On/Off-key pressed, proceed to

section 3.4.4.

• If the phone doesn’t start, try to program it in the flash programmer.

* If it doesn’t start in the flash programmer, proceed to section 3.4.1

* If you are able to program the phone in the flash programmer but it doesn’t

start afterwards or if it is troublesome when trying to program it, proceed to

section 3.4.2.

* If the phone starts after programming it in the flash-programmer then the

problem is probably solved, but to eliminate intermittent errors check the circuit board for liquid damage or faulty solderings on D600, D610 and D620

(fig. 3.2).

4/00021-2/FEA 209 544/1.G 16 (112)

GH688,GA628, Standard Electrical Repairs

3.4 Measuring at a powered circuit board.

3.4.1 Doesn’t start in the flash programmer.

Open the phone and check for liquid damage.

Make sure the system connector pads aren’t burnt.

Place the board in the fixture. Start it up and keep it running by keeping DCIO high.

Check VDIG and VDSP voltages (~3.2 V, fig. 3.2).

• If any of the voltages are too low,measure the resistance to ground (VDIG > 500

ohms, VDSP > 25 kohms).

* If the resistances are correct, replace the corresponding circuit (VDIG –

N702, VDSP – N701, both of class A).

* If the resistance is too low, send the phone to next level.

• If any of the voltages are too high, replace the corresponding circuit.

Check the power reset voltage at C710 (fig. 3.2, >3V).

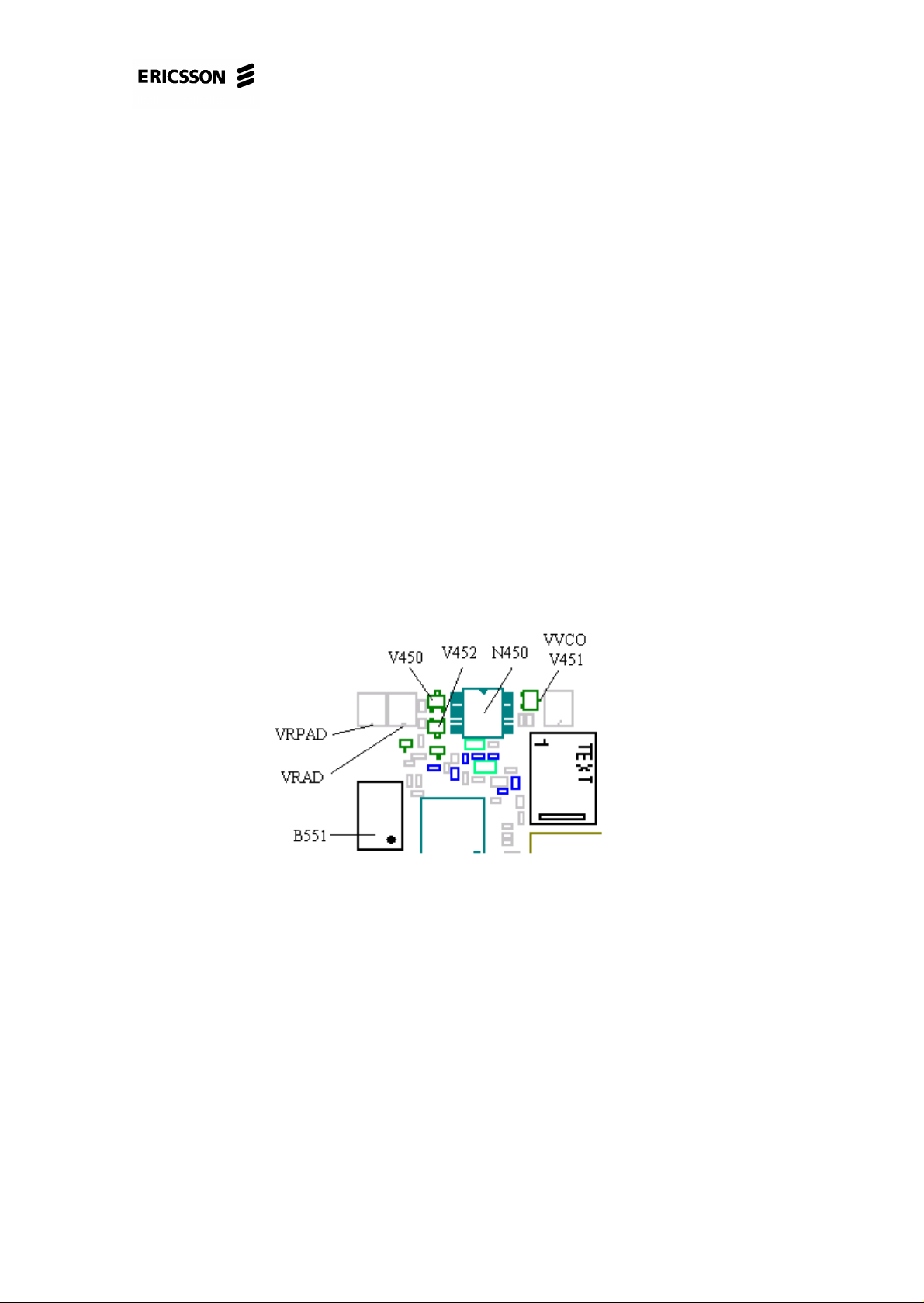

• If it’s lower, replace N450 (class A, fig. 3.6) and try again.

* If it didn’t work, replace C710 (class A).

Fig. 3.6

Check VRAD, VVCO and VRPAD (~3.8V, fig. 3.6).

• If all three voltages are wrong, measure the resistance from N450 pads 8, 11, 12,

13 and 14 to ground (~0 ohms).

* If the resistance is too high there is a foil damage and the phone is to be discarded.

* If it is correct, replace the circuit and eventually the transistors (V452,

V451 and V450, all of them class A).

• If one or two of the voltages are wrong, measure the resistance from the corre-

sponding voltage source to ground (>50 kohms).

* If the resistance is correct, replace the corresponding transistor.

4/00021-2/FEA 209 544/1.G 17 (112)

GH688,GA628, Standard Electrical Repairs

* If that doesn’t help, replace N450 (class A).

* If the resistance of any of the voltage sources is too low, send the phone to

the next level.

Measure the amplitude of B551 pin 3 (class C, >1V t-t) with an oscilloscope, spectrum analyzer, frequency counter, diode probe…

• If the amplitude is too low, send the phone to the next level.

Check for bad solderings at D600, D610 and D620 (fig 3.2).

• If they look ok, replace D600 (class B).

* If that doesn’t work, first replace D610 (class A) and then D620 (class A).

Try to program the phone in the flash programmer for every circuit you

replace. Don’t replace any circuit if you haven’t established the fact that

B551 is working.

3.4.2 Is programmable in the flash programmer but

doesn’t start afterwards or is troublesome in the

flash programmer.

Open the phone and check for liquid damages.

Make sure the system connector pads aren’t burnt.

Insert the board in the fixture. Start it up and keep it going by keeping DCIO high.

Check VDIG and VDSP (~3.2V, fig. 3.2).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG >500 Ohms, VDSP >25 kohms).

* If the resistance is correct, replace the corresponding circuit (VDIG – N702

– class A, VDSP – N701 – class A).

* If the resistance is too low, send the phone to the next level.

• If any of the voltages are too high, replace the corresponding circuit.

Check VRAD, VVCO and VRPAD (~3.8V, fig. 3.6).

• If all the voltages are incorrect, measure the resistance from N450 pads 8, 11, 12,

13 and 14 to ground (~0 ohms).

* If any of the resistances are too high there is a foil damage and the phone

should be discarded.

* If all the resistances are correct, replace the circuit and eventually the transistors (V450, V451, V452, all class A).

• If one or two of the voltages are incorrect, measure the resistance from the incor-

rect voltage(s) to ground (>50 kohms).

* If the resistance is correct replace the corresponding transistor. If that

doesn’t help, replace N450 (class A).

4/00021-2/FEA 209 544/1.G 18 (112)

GH688,GA628, Standard Electrical Repairs

* If the resistances from any of the voltages to ground are too low, send the

phone to the next level.

Make sure that there are no faulty solderings on D600, D610 and D620.

• If the solderings look good, replace D610 (class A).

* If that doesn’t help, first replace D600 (class B) and then D620 (class A).

Try to program the phone in the flash programmer for every circuit you

replace.

3.4.3 Consumes more than 200mA.

Open the phone and check for liquid damage.

Make sure that the system connector pads aren’t burnt.

Insert the board in the fixture. Start it up and keep it going by keeping DCIO high.

Check VDIG and VDSP (~3.2V, fig. 3.2).

• If any of the voltages are too low, measure the resistance from it to ground

(VDIG >500 ohms, VDSP >25 kohms).

* If the resistance is correct, replace the corresponding circuit (VDIG – N702

– class A, VDSP – N701 – class A).

* If the resistance is too low, send the phone to the next level.

• If any of the voltages are too high, replace the corresponding circuit.

Check VRAD, VVCO and VRPAD (~3.8V, fig. 3.6).

• If all three voltages are incorrect, measure the resistance from N450 pads 8, 11,

12, 13 and 14 to ground (0 ohms).

* If the resistance is too high there is a foil damage and the phone should be

discarded.

* If the resistance is correct, replace the circuit and eventually transistors

(V450, V451, V452, all class A).

• If one or two of the voltages are incorrect, measure the resistance to ground (>50

kohms).

* If the resistance is correct, replace the corresponding transistor.

* If that doesn’t help, replace N450 (class A).

* If the resistance from any of the voltages to ground is too low, send the

phone to the next level.

4/00021-2/FEA 209 544/1.G 19 (112)

GH688,GA628, Standard Electrical Repairs

3.4.4 The phone works as long as the On/Off-key is

pressed.

GH688

Open the phone and check for liquid damages.

Make sure the system connector pads aren’t burnt.

Insert the board in the fixture. Start it up and keep it going by keeping DCIO high.

Measure the voltage at C692 (~3.1V, fig. 3.2).

• If there is voltage, check the soldering at D600 pin 119.

• If there isn’t voltage, measure the resistance of C692 (class A, >200 kohms).

* If the resistance is correct, measure the input voltage at N706 pin 2

(VBATT) and the output voltage at N706 pin 3 (~3.5V). Make sure that the

regulator has ground at N706 pin 1. There is a foil damage if the ground or

VBATT is missing at N706 and the phone should be discarded.

* If the input voltage and the ground are correct, replace N706 (class A).

* If the output voltage is correct, measure the voltage at the positive side

of the backup capacitor (C720, class A, ~3.1V).

* If there is no voltage, replace V711 (class A).

* If there is voltage,check the resistance from the positive side of C720

(fig. 3.5) to C692 (~0 ohms).

* If the resistance is too high there is a foil damage and the phone

should be discarded.

GA 628

Open the phone and check for liquid damage.

Make sure that the system connector pads aren’t burnt.

Insert the board in the fixture. Start it up and keep it going by keeping DCIO high.

Measure the voltage at C692 (~3.1V, fig. 3.2, the figure shows a GH 688 board but

the capacitor is placed at the same location).

• If there is voltage, check the soldering at D600 pad 119.

• If there is no voltage, measure the resistance of C692 (class A, >200 kohms).

* If the resistance is correct, measure VDIG.

* If the voltage at VDIG is incorrect, see 3.4.1, 3.4.2 or 3.4.3.

* If VDIG is correct, check the resistance from N702 pin5 (fig. 3.2) to

C692 (~0 ohms).

4/00021-2/FEA 209 544/1.G 20 (112)

GH688,GA628, Standard Electrical Repairs

* If the resistance is too high, measure the resistance of R721 (class A,

~0 ohms).

* If R721 is correct there is a foil damage and the phone should be

discarded.

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/1.G 21 (112)

4 Audio.

GH688,GA628, Standard Electrical Repairs

4.1 Type of fault.

Make a call from the phone that is to be tested (later called the phone) to a phone

that is working correctly (later called the reference phone).

Check the function of the microphone and the earphone.

Connect a handsfree unit to the system connector of the phone.

Check the function of the phone’s external connections by listening to the external

speaker/earphone when talking in the reference phone and by listening to the earphone of the reference phone when talking in the external mic of the phone.

• If there is low or no sound in the earphone of the phone, proceed to section 4.2.

• If both the earphone and the handsfree speaker don’t work, send the phone to the

next level.

• If the sensitivity of the microphone is low (low or no sound in the reference

phone), proceed to section 4.3.

• If both the microphone in the phone and the microphone of the handsfree don’t

work, send the phone to the next level.

• If both the microphone and the earphone don’t work, proceed to section 4.4.

• If the microphone, the earphone and the handsfree don’t work, send the phone to

the next level.

• If the microphone of the handsfree doesn’t work, proceed to section 4.5.

• If the speaker of the handsfree doesn’t work, proceed to section 4.6.

• If both the microphone and the speaker of the handsfree don’t work, proceed to

section 4.7.

• If the phone sounds strange (the sound is distorted, scrambled, full of static or

“chopped”), send the phone to the next level.

4.2 Earphone out of order.

Open the phone and check for liquid damages.

Most of the earphone faults are mechanical. Therefore you should start with replac-

ing the front (with the earphone) to one you know works and try again.

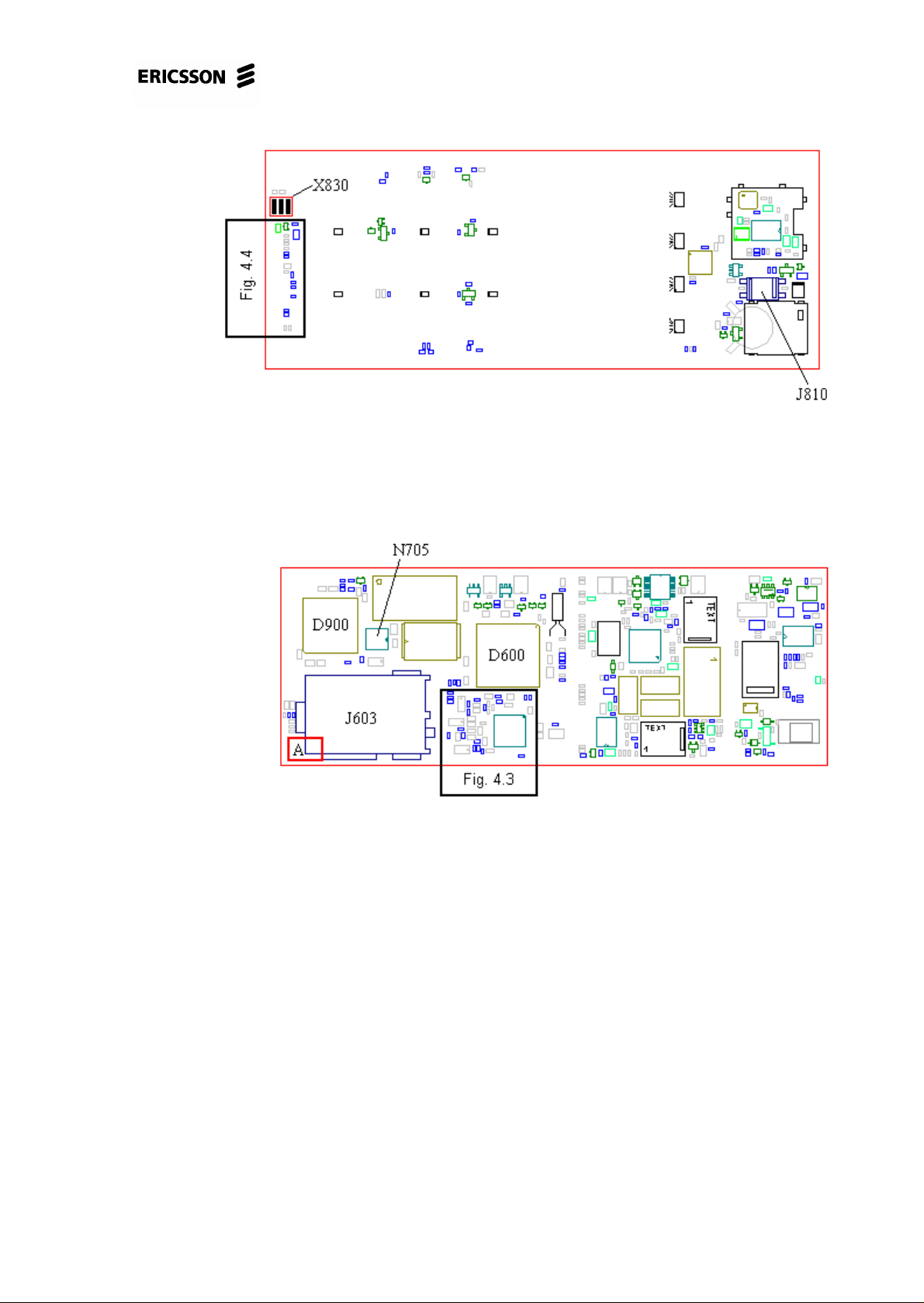

• If the fault remains, make sure the earphone connector (J810, fig. 4.1) is intact

and correctly soldered.

4/00021-2/FEA 209 544/1.G 22 (112)

GH688,GA628, Standard Electrical Repairs

Fig. 4.1

Check the solderings of N800 (fig. 4.3).

Fig. 4.2 shows the component side of the circuit board.

Fig. 4.2

4/00021-2/FEA 209 544/1.G 23 (112)

GH688,GA628, Standard Electrical Repairs

Fig. 4.3

If the fault remains, send the phone to the next level.

4.3 Microphone out of order.

Open the phone and check for liquid damages, especially around X830 (fig. 4.1) and

below J603 (marked area A in fig. 4.2).

Clean the system and microphone connector pads if needed.

Most of the microphone faults are mechanical. Therefore you should start with

replacing the front (with microphone) and elastomer to one you know works and try

again.

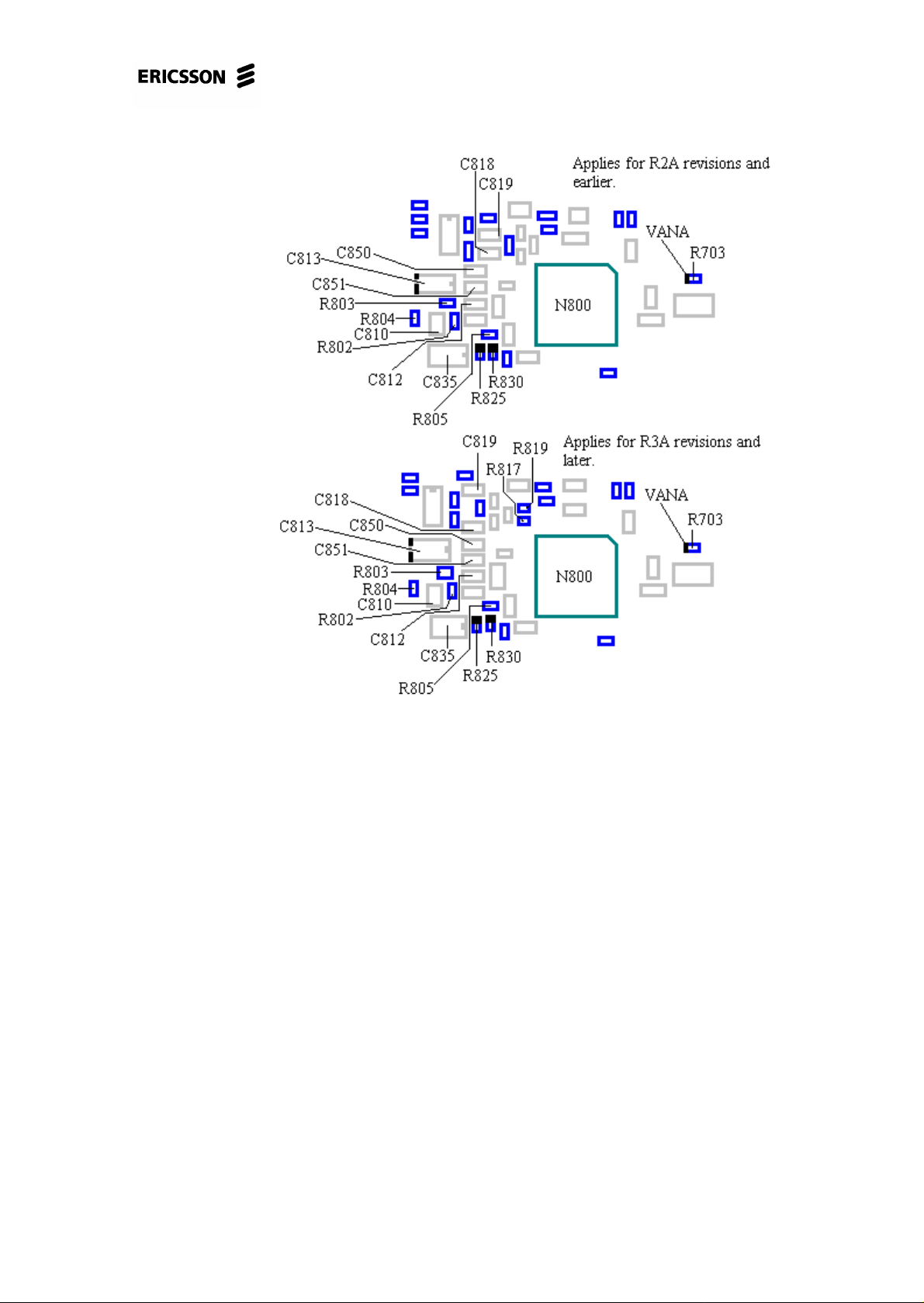

If the fault remains, measure the resistances of C850 (>100 kohms), C851 (>1

kohms), R817 (~1 kohms) and R819 (~1kohms, all of class A and in fig. 4.3). Note!

The resistors are mounted at boards from revision R3A and above.

Check the solderings of N800 (fig. 4.3).

Replace C818 and C819 (fig. 4.3).

If the fault still remains, send the phone to the next level.

4/00021-2/FEA 209 544/1.G 24 (112)

GH688,GA628, Standard Electrical Repairs

4.4 Both the earphone and microphone out of

order.

Open the phone and check for liquid damages.

Make sure there is no dirt or oxide between the components above the system con-

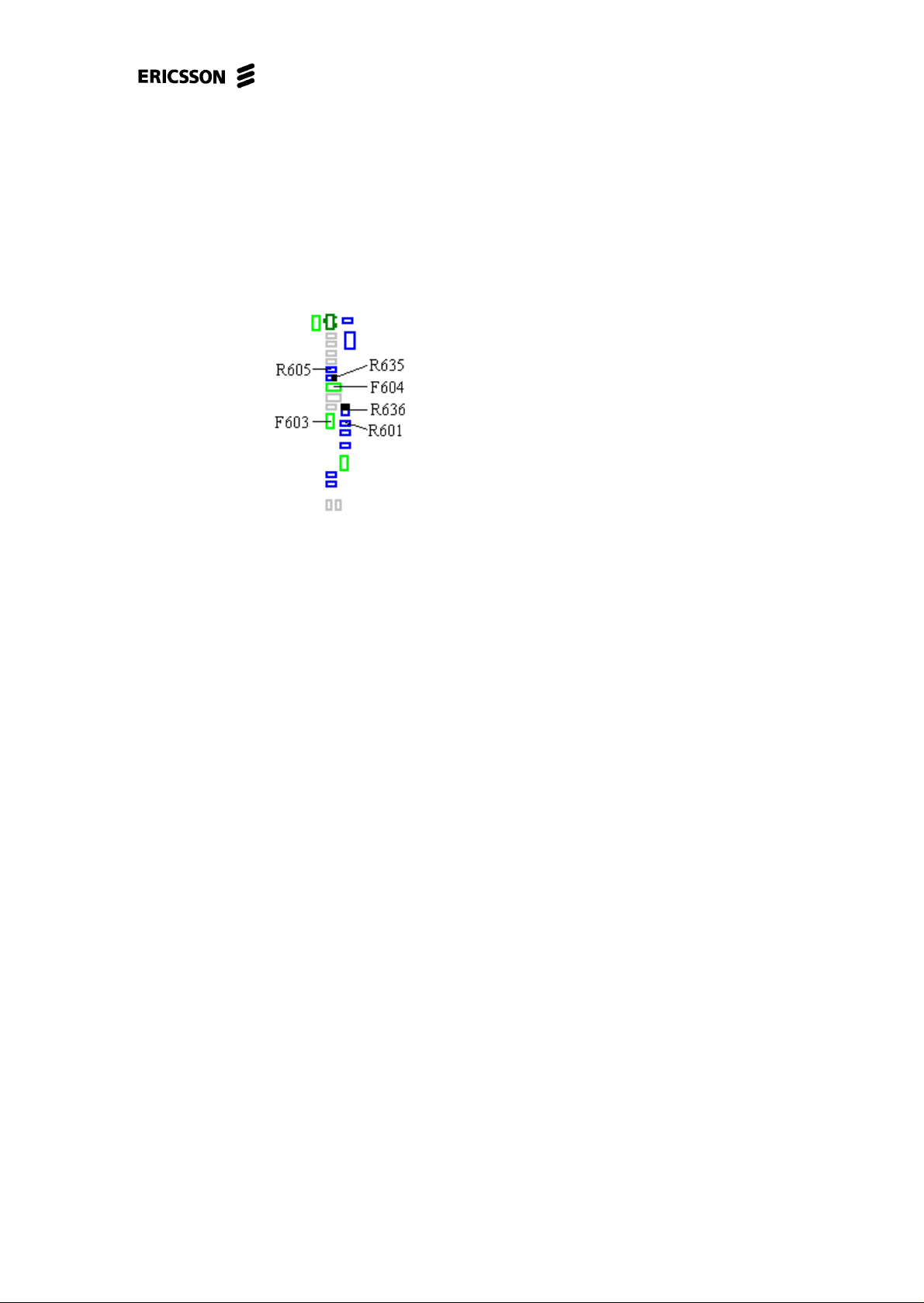

nector pads (fig. 4.4 or marked area in fig. 4.5). Check very thoroughly!

Fig. 4.4

Clean the marked surface using alcohol and a brush. Note! The dirt can be very hard

to remove but it’s important to wash it away.

Assemble the phone and try again as in 4.1.

If the fault remains, replace F603 and F604. It’s important to clean where the com-

ponents are supposed to be before mounting new ones.

Assemble the phone and try again as in 4.1.

If it still doesn’t work, open the phone, give the board power and start it up by press-

ing the On/Off key without the system cable connected.

Measure the voltage at both sides of R601 and at D600 pin 70 (~5V, fig. 4.4 and 4.2,

you follow the PHFI signal).

Measure the voltage at both sides of R605 and at D600 pin 67 (~5V, fig. 4.4 and 4.2,

you follow the EXTAUDI signal).

• If the voltage is low only at one side of R601 or R605, replace the corresponding

resistor (fig. 4.4, both of class A).

• If the voltage is low at both sides of R601 or R605, check the VSIMPAD voltage

at the marked sides of R635 and R636 (~5V, fig. 4.4).

* If there is no voltage, check the resistance from the marked side of R635 or

R636 to N705 pin 3 (~0 ohms, fig. 4.4 and 4.2).

* If the resistance is too high there’s a foil damage and the phone is to be

discarded.

* If the resistance is correct, proceed to section 4.3.

* If there is VSIMPAD voltage at the marked side of R635 or R636, measure

the resistances of them (both are ~22 kohms and in fig. 4.4).

* If any of the resistances are incorrect, replace the corresponding resistor.

4/00021-2/FEA 209 544/1.G 25 (112)

GH688,GA628, Standard Electrical Repairs

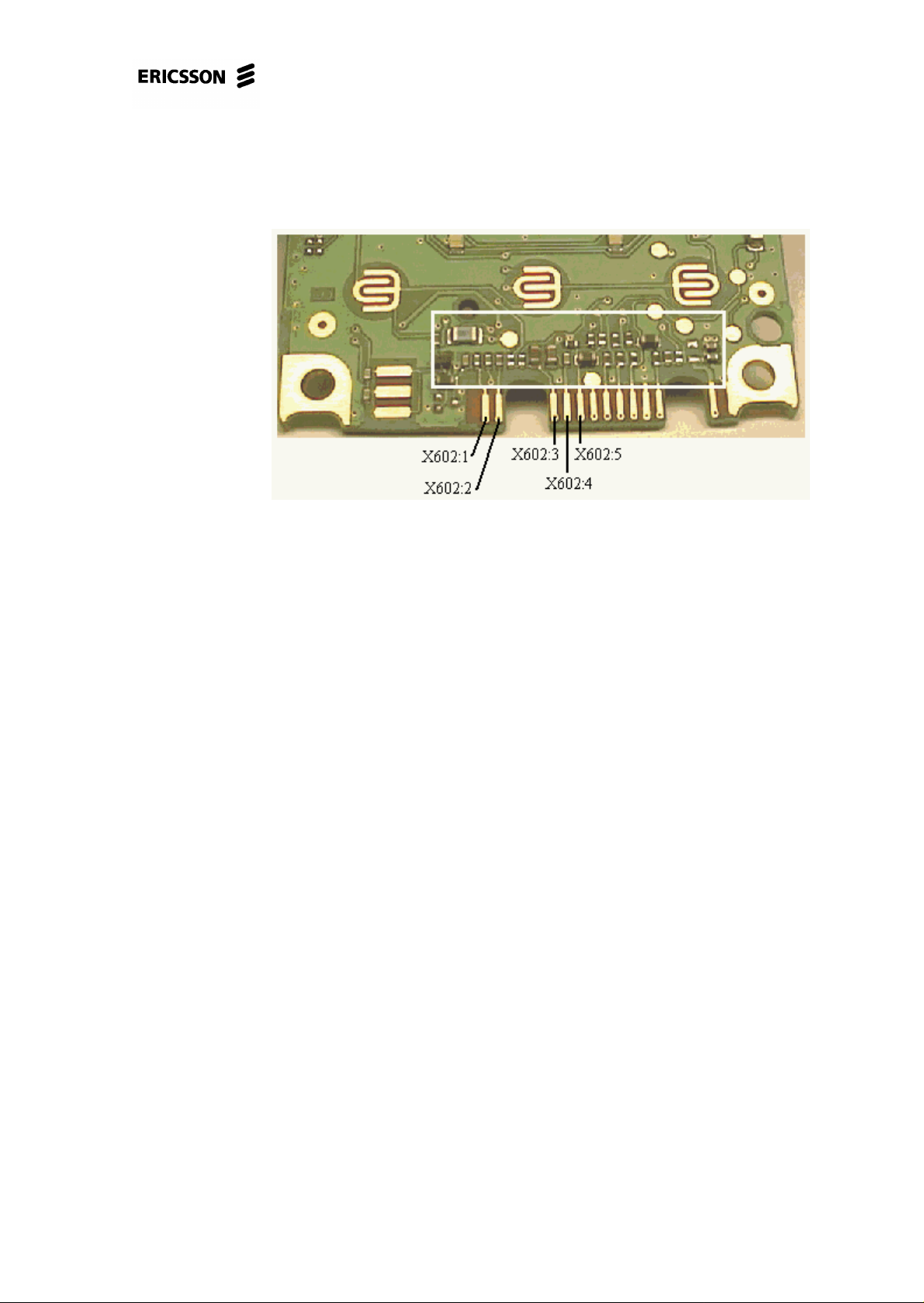

* Measure the resistance from X602 pad 5 to ground (>100 kohms).

* If it’s too low, make sure there’s no dirt or oxide between the components in the marked area (fig. 4.5). Clean thoroughly and measure again.

Fig. 4.5

* If the resistance still is too low, remove R601 (class A, fig. 4.4).

* If the resistance increased, replace D600 (class B, fig. 4.2) and

mount a new R601.

* If the resistance didn’t increase when removing R601 or it

didn’t help by replacing D600, send the phone to the next level.

* Measure the resistance from X602 pad 3 to ground (>100 kohms).

* If it’s too low, make sure there’s no dirt or oxide between the components in the marked area (fig. 4.5). Clean thoroughly and measure again.

* If the resistance still is too low, remove R605 (class A, fig. 4.4) and

measure again.

* If the resistance increased, replace D600 (class B, fig. 4.2) and

mount a new R605.

* If the resistance didn’t increase when removing R605 or it

didn’t help by replacing D600, send the phone to the next level.

If all the above measured resistances are correct, but some of the voltages at

R601 or R605 are low it’s either caused by a slight short circuit due to dirt at

the marked area in fig. 4.5, broken F603 or broken F604.

• If the voltages at R601 and R605 are correct, connect a handsfree to the system

connector.

• Measure the voltages at both sides of R601 (~0V, fig. 4.4) and at D600 pin 70

(~0V, fig. 4.2).

4/00021-2/FEA 209 544/1.G 26 (112)

GH688,GA628, Standard Electrical Repairs

* If the voltages aren’t correct, check the soldering of D600 pin 70 (fig. 4.2).

* If the soldering is correct, check the resistance of R601 (~1 kohms, class

A).

* If the resistance is correct, replace D600 (class B, fig. 4.2).

* If the voltages are correct, check the solderings of N800, D600 and D900

(fig. 4.3 and 4.2).

If the fault remains, send the phone to the next level.

4.5 Handsfree microphone out of order.

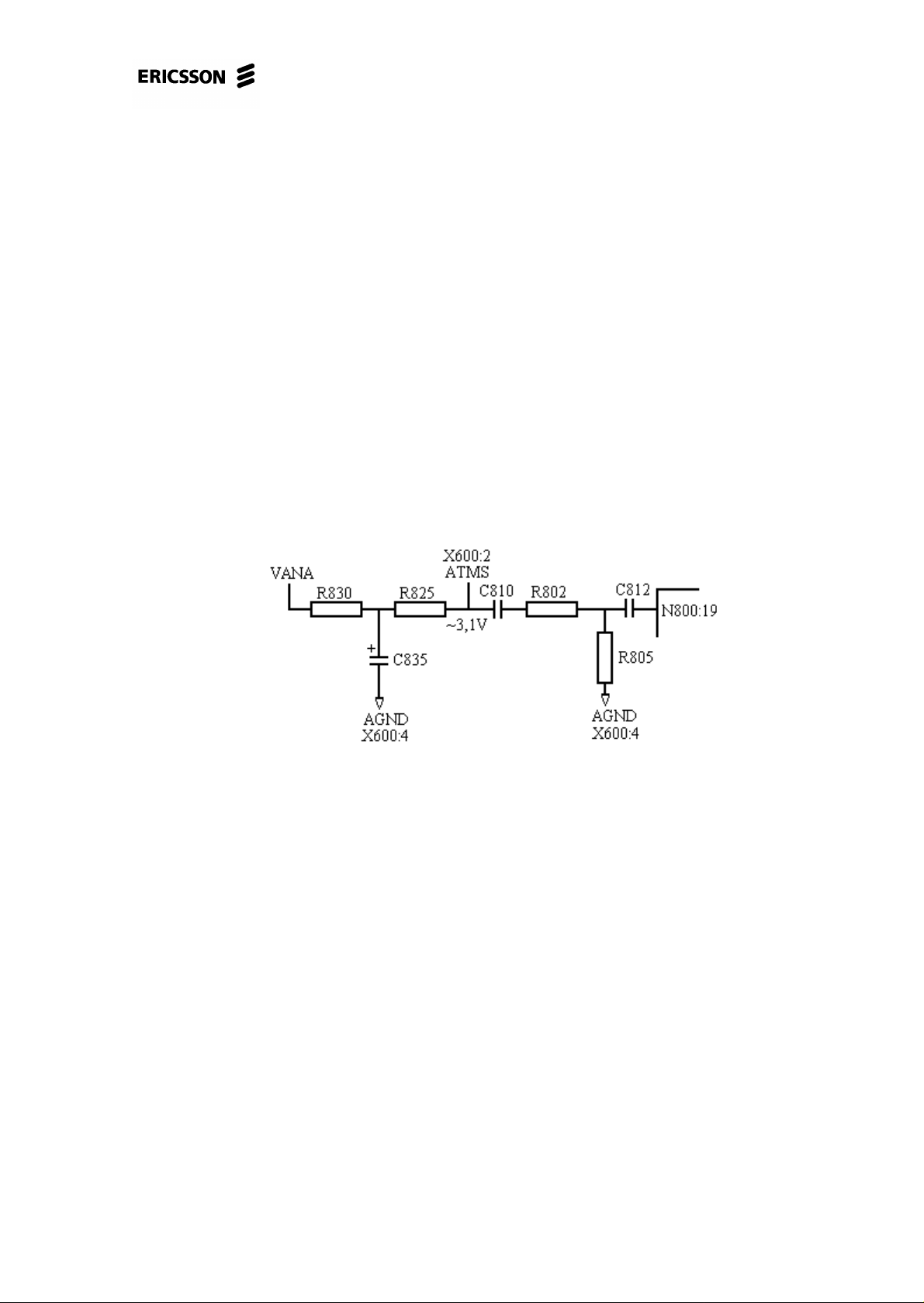

The fault is caused by an interruption somewhere in the audio path from the handsfree microphone (connected at the system connector) to the input at N800. The

audio path is shown in fig. 4.6.

Fig. 4.6

Open the phone and check for liquid damages, especially around the system connector (X602) pads 1, 2 and 4 (fig. 4.5).

Measure the resistances of C850 (>100 kohms) and C851 (>1 kohms, both in fig.

4.3).

Make sure all the components shown in fig. 4.6 (R830, R825, R802, R805, C835,

C810 and C812) are mounted at the circuit board (fig. 4.3).

Check the solderings of N800.

Give the board power and start it up by pressing the On/Off key without the system

cable connected.

Measure the voltage at the marked side of R825 (~3.1V, fig. 4.3).

• If the voltage isn’t there or if it is incorrect, check the VANA voltage at the

marked side of R830.

4/00021-2/FEA 209 544/1.G 27 (112)

GH688,GA628, Standard Electrical Repairs

* If the VANA voltage isn’t correct, proceed to chapter 3 (“Doesn´t start”fault).

* If VANA is correct, check the resistances of R830 (470 ohms), R825 (3.3

kohms) and C835 (>1 kohms, all of class A and in fig. 4.3).

• If the voltage at R825 is correct, check the resistances of C810 (>10 kohms),

C812 (>100 kohms), R802 (~3.9 kohms) and R805 (~15 kohms, all four of class

A and in fig. 4.3).

If the fault remains, send the phone to the next level.

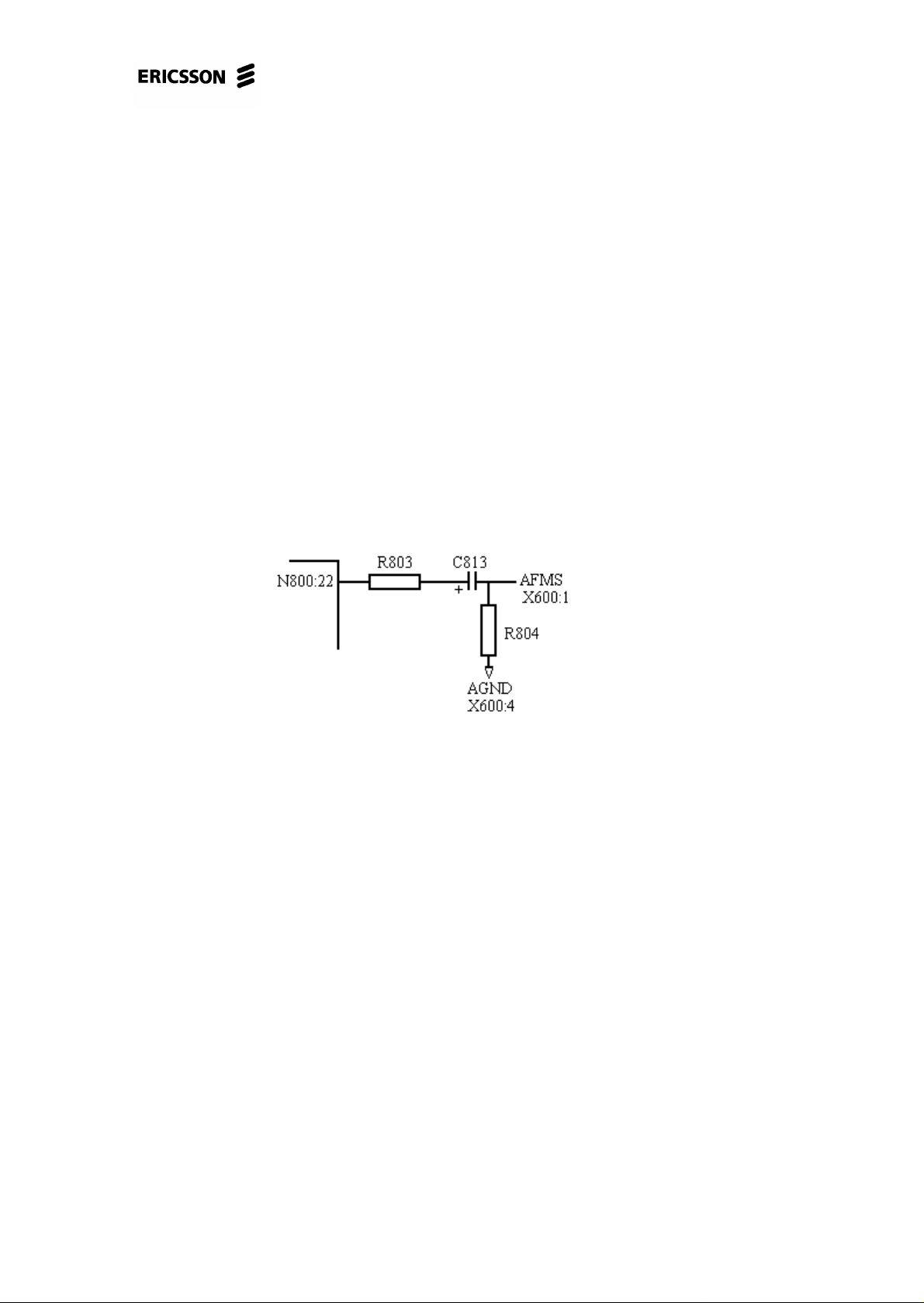

4.6 Handsfree speaker out of order.

The fault is caused by an interruption somewhere in the audio path from the output

of N800 to the handsfree speaker (connected at the system connector). The audio

path is shown in fig. 4.7.

Fig. 4.7

Open the phone and check for liquid damages, especially around the system connector (X602) pads 1, 2 and 4 (fig. 4.5).

Measure the resistances of C850 (>100 kohms) and C851 (>1 kohms, both in fig.

4.3).

Make sure all the components shown in fig. 4.7 (R803, R804 and C813) are

mounted at the circuit board (fig. 4.3).

Check the solderings of N800 (fig. 4.3).

Measure the resistances of R803 (~100 ohms), R804 (~100 kohms) and C813 (>100

kohms, all of class A and in fig. 4.3).

Measure the resistance from the marked side of C813 to system connector (X602)

pad 1 (~0 ohms, fig. 4.5)

• If the resistance is too high there’s a foil damage and the phone is to be dis-

carded.

If the fault remains, use the schematics.

4/00021-2/FEA 209 544/1.G 28 (112)

GH688,GA628, Standard Electrical Repairs

4.7 Both the microphone and the speaker of

the handsfree out of order but the earphone and the microphone of the phone is

working.

Open the phone and check for liquid damages, especially within the marked area

above the system connector pads in fig. 4.5.

Clean the marked area using alcohol and a brush.

Measure the resistance from X602 pad 3 to the unmarked side of R635 (~0 ohms,

fig. 4.4 and 4.5).

Measure the resistance from X602 pad 5 to the unmarked side of R636 (~0 ohms,

fig. 4.4 and 4.5).

• If any of the resistances are too high there’s a foil damage and the phone is to be

discarded.

Measure the resistances of R601 and R605 (both are 1 kohms, of class A and in fig.

4.4).

If all the resistances are correct, check the solderings of N800 and D600 (fig. 4.3

and 4.2).

If the fault remains, send the phone to the next level.

4/00021-2/FEA 209 544/1.G 29 (112)

GH688,GA628, Standard Electrical Repairs

5 Display.

5.1 Kind of fault.

Insert a fully charged battery and start it up using the On/Off-key.

• If it doesn’t start, proceed to chapter 3 (“Doesn´t start”-fault).

• If the display is missing one or more segments, proceed to section 7.2.

• If the display is totally empty, proceed to section 7.3.1.

• If the contrast is low, proceed to section 7.3.2.

• If the all the segments in the display are “lit” proceed to section 7.4.

5.2 Segments are missing.

Open the phone and check for liquid damage. Replace the display. Observe that

there are two kinds of display for GH 688.

5.3 The display is totally empty or the contrast

is low.

5.3.1 The display is totally empty.

Start the phone using a dummy battery. Check the current consumption.

• If the phone consumes more than 200mA, check the display and see if it is dam-

aged.

* If it isn’t, replace the elastomer and try again.

* If it doesn’t help, replace the display and try again. If the current consumption still is high, proceed to chapter 3 (“Doesn´t start”-fault).

• If the phone consumes less than 200mA, open the phone and check for liquid

damages.

4/00021-2/FEA 209 544/1.G 30 (112)

Loading...

Loading...