Errebi COMPACT KS10 Use And Maintenance Manual

KNIVES AND SCISSORS SHARPENING MACHINE

(by Fazzini Technology)

USE AND MAINTENANCE

MANUAL

MODEL

COMPACT KS10

SERIAL NUMBER

ERREBI S.p.A.

Via Pianezze, 42-49

32040 CIBIANA DI CADORE - ITALY

Tel. 0435-542500 Fax 0435-542522

info@errebispa.com

www.errebispa.com

PRELIMINARY INSTRUCTIONS

We thank you for your purchase of the COMPACT KS10 knives and scissors sharpener .

This manual contains general data and information about the machine use and maintenance. The

manual must be always available for the operators . Before operating the unit please read this manual

and mantain it for future referral .

For any communication concerning the machine, please always indicate the serial number contained

in this manual and on the label applied on the machine side.

All machines are factory tested before shipment.

A different use of the machine as that foreseen in this manual is forbidden. The company Errebi Spa

disclaims all responsibility for the improper use of the machine.

INDEX

1. Machine description and installation 3

1.1 Machine description

1.2 Technical data

1.3 Installation and starting

2. Instructions 9

2.1 General instructions

2.2 User obligations

2.3 Maintenance instructions

2.4 Personnel – training

3. Use instructions 11

3.1 Operations and controls - use instructions

3.1.1 First starting of the machine

3.1.2 Starting of the machine

3.1.3 Start and stop the safety device

3.1.4 Sharpening instructions

4. Maintenance 19

4.1 Routine maintenance

4.2 Special maintenance

4.3 Operations and personnel in charge

5. Declaration of conformity 23

6. Electrical diagram 24

7. Symbols 24

6. Warranty 25

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

2

1. MACHINE DESCRIPTION AND INSTALLATION

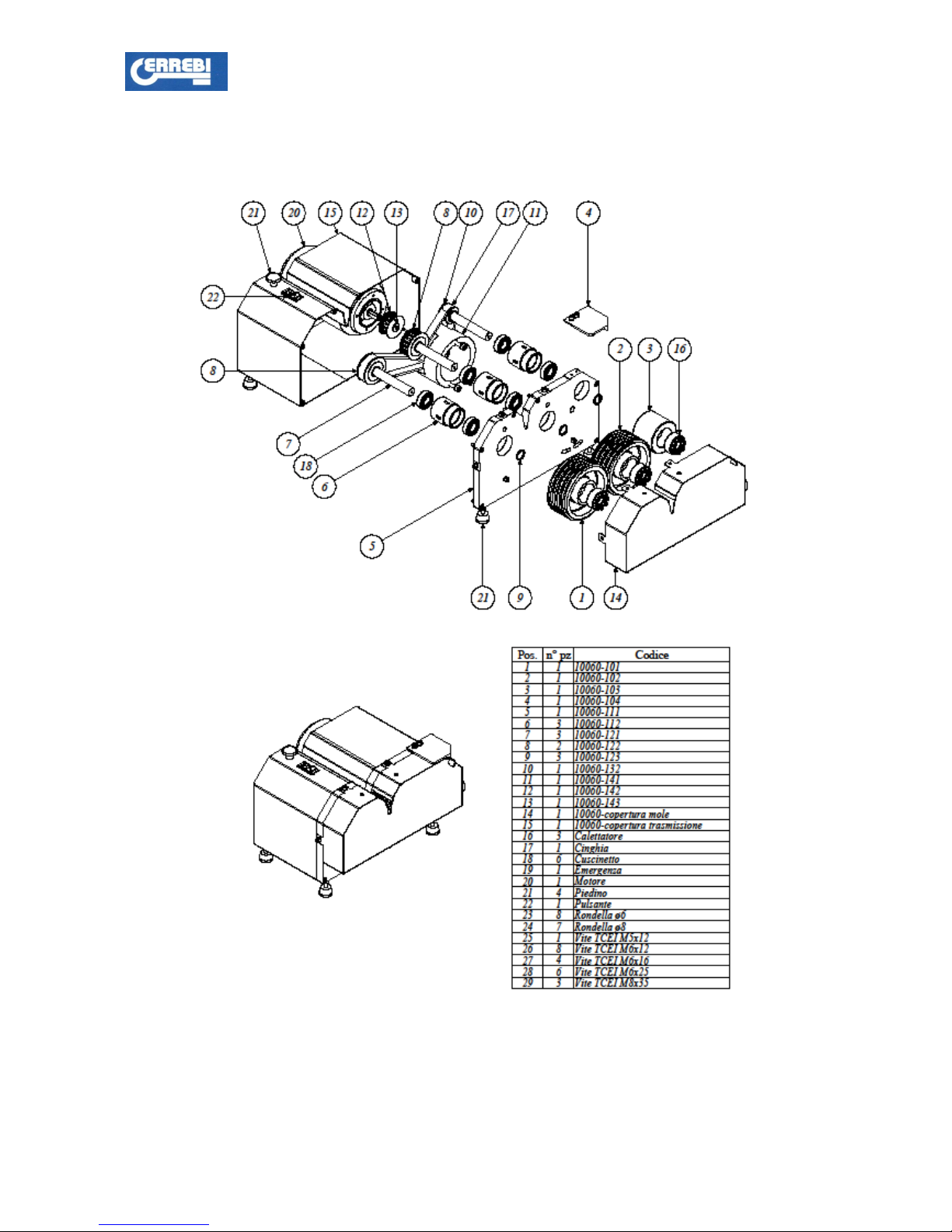

1.1 Machine description ( FIG. 1.1 – FIG. 1.2 – FIG. 1.3- FIG. 1.4 – FIG. 1.5 )

This sharpener has been designed to simply and effectively solve the problem of sharpening knives and

scissors .

It consists of a aluminium structure (5) , a painted steel basement (15) containing the electric system and a

front paitend steel structure (14) containing the wheels (1-2-3 ) . The control button and the emergency stop (

22-21 ) are placed on the basement (15) on the left side (FIG. 1.3) . On the back of the basement (15) there

is a cable with a socket for the power supply .

The structure (5) supports 3 C40 steel shafts (7) placed horizontally and supported by 6 bearings (18). Two

helicoidal C.B.N.-coated wheels are placed on the 2 central shafts in order to sharpen knives ( 1-2 ). A

cylindrical C.B.N.-coated wheel is mounted on the right shaft to sharpen scissors (3) .The wheel-holding

shafts are moved by a system consisting of 4 toothed pulleys ( 8-10-12 ) and a double toothing belt ( 17 ) ,

placed in the basement (15).

The knives sharpening wheels (1-2) are penetrating and form a constant angle. The knives sharpening

wheels turn upwards opposing each other so that they are opposed to the edge of the blade to be

sharpened .The scissors sharpening wheel (3) turns anticlokwise. On the structure is mounted a reference

inclined surface for scissors sharpening ( 4 ) ( FIG. 1.2 ).

A connection to insert the vacuum cleaner tube is mounted on the right side of the front structure (14).

The machine can be provided by a system ( Optional ) that allows to keep the blade of the knife in the right

position during the sharpening operation ( Right Position System ) ( FIG. 1.5 ) .

The machine was designed and constructed to sharpen only metal knives ans scissors . The

sharpening of any other cutting and/or working tool is forbidden.

The following blades can be sharpened: knives : flat blades with straight or convex edge ;

scissors : flat blades and straight edge .

The following blades cannot be sharpened: deformed or non-flat blades, broken or splintered blades,

blades with concave edge, hook-shaped blades, too long and thick blades (max. thickness 4 mm,

max. length 400 mm) , serrated blades , blades with hardness < 50 Hrc , cleavers , heavy butcher

knives , half heavy butcher knives .

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

3

FIG. 1.1

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

4

FIG. 1.2

FIG. 1.3

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

5

1.2 TECHNICAL DATA

PERFORMANCES :

Sharpening : knives and scissors

Wheels tip speed : 8,21 m/sec

MOTOR :

Power : 0,37 kw

Revolutions : 1400 rev/min

ELECTRICAL VOLTAGE / FREQUENCY :

Voltage : 230 Volt

Frequency : 50 Hz

HELICOIDAL WHEELS FOR KNIVES :

Diameter : 140 mm

C.B.N.grit : B107

Angle of the edge : 27°

CYLINDRICAL WHEEL FOR SCISSORS :

Diameter : 80 mm

C.B.N.grit : B107

Angle of the edge : 80°

DIMENSIONS AND WEIGHT :

Wight : 410 mm

Leght : 390 mm

Height : 270 mm *

Weght : 32 Kg **

* with R.P.S. : 410 mm 500 mm

** with R.P.S. : 32,400 Kg

SOUND EMISSION :

Leq dBA machine on : 80,5 dB

Leq dBA sharpening : 81,8 dB

Data taken at 10 cm from the ear of the operator . Height of the operator 173 cm .

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

6

1.3 Installation and starting ( Fig. 1.4 – 1.5 )

WARNING : Carefully read this manual before installing and using the machine and carrying

out maintenance operations. Respecting the instructions indicated in this manual it is possible to

obtain better performances and to guarantee the personnel safety.

WARNING : Do always handle and store the machine in a careful manner paying attention to

the fingers .

Unpack the machine and check that it was not damaged during transport.

Place the machine at approx. 90 cm on a stable working surface checking that it lays on the four lower

supports .

WARNING : Failure to properly ground this power tool can cause serious electrical shock. It

is absolutely necessary that the machine is connected to a power grid equipped with suitable

earthing. The power supply should be equipped with protection fuses ( 6 Amp. ).

Check that the line voltage and frequency correspond to the connection voltage and frequency of the

machine motor.

Dust control ( Fig. 1.4 )

WARNING : Grinding generates dust. Most of the dusts generated when grinding are from

the material being ground. Excessive dust inhalation may affect the breathing function. To avoid

breathing impairment always employ dust controls . Contact the department responsible personnel

concerning the safety regulations in force and the accident preventing devices .

The vacuum cleaner must be :

- in conformity with safety regulations ;

- with a power minimum of 1000 watts .

Connect the vacuum cleaner tube to the connection and verify that the line voltage and frequency

correspond to the voltage and frequency connection .

Connect the outlet to the power supply socket.

Right Position System ( R.P.S. ) ( Fig. 1.5 )

If the machine it is provided by the R.P.S. , it is necessary assemble it on the front structure . Place it in the

perfect centre and before to start the machine verify manually that the R.P.S. do not touch the wheels .

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

7

FIG. 1.4

FIG. 1.5

ERREBI S.p.A.

Sharpener model COMPACT KS10

Use and maintenance manual Version 01-2013

8

Loading...

Loading...