Page 1

Variable Speed PTZ Receiver

R131VX

Installation

Manual

2852-00001

SYS E

M

Page 2

SYS

EM

2852-00001

Page 3

Introduction

The R131VX is a LONWORKS® telemetry receiver designed for driving a 24 VDC variable

speed pan & tilt head, a motorised zoom lens and six auxiliary functions operated via the

potential free relay contacts.

A 12 VDC power supply output for driving e.g. a camera is available as well as possible

fitting of an optional video transmission module; for twisted pair or optical fiber.

The R131VX features 128 pre-positions, four fully programmable pre-set tours, four privacy

zones, Auto-pan, Home-function, soft-limits, programmable lens drive voltage, tamper alarm

and selection of pan & tilt head brand and type.

All settings are selected remotely using the S111SX Node Manager - no on-board settings

are required or even possible.

Daily operation is carried out using the keyboards Series K111DX.

Validity

This manual cover the R131VX, serial number R131VX-000100 or higher.

Compatibility

The R131VX is compatible with any SYSTEM X component.

Any motorised lens with two individual wires per function driven by 6-12 VDC can be used,

however, to ease installation and for optimum Privacy Zone performance the use of the

Ernitec motorised zoom lenses Series Q is highly recommended.

The following DC pan & tilt heads are compatible:

v Ernitec MPT-5P

v Conway C2020

v Molynx Mustang PT12

v Shawley Prince 165

v Videmech 555P

Approvals

The R131VX is -certified and approved in accordance with the EU directives regarding

Electromagnetic Compatibility (EMC) and Low Voltage safety (LVD) with respect to the

EN 50081-1 (EMC, emission), the EN 50130-4 (EMC, immunity) and the EN 60950 (LVD,

safety) standards.

Warning: To fulfil the above regulations make sure to carefully follow the installation

instructions in this manual.

Trademarks

Echelon®, LON® and LONWORKS® are trademarks of Echelon Corporation registered in the

United States of America and other countries.

2852-00001 Page 1

SYS

EM

Page 4

Installation

All connections are shown on Figure 1 at the fold-out page at the back of this manual.

Carefully follow the instructions in order not to cause mal-function, damage to the

equipment or humans. Incorrect installation will void the warranty and repairs will

consequently be invoiced according to current scale charges.

All settings are selected remotely using the S111SX Node Manager - no on-board settings

are required or even possible.

Once all cable connections have been done installation is completed by activating the mains

switch. Prior to activating the mains switch make sure the S111SX Node Manager is running

and connected to the network.

If several R131VX units are present carefully note the exact time of mains switch activation this information is crucial when identification and configuration of each unit later is carried

out using the S111SX Node manager.

Warning: Self-test procedures, including moving the pan & tilt head to end-stops, are

initiated when the calibrate function is activated from the S111SX Node Manager. Make sure

all connections and adjustments, including setting the pan & tilt end-stops and/or limit

switches are made prior to activating the calibrate function.

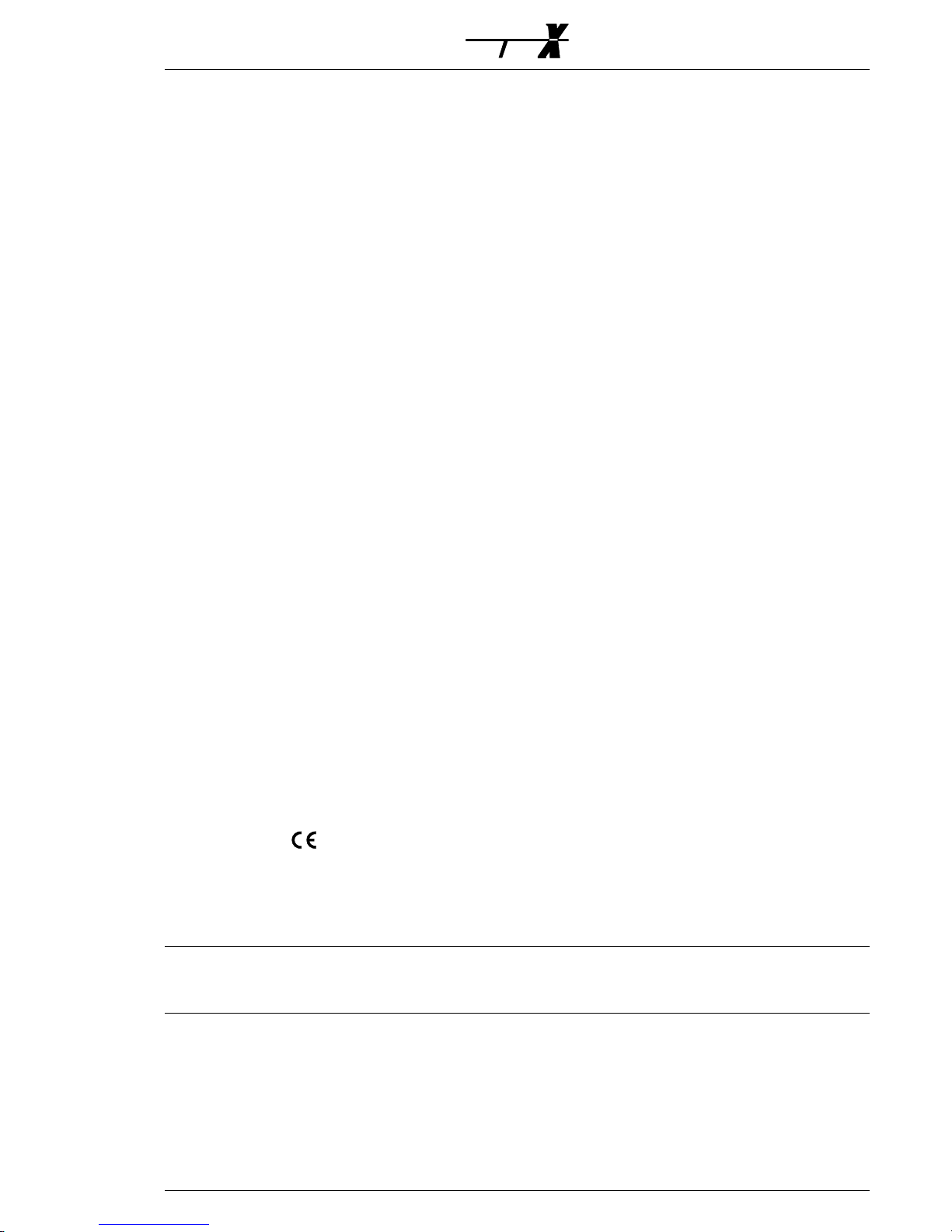

Unpacking the unit

Check that the carton box contains the following items:

v R131VX unit

v Connector kit

v Box mounting kit

v Installation Manual (this manual)

Carefully check for any sign of damage. Any such damage or parts missing should be

reported to your supplier prior to installation.

Box installation

The box must be mounted on a plane surface to prevent the box from being twisted and

thereby become leaky. The box should be oriented with the cable glands pointing

downwards.

Fit the plastic mounting ears on the box. The mounting ears and screws are enclosed in the

box mounting kit.

Drilling pattern: 203 mm (width) x 329 mm (height). For further details refer to Figure 2 at

the back of the fold-out page.

Cable glands

All cables are fed through the cable glands. For each cable choose an appropriate sized

gland according to the table below close to the connector inside. Make sure to tighten the

glands properly. For further details refer to Figure 2 at the back of the fold-out page.

Cable diameter ø6-12 mmCable gland, Type 2

Cable diameter ø5-9 mmCable gland, Type 1

SYS

EM

Page 2 2852-00001

Page 5

Mains connection

Mains connection is located on the relay board, terminal J1.

The R131VX must be used with a 3-wire mains connection (2W+PE @ min. 0,75 mm2,

PE=yellow/green, neutral=blue).

Note: Terminals marked with hazardous live symbol requires installation by an

instructed person.

The wires must be secured to the Cable Anchoring Fingers on the board using a cable tie.

Each wire must be connected exactly as shown on the fold-out page drawing.

The unit is designed for continous operation.

Warning: Make sure correct mains voltage 230/115 VAC is selected with the voltage

selector S2 prior to activating the mains switch.

Mains voltage selector and mains fuse

Prior to connecting mains voltage make sure the correct nominal mains voltage 230VAC

(factory default position) or 115 VAC is selected with S2 located on the relay board.

The mains fuse F1 located on the relay board is factory set for 230 VAC operation. A fuse

suitable for 115 VAC operation is included in the connection kit.

Replace with same type and rating only; i.e.:

v 230 VAC: T500mA

v 115 VAC: T1A

LON® Network Installation

All SYSTEM X components (nodes) are connected together in a common LONWORKS

®

communication network.

The network is polarity insensitive and therefore either of the two twisted pair wires can be

connected to either of the LON® connectors on the SYSTEM X components.

Due to the risk of cross-talk/interference, it is recommended not to run LON

®

Network cables

close to high voltage cable, or cables carrying video signals.

In countries where the CE approval is mandatory, LON

®

cables with an overall

screen must be used in order to comply with EMC/EMI standard EN 50130-4.

The cable screen should be connected to the cable clamp next to the LON

®

connector.

2852-00001 Page 3

SYS

EM

Page 6

Selection of network Topology

In a free topology network, there are no demands as to how the cables are routed

between the nodes. It can be point-to-point, bus, star, tree, or a mixture.

Free Topology

Termination

When using free topology, the maximum cable length in one segment is approx. 500 meters,

and is calculated adding together all cables used. The maximum number of nodes in one

segment is 64. If more that 500 meters, or more than 64 nodes, is required, two or more

network segments can be made, using a repeater between each segment.

Bus Topology

In a bus topology network, all nodes are connected on a bus. Cable stubs can be used to

connect the individual nodes to the bus, as long as the length of the stub is maximum 3

meters. The advantage of bus topology, is that the cable length can be longer than when

using free topology. This can be useful e.g. when making network connection to remote PTZ

cameras.

Bus Topology

Termination Termination

The maximum number of nodes on one bus is 64. Maximum length of the network bus

depends on the type of cable used. If more nodes, and/or longer cable length, is required,

two or more network segments can be made, using a repeater between each segment.

Termination

Each network segment require termination for proper data transmission performance. The

type of termination varies depending on whether Free topology or Bus topology is used.

In a free topology network segment, only one termination is required and may be placed

anywhere on the network. The termination resistor should be a 52 Ω, 1/4W type.

In a bus topology network segment, two terminations are required, one at each end of the

bus. The termination resistors should each be a 105 Ω, 1/4W type.

Termination resistors, which are included with the SYSTEM X keyboard, are easily fitted using

the LON® connectors on the SYSTEM X units as shown below.

SYS

EM

Page 4 2852-00001

LON® cable

Termination

resistor

Page 7

Repeater

If the maximum numbers of nodes (max. 64) or total cable distance are exceeded, a repeater

can be added to interconnect two or more network segments.

A repeater can also be used to convert from a free topology network to a bus topology

network. This can be useful when e.g. making network connection to remote PTZ cameras.

Note that only one Repeater should be placed in series between any two nodes in a segment

Bus Topology

Termination Termination

Free Topology

Termination

3-way

Repeater

Free Topology

Termination

LON® Network Cables

The following five cables/cable types have been validated by Echelon

®

, but other cables may

be used provided they have specifications similar to the ones listed below:

Anixter 4QJB2

5)

Coferro J-Y(St)Y

5)

Waschek 240208

5)

Eupen J-Y(St)Y Lg

5)

Yes0,8mm20,4AWGJ-Y(St)Y3) 2x2x0.8

Anixter 9F220154

5)

Available0,65mm22AWGLevel IV2) cable

-No1,3mm16AWGBelden 85102 (Tefzel jacket) or equivalent

-No1,3mm16AWGBelden 8471 (PVC jacket) or equivalent

Belden 1624

5)

Belden 1633A

5)

Belden 1668A

5)

Available0,5mm24AWGTIA/EIA 568A1) Category 5 cable

ExamplesShield

4)

DiameterAWGValidated Cables and Cable Types

1)

Any cable that meets the TIA/EIA 568A standard, is suitable for LON® Networks.

2)

Standard originally specified by the National Electrical Manufacturers Association (NEMA).

3)

The J-Y(St)Y cable is normally only available in Europe.

4)

In order to comply with EMC/EMI standard EN 50130-4, shielded cable must be used.

5)

With shield.

A list of cable suppliers can be found in e.g. the K111DX Keyboard X manual

.

2852-00001 Page 5

SYS

EM

Page 8

LON® Network Cable Lengths

900 meters320/500 metersJ-Y(St)Y 2x2x0,8

1400 meters400/500 metersLevel IV

2700 meters500/500 metersBelden 85102

2700 meters400/500 metersBelden 8471

900 meters250/450 metersTIA/EIA 568A Category 5

Bus Topology

Max. Total Length

Free Topology

Max. Node-to-Node/Total Length

Cable type

Junction Boxes

When splicing/terminating cables in the LON® Network installation, the following methods are

normally used:

A Pass-Thru Junction Box is used to splice two cables. No SYSTEM X nodes or connectors

are provided at a pass-thru junction box.

Pass-Thru Junction Box

LON Network

LON Network

A Stub Junction Box is used to splice two cables and provide a stub for servicing a local

SYSTEM X node.

Stub Junction Box

LON Network

LON Network

To local node

A local Loop Junction Box is used to terminate two cables, and provide a wiring loop for

servicing one, or more, local SYSTEM X nodes.

Loop Junction Box

LON Network

LON Network

Local loop

SYS

EM

Page 6 2852-00001

Page 9

Pan & tilt head connection

Connections are shown on the fold-out drawing.

Do not use other heads than specified in the Compatibility section. The actual pan & tilt

head type is set using the S111SX Node Manager.

Cables should be kept as short as possible and should not exceed 5 meters. When installed

in areas where interference may be present, such as close to high-voltage cables,

transformers, heavy duty motors, electrical trains, radar or radio transmitters, including GSM,

GPRS, cell phone, DECT or similar digital mobile phone base antennas, shielded cable should

be used. Cable shield should be connected to the X5-5 terminal.

In general it is recommended to run the feed-back potentiometer wires, i.e. the wires

connected to X5 in a separate shielded cable, for optimum preset performance.

Motorised lens connection

Connections are shown on the fold-out drawing.

Any motorised lens with two individual wires per function driven by 6 to12 VDC can be

used, however, to ease installation and for optimum Privacy Zone performance the use of the

Ernitec motorised zoom lenses Series Q is highly recommended. Lens drive voltage is set

using the S111SX Node Manager.

Cables should be kept as short as possible and should not exceed 5 meters.

When installed in areas where interference may be present, such as close to high-voltage

cables, transformers, heavy duty motors, electrical trains, radar or radio transmitters, including

GSM, GPRS, cell phone, DECT or similar digital mobile phone base antennas, shielded cable

should be used. Cable shield should be connected to the X3-5 terminal.

AUX-connection

Six auxiliary functions can by operated via the AUX1 to AUX6 relays located on relay board.

The relay contacts are potential free and may be loaded with maximum 230 V, 5 A.

Note, that the relay contacts are un-fused. High voltage wires must be secured with cable

ties to the Cable Anchoring Fingers located on the edge of the board. Cable ties are not

included.

Camera power supply

A fully regulated 12 VDC output with a maximum load of 800 mA for driving e.g. a camera

is available. Connections are shown on the fold-out drawing. The output is over-load

protected.

Other connections

An optional video transmission module for twisted pair or fiber optical cable may be fitted in

the R131VX. Refer to the manual supplied with the module for installation instructions.

Connections X6-1 & 2 and connector J2 are reserved for internal use within Ernitec only.

All jumpers/pin-headers are factory set and should not be altered.

Warning: Do not make any connections to X6-1 or X6-2 and J2. All jumpers/pin-headers

are factory set and must not be altered.

2852-00001 Page 7

SYS

EM

Page 10

Mains switch activation

Once all cable connections have been done installation is completed by activating the mains

switch. This will identify the unit on the network. Prior to activating the mains switch make

sure the S111SX Node Manager is running and on-line to the network.

Warning: Make sure correct mains voltage 230/115 VAC is selected prior to activating the

mains switch.

Note: If several R131VX units are present carefully note the exact time of activation of the

mains switch - this information is crucial when identification and configuration of each unit

later is carried out using the S111SX Node manager.

Push-buttons

Pressing S1

LONW

ORKS® Service Pin will identify the unit on the network, just as when the

mains switch is activated. Prior to pressing the Service Pin S1 make sure the S111SX Node

Manager is running and on-line to the network.

The S2 Start/Stop and S3 Choose push-buttons are reserved for future applications and

should not be activated.

SYS

EM

Page 8 2852-00001

Page 11

Fault finding guide

If the quide below suggests new configuation use the S111SX Node Manager to configure

the unit.

No operation possible

v If green “RUN CPU” LED H2 is off check mains fuse F1 located on

the relay board. The unit is also equipped with resettable overload

components - disconnect from mains supply and allow the unit to

cool down for a few seconds.

v If yellow “LON” LED H1 is on or blinking the unit is unconfigured.

v Check the network cable connections and network termination.

No or intermediate Pan- and/or Tilt operation

v Check that the unit is configured for the actual pan & tilt head.

v Check the wiring for short-circuits or broken wires.

v If one function only is failing try to swap the pan and tilt wiring to

determine the fault location. If e.g. the tilt initially was faulty

connect the tilt wires to the pan output and try to operate the tilt

by activating the pan function. If inoperative still the pan & tilt

head is faulty - if operative now the output is overheatet or

defective.

v The outputs are overload protected - disconnect from the mains

supply and allow the unit to cool down for a few seconds.

No or slow Zoom- and/or Focus operation

v Check the wiring for short-circuits or broken wires.

v If one function only is failing try to swap the zoom and focus

wiring to determine the fault location. If e.g. the zoom initially

was faulty connect the zoom wires to the focus output and try to

operate the zoom by activating the focus function. If inoperative

still the lens is faulty - if operative now the output is overheatet or

defective.

v If running too slow or fast reconfigure the lens setup.

Pre-positions cannot be found, are in-accurate or drifting

v Check the wiring for short-circuits or broken wires. Check

feed-back potentiometers fitted in the pan & tilt head and lens

electrically and mechanically. Note, that most potentiometers

wear out in 4-18 months if used on a 24-hour tour basis.

v Cables are too long or exposed to excessive noise. Refer to the

Pan & Tilt head connection section for possible solutions.

2852-00001 Page 9

SYS

EM

Page 12

Technical specifications

TP/FT Free- or Bus-topology

LONW

ORKS® Communication interface

278 x 318* x 267 mm / 5,2 kgDimensions (X x Y*x Z ) / Weight (*excl. glands)

EN 50081-1 , EN 50130-4 / EN 60950CE-approvals (EMC / LVD)

12 VDC, 800 mAPower supply output (fully regulated)

230 V, 5 AAUX-relays, max. load (unfused)

<1°Pre-position accuracy with Ernitec MPT-5P pan & tilt head

-15° to +55° CelciusTemperature range

IP65 / UL 94-5VEnclosure (protection / fire), glass-fiber reinforced polyester

155 mA @ 230 VAC, 310 mA @ 115 VACCurrent consumption

115/230 VAC, ± 10%, 45-60 HzMains voltage, selectable

SYS

EM

Page 10 2852-00001

HEAD OFFICE: ERNITEC A/S, HØRKÆR 24, P.O. BOX 720, DK-2730 HERLEV, DENMARK

TELEPHONE: +45 44 50 33 00, TELEFAX: +45 44 50 33 33

HOMEPAGE: http://www.ernitec.dk, E-MAIL: ernitec@ernitec.dk

UK OFFICE: ERNITEC UK, GERRARD HOUSE, WORTHING ROAD, EAST PRESTON, WEST SUSSEX BN16 1AW, ENGLAND

TELEPHONE: 01903 77 27 27, TELEFAX: 01903 77 27 07

E-MAIL: sally@ernitec-uk.co.uk

GERMAN OFFICE: ERNITEC GmbH., STORMARNRING 28, 22145 STAPELFELD, GERMANY

TELEPHONE: (040) 6756 25 0, TELEFAX: (040) 67 56 25 25

E-MAIL: ernitec@aol.com

FRENCH OFFICE: ERNITEC FRANCE,

N° 29

PARC CLUB DU MILLENAIRE, 1025 RUE HENRI BECQUEREL, 34036 MONTPELLIER CEDEX 1, FRANCE

TELEPHONE: (4) 67 15 10 15, TELEFAX: (4) 67 64 01 81

E-MAIL: ernitec@ernitec.fr

MIDDLE EAST OFFICE: ERNITEC ME, HAMRA-MAKDESI STR., YOUNIS CENTER-5th FLOOR, OFFICE NO. 503

P.O. BOX 113/5721, BEIRUT, LEBANON TELEPHONE: +961 1 751 796, TELEFAX: +961 1 751 795

HOMEPAGE: http://www.ernitecme.com, E-MAIL: malek_kabrit@ernitecme.com

Loading...

Loading...