L-PRO 4000

Transmission Line Protection Relay

User Manual

Version 2.3 Rev 0

Preface

Information in this document is subject to change without notice.

© 2013 ERLPhase Power Technologies Ltd. All rights reserved.

Reproduction in any manner whatsoever without the written permission of

ERLPhase Power Technologies Ltd. is strictly forbidden.

This manual is part of a complete set of product documentation that includes

detailed drawings and operation. Users should evaluate the information in the

context of the complete set of product documentation and their particular

applications. ERLPhase assumes no liability for any incidental, indirect or

consequential damages arising from the use of this documentation.

While all information presented is believed to be reliable and in accordance

with accepted engineering practices, ERLPhase makes no warranties as to the

completeness of the information.

All trademarks used in association with B-PRO, F-PRO, L-PRO, ProLogic,

T-PRO, TESLA, TESLA Control Panel, Relay Control Panel, RecordGraph

and RecordBase are trademarks of ERLPhase Power Technologies Ltd.

Windows

Procomm

HyperTerminal

Modbus

®

is a registered trademark of the Microsoft Corporation.

®

is a registered trademark of Symantec.

®

is a registered trademark of Hilgraeve.

®

is a registered trademark of Modicon.

Contact Information

ERLPhase Power Technologies Ltd.

Website: www.erlphase.com

Email: info@erlphase.com

Technical Support

Email: support@erlphase.com

Tel: 1-204-477-0591

D02706R02.20 L-PRO 4000 User Manual i

Table of Contents

Preface ......................................................................................i

Contact Information ...................................................................i

Table of Contents ....................................................................iii

Using This Guide .................................................................... vii

Acronyms.................................................................................ix

Version Compatibility ...............................................................xi

PC System Requirements and Software Installation ............. xiii

1 Overview ................................................................. 1-1

Introduction ...................................................................... 1-1

Front View........................................................................ 1-3

Rear View ........................................................................ 1-4

Model Options/Ordering................................................... 1-6

2 Setup and Communications.................................. 2-1

Introduction ...................................................................... 2-1

Power Supply................................................................... 2-1

IRIG-B Time Input ............................................................ 2-1

Communicating with the Relay Intelligent Electronic

Device (IED)..................................................................... 2-2

USB Link .......................................................................... 2-3

Network Link .................................................................... 2-5

Direct Serial Link.............................................................. 2-6

Modem Link ..................................................................... 2-7

Using HyperTerminal to Access the Relay’s Maintenance

Menu ................................................................................ 2-9

Firmware Update ........................................................... 2-12

Setting the Baud Rate.................................................... 2-13

Accessing the Relay’s SCADA Services........................ 2-14

Communication Port Details .......................................... 2-15

3 Using the IED (Getting Started) ............................ 3-1

Introduction ...................................................................... 3-1

Start-up Sequence ........................................................... 3-1

Interfacing with the Relay................................................. 3-1

Front Panel Display.......................................................... 3-2

Terminal Mode ................................................................. 3-7

Relay Control Panel ......................................................... 3-7

4 Protection Functions and Specifications ............ 4-1

D02706R02.30 L-PRO 4000 User Manual iii

Table of Contents

Protection and Recording Functions................................ 4-2

Communication-Aided Scheme ..................................... 4-47

Recording Functions ...................................................... 4-51

Event Log....................................................................... 4-54

Fault Log ........................................................................ 4-55

5 Data Communications ........................................... 5-1

Introduction ...................................................................... 5-1

SCADA Protocol .............................................................. 5-1

IEC 61850 Communication .............................................. 5-7

6 Offliner Settings Software ..................................... 6-1

Introduction ...................................................................... 6-1

Offliner Features .............................................................. 6-2

Offliner Keyboard Shortcuts............................................. 6-5

Handling Backward Compatibility .................................... 6-6

RecordBase View Software ............................................. 6-8

Main Branches from the Tree View.................................. 6-9

Settings From a Record ................................................. 6-29

7 Acceptance/Protection Function Test Guide ...... 7-1

Introduction ...................................................................... 7-1

Acceptance Testing ......................................................... 7-1

L-PRO Acceptance Test Procedure Outline .................... 7-4

8 Installation .............................................................. 8-1

Introduction ...................................................................... 8-1

Physical Mounting............................................................ 8-1

AC and DC Wiring............................................................ 8-1

Communication Wiring..................................................... 8-1

Appendix A IED Specifications..................................... A-1

Distance Element Operating Time Curves at Nominal

Frequency ........................................................................A-7

Frequency Element Operating Time Curves....................A-9

External Input Pickup Filter ............................................A-11

Appendix B IED Settings and Ranges .........................B-1

Settings and Ranges........................................................B-1

Appendix C Hardware Description ............................... C-1

Appendix D Event Messages ....................................... D-1

Appendix E Modbus RTU Communication Protocol ....E-1

Appendix F DNP3 Device Profile ................................. F-1

Appendix G Mechanical Drawings ...............................G-1

iv L-PRO 4000 User Manual D02706R02.30

Table of Contents

Appendix H Rear Panel Drawings................................H-1

Appendix I AC Schematic Drawings ............................. I-1

Appendix J DC Schematic Drawings ............................J-1

Appendix K Function Logic Diagram............................ K-1

Appendix L L-PRO Setting Example ............................ L-1

Switching Setting Groups................................................. L-2

79 Auto-recloser Examples.............................................. L-9

Appendix M Failure Modes ......................................... M-1

Actions ............................................................................ M-1

Appendix N IEC61850 Implementation ........................ N-1

Protocol Implementation Conformance Statement

(PICS) ..............................................................................N-1

Model Implementation Conformance Statement

(MICS)..............................................................................N-8

Data Mapping Specifications .........................................N-40

Index ......................................................................................... I

D02706R02.30 L-PRO 4000 User Manual v

Using This Guide

This User Manual describes the installation and operation of the L-PRO line

protection relay. It is intended to support the first time user and clarify the details of the equipment.

The manual uses a number of conventions to denote special information:

Example Describes

Start>Settings>Control Panel Choose the Control Panel submenu in the Set-

Right-click Click the right mouse button.

Recordings Menu items and tabs are shown in italics.

Service User input or keystrokes are shown in bold.

Text boxes similar to this one Relate important notes and information.

tings submenu on the Start menu.

.. Indicates more screens.

Indicates further drop-down menu, click to display list.

Indicates a warning.

D02706R02.30 L-PRO 4000 User Manual vii

Acronyms

ASG - Active Setting Group

CCVT - Capacitance Coupled Voltage Transformer

CID - file extension (.CID) for Configured IED Description

CS - Control Switch

CT - Current Transformer

DCB - Directional Comparison Blocking

DCE - Data Communication Equipment

DIB - Digital Input Board

DIGIO - Digital Input/Output Board

DMDA - Dead Main Dead Aux

DMLA - Dead Main Live Aux

DSP - Digital signal processor

DTE - Data Terminal Equipment

GFPCB - Graphics Front Panel Comm Board

GFPDB - Graphics Front Panel Display Board

GPS - Global Positioning System

HMI - Human Machine Interface

ICD - file extension (.ICD) for IED Capability Description

IEC - International Electrotechnical Commission

IED - Intelligent Electronic Device

IP - Internet Protocol (IP) address

IRIG-B - Inter-range instrumentation group time codes

LE- Load Encroachment

LED - Light-emitting Diode

LHS - Left Hand Side

LMDA - Live Main Dead Aux

D02706R02.30 L-PRO 4000 User Manual ix

Acronyms

LOCB - L-PRO Output Contact Board

LOP - Loss of Potential

MPB - Main Processor Board

MPC - Micro Processor

PLC - Programmable Logic Controller

POTT - Permissive Over-reaching Transfer Trip

PUTT - Permissive Under-reaching Transfer Trip

PT - Permissive Trip

RAIB -Relay AC Analog Input Board

RASB -Relay AC Analog Sensor Boards

RHS - Right Hand Side

RPCB - Rear Panel Comm Board

RTOS - Real Time Operating System

RTU - Remote Terminal Unit

SCADA - Supervisory Control And Data Acquisition

SG - Setting Group

SIR ratio - Source Impedance Ratio

SOTF - Switch On To Fault

TT - Transfer Trip

TUI - Terminal User Interface

UI - User Interface

VI - Virtual Input

WI - Weak Infeed

x L-PRO 4000 User Manual D02706R02.30

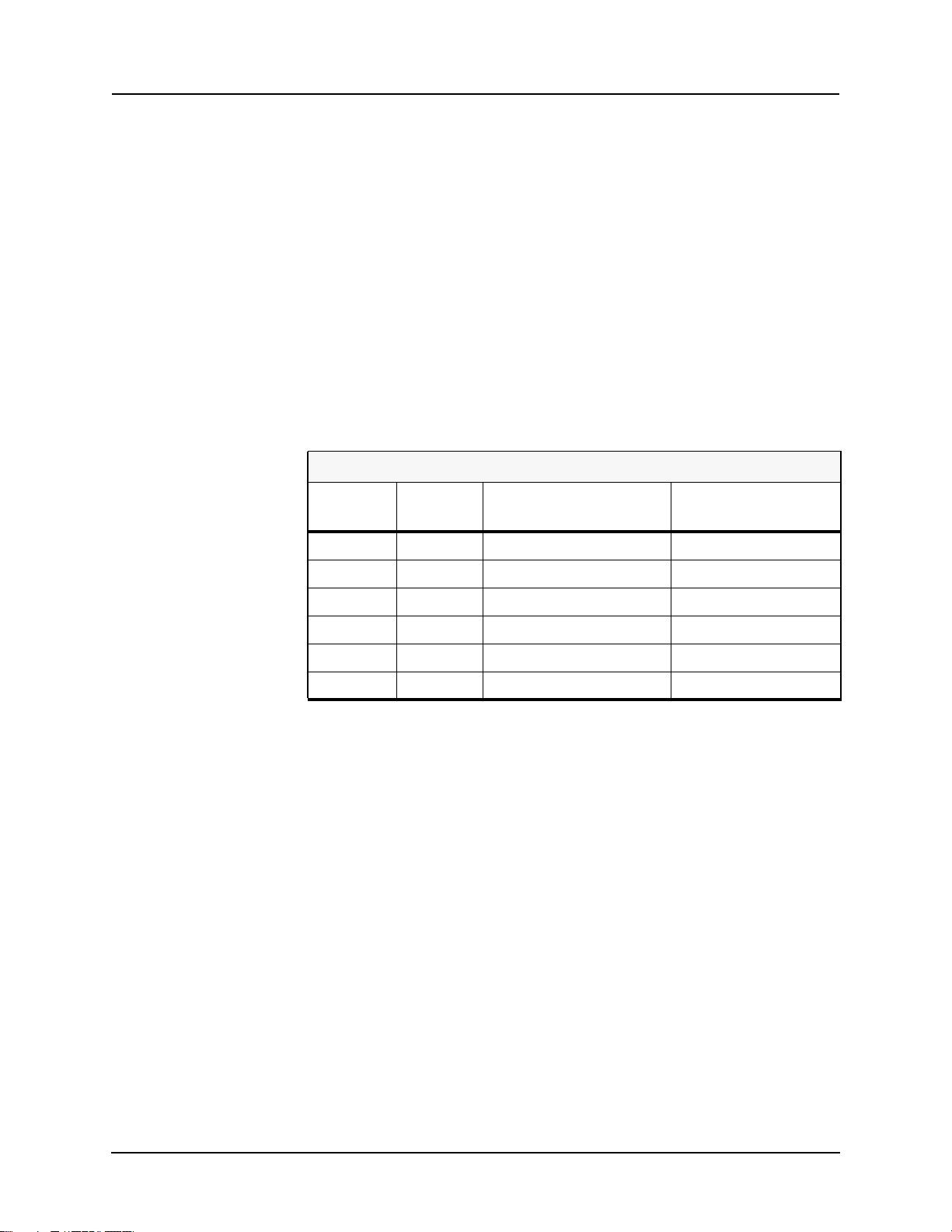

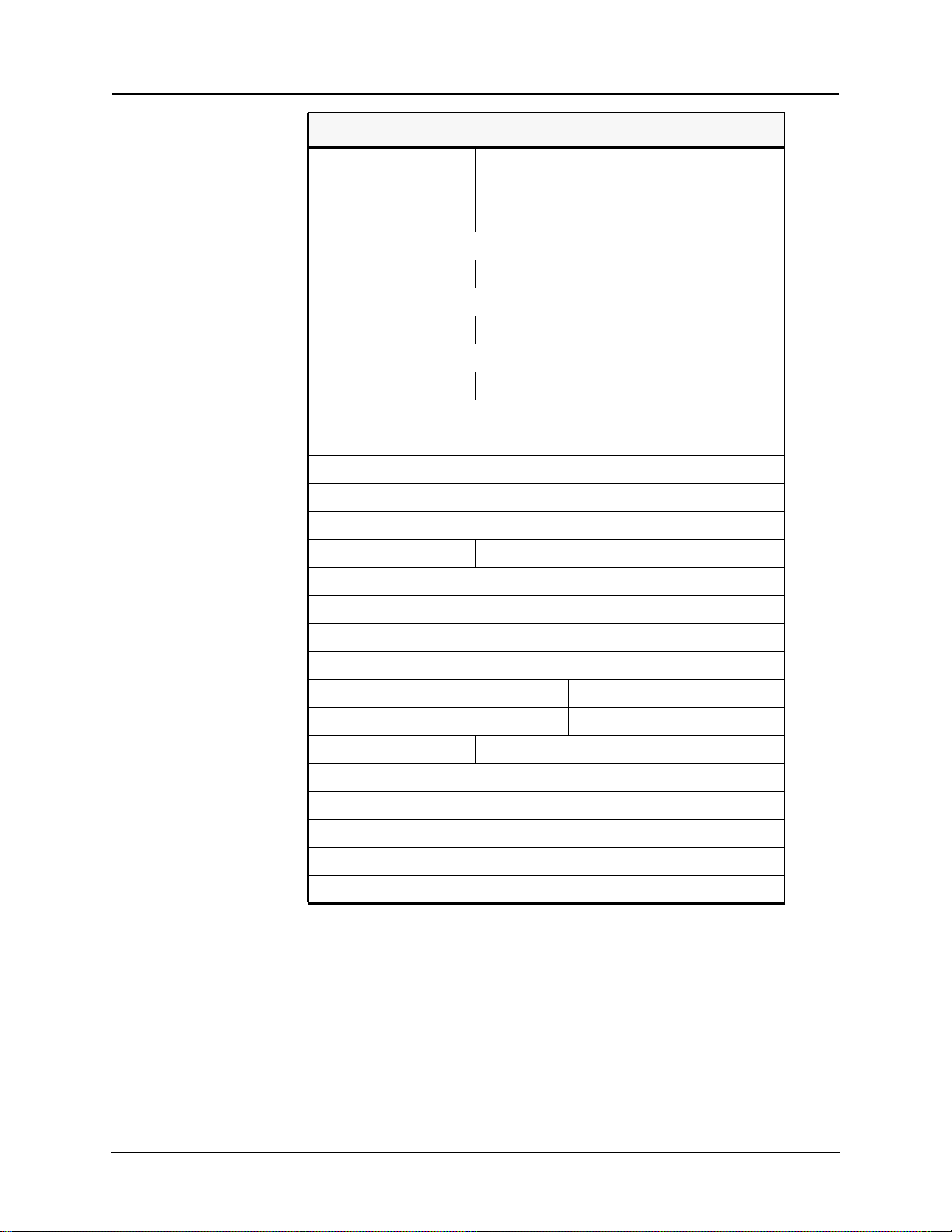

Version Compatibility

This chart indicates the versions of Offliner Settings, RecordBase View and

the User Manual which are compatible with different versions of L-PRO firmware.

RecordBase View and Offliner Settings are backward compatible with all earlier versions of records and setting files. Use RecordBase View to view records

produced by any version of L-PRO firmware and Offliner Settings can create

and edit older setting file versions.

Minor releases (designated with a letter suffix - e.g. v3.1a) maintain the same

compatibility as their base version. For example. L-PRO firmware v3.1c and

Offliner Settings v3.1a are compatible.

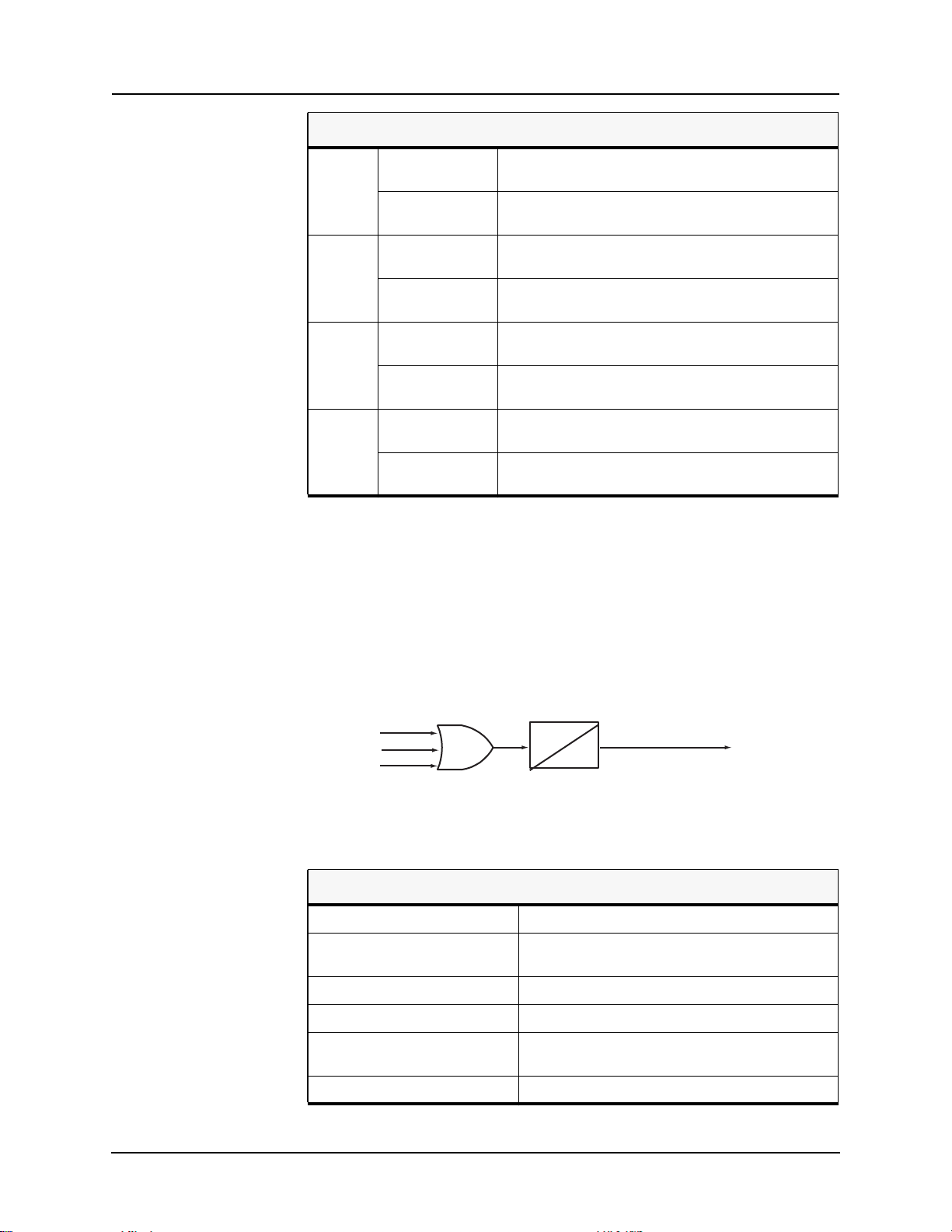

L-PRO 4000 Firmware/Software Compatibility Guide

L-PRO

Firmware

v2.3 404 v2.3 or greater 2.0

v2.2 404 v2.3 or greater 2.0

v2.1a 403 v2.1 or greater 0.0

v2.1 403 v2.1 or greater n/a

v2.0 402 v2.0 or greater n/a

v1.0 401 v1.0 or greater n/a

Setting

Version

Compatible Offliner Settings ICD File Version

Please contact ERLPhase Customer Service for complete Revision History.

D02706R02.30 L-PRO 4000 User Manual xi

PC System Requirements and Software Installation

Hardware

The minimum hardware requirements are:

• 1 GHz processor

• 2 GB RAM

• 20 GB available hard disk space

• USB port

• Serial communication port

Operating System

The following software must be installed and functional prior to installing the

applications:

• Microsoft Windows XP Professional Service Pack 3 or

• Microsoft Windows 7 Professional Service Pack 1 32-bit or 64-bit

Relay Control Panel requires Windows XP SP3 (it will not work on earlier versions of Windows).

Software Installation

The CD-ROM contains software and the User Manual for the L-PRO Transmission Line Protection Relay.

Software is installed directly from the CD-ROM to a Windows PC. Alternatively, create installation diskettes to install software on computers without a

CD-ROM drive.

The CD-ROM contains the following:

• L-PRO Offliner Settings: Offliner settings program for the relay

• L-PRO Firmware: Firmware and installation instructions

• L-PRO User Manual: L-PRO manual in PDF format

• L-PRO Function Logic Diagram: diagram in PDF format

• Relay Control Panel: software

• Relay Control Panel User Manual: manual in PDF format

• USB Driver

To Install Software on the Computer

Insert the CD-ROM in the drive. The CD-ROM should open automatically. If

the CD-ROM does not open automatically, go to Windows Explorer and find

the CD-ROM (usually on D drive). Open the ERLPhase.exe file to launch the

CD-ROM.

D02706R02.30 L-PRO 4000 User Manual xiii

PC System Requirements and Software Installation

To install the software on the computer, click the desired item on the screen.

The installation program launches automatically. Installation may take a few

minutes to start.

To view the L-PRO User Manual the user must have Adobe Acrobat on the

computer. If a copy is needed, download a copy at www.adobe.com.

Anti-virus/Anti-spyware Software

If an anti-virus/anti-spyware software on your local system identifies any of

the ERLPhase applications as a “potential threat”, it will be necessary to configure your anti-virus/anti-software to classify it as “safe” for its proper operation. Please consult the appropriate anti-virus/anti-spyware software

documentation to determine the relevant procedure.

xiv L-PRO 4000 User Manual D02706R02.30

1 Overview

1.1 Introduction

The L-PRO 4000 provides easy-to-use, state-of-the-art comprehensive distance and directional line protection for medium to extra-highvoltage transmission lines using communication-based schemes. It provides control,

automation, metering, monitoring, fault oscillography, dynamic swing recording, event logging with advanced communications in a flexible cost effective

package.

The primary protection is line protection with 5 zones of phase and ground distance functions – user-defined Mho or Quadrilateral shapes and communications based schemes (i.e. teleprotection or pilot schemes).

To provide a complete package of protection and control the relay supplies other functions such as:

• 1.0 to 1.3 cycle operation at 80% reach, ideal for EHV transmission line

• Ring bus capability – breaker failure and individual breaker monitoring

• 4-shot recloser with dead line/dead bus control and sync check

applications

• Single pole and three pole trip and reclose

• 24 statements of ProLogic addresses special protection needs

• Power Swing Blocking / Tripping

• Load Encroachment

• Switch On To Fault function

• VT Supervision function

• CT Supervision function

• Over / Under Voltage functions

• 8 Setting Groups (SG) with setting group logic

• Back up Directional overcurrent and earth fault protection

• Over / Under / Rate of change of frequency devices

Relay Control Panel (RCP) is the Windows graphical user interface software

tool provided with all 3000, 4000 series and higher (new generation) ERL relays to communicate, retrieve and manage records, event logs, fault logs, manage settings (identification, protection, SCADA etc.,), display real time

metering values, view, analyze, and export records in COMTRADE format.

In addition to the protection functions the relay provides fault recording (96

samples/cycle) to analyze faults and to review the operation of the overall protection scheme. The relay also has low speed swing recording which can be

used to analyze system stability. The triggers for fault recording are established

D02706R02.30 L-PRO 4000 User Manual 1-1

1 Overview

by programming the output matrix and allowing any internal relay function or

any external input or any GOOSE messaging input to initiate recording.

Bus 2

CT

52-1

CT

Line

52-2

50

LS

50

LS

PT

50

BF

50

BF

79-1,3

79-1,3

PL

6 Analog

Current

Inputs

Optional I/O

Rec.

21P 21N 68 50/67 51/67

Σ

Rec.

Rec.

5 Zones 5 Zones

9 External

Inputs

11 External

Inputs

14 Output Contacts

1 Relay Inoperative

Alarm Contact

7 Output Contacts

Figure 1.1: L-PRO Relay Function Line Diagram

50LS: Low set overcurrent

PL: ProLogic

WI: Weak infeed

Bus 1

50N/6751N/

27 59 60 WI Rec.

59N

CTS

Swing Recording

Positive Sequence Voltage

Positive Sequence Current

System Frequency

Real Power

Reactive Power

46/50

46/51

/67

67

60

81

/67

5050N

/67

Dead

Line

Pickup

25/27

Rec.

/59

Fault Recording

6 Voltages

12 Currents

Protection Elements

External Inputs

Active Setting Group

Output Contacts

Rec.

PT

59 27

1-2 L-PRO 4000 User Manual D02706R02.30

1.2 Front View

RELAY FUNCTIONAL

IRIG-B FUNCTIONAL

SERVICE REQUIRED

TEST MODE

ALARM

100BASE-T

(119) (150)

USB

RELAY FUNCTIONAL

IRIG-B FUNCTIONAL

SERVICE REQUIRED

TEST MODE

ALARM

100BASE-T

(119) (150)

USB

1 Overview

2

L-PRO

1

LINE PROTECTION RELAY

X

1. Front display of time, alarms and relay target

2. LEDs indicating status of relay

3. USB Port 150 for maintenance interface

4

4. Push buttons to manipulate information on settings, display and to clear targets

5. 11 Target Programmable LEDs

6. Ethernet Port 119

Figure 1.2: L-PRO Relay Front View (3U)

1

2

3

5

6

L-PRO

LINE PROTECTION RELAY

X

1. Front display of time, alarms and relay target

4

2. LEDs indicating status of relay

3. USB Port 150 for maintenance interface

4. Push buttons to manipulate information on settings, display and to clear targets

5. 11 Target Programmable LEDs

6. Ethernet Port 119

Figure 1.3: L-PRO Relay Front View (4U)

5 6

3

D02706R02.30 L-PRO 4000 User Manual 1-3

1 Overview

1.3 Rear View

15

91310 11

48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250

7

8

External

Inputs

123456789

100 101 102 103 104 105 106 107 108 109 110

NCNO

Output

Contacts

Input

1A

Main AC Line Currents

I

300 312 324

Made in Canada

NCNO

RELAY

INOPERATIVE

1

200 218201 219202 220203 221204 222205 223206 224207 225208 226209 227210 228

50Hz5A 60Hz

1A

1B

1C

I

I

301 313 325302 314 326303 315 327304 316 328305 317 329306 318 330307 319 331308 320 332309 321 333310 322 334

NO

NCNO

3

2

Aux. AC Line Currents

2A

2B

I

I

NO

4

2C

I

113

111 112

NO

NO

67

5

211 229

212 230213 231214 232215 233216 234217 235

AC Current Inputs (Record Only)

3A

I

I

311 323 335

114

NO NO

3B

V

116

117

115

3C

I

Output

Contacts

8

4A

4B

I

I

119 120

118

100BASE-

Modem

1000BASE-

NO NO NO NO NO NO

9

10

Aux. AC Volts Main AC Volts

VA VAVB VBVC VCNN

4C

I

RXRX TXTX

FXT

FXT

100BASE-

LXTX

LXTX

1000BASE-

12

11

Unused Unused

14

12

121

122 123

IRIG-B SCADA COM

13

14 18

Unused

14

Power Supply

±10%

48 to 250 Vdc

100 to 240 Vac

336

337

16

17

8

7. Ports 100-117: 9 External Programmable Inputs

8. Ports 200-201: Relay inoperative contact

Ports 202-229: 14 programmable output contacts

Ports 230-235: Unused

9. Port 118: Internal modem

10.Port 119-120: 100BASE-T or 100BASE-FX Ethernet Ports

11.Port 121: External clock, IRIG-B modulated or unmodulated

12.Port 122: SCADA

13.Port 123: Direct/Modem RS-232 Port

14.Ports 324-327, 330-333: AC voltage inputs

15.Ports 300-323: AC current inputs

16.Ports 230-235, 328, 329, 334, 335: Unused

17.Ports 336-337: Power supply

18.Port with GND symbol: Chassis Ground

Figure 1.4: L-PRO Relay Rear View (3U)

1-4 L-PRO 4000 User Manual D02706R02.30

1 Overview

13

8129 10

48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250V48 125 250

External

Inputs

7

7

123456789

100 101 102 10 3 104 105 106 107 10 8 109 110

48 V

48 V

125 V

125 V

48 125 250V48 125 250

250 V

External

Inputs

Output

Contacts

Input

1A

Made in Canada

250 V

400 418401 419402 420403 421404 422405 423406 424407 425

RELAY

1

INOPERATIVE

200 218201 219202 220203 221204 222205 223206 224207 225208 226209 227210 228

50Hz5A 60Hz

Main AC Line Currents

I1A I 2A I3A I 4AI1B I 2B I3B I 4BI1C I2C I 3C I4C

301 313 325302 314 326303 315 327304 316 328305 317 329306 318 33030 7 319 331

300 312 324

48

125

V

250

14

408 426409 427

NO NO

NCNONCNONCNO

34

2

Aux. AC Line Currents

308 320 332309 321 333

310 322 334

113

111 112

V

V

48 125 250V48 125 250

V

V

15 16 17 18

410 428

413 431

411 429412 430

NO

NO

67

5

211 229

212 230213 231214 232215 233216 234217 235

AC Current Inputs (Record Only)

311 323 335

V

116

114

117

115

48 V

48 V

125 V

125 V

250 V

250 V

External

Inputs

416 434

414 432

417 435

415 433

NO NO

Output

Contacts

8

119 120

118

100BASE-

Modem

1000BASE-

48 125 250V48 125 250

19 2010 11 12 13

NO NO NO NO NO NO

9

10

Aux. AC Volts Main AC Volts

VA VAVB VBVC VCNN

RXRX TXTX

FXT

FXT

100BASE-

LXTX

LXTX

1000BASE-

V

NONO NO NO NC NO NC NO NC NO NC

1615

12

11

Unused Unused

14 15 16

11

121

122 123

IRIG-B SCADA COM

18 19 20

17

13

Unused

14

Power Supply

±10%

48 to 250 Vdc

100 to 240 Vac

336

1817 2019

Output

Contacts

21

337

7. Ports 100-117, 400-421: 20 External Programmable Inputs

8. Port 118: Internal modem

9. Port 119-120: 100BASE-T or 100BASE-FX Ethernet Ports

10.Port 121: External clock, IRIG-B modulated or unmodulated

11.Port 122: SCADA

12.Port 123: Direct/Modem RS-232 Port

13.Port 200-229, 422-435: 21 programmable output contacts

14.Port 324-327: AC voltage inputs

15.Port 328-329: unused

16.Port 330-333: AC voltage inputs

17.Port 334-335: unused

18.Port 336-337: Power supply

19.Port 300-323: AC current inputs

20.Port with GND symbol: Case ground

Figure 1.5: L-PRO Relay Rear View (4U)

AC Current and Voltage Inputs

The relay is provided with terminal blocks for up to 12 ac currents and 6 phaseto-neutral voltages.

Each of the current input circuits has polarity (•) marks.

A complete schematic of current and voltage circuits is shown, for details see

“AC Schematic Drawings” in Appendix I and “DC Schematic Drawings”

in Appendix J.

External Inputs The relay contains 9 (3U) or 20 (4U) programmable external inputs.

Output Relay

The relay has 14 (3U) or 21 (4U) programmable relay contacts.

Contacts

Relay

Inoperative

If the relay is in self check program or becomes inoperative, then the Relay Inoperative Alarm output contact closes and all tripping functions are blocked.

Alarm Output

D02706R02.30 L-PRO 4000 User Manual 1-5

1 Overview

1.4 Model Options/Ordering

The relay is available as a horizontal mount, for details see “Mechanical Drawings” in Appendix G.

The relay is available with an optional internal modem card.

The two rear Ethernet ports can be ordered as one copper-one optical port or

both optical ports or both copper ports. These ports on the rear panel are available as either 100BASE-T (RJ-45) or 100BASE-FX (optical ST).

The Current Transformer (CT) inputs are 1 A nominal or 5 A nominal.

The external inputs are 48, 110/125 or 220/250 Vdc.

The system base frequency is either 50 Hz or 60 Hz.

The L-PRO 4000 is available in a standard 3U rack model or as 4U model with

an optional I/O board as described above.

All of the above options must be specified at the time of ordering.

1-6 L-PRO 4000 User Manual D02706R02.30

2 Setup and Communications

2.1 Introduction

This chapter discusses setting up and communicating with the relay including

the following:

• Power supply

• Inter-Range Instrumentation Group time codes (IRIG-B) time input

• Communicating with the relay using a network link, a direct serial link and

a modem link (internal, external)

• Using Relay Control Panel to access the relay’s user interface

• Using HyperTerminal to access the relay’s maintenance menu

• Setting the Baud rate

• Accessing the relay’s Supervisory Control And Data Acquisition (SCADA)

services

2.2 Power Supply

A wide range power supply is standard. The nominal operating range is 48 –

250 Vdc, 100 – 240 Vac, +/-10%, 50/60 Hz. To protect against a possible short

circuit in the supply use an inline fuse or circuit breaker with a 5 A rating. Ensure that the chassis is grounded for proper operation and safety.

There are no power switches on the relay. When the power supply is connected, the relay starts its initialization process. See “Using the IED (Getting Started)” on page 3-1 for the start up process details.

Case Grounding

Ground the relay to the station ground using the case-grounding terminal at the

back of the relay, for details see Figure 1.5: L-PRO Relay Rear View (4U) on

page 1-5.

WARNING!

Ground the relay to station ground using the case-grounding terminal

at the back of the relay, for details see Figure 1.5: L-PRO Relay Rear

View (4U) on page 1-5.

2.3 IRIG-B Time Input

The relay is equipped to handle modulated or unmodulated GPS satellite time

IRIG-B signals. The IRIG-B time signal is connected to the BNC connection

on the back of the relay. When the IRIG-B signal is provided to the relay the

IRIG-B functional Light-Emitting Diode (LED) comes on and the relay clock

D02706R02.30 L-PRO 4000 User Manual 2-1

2 Setup and Communications

is referenced to this signal. No settings are required to differentiate between

modulated or unmodulated signals; this is automatically detected by the relay.

Enable or disable the IEEE 1344 extension in the Relay Control Panel. The enabled mode allows the year to be received from the IRIG-B signal. If the available IRIG-B signal has no year extension, this setting should be disabled.

2.4 Communicating with the Relay Intelligent Electronic Device (IED)

Connect to the relay to access its user interface and supervisory control and

data acquisition (SCADA) services by:

• Front USB 2.0 interface (maintenance)

• 1 front and 2 rear Ethernet network links (user interface and SCADA)

• Direct serial link (user interface and SCADA)

• External or internal modem link (user interface only)

The relay has a front panel USB( Port 150) and 1 front Port 119 and 1 rear panel

Ethernet port 119 and 1 rear panel Ethernet Port 120 and 2 rear serial Ports 122

and 123) to provide direct access to its user interface and SCADA services.

The relay’s user interface is accessed through the Relay Control Panel.

2-2 L-PRO 4000 User Manual D02706R02.30

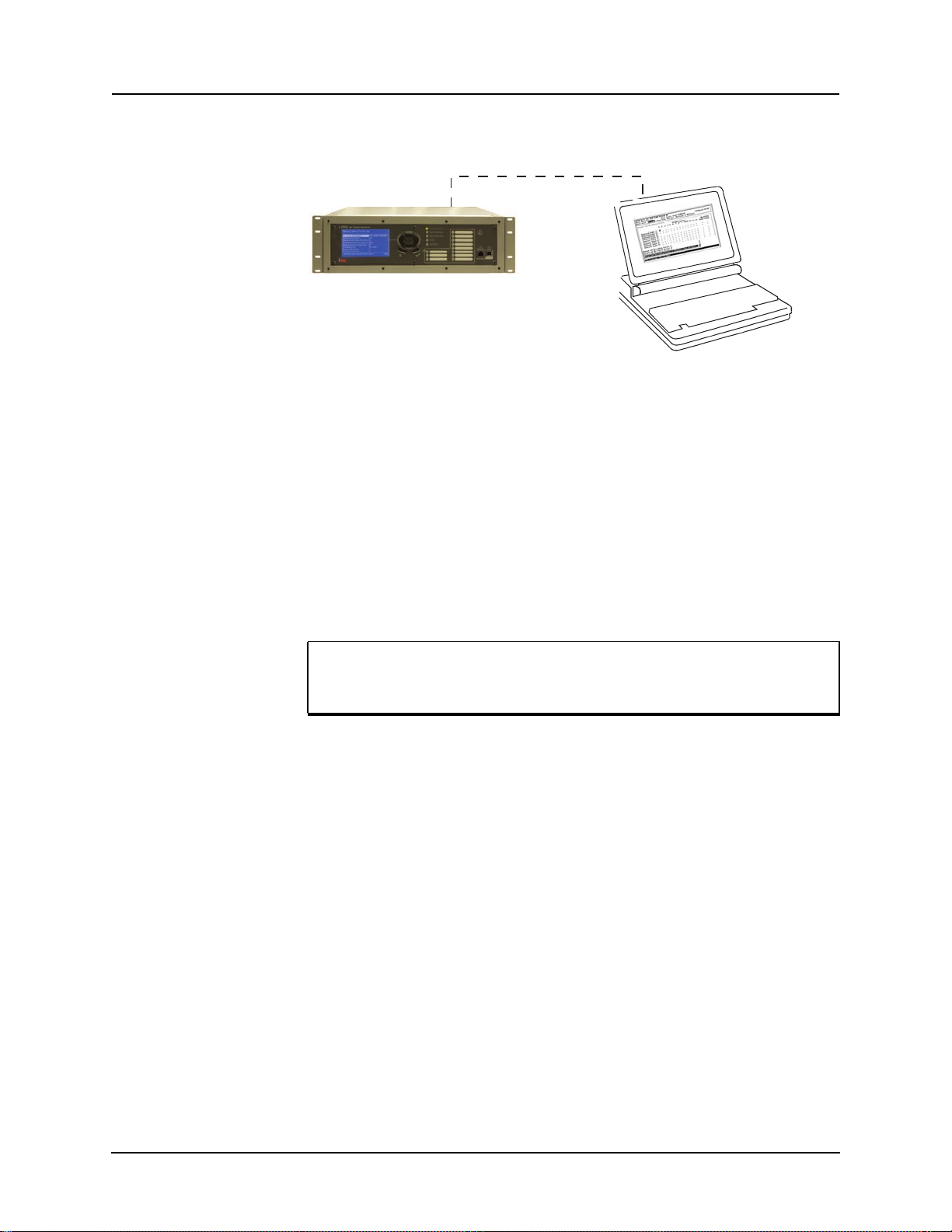

2.5 USB Link

2 Setup and Communications

The PC must be appropriately configured for USB communication.

Port 150 - USB

Laptop PC

Figure 2.1: USB Link

USB Driver Installation

To create an USB link between the relay and the computer, first the USB driver

for the ERLPhase 4000 series device needs to be installed, as follows:

Unzip the file (can be obtained from ERL website):

ERLPhase_USB_driver.zip

In this case we assume you unzipped to the desktop.

In Windows XP or Windows 7

Connect a USB port of the PC to Port 150 (USB front) of the LPRO-4000.

The LPRO-4000 was already powered on.

In the window

“Welcome to the Found New Hardware Wizard”

“Can Windows connect to Windows Update to search for software?”

Check the option “No, not this time”.

In the window

“This wizard helps you install software for:”

“ERLPhase 4000 Series Device”

“What do you want the wizard to do?”

Check the option “Install from a list or specific location (Advanced)”.

In the window

“Please choose your search and installation options”

“Search for the best driver in these locations”

D02706R02.30 L-PRO 4000 User Manual 2-3

2 Setup and Communications

Uncheck the option “Search removable media (floppy, CD-ROM.)”.

Check the option “Include this location in the search”.

Browse for the following folder:

C:\WINDOWS\tiinst\TUSB3410

In the window

“Hardware Installation”

“The software you are installing for this hardware”

“ERLPhase 4000 Series Device”

“has not passed Windows Logo testing to verify its compatibility with

Windows XP” or “Windows can’t verify the publisher”

Hit Continue Anyway.

In the window

“Completing the Found New Hardware Wizard”

“The wizard has finished installing the software for”

“ERLPhase 4000 Series Device”

Hit Finish.

To verify the installation was successful, and to which comm port is the ERLPhase 4000 Series Device configured, do the following:

In Windows XP

Start > Control Panel->Performance and Maintenance->System >Hardware > Device Manager > Ports

or (if using Control Panel’s Classic View)

Start > Control Panel > System > Hardware >Device Manager >Ports

In Windows 7 ‘small icons’ view, go to

Start>Control Panel>Device Manager>Ports.

Look for the port number associated to this device.

“ERLPhase 4000 Series Device”

Look for a COM#, where “#” can be 1, 2, 3, etc. Leave the default settings

for this port.

It is recommended to restart the PC after the USB driver installation.

The default baud rate for the relay USB Port 150 is 115200, however to double

check it login to the relay display and go to:

Main Menu > System > Relay Comm Setup

2-4 L-PRO 4000 User Manual D02706R02.30

2.6 Network Link

Figure 2.2: Network Link

Access both the relay’s user interface and DNP3 SCADA services simultaneously with the Ethernet TCP/IP LAN link through the network ports Port 119

and Port 120. The rear Port 119 and 120 are either 100BASE-T copper interface with an RJ-45 connector or 100BASE-FX optical interface with an ST

style connector. Each port is factory configurable as a copper or optical interface. The front Port 119 is 100BASE-T copper interface with an RJ-45 connector.

PC with TCP/IP

TCP/IP

Network

2 Setup and Communications

Port 119 or Port 120

Port 119 - RJ-45

Network

DNP3 SCADA services can also be accessed over the LAN, for details see

“Communication Port Details” on page 2-15.

Connect to the Ethernet LAN using a Cat 5 cable with an RJ-45 connector or

100BASE-FX 1300 nm, multimode optical fiber with an ST style connector.

By default, the Port 119 is assigned with an IP address of 192.168.100.80 Port

120 is assigned with an IP address of 192.168.101.80. If this address is not suitable, it may be modified using the relay’s Maintenance Menu. For details see

“Using HyperTerminal to Access the Relay’s Maintenance Menu” on page 2-

9.

D02706R02.30 L-PRO 4000 User Manual 2-5

2 Setup and Communications

2.7 Direct Serial Link

Port 150 - USB

Port 123 - Serial

Figure 2.3: Direct Serial Link

To create a serial link between the relay and the computer, connect the computer’s serial port and Port 123 on the relay’s rear panel provided the port is

not configured for modem use.

The serial ports are configured as EIR RS-232 Data Communications Equipment (DCE) devices with female DB9 connectors. This allows them to be connected directly to a PC serial port with standard straight-through male-to

female serial cable, for pin-out details see “Communication Port Details” on

page 2-15. Rear Port 122 is for SCADA and Port 123 can be used for direct serial access and external modem.

Laptop PC

Ensure the relay port and the PC’s port have the same baud rate and

communications parameter, see “Maintenance Menu Commands”

on page 2-11.

2-6 L-PRO 4000 User Manual D02706R02.30

2.8 Modem Link

External

2 Setup and Communications

Analog

Port 123 - RJ-11 modem

Figure 2.4: External Modem Link

Telephone

Line

Telephone

System

Analog

Telephone

Line

Desktop Computer

Using an external modem, access the relay’s user interface through a telephone

link between the relay and the computer.

Connect the serial port on the external modem to the Port 123 on the relay’s

rear panel. Both devices are configured as RS-232 DCE devices with female

connectors, so the cable between the relay and the modem requires a crossover

and a gender change. Alternatively, use the ERLPhase modem port adapter

provided with the relay to make Port 123 appear the same as a PC’s serial port.

A standard modem-to-PC serial cable can then be used to connect the modem

and the relay. For pin-out details see “Communication Port Details” on page 2-

15.

Connect the modem to an analog telephone line or switch using a standard RJ11 connector.

Configure the relay’s Port 123 to work with a modem. Log into the relay

through Relay Control Panel, go to Utilities>Communication and select port

123. Set the Baud Rate as high as possible – most modems handle 57,600 bps.

The Initialize setting allows the user to set the control codes sent to the modem

at the start of each connection session. The factory defaults are:

“M0S0=0&B1” for an external modem and “M0S0=0” for an internal modem.

D02706R02.30 L-PRO 4000 User Manual 2-7

2 Setup and Communications

Internal

Port 118 - RJ-11 modem

Analog

Telephone

Line

Telephone

System

Analog

Telephone

Line

Desktop Computer

Figure 2.5: Internal Modem Link

Access the relay’s user interface through a telephone link between the relay

and the computer using an optional internal modem. If the modem has been installed, Port 118 on the rear panel is labelled “INTERNAL MODEM.”

Connect the relay’s Port 118 to an analog telephone line or switch using a standard RJ-11 connector.

When an internal modem is installed, the relay’s Port 118 is used to interface

to the modem internally. Appropriate Port 118 settings are configured at the

factory when the internal modem is installed. The factory defaults are:

“M0S0=0&B1” for an external modem and “M0S0=0” for an internal modem.

2-8 L-PRO 4000 User Manual D02706R02.30

2 Setup and Communications

2.9 Using HyperTerminal to Access the Relay’s Maintenance Menu

This section describes how to configure a standard Windows VT-100 terminal

program on the PC for use with the relay.

The computer must be connected to the relay via the front USB port 150.

The relay is accessed using a standard VT-100 terminal style program on the

computer, eliminating the need for specialized software. Any terminal program

that fully supports VT-100 emulation and provides z-modem file transfer services can be used. HyperTerminal, which is included in Windows XP and is

also available separately as HyperTerminal PE, is used here as an example.

Configure the terminal program as described in Table 2.1:Terminal Program

Setup and link it to the appropriate serial port, modem or TCP/IP socket on the

computer.

Table 2.1: Terminal Program Setup

Baud rate Default fixed baud rate 115,200 N81 (no parity, 8 data bits, 1 stop bit).

Data bits 8

Parity None

Stop bits 1

Flow control Hardware or Software.

Hardware flow control is recommended. The relay automatically supports both on all its serial ports.

Function, arrow

and control keys

Emulation VT100

Font Use a font that supports line drawing (e.g. Terminal or MS Line Draw).

Terminal keys

If the menu appears outlined in odd characters, the font selected is not

supporting line drawing characters.

To configure HyperTerminal follow these instructions:

In Windows 7 open HyperTerminal PE; in Windows XP go to

Start > All Programs > Accessories > Communications > HyperTerminal

If “Default Telnet Program?” windows pops up,

Check “Don’t ask me this question again”

Hit No.

First time use of HyperTerminal will ask for “Location Information”.

Fill with appropriate information, e.g.:

“What country/region are you in now”

Choose “Canada”

D02706R02.30 L-PRO 4000 User Manual 2-9

2 Setup and Communications

“What area code (or city code) are you are in now?”

Enter “306”

“If you need to specify a carrier code, what is it?”

Enter “”, i.e. leave blank

“If you dial a number to access an outside line, what is it?”

Enter “”.

“The phone system at this location uses:”

Choose “Tone dialing”.

Hit OK.

First time use of HyperTerminal will show “Phone and Modem Options”.

Hit Cancel.

HyperTerminal will show initially “Connection Description”.

Enter a name for the relay, e.g: “LPRO4000”.

Hit OK.

In the window “Connect To”

“Connect using”

Choose “COM#”, where “#” was obtained previously in Section 2.5 USB

Link, after installing the USB driver.

Let’s assume in this case it is COM3.

In the window “COM3 Properties” choose:

“115200”

“8”

“None”

“1”

“Hardware”

Hit Apply then hit OK

At this time the connection should already be established.

Hit Enter in the terminal window.

2-10 L-PRO 4000 User Manual D02706R02.30

Login as maintenance in lower case.

Figure 2.6: Maintenance Menu

2 Setup and Communications

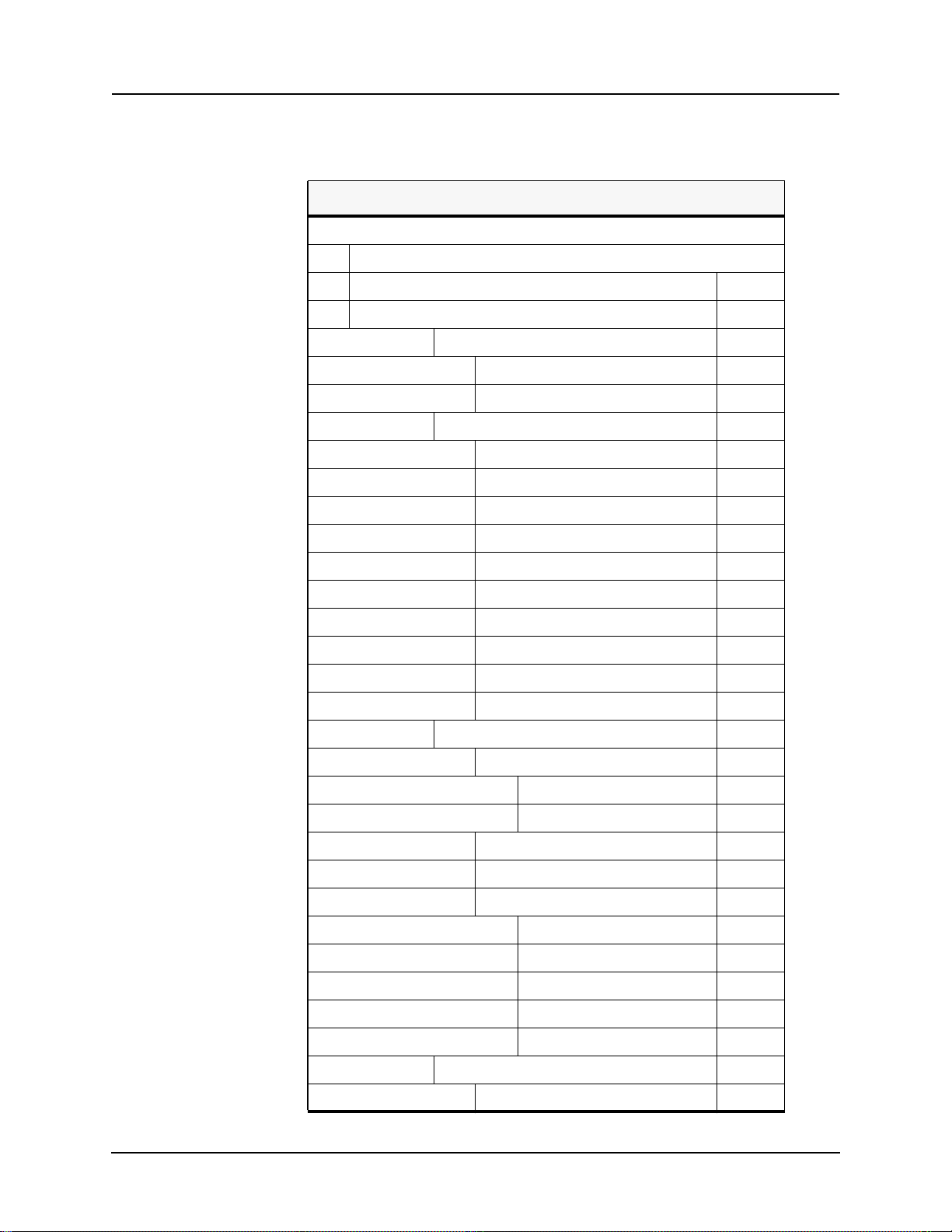

Maintenance Menu Commands

Commands 1, 4, 5, 6 and 7 are Port 150 access only.

Table 2.2: Maintenance Menu Commands

Modify IP address

View system diagnostic

Retrieve system diagnostics

Restore settings (commands 4, 5 and 6)

Force hardware reset

Modifies the LAN IP addresses, network mask, default gateway

and IEC61850 network port assignment.

Displays the internal status log.

Automatically packages up the internal status log plus setting

and setup information and downloads it in compressed form to

the computer. This file can then be sent to our customer support

to help diagnose a problem.

Use these commands to force the system back to default

values, if a problem is suspected due to the unit's settings,

calibration and/or setup parameters.

Manually initiates a hardware reset. Note that the

communication link is immediately lost and cannot be

reestablished until the unit completes its start-up.

Network utilities

Monitor SCADA

D02706R02.30 L-PRO 4000 User Manual 2-11

Enters network utilities sub-menu.

Shows real time display of SCADA data.

2 Setup and Communications

Table 2.3: Network Utilities Menu Commands

View protocol statistics View IP, TCP and UDP statistics

View active socket states View current states of active sockets

View routing tables View routing tables

Ping Check network connection to given point

Exit network utilities Exit network utilities menu and return to Maintenance Menu

2.10 Firmware Update

The relay has an update login that can be accessed by a connection through a

VT100 terminal emulator (such as HyperTerminal). This login is available

only from Port 150.

1. Use the terminal program to connect to Port 150.

2. Select Enter, the terminal responds with a login prompt.

3. Login as update in lower case.

Commands

The firmware update is used to update the relay’s software with maintenance

or enhancement releases. Please see the L-PRO Firmware Update Procedure

documentation that comes with the firmware update for instructions on how to

update the firmware on the relay.

2-12 L-PRO 4000 User Manual D02706R02.30

2.11 Setting the Baud Rate

The baud rate is available on the LCD screen from the top level menu

selecting System then Relay Comm Setup.

2 Setup and Communications

Direct Serial Link

For a direct serial connection, both the relay and the computer must be set to

the same baud rate.

To change the baud rate of a relay serial port:

1. The user needs to log into the relay as Change (any port) or Service (USB

port only) using RCP.

2. Then choose Utilities>Communication tab.

Modem Link Unlike a direct serial link, the baud rates for a modem link do not have to be

the same on the computer and on the relay. The modems automatically negotiate an optimal baud rate for their communication.

The baud rate set on the relay only affects the rate at which the relay communicates with the modem. Similarly, the baud rate set in HyperTerminal only affects the rate at which the computer communicates with its modem. Details on

how to set these respective baud rates are described above, except that the user

modifies the Port 123 baud rate on the relay and the properties of the modem

in HyperTerminal.

D02706R02.30 L-PRO 4000 User Manual 2-13

2 Setup and Communications

2.12 Accessing the Relay’s SCADA Services

The relay supports DNP3 (Level 2) and Modbus SCADA protocols as a standard feature on all ERLPhase relays. DNP3 is available through a direct serial

link or the Ethernet LAN on top of either TCP or UDP protocols. The Modbus

implementation supports both Remote Terminal Unit (RTU) binary or ASCII

modes and is available through a direct serial link.

The relay’s Port 122 is dedicated for use with Modbus or DNP3 serial protocols. Port 122 uses standard RS-232 signalling. An external RS-232<->RS-485

converter can also be used to connect to an RS-485 network.

For details on connecting to serial Port 122 see “Communicating with the Relay Intelligent Electronic Device (IED)” on page 2-2 and “Communication

Port Details” on page 2-15.

The DNP3 protocol can also be run across the Ethernet LAN. Both DNP over

TCP and DNP over UDP are supported. For details on connecting to the Ethernet LAN see “Network Link” on page 2-5.

Complete details on the Modbus and DNP3 protocol services can be found in

the Appendices, for details see “Modbus RTU Communication Protocol”

in Appendix E and “DNP3 Device Profile” in Appendix F

Protocol Selection

Communication Parameters

To select the desired SCADA protocol go to L-PRO 4000 Offliner SCADA

communications section. Select the protocol and set the corresponding parameters.

Port 122’s communication parameters are set in the L-PRO 4000 Offliner

SCADA communications section Both the baud rate and the parity bit can be

configured. The number of data bits and stop bits are determined automatically

by the selected SCADA protocol. Modbus ASCII uses 7 data bits. Modbus

RTU and DNP Serial use 8 data bits. All protocols use 1 stop bit except in the

case where either Modbus protocol is used with no parity; this uses 2 stop bits,

as defined in the Modbus standard.

Diagnostics Protocol monitor utilities are available to assist in resolving SCADA commu-

nication difficulties such as incompatible baud rate or addressing. The utilities

can be accessed through the Maintenance Menu Commands, see “Maintenance

Menu Commands” on page 2-11

2-14 L-PRO 4000 User Manual D02706R02.30

2.13 Communication Port Details

Table 2.4: Communication Port Details

Location Port Function

Front Panel 119 RJ-45 receptacle, 100BASE-T Ethernet interface. Default IP =

192.168.100.80

Used for user interface access or SCADA access through Ethernet LAN.

Front Panel 150 USB-B receptacle, High speed USB 2.0 interface

Used for user interface access

Default fixed baud rate 115,200 N81 (no parity, 8 data bits, 1 stop

bit).

Rear Panel 118 RJ-11 receptacle, Internal modem interface.

Default Baud rate 38,400 N81 (no parity, 8 data bits, 1 stop bit)

Rear Panel 119 Rear panel, RJ-45 receptacle or ST type optical receptacle (fac-

tory configured). 100BASE-T or 100BASE-FX (1300nm, multimode) Ethernet interface. Same subnet as front panel port 119.

Used for user interface access or IEC61850/DNP SCADA access

through Ethernet LAN.

2 Setup and Communications

Rear Panel 120 ST type optical receptacle. 100BASE-FX (1300 nm, multimode)

Ethernet interface.

Used for user interface access or IEC61850/DNP SCADA access

through Ethernet LAN

Rear Panel 121 BNC receptacle, IRIG-B Interface. Modulated or un-modulated,

330 ohm impedance.

Rear Panel 122 RS-232 DCE female DB9.

Used for SCADA communication.

Default Setting: 19,200 baud O71 (odd parity, 7 data bits, 1 stop)

Rear Panel 123 RS-232 DCE female DB9.

Used for:

• User interface access through a direct serial connection.

• Default Setting: 9600 baud N81 (no parity, 8 data bits, 1

stop bit).

• User interface access through an external modem. The

optional ERLPhase Modem Adapter converts this port to a

Data Terminal Equipment (DTE) to simplify connection to

an external modem.

D02706R02.30 L-PRO 4000 User Manual 2-15

Table 2.5: Signal connections to pins on Relay Port

Signal Name

DCD 1

RxD 2

TxD 3

DTR 4

Common 5

DSR 6

RTS 7

CTS 8

No connection 9

Notes:

Relay is DCE, PC is DTE.

Pins 1 and 6 are tied together internal to the relay.

Direction PC<-> Relay Pin # on the Relay Port

Table 2.6: Cable Pin Connections

Male DB-9 Cable End for Relay Port Female DB-9 Cable End for Computer Port

Pin # on Cable Pin # on Cable

11

22

33

44

55

66

77

88

99

2 Setup and Communications

Table 2.7: Signal name connections to pins on Modem Adapter

Signal Name Direction Modem <-> Relay Pin # on the Modem Adapter

DCD 1

RxD 2

TxD 3

DTR 4

Common 5

DSR 6

RTS 7

CTS 8

No connection 9

Notes:

Relay (with modem adapter) is DTE, modem is DCE.

Pins 1 and 6 are tied together internal to the relay.

D02706R02.30 L-PRO 4000 User Manual 2-17

3 Using the IED (Getting Started)

3.1 Introduction

This section provides information on the start-up sequence and ways to interface with the relay. Descriptions of the Front Panel Display, Terminal Mode

and Metering Data are provided.

3.2 Start-up Sequence

When the power supply is connected, the following initialization initializing

sequence takes place:

Table 3.1: Initialization Sequence

TEST MODE — red LED on when power applied

RELAY FUNCTIONAL — green LED on within 5 seconds after power applied

TEST MODE — red LED off then on within 10 seconds

Front Display — on on within 20 seconds after power applied

TEST MODE — red LED off within 20 seconds after power applied

When the Relay Functional LED comes on, it indicates that the DSP is actively

protecting the system.

When the test mode LED goes off, the relay is capable of recording and communicating with the user.

3.3 Interfacing with the Relay

The following ways can be used to interface with the relay:

• Front panel display

• Terminal mode (for maintenance and firmware upgrade)

• Relay Control Panel

D02706R02.30 L-PRO 4000 User Manual 3-1

3 Using the IED (Getting Started)

3.4 Front Panel Display

The front panel display is the fastest and easiest way of getting information

from the relay.

Display 16 LED Lights

LED Lights

6 Push Buttons

USB Port 150

Ethernet Port 119

Figure 3.1: Front Panel Display

The display, the 16 LED lights and the 6 push buttons, provide selective information about the relay.

Table 3.2: Description of LED Lights

Relay Functional Indicates when the relay is functional. When the Relay Functional

green LED goes on, the rear Relay Inoperative contact changes to

an open and the protective functions become functional.

IRIG-B Functional

Service Required Indicates the relay needs service. This LED can be the same state

Indicates the presence of a valid IRIG-B time signal where the LED

is on.

as the Relay Functional LED or can be of the opposite state

depending on the nature of the problem.

The following items bring up this LED:

• DSP failure - protection difficulties within the relay.

• Communication failure within the relay.

• Internal relay problems.

Test Mode Occurs when the relay output contacts are intentionally blocked.

Possible reasons are:

• Relay initialization on startup

• User interface processor has reset and is being tested.

The user cannot communicate with the relay through the ports until

the front display becomes active and the TEST MODE LED goes

out. Normally, the red Target LED remains off after this start-up

unless the relay had unviewed target messages.

Alarm Occurs when an enabled relay function picks up.

The red Alarm LED should be off if there are no inputs to the relay.

If the Alarm LED is on, check the event log messages which are

available through the menu system.

3-2 L-PRO 4000 User Manual D02706R02.30

Table 3.2: Description of LED Lights

Target LED Number Description (Default values)

3 Using the IED (Getting Started)

1

2

3

4

5

6

7

8

9

10

11

Any device 21P trip operation (phase distance - 21P1, 21P2, 21P3,

21P4)

Any device 21N trip operation (ground distance - 21N1, 21N2,

21N3, 21N4)

Any device 50 or 51 trip operation (phase overcurrent - 50 or 51,

neutral overcurrent - 50N or 51N, negative sequence overcurrent

46-50 or 46-51)

Any device 50BF trip operation (breaker failure - 50BF Main-1,

50BF Main-2, 50BF Aux-1, 50BF Aux-2)

Any device 81 trip operation (over/under-frequency - 81-1, 81-2, 813, 81-4)

Switch On To Fault trip operation

Communication Scheme trip operation

Device 68 trip operation Power Swing trip

ProLogic 1 - 8

ProLogic 9 - 16

ProLogic 17 - 24

Push Buttons

Target LED assignments are the default values but are configurable

by the user through the Offliner settings (output matrix configuration).

Table 3.3: Identification of Push Buttons

Up, Down, Right, Left, Enter, Escape

Used to navigate the front panel screens.

D02706R02.30 L-PRO 4000 User Manual 3-3

3 Using the IED (Getting Started)

Display The basic menu structure for navigation of the LCD screen is given below:

Table 3.4: Navigation of the LCD Screen

Main Screen

View / Change / Service : Choice Menu

Enter Password

Main Menu (V)

System (V)

Relay Identification (V)

Relay Comm Setup (V)

Settings

System Parameters

Record Length

Setting Group 1

Setting Group 2

Setting Group 3

Setting Group 4

Setting Group 5

Setting Group 6

Setting Group 7

Setting Group 8

Metering (V)

Analog (V)

Analog Inputs (V)

Line Quantities (V)

External Inputs (V)

Output Contacts (V)

Logic (V)

Logic Protections 1 (V)

Logic Protections 2 (V)

ProLogic (V)

Group Logics (V)

Virtual Inputs (V)

Records (V)

View Record List (V)

3-4 L-PRO 4000 User Manual D02706R02.30

Table 3.4: Navigation of the LCD Screen

Fault Recording (C,S)

Swing Recording

Event Recording

Fault Log

Fault List

Event Log (V)

Event List

Utilities (V)

Setup (V)

Timeouts (V)

Time Settings (V)

Set Manual Time (V)

Set DST Time (V)

External Inputs (V)

3 Using the IED (Getting Started)

Maintenance (V)

Output Contacts Control (S)

Virtual Inputs Control (C,S)

Setting Groups Control (C,S)

Erase (C,S)

Erase Records (C,S)

Erase Event Logs (C,S)

Network (V)

Network Protocol Stats (V)

Active Sockets (V)

Routing Tables (V)

Ping (V)

Logout (V)

Where the access levels required to access each are indicated by:

V: view

C: change

S: service

To login into the LCD menu structure, follow these steps:

D02706R02.30 L-PRO 4000 User Manual 3-5

3 Using the IED (Getting Started)

2012Oct24

12:17

LPRO-4000-101224-01

Figure 3.2: Main Screen

ERLPhase LPRO 4000

2011Aug06

21:48:54

View

Change - read/write

Service - full access

*passwords are case sensitive

*logins have an activity timeout of:

Figure 3.3: View / Change / Service: Choice Menu

Enter Password

60mins

2011Aug06

21:48:54

****

1 2 3 4 5 6 7 8 9 0 - + =

a b c d e f g h i j k l m n o

Sp p q r s t u v w x y z , .

back

Figure 3.4: Enter Password

3-6 L-PRO 4000 User Manual D02706R02.30

select view

3 Using the IED (Getting Started)

Main Menu

2011Aug06

21:48:54

System

Settings

Metering

Records

Fault Log

Event Log

Utilities

Logout

select view

Figure 3.5: Main Menu

In the Main Screen, hit Enter.

In the View / Change / Service: Choose Menu screen, choose desired access

level, hit Enter.

In the Enter Password screen, enter appropriate password, hit Enter on the return character (right bottom one)

The Main Menu screen should appear.

Note: The default passwords are (remove quotation marks)

View Access “view”

Change Access “change”

Service Access “service”

3.5 Terminal Mode

The terminal mode is used to access the relay for maintenance functions see

“Using HyperTerminal to Access the Relay’s Maintenance Menu” on page 29 and “Firmware Update” on page 2-12.

3.6 Relay Control Panel

RCP is used for all user interface. A short description of the RCP configuration

to connect to a relay is given here. Please refer to the Relay Control Panel User

Manual for details.

Follow this sequence to configure RCP for USB link to the relay.

1. Execute.

Relay Control Panel.exe

2. Execute.

L-PRO 4000 Offliner.exe

3. Install Null Modem Driver.

D02706R02.30 L-PRO 4000 User Manual 3-7

3 Using the IED (Getting Started)

Please refer to the Relay Control Panel User Manual for details.

4. Run Relay Control Panel.

Go to:

Start > All Programs > ERLPhase > Relay Control Panel > Relay Control

Panel

First time RCP is run.

Hit Add New.

“Add New Relay”

Choose Communication > Direct Serial Link.

Hit Get Information From Relay.

Then RCP will communicate with the LPRO-4000 and retrieve information to fill required fields.

When this is done, hit Save Relay.

If the window “Relay already exists...” pops up, you may need to rename the relay changing the “Relay Name” in the “Relay Definition”

category, before saving.

After first time, in “Select Relay”, choose relay and hit Connect.

In “Relay Password Prompt”

Choose desired access level, enter appropriate password

Note: Default passwords are listed below (remove the quotation

marks)

View Access “view”

Change Access “change”

Service Access “service”

The basic structure of the Relay Control Panel information, including basic

actions available, is given below:

Table 3.5: Relay Control Panel Structure

View Change Service

Relay Control Panel

Records Trigger Fault Trigger Fault

Trigger Swing Trigger Swing

Trigger Event Trigger Event

Faults Erase Erase

Events Erase Erase

Metering

3-8 L-PRO 4000 User Manual D02706R02.30

Table 3.5: Relay Control Panel Structure

Analog

Line

External

Logic 1

Logic 2

ProLogic

Outputs

Group Logic

Virtual

Utilities

Unit Identification

Communication

Time

3 Using the IED (Getting Started)

Analog Input Calibration N/A N/A

External Input

Virtual Inputs N/A Latch/Pulse Latch/Pulse

Toggle Outputs N/A N/A Close/Open

Settings Group Save Save

Passwords N/A N/A

Configuration

Present Settings (Get From

Relay)

Saved Settings (Load to

Relay)

(Load to

Relay)

Notice that some options are not available (N/A) depending on the access level.

D02706R02.30 L-PRO 4000 User Manual 3-9

4 Protection Functions and

Specifications

Introduction ...... page 4-2

Protection and Recording Functions ...... page 4-2

21P Phase/21N Ground Distance ...... page 4-2

Load Encroachment (LE) ...... page 4-5

Relay Method of Memory Polarization ...... page 4-8

Relay Method of Memory Polarization ...... page 4-8

Ring Filter ...... page 4-9

Directional Element ...... page 4-10

Directional Element Outputs ...... page 4-12

21P and 21N Phase Selector ...... page 4-13

Capacitance Coupled Voltage (CCVT) Transformer on 21 Devices ...... page

4-16

68 Power Swing ...... page 4-17

Line Energization Supervision Logic ...... page 4-19

Switch On To Fault (SOTF) ...... page 4-20

Weak Infeed (WI) ...... page 4-22

25/27/59 Sync Check ...... page 4-23

79 Recloser ...... page 4-24

Summary of Trip and Reclose Schemes ...... page 4-28

59 Main/Auxiliary Overvoltage ...... page 4-28

...... page 4-28

60 Loss of Potential (LOP) ...... page 4-31

81 Frequency ...... page 4-34

50LS Overcurrent ...... page 4-35

50BF Breaker Failure ...... page 4-36

50/51/67 Phase Overcurrent ...... page 4-38

50N/51N/67 Neutral Overcurrent ...... page 4-40

46-50/46-51/67 Negative Sequence Overcurrent ...... page 4-41

Adaptive Additional Delay for 50 O/C Elements ...... page 4-42

Z Circle Trigger ...... page 4-43

Fault Locator ...... page 4-43

ProLogic ...... page 4-44

Group Logic ...... page 4-45

Communication-Aided Scheme ...... page 4-47

50/51N OC Carrier Start and Block Logic ...... page 4-47

Basic Logic ...... page 4-48

POTT Logic ...... page 4-49

DCB Logic ...... page 4-50

PUTT Logic ...... page 4-51

Recording Functions ...... page 4-51

Introduction ...... page 4-51

Fault Recording ...... page 4-51

Swing Recording ...... page 4-52

D02706R02.30 L-PRO 4000 User Manual 4-1

4 Protection Functions and Specifications

Event Recording ...... page 4-52

Record Initiation ...... page 4-52

Record Duration and Extension ...... page 4-53

Record Storage ...... page 4-53

Record Retrieval and Deletion ...... page 4-53

Event Log ...... page 4-54

Fault Log ...... page 4-55

4.1 Protection and Recording Functions

Introduction This section describes the equations and algorithms of the relay protection

functions. All functions with time delay provide an alarm output when their

pickup level is exceeded.

The following functions are exceptions: 27 Auxiliary, 27 Main, 59 Auxiliary,

59 Main, 25/27/59 Sync Check, 50LS Main, 50LS Auxiliary, 50BF Main,

50BF Auxiliary, 81 Frequency and ProLogic elements.

A complete list of the settings and their range values can be found in “IED Settings and Ranges” in Appendix B.

21P Phase/21N Ground Distance

The relay 21P contains 5 zones of phase distance elements; all 5 zones of 21P

can be set to either Mho or Quadrilateral type. Note that only one type can be

used at a time. The 21P can contain a mixture of Mho and Quadrilateral shapes,

for example the 21P1 and 21P2 can be set to a Mho characteristic and the 21P3,

21P4 and 21P5 could be set to a Quadrilateral characteristic.

The relay 21N contains 5 zones of ground distance elements; all 5 zones of 21N

can be set to either Mho or Quadrilateral type. Note that only one type can be

used at a time. The 21N can contain a mixture of Mho and Quadrilateral

shapes, for example the 21N1 and 21N2 can be set to a Mho characteristic and

the 21N3, 21N4 and 21N5 could be set to a Quadrilateral characteristic.

The Quadrilateral shape is parallel to the positive sequence line angle setting.

The user-defined Mho Characteristic Angle is not selectable when a Quadrilateral characteristic for that particular zone is defined. All other settings are selectable and user-definable.

Zones 3, 4 and 5 reach can be set in either forward direction or reverse direction

or offset as required. All the distance functions are set in secondary ohms. The

available range of impedance settings is based on the nominal current specified

when the relay was ordered. The impedance reach ranges are given in “21P

Phase/21N Ground Distance” on page 4-2.

4-2 L-PRO 4000 User Manual D02706R02.30

Line Z1

X

Zone 4

X

Zone 5

Zone 3

Zone 2

Characteristic Angle

Zone 1

Line Angle

4 Protection Functions and Specifications

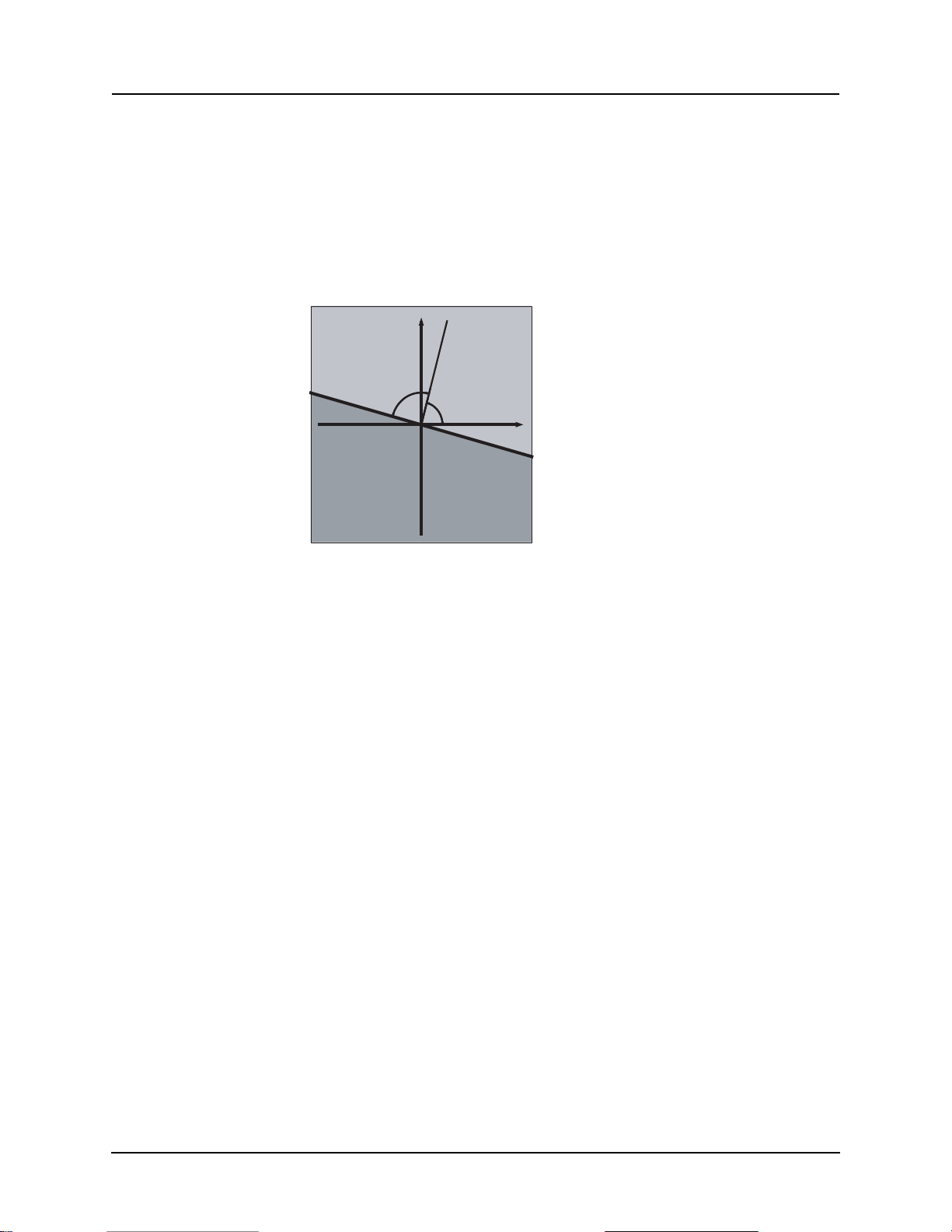

R

Figure 4.1: Phase and Ground distance protection Mho relay characteristic

The shape of the phase and ground distance relays is adjustable. For the circular Mho characteristic shape, the characteristic angle is 90 degrees. Determine

this angle by drawing 2 lines from any point on the impedance locus to the diameter of the characteristic. Produce a tomato-shaped characteristic by selecting an angle less than 90 degrees or a lens-shaped characteristic with angles

greater than 90 degrees.

X

Zone 5

Zone 3

Zone 2

Zone 1

Line Z1

Forwa rd

Line Angle

Zone 4

R

Directional Element

Reverse

Figure 4.2: Phase and Ground distance protection Quadrilateral Characteristics

The shape of the Mho characteristic means that significant extensions are made

to the relay characteristics in the R region of the R-X plane for ground faults.

D02706R02.30 L-PRO 4000 User Manual 4-3

4 Protection Functions and Specifications

A

V

B

0

K

Restrict the reach in the R region for the phase distance relays where load encroachment is an issue. The shaped Mho characteristic provides the best fit for

the application keeping the number of relay settings at a minimum and provides the benefits associated with the Mho characteristic.

The Mho characteristic used by the relay is developed by the classical approach using the measurement of the angle between 2 vectors.

These vectors are defined as:

(1)

(2)

(3)

=

phase

IZ

set

V

ref

Ko3I

–=

+

where

V is the actual line voltage for ground distance relays or the actual line to

line voltage for the phase distance relay.

I is defined as above for ground distance relays or the line to line current for

phase distance relays.

Z

is the setting reach and V

set

is a positive sequence memory voltage

ref

stored within the relay.

V

is the polarizing quantity for the Mho elements, and is more completely

ref

described in “Relay Method of Memory Polarization” on page 4-8.

To make the reach of the ground distance relay relate to the line positive sequence impedance the classical K

factor is used.

o

This factor is defined as

(4)

0

Z0Z1–

=

-----------------3Z

1

The relay includes a directional element to supervise the phase (21P) and

ground (21N) Mho elements, for all five Zones (21P1 to 21P5 and 21N1 to

21N5). The directional element improves security of the Mho elements for reverse faults such as: bus faults, phase-phase faults during high load conditions.

The directional element does not supervise Zone 3, Zone 4 and Zone 5 elements if these zones are set as offset characteristic. The directional element is

described in “Directional Element” on page 4-10.

4-4 L-PRO 4000 User Manual D02706R02.30

4 Protection Functions and Specifications

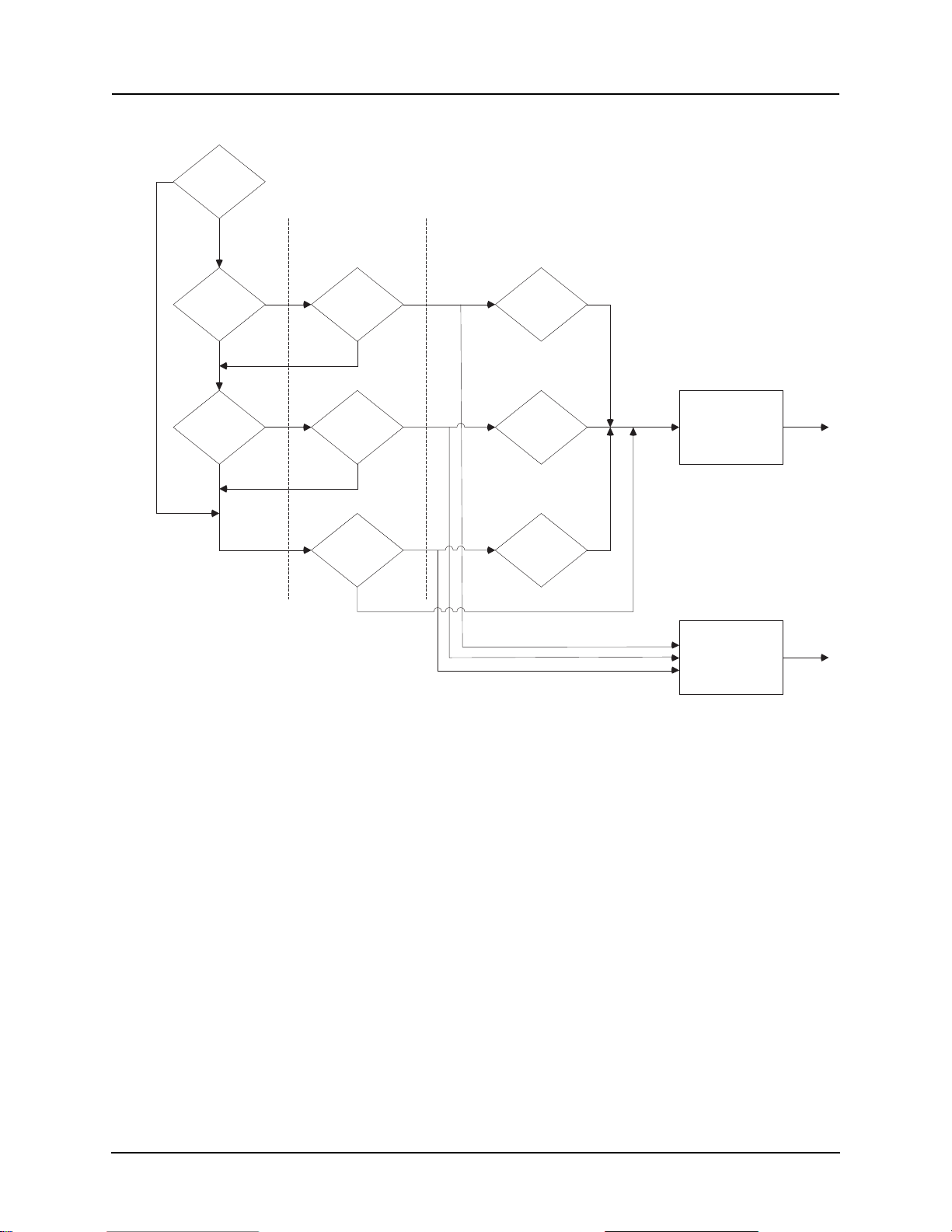

Load Encroachment (LE)

Line angle

Circle (90°)

Figure 4.3: Mho Characteristic Shapes

Line angle

Tomato (<90°)

Line angle

Lens (>90°)

The load impedance may enter into the protection zones permanently or temporarily due to system condition. This is observed in very long lines or heavily

loaded medium lines will have issue. This is a normal load conditions and it is

not an abnormal/fault conditions. Therefore, the relay should not initiate any

trip command during this condition. The relay should identify properly whether the impedance entered into the protection zone is normal load condition or

fault condition.

This is distinguished by monitoring all phase-to-phase impedance values (i.e.

Zab, Zbc & Zca).If all the three phase impedances enter into the protection

zones with the limited load angle area, it is declared as a loading condition and

21P function is blocked. If only one of the phase-to-phase impedance enters

into the protection zones with the limited load angle area then this can be declared as fault condition.

Generally, the three phase fault will not have any additional resistance component other than the conductor resistance. Therefore, three phase fault will always have the fault angle as close to line angle only and it will not enter into

the loading area.

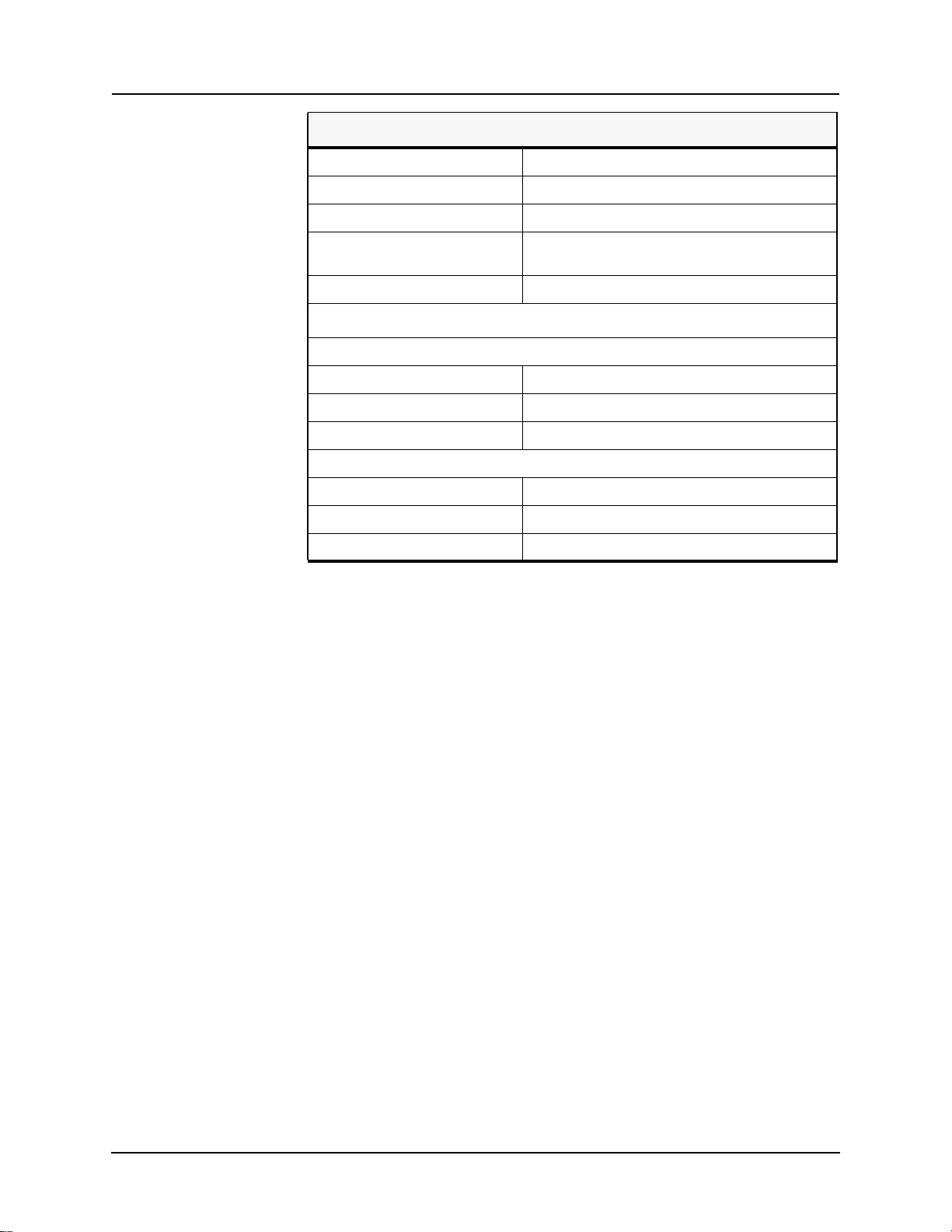

Figure 4.4: Load Encroachment (LE) Logic on page 4-5 shows how the LE

function works. Phase-to-phase current monitoring has been added to the logic

to ensure stable operation.

Figure 4.4: Load Encroachment (LE) Logic

D02706R02.30 L-PRO 4000 User Manual 4-5

4 Protection Functions and Specifications

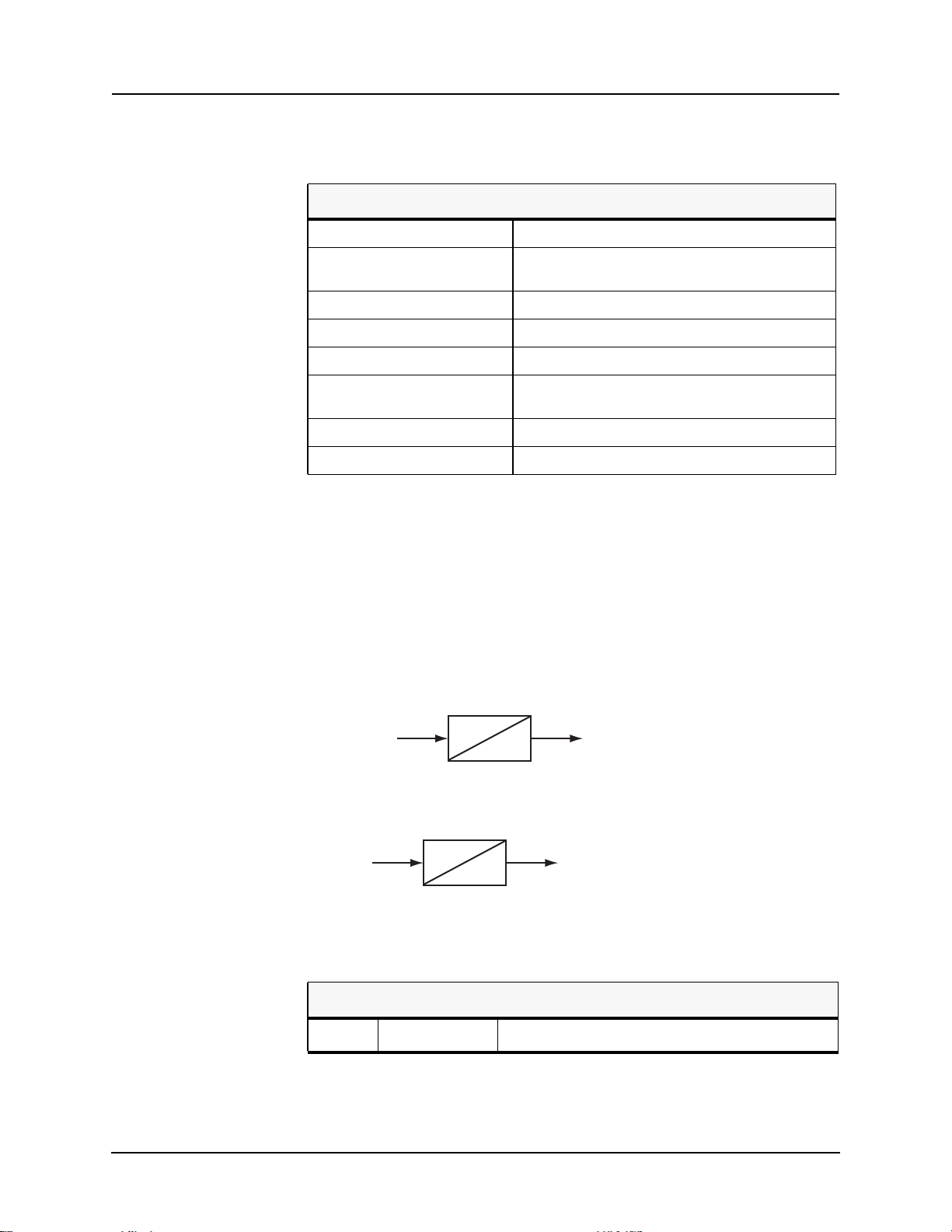

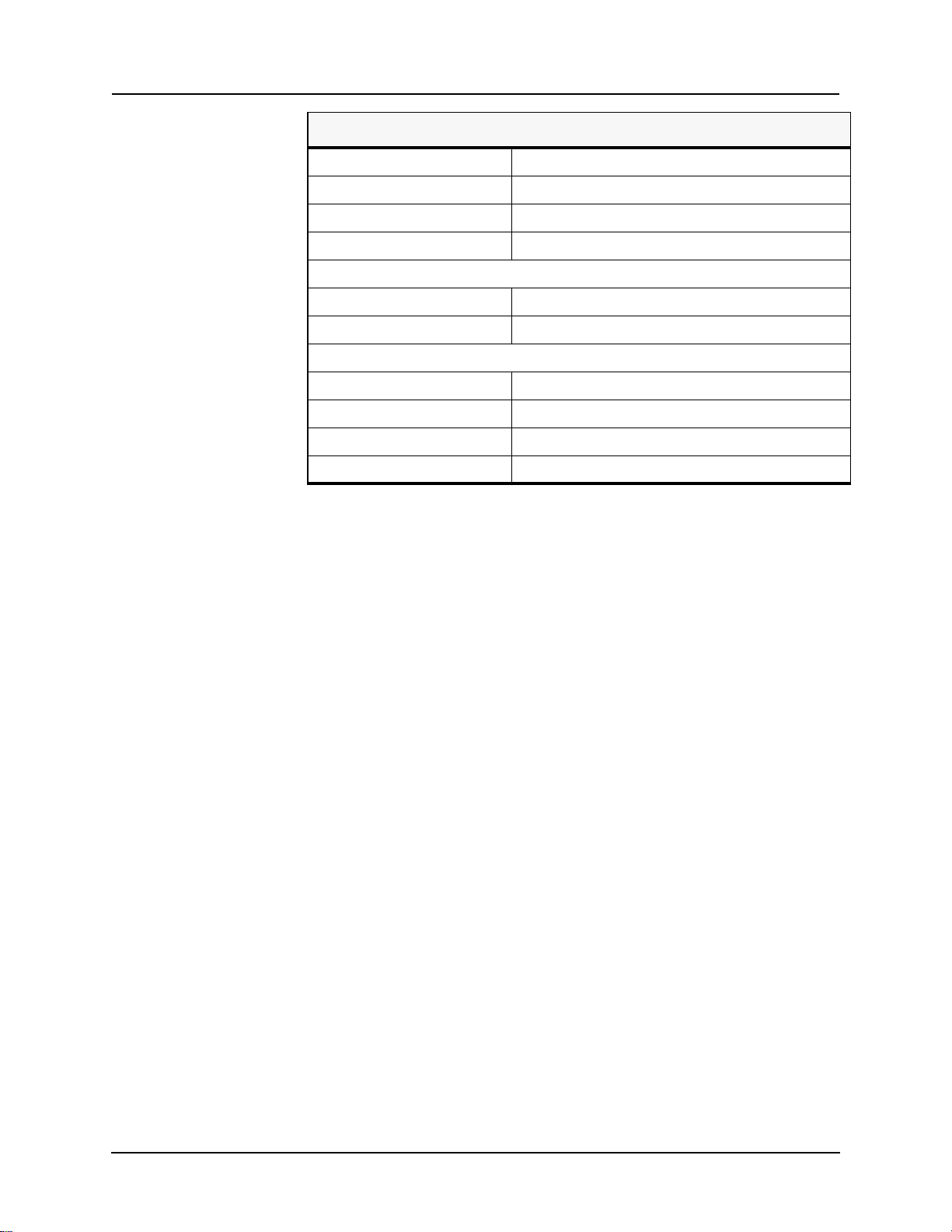

Table 4.1: 21P Phase Distance Element Settings

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

Enable/ Disable

Characteristic Type Mho / Quadri-

lateral

Forward Impedance

Reach (Ohms secondary)

Forward Reactance

Reach (Ohms secondary)

Reverse Impedance

Reach (Ohms secondary)

Reverse Reactance

Reach (Ohms secondary)

Left Reach (R1) (Ohms

secondary)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Both

Quadrilateral

Both

Quadrilateral

Quadrilateral

Right Reach (R2) (Ohms

secondary)

Mho Characteristic Angle

(degrees)

Pickup Delay (seconds) 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 Both

Id Supervision (A secondary)

Line Angle (degrees) 5.0 to 89.0

Load Impedance (Ohms)

R (Ohms secondary) -150.0 to 150.0 Both

X (Ohms secondary) -150.0 to 150.0 Both

Load Encroachment Enable/Disable Both

LHS

Impedance (Ohms secondary)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 Mho

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

Setting is made in Line Parameters (Positive Sequence Angle)

0.01 to 66.0 (5 A)

0.05 to 330.0 (1 A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

Quadrilateral

Both

Both

4-6 L-PRO 4000 User Manual D02706R02.30

4 Protection Functions and Specifications

Table 4.1: 21P Phase Distance Element Settings

Upper angle (degrees) 90.1 to 179.9 Both

Lower angle (degrees) 180.1 to 269.9 Both

RHS

Impedance (Ohms secondary)

Upper angle (degrees) 0.1 to 89.9 Both

Lower angle (degrees) -0.1 to -89.9 Both

0.01 to 66.0 (5 A)

0.05 to 330.0 (1 A)

Both

Table 4.2: 21N Ground Distance Element Settings

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

Enable/ Disable

Characteristic Type Mho / Quadri-

lateral

Forward Impedance

Reach (Ohms secondary)

Forward Reactance

Reach (Ohms secondary)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

Enable/ Disable

Mho / Quadrilateral

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

Both

Quadrilateral

Reverse Impedance

Reach (Ohms secondary)

Reverse Reactance

Reach (Ohms secondary)

Left Reach (R1) (Ohms

secondary)

Right Reach (R2) (Ohms

secondary)

Mho Characteristic Angle

(degrees)

Pickup Delay (seconds) 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 0.00 to 99.00 Both

D02706R02.30 L-PRO 4000 User Manual 4-7

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 70.0 to 140.0 Mho

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.00 to 66.00

(5A)

0.00 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

0.05 to 66.00

(5A)

0.25 to

330.00 (1A)

Both

Quadrilateral

Quadrilateral

Quadrilateral

4 Protection Functions and Specifications

R

X

Line Z

Source Z

No Memory

Voltage

Full

Memory

Voltage

Table 4.2: 21N Ground Distance Element Settings

Id Supervision (A secondary)

3I0 Supervision (A secondary)

Line Angle (degrees) 5.0 to 89.0

Load Impedance (Ohms)

R (Ohms secondary) -150.0 to 150.0 Both

X (Ohms secondary) -150.0 to 150.0 Both

Relay Method of Memory Polarization

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

Setting is made in Line Parameters (Positive Sequence Angle)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)

0.2 to 50.0

(5A) 0.04 to

10.00 (1A)