Page 1

I. Safety Instructions

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated “dangerous

voltage” within the product’s enclosure that may

be of sufficient magnitude to constitute a risk of

electric shock to persons.

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE COVER (OR BACK). NO

USER-SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE PERSONNEL

ONL Y.

PRECAUTIONS DURING SERVICING

1. In addition to safety, other parts and assemblies are

specified for conformance with such regulations as

those applying to spurious radiation. These must

also be replaced only with specified replacements.

Examples: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

3. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulating Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components

(transformers, power cords, noise blocking

capacitors, etc.), wrap ends of wires securely about

the terminals before soldering.

5. Make sure that wires do not contact heat generating

parts (heat sinks, oxide metal film resistors, fusible

resistors, etc.)

6. Check if replaced wires do not contact sharply edged

or pointed parts.

7. Make sure that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

MAKE YOUR CONTRIBUTION TO

PROTECT THE ENVIRONMENT

Used batteries with the ISO symbol

for recycling as well as small

accumulators (rechargeable batteries), mini-batteries

(cells) and starter batteries should not be thrown

into the garbage can.

Please leave them at an appropriate depot.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

WARNING:

Before servicing this TV receiver, read the X-RAY

RADIATION PRECAUTION, SAFETY INSTRUCTION

and PRODUCT SAFETY NOTICE.

X-RAY RADIATION PRECAUTION

1. Excessively high can produce potentially hazardous

X-RAY RADIATION. To avoid such hazards, the high

voltage must not exceed the specified limit. The

normal value of the high voltage of this TV receiver

is 27 KV at zero bean current (minimum brightness).

The high voltage must not exceed 30 KV under any

circumstances. Each time when a receiver requires

servicing, the high voltage should be checked. The

reading of the high voltage is recommended to be

recorded as a part of the service record, It is

important to use an accurate and reliable high

voltage meter.

2. The only source of X-RAY RADIATION in this TV

receiver is the picture tube. For continued X-RAY

RADIATION protection, the replacement tube must

be exactly the same type as specified in the parts

list.

3. Some parts in this TV receiver have special safety

related characteristics for X-RADIATION protection.

For continued safety, the parts replacement should

be under taken only after referring the PRODUCT

SAFETY NOTICE.

SAFETY INSTRUCTION

The service should not be attempted by anyone

unfamiliar with the necessary instructions on this TV

receiver. The following are the necessary instructions

to be observed before servicing.

1. An isolation transformer should be connected in the

power line between the receiver and the AC line

when a service is performed on the primary of the

converter transformer of the set.

2. Comply with all caution and safety related provided

on the back of the cabinet, inside the cabinet, on the

chassis or picture tube.

1

Page 2

3. To avoid a shock hazard, always discharge the

picture tube's anode to the chassis ground before

removing the anode cap.

4. Completely discharge the high potential voltage of

the picture tube before handling. The picture tube is

a vacuum and if broken, the glass will explode.

5. When replacing a MAIN PCB in the cabinet, always

be certain that all protective are installed properly

such as control knobs, adjustment covers or shields,

barriers, isolation resistor networks etc.

6. When servicing is required, observe the original lead

dressing. Extra precaution should be given to assure

correct lead dressing in the high voltage area.

7. Keep wires away from high voltage or high tempera

ture components.

8. Before returning the set to the customer, always

perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas,

terminals, screwheads, metal overlay, control shafts,

etc., to be sure the set is safe to operate without

danger of electrical shock. Plug the AC line cord

directly to the AC outlet (do not use a line isolation

transformer during this check). Use an AC voltmeter

having 5K ohms volt sensitivity or more in the

following manner.

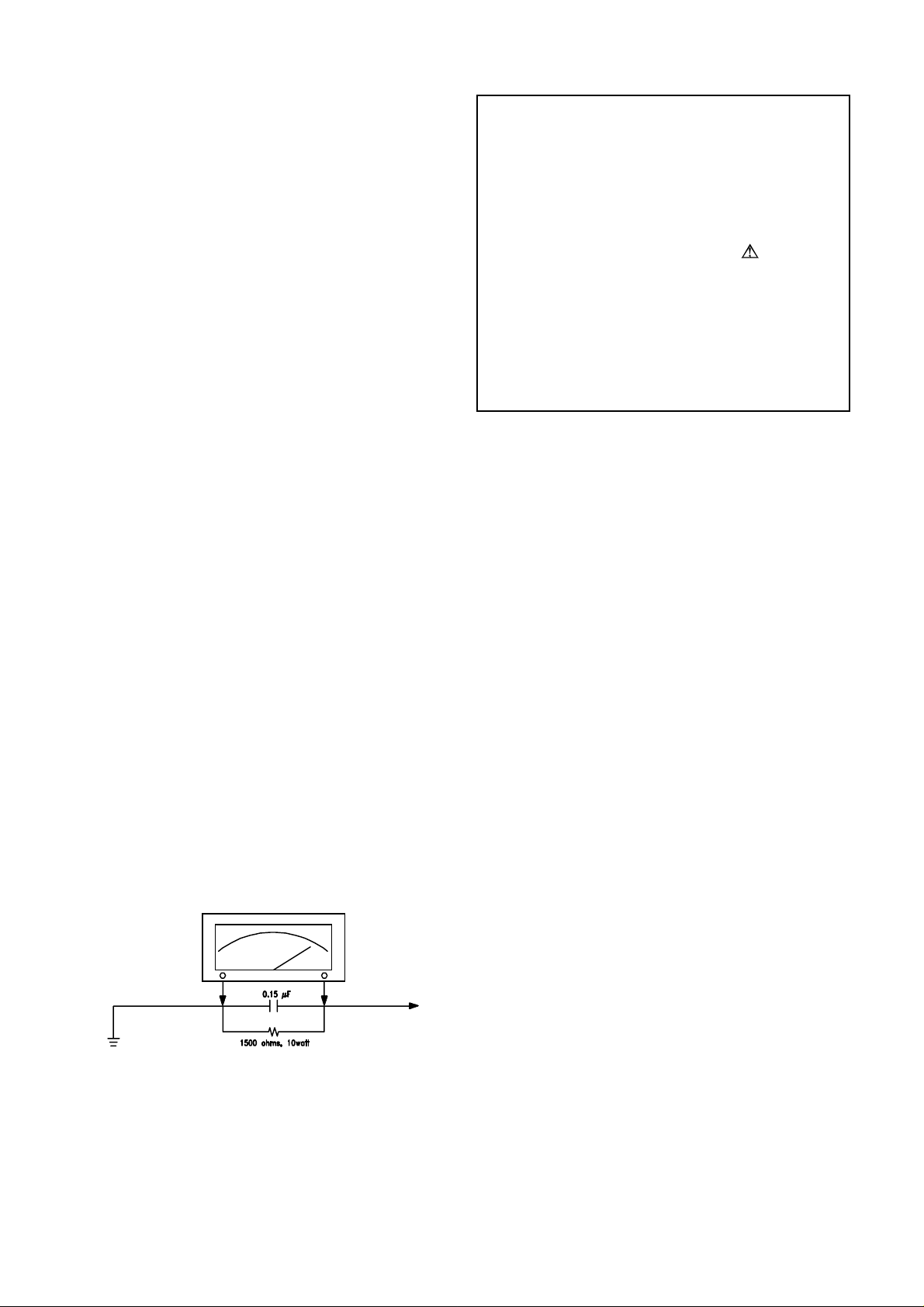

Connect a 1.5K ohm 10 watt resistor paralleled by a

0.15µF AC type capacitor, between a good earth

ground (water pipe, conductor etc.,) and the exposed

metallic parts, one at a time.

Measure the AC voltage across the combination of

the 1.5K ohm resistor and 0.15 uF capacitor. Reverse

the AC plug at the AC outlet and repeat the AC

voltage measurements for each exposed metallic

part.

The measured voltage must not exceed 0.3V RMS.

This corresponds to 0.5mA AC. Any value exceeding

this limit constitutes a potential shock hazard and

must be corrected immediately.

The resistance measurement should be done

between accessible exposed metal parts and power

cord plug prongs with the power switch "ON". The

resistance should be more than 6M ohms.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this TV

receiver have special safety-related characteristics.

These characteristics are offer passed unnoticed by

visual spection and the protection afforded by them

cannot necessarily be obtained by using replacement

components rates for a higher voltage, wattage, etc.

The replacement parts which have these special

safety characteristics are identified by

the schematic diagram and on the parts list.

Before replacing any of these components, read the

parts list in this manual carefully. The use of

substitute replacement parts which do not have the

same safety characteristics as specified in the parts

list may create shock, fire, X-RAY RADIATION or

other hazards.

marks on

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leakage Current Check

AC VOLTMETER

Place this probe

on each exposed metallic

part

2

Page 3

II. Specifications

1.Power supply TV: AC 220Vrms, 50Hz

Remote control battery: 3V (UM-3X2)

2. TV system RF input : PAL BG/DK, SECAM BG/DK

Video input: PAL/SECAM/NTSC 3.58/NTSC 4.43

3.Receiving channels VHF-L : E2-S10

VHF-H : E5-S41

UHF : E21-E69

4.Intermediate frequencies Picture: 38.9MHz

5.Scanning Horizontal (Hz): 15625/15750

Vertical (Hz) : 50/60

6.Color picture tube: 25” 29” 34” 110 degree north(1) hemisphere Bv=+0.35G±0.2G

7.Operating temperature Fulfil all specifications: 15°C ~ 35°C

Accept picture/tone reproduction: 5°C ~ 45°C

8.Operating relative humidity Fulfil all specifications: 45% ~ 75%

Accept picture/tone reproduction: 15% ~ 90%

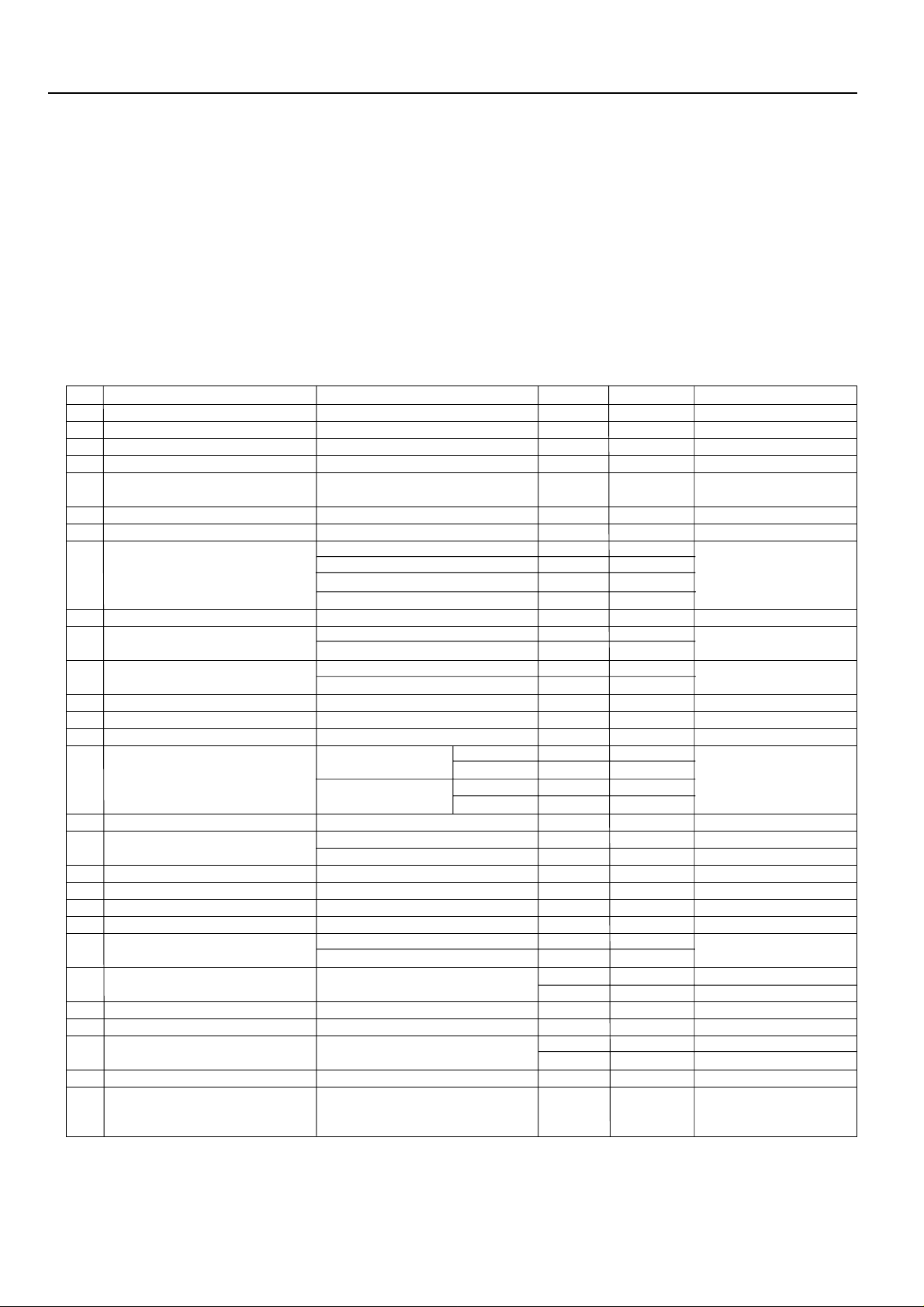

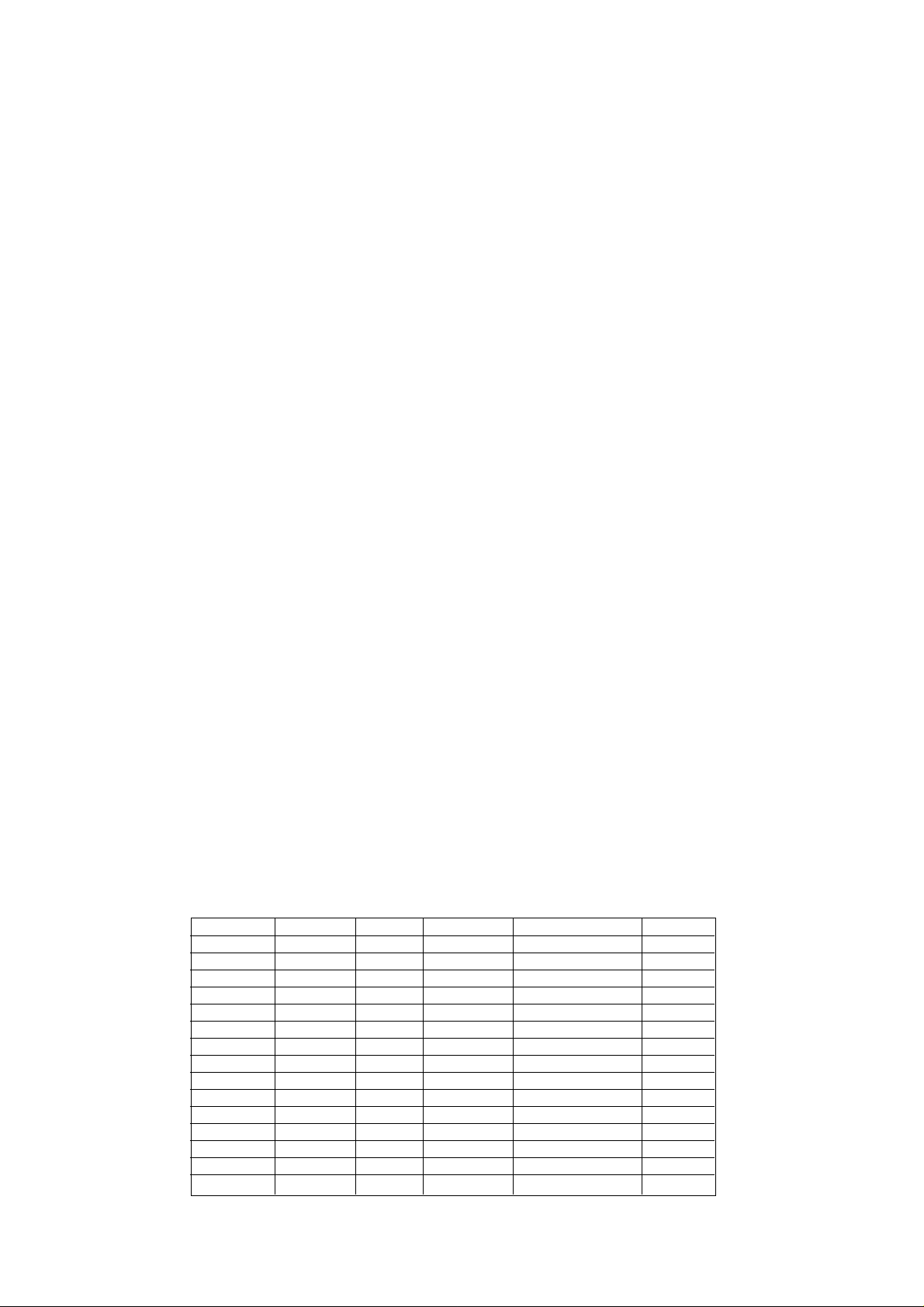

9.Electrical & Optical Specification:

No. Items Instruction Typical Limit Unit

1 Video sensitivity For 30dB S/N 45 ≤51 dBuV

2 FM sound sensitivity For 30dB S/N 28 ≤35 dBuV

3 Synchronizing sensitivity For RF transmission 25 ≤30 dBuV

4 Color sensitivity For RF transmission 32 ≤40 dBuV

5 Teletext sensitivity TV screen refreshes 40 times

number of mistakes ≤8 N/A N/A dBu

6 Minimum NICAM threshold Without crackline noise N/ A N/A dBu

7 AGC static characteristic Accept. Picture/tone repr. 103 ≥100 dBu

8 Selectivity Adjacent sound carrier 40 ≥35

Below adjacent sound carrier 35 ≥30 dB

Adjacent picture carrier 50 ≥40

Up adjacent picture carrier 45 ≥30

9 IF rejection 55 ≥50 dB

10 Image rejection VHF 55 ≥50 dB

UHF 50 ≥45

11 AFT pull-in range M/N N/A N/A MHz

DK/I/BG ±1.5 ≥|±1.0|

12 Chroma sync pull-in range ±500 ≥|±200| Hz

13 Color killer function -25 ≤-16 dB

14 DC restoration 3 ≤10 %

15 Resolution Horizontal PAL/SECAM 320 ≥300

NTSC 270 ≥250

Vertical PAL/SECAM 410 ≥400 lines

NTSC 320 ≥300

16 Overscan Cross hatch signal 93 90~96 %

17 Linearity Horizontal 7 ≤10 %

Vertical 6 ≤8%

18 Pattern distortion 1.5 ≤3%

19 Picture position In all direction ±3 ≤|±6| mm

20 Raster rotation In all direction 4 ≤6mm

21 Convergence error 0.4 ≤0.6 %

22 White balance (8700°K) X 0.288 0.288±0.015

Y 0.298 0.298±0.015 /

23 Maximum full white At picture tube center 80 ≥60 cd/m

90 ≥80 cd/m

24 H sync pull-in range ±500 ≥|±200| Hz

25 V sync pull-in range 7 ≥6Hz

26 Anode voltage 29 ≤32.5 KV For 29” 34”

27.5 ≤30 KV For 25”

27 Audio frequence response ±3dB ref. to 1KHz 0.2~10 0.2~10 KHz

28 Audio output power 1KHz 10% THD 2x7.5 ≥2x7.5 W For 34”

50KHz DEV. (BG/I/DK) 2x5 ≥2x5 W For 25” 29”

25KHz DEV. (M/N)

2

For 29” 34”

2

For 25”

3

Page 4

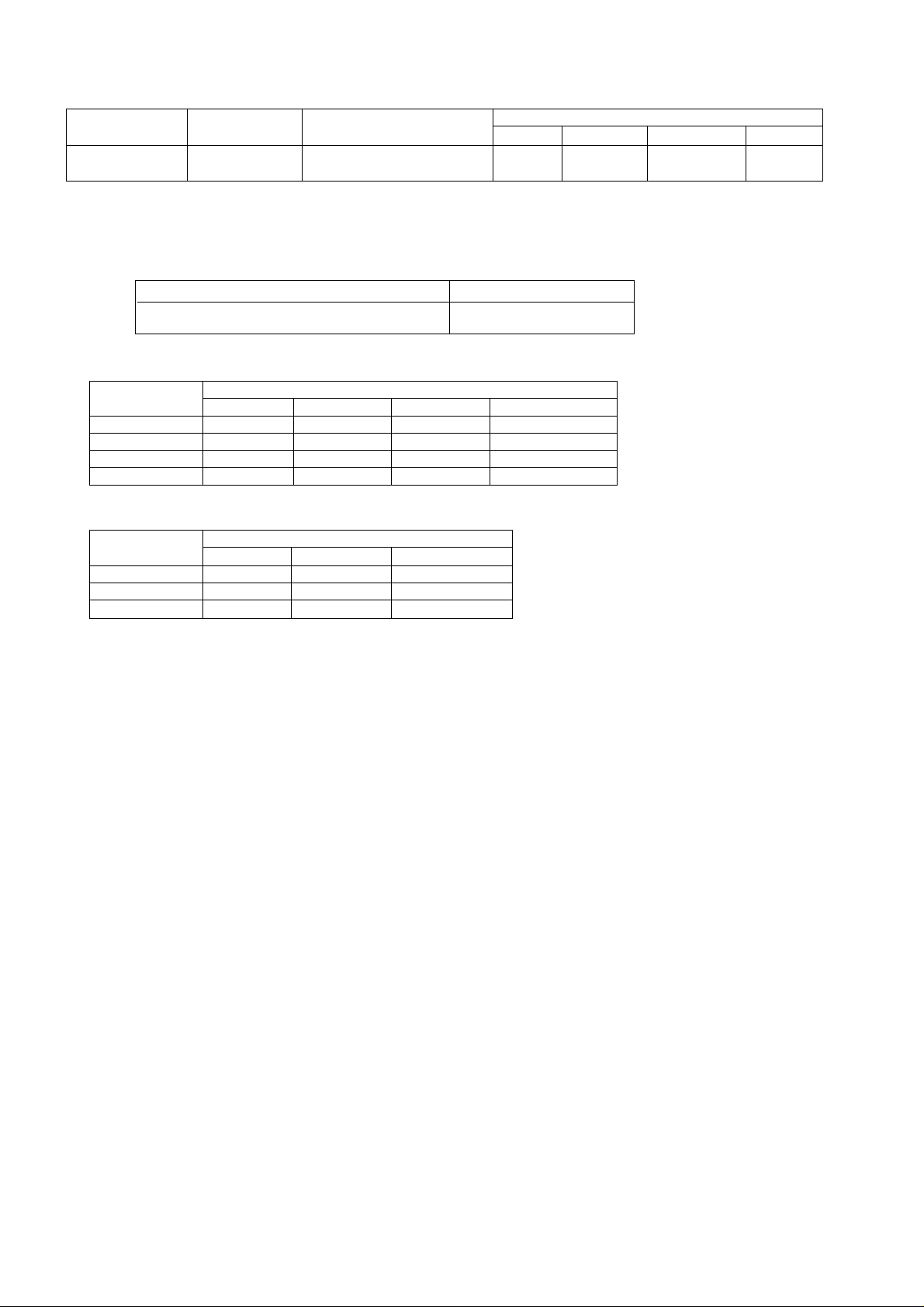

No. Items Instruction Typical Limit Unit

29 THD Po=0.5W 1KHz 1 ≤3%

30 Signal to buzz ratio 42 ≥40 dB

31 Minimum volume hum 6 ≤10 mVrms

32 Maximum woofer output power N/A N/A W

33 Woofer audio freqency response ±3dB ref. to 80Hz AV mode N/A N/A Hz

34 Bass control range 100Hz ref. to 1KHz AV mode N/A N/A dB

35 Treble control range 10KHz ref. to 1KHz AV mode N/A N/A dB

36 Balance Center N/A N/A

Max. N/A N/A dB

Min. N/A N/A

37 Volume control curve Kawa A /

38 Video input level 1.0 1±0.2 Vpp

39 Audio input level 0.5 0.5±0.3 Vrms

40 Video output level 1.0 1±0.2 Vpp

41 Audio output level 0.5 0.5±0.3 Vrms

42 Power consumpution Operating 180 ≤200 W For 34”

110 ≤150 W For 25”

120 ≤160 W For 29”

Stand by 10 ≤15 W

43 IR receiving distance ±30° 6 ≥4m

44 X-ray radiation <0.1 ≤0.5 mR/h

45 Dielectric strength AC 3KVrms 2 sec. 3 ≤5 mArms

Test Condition

1 Picture Modulation 87.5%

2 Sound Modulation 27KHz Dev. For DK/I/BG

15KHz Dev. For M/N

3 Picture to Sound Ration 10dB

4 Sound Artificial Load Resistor 8 ohm

5 Video signal White and black

(three white & two black)

6 Audio signal 1KHz sine wave 0.5Wrms

7 Conditions of the TV setting:screen

A. Switch TV on and let it warm up for more than 30 minutes.

B. Connect RMS volt meter to speaker terminals and adjust theTV volume to get 500mW RMS power at each terminal.

C. Place the MINOLTA CA-100 test probe to white part of the screen,adjust the contrast until a reading of 80cd/m

is obtained.

D. Place the MINOLTA CA-100 test probe to black part of the screen,adjust the brightness until a reading of 2cd/m

is obtained.

E. Repeat step C & D until the exact luminance values is obtained or the nearest possible values you can get.then

record the luminance values & R.G.B gun voltage values at the same time. and take the largest values for

measurement referenct.

F. Input standard color bar(100/0/75/0),then adjust the colour.until the waveforms at the blue gun of same level

is obtained.

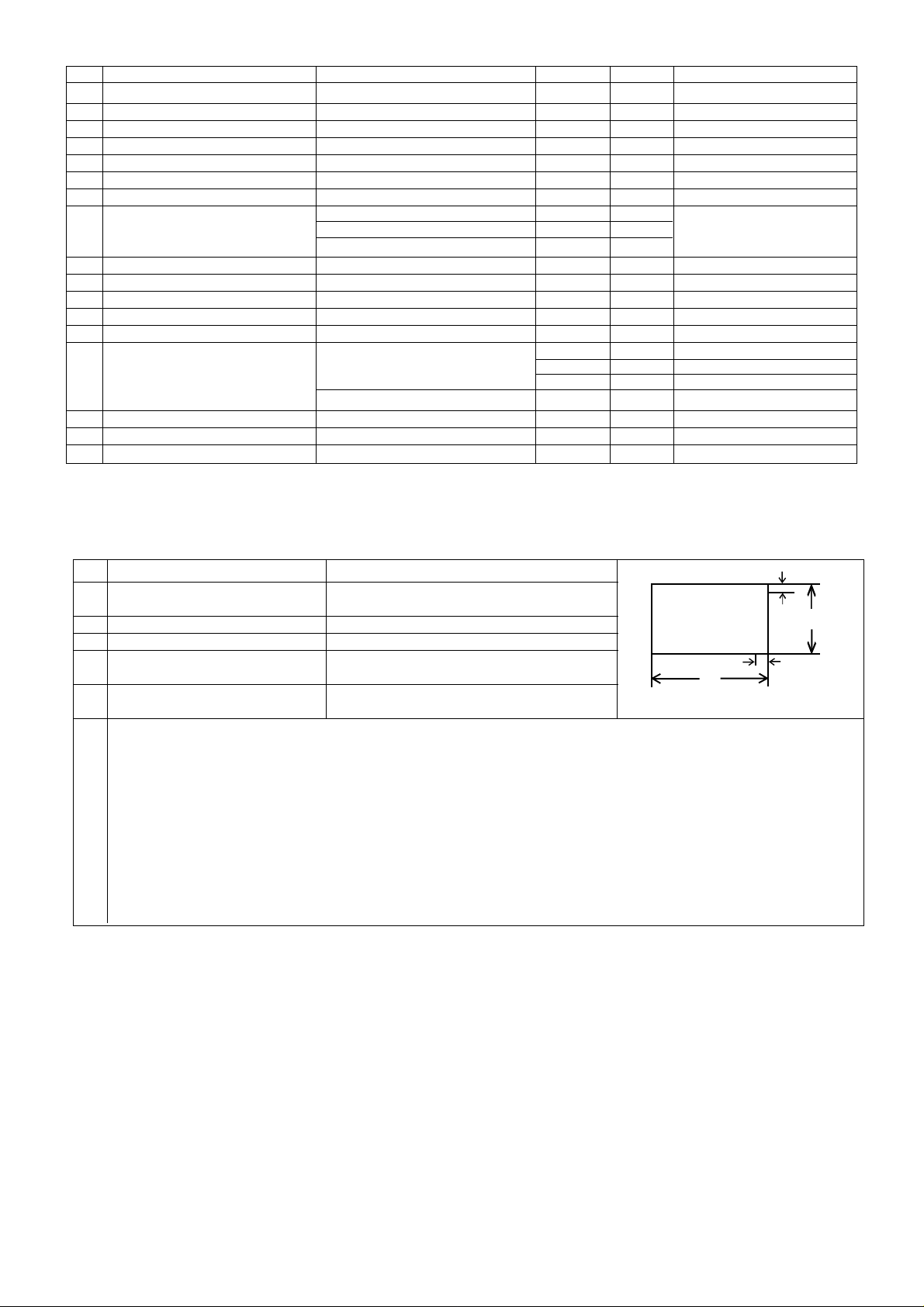

+P8 P5+

+P1

1/9H

+P4 P2++P0

+P7 P6+

+P3

H

1/9W

W

Convergence error test point on

2

2

4

Page 5

III. Level List of Equipments & Instruments Required for Production

No. Designation Requirement Reference Model Remark

1 Pattern Generator System of output signal: PHILIPS

RF out: PAL BG/SUB/DK/I, PM5518-TN

SECAM B/G/D/K, NTSC M PM5418-TN

Video out: NTSC 4.43/3.58 PAL 60Hz

2 Digital voltmeter Input Resistance 10M FLUKE 45

3 Withstanding Withstanding Voltage: KIKUSUI TOS 8650 Irresistible Voltage Measure

Voltage Tester AC 1.5KV, 5KV/0-5KV ± 3%

Cut-off current: AC 0-2mA,

20mA / continuously Adjustable

4 Insulation Tester Test voltage:1000V. 500V KIKUSUI TOS 7100L

5 Sine wave Signal Frequency Range: 0.1~140MHz LEADER 3216 For generating IF Signal

Generator ( Precision:10KHz )

Level Range: -20~126dB

6 Oscilloscope Frequency response: 20MHz or above

7 CRT Color MINOLTA CA-100 For White Balance Adjustment

Analyzer

8 DC Regulated Max output Voltage

Power Supply

9 Color Monitor AV receiving system: Should include Same model (of TV set) For operation check

all the AV output system of the as the products For resolution check

products at least. For Skew Check

10 Audio Signal Frequency of output signal: KENWOOD AG-203A For generating audio signal

Generator 20Hz-20kHz

14V Supply DC power

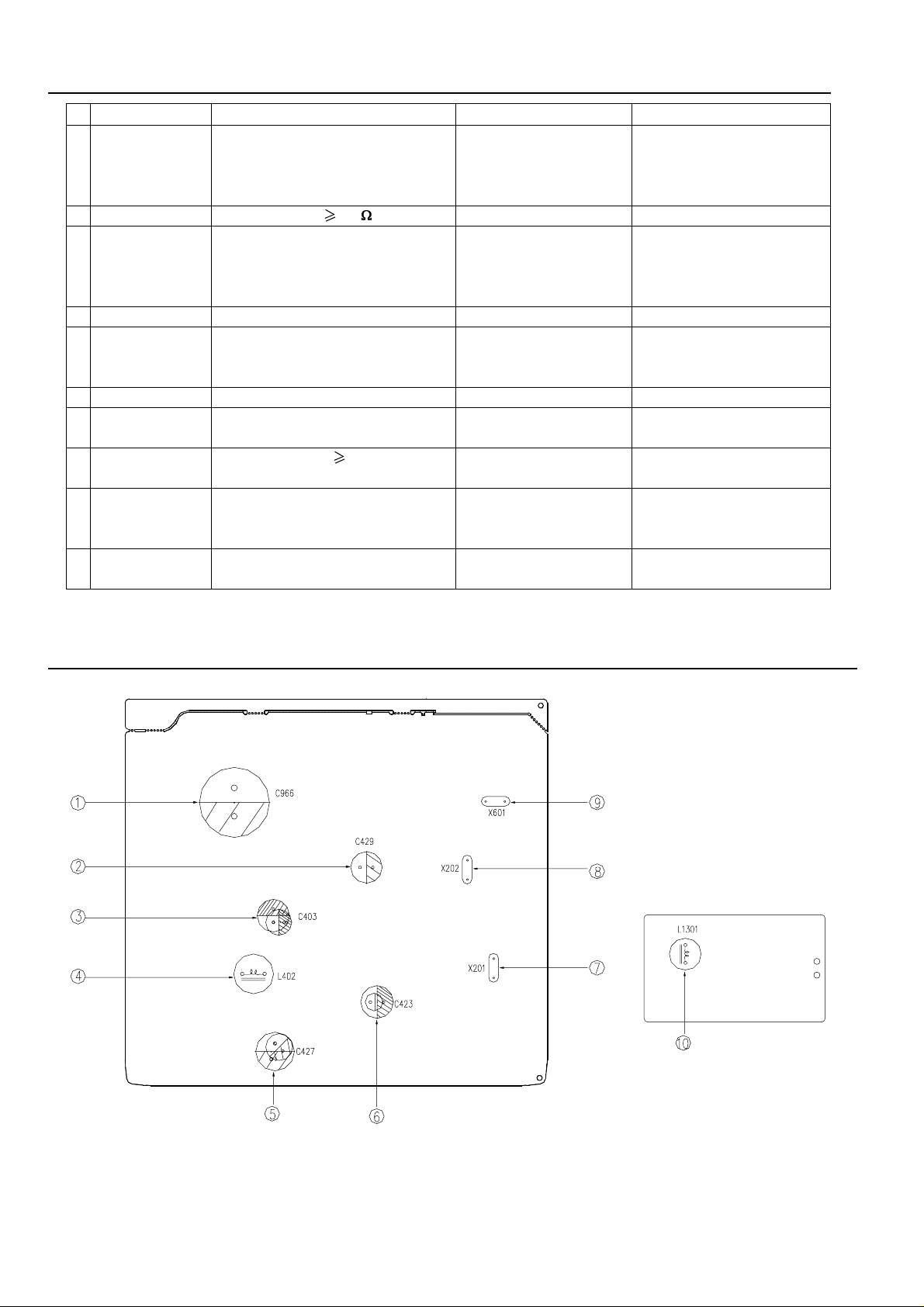

IV. Applying Adhesive on Main PCB

Note: The ref. No. from 1 to 10 should be applied one Diabond 1603HFR Ivony Adhesive for each.

5

Page 6

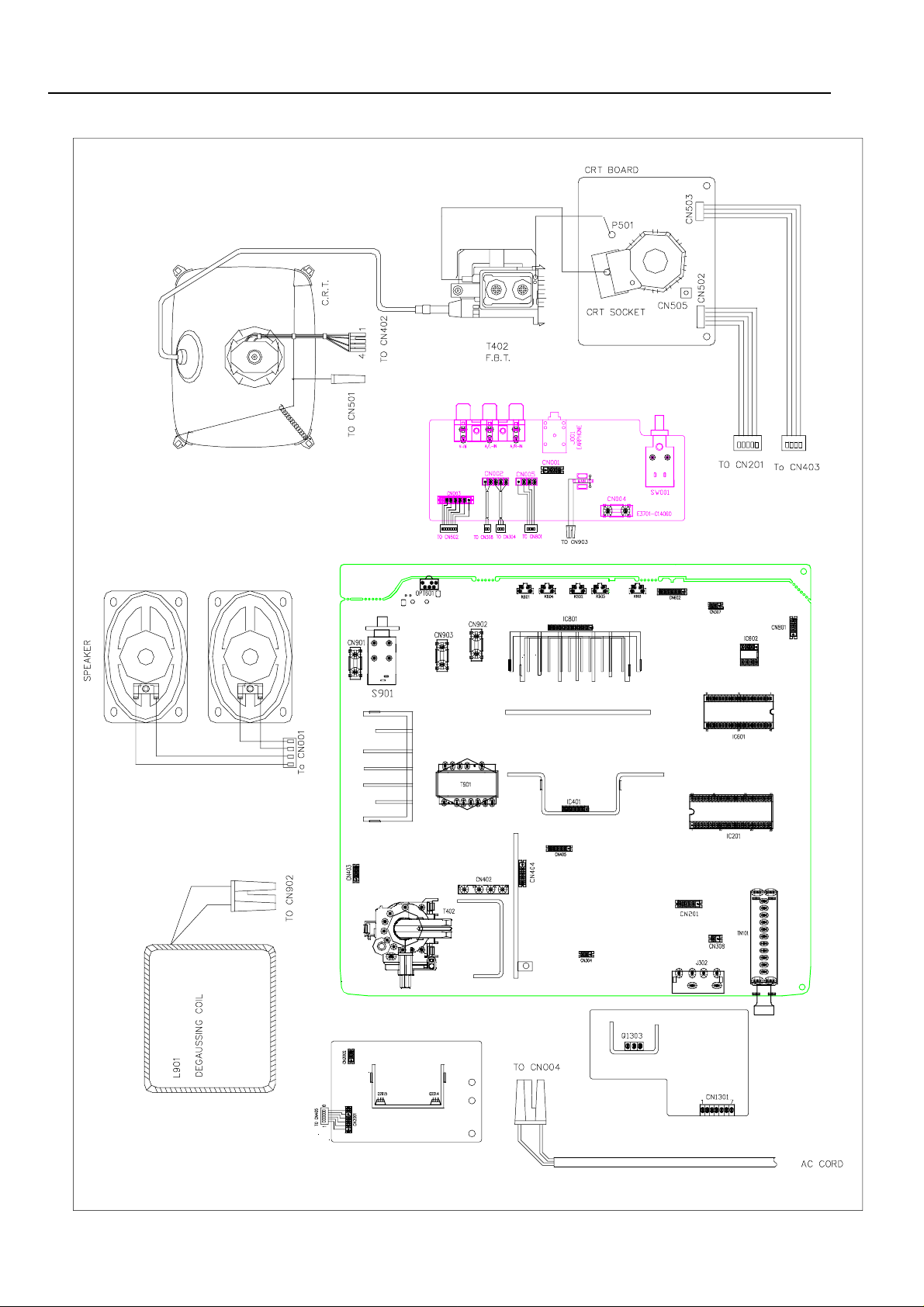

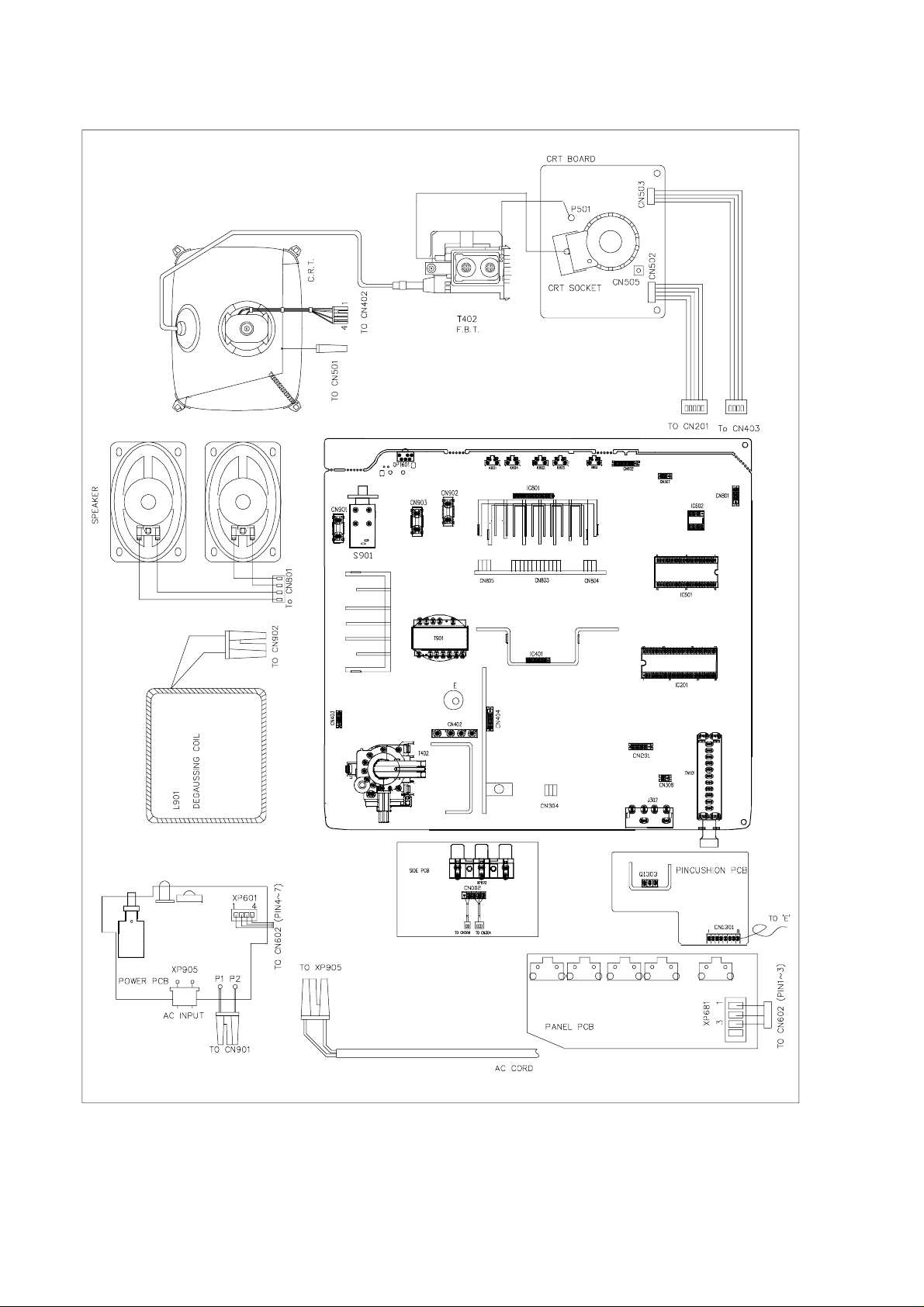

V. Wiring Diagram

A. For model 34E2ABN88

6

Page 7

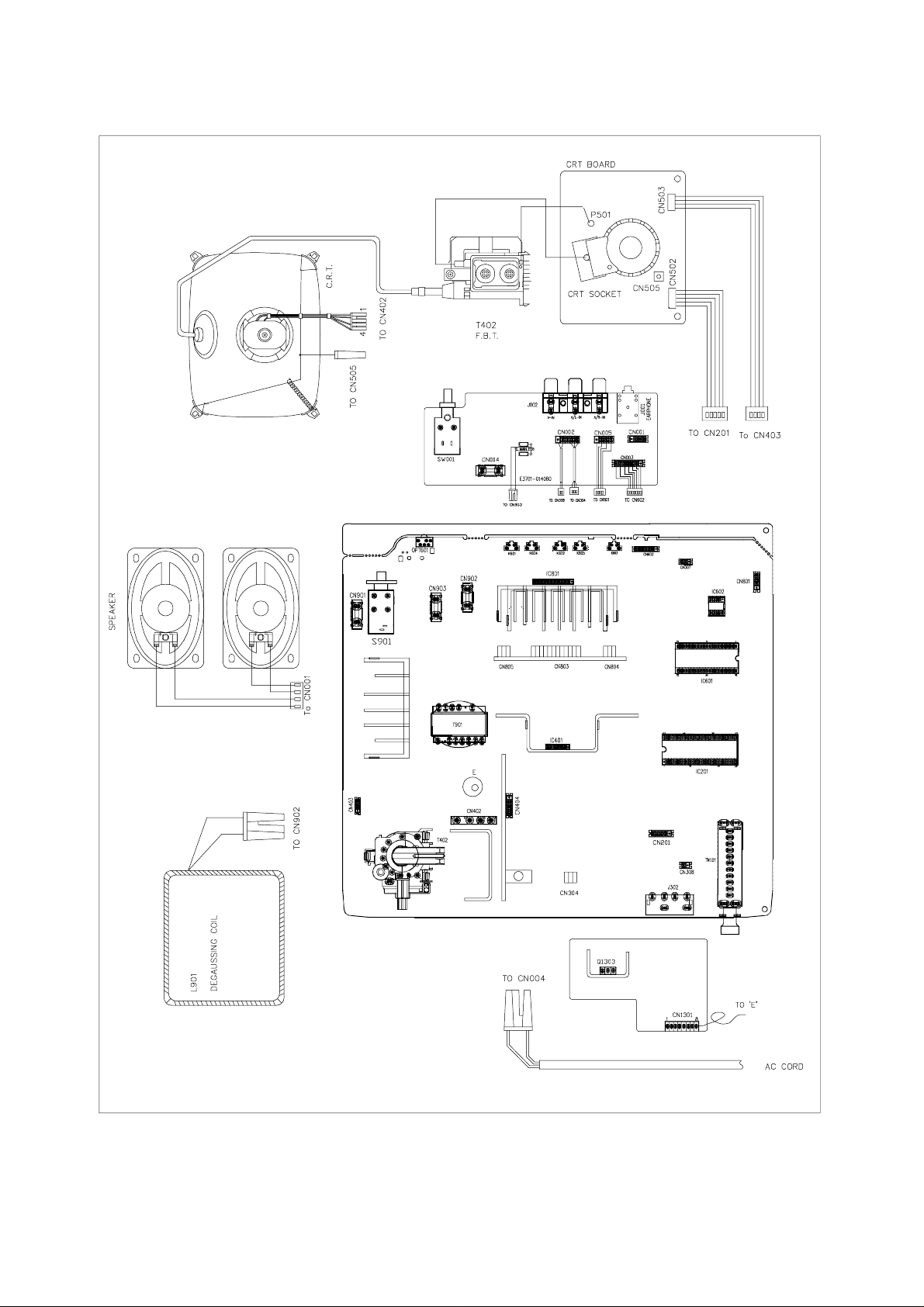

B. For models 25A9/29A9ABN88

7

Page 8

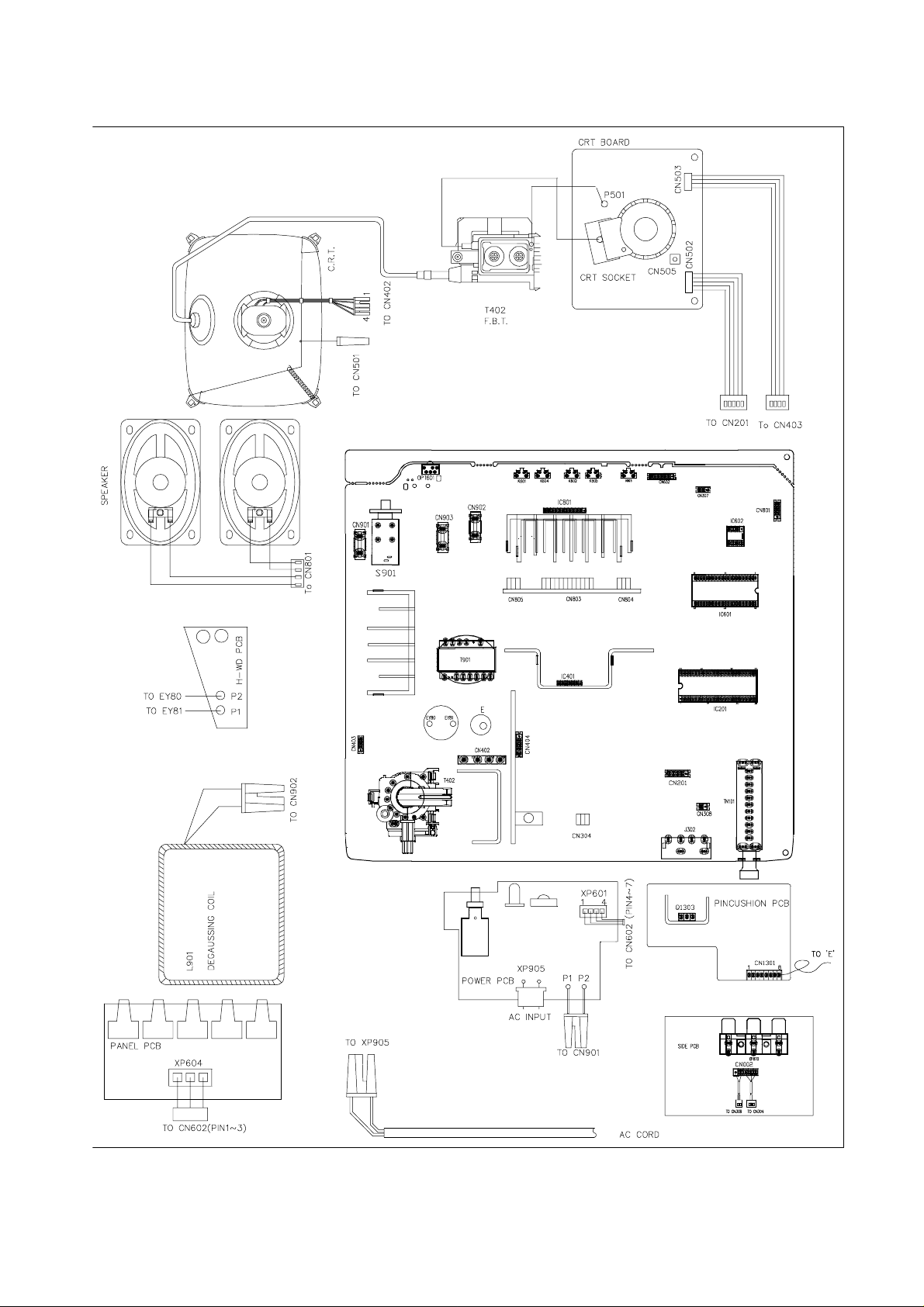

C. For model 25B8ABN88

8

Page 9

D. For model 29B8ABN88

9

Page 10

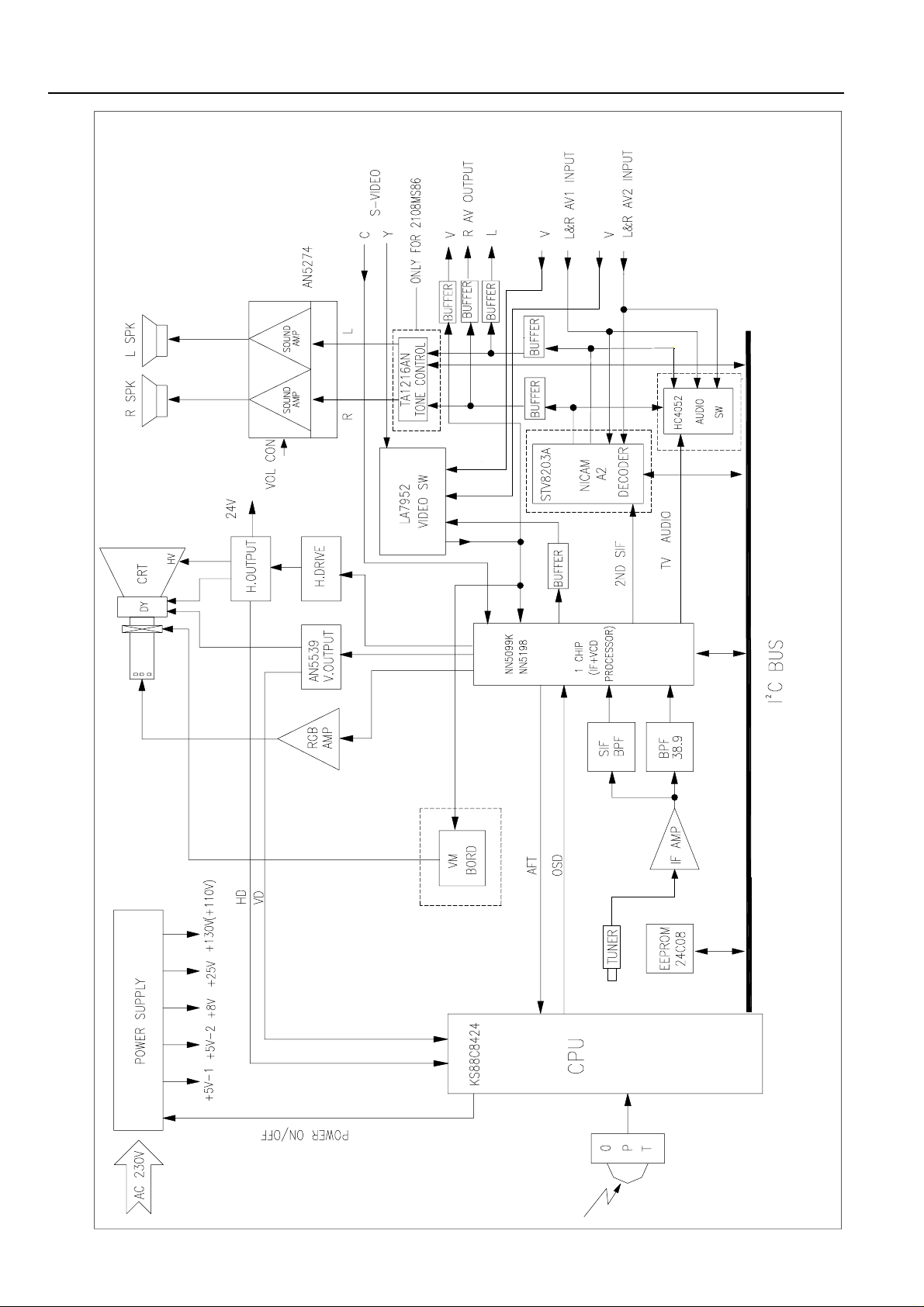

VI. Block Diagram

10

Page 11

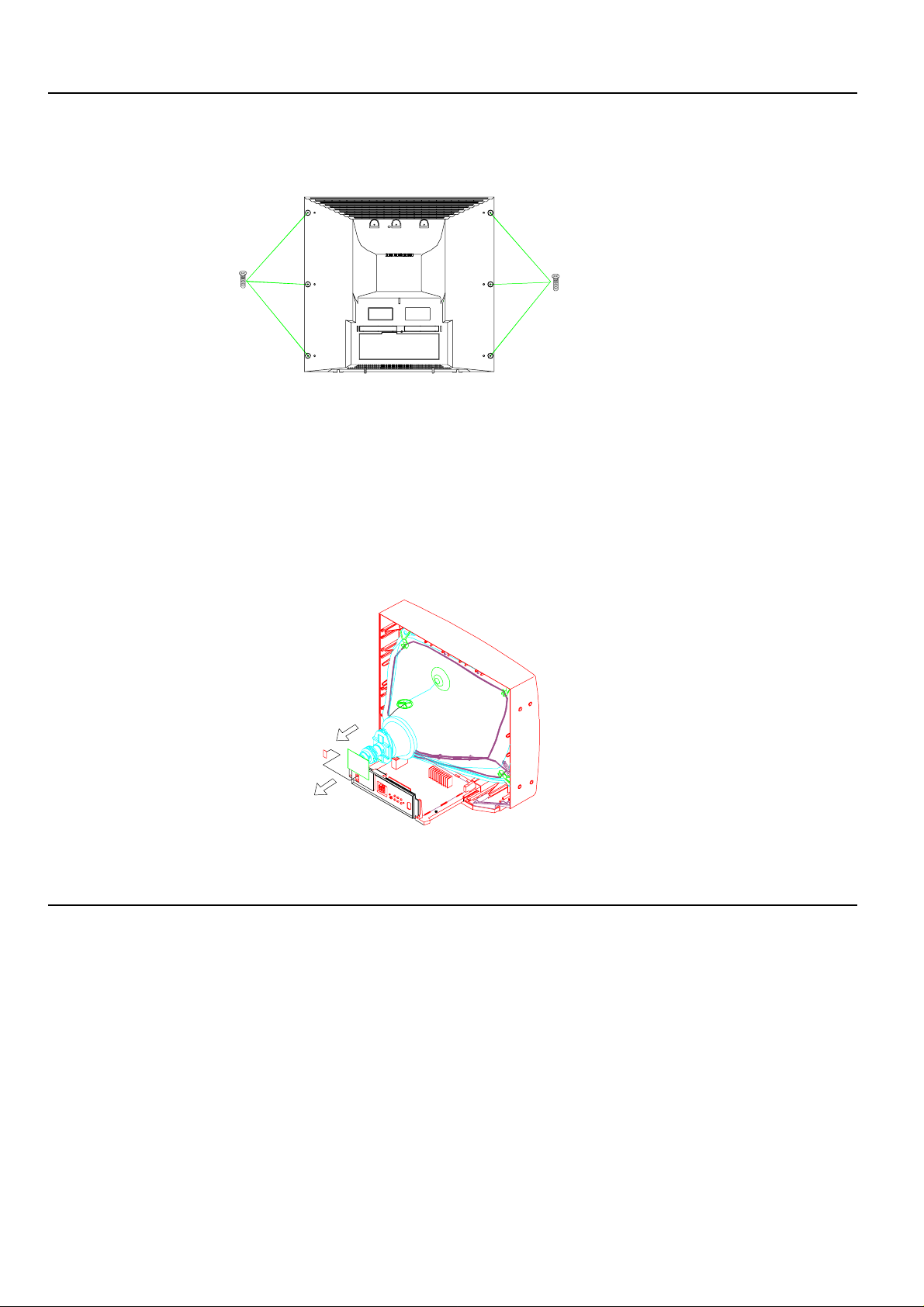

VII. Disassembly

In case of trouble, etc., necessitating disassemble, please disassemble in the order shown in the illustrations. Reassemble in the reverse order.

1. Removal of the Back Cover

2. Removal of the MAIN PCB

a. Remove the screws.

b. Slide out the TV chassis slightly; pull up the connector of AC cord from PCB; pull up the CRT PCB from

CRT.

c. Remove the anode cap from the picture tube. To avaid a shock hazard, be sure to discharge the picture

tube’s anode to the chassis ground before removal.

d. Take out the TV chassis.

VIII. Input Signals & Equipments List for Alignment

A. Equipments List

1. Pattern Generator 2. Digital Voltmeter 3. High Voltage Meter

4. Sine Wave Signal Generator 5. Demagnetizer 6. Personal Computer (486)

7. DC Regulated Power Supply 8. Oscilloscope 9. CRT Colour Analyzer

B. Input Signals

1. Philips Pattern 2. Color Bar 3. Cross Hatch

4. Grey Scale Bar 5. Monoscope Pattern 6. Moving Picture With Sound

11

Page 12

IX. E2PROM (IC602) Setting

A. Option Code

The option code listed below is for selection of different TV systems, features and functions, the code is preset in

factory, in case of changing the EEPROM, the option code will not be the same as before. In this case, it is

necessary to adjust the option code again. How to set the option code by hand is described in “method to enter

into SERVICE MENU and ADJUST MENU”. Please refer to “IV. Electrical Adjustment”.

Model Option code

25B8/29B8/34E2ABN88 7063123784

25A9/29A9ABN88 5063123784

The “option setup” is shown as following:

There are 5 bytes in EEPROM, and each of the bits stands for an option function, the option bits listed below:

OPTION SET

KWTVD OTHER XX-XX

PRODUCTION OFF

OPTION 0123456789

READ 5198 CNT: 11

BIT7 BIT6 BIT5 BIT4 BIT3 BIT2 BIT1 BIT0

BYTE1 OCHA OQSS OSVD OAV2 NU OCHIL OWOO OUHF

BYTE2 NU OSYS1 OSYS2 OSYS3 NU OTUN1 OTUN2 OTUN3

BYTE3 NU OBL OSND1 OSNDB N U OSNDI OSNDD OSNDM

BYTE4 NU NU OBB OTVO NU OCHIT OCHIS OENG

BYTE5 ODKSIF OMSIF OBGSIF OISIF SRS TONE NICAM TEXT

DIGIT 1:

1 OCHA 0 = 256 CHANNELS 1 = 101 CHANNELS

2 OQSS 0 = QSS OFF 1 = QSS ON

3/4 MODE OSVD OA V2

TV/AV 0 0

TV/AV1/AV2 0 1

TV/AV1/AV2/SVD 1 1

Digit 2:

5 NULL

6 OCHIL 0 = CHILD LOCK NOT AVAILABLE

1 = CHILD LOCK AVAILABLE

7 OWOO 0 = WOOFER NOT AVAILABLE

1 = WOOFER AVAILABLE

8 OUHF 0 = ALL BAND ( VL, VH, UHF )

1 = UHF ONLY

Digit 3:

9 NULL

10 OSYS1 0 = SINGLE COLOR SYSTEM (PAL) AVAILABLE

1 = MULTI COLOR SYSTEM(AUTO/PAL)AVAILABLE

11 OSYS2 0 = MULTI SYSTEM SECAM NOT AVAILABLE (TV & AV)

1 = MULTI SYSTEM SECAM AVAILABLE (TV & AV)

12 OSYS3 0 = MULTI SYSTEM NTSC NOT AVAILABLE (TV)

1 = MULTI SYSTEM NTSC AVAILABLE (TV)

Digit 4:

13 NULL

14/15/16 TUNER IF SETUP OTUN1 OTUN2 OTUN3

34.47 MHz 0 0 0

36.875 MHz 0 0 1

38 MHz 0 1 0

38.9 MHz 0 1 1

39.5 MHz 1 0 0

45.75 MHz 1 0 1

Digit 5

17 NULL

18 OBL 0 = BILINGUAL (MAIN/SUB) NOT AVAILABLE

1 = BILINGUAL (MAIN/SUB) AVAILABLE

19 OSND1 0 = MULTI SIF SYSTEM AVAILABLE

1 = SINGLE SIF SYSTEM AVAILABLE

— THIS OPTION IS NOT COUNT BILINGUAL

12

Page 13

20 OSNDB 0 = SIF [BG] NOT AVAILABLE

1 = SIF [BG] AVAILABLE

Digit 6:

21 NULL

22 OSNDI 0 = SIF [I] NOT AVAILABLE

1 = SIF [I] AVAILABLE

23 OSNDD 0 = SIF [DK] NOT AVAILABLE

1 = SIF [DK] AVAILABLE

24 OSNDM 0 = SIF [M] NOT AVAILABLE

1 = SIF [M] AVAILABLE

Digit 7:

25 NULL

26 NULL

27 OBB 0 = BLUE BACK NOT AVAILABLE

1 = BLUE BACK AVAILABLE

28 OTVO 0 = SCART MONITOR OUTPUT

1 = SCART TV OUTPUT

Digit 8:

29 NUL

30 OCHIT 0 = RUSSIA OSD NOT AVAILABLE

1 = RUSSIA OSD AVAILABLE

31 OCHIS 0 = SIMPLE CHINESE (CHINA) OSD NOT AVAILABLE

1 = SIMPLE CHINESE (CHINA) OSD AVAILABLE

32 OENG 0 = ENGLISH OSD NOT AVAILABLE

1 = ENGLISH OSD AVAILABLE

Digit 9:

33 ODKSIF 0 = DK SIF INTERNAL

1 = DK SIF EXTERNAL

34 OMSIF 0 = M SIF INTERNAL

1 = M SIF EXTERNAL

35 OBGSIF 0 = B G SIF INTERNAL

1 = BG SIF EXTERNAL

36 OISIF 0 = I SIF INTERNAL

1 = I SIF EXTERNAL

Digit 10:

37 SRS 0 = SRS NOT AVAILABLE

1 = SRS AVAILABLE

38 TONE 0 = TONE NOT AVAILABLE

1 = TONE AVAILABLE

39 NICAM 0 = NICAM NOT AVAILABLE

1 = NICAM AVAILABLE

40 TEXT 0 = TELETEXT NOT AVAILABLE

1 = TELETEXT AVAILABLE

B. Data Setting

The data setting item B~D is the initialization data preset in the EEPROM before adjustment in case of

changing the EEPROM, please set the data to initialization data listed below before adjustment. How to set

the data by hand is described in “method to enter into SERVICE MENU and ADJUST MENU”. Please refer

to “IV. Electrical Adjustment”.

Parameter Value(DEC) Remark Parameter Value(DEC) Remark

SUB BRI 63 HOR.POS60 13

CUTOFF R 63 VER.POS60 0

CUTOFF G 63 VER.H60 81

CUTOFF B 63 VER.LIN60 40 Remark1

DRIVE R 63 VER.S C60 20 Remark1

DRIVE B 63 SUBTINT 16

AFT ADJ 55 AV S TINT 16

RFAGCDP 45 C-Y 1 Remark4

SECAM BL 0 HOR.VCO 52

RGB LIMIT 0 VIF.VCO 26

HOR.POS 18 ISUD5 0 Remark2

VER.POS 0 Remark3 ISUD4 1

VER.HEI 84 ISUD3 1

VER.LIN 40 Remark1 CONTR 32 0

VER.S CUR 20 Remark1 SWMODE 0,1 Remark5

13

Page 14

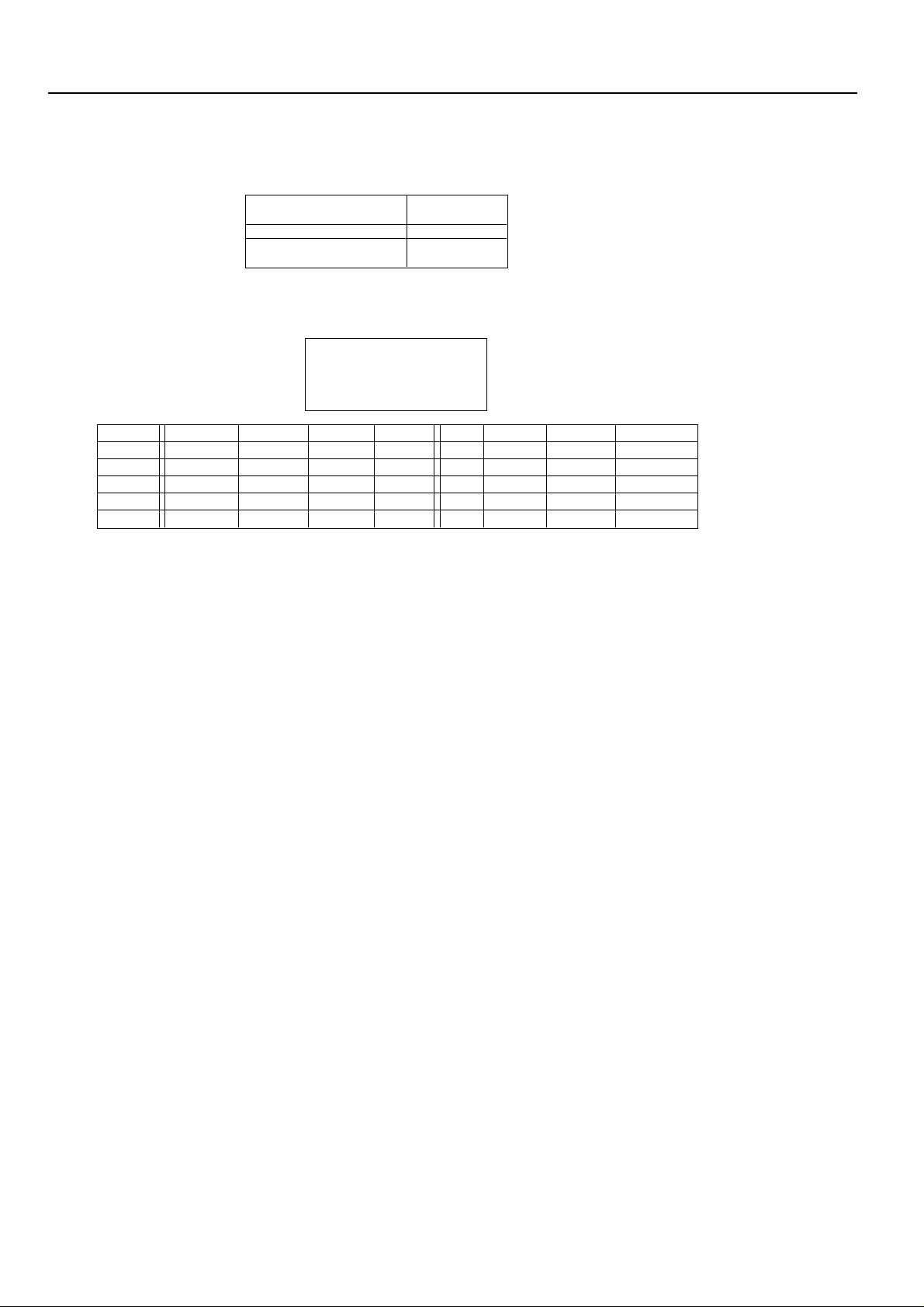

Remark1: For different CRT, the following data are recommended to change for better performance before

alignment. These Data Settings are listed as following:

CRT CRT Type No. Value

VER.LIN VER.SCUR VER.LIN60 VER.SC60

34” E6101-082005 A80LJF60X10(C) N1 40 22 40 22

SEG

Remark2: ISUD5 must set to “0”. Please check ISUD5 after read 5198. If ISUD5 is “1”, please set to “0”.

Remark3: PAL or NTSC VER.POS only can select 0 or 1.

Remark4: C-Y:0 For MS models(using NN5198K) C-Y:1 For other models(using NN5199K or NN5099K)

Remark5:

MODEL SWMODE

25A9/29A9/25B8/29B8/34E2ABN88 0

C. Intelligent picture control (I.P.C) DATA SETTING

Control Value

Natural Sharp Cinema Personal

Brightness 16 24 12 16

Contrast 24 32 16 24

Colour 16 20 16 16

Sharpness 16 24 16 16

D. AFT Data Setting

Description Value

VHFL VHFH UHF

Low 120 56 35

Middle 97 40 31

High 131 76 60

Remark: This table of AFT DATA setting is only for:

SAMSUNG tuner: TECC0949VG28B, TECC7949VG28B and WITTIS tuner: UVS1051-CW1/UVS1051-NEW.

14

Page 15

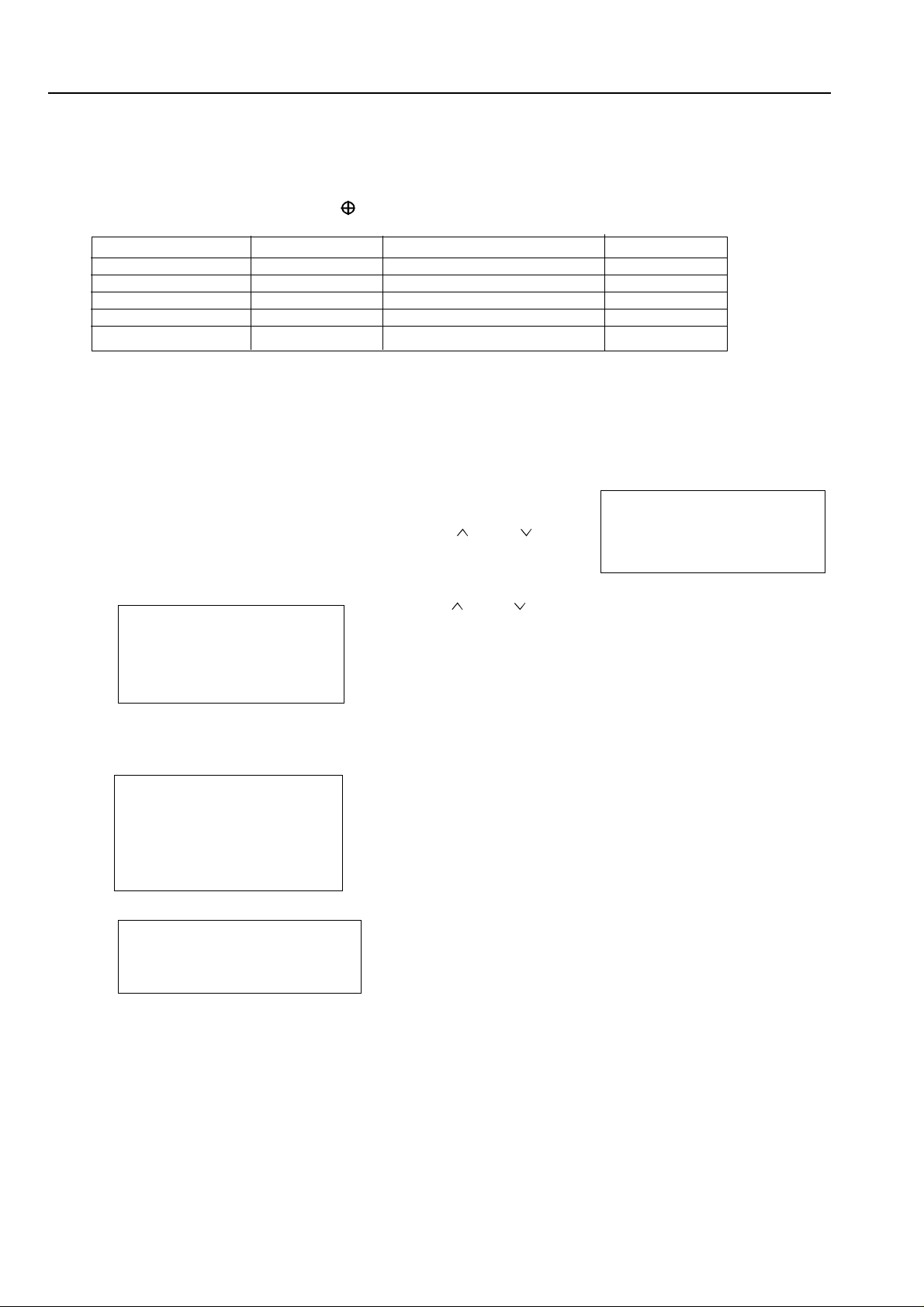

X. Electrical Adjustment

A. Chassis Adjustment

i. +B Voltage Alignment

a. Preparation Procedure

1).Receive standard colour bar signal.

2).Press key "I.P.C." to select “Natural” mode.

3).Connect digital voltmeter between

4).+B voltage.

Model CRT CRT Type No. +B

34E2ABN88 E6101-082005 A80LJF60X10(C) N1 132V

25A9ABN88 E6101-059006 A59KYL220X08B USA LG 130V

29A9ABN88 E6101-114001 A68KYN690X55M N1 LG 135V

25B8ABN88 E6120-008001 A59QDC257X030 N1 LG 135V

29B8ABN88 E6120-006001 A68QCU259X530 N1 130V

Note: Please refer to the CRT conversion table for other CRT.

b. Adjustment Step

Adjust VR901 (or VR902) to make the read-out on the Voltmeter to be +B±0.3V.

ii. Method to enter into SERVICE MENU and ADJUST MENU

a. Turn on the Main Power Switch, then press volume buttons both "+" and "-" simultaneously for over 5 seconds,

the "KWTVxx SERVICE" will be displayed on the screen.Press “MENU” key (on the unit or the remote control)

to select “SERVICE” , “AFT-SET” , “IPC SET” or “OTHER” MENU.

b. The “KWTVxx SERVICE” menu is indicated with each item on the

screen. The item can be selected by pressing channel “

keys.Press volume “+” and “-” keys to change the parameter value.

c. AFT-Step

Selecting “AFT-SET” to set AFT DATA, on-screen display will be shown as:

KWTVxx AFT-STEP x-xx

Band VHFL

Low 120

Middle 97

High 131

of C403 and GND.

KWTVxx SERVICE x-xx

” and “ ”

AFT 80 HVCO 59

AGC 50 TINT 16

IFVCO 40 AVTINT 16

Use channel “ ” and “ ” keys to select the parameter, the

parameter value can be changed by pressing volume “+” and “-”

keys. See “AFT data setting”. Press “MENU” key to exit.

d. IPC

Press “MENU” key to selecting “IPC-SET” to set picture mode data, the picture mode data is indicated with

each parameter on the screen. On-screen display will be shown as:

KWTVxx IPC-SET x-xx

MODE Personal

Bright 16

Contrast 16

Colour 16

Sharp 16

Press volume “+” and ”-” keys to select picture mode, then select

the parameter and change the parameter value. When all picture

mode data is being set, press “MENU” key to exit.

e. Press “MENU” key,select “Other”,on-screen display will be shown as following:

KWTVxx OTHER x-xx

Production on

Option xxxxxxxxxx

Read 5198 CNT: x

1). Production

The function of ”Production” is for production aging purpose. When no RF signal input and if it is set

to “on”, the TV set will not be blue back and standby shortly. When the TV set is finished, it must be

set to “off”. If it is set to “on”, a character “P” will appear on the top of the screen when changing

channel, this means that it is set for production purpose. By pressing the volume “+” and “-” keys,

“Production” can be set to “off” or “on”. By pressing the “MENU” ,it will exit the “OTHER” menu.

2) Option

Selecting “Option”, input the option code by number keys on the remote handset according to the

“Option code”.Then pess “MENU” to store. After changing “OPTION”, the TV set must be set to

standby and power on again, then enter into “SERVICE MENU”.

15

Page 16

3) Selecting “Read 5198”, press “MENU” key to read IC NN5099K/NN5198K DATA in order to operate the

TV set. Press “standby” key to exit.

Note: 1. Many standard data are already pre-set in the EEPROM inside IC NN5198K or NN5099K by the

IC manufacturer. During manufacturing the TV set, it is necessary to read those data stored in

EEPROM of IC NN5198K or NN5099K and memorize it in external EEPROM. By doing so,

some alignment can be omitted, or the data memorized in the external EEPROM can be changed

according to the situation. Please note that according to the specification, the operation of

“reading” data from the EEPROM inside NN5198K or NN5099K only can be done 1000 times.

When changing IC201 (NN5198K or NN5099K)/IC602 (EEPROM) or before adjusting, it isnecessary

to read NN5198K or 5099K data one time.

2. “CNT:X” means number of times that the data stored in the EEPROM of NN5198K or NN5099K

has been read. For example, CNT:19, it means the data stored in the EEPROM of NN5198K or

NN5099K has been read 19 times.

iii. Adjustment of T101(31.9MHz trap) and AFC

A. Adjustment for T101(31.9MHz trap) (for using T101 models)

1. Turn on the main power switch.

2. Apply 100dBµv 31.9MHz signal between IF input pin and GND of the TUNER on main PC board.

3. Put the probe of oscilloscope to SA102 pin1 and GND.

4. Adjust T101 until the waveform in oscilloscope to minimum.

B. Adjustment of AFC

a. Preparation procedure

1) Turn on the main power switch.

2) Set digital voltmeter at DC, then connect it’s probe across of R603 and GND.

3) Apply 100dBµV IF signal between IF input pin and GND of the TUNER on main PC board (see Fig.1).

(Fig.1)

b. Adjustment Step

Enter SERVICE MENU, adjust the “AFT ADJ” DATA until the meter indicates 2.4±0.1V.

c. AFC Check.

After adjustment, it is necessary to confirm the DC voltage across R603 when Changing the RF output

frequency of pattern generator (PM5518) by ±o.1MHz, the DC voltage shoud be as following:

RF FREQUENCY DC VOLTMETER INDICATION

IF+0.1MHz 1.2±0.5V

IF-0.1MHz 3.3±0.5V

Remark: IF=38.9MHz

If the result is not satisfactory, repeat adjustment step "b. Adjustment Step" until correct voltage is obtained.

d. Press “standby” key to exit.

iv. Adjustment for H position and V position, V-height and V linearity.

a. Receive

pattern signal (PAL).

b. Enter SERVICE MENU.

1) Adjust value of HOR.POS to get a good H position picture.

2) Adjust value of VER.HEI to get a normal picture.

3) Adjust value of VER.POS to get a good V position picture.

4) Normal VER.LIN and VER.S CUR doesn’t need adjustment. If V linearity is not good, please adjust

value of VER.LIN and VER.S CUR to get a good V linearity picture.

c. Receive

pattern signal (NTSC).

16

Page 17

d. Enter SERVICE MENU

1) Adjust value of HOR.POS60 to get a good H position picture.

2) Adjust value of VER.H60 to get a normal picture.

3) Adjust value of VER.POS60 to get a good V position picture.

4) Normal VER.LIN60 and VER.SC60 doesn’t need adjustment. If V linearity is not good, please adjust

value of VER.LIN60 and VER.SC60 to get a good V linearity picture.

e. press “standby” key to exit.

v. Adjustment for TV TINT (TV picture) and AV TINT (AV picture)

(Steps a~d are only for models with NTSC-M SYSTEM)

a. Receive a NTSC color bar pattern signal from RF.

b. Press key “I.P.C.” to set contrast, Brightness, Color and Tint at normal position.

c. Put the probe of Oscilloscope to “B-out” terminal of IC201 PIN 12.

d. Enter SERVICE MEMU

Adjust value of SUBTINT and notice the waveform change until the waveform is shown as below:

e. Receive a NTSC color bar Signal from AV.

f. Enter SERVICE MENU

Adjust the value of AV S TINT until the waveform of Oscilloscope is shown as above.

vi. Adjustment for SECAM BL(only for models with SECAM SYSTEM)

a. Receive a SECAM dot pattern signal from RF.

b. Press key “I.P.C” to select “NATURAL” status.

c. Put the probe of Oscilloscope to “B-out” terminal of IC201 Pin12 and GND.

(Probe: 10:1, Oscilloscope VOLTS/DIV: 20mv/DIV)

d. Enter ADJUST MENU.

Adjust value of SECAM BL until

vii. Adjustment for RF AGC

a. Receive RF signal (62±3dBµV).

b. Enter into SERVICE MENU.

c. Pressing channel “

d. Press volume "+" or "-" on the remote handset to change the value of RFAGCDP until snow noise on

the screen just disappears.

e. press “STANDBY” key to exit.

viii. Adjustment for Sub-brightness

a. Receive MONOSCOPE pattern.

b. Press key “I.P.C” on the remote handset to set Brightness and Contrast at natural state.

c. Enter into SERVICE MENU.

d. Pressing channel “

e. Press volume “+” or “-” on the remote handset to change the value of

SUB BRI until eight and half of portions indicated in Fig.3 is just visible.

f. press “STANDBY” key to exit.

” and “ ” keys on the remote handset and on-screen display will be shown as following:

RFAGCDP XX

” and “ ” on the remote handset, the display on screen will be:

SUB BRI XX

V is smallest.

V

Just visible

(Fig.3)

17

Page 18

ix. Pincushion Correction (For using pincushion bord models)

a. Receive crosshatch pattern. (croix centrale pattern).

b. Adjust keystone correction control VR1303 to obtain symmetrical

pattern about horizontal center as shown in Fig.4a.

c. Adjust pillow correction control VR1301 to obtain vertical straight

lines on screen as shown in Fig.4b.

d. Adjust horizontal width control VR1302 to desired picture width.

e. Adjust top correction control VR1304 to obtain proper top picture

on the screen.

f. Control contrast brightness from mini to maxi, check the picture

of pattern, repeat step 3-5 until a desired picture is obtained.

x. Adjustment for FOCUS (See Fig.5)

a. Press key "I.P.C." on the remote handset to set Brightness and

Contrast both at normal position.

b. Adjust knob "FOCUS" on FBT to make the picture on the screen

to be the most distinct.

xi. Adjustment with computer.

INTRODUCTION

"UBM" is an adjustment program for colour TV set which use NN5099K/NN5198K as the chroma processing

IC.This program can change the TV set data of different function though IIC interface and provides Auto

Adjustment of the White-Balance by using the Colour Analyzer (MINOLTA CA-100).

SET UP

1. The computer must be installed with the software program named UBM.

2. Power on the TV set and the computer.

3. Connect the computer and connect the adjustment cable from the computer to the TV chassis at

location CN601 as following:

(Fig.4a) (Fig.4b)

(Fig.5)

4. C:\ cd UBM ENTER

5. C:\ cd UBM >UBM ENTER

The screen will display:

ZHONG SHAN KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTER

AUTO ADJUSTMENT FOR COLOUR TV SET (VERSION V1.00 FOR )

CPU Program Name:

UBM UBMT

Your Computer is: PC/AT 80386 33MHz

If Information of Your Computer not Right, Please Run SELF TEST.

↑

Use , Key to Select Options, Enter to Confirm or Esc to Quit.

↑

18

Page 19

6. Use keys in the computer to select the software program named UBM, then press “enter” key in

the computer. The screen will display:

ZHONG SHAN KAWA ELECTRONIC RESEARCH & DEVELOPMENT CENTER

↑

↑

(A) WB AUTO ADJUST

(B) SETUP EEPROM

(C) READ EEPROM

(D) PC SELF TEST

(E) WB PARMS SETUP

Your Computer is: PC/AT 80386 33MHz

If Information of Your Computer not Right, Please Run SELF TEST.

↑

↑

This is the main menu for adjustment and the different data can be changed and viewed.

It consists of following functions.

(A) WB AUTO ADJUST (B) SETUP EEPROM (C) READ EEPROM

(D) PC SELF TEST (E) WB PARMS SETUP (F) EXIT TO DOS

(A). WB AUTO ADJUST

Before enter to WB AUTO ADJUST, make sure the WB PARMS SETUP (E) is fulfil your adjustment

requirement.

Procedure:

1) Check WB setup and to define standard and tolerance.

2) Connect the colour Analyzer (Minolta CA-100) to the computer (COM 1).

3) Turn on the TV set and receive the White-Grey signal.

4) Connect the adjustment cable to the TV at location CN601.

5) Press Space Bar, the computer will display "Please adjust screen Voltage,

space Bar to continue".Now change to TV service mode and adjust the

screen voltage until ahorizontal line is just visible on the screen, then back

to normal mode by pressing “Space” bar in the computer.

6) Put the colour probe 1 to the low luminance side and colour probe 2 to the high

luminance side of the screen. (It is better to place near the center of the screen.)

7) Press Space Bar to start WB adjustment.

P1 P2

Automatic White Balance Adjustment for UBM

Parameter: COM1: 9600, E, 7, 2 / PAL / Probe1 = Low, Probe2 = High

++

LOW

STD TEST STD TEST

x = 288 x = x = 288 x =

y = 298 y = y = 298 y =

Y = 7.5 Y = Y = 160 Y =

Press Space Bar to Continue

HIGH

19

Page 20

If the WB adjustment is success, the computer will display "Finished to adjust white Balance and show all

value and adjustment time used. Then the user must put off the adjustment cable from the TV IIC interface

now. Then repeat from the step 3 for another TV set adjustment.

If the adjustment cannot be finished within your presetted time limit, the computer will display "Sorry,

adjustment stopped!" and the adjustment is failed. It is better to call technician to check the TV hardware

if the adjustment failed several times.

(B). SETUP EEPROM

The function: "SETUP EEPROM" is used for writing a date file to the TV set's EEPROM.

Before to do this process, it is needed to read the date file from a TV set first, otherwise the computer

will display the warning message and back to main menu.

Channel File not Found!

Press enter to Continue.

If you already have had Previous EEPROM file, the program will ask for select:

a) (24C02) b) UBM/UBMT (24C04) c) (24C08)

After EEPROM SIZE selection, it will list the data files which are the same size as the user select, the

user now need to select one of the files, and press «Enter» to confirm writing the data to TV set's EEPROM.

* Remark: "SETUP EEPROM" will overwrite all the data in EEPROM. Please make a data backup before

to do this process.

Colour TV Channel Parameter Setup

Search: ST24C0X DATA FILE

Please Select What Kinds of EEPROM You Want to Setup

(24C02)

UBM/UBMT (24C04)

(24C08)

INFORMATION

There are 1 kind in the disk only, so you have not choice to select another. If it

is what you need, please press Enter, start to send DATA to EEPROM.

Otherwise, please press ESC to quit, run READ EEPROM and get new channel

DATA from good color TV.

Use Enter to Confirm, Esc to Quit, to Select

↑

↑

(C). READ EEPROM

The function "READ EEPROM" is to read full data from a TV set's EEPROM. First the user must check

the TV's EEPROM number for select a) 24C02, b) 24C04 or c) 24C08. Then the program will ask for

confirmation to read. After that, it will show the values of EEPROM, the user can save it by pressing

«Enter» and enter the model name.

20

Page 21

Colour TV Channel Parameter Gather

---------- NOTE ----------

This part is used to gather parameter of Colour TV channel.

The Colour TV you use must have been adjusted by technician and passed by EQ. Make sure

the EEPROM in your Colour TV is 24C02 (BSAV02 W/O Name), 24C04 (UBM) or 24C08

(UBM KWTVA). Please use to select one and press Enter to Start or press Esc to Quit.

↑

↑

24C02

24C04 (UBM/UBMT)

24C08 (UBM KWTVA)

Use Enter to Confirm, Esc to Quit, to Select

↑

↑

(D). PC SELF TEST

The user are allowed to run the PC SELF TEST by selecting this option and press «Enter». The computer

will show the system details such as Processor Name, CPU Speed of your computer.

Further more, the user can adjust the high level and low level period length of data transfer.

Computer and Output Test

Test Finished, Now Create Report

Your Computer is :

computer Name : IBM PC/AT

Main Processor : Intel 80486

CPU Speed : 332MHz

User Parameters Setup

SCL/SDA Pulse Width: 91 (4.7µS = 91)

IIC BUS Write Delay: 51 (1.5µS = 38)

IIC BUS Connected With: LPT1 (Total 1 port)

CA-100 Connected With: COM1 (Total 2 ports)

Serial Port Buad Rate: 9600 (Total 5 kinds)

<Buad Rate = 19200, 9600, 4800, 2400, 1200>

Use Enter to Confirm or Esc to Quit

(E). WB PARMS SETUP

The function of "WB PARMS SETUP" is to preset a group of data which for the “(A) WB AUTO ADJUST"

Chrominance and Luminance Standard and Tolerance.

21

Page 22

First the computer ask for select WB configuration file, then the user can set the WB data:

a) x = x coordinate of colour

b) y = y coordinate of colour

c) Y = luminance

d) X = Acceptable tolerance of x

e)

f)

g)

Y = Acceptable tolerance of y

Y = Acceptable tolerance of Y

Max time = Max time for adjustment

h) Luminance level offer adjust = low Bright luminance

i) Color = Color of NN5198K/NN5099K

J) Tint = Tint of NN5198K/NN5099K

k) S-Bright = S-Bright

l) U-Bright = U-Bright

m) Contrast = Contrast

n) Cut off R =Cut off R

of NN5099K

o) Cut off G =Cut off G

p) Cut off B =Cut off B

q) Drive R = Drive R

r) Drive B = Drive B

The following data is recommended to use in UBM chassis.

Low Bright

Standard

x = 288

y = 298

Y = 3.5

x = ± 5

y = ± 5

Y = ± 1

High Bright

Standard

x = 288

y = 298

Y = 160

x= ± 5

y= ± 5

Y = ± 10

Maximum time = 30 Sec

Luminance level after adjustment: 14

AN5195K Initialize:

Color = 63 Cut off R = 31

Tint = 63 Cut off G = 31

S-Bright = 127 Cut off B = 31

U-Bright = 127 Drive R = 63

Contrast = 63 Drive B = 63

Model : UBM

After finishing setup, press «Esc» and confirm to save setup or leave the menu.

(F).EXIT TO DOS

Just exit the adjustment program and back to dos environment.

B. Colour Purity, Convergence Adjustment and +B Voltage Check

i. Colour Purity Adjustment (See Fig.6)

BEFORE ANY ADJUSTMENT DESCRIBED BELOW ARE ATTEMPTED, V-HIGH, B+ VOLTAGE AND FOCUS

ING ADJUSTMENT MUST BE COMPLETED.

a. Place the TV receiver facing NORTH or SOUTH.

b. Plug in TV receiver and turn it on.

c. Operate the TV receiver over 30 minutes.

d. Fully degauss the TV receiver by using an external degaussing coil.

e. Receive a crosshatch pattern and adjust the static convergence control roughly.

f. Loosen the clamp screw of the deflection yoke and pull the deflection yoke towards you.

22

Page 23

g. Enter into SERVE MENU. Set the values of C-R, C-G, C-B to "00".

h. Adjust the purity magnets until green field is obtained at the center of the screen.

i. Slowly push the deflection yoke toward cone of CRT and set it where a uniform green field is

obtained.

j. Tighten the clamp screw of the deflection yoke.

k. After COLOUR PURITY ADJUSTMENT, you must adjust the WHITE BALANCE again.

ii. Convergence Adjustment (See Fig.6)

a. Receive a dotted pattern.

b. Unfix the convergence magnet clamper and align red with

blue dots at the center of the screen by rotating (R,B) static

convergence magnets.

c. Align Red/Blue with green dots at the center of the screen

by rotating (RB-G) static convergence magnets.

d. Fix the convergence magnets by turning the clamper.

e. Remove the deflection yoke wedges and slightly tilt the

deflection yoke horizontally and vertically to obtain the

good overall convergence.

f. Fix the deflection yoke by wedges.

g. If purity error is found, follow "PURITY ADJUSTMENT".

iii. +B Voltage check

After production aging, it is necessary to check +B voltage.

a. Receive standard colour bar signal.

b. Press key “I.P.C” to select “Natural” mode.

c. Connect digital voltmeter between C403 and GND. the read-out on the voltmeter

should be +B±1V. If the result is not satisfactory, adjust VR901 (or VR902) to make the correct voltage to be

+B±1V.

(Fig.6)

23

Page 24

XI. Transistor and IC Identification

A. Main Unit:

B. Remote Control Handset:

24

Page 25

XII. Schematic Diagram

(Please refer to 2908-003/34E2-006/34E2-010.pdf)

25

Page 26

XIII. Component Diagrams

i. PCB Main Component Diagram (Top view)/(Bottom view)

(Please refer to E3701-014030-5.pdf)

26

Page 27

ii. PCB CRT Component Diagram (Top view)/(Bottom view)

(Please refer to 090-962523-02.pdf) (For models25A9/25B9/25B8/34E2 ABN88)

ii. PCB CRT Component Diagram (Top view)/(Bottom view)

(Please refer to E3701-020020.pdf) (For model 29B8ABN88)

27

Page 28

iii. PCB VM Component Diagram (Top view)/(Bottom view)

(Please refer to 014040-1.pdf) For model 34E2ABN88

28

Page 29

iv. PCB PINCUSHION Component Diagram (Top view)/(Bottom view)

(Please refer to E3701-014150-1.pdf)

29

Page 30

v. PCB PENEL Component Diagram (Top view)/(Bottom view)

A.(Please refer to E3701-014060-1.pdf) For model 34E2ABN88

30

Page 31

B.(Please refer to E3701-014080-1.pdf) For models 25A9/29A9 ABN88

31

Page 32

C.(Please refer to E3701-023050A1/B1/C1.pdf) For models 25B8/29B8 ABN88

32

Page 33

vi. PCB HANDSET Component Diagram (Top view)/(Bottom view)

A.(Please refer to E3741-014010.pdf) For model 34E2ABN88

33

Page 34

B.(Please refer to E3741-026040.pdf) For models 25A9/29A9/25B8/29B8 ABN88

34

Page 35

vii. PCB TONE Component Diagram (Top view)/(Bottom view)

A.(Please refer to E3701-014100.pdf) For models 25A9/29A9/25B8/29B8 ABN88

35

Page 36

viii. PCB H-WID ADJ Component Diagram (Top view)/(Bottom view)

B.(Please refer to E3701-004040.pdf) For models `25B8/29B8 ABN88

36

Page 37

XIV. Assembly Instruction

A. Front cabinet block

No. Description QTY. Action Remark

1 Front Cabinet 1 Place

2 Speak Grill 2 Buckle on front cabinet

3 N/P 1 Put in front cabinet

4 AC line cord clip 1 Buckle on front cabinet

5 Door locker Ass’y 1 Buckle in front cabinet

6 Speaker 2 Put in front cabinet

7 S-TAP. screw BID 4x10 8 Locking speaker to front cabinet

8 Front panel 1 Put in front cabinet

9 Control PCB Ass’y 1 Put in front panel

10 S-TAP. screw BWH 4x20 2 Locking speaker to front panel

11 AC cord Ass’y 1 Buckle on front cabinet

12 Function knob 1 Put in front panel

13 SPG+KBPWR 1 Put in front panel

14 Power knob 1 Put in front panel

15 S-TAP. screw WHR 3x10 3 Locking function knob to front panel

16 Front cabinet Ass’y 1

37

Page 38

B. CRT block

No. Description QTY. Action Remark

1 CRT 1 Place

2 Degaussing Coil Clip 2 Hang on CRT ears

3 CRT Earth Line 1 Hang on CRT ear and degaussing coil clips

4 CRT Spring 1 Hang on CRT ear and tight CRT earth line

5 Degaussing Coil Clip 2 Hang on CRT ears

6 Degaussing Coil 1 Buckle on degaussing coil clips

7 CRT. Ass’y 1

C. Assembly of chassis block

No. Description QTY. Action

1 PCB Bracket 1 Buckle

2 Main PCB 1 Insert

3 PAL BK 1 Fit on

4 Self-Tapping Screw 4 Tighten screw

5 Self-Tapping Screw 4 Tighten screw

6 Self-Tapping Screw 1 Tighten screw

7 Self-Tapping Screw 3 Tighten screw

8 Panel PCB 1 Fit on

9 AC Line 1 Fit on

38

Page 39

D. Whole unit without rear cabinet block

No. Description QTY. Action Remark

1 Front Cabinet Ass’y 1 Place

2 CRT Ass’y 1 Fit on

3 Rubber ring 4 Put on front cabinet

4 Special washer CRT 4 Put on CRT

5 MS+CRT MTTG 7x40 4 Locking CRT to front cabinet

6 PCB Ass’y 1 Buckle in front cabinet

7 FR CAB & CRT &PCB Ass’y 1

E. Rear cabinet block

No. Description QTY. Action Remark

1 Front Cabinet ASS’Y 1

2 Back Cabinet 1

3 Self-Tapping 4x20 6 Locking back cabinet.

4 Panel Door 1 Buckle in front cabinet.

39

Page 40

XV. Packing

No. Description QTY. Action

1 Gift Box 1 Place

2 Nail 6 Hook

3 Masking Tape Affix

4 Hold Gift Box 4 Place

5 Fiber Hold 4 Place

6 Polyfoam (bottom) 1 Place

7 PBAG 50”x52”x0.04 1 Place

8 PBAG 5”x10”x0.04 2 Place

9 Masking tape Affix

10 TV set 1set Place

11 PBAG

No. Description QTY. Action

12 Polyfoam (Top) 1 Place

13 I B 1 Place

14 PBAG 11”x14”x0.04 1 Place

15 Masking tape 1 Affix

16 WF Wire 2 Place

17 PBAG 5”x10”x0.04 1 Place

18 Remote 1 Place

19 Masking tape Place

20 Masking Tape Affix

21 Nail 4 Hook

40

Page 41

XVI. Exploded View Diagram and Parts List

A. TV unit

i.For model 34E2ABN88

Parts List for Exploded View Diagram

Item Part NO. Description QT Y.

1 200- Cabinet Front 1

2 432- Speaker Grille 2

3 386- N/P 1

4 237- Panel Door 1

5 702- Door Locker Ass’y 1

6 E4801- Speaker 2

7 614- S-TAP. Screw BID 4x10 8

8 230- Front Panel 1

9 E3701- Control PCB 1

10 315- S-Tap Screw BWH 4x20 2

11 E6101- CRT 1

12 376- Rubber Ring 4

13 249- PP+CLP D.C 4

14 E3408- Wire Braided 1

15 639- Special Washer CRT 4

16 609- MS+CRT MTTG 7x40 4

17 E1115- Coil Degauss XC-WH84104 1

Item Part NO. Description QT Y.

18 E3701- CRT PCB 1

19 202- Cabinet Back 1

20 614- Self-Tapping 4x20 6

21 389- PLT+CV FLY 1

22 389- PLT+CV FLY 1

23 611- S-Tap 3x12mm BLK 2

24 614- S-Tap 4x12mm 4

25 236- PNL Back 1

26 E3701- Main PCB 1

27 220- Main PCB Bracket 1

28 E3404- AC Cord Ass’y 1

29 277- Function Knob 1

30 477- SPG+KBPWR 1

31 279- Power Knob 1

32 254- AC Line Cord Clip 1

33 612- S-Tap Screw WHR 3x10 3

34 614- S-Tap Screw BID 4x12 1

41

Page 42

ii.For models 25A9/29A9ABN88

Item Part No. Description Qty.

1 200- Front CAB. 1

2 423- MTB. CRT 4

3 614- S-TAP Screw 5X6MM 20

4 E4801- SPEAKER 2

5 614- S-TAP Screw BID 4X8 12

6 254- CLP C RD PW R 1

7 277- Function Key 1

8 612- S-TAP Screw WHR 3X10 3

9 E3701- Key Board 1

10 615- S-TAP Screw 4X20 2

11 E6120- CRT (FD) 1

12 639- WHR+CRT 4D 4

13 660- Nut 8X13X6.3 4D 4

14 E3701- CRT PCB 1

15 202- CAB. Back 1

16 614- S-TAP Screw 5X25 8

17 560- Model Plate 1

Item Part No. Description Qty.

18 389- Cover Plate 1

19 236- Back Panel 1

20 614- S-TAP Screw BID 4X10 6

21 477- SPG+CRT 9128 2

22 E3701- Main PCB 1

23 612- S-TAP Screw WHR 3X10 2

24 E3701- N.P. Led PCB 1

25 250- N.P . Led Holder 1

26 286- Name Plate 1

27 832- Speaker Net 2

28 230- Front Panel 1

29 702- Door Lock 1

30 237- Push Door 1

31 279- Power Knob 1

32 477- Compressing Spring 1

33 269- Sensor Lens 1

34 269- Power Lens 1

42

Page 43

iii. For model 25B8ABN88

Item Part No. Description Qty.

1 234- SUB Panel 1

2 230- Front Panel (B) 1

3 612- S-TAP Screw 3x10mm 2

4 279- Power Knob 1

5 477- Spring Wire 1

6 200- Front Cabinet 1

7 219- Left Cover 1

8 379- Special Rubber 8

9 Speaker 2

10 379- Special Rubber 8

1 1 615- S-TAP Screw 4x14 8

12 254- AC Line Clip 1

13 771- Kunction Key PCB Ass’y 1

14 530- Fiber Paper 3

15 612- S-TAP Screw 3x12 9

16 241- Apdptor 1

17 771- Power Knob PCB Ass’y 1

18 615- S-TAP Screw 4x20 2

19 376- Rubber Ring 4

20 CRT Ass’y 1

21 639- Special Washer

4

Item Part No. Description Qty.

22 609- MS +CRT MTG. 7x40 4

23 771- CRT PCB Ass’y 1

24 202- Back Cabinet 1

25 614- S-TAP Screw 5x25 8

26 387- Model Plate 1

27 202- Back Cabinet 1

28 389- Back A V Plate (Option) 1

29 236- Back Panel 1

30 614- S-TAP . Screw 4x10 6

31 477- Spring +CRT 2

32 771- Main PCB Ass’y 1

33 220- Chassis Bracket 1

34 612- S-TAP Screw 3x10 12

35 639- WHR +CRT (For 25B8) 4

36 269- Led Lens 1

37 269- Sensor Lens 1

38 771- RCA PCB Ass’y 1

39 219- Right Cover 1

40 614- S-TAP Screw 4x20 10

41 230- Front Panel (C) 1

43

Page 44

iv. For model 29B8ABN88

Item Part No. Description Qty.

1 200- Front Cabinet 1

2 234- B Panel Bar (for B Panel) 1

3 230- Front Panel 1

4 448- C Ring (for A Panel) 2

5 614- S-TAP Screw 4x20 18

6 614- S-TAP Screw 4x12 17

7 Name Plate 1

8 269- Sensor Lens 1

9 269- Led Lens 2

10 277- Function Key 1

1 1 612- S-TAP Screw 3x10 4

12 Function PCB Ass’y 1

13 530- Fibre Washer 3x8x1 2

14 279- Power Knob 1

15 477- Power Knob Spring 1

16 376- Rubber Washer 2 8

17 Speaker 2

18 615- S-TAP Screw 4x14 8

19 376- Rubber Washer 1 8

20 Power PCB Ass’y 1

21 241- Adapter 1

Item Part No. Description Qty.

22 615- S-TAP Screw 4x14 2

23 AV PCB Ass’y 1

24 530- Fibre Washer 4x10x1 2

25 205- Speaker Cover 2 2

26 423- CRT Mounting Bracket 4

27 639- Plate Washer (for 29B9) 4

28 376- Rubber Ring 4

29 639- Fitting Washer (for 29B8) 4

30 CRT 29” 1

31 639- CRT Mounting Washer 4

32 660- NUT M8 4

33 Main PCB Ass’y 1

34 254- AC Line Cord 1

35 202- Back Cabinet 1

36 236- Back Panel 1

37 614- S-TAP Screw 4x10 6

38 614- S-TAP Screw 5x16 8

39 832- PVC Speaker Net (for B Panel) 1

40 237- AV Door 1

41 Model Plate (Label)

44

Page 45

B. Remote handset unit

Item Part No. Description Qty.

1 384- Overlay RCN 1

2 201- CAB. TP 1

3 263- Lens FR 1

4 279- KB 1

5 279- KB 1

6 279- KB 1

7 373- Conductive Rubber 1

8 E3741- PCB Handset 1

9 203- CAB. BM 1

10 610- TS RND2.6X8 2

11 210- DR BAT 1

12 474- SPG BAT AA+- 1

13 474- SPG BAT AA- 1

14 474- SPG BAT AA+ 1

45

Page 46

SERVICE MANUAL

34”

Colour Television Receiver

(UBN CHASSIS)

MODEL: 2515[25A9ABN88]/2915[29A9ABN88]

25F2[25B8ABN88]/29F2[29B8ABN88]

3410[34E2ABN88]

Contents

I. Safety Instructions.................................................................................................................................1

II. Specifications........................................................................................................................................3

III. Level List of Equipments & Instruments Required for Production ............................................... 5

IV. Applying Adhesive on Main PCB........................................................................................................5

V . Wiring Diagram.............................................................................................................. ........................6

VI. Block Diagram ....................................................................................................................................10

VII. Disassembly ......................................................................................................................................11

VIII. Input Signals & Equipments List for Alignment............................................................................11

IX. E2PROM (IC602) Setting ..................................................................................................................12

X. Electrical Adjustment .........................................................................................................................15

XI. Transistor and IC Identification .......................................................................................................24

XII. Schematic Diagram...........................................................................................................................25

XIII. Component Diagrams .....................................................................................................................26

XIV . Assembly Instruction......................................................................................................................37

A. Front cabinet block .......................................................................................................................................37

B. CRT block......................................................................................................................................................38

C. Assembly of chassis block ..........................................................................................................................38

D. Whole unit without rear cabinet block .........................................................................................................39

E. Rear cabinet block ........................................................................................................................................39

XV . Packing..............................................................................................................................................40

XVI. Exploded View Diagram and Parts List.........................................................................................41

A. TV unit ...........................................................................................................................................................41

B. Remote handset unit.....................................................................................................................................45

Page 47

Loading...

Loading...