Page 1

SERVICE MANUAL

21P8MDY5-A02

21T8MDY5-A01

I. Safety Instructions.........................................................................................................................2

II. Specifications..............................................................................................................................4

III. Level List of Equipments & Instruments Required for Production.................................................6

IV.Wiring Diagram...........................................................................................................................7

V. Block Diagram............................................................................................................................8

VI.Disassembly...............................................................................................................................9

VII. Input Signals & Equipments List for Alignment...........................................................................9

VIII. EEPROM Setting....................................................................................................................10

IX. Electrical Adjustment...............................................................................................................17

X. Transistor and IC Identification..................................................................................................18

XI. Schematic Diagram.................................................................................................................19

XII. Component Diagrams.............................................................................................................20

XIII. Exploded View Diagram.........................................................................................................24

This manual is the latest at the time of printing, and does not include the modification which

may be made after the printing, by the constant improvement of product.

Page 2

I. Safety Instructions

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to alert

the user to the presence of uninsulated “dangerous

voltage” within the product’s enclosure that may

be of sufficient magnitude to constitute a risk of

electric shock to persons.

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE COVER (OR BACK). NO

USER-SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE PERSONNEL

ONLY.

PRECAUTIONS DURING SERVICING

1. In addition to safety, other parts and assemblies are

specified for conformance with such regulations as

those applying to spurious radiation. These must

also be replaced only with specified replacements.

Examples: RF converters, tuner units, antenna

selection switches, RF cables, noise-blocking

capacitors, noise-blocking filters, etc.

2. Use specified internal Wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

3. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulating Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulating sheets for transistors

5) Plastic screws for fixing micro switches

4. When replacing AC primary side components

(transformers, power cords, noise blocking

capacitors, etc.), wrap ends of wires securely about

the terminals before soldering.

5. Make sure that wires do not contact heat generating

parts (heat sinks, oxide metal film resistors, fusible

resistors, etc.)

6. Check if replaced wires do not contact sharply edged

or pointed parts.

7. Make sure that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

MAKE YOUR CONTRIBUTION TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol

for recycling as well as small

accumulators (rechargeable batteries), mini-batteries

(cells) and starter batteries should not be thrown

into the garbage can.

Please leave them at an appropriate depot.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance

(servicing) instructions in the literature

accompanying the appliance.

WARNING:

Before servicing this TV receiver, read the X-RAY

RADIATION PRECAUTION, SAFETY INSTRUCTION

and PRODUCT SAFETY NOTICE.

X-RAY RADIATION PRECAUTION

1. Excessively high can produce potentially hazardous

X-RAY RADIATION. To avoid such hazards, the high

voltage must not exceed the specified limit. The

normal value of the high voltage of this TV receiver

is 27 KV at zero bean current (minimum brightness).

The high voltage must not exceed 30 KV under any

circumstances. Each time when a receiver requires

servicing, the high voltage should be checked. The

reading of the high voltage is recommended to be

recorded as a part of the service record, It is

important to use an accurate and reliable high

voltage meter.

2. The only source of X-RAY RADIATION in this TV

receiver is the picture tube. For continued X-RAY

RADIATION protection, the replacement tube must be

exactly the same type as specified in the parts list.

3. Some parts in this TV receiver have special safety

related characteristics for X-RADIATION protection.

For continued safety, the parts replacement should

be under taken only after referring the PRODUCT

SAFETY NOTICE.

SAFETY INSTRUCTION

The service should not be attempted by anyone

unfamiliar with the necessary instructions on this TV

receiver. The following are the necessary instructions

to be observed before servicing.

1. An isolation transformer should be connected in the

power line between the receiver and the AC line

when a service is performed on the primary of the

converter transformer of the set.

2. Comply with all caution and safety related provided

on the back of the cabinet, inside the cabinet, on the

chassis or picture tube.

- 2 -

Page 3

3. To avoid a shock hazard, always discharge the

picture tube's anode to the chassis ground before

removing the anode cap.

4. Completely discharge the high potential voltage of the

picture tube before handling. The picture tube is a

vacuum and if broken, the glass will explode.

5. When replacing a MAIN PCB in the cabinet, always

be certain that all protective are installed properly

such as control knobs, adjustment covers or shields,

barriers, isolation resistor networks etc.

6. When servicing is required, observe the original lead

dressing. Extra precaution should be given to assure

correct lead dressing in the high voltage area.

7. Keep wires away from high voltage or high tempera

ture components.

8. Before returning the set to the customer, always

perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas,

terminals, screwheads, metal overlay, control shafts,

etc., to be sure the set is safe to operate without

danger of electrical shock. Plug the AC line cord

directly to the AC outlet (do not use a line isolation

transformer during this check). Use an AC voltmeter

having 5K ohms volt sensitivity or more in the

following manner.

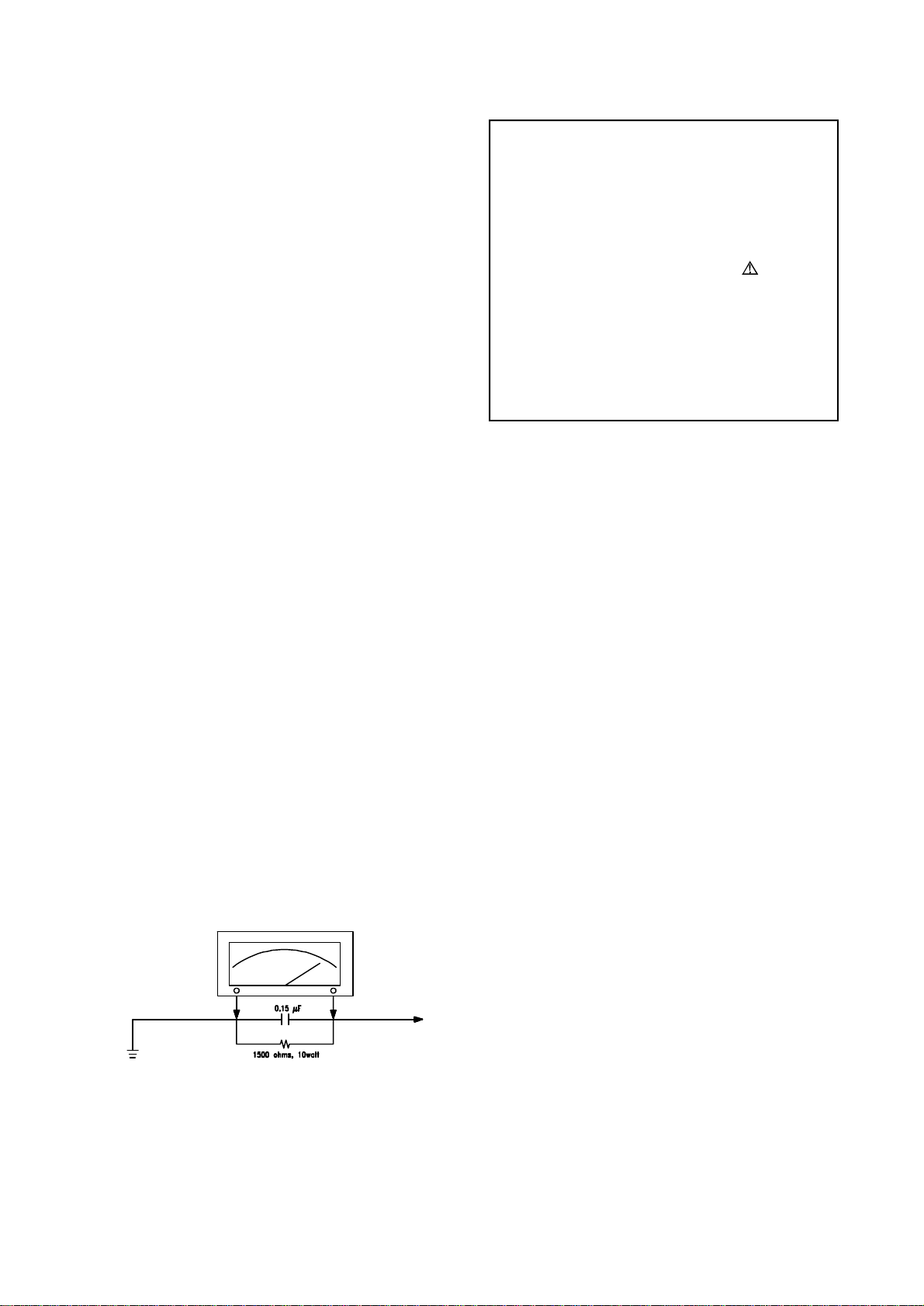

Connect a 1.5K ohm 10 watt resistor paralleled by a

0.15µF AC type capacitor, between a good earth

ground (water pipe, conductor etc.,) and the exposed

metallic parts, one at a time.

Measure the AC voltage across the combination of

the 1.5K ohm resistor and 0.15 uF capacitor. Reverse

the AC plug at the AC outlet and repeat the AC

voltage measurements for each exposed metallic

part.

The measured voltage must not exceed 0.3V RMS.

This corresponds to 0.5mA AC. Any value exceeding

this limit constitutes a potential shock hazard and

must be corrected immediately.

The resistance measurement should be done

between accessible exposed metal parts and power

cord plug prongs with the power switch "ON". The

resistance should be more than 6M ohms.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this TV

receiver have special safety-related characteristics.

These characteristics are offer passed unnoticed by

visual spection and the protection afforded by them

cannot necessarily be obtained by using replacement

components rates for a higher voltage, wattage, etc.

The replacement parts which have these special

safety characteristics are identified by marks on

the schematic diagram and on the parts list.

Before replacing any of these components, read the

parts list in this manual carefully. The use of

substitute replacement parts which do not have the

same safety characteristics as specified in the parts

list may create shock, fire, X-RAY RADIATION or

other hazards.

Good earth ground

such as the water

pipe, conductor,

etc.

AC Leakage Current Check

AC VOLTMETER

Place this probe

on each exposed metallic

part

- 3 -

Page 4

II. Specifications

1. Power supply TV: AC 220-240V, 50/60Hz

Remote control battery: 3V (UM-4X2)

2. TV system RF input: PAL BG/DK/I, SECAM BG/DK, NTSC M /N

Video input: PAL/NTSC 3.58/NTSC 4.43/SECAM

3. Receiving channels 48.25MHz~588.25MHz

4. Intermediate frequencies Picture: 38.9MHz

5. Scanning Horizontal (Hz): 15625/15750

Vertical (Hz) : 50/60

6. Color picture tube : 21" 90 degree N(3) hemisphere Bv=0.5G(+0.1G/-0.15G)

7. Operating temperature Fulfil all specifications: 15°C ~ 35°C

Accept picture/tone reproduction: 5°C ~ 45°C

8. Operating relative humidity Fulfil all specifications: 45% ~ 75%

Accept picture/tone reproduction: 15% ~ 90%

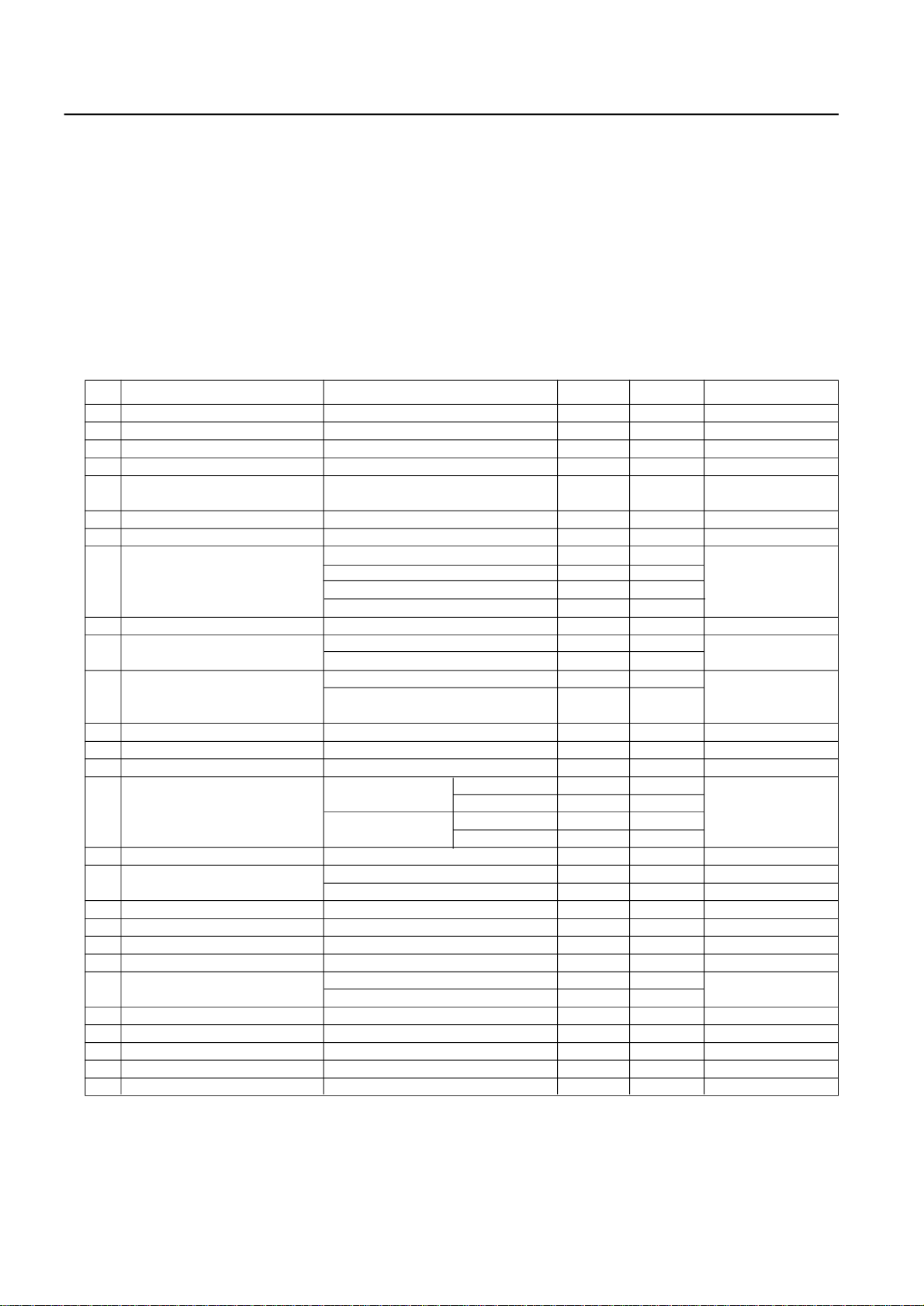

9. Electrical & Optical Specification:

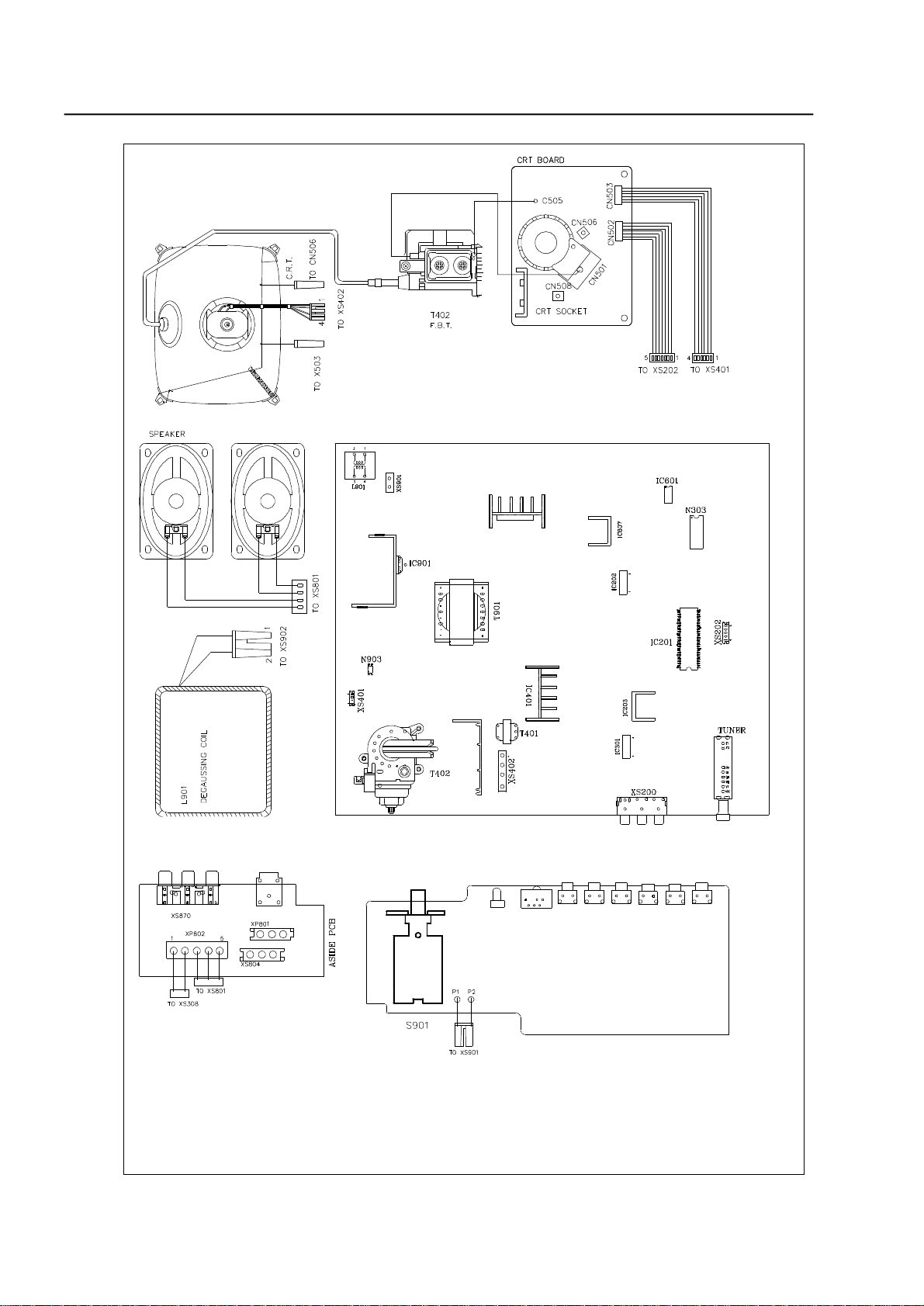

No. Items Instruction Typical Limit Unit

1 Video sensitivity For 30dB S/N ≤45 ≤51 dBuV

2 FM sound sensitivity For 30dB S/N 30 ≤35 dBuV

3 Synchronizing sensitivity For RF transmission 30 ≤35 dBuV

4 Color sensitivity For RF transmission 32 ≤40 dBuV

5 Teletext sensitivity TV screen refreshes 40 times N/A N/A dBu

number of mistakes ≤8

6 Minimum NICAM threshold Without crackline noise N/A N/A dBu

7 AGC static characteristic Accept. Picture/tone repr. 103 ≥100 dBu

8 Selectivity Adjacent sound carrier 35 ≥30

Below adjacent sound carrier 35 ≥30 dB

Adjacent picture carrier 50 ≥40

Up adjacent picture carrier 45 ≥30

9 IF rejection 55 ≥50 dB

10 Image rejection VHF 55 ≥50 dB

UHF 50 ≥45

11 AFT pull-in range M/N ±1.0 ≥|±0.5| MHz

DK/I/BG +1.5 ≥|±1.0|

-1.0 ≥|±-0.75|

12 Chroma sync pull-in range ±500 ≥|±200| Hz

13 Color killer function -25 ≤-16 dB

14 DC restoration 3 ≤10 %

15 Resolution Horizontal PAL/SECAM 320 ≥300

NTSC 270 ≥250

Vertical PAL/SECAM 410 ≥400 lines

NTSC 320 ≥300

16 Overscan Cross hatch signal 93 91~97 %

17 Linearity Horizontal 7 ≤10 %

Vertical 6 ≤8 %

18 Pattern distortion 1.5 ≤3 %

19 Picture position In all direction ±3 ≤|±6| mm

20 Raster rotation In all direction 4 ≤6 mm

21 Convergence error 0.4 ≤0.6 %

22 White balance (8700°K) X 0.288 0.288±0.015

Y 0.298 0.298±0.015 /

23 Maximum full white At picture tube center 140 ≥100 cd/m

24 H sync pull-in range ±500 ≥|±200| Hz

25 V sync pull-in range 7 ≥6 Hz

26 Anode voltage 26.5 ≤27.5 KV

27 Audio frequence response ±3dB ref. to 1KHz 0.1~8.2 0.18~7.1 KHz

2

- 4 -

Page 5

No. Items Instruction Typical Limit Unit

28 Audio output power 1KHz 10% THD N/A N/A W

50KHz DEV. (BG/DK/I)

25KHz DEV. (M/N)

29 THD Po=0.5W 1KHz 1 ≤3 %

30 Signal to buzz ratio TV/AV 42 ≥40 dB

31 Minimum volume hum 6 ≤10 mVrms

32 Maximum woofer output power N/A N/A W

33 Woofer audio freqency response ±3dB ref. to 80Hz AV mode N/A N/A Hz

34 Bass control range 100Hz ref. to 1KHz AV mode N/A N/A dB

35 Treble control range 10KHz ref. to 1KHz AV mode N/A N/A dB

36 Balance Center 0 ≥|±2| dB

Max. 3 >2 dB

Min. -35 <−30 dB

37 Video input level 1.0 1±0.2 Vpp

38 Audio input level 0.5 0.5±0.3 Vrms

39 Video output level 1.0 1±0.2 Vpp

40 Audio output level 0.5 0.5±0.3 Vrms

41 Power consumpution Operating 75 ≤80 W

Stand by 6 ≤10 W

42 IR receiving distance ±30° 6 ≥4 m

43 X-ray radiation <0.1 ≤0.5 mR/h

44 Dielectric strength AC 3KVrms 1min. 3 ≤5 mArms

45 Y input level N/A N/A Vpp

46 Cr input level N/A N/A Vpp

47 Cb input level N/A N/A Vpp

48 White uniformity L edge or angle/L center 47 ≥45 %

49 Cross modulation Receiving Kawa central No visible interference at 80dBuv

interference system signals

50 The vibration noise from The distance between the No obvious vibration noise can be heard

electromagnetic devices in tester and the TV set is four

TV set times as many as the screen height

Test Condition

1 Picture Modulation 87.5%

2 Sound Modulation 27KHz Dev. For DK/I/BG

15KHz Dev. For M/N

3 Picture to Sound Ration 10dB

4 Sound Artificial Load Resistor 16 ohm

5 Video signal White and black

(three white & two black)

6 Audio signal 1KHz sine wave 0.5Vrms Convergence error test point on screen

7 Conditions of the TV setting:

A.Switch TV on and let it warm up for more than 30 minutes.

B.Connect RMS volt meter to speaker terminals and adjust theTV volume to get 500mW RMS power at each terminal.

C.Place the MINOLTA CA-100 test probe to white part of the screen,adjust the contrast until a reading of 80cd/m

D.Place the MINOLTA CA-100 test probe to black part of the screen,adjust the brightness until a reading of 2cd/m

E.Repeat step C & D until the exact luminance values is obtained or the nearest possible values you can get.then record the

luminance values & R.G.B gun voltage values at the same time. and take the largest values for measurement referenct.

F.Input standard color bar(100/0/75/0),then adjust the colour.until the waveforms at the blue gun of same level is obtained.

+P8 P5+

+P1

+P4 P2++P0

+P7 P6+

+P3

W

1/9H

1/9W

H

2

is obtained.

2

is obtained.

- 5 -

Page 6

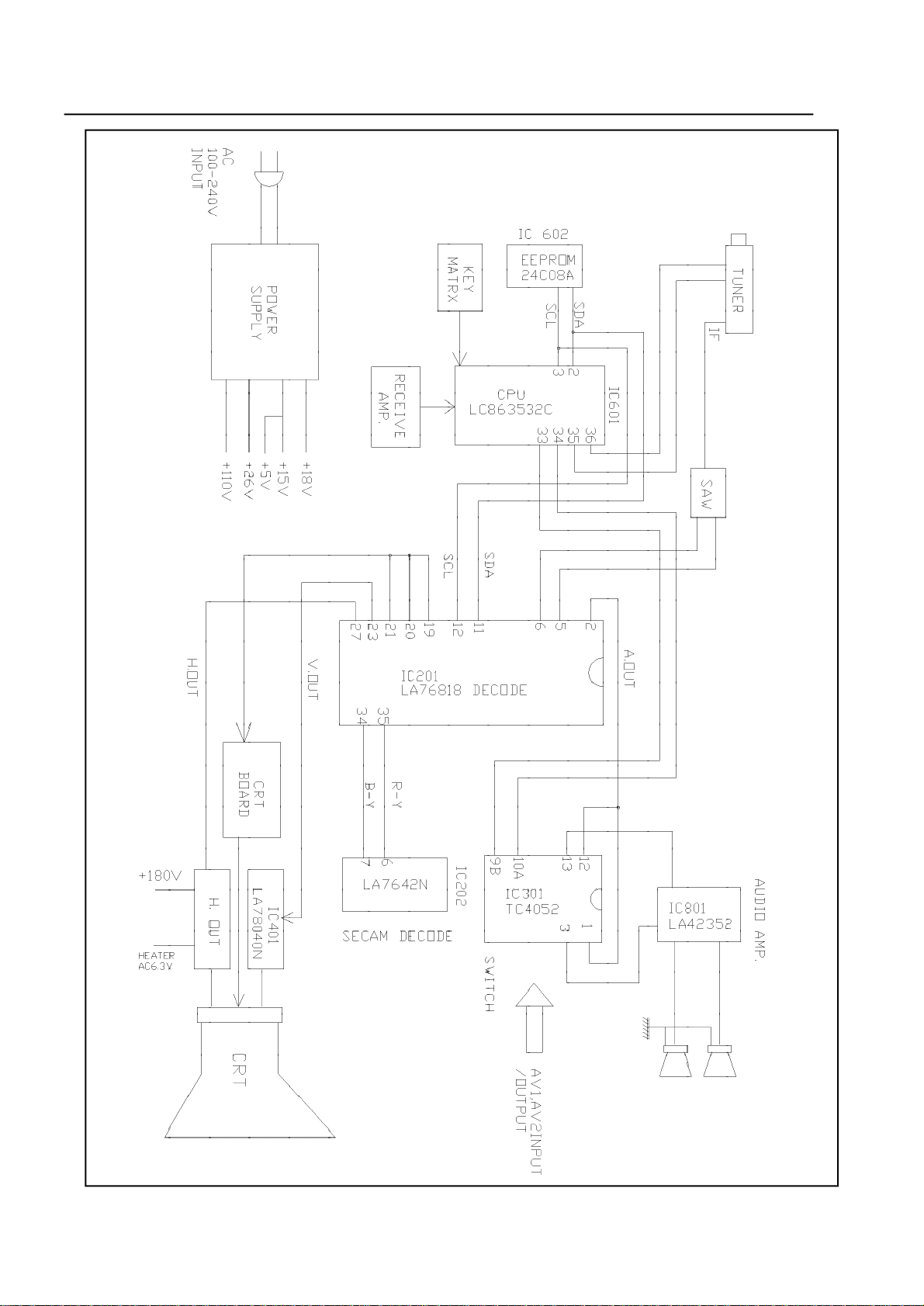

III. Level List of Equipments & Instruments Required for Production

No. Designation Requirement Reference Model Remark

1 Pattern Generator System of output signal: PHILIPS

PAL DK/I., NTSC 3.58/4.43 PM5518-TN/ PM5418-TN

2 Digital voltmeter Input Resistance 10M FLUKE 45

3 Withstanding Withstanding Voltage:AC 1.5KV, KIKUSUI TOS 8650 For Irresistible Voltage

Voltage Tester 5KV/0-5KV±3% measurement

Cut-off current:AC 0-2mA,20mA/

Continuously Adjustable

4 Insulation Tester Test voltage:1000V. 500V KIKUSUI TOS 7100L

5 Oscilloscope Max Frequency of input signal:

20MHz or above

6 CRT Color MINOLTA CA-100 For White Balance

Analyzer Adjustment

7 Oscillator Frequency range of output KENWOOD AG-203A For generating Audio Signal

signal: 20Hz-20kHz

8 HV Probe FLUKE For screen voltage

adjustment

- 6 -

Page 7

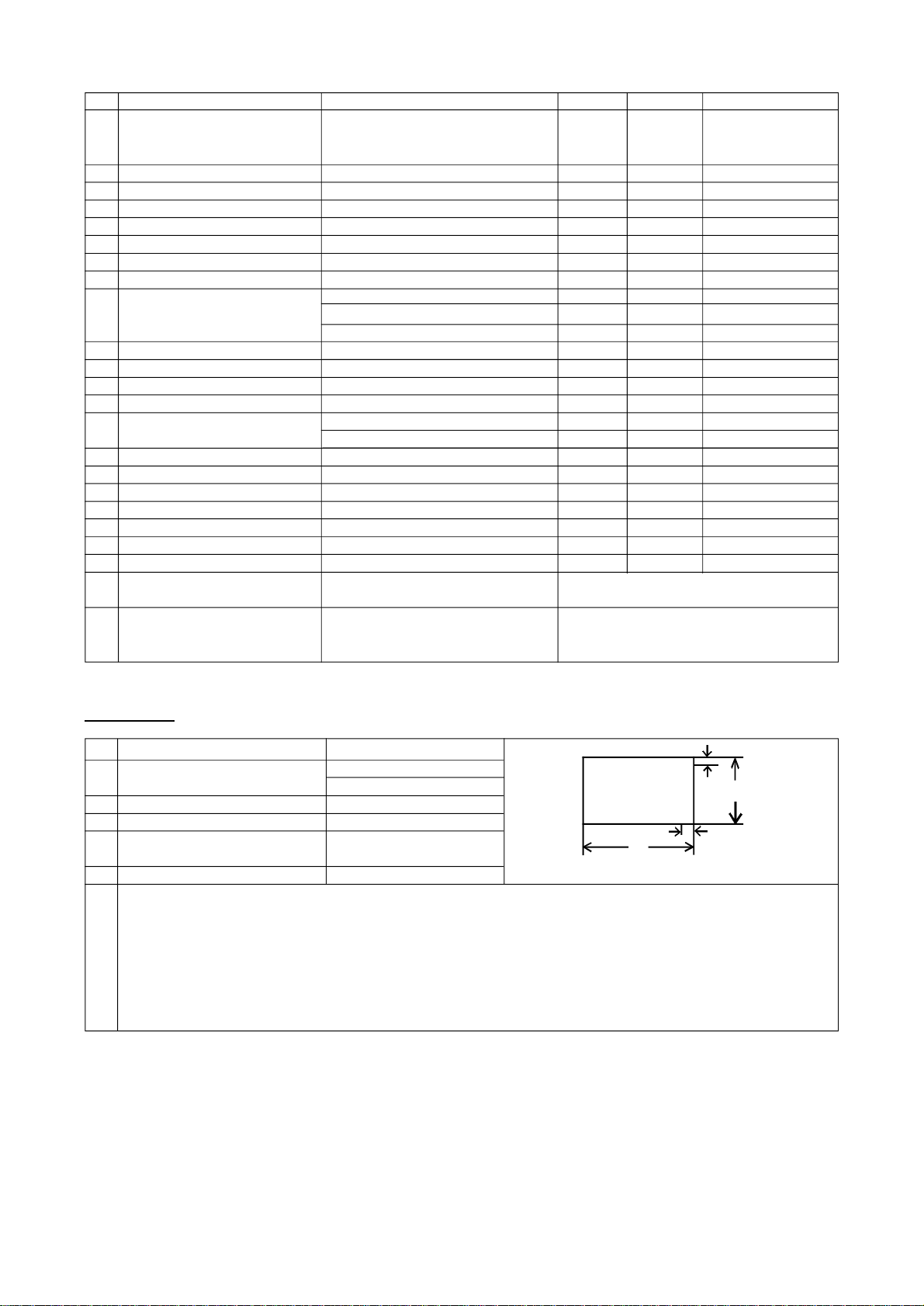

IV. Wiring Diagram

- 7 -

Page 8

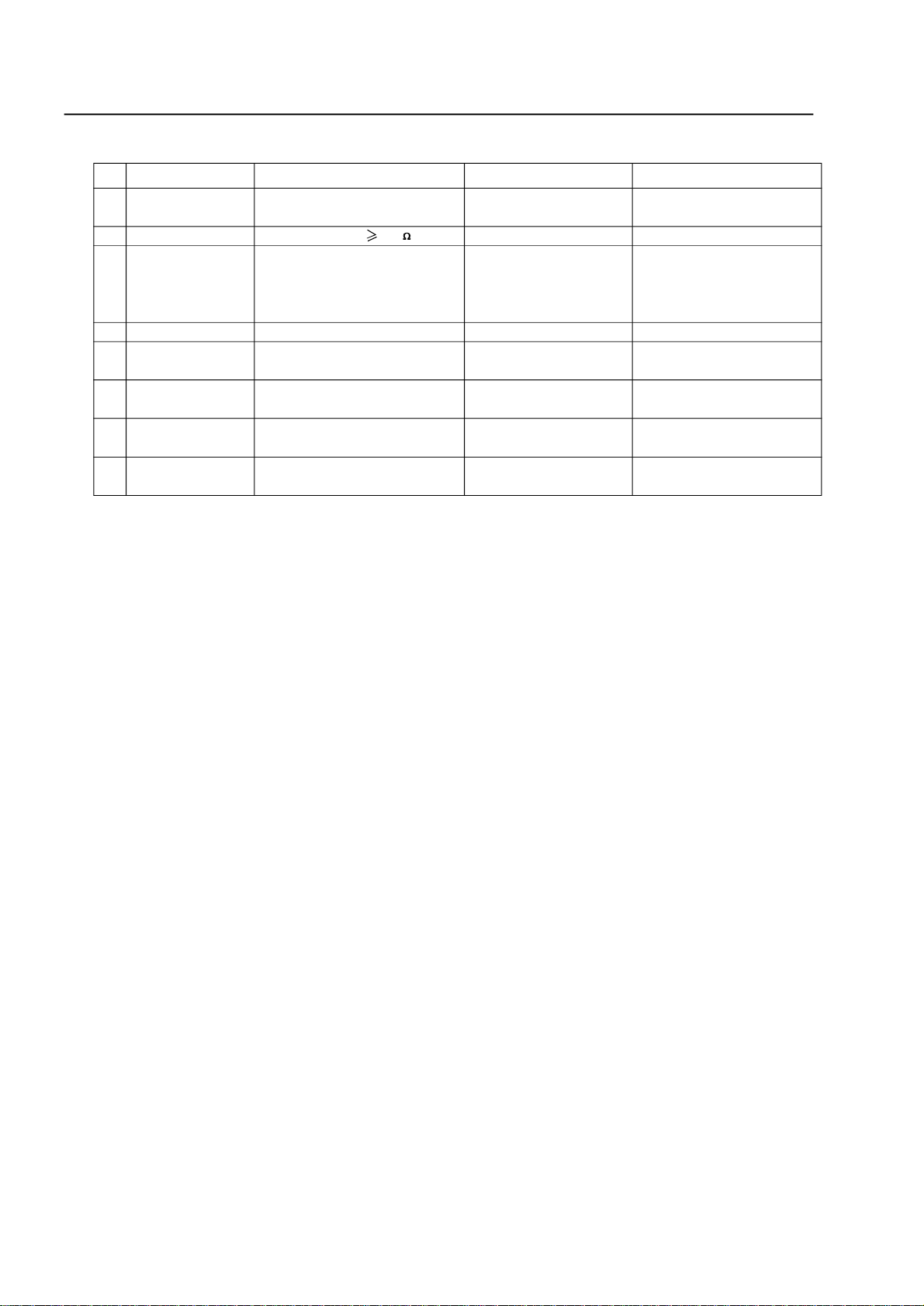

V. Block Diagram

- 8 -

Page 9

VI. Disassembly

In case of trouble, etc., necessitating disassemble, please disassemble in the order shown in the illustrations.

Reassemble in the reverse order.

1. Removal of the Back Cover

2. Removal of the MAIN PCB

a.Remove the screws.

b.Slide out the TV chassis slightly; pull up the connector of AC cord from PCB; pull up the CRT PCB from

CRT.

c. Remove the anode cap from the picture tube. To avaid a shock hazard, be sure to discharge the picture

tube’s anode to the chassis ground before removal.

d.Take out the TV chassis.

VII. Input Signals & Equipments List for Alignment

1. Equipments for adjustment

a. Pattern generator(PHILIPS PM 5518) b. Digital voltmeter

c. High voltage meter d. Demagnetiser

e. Personal computer (486) f. CRT colour analyzer (MINOLTA CA-100)

g. High voltage probe

2. Input signals

a. Color bar b.Cross hatch

c. Grey scale bar d. Monoscope pattern

e. Circle cross pattern

- 9 -

Page 10

VIII. EEPROM Setting

A. Factory debugging description

1. Enter/Exit factory debugging menu.

★ working keys

☆ Factory

* It can be enter to the factory menu directly.

* It can be turned over page after entering the factory debugging menu.

The content can be saved and exit the factory menu if pressing the key at the last pages of the factory

debugging menu.

☆ MENU

* Save the content and exit.

☆ ENTER WITH PASSWORD

* Press “2483” to enter the factory menu at “system menu” and “channel exchange” items.

2. Turn over pages of the factory debugging menu

★ working keys

☆ MUTE, FACTORY: turn over page backward

☆ CH.REV: turn over page forward

3. Change settings

★ working keys

☆ CH+/CH-: choose the items which going to be changed.

☆ VOL+/VOL-: to change the items which selected.

4. TV/AV switch

★ working keys

☆ TV/AV: press this button to switch the horizontal brightness line to adjust the G2 voltage.

B.Data Setting

Following data should be preset into the E2PROM IC before they are inserted to PCB.

P1

Name Adjust Range Advise value

*H.PHASE 0~31 13

*V.SIZE 0~127 52

*V.POS 0~63 27

*V.LIN 0~31 14

*V.SC 0~31 12

*NT.H.PHASE 0~7 6

*NT.V.SIZE 0~31 17

*NT.V.POS 0~31 25

*NT.V.LIN 0~7 4

1. Prss ‘ DISP ’ button to display the internal signal

2. When the “ + ” singal active

★ If select 50HZ of the item, the displaying frequence will force to 50HZ.

★ If select 60HZ of the item, the displaying frequence will force to 60HZ.

P2

Name Adjust Range Advise value

*R.B 0~255 100

*G.B 0~255 100

*B.B 0~255 100

*R.D 0~127 52

*G.D 0~15 12

*B.D 0~127 88

*S.B 0~127 63

V.K 0~1 0

1. While balance brightness line

★ Special working keys

☆ TV/AV button can turn on/off the white balance brightness line

2. Red, Green, Blue deflection voltage

★ Special working keys

☆ ‘1’/’4’: key can change the data of red deflection voltage.

☆ ‘2’/’5’: key can change the data of green deflection voltage.

☆ ‘3’/’6’: key can change the data of blue deflection voltage.

☆ ‘7’/’8’: key can change the data of accessory brightness.

- 10 -

Page 11

3. Auto while balance debugging

★ Enter to the debugging mode.

☆ Connect the MCU pin 25 to 0V under the factory menu.

★ After entering to the debugging mode, MCU will not control the IIC general line. Auto while balancecontrol program

can change the data of ‘ picture decode COMS chip ’ and ‘ 24C04/24C08’ freely.

★ About the while balance data’s relative address of the ‘ picture decode COMS chip ’ and 24C04/24C08.

Name Picture decode COMS Location 24C04/24C08 Location

chip address(HEX) address(HEX)

RED BIAS 07 7~0 1E 7~0

GREEN BIAS 08 7~0 1F 7~0

BLUE BIAS 09 7~0 20 7~0

RED DRIVE 0A 6~0 21 6~0

GREEN DRIVE 0B 3~0 22 3~0

BLUE DRIVE 0C 6~0 23 6~0

R-Y DC 1B 3~0 2C 3~0

B-Y DC 1B 7~4 2C 7~4

YUV R-Y DC 1B 3~0 2A 3~0

YUV B-Y DC 1B 7~4 2A 7~4

SECAM R-Y DC 1B 3~0 0D 5~2

SECAM B-Y DC 1B 7~4 09 6~3

P3

Name Adjust Range Advise value

SUB.CONT 0~31 10

SUB.COL 0~3 1

SUB.SHP 0~15 8

OSD.CONT 0~127 30

*OSD.POS 0~127 26

H.BLK.L 0~7 7

H.BLK.R 0~7 2

VIDEO.LVL 0~7 4

P4

Name Adjust Range Description Advise value

ENGLISH 0~1 ENGLISH OSD 1

0: NO; 1: YES

RUSSIAN 0~1 RUSSIAN OSD 1

0: NO; 1: YES

TURKISH 0~1 TURKISH OSD 0

0: NO; 1; YES

FRENCH 0~1 FRENCH OSD 0

0: NO; 1: YES

ARABIC 0~1 ARABIC OSD 1

0: NO; 1: YES

PERSIAN 0~1 PERSIAN OSD 0

0: NO; 1: YES

SPANISH 0~1 SPANISH OSD 0

0: NO; 1: YES

GERMAN 0~1 GERMAN OSD 0

0: NO; 1: YES

ITALIAN 0~1 ITALIAN OSD 0

0: NO; 1: YES

- 11 -

Page 12

P5

Name Adjust Range Description Advise value

VS/FS 0~1 0:Voltage synthesize high frequence cobbra 0

1:Frequence synthesize high frequence cobbra

VL/VH FREQ 0~255 Frequence: [(VL/VH FREQ.) + 100.25] MHZ 64

VH/UHF FREQ 0~255 Frequence: [(VH/UHF FREQ.) + 300.25] MHZ 164

AT.SCH.SIF 0~3 0: 6.5MHZ

1: 4.5MHZ 0

2: 5.5MHZ

3: 6.0MHZ

WOOFER 0~1 0: OFF 1: ON 0

INT.DVD 0~1 0: OFF 1: ON 0

DVD BLK. TIME 0~1 DVD and black screen time switch control 1

*VOL.CHANGE 0~1 0

*SEARCH SPEED 0~3 2

*Because of the port conflict, you can only select one between WOOFER and INT.DVD function, when one of it set to 1, another

will be set to 0 compulsively.

P6

Name Adjust Range Description Advise value

1-CHIP LA76818 Select decode IC LA76818

E2 CLEAR 0~1 1: Power on time, E2PROM data rewrite. 0

V-L 0~7 2

V-H 0~7 1

UHF 0~7 3

P.ON RESET 0~1 0: OFF mode 1

1: The mode before power off

H.TONE.MENU 0~1 1: Translucent user menu 1

V. MUTE.P.OFF 0~1 1: Turn off discharge 0

TEXT MENU 0~1 0: Picture menu title 1

1: teletext menu title

P7

Name Adjust Range Advise value

TV 0~1 1

AV1 0~1 1

AV2 0~1 1

DVD 0~1 0

TV.VLT 0~3 0

AV1.VLT 0~3 1

AV2.VLT 0~3 2

DVD.VLT 0~3 3

*INT.DVD.CH 0~2 0

P8

Name Adjust Range Advise value

ST.BRI 0~15 9

ST.CONT 0~15 9

ST.COL 0~15 7

ST.SHP 0~15 7

L.BRI 0~15 10

L.CONT 0~15 11

L.COL 0~15 9

L.SHP 0~15 7

- 12 -

Page 13

P9

Name Adjust Range Advise value

V.BRI 0~15 10

V.CONT 0~15 13

V.COL 0~15 11

V.SHP 0~15 7

SO.BRI 0~15 5

SO.CONT 0~15 7

SO.COL 0~15 5

SO.SHP 0~15 1

* P8, P9 for debugging each preparing value of four special picture mode, you can press P.P button directly at this two

pages toswitch different picture mode and observe the effect.

P10

Name Adjust Range Description Advise value

VIF.SYS 0~3 0=38.0MHZ 1

1=38.9MHZ

2=45.75MHZ

3=39.5MHZ

PAL 0~1 0:NO PAL COLOR DEMODULATION 1

1:PAL COLOR DEMODULATION

N3.58 0~1 0: NO NTSC3.58 COLOR DEMODULATION 1

1:NTSC3.58 COLOR DEMODULATION

N4.43 0~1 0: NO NTSC4.43 COLOR DEMODULATION 1

1:NTSC4.43 COLOR DEMODULATION

SECAM 0~1 0: NO SECAM COLOR DEMODULATION 1

1: SECAM COLOR DEMODULATION

DK 0~1 0:NO 6.5M SOUND DEMODULATION 1

1: 6.5M SOUND DEMODULATION

BG 0~1 0: NO 5.5M SOUND DEMODULATION 1

1: 5.5M SOUND DEMODULATION

I 0~1 0: NO 6.0M SOUND DEMODULATION 1

1: 6.0M SOUND DEMODULATION

MN 0~1 0: NO 4.5M SOUND DEMODULATION 1

1: 4.5M SOUND DEMODULATION

P11

Name Adjust Range Description Advise value

BG 0~3 No singal background

0: bule 0

1: black

2: red

3: yellow

BG.BRI 0~15 No singal background brightness 8

LOGO 0~1 0: No logo 1

1: personal logo

M.SCR.POS 0~31 openning center adjustment 0

M.SCR.TIME 0~3 0: 4s 2: 6s 1

1: 5s 3: 7s

TV ON EFF 0~2 0: Black screen > turn on

1: Black screen> opening>turn on 1

2: Black screen> logo> turn on

TV. OFF.SCR 0~1 TV OFF SCREEN 1

0:No TV off screen; 1:TV off screen

* When the cursor mark stay at item ‘BG’, ‘BG.BRI’, the ‘no singal backgroud’ effect which you have selected would

open automatically, the ‘ no singal backgroud brightness’ will also active at the same time.

- 13 -

Page 14

P12

Name Adjust Range Advise value

BY 0~15 8

RY 0~15 9

YUV.BY 0~15 8

YUV.RY 0~15 8

SCM.BY 0~15 5

SCM.RY 0~15 6

P13

Name Adjust Range Description Advise value

PWM. VOL 0~1 PWM volume control

0: no PWM volume control 1

1: pin 29,30 PWM volume control

PWM.2CH 0~1 0: pin29, 30 PWM volume can not 0

control single.

1: pin29, 30 PWM volume can control

single

1- CHIP VOL 0~127 PWM volume control, bring to front 127

and zoom in output control

RF.AGC 0~31 loudspeaker AGC 24

AV.OUT.OPT 0~1 AV output singal selection

0: AV output watching picture 0

1: AV output the TV signal

CH.OSD.BLACK 0~1 1: Channel exchange OSD black 1

screen

CH. TURN.MUTE 0~1 0: No black screen 1

1: Black screen

A.PMUTE 0~1 MCU 24pin exchange channel mute

0: Mute ; 1: No mute 0

P14

Name Adjust Range Description Advise value

AFC.G.G 0~1 AFC Stronger 0

VSEPUP 0~1 0: Normal; 1: Stronger 0

CD. MODE 0~7 3

DIGITAL. OSD 0~1 0: simulate; 1: Digital 0

V.OFFSET 0~3 0: min.; 3: max. 3

FM.LVL 0~31 31

P15

Name Adjust Range Description Advise value

BRT.ABL.DEF 0~1 0: ON; 1: OFF 0

MID.STP.DEF 0~1 0: ON; 1: OFF 0

BRT.ABL.TH 0~5 3

RB. GAIN.BAL 0~15 8

RB.ANG 0~15 8

AT. FLESH 0~1 0

VOL. FIL 0~1 0

- 14 -

Page 15

-Factory debugging menu 818/828 P1

Name Adjust Range Description Advise value

V.R.TIME 0~1 0: Normal; 1:0.25 horizontal windage 0

A.M.SW 0~1 0: Normal; 1: External sound 1

WPL 0~3 0

Y.APF 0~1 1

Y.GAM.ST 0~3 0

VCO.SW 0~1 0: debugging backward; 0

1: debugging forward

VCO.ADJ 0~3 0: 0HZ

1: 30HZ 2

2: 60HZ

3: 90HZ

PAL.COL.SW 0~1 1

PAL.COL 0~15 7

-Factory debugging menu 818/828 P2

Name Adjust Range Description Advise value

H.TONE 0~3 0: Darkness; 3: lightness 3

GRAY. MODE 0~1 0:100% White singal 0

1: 60% White singal

CROSS 0~3 Internal singal

0: undisplay the internal signal 0

1: Black singal

2: While singal

3: Cross singal

GY.ANG 0~1 0: 240 angle; 1:253 angle 1

C.KILL.OPE 0~7 0: -30dB

7: -40Db 7

-Factory debugging menu 818/828 P3

Name Adjust Range Description Advise value

VBLK.SW 0~1 0: Normal; 1: stronger 0

FBPBLK.SW 0~1 0: LA76818 control 1

1: Internal/External control

P/O.SW 0~3 0: Debugging forward 1

1: Debugging backward

P/O.SHOOT 0~1 Signal forward and backward debugging 3

DC.REST 0~3 0: 100%

1: 107% 0

2: 113%

3:129%

BLK.STR.ST 0~3 0: black electricity extend=OFF

1:black electricity extend=ON(40IRE)

2:black electricity extend=ON(60IRE) 1

3: black electricity extend=OFF

BLK.STR.GN 0~3 0: Min.; 2: Max. 2

RGB.TEMP.SW 0~1 0: -1VBE

1: Normal 0

CORING.GN 0~3 0: Min. ; 3: Max. 2

* When the cursor mark stay at ‘ BLK.STR.ST’, ‘BLK.STR.GN’ , the customer ‘ picture stronger’ function will open automatically in

order to adjust the function effect expediently.

* when the cursor mark stay at ‘ CORING.GN’ , the custormer’ decrease noise’ function will open automatically in

order to adjust the function effect expediently.

- 15 -

Page 16

- Input the LOGO: “ERISSON”

★ This page will not appear unless the E2PROM set to 24C08

★ working key:

☆ ‘0’ / ‘1’: LOGO up/move down

☆ ‘2’ / ‘3’: LOGO left/move right

☆ ‘4’: to change the LOGO color

☆ ‘5’: to change the LOGO size

☆ ‘6’: to switch the rows of the LOGO

☆ ‘7’: reset

★ MENU: save and exit

★ CH+ / CH-: to change the letter position which need to be changed.

★ VOL+ / VOL-: to change the letter

★ aging debugging page

★ The TV will not Off automatically without signal

The chassis address which require from the white balance debugging as below:

LA76818 Sub Address AT24C08 Sub Address

Device Address BAH A0H Bit Map

Red Bias 07H 16H+08H=1EH 0FFH

Green Bias 08H 17H+08H=1FH 0FFH

Blue Bias 09H 18H+08H=20H 0FFH

Red Drive 0AH 19H+08H=21H 07FH

Green Drive 0BH 1AH+08H=22H 00FH

Blue Drive 0CH 1BH+08H=23H 07FH

Sub Bright 0DH 1CH+08H=24H 07FH

“ * ” means that the data can be changed during the production or debugging.

- 16 -

Page 17

IX. Electrical Adjustment

A. +B Voltage Alignment

a. Preparation Procedure

1).Receive standard colour bar signal.

2).Press key "P.MODE." to select “STANDARD” mode.

3).Connect digital voltmeter between of C917 and GND.

4).Adjustment Step

Adjust RP901 to make the read-out on the Voltmeter to be as follows:

MODEL CRT CRT TYPE NO +B

21P8/T8MDY5 E6120-027006 A51MAT70X5S(C) N3 SEG 110V

B. Adjustment for AFC

a.Preparation procedure

1.Turn on the main power switch.

2.Set digital voltmeter at DC, then connect it’s probe across of IC201 PIN47 and GND.

3.

a. To set the pattern generator under the color bar and pal system. Apply 100dBµV 38.9 MHz

IF signal between IF input pin and GND of the TUNER on main PCB board

21P8/T8MDY5

b. (see Fig.1).

C212

(Fig.1)

IF

C101

b. Adjust the IFT coil T202 until the meter indicates 3.6V±0.05V.

DIGITAL VOLTMETER

Output

Pattern

Generator

- 17 -

Page 18

X. Transistor and IC Identification

A. Main Unit:

- 18 -

Page 19

XI. Schematic Diagram

i.(Please refer to A315-004.pdf)

- 19 -

Page 20

XII. Component Diagrams

i. Main & CRT PCB component diagram (Top/Bottom view)

(Please refer to E3701-054080A/B pdf)

- 20 -

Page 21

ii. CRT ERISSON PCB component diagram (Top/Bottom view)

(Please refer to E3701-021080-10 pdf)

- 21 -

Page 22

iii. KEY&POWER&ASIDE PCB component diagram (Top/Bottom view)

(For 21P8MDY5 model)

(Please refer to E3701-054100A/B/C .pdf)

iii. KEY&POWER&ASIDE PCB component diagram (Top/Bottom view)

(For 21T8MDY5 model)

(Please refer to E3701-054130A/B/C .pdf)

- 22 -

Page 23

XIII. Exploded View Diagram

Main Unit

i. For 21P8MDY6-A02 model

Item Part No. Description Qty.

1 200-21P801-XXR Cabinet Front 1

2 612-300310-10 S-TAP.Scerw Flt 3x10 3

3 279-21P801-XXS Power Knob 1

4 E3701-022070C LED PCB 1

5 E3701-022070A Power PCB 1

6 615-400214-10 Screw 4x14 2

7 254-871401-01R CLP CRD PER 8714 1

8 376-391501-01Y Pubber Ring (T=3.0mm) 4

9 21” Colour CRT 1

10 639-382802-01 Special WasherCRT 4

11 614-500430-10 S-TAP. Screw Bid 4x30 4

12 249-922002-01F Special Plastic Part 2

13 E3701-XXXXXX CRT PCB 1

14 202-21T80X-0XX Back Cabinet Black HI-PS 1

15 614-500425-00 S-TAP. Screw B/T 5x25mm Black 6

Item Part No. Description Qty.

16 387-21T801-XXH Model Plate 1

17 614-400414-10 S-TAP. Screw B/T 4x14mm White 1

18 389-21B8XX-0XH RCA Plate 1

19 611-300310-00 S-TAP. Screw Flt 3x10 2

20 389-21T80X-XXH RCA Cover Plate 1

21 477-371601-01 Spring + CRT 1

22 E3701-XXXXXX Main PCB Ass’y 1

23 E3701-022070B AV PCB Ass’y 1

24 615-400414-10 S-TAP. Screw Bwh 4x14 8

25 379-972501-01Y Special Rubber Parts 8

26 379-972502-01Y Special Rubber Parts 8

27 E4801-XXXXXX Speaker 2

28 486- Name Plate 1

29 269-25P801-01L Sensor Lens 1

30 277-21P801-XXS Func Keys 1

- 23 -

Page 24

ii. For 21T9MDY5-A01 model

Item Part No. Description Qty.

1 200-21T801-XXR Cabinet Front 1

2 612-300310-10 S-TAP.Scerw Flt 3x10 3

3 279-21T801-XXS Power Knob 1

4 E3701-022060C LED PCB 1

5 E3701-022060A Power PCB 1

6 615-400214-10 Screw 4x14 2

7 254-871401-01R CLP CRD PER 8714 1

8 376-391501-01Y Pubber Ring (T=3.0mm) 4

9 E6101-XXXXXX21” Pure Flat CRT or Nomal Flat CRT 1

10 639-382802-01 Special WasherCRT 4

11 614-500430-10 S-TAP. Screw Bid 4x30 4

12 249-922002-01F Special Plastic Part 2

13 E3701-XXXXXXCRT PCB 1

14 202-21T80X-0XX Back Cabinet Black HI-PS 1

15 614-500425-00 S-TAP. Screw B/T 5x25mm Black 6

Item Part No. Description Qty.

16 387-21T801-XXH Model Plate 1

17 614-400414-10 S-TAP. Screw B/T 4x14mm White 1

18 389-21B8XX-0XH RCA Plate 1

19 611-300310-00S-TAP. Screw Flt 3x10 2

20 389-21T80X-XXH RCA Cover Plate 1

21 477-371601-01 Spring + CRT 1

22 E3701-XXXXXXMain PCB Ass’y 1

23 E3701-022060B AV PCB Ass’y 1

24 615-400414-10 S-TAP. Screw Bwh 4x14 8

25 379-972501-01Y Special Rubber Parts 8

26 379-972502-01Y Special Rubber Parts 8

27 E4801-XXXXXXSpeaker 2

28 486- Name Plate 1

29 277-21P801-XXS Func Keys 1

30 269-210801-01L Sensor Lens 1

- 24 -

Loading...

Loading...