Erika HGS 1-3 600 Installation Manual

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 1 of 42

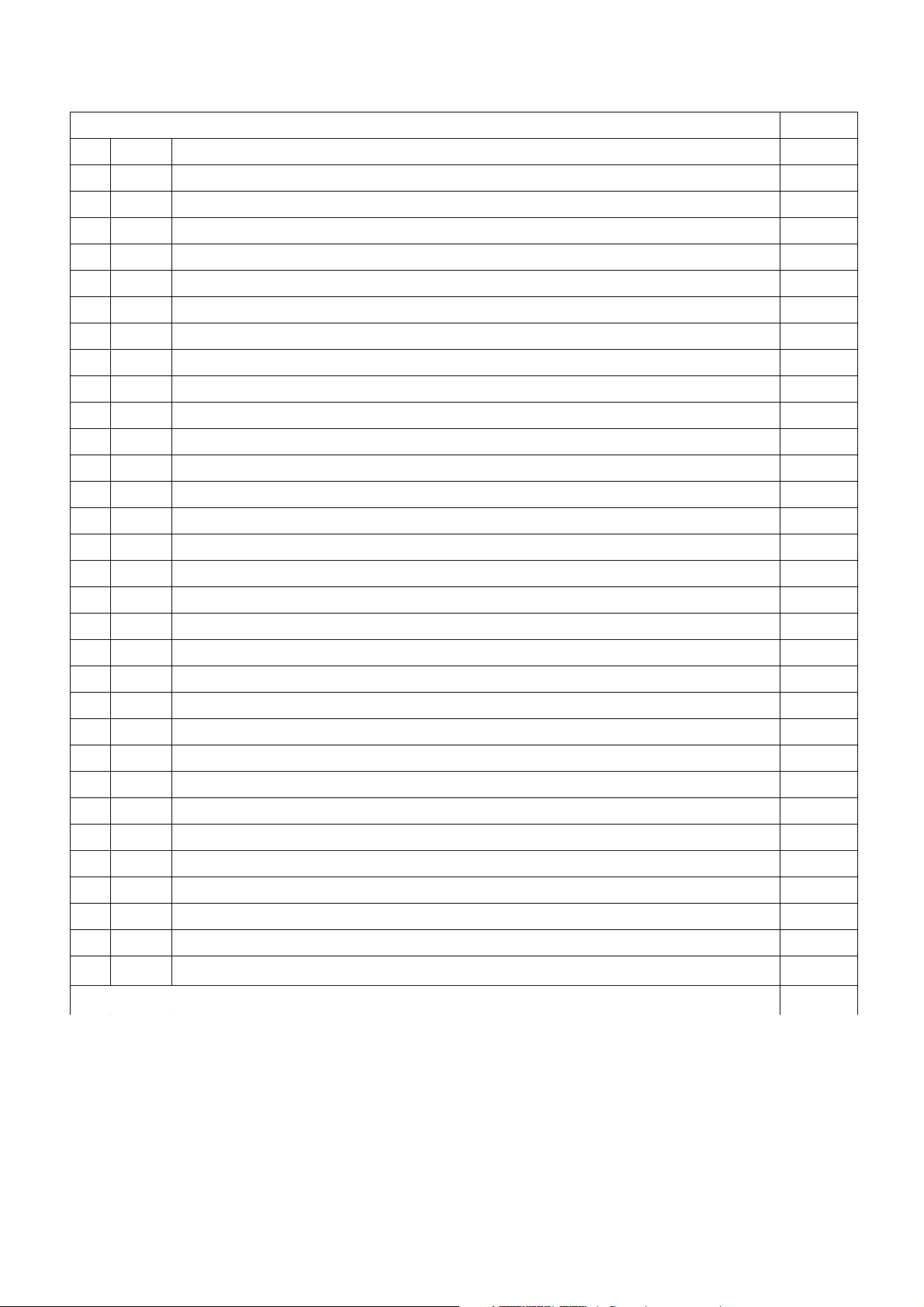

content

1.

Introduction and general

3 - 4

1.1.

Introduction

3

1.2.

Identification plate

4

2.

Basic safety instructions

5 - 8

2.1.

Obligation and liability

5

2.2.

Specific safety instructions of the manufacturer

6

2.3.

Protective equipment

6

2.4.

Safety instruction for the blades

7

2.5.

Installation and use according to purpose

7

2.6.

Danger from electric energy

8

2.7.

Instructions of the manufacturer concerning residual danger

8

2.8.

Constructional changes on the machine

8

3.

Description of the machine

9 - 10

3.1

Technical details

9

3.2.

Purpose

9

3.3

Description of the machine

9

3.4

Functional description

10

4. Machine parts and control elements

10 - 11

5.

Electrical connection

12

6.

Handling of the machine

12 - 13

6.1

Commissioning

12

6.2

Cleaning the machine

13

7.

Service and maintenance

14 - 26

7.1

Maintenance of the double-blade cutting system

14

7.2

Blade exchange

14

7.3

Adjustment of the blade tension

17

7.4

Adjustment of the tension rollers

20

7.5

Exchange the upper belt

22

7.6

Exchange the feed belt / lower belt

23

7.7

Maintenance the machine

25

8.

EC conformity declaration

26

9.

Exploded view drawings

28 - 40

page

10. Circuit diagram 41

11. Service stations 42

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 2 of 42

1. Introduction and general

1.1. Introduction

We thank for the confidence you had shown, and we are pleased to be able to regard you as

one of our esteemed clientele. We are quite confident, that the machine you purchased, works

to your full satisfaction.

These operating instructions are subject to the copyright which is held by the

KRUMBEIN.rationell company. Their reproduction, even if only of an extract, as well as adding

or removing pages, is not allowed.

These operating instructions have to be kept immediately and accessibly at the machine.

These operating instructions shall make possible to you to get to know the machine considering

all safety instructions and its functions, thus to achieve optimal exploitation.

The operating instructions will give you pieces of advice how to operate the machine safely,

properly and economically.

In order to minimize danger, down time and repair costs as well as to increase reliability and

lifetime of the machine, the pieces of advice from these operating instructions have to be

absolutely observed.

These operating instructions are to be completed

due to existing national rules

by orders about accident prevention and

environmental protection.

The operating instructions have to be permanently available at the place of operation.

The operating instructions have to be read by any person that is charged with work with or on

the machine.

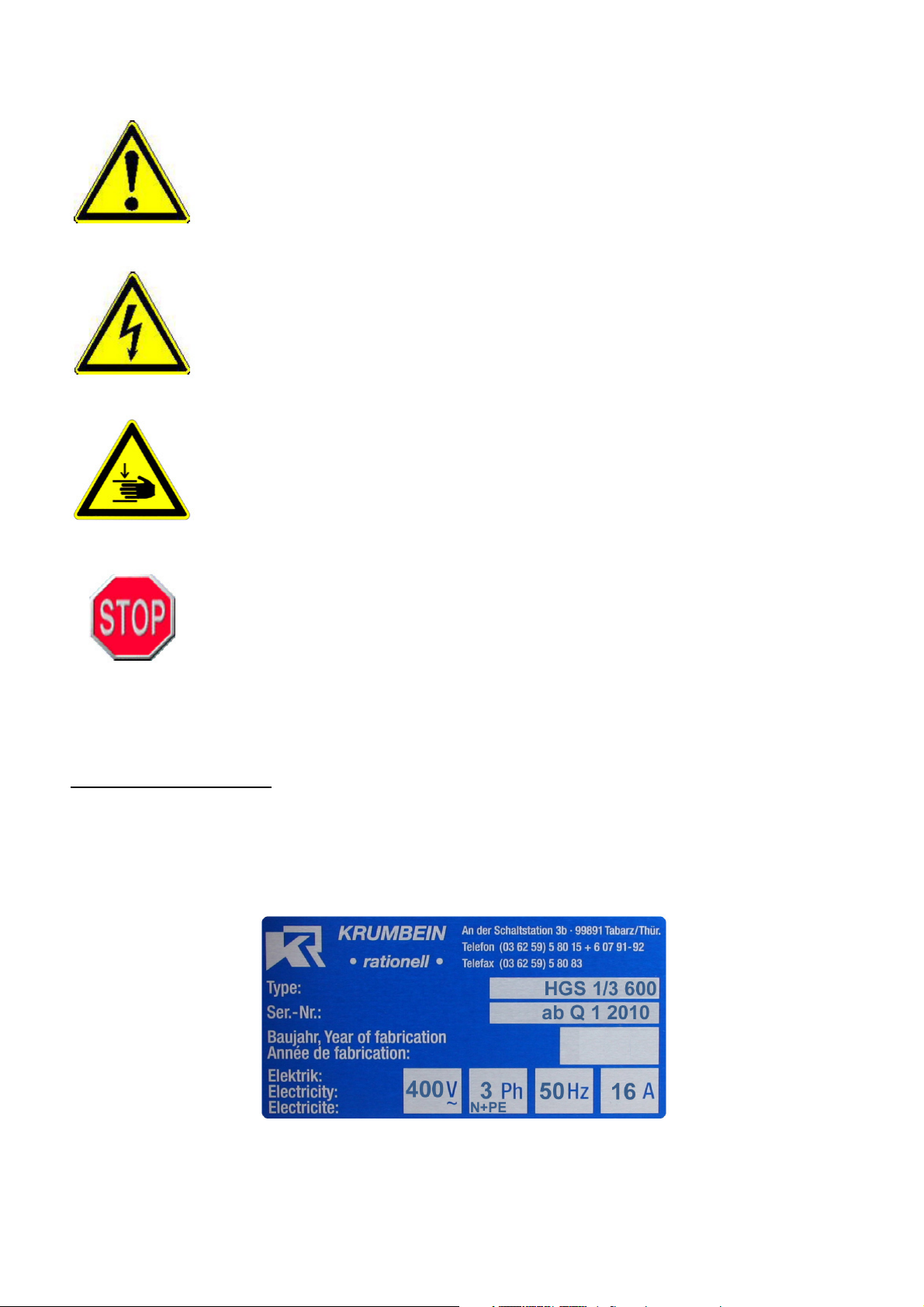

The operating instructions contain safety instructions in form of pictograms, which point to

danger.

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 3 of 42

Meaning of the pictograms

Danger – warning about general danger

Danger – warning about voltage

Danger – warning about danger of injury

STOP – warning about property damage

1.2. Identification plate

There is an identification plate mounted on the machine from which one can gather the most

important details of the machine.

These operating instructions are only valid for machines of the following machine type.

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 4 of 42

2. Basic safety instructions

2.1. Obligation and liability

* Knowing the basic safety instructions and safety rules is the essential prerequisite of

trouble-free operation that fulfils the safety conditions.

* This documentation, in particular the safety instructions, must be heed by all persons, who

are working at the machine.

* Over and above that, the regulations and rules of accident prevention have to be observed

on the place of operation.

* The operator obliges himself, to assign only such personnel to work with the machine:

who have read the safety instructions and the warning notices, understood them and

confirmed these by signing it.

* The machine has been constructed according to the state-of-art and the recognized safety

regulations. Nevertheless by the use of the machine may occur danger to body and life of

the user or third persons respectively impairments of the machine and other material or

assets. The machine can be used only

=> in accordance with its purpose

=> in safety-perfect conditions

* Defects, which can impair safety, have to be remedied immediately.

* In principle our “general terms of sale and delivery” are effective.

Warranty and liability claims in case of personal injury and property damage are excluded,

if they are caused as follows by:

=> using the machine in a way in which it is not intended to be used

=> improper mounting, activation, operation and maintenance of the machine

=> operating the machine in case of defective safety devices or safety equipment and

protective devices that are unable to function

=> constructional changes of machine taken on one’s own authority

=> changes (e.g. driving, performance and number of revolutions ….)

=> insufficient monitoring of the machine parts that are subject to wear

=> repair carried out improperly

=> cases of disaster caused by foreign matters or elements and force majeure

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 5 of 42

2.2. Specific safety instructions of the manufacturer

* These safety instructions do not claim to be exhaustive.

In case of questions please contact KRUMBEIN.rationell company, Tabarz.

* Repair, installation, maintenance and cleaning work as well as transportation of the machine

is only allowed to be done, when drives are switched off and tools are motionless.

* Attention has to be paid that no persons are present of the area of the machine who do not

know or are not able to assess the dangers of the machine (e.g. children).

* Never let the machine running without supervision.

After having finished work and before leaving workplace the motor of the machine has

2.3. Protective equipment

* Before putting the machine into operation, all protective equipment must be proper and able

to function

* Protective devices are allowed to be removed

- after rest and

- after securing against restart of the machine (e.g. switching off power supply)

* The machine has to be checked at least once per day with regard to externally visible

damages and working order of the safety equipment.

* The protective equipment which can be opened (cover hoods), are equipped with

safety switches. Opening these protective covers while the machine is running, will

lead to an immediate stop of the machine.

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 6 of 42

2.4. Installation and use according to purpose

* Installation of the machine only in dry rooms.

* It is only allowed to use the machine to cut freshly and unfrozen products.

* Inappropriate use may lead to destruction of the machine and excludes any warranty claims.

* Use according to the purpose includes also observation of the operating instructions and

keeping of inspection and maintenance conditions.

2.5. Danger from electric energy

* Work on the electric supply is only allowed to be done by a qualified electrician.

* The electric equipment of the machine has to be checked regularly. Loose connections and

damaged cables have to be fixed immediately.

* The switch cabinet as well as the terminal boxes must be always closed.

Only authorized persons with key an approved tools should have access to the switch

cabinet and terminal boxes.

* a second person is needed in case of work on live parts. if necesary this person can actuate

the emergency switch

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 7 of 42

2.6. Instructions of the manufacturer concerning residual danger

The delivered machine meets a high safety standard, however, the following residual risk

factors remain:

* Damage of live circuits by external impacts

* Failure of protective equipment

* Using the machine in a way in which it is not intended to be used

* Setting up of machine without protective gloves

* Errors in operation occurring due to unqualified and untrained personnel

* Use of spare parts which not be admitted by the manufacturer

2.7. Constructional changes of the machine

Do not make changes, extensions or reconstruction of the machine without the manufacturer’s

permission. All reconstruction measures need a written permit from

KRUMBEIN.rationell

company.

Exchange immediately machine parts that are not in a proper condition! Use only original spare

and wear parts ! In case of outsourced parts it is not ensured that these are designed and

manufactured fulfilling the conditions of stress and safety.

2.8. Safety instruction for the blades

* Use only original KRUMBEIN HGS-blades in this machine.

* Don´t use blades with any damages.

All scales are labeled in metric system

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 8 of 42

3. Description of the machine

3.1 Technical details

Dimension in working position:

Length: 2000 mm With: 740 mm Height: 1320 mm

Dimension in park position:

Length: 1360 mm With: 740 mm Height: 1630 mm

Weight: app. 170 kg

max. cutting with: 600 mm

max. product height: 100 mm

min. cutting height: 5.0 mm (product-dependent)

Electr. connection: 230/400 V; 50 HZ; 3 Ph

Power consumption: 0,6 kW

3.2. Purpose

The machine is used for horizontal slicing of fresh and unfrozen baking goods in two or more

layers. Per pass, the product is separated into four layers.

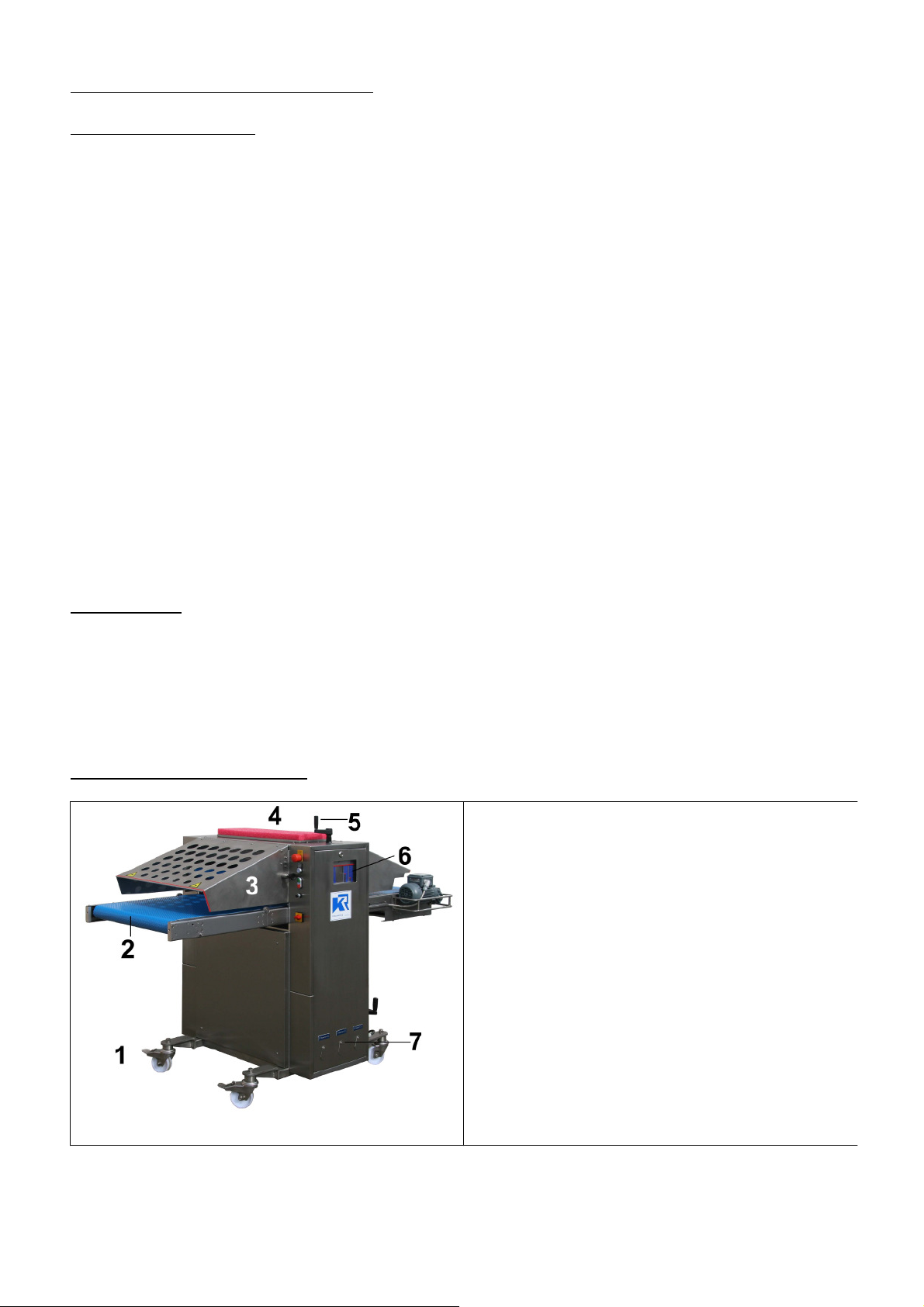

3.3 Description of machine

•

1 Base frame, wheeled

•

2 Lower belt / feed belt

•

3 front-side protective cover

•

4 Cleansing sponge

•

5 Height adjustment upper belt

•

6 Display height adjustment

•

7 Height adjustment blades

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 9 of 42

•

1 upper belt / pressure belt

•

2 lower belt / feed belt

3.4. Functional description

The feed of the baking products is made by a special conveyor belt - below - and a

synchronized rotating contact pressure band - above -. The horizontal cut is carried out by a

special double-blade knife.

The upper belt and the blades can be adjusted by cranking to the desired heights.

The tape feed rate is adjustable designed, to adapt the machine for several product

characteristics.

The feed band is swivel-mounted at the inlet side. The feed band can lift, when the machine is

not in use to save space

4. Machine parts and control elements

Element Description

Electric control elements

•

1 Kill switch

•

2 Reset emergency shutdown

•

3 Start/Stop – switch

•

4 Potentiometer

•

5 Main switch

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 10 of 42

Machine in park position

•

Locking bolt at the feed band (detail)

Height adjustment upper band

•

1 crank for height adjustment

•

2 display of the height adjustment

Display height adjustment

•

1 Height of the upper belt

•

2 Height of the double-blade

Height adjustment double-blade

•

1 crank for the height adjustment

(in park position)

•

2 intake of the height adjustment

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 11 of 42

5. Electrical connection

The connection is restricted to a power grid, that corresponds with the (in the technical data

section 3) specified values for voltage and frequency.

The connection takes place via a 3-Ph-protective contact plug to the mains.

The grounding of the connection must be installed according to EC 536 - Class 1, NEC and

other current standards. An upstream RCDs must be designed for a fault current > 350 mA.

6. Handling of the machine

6.1. Commissioning

•

place the machine on the intended position, apply the roller-brakes, fold down the feed

band (thereto unlock the locking bolt)

•

Take care that no foreign element is in the machine before the machine is switched on

•

Verify the correct fit of all protective devices

•

It is also necessary to consider that no persons may be endangered or injured by the

start of the machine.

•

The blade system must be cleaned and must not be defect.

- Knives must be tensioned -

•

Connect to electrical power

•

Then, the machine can be started as follows:

- unlock Emergency-off switch (if necessary)

- activate main switch

- press Reset emergency shutdown

- Set cutting height and upper band height

•

apply the products to the feed belt

•

after the end of production, switch off the machine on the main switch and relax the

blades

•

The unlock of the knife is used to prevent the material fatigue of the clamping element

and to avoid the conglutination of the knife through product residues (see the following

point Cleaning)

Permanent tension of the blades leads to material fatigue of the plate springs

in the compensation unit and therefore to a shorter lifetime.

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 12 of 42

6.2. Cleaning the machine

The machine is switched off and protect against restart before cleaning .The exterior cleaning is

permitted only with a damp cloth. The use of chemical cleaners are permitted conditionally.

The cleaning with a water jet or pressure washer leads to disturbances in the mechanic, the

electric and the control device and is therefore prohibited. The cleaning of the tapes (feeding

belt / upper belt) takes place with the customary and approved cleaners for the material of PE.

The double-knife have to be cleaned in specific manner for hygienic reasons.

An optimal cleaning of exterior surfaces can be reached by cleaning sponge,

if the sponge is soaked with water, that is mixed with some citric acid.

The sponge runs several times through the machine with a fixed blade height of 20 mm / upper

band height of 40mm .

Product residues on the inner sides (tread section) are necessarily to remove, otherwise

the blades stick together and this can lead to cracks.

Thereto: remove the double blades (use the instructions in section 7.2 Blade exchange). To

avoid conglutination of the blades, it is recommended to apply a thin layer of food-save oil on all

sides of the blades.

Product residues must be removed from the crumb tray daily. Furthermore the cleaning brush

should periodically clean under running water or be washed in the dishwasher (cleaning brush

is located behind the crumb tray).

The feed belt have to be removed after an operating time of 40 hours, in order to clean the belt

and the rollers (use the instructions in section 7.6 feed belt change). Remove residues on

rollers and on feed table with a damp cloth. The drive and support rollers have to be cleaned

regularly.

7. Service and maintenance

7.1. Maintenance of the double-blade cutting system

To achieve an optimum of cutting results always, it is necessary, to moisten all sides of the

blades with a suitable and approved food-saved oil before starting the machine.

After a service life, of about 50 hours, the tension rollers of the double-blade system are to regreased with an approved grease.

The blade tension may decrease over time and should accordingly

be reviewed and possibly improved. (Section 7.3 Adjustment of the blade tension)

© KRUMBEIN.rationell HGS 1/3 600 V 02/2010 page 13 of 42

Loading...

Loading...