Erika FG149 Installation Manual

OVEN SERIAL NO.

OVEN CODE 149 150 153 156 158 159

CONDENSER SERIAL No. _____________________________________(IF FITTED)

In the event of an enquiry please quote these numbers.

Store this document safely and ensure it

is available at all times.

Non-availability may affect the service or

repair of your machine.

MANUAL No.Y-BX-01E

Bx OVEN

SET UP AND OPERATION OF OVEN

AND CONDENSER UNIT (IF FITTED)

CLASSIC

COLOUR

Bx oven range inc condenser 05-06 (2-10) RAC

2

2

ATTENTION

IF OVEN FAILS TO HEAT UP, WHEN FIRST CONNECTED TO A

POWER SUPPLY OR DURING USE AT ANYTIME,

PRESS RESET BUTTON(S) LOCATED THROUGH THE REAR BACK PANEL.

(DO NOT REMOVE BACK PANEL)

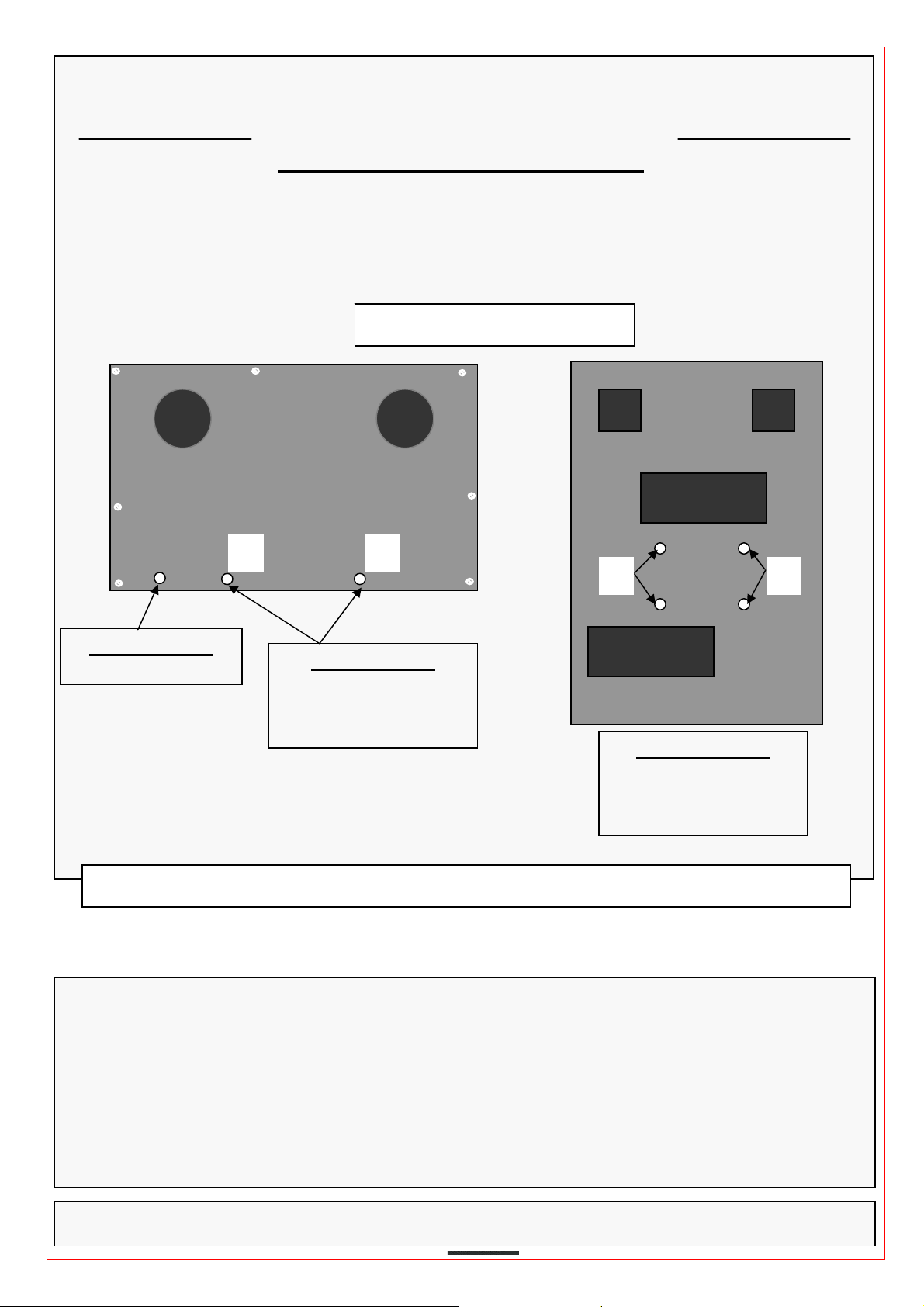

REAR VIEW OF OVENS

2 TRAY OVEN

HOLE LOCATION

(IF THIS FAILS TO CORRECT THE SITUATION, PLEASE CONTACT YOUR SUPPLIER)

1

4 TRAY OVEN

HOLE LOCATION

HOLE CAN BE AT POSITION 1

POSITION 2 DEPENDING

OR

ON OVEN

2

1

10 TRAY OVEN

HOLE LOCATION

HOLES CAN BE AT POSITION 1

POSITION 2 DEPENDING

OR

ON OVEN

OVEN DISPOSAL

CARE SHOULD BE TAKEN WHEN THE MACHINE COMES TO THE END OF ITS

WORKING LIFE. ALL PARTS SHOULD BE DISPOSED OF IN THE APPROPRIATE

PLACE, EITHER BY RECYCLING OR OTHER MEANS OF DISPOSAL THAT

COMPLIES WITH LOCAL REGULATIONS.

(IN UK, ENVIRONMENTAL PROTECTION ACT 1990 APPLIES)

MONO are in the process of applying for WRAS accreditation

Bx oven range inc condenser 05-06 (2-10) RAC

(all associated components within this equipment are WRAS approved)

3

CONTENTS

PAGE

PART 1.0 Introduction 5

PART 2.0 Specifications 6

PART 3.0 Safety 7

PART 4.0 Installation 8

PART 5.0 Isolation 9

PART 6.0 Daily / Weekly Cleaning 10

PART 7.0 Ideal Operating Conditions 12

PART 8.0

CLASSIC Operation 14

Running preset programs

PART 9.0 Programming 15

Creating and changing program values

PART 10.0

COLOUR Operation 17

PART 11.0 Programming 21

Creating and changing program values

PART 12.0 Upload / Download 23

PART 13.0 Maintenance 28

PART 14.0 Bulb Replacement 28

PART 15.0 Steam System Maintenance 28

PART 16.0 CONDENSER INFORMATION

(IF FITTED)

29

SERVICE / SPARES Contact Information 41

Bx oven range inc condenser 05-06 (2-10) RAC

4

•

1.0 INTRODUCTION

• A combination of clean industrial design and the latest technology,

the MONO BX oven range is designed specifically to take the baking

Industry’s standard trays.

• The ovens in the range are of stainless steel construction and some have

removable tray racks to aid cleaning.

• The smaller ovens are designed to be stackable without separate support, so your

business can grow without taking up more ground space.

• The high-speed fans, elements and steam systems give efficient air circulation to

produce a professional bake across a range of products.

• The doors are double glazed to increase the efficiency of the ovens well-insulated

baking chamber

• Ovens are available with either LED (classic) or LCD (colour) displays for the user-

friendly control panels.

2-TRAY Bx OVEN 4-TRAY Bx OVEN

The 10-tray Bx is supplied with a

10-tray capacity stainless steel

base with locking castors.

10-TRAY Bx OVEN

• The optional condenser unit can be fitted to any Bx oven or stacked Bx ovens

as required.

With thermostatic control it can be adjusted to operate in most ambiant temperatures.

Bx oven range inc condenser 05-06 (2-10) RAC

5

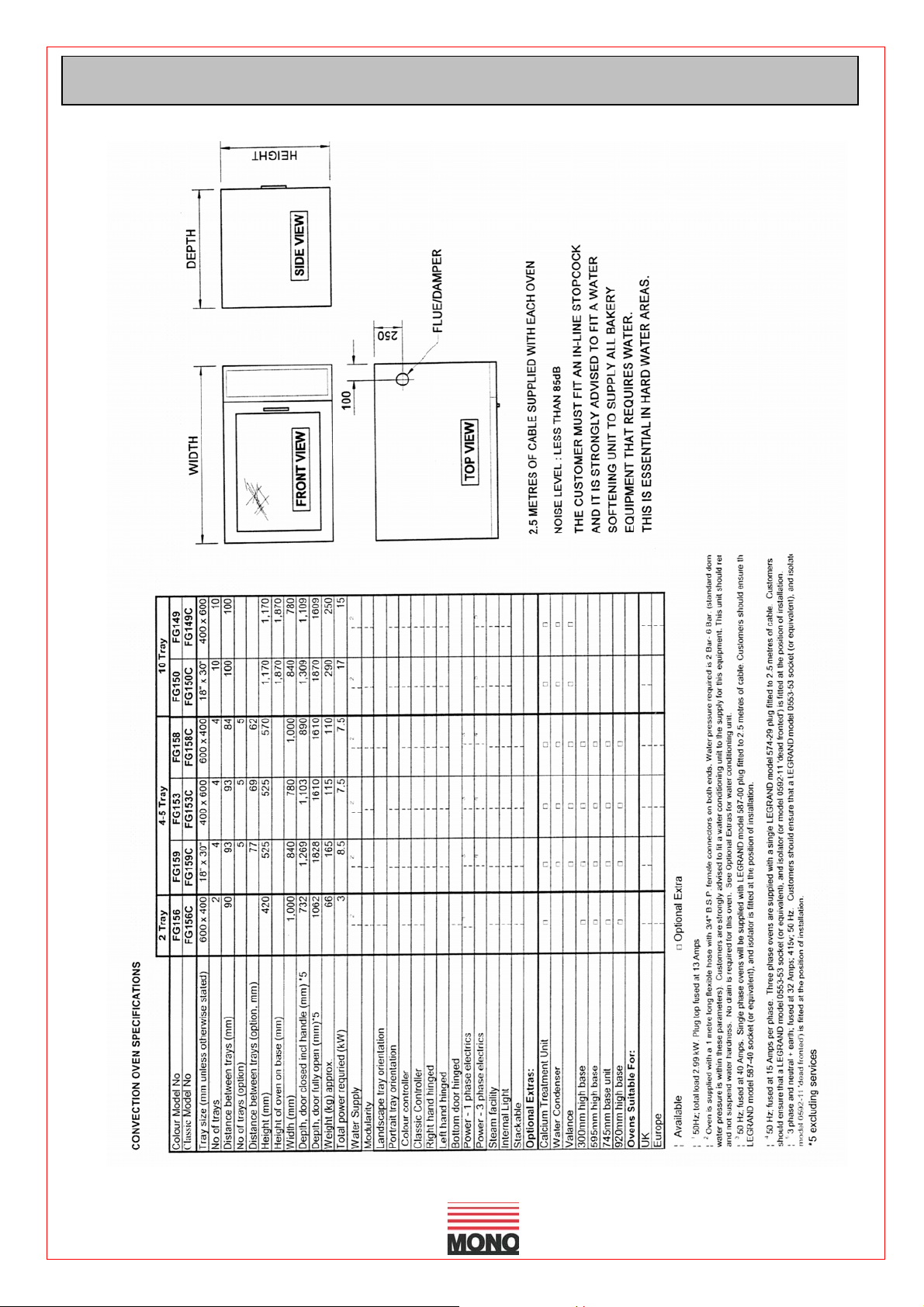

2.0 SPECIFICATIONS

Bx oven range inc condenser 05-06 (2-10) RAC

6

3.0 SAFETY

In the interest of safety and efficient operation of the oven, it is

essential that this manual should be made available to the operator

before work is commenced. The following points should be observed

and followed at all times.

1. The oven is designed for baking of bread, confectionery and savoury products

only. DO NOT use it for any other items without consulting with MONO.

2. The oven must be allowed to cool before any form of cleaning is started.

3. All repairs and maintenance of electrical units must be carried out by authorised

electricians; even then, electrical access panels must not be opened unless the

mains supply to the oven is isolated.

4. All connections to the oven must be made in accordance with the statuary

requirements of the country of installation.

5. While the oven is in operation (and for some time after use), it is inadvisable to

touch the oven window or the surrounds because of conducted heat.

6. The oven must be operated as described in this manual.

7. Only MONO spare parts should be used on this oven.

8. The construction of the oven must not be changed.

9. The owner of the oven is legally obliged to instruct staff of these safety points and

of the safe operation of the oven. These instructions should not be removed

from the working area.

10. To prevent door glass from shattering -

DO NOT CLEAN OVEN GLASS WHEN HOT.

11. Customers operating a BX oven in a hard water area must ensure that an efficient

water-softening device protects the water supply to the equipment.

12. Oven gloves should be worn when moving products in or out of the oven.

Bx oven range inc condenser 05-06 (2-10) RAC

7

4.0 INSTALLATION

A

1. The oven should be connected to a wall isolator.

2. It is the customers’ sole responsibility to arrange adequate ventilation and it should be

sufficient to ensure water does not condense on or around the oven. A 50mm gap is

required at the sides and rear of this oven.

Chimneys and evacuation ducts, fitted above mono ovens should be insulated.

3. If an oven with steam has been chosen, connect to a suitable water supply making sure that

the pipes are flushed out to remove all foreign bodies i.e. flux or solder. Customers in hard

water areas must ensure that an efficient water treatment device protects the supply to the

oven. It is the customers’ responsibility to install and maintain an adequate water supply to

the oven, which should comply with local water regulations.

4. In the interests of hygiene, we strongly recommend that before using the oven for the first

time you wipe the inside of the oven and all accessories thoroughly with a clean cloth

soaked in warm soapy water. Although the utmost care is taken during assembly and predelivery inspection, there is always a possibility of residue contaminating the first bake if this

is not done.

5. Ensure that the locking castors on the base unit (if supplied) are locked into position.

6. AMBIENT WORKING TEMPERATURES.

mbient working temperatures for electric/electronic components such as solenoid switches,

circuit breakers, motors etc should be

Manufacturers of these and other electrical components advise that any ambient temperature above 40°C

affects the functionality of the components and any related guarantees become void. For example, above this

temperature motors are not satisfactorily cooled, contactor efficiency is seriously impaired and electronic

components shut down. It is the customers’ sole responsibility to arrange for ad equate ventilation. Any

component malfunctioning during the guarantee period that is found to have been subject to excessive

humidity or ambient working temperature above 40

’

no more than 40°C (115° f)

°

C (115°F) will not be covered by the component

Bx oven range inc condenser 05-06 (2-10) RAC

8

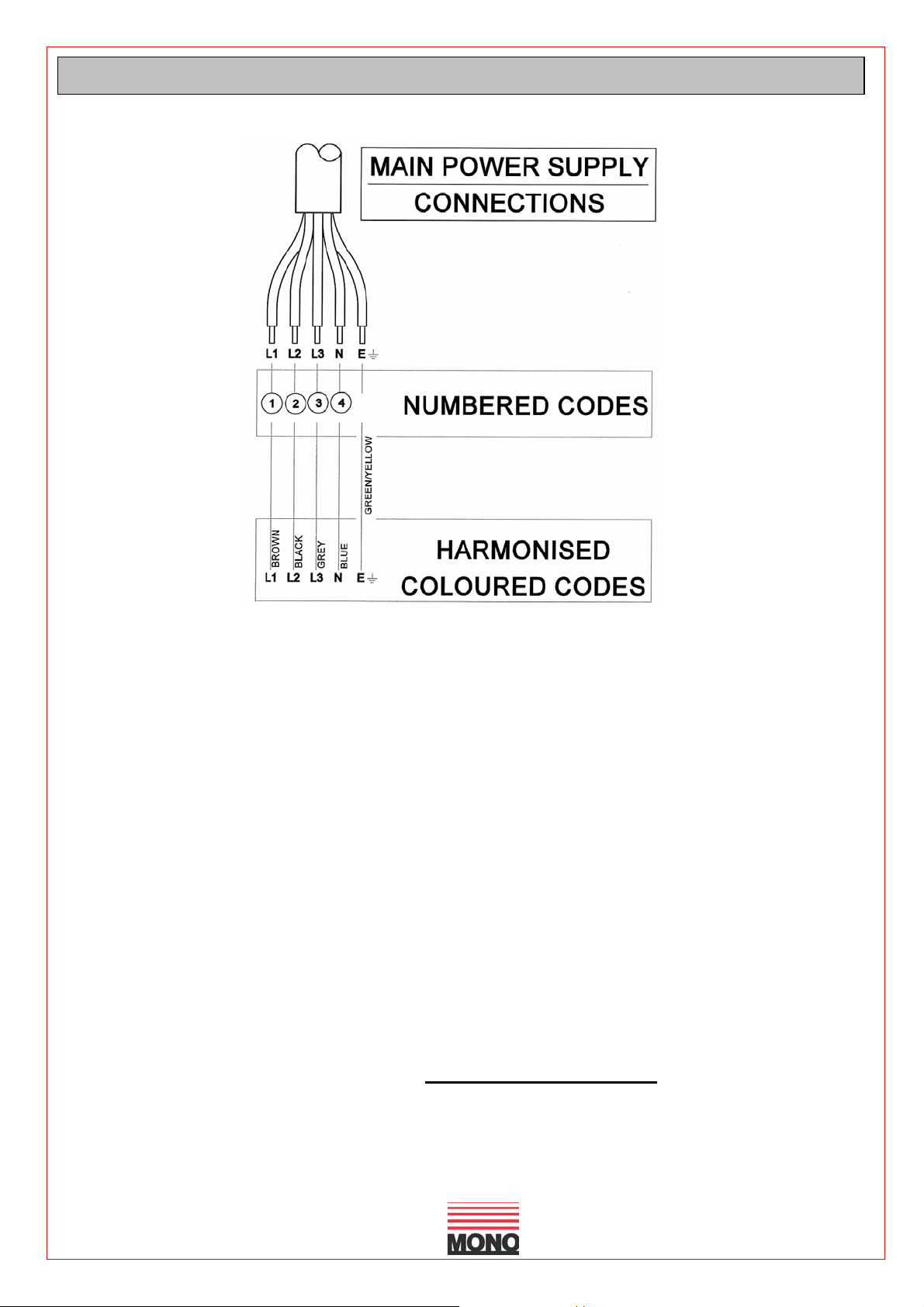

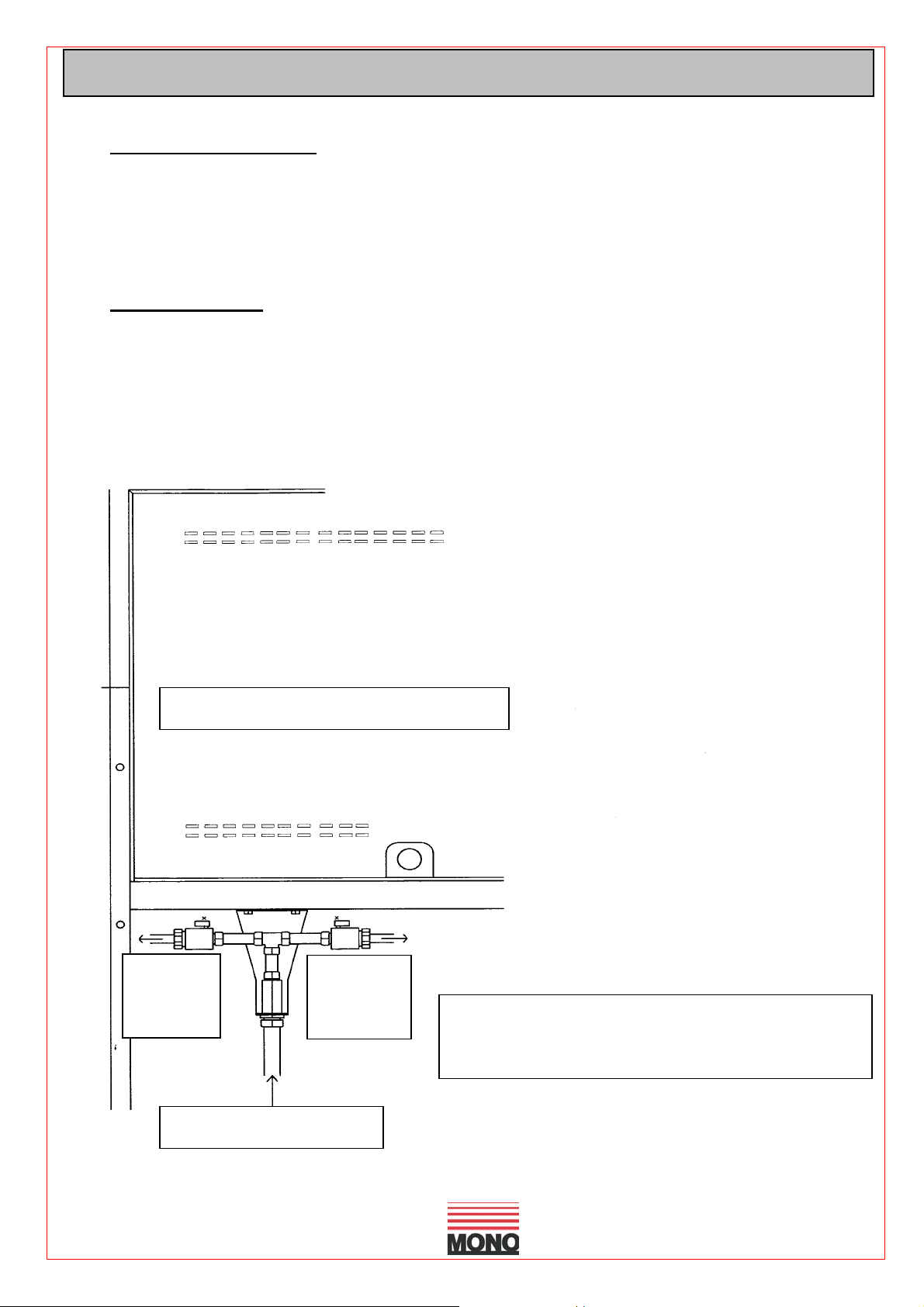

5.0 ISOLATION

ELECTRICITY SUPPLY

To stop the oven in an emergency, switch off electricity at the wall isolator

WATER SUPPLY

For stacked ovens, the water supply can be shut off by closing the shut-off valves

(See diagram)

For non-stacked ovens the water supply should be shut off at the nearest shut-off point

.

VIEW OF REAR CONNECTIONS

TOP

OVEN

SUPPLY

WATER SUPPLY IN

BOTTOM

OVEN

SUPPLY

TO TURN OFF WATER SUPPLY

TURN APPROPRIATE VALVE 90 DEGREES

ANTICLOCKWISE

Bx oven range inc condenser 05-06 (2-10) RAC

9

6.0 CLEANING INSTRUCTIONS

DAILY

NOTE: BEFORE CLEANING ISOLATE OVEN FROM MAINS SUPPLY

AND ALLOW TO COOL.

• The equipment is to be cleaned daily using approved chloride–free cleaning fluid

• Sweep any debris (after it has been allowed to cool) onto oven removable trays and

remove for cleaning.

• Brush down and wipe oven front, back and sides.

• Wipe clean with a damp cloth that has been soaked in a solution of mild detergent

and hot water, paying particular attention around control switches.

IMPORTANT:

TAKE CARE WATER DOES NOT ENTER CONTROL PANEL OR

REAR ACCESS PANEL.

DO NOT REMOVE THE REAR PANELLING INSIDE THE OVEN.

THIS ALLOWS ACCESS TO THE FAN ASSEMBLY WHICH IS NOT SAFETY

INTERLOCKED AND COULD CAUSE INJURY

WEEKLY

NOTE: BEFORE CLEANING ISOLATE OVEN FROM MAINS SUPPLY

Complete daily check then

• Clean any burnt-on debris by careful use of a proprietary oven cleaner, carefully

following the manufacturer's instructions. Do not allow the oven cleaner to get

onto control panel.

• Scrub cabinet wheels (if fitted), with a mild detergent and hot water using nylon

cleaning brush.

AND ALLOW TO COOL.

Bx oven range inc condenser 05-06 (2-10) RAC

10

Ovens using 60cm x 40cm trays ( FG156 2 tray / FG158 4 tray)

Open oven door and remove internal racking from sides of oven.

(lift and unlatch racking).

This allows access to hidden areas in the oven, which can be wiped with a damp cloth.

Wipe down, and clean racking with damp cloth and replace.

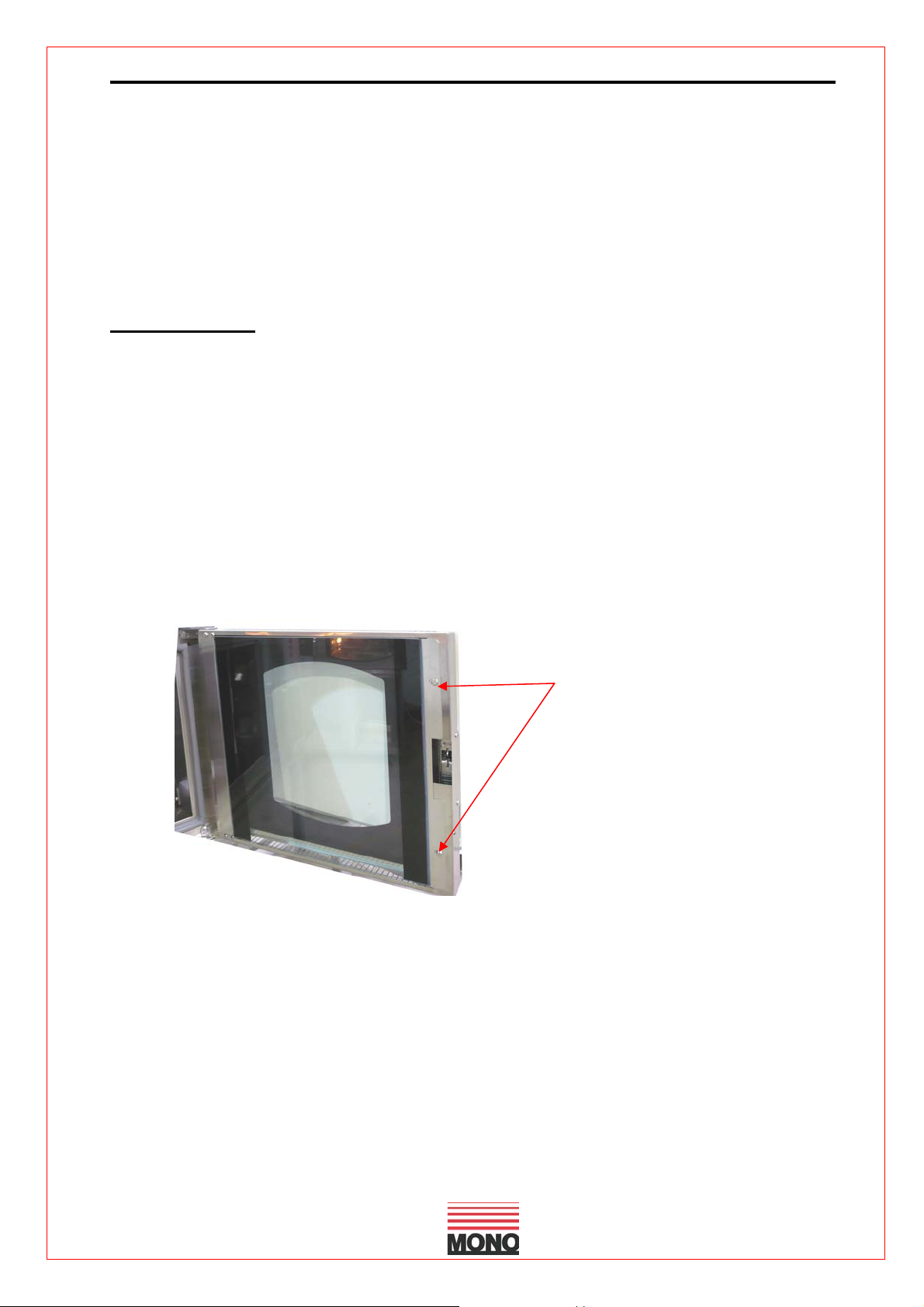

4 tray ovens

The inner door glass is hinged to enable cleaning of internal surfaces.

To open, remove the two screws shown in the sketch below.

The internal surfaces of the door glass can then be cleaned using a suitable glass

cleaner.

Remove these screws

to release inner glass

for cleaning

Bx oven range inc condenser 05-06 (2-10) RAC

11

7.0 IDEAL OPERATING CONDITIONS

• Room should be allowed for the door to open fully to allow easy loading and unloading of

product without people coming in contact with hot surfaces.

• Racks should be available to allow cooked products to cool safely.

• Oven gloves should be available at all times.

• It is the customers’ sole responsibility to arrange adequate ventilation and it should be

sufficient to ensure water does not condense on or around the oven. A 50mm gap is

required at the sides and rear of this oven.

• Chimneys and evacuation ducts, fitted above mono ovens should be insulated

AMBIENT WORKING TEMPERATURES.

Ambient working temperatures for electric/electronic components such as

solenoid switches, circuit breakers, motors etc should be

Manufacturers of these and other electrical components advise that any ambient temperature

above 40

void. For example, above this temperature motors are not satisfactorily cooled, contactor

efficiency is seriously impaired and electronic components shut down. It is the customers’ sole

responsibility to arrange for adequate ventilation. Any component malfunctioning during the

guarantee period that is found to have been subject to excessive humidity or ambient working

temperature above 40

guarantee or MONO’s product warranty.

°

C affects the functionality of the components and any related guarantees become

°

C (115°F) will not be covered by the component manufacturers

no more than 40°C (115° f)

Bx oven range inc condenser 05-06 (2-10) RAC

12

Bx CLASSIC

Operating

Instructions

Bx oven range inc condenser 05-06 (2-10) RAC

CLASSIC

13

Loading...

Loading...