Erika CCP-98 Installation Manual

AUTOMATIC INTERMEDIATE PROOFER

INSTRUCTIONS MANUAL

INSTALLATION, WORKING, MAINTENANCE

INTERMEDIATE PROOFER MOD. 98

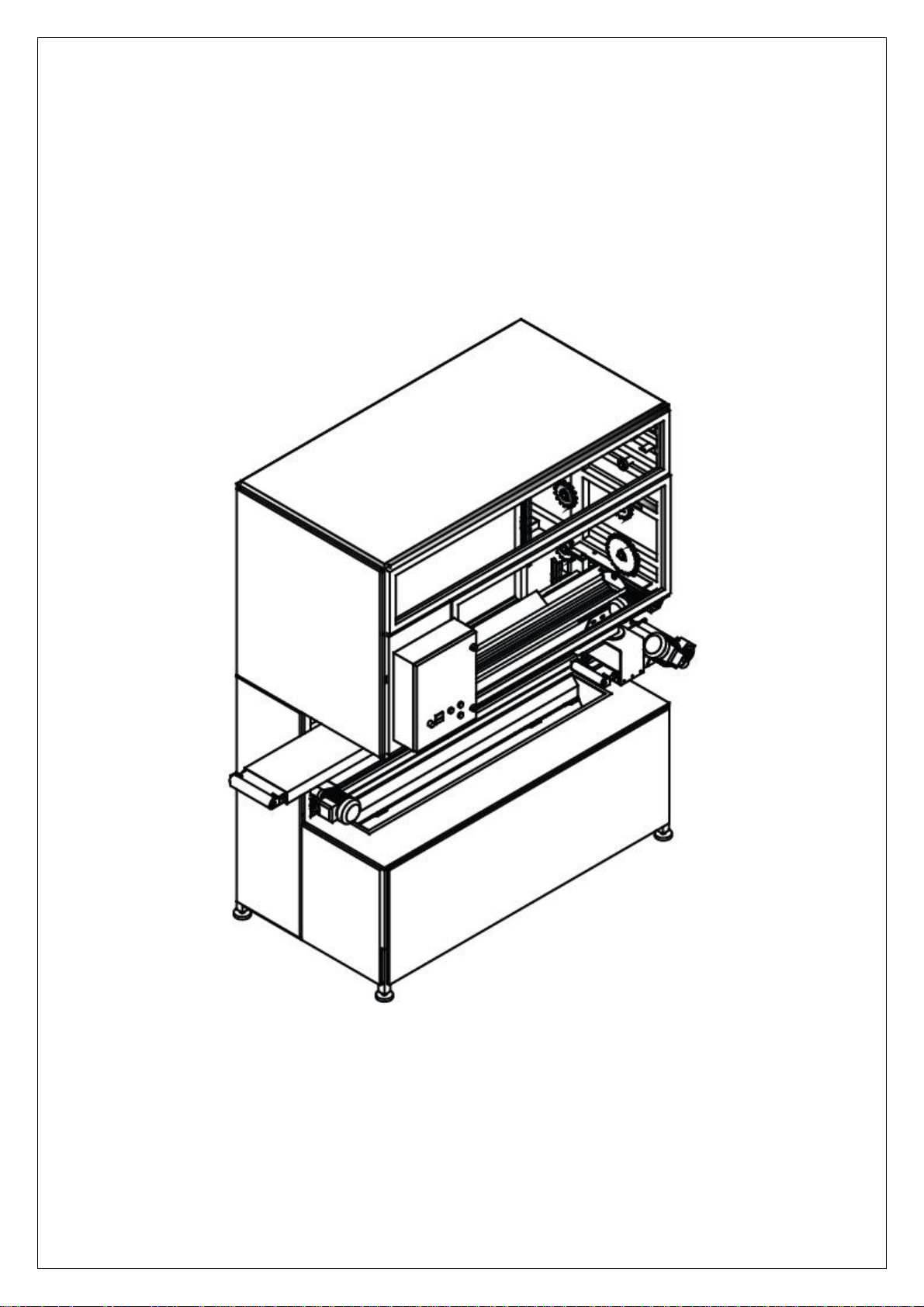

INTERMEDIATE PROOFER CCP-98

GENERAL DESCRIPTION

The intermediate proofer model CCP-98 is a static proofer, specially designed to work within

an automatic processing group. It works in combination with a divider, a rounder and a moulder. The

function of the proofer is to let the dough repose during the necessary time to lose the tensions

acquired in the divider and the rounder before being formed in the moulder.

In this model there is flexibility relating to the number of pieces to load, because the speed of

the loader and of the unloading belt can be regulated. This allows a wide margin in the reposing time.

There is also flexibility in the size of the pieces to load, because they are used buckets without bags.

As an approximation, in the basic model, the capacity of the machine loading pieces of 300g,

is 300 pieces. This machine can be upgraded with frontal, rear and top modules if it is needed. With

those modules the capacity can be increased until near 900 pieces.

MACHINE COMPONENTS

The intermediate proofer model CCP-98 is composed by:

- 1 Loading conveyor belt.

- 1 Loader.

- 2 parallel chains and a variable number of buckets.

- 1 big flour sprinkler.

- 1 unloading conveyor belt.

- 1 electric main board.

- 1 set of germicide tubes.

INSTALLING THE MACHINE

Usually, the machine is delivered assembled, but for the transport and handle of the machine,

there are installed some cross bars, with section of 40x80, which are not painted. They must be

replaced for the painted ones (supplied with the machine, and with the correspondent holes for the

covers). Check all the received material and do the appropriate changes before connecting the

machine.

FIRST CONNECTION

Once verified that the machine is ready to start working, verify that the voltage at which the

machine is connected is the same one available in the local net. The machine can work at 220V and

at 380V, as well as at 50 or 60 Hz. After doing this, connect the machine to the electric net and switch

on the main switch on the main board. Then, giving a short impulse to the green button of the remote

control, verify that the buckets turn in the correct direction, if this does not occur, change the phases to

invert the motor turning sense.

STARTING THE WHOLE LINE

If the main switch is disconnected, none of the machines will work, because the divider and

the moulder are powered from the main board on the proofer. When the main switch is connected the

power led lights, but the machine does not start until the green button on the remote control is

pressed. Once it is pressed the loader and unloading belts will move, if the “Divider – Unload”

selector is in the “Divider” position. It will also work the small entrance belt. Connect the divider and

the rounder. If the rounder is incorporated on the divider, the flour of the sprinkler must fall in the small

case over the entrance belt. If a conic or carrier band rounder is used the dough pieces coming from

the rounder must fall correctly impregnated with flour in the small case placed over the entrance belt.

SPEED REGULATION

From the entrance belt, the balls fall to the cavity formed by the bands of the loader. These

bands transport the pieces with the speed selected in the potentiometer of the main board. The

number of pieces that will be loaded on each bucket depends on the divider speed and the speed of

the loader bands. To regulate the number of pieces to load on each bucket reasonably, first adjust the

speed of the divider as desired (the speed of the divider will depend on the number of workers that

collect pieces at the moulder, the speed must be low if there is only one person, faster if there are two,

etc).

Once adjusted the speed of the divider, increase or reduce the speed of the loader bands until

the desired number of pieces is loaded on each bucket (the speed of the unloading and loader belts is

controlled from the same frequency inverter, therefore the speed of one relating to the other is always

proportional).

LOADING THE INTERMEDIATE PROOFER

Once the number of pieces to load on each bucket is adjusted, it can be adjusted the moment

in which the loader’s bands open, by means of the micro-switch that controls it. This micro is placed

inside a stainless steel box, placed on the opposite side of the entrance belt. If it is moved a little to the

right or the left, it will advance or retard the moment in which the loader bands open releasing the

balls. Adjust the micro-switch in such a way that the bands open precisely when the last piece of each

loading cycle has been loaded.

Notice that the divider has priority while it is working. This means that the proofer will load as

many pieces as the divider sends. That number of pieces can only be changed changing the speed of

the divider. When the proofer is full, it can work in a continuous cycle, that is, the divider can continue

working and the proofer will unload pieces as fast as it loads them. So once the proofer is full, for each

piece that enters, there is another one that comes out, and this is the most usual system of work.

UNLOADING THE MACHINE

Only when there is not any dough left inside the hopper of the divider, and the proofer is full

loaded, change the selector “divider – unload” to the “unload” position. Now adjust the unloading

speed from the timer in the main board.

STOPPING THE LINE

If stop button of the remote control is pushed, all the line stops except the moulder, which

works during some seconds to impede any dough piece to remain between the rollers, and stuck on

them creating a little problem.

MAINTENANCE

The intermediate proofer is equipped with a big flour sprinkler placed over the loader. It is

indispensable to keep it full with flour for the machine correct working. The amount of flour that the

sprinkler dusts can be adjusted.

SAFETY NORMS

The machine is completely covered with metal panels in the parts that could be dangerous for

the user. These panels must not be removed while the machine is working. This task must be done

only for qualified personnel.

MECHANICAL CARES

The machine has been designed to work without special cares. It has no lubricating system.

The only task that should be done is greasing the chains once every 2 or 3 years, because they are

the mechanic part that more work. The greasing of the chains must be done by qualified personnel.

Loading...

Loading...