Erika C230 Installation Manual

COMMERCIAL

SPREAD·MATIC

Instruction manual

Gibson Street, Leeds Road, Bradford,

West Yorkshire, England. BD3 9TR

Telephone: +44 (0) 1274 668771 Fax: +44 (0) 1274 665214

SPREAD·MATIC (Commercial) Rev - 1 Page 1 of 22

COMMERCIAL SPREAD·MATIC

This manual provides information on the Commercial SPREAD·MATIC with instructions on installation,

operation, cleaning and maintenance.

CONTENTS

1.0 Introduction

2.0 Technical Specification

3.0 Safety

4.0 Installation / Preparation for Production

5.0 Operating the machine

6.0 Maintenance

7.0 Cleaning

8.0 Fault Finding Guide

9.0 Recommended Spares List

10.0 Wiring Diagrams

11.0 Declaration of Conformity

SPREAD·MATIC (Commercial) Rev - 1 Page 2 of 22

GUARANTEE

The machine is guaranteed for twelve months against breakdown. The items not covered under

guarantee are those which wear through normal operation. Replacements are readily available from

the manufacturer.

SPREAD·MATIC (Commercial) Rev - 1 Page 3 of 22

Section 1.0 INTRODUCTION

1.1 SIMPLE AND SMOOTH OPERATION

This booklet should be read before attempting to use the machine, training is also

recommended.

The Deighton Manufacturing Commercial SPREAD·MATIC is a stand alone bread buttering

machine, which can also be incorporated into a sandwich making line. It can be used to

spread butter, margarine, butter containing ingredients, tomato puree or mayonnaise

achieving a high quality consistency.

Certain types of spread are not suitable for use in the SPREAD·MATIC, i.e. cooking butter and

some margarines containing minimul amounts of fats.

The SPREAD·MATIC can cover sliced bread, soft rolls, baps, scones and tea cakes up to a

thickness of 30mm.

The butter-box is accessed by the safety guarded lid. A set of easy to use controls operate

the buttering rollers and conveyor belt.

Once the process is complete the butter-box and conveyor belt can be removed for cleaning.

The unit is controlled from the front of the machine, the stop and start controls are situated on

the electrical enclosure. Spread thickness is set using a knob on the butter-box, height

adjustment is set with the knob on the top of the machine.

1.2 HYGIENE

The SPREAD·MATIC assembly is of a stainless steel and Delrin construction which lends itself

to ease of cleaning. All controls are sealed to at least IP67.

SPREAD·MATIC (Commercial) Rev - 1 Page 4 of 22

Section 2.0 TECHNICAL SPECIFICATION

COMERCIAL SPREAD·MATIC

Model No’s

C230

C120

Region

UK

EU

US

ELECTRICAL SPECIFICATIONS.

The SPREAD·MATIC is configured for the appropriate electrical supply

and supplied with a fixed cordset for the appropriate region

Voltage

230 VAC

120 VAC

Frequency

50 Hz

60 Hz

Power

65 W

90 W

Input Supply

requirements

230V, 50Hz 13A

230V, 50Hz 16A

120V, 60Hz 10A

Cordset

3 Core 0.75 mm² (L,N+E) supplied with

a moulded plug.

UK model fitted with 13 Amp fuse.

2 wire + Gnd (3 x 18 Awg,

SVT, 300V, 60°C VW-1

Input Protection

The SPREAD·MATIC is to be connected to an appropriately rated

Branch Circuit protected supply.

THIS MACHINE MUST BE GROUNDED/EARTHED.

ENVIRONMENTAL

Operating

Temperature:

16°C to 25°C (61°F to 77°F)

Altitude:

Less than 2000 m

Noise:

Emissions do not exceed 70 dB at workstation position

MECHANICAL

Dimensions:

Length - 722 mm

Depth - 291 mm

Height - 586 mm

Weight (Approx):

40 kg (88.2 lbs)

Hopper Capacity:

1 Litre

Belt Speed Approx:

12m/min

Bread Width Max:

135mm

Bread Thickness:

5 to 30mm

Output Approx:

3000 slices per hour

Spread Weight per

Slice Max:

8 g

2.1 RATINGS AND SPECIFICATIONS:

SPREAD·MATIC (Commercial) Rev - 1 Page 5 of 22

Section 3.0 SAFETY INSTRUCTIONS

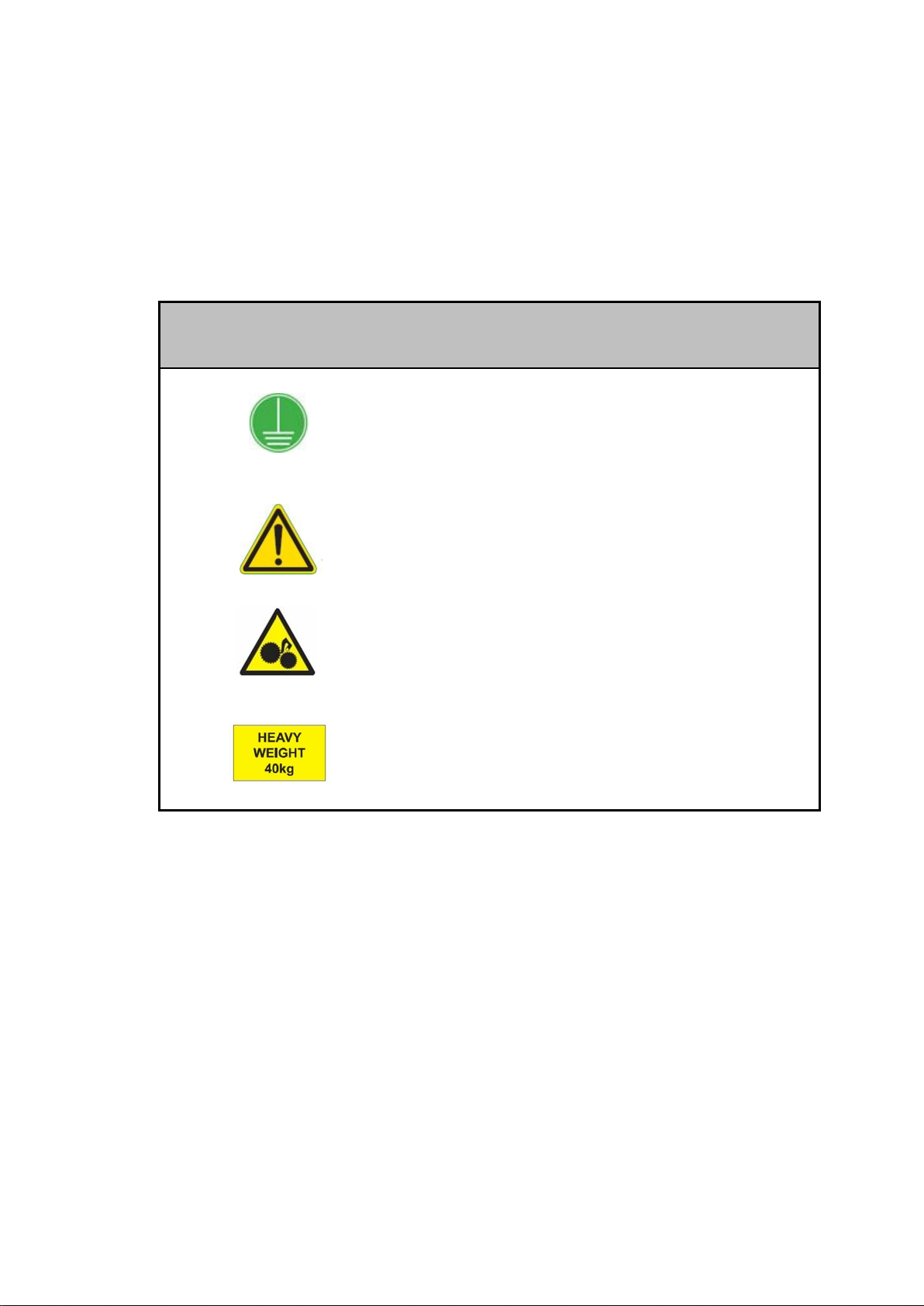

SYMBOL

MEANING

Protective Earth

Warning or caution.

A hazard or caution may exist, refer to the appropriate

section within this instruction manual.

Moving Parts

Heavy weight, lifting required by two persons

3.1 SAFETY SYMBOLS

The following safety symbols, are used and maybe referenced on the Commercial

SPREAD·MATIC and within the supporting documentation.

SPREAD·MATIC (Commercial) Rev - 1 Page 6 of 22

3.2 SAFETY INSTRUCTIONS

The SPREAD·MATIC contains no serviceable or re-useable parts.

All cleaning and servicing requires the equipment to be isolated from the power

source and disconnected.

The SPREAD·MATIC weighs in the excess of 40kg (88.2 lbs) and requires 2 persons to

lift.

Should a fault occur with the SPREAD·MATIC, immediately isolate and disconnect the

incoming power.

When the machine is being transported it should be sat firmly on its feet. The

machine should be strapped upright to a flat pallet during transport.

When the machine is not in use power should be disconnected.

Ensure the equipment is installed, operated and maintained by trained and authorised

personnel.

Always make sure that there are no hard items in the mix as they can damage your

machine.

Keep hands and loose clothing away from the machine when in operation.

Always isolate the machine before cleaning or maintenance.

Always ensure the machine is level when in use.

In an emergency press the red ‘E’ stop button situated on the front of the control box.

The machine should be used as provided and should not be tampered with nor

altered as the machine contains inbuilt safety systems which could be compromised

by any interference.

Ensure safe storage/positioning of electrical cabling. Should the electrical cable

become damaged do not operate the SPREAD·MATIC.

SPREAD·MATIC (Commercial) Rev - 1 Page 7 of 22

Loading...

Loading...