Erika AUTO SMART Installation Manual

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

Revision

21.04.2009

AUTOMATIC DOUGH SHEETER

AUTOSMART – SMART

INDISMART - ECOSMART

1/96

n°1

date

20.07.2006

HIS MANUAL CONTAINS THE GUARANTEE COUPON

T

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

2/96

Revision

n°1

date

21.04.2009

1- GENERAL.............................................................................................................4

1.1. GUARANTEE ................................................................................................................. 5

to be copied and rendered to the supplier .................................................................................. 5

This coupon has to be mailed back to the supplier before starting working with the machine ....5

1.2 GENERAL WARNINGS AND APPLICATION....................................................................... 6

1.3 RATING PLATE DATA......................................................................................................... 7

1.4 TRANSPORT INSTRUCTIONS............................................................................................ 8

1.5 ASSEMBLY.......................................................................................................................... 9

1.7 INSTRUCTIONS FOR INDOOR HANDLING...................................................................... 10

1.8 DECOMMISSIONING......................................................................................................... 12

2- TECHNICAL SPECIFICATION...........................................................................13

2.1 TECHNICAL DESCRIPTION.............................................................................................. 14

2.2 TECHNICAL SPECIFICATIONS ........................................................................................ 31

2.3 ELECTRIC DIAGRAMS...................................................................................................... 34

3- STARTING UP....................................................................................................46

3.1 INSTALLATION.................................................................................................................. 47

3.2 CONNECTION TO THE MAINS......................................................................................... 48

4 - INSTRUCTIONS FOR USE................................................................................49

4.1 GENERAL INFORMATION................................................................................................ 50

4.2 USE OF THE MACHINE .................................................................................................... 52

4.3

COMMANDS ON THE SHEETER................................................................................ 53

5- MAINTENANCE AND CLEANING......................................................................54

5.1 MAINTENANCE................................................................................................................. 55

5.2 CLEANING......................................................................................................................... 55

6- OPERATING FAULTS........................................................................................58

6.1 TROUBLE SHOOTING ...................................................................................................... 59

7- SAFETY WARNINGS..........................................................................................60

7.1 SAFETY DEVICES............................................................................................................. 61

7.2 SAFETY AND IDENTIFICATION PLATES......................................................................... 62

7.3 PROHIBITIONS AND OBLIGATIONS FOR PREVENTION OF ACCIDENTS ....................64

8- SPARE PARTS...................................................................................................65

8.1 INSTRUCTIONS FOR ORDERING.................................................................................... 66

8.2 TAV. N° 1 - - STRUCTURE AND COMPONENTS...... .................................................... 67

8.3 TAV. N° 2 - CLUTCH UNIT ............................................................................................... 68

8.4 TAV. N° 3 - SIDE PANEL CLUTCH UNIT............ .............................................................. 70

8.5 TAV. N° 4 - TOUCH-SCREEN UNIT................. ................................................................ 71

8.6 TAV. N°5 – REAR SIDE UNIT...................... ...................................................................... 72

8.7 TAV. N° 6 – CHAINS UNIT........................ ......................................................................... 74

8.8 TAV. N°7 – PULLEYS UNIT........................ ....................................................................... 75

8.9 TAV. N.8 – SCRAPERS UNIT............................................................................................ 77

8.10 TAV. N° 9 - CONVEYOR BELT UNIT............... ............................................................... 78

8.12 TAV. N° 11 – SAFETY GRIDS UNIT............................................................... 82

8.13 TAV. N° 12 - FLOUR DUSTER.................... .................................................................... 84

8.14 TAV. N° 13 - FLOUR DUSTER.................... .................................................................... 85

8.15 TAV. N° 14 - FLOUR DUSTER.................... .................................................................... 86

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

8.16 TAV. N° 15 - FLOUR DUSTER.................... .................................................................... 86

Revision

n°1

date

21.04.2009

3/96

8.17 TAV. N° 16 – FLOUR DUSTER UNIT .............................................................88

8.18 TAV. N° 17 – ELECTRIC PLANT.................................................................... 90

8.19 TAV. N° 18 – PANELS UNIT........................................................................... 91

9- ACCESSORIES ON REQUEST..........................................................................92

9.1 - AUTOMATIC FLOUR DUSTER.................................................................................. 93

9.2

- AUTOMATIC DOUGH WINDER................................................................................. 93

9.3

- CUTTING DEVICE..................................................................................................... 93

9.4

– DIE-CUTTERS UPON REQUEST ............................................................................. 93

10- ELECTRICAL EQUIPMENT .............................................................................94

10.1 DESCRIPTION................................................................................................................. 95

10.2 DOCUMENTATION.......................................................................................................... 96

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

date 20.07.2006

4/96

Revision n°1

1- GENERAL

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

date 20.07.2006

5/96

Revision n°1

1.1. GUARANTEE

The manufacturer guarantees the good working and the quality of this sheeter for a period of 6

months from the shipping date, in the case ONLY of mailing the underneath filled and signed

coupon within 15 days from receipt of the machine.

The guarantee will be valid only with the correct use and maintenance of the machine as per

enclosed instructions.

The guarantee won’t be any more valid in in the following cases:

− non-authorised modifications or work on the machine;

− use of non-original spare parts or parts not specific for the model;

− failure to follow the instructions, even partially.

− normal wear of the concerned parts.

The guarantee is limited to the substitution of the defected part only. All the other claims such as

indemnities for interruption of the production or similar are not considered in the guarantee.

If necessary, the supplier can ask the machine to be returned for repair during the guarantee

period.

---------------------------------------------------------------------------------------------------------------------------------

to be copied and rendered to the supplier

This coupon has to be mailed back to the supplier before starting working with the

machine

GUARANTEE COUPON

T

HE MANUFACTURER GUARANTEE FOR

MODEL

SERIAL NUMBER

DATE OF INSTALLATION

NAME AND COMPLETE ADDRESS

_____________________________________________________________

_______________________________________________________

__________________________________________________

____________________________________________

:

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

date 20.07.2006

6/96

Revision n°1

1.2 GENERAL WARNINGS AND APPLICATION

The aim of this manual is:

− To facilitate understanding and operation of the machine and enable the system to be used to

its full technical potential.

− To provide instructions for the most effective and rational maintenance and help the operator to

understand any faults and how to remedy them.

− To warn against risks inherent in use of the machine due to failure to observe the safety

regulations.

− To indicate working limits for maintaining hygiene and environmental conditions and to ensure

health at work.

These pages must be read carefully before starting the machine.

This manual forms an integral part of the product; it must be kept near the machine for prompt

easy consultation and must also be kept for future reference until the machine is scrapped.

The manufacturer does not guarantee the technical-legal suitability of the installation premises and

machine supporting services but provides all instructions for correct installation in the relevant

section of this manual.

For the above, the user is advised to contact an expert professional technician, also for

compliance with any local laws or regulations.

• The machine is designed for the food industry.

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency for cake-making in

general.

• The machine must be used only for the purpose for which it has been designed. All other uses

are considered inappropriate and therefore unreasonable.

The manufacturer cannot be held liable for incorrect use, inappropriate and/or

unreasonable acts.

The manufacturer cannot be held liable for any damage caused by inappropriate, incorrect

or unreasonable use, for example:

− inappropriate use by non-trained personnel;

− non-authorised modifications or work on the machine;

− use of non-original spare parts or parts not specific for the model;

− failure to follow the instructions, even partially.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

date 20.07.2006

7/96

Revision n°1

1.3 RATING PLATE DATA

the picture 0A shows exactly the registration plate applied on the machine. On picture 2 an arrow

indicates the position where this plate is fixed on the basement of the machine. The plate is

realised in serigraphed aluminium and all the registration datas are wirtten with permanent ink, to

last as long as possible.

It is forbidden to remove of replace the plate “CE MARKING”. If the plate is damaged or removed

please inform TeknoStamap immediately

picture 0A

GRISIGNANO - VICENZA

SERIAL N°

CONSTR. YEAR

V Hz

KV

ITALY

A

PHASES

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

H

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

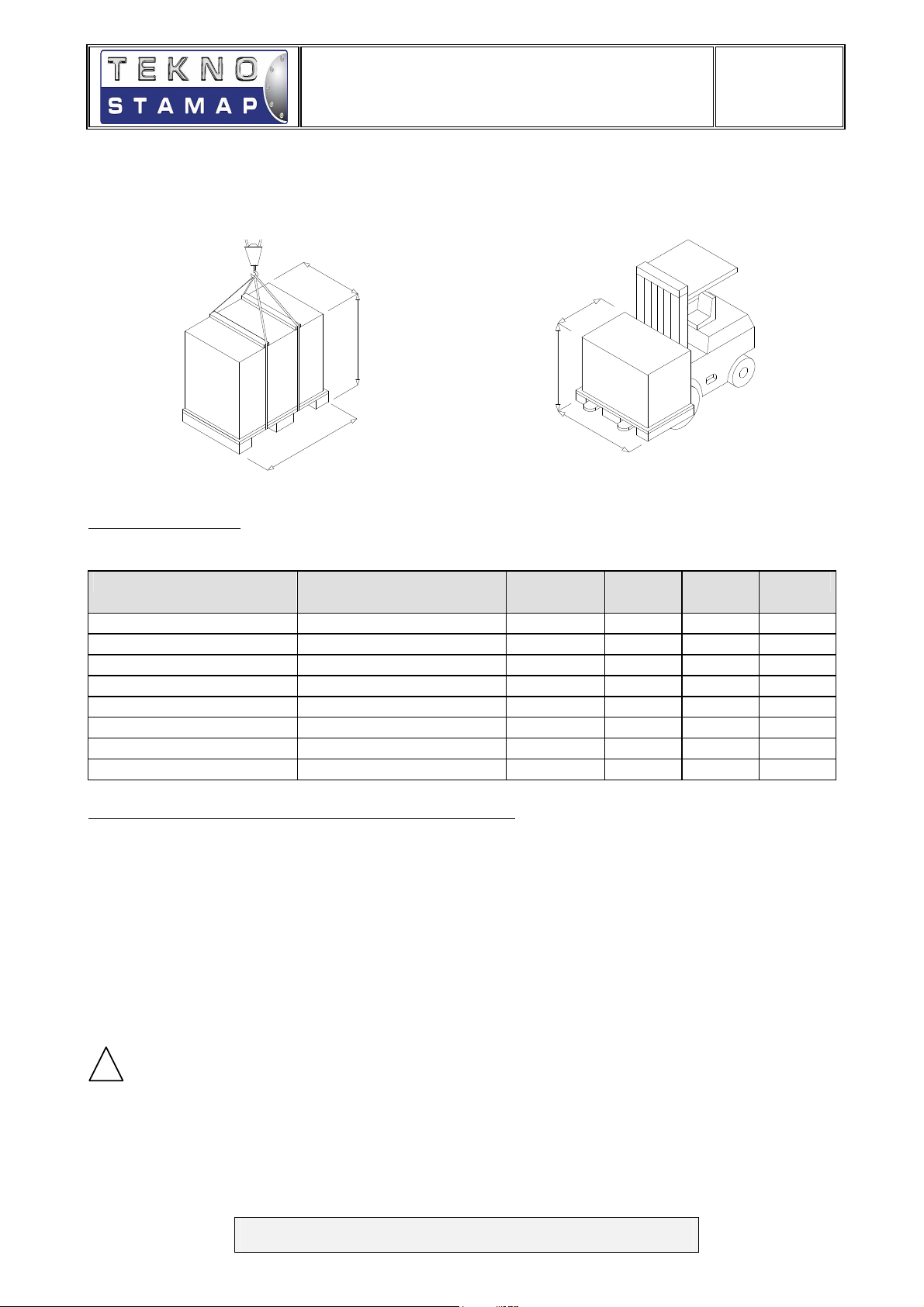

1.4 TRANSPORT INSTRUCTIONS

B

8/96

Revision n°1

date 20.07.2006

B

H

A

A

A B

PACKAGING DATA

− The machine is supplied on a pallet, in a strapped triple-layer corrugated cardboard box.

Mod. packaging weight

A mm B mm H mm

KG.

ECO SMART 6514 Pallet and wooden crate 1490 1440 1900

ECO SMART 6516 Pallet and wooden crate

SMART 6514 Pallet and wooden crate

SMART 6516 Pallet and wooden crate

AUTO SMART 6514 Pallet and wooden crate

Pallet and wooden crate

AUTO SMART Pallet and wooden crate

Pallet and wooden crate

1490 1440 1900

1490 1440 1900

1490 1440 1900

1490 1440 1400

940 2040 700

1490 1440 1400

940 2040 700

INSTRUCTIONS FOR TRANSPORT AND UNLOADING

− Loading and unloading from the vehicle can be performed:

− by means of crane, see figure “A”

− by means of forklift truck, see figure “B”.

− The machine must be transported adopting all precautions to prevent damage to the machine.

− In particular the machine must not be placed on top of other materials and vice versa either

during transport or storage.

− During transport the machine must be positioned so that it cannot be knocked by other

materials loaded on the same vehicle.

− Before unloading from the vehicle, check that the packaging is intact and that there is no risk of

tipping over.

− During unloading, place the machine carefully on the ground to prevent it being knocked.

!

CAUTION When handling, pay attention to all the indications on the packaging. The

capacity of the belts must be adequate for the weight of the packages. Do

not use metal belts.

Technical Assistance Service tel. +39/0444414731

1.5 ASSEMBLY

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

date 20.07.2006

9/96

Revision n°1

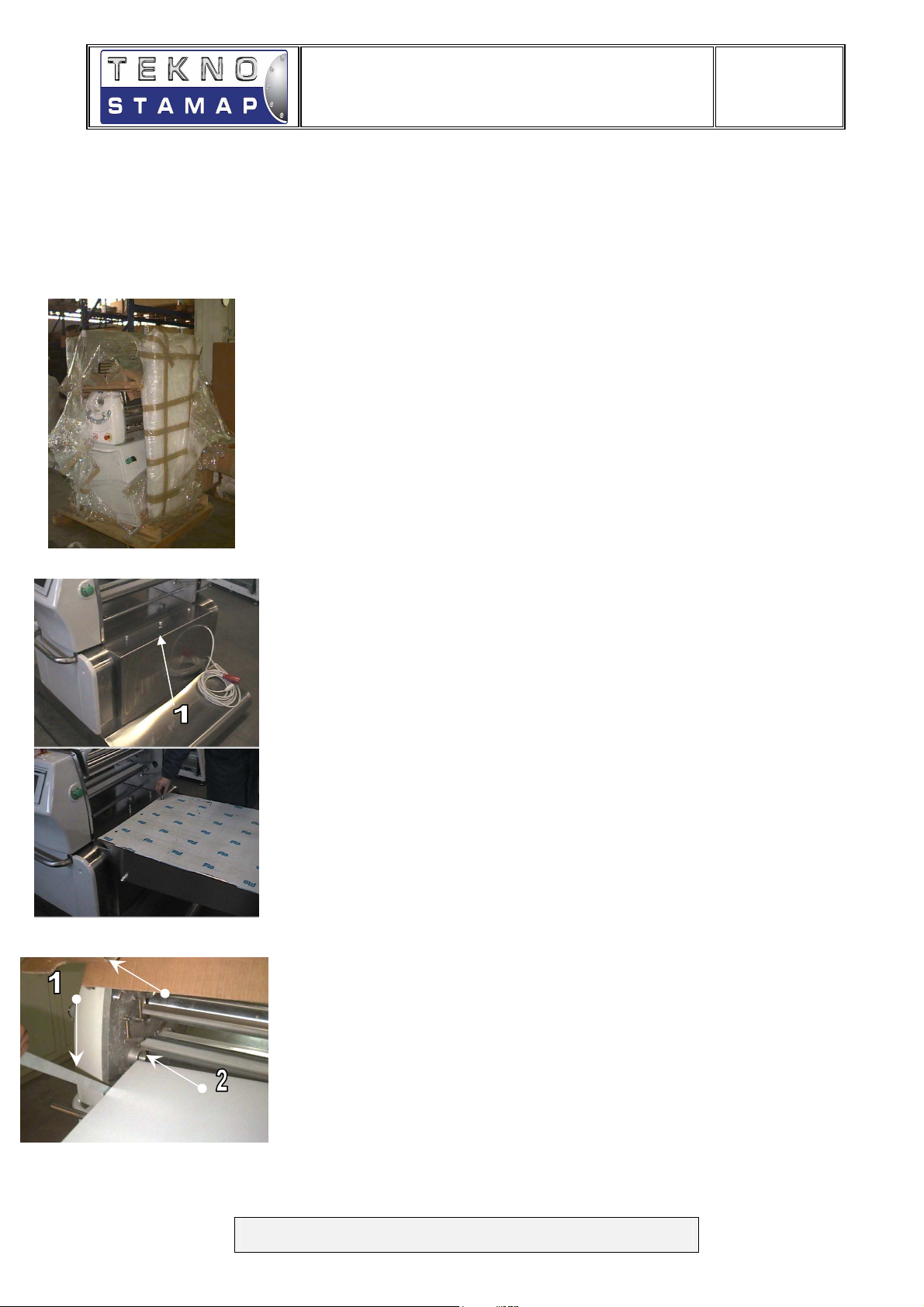

The machine is delivered on a pallet and wrapped with plastic and protected

by a wooden crate.. In order to assure a safe transportation, the working

tables are diassembled and packed separately.

It is necessary to take off the plastic carefully in order to avoid the tables or

other compounds to fall down.

Unpack the machine from the crate rendering free all the components.

Release the screws (1)

Before proceeding with assembly of the flour recovers and worktops see

item 1.7 instructions for inside handling. Lay the flour recovering sheet as

per picture and proceed with screwing (1). The worktops are assembled

through a baionnet coupling. Use a rigid lever of 50 cm to work easily.

The rotation pin has to be inserted on the rear side of the machine first as

per side picture.

By using the lever (1) push the worktop unitl

the grooved shaft will go inside the proper seat (2). To facilitate this

operation a porthole has been done on the side panel for the grooved

shaft passage. Once the link is done, pull the belt on order to make the

shaft rotating (motorised cylinder); in this way the coupling is perfectly

done. A plug located near to the flour duster will be connected to the

Mains.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

10/96

Revision n°1

date 20.07.2006

1.7 INSTRUCTIONS FOR INDOOR HANDLING

mod. AUTOSMART. The most easy way to

move this automatic sheeter is to position it

meanwhile the worktops and flour

recovering sheets are not assembled. The

machine is provided with 2 rear wheels, 2

front wheels and 2 levelling feet (which have

to be adjusted in a second time to ensure a

correct stability). The 2 front wheels are

operated by 2 small pedals. Locate the

sheeter on the suitable place with enough

room for the worktop assembly. The front

wheels can be moved lifting the basement for a few cm by means of the front handle. Once the

sheeter is positionned the wheels are stopped through the pedals. Once the worktops are

assembled it is possible to make some small adjustments acting always on the front wheels. To

give more stability just act on the levelling feet located close to the front wheels.

Modello SMART Modello ECOSMART

The sheeter mod. SMART is provided with three wheels, two rear wheels(*) and one front wheel,

and two stabiliser feet located at the side of the front wheel. The front wheel is operated by a

mechanical pedal located at the front of the machine just above floor level. The stabiliser feet are

designed to ensure correct machine stability with respect to the floor. The machine must be

positioned in its place of work using the wheels. As soon as you have found the ideal work

position, press the pedal: the machine will be lowered slightly and the two feet will rest on the floor.

To move the machine again, raise it four centimetres by means of the handle and release the

weight. The front wheel is now ready for operation.

If you need to clean the floor or other, the two side worktops can be raised. This operation must be

performed raising one worktop at a time. Once maximum lifting position has been reached, a

mechanical stop will cut in consisting of a pin in the worktop engaging in a slot in the protection

grid.

Once the machine is positionned on the other place, stabilise it through the pedal located on the

bottom of the basement.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

!

CAUTION Indoor handling must be performed by adopting all the precautions

Mod. SMART-AUTOSMART

11/96

Revision n°1

date 20.07.2006

necessary to prevent damage to the machine components.

(*) The front or rear position is defined with respect to an operator standing in front of the

calibration thickness adjustment handle.

.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

12/96

Revision n°1

date 20.07.2006

1.8 DECOMMISSIONING

1.7.1 SETTING ASIDE

− If the machine has to be stored, it must be protected against dust and stored in a covered

place.

− If the machine is not going to be used for a long time, it must be protected against dust and

atmospheric agents by means of appropriate covering.

− No special precautions are required for the motor and electrical system; simply follow the above

instructions.

1.7.2 DISMANTLING

− To dismantle the machine, proceed as follows:

1. Eliminate the electricity supply cable.

2. Remove all moving parts that could be a hazard.

3. Dispose of the majority of parts as scrap metal and take to authorised scrapyards.

4. The other parts, plastic for example, must be disposed of according to current

regulations, via specialist firms if necessary.

Norm CEE 75/442 concerning dismantling of general waste materials

Norm CEE 78/319 concerning dismantling of toxic and noxious substances

Norm CE 75/439 concerning the elimination of used oils

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

13/96

Revision n°1

date 20.07.2006

2- TECHNICAL SPECIFICATION

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

14/96

Revision n°1

date 20.07.2006

2.1 TECHNICAL DESCRIPTION

APPLICATION

• The machine is designed for the food industry.

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency for cake-making in

general.

• The machine must be used only for the purpose for which it has been designed. All other uses

are considered inappropriate and therefore unreasonable.

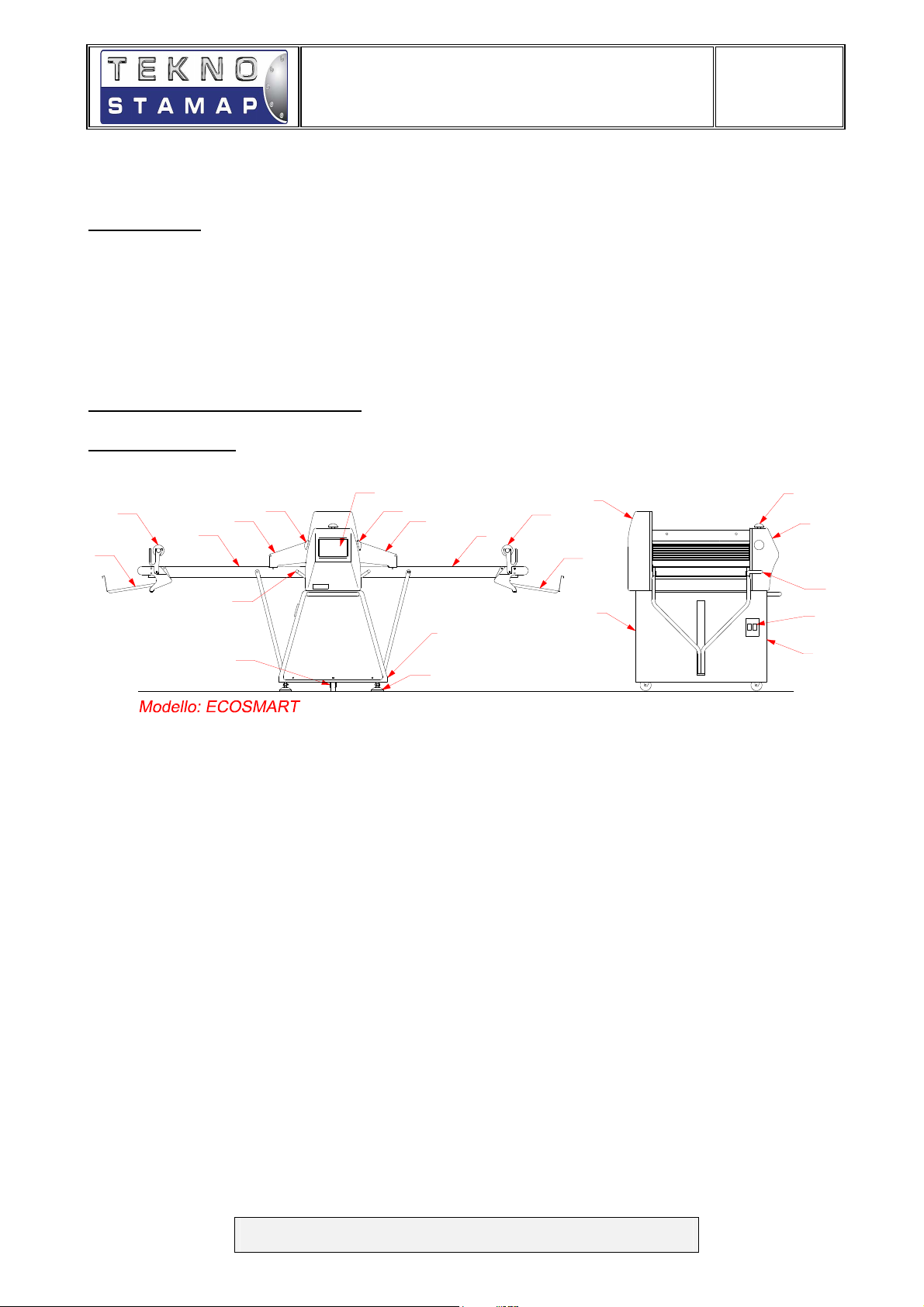

COMPOSITION OF THE MACHINE

Model ECOSMART

19

18

17

16

22

15

13

14

11

10

3

9

12

6

8

4

22

7

1

21

5

20

− The dough sheeter consists mainly of a supporting structure (1) two plastic covering panels (3)

- (4) and two side structure covering panels (5) – (6).

− The supporting structure (1) consists of a shaped welded metal sheet made of painted steel

with two sides (in aluminium) fitted above it and screwed together by means of metal spacers.

− Cover (3) houses the belt drive unit. Cover (6) houses the electric motor and cover (4) the drive

unit, called clutch unit, for reversing the movement of the machine.

− The basement is provided with levelling system (20) to ensure machine stability.

Optionals: automatic dough winder, automatic flour duster, cutting device, all the items are in

stainless steel.

Technical Assistance Service tel. +39/0444414731

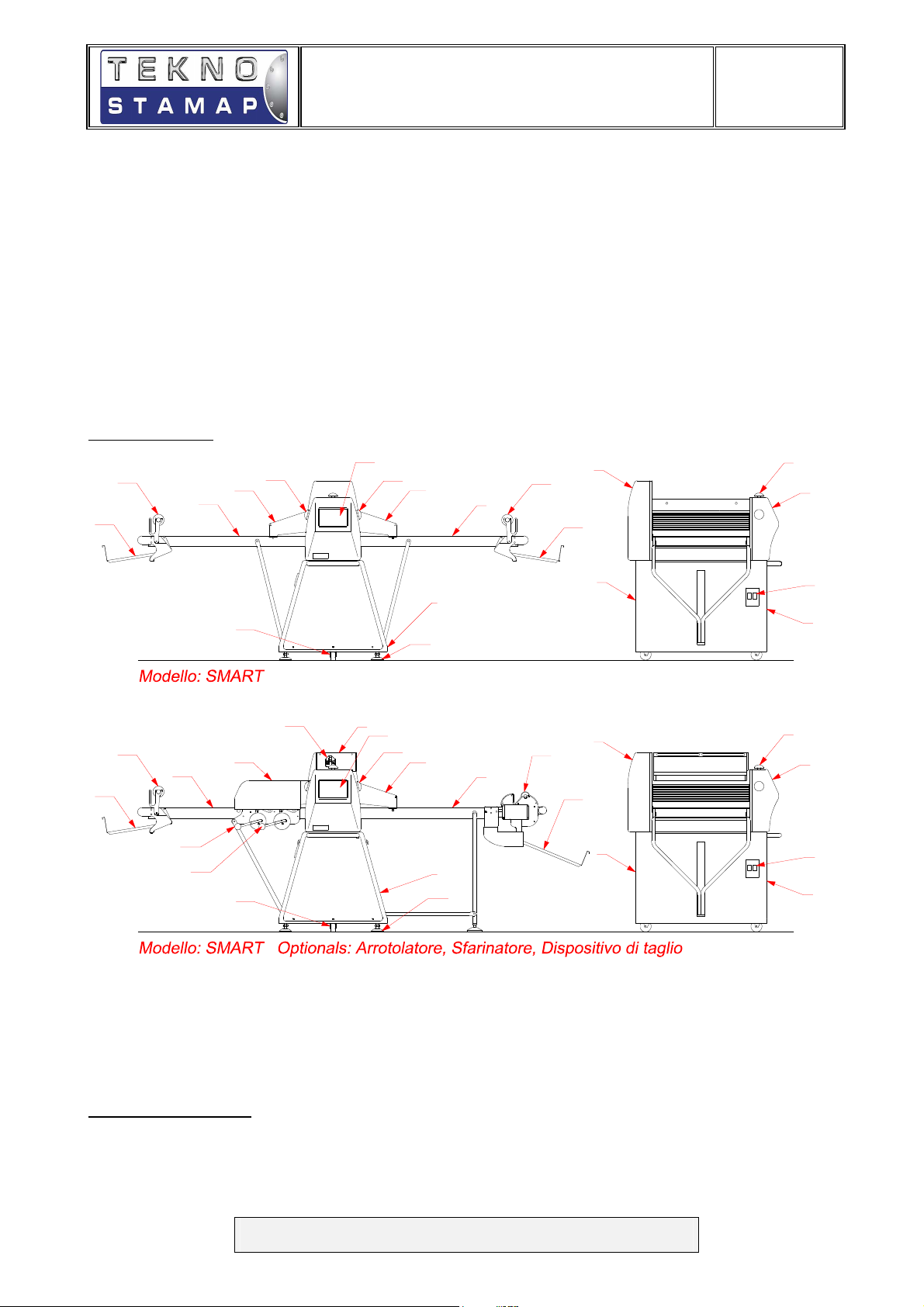

Model : SMART

18

17

19

16

15

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

13

14

11

10

9

3

12

15/96

Revision n°1

date 20.07.2006

8

4

6

7

1

21

5

20

10

18

16

17

19

22

23

21

This model is similar to ECOSMART except for the lever 22 which has not been foreseen on the

SMART version.

Optionals: automatic dough winder as per AUTOSMART version (10), automatic flour duster as

per AUTOSMART version (9), cutting device (16) with command levers (22 and 23), all the items

are in stainless steel

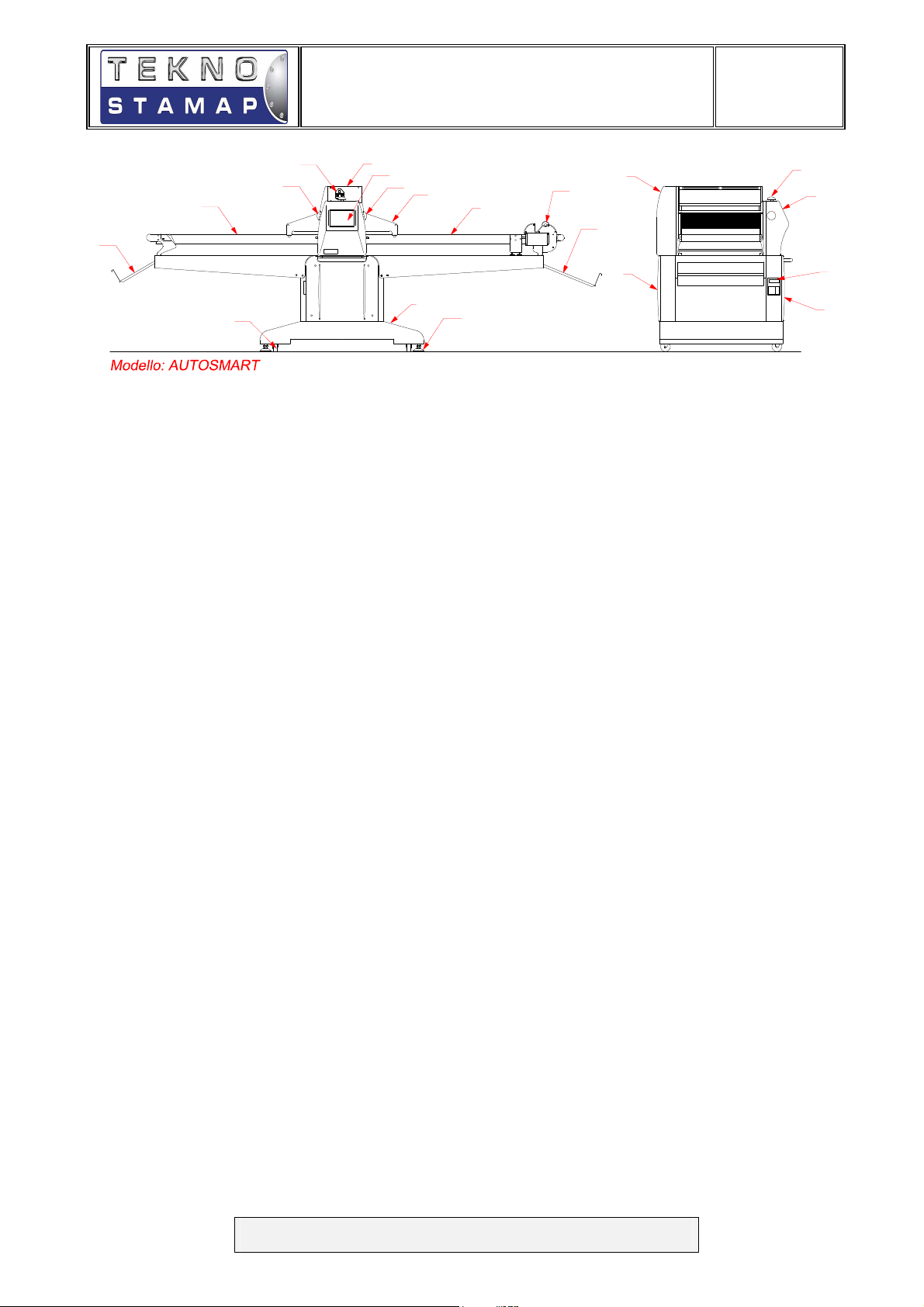

Model: AUTOSMART

9

13

14

11

10

3

9

8

4

12

6

7

1

20

5

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

10

15

17

Mod. SMART-AUTOSMART

9

13

14

11

10

9

3

16/96

Revision n°1

date 20.07.2006

8

4

12

19

7

5

21

6

1

20

The floor standing basement (1) is entirely made of stainless steel, inside is located the electric

installation and the motor. 2 side panels (5,6) can be easily removed for local inspections and

mechanical or electrical repairs.

The upper part of the machine consists of 2 sides in aluminium screwed together by means of

steel spacers. All the machine components are assembled on these sides and protected by 2

plastic covers (3 and 4). Inside the larger panel (the back one 3) is located the pulleys group and

all the devices for the automatic moving system of cylinders. Inside the front panel (4) is located

the clutch group.

The basement is provided with levelling system (20) to ensure machine stability.

An automatic dough winder (10) with its dough pin allows to wind automatically the dough.

The automatic flour duster (9) with digital touch-screen for automatic settings allows the uniform

distribution of a light voile of flour during the working phase

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

WORKING

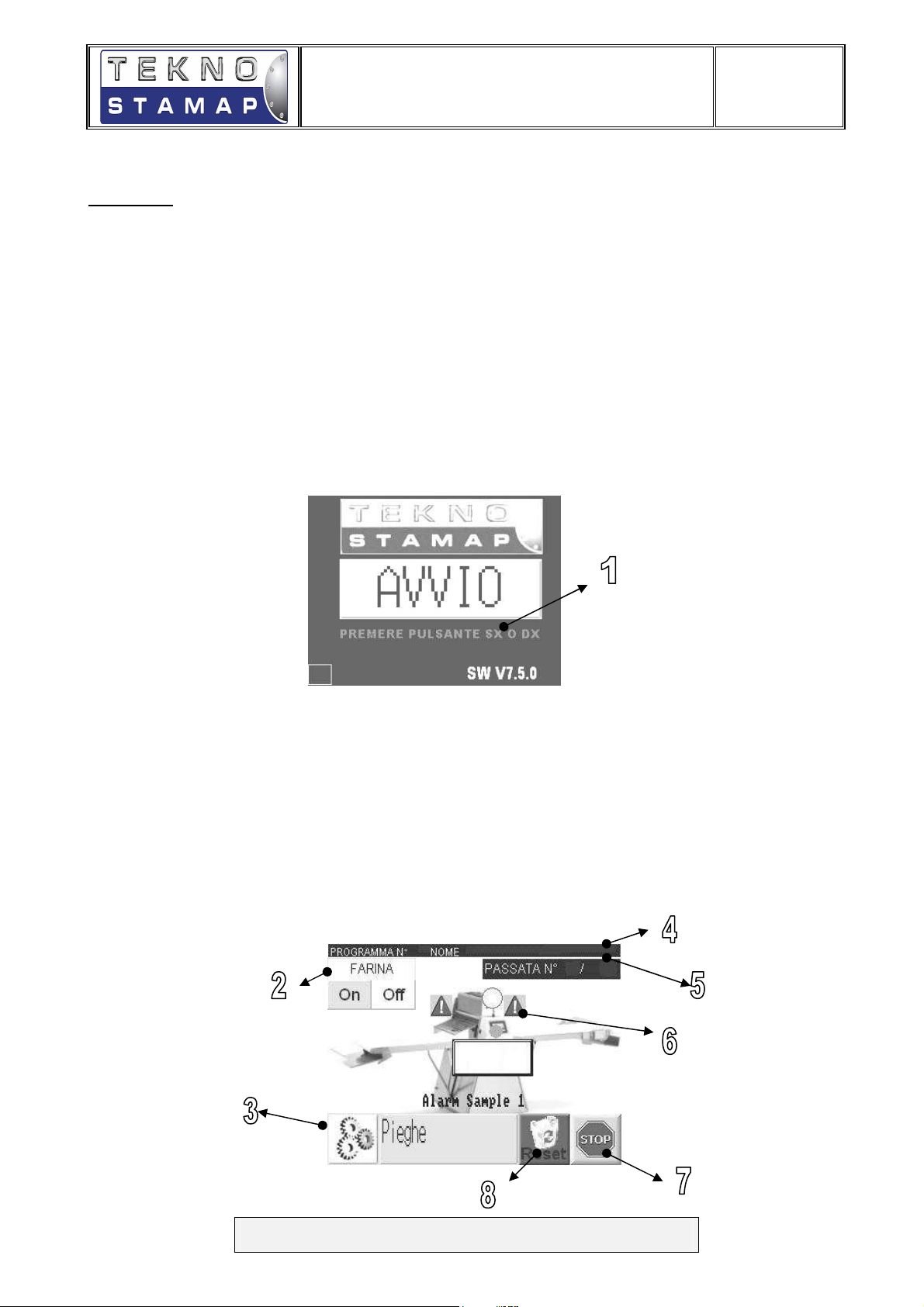

1. START: once everything has been carefully checked it is possible to start the machine by

pressing the general switch (7) (see illustrated drwg on chap.2.1 – technical description).

The Touch-screen will inform the operator that the sheeter is poceeding with a general

automatic control in order to verify all the inside processors; a few minutes later the loadprogram will start. Once the program loading is over, an automatic PCMCA files

scanning will start to reset the touch-screen. The fig. 1 will appears on the touch-screen.

(AVVIO= START – premere pulsante sx o dx= press right or left key-button)

Fig. 1

Once the fig. 1 is appeared, under the word “START” the writing (1)“press on right or left

keybutton” appears ; it means it will be necessary to press on green keybuttons (14,15)

(see illustrated drwg chap.2.1 technical description) after having been ensured that the

emergency push-button is unlocked

Fig. 2

Technical Assistance Service tel. +39/0444414731

Mod. SMART-AUTOSMART

Revision n°1

date 20.07.2006

17/96

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Before starting any manoeuvre be sure that red push-button is unlocked and the safety

grids are down. Fig.2 will appear on the screen as working screen; before starting the

programation we advise to cancel all the alarm information (6).

The key-button (8) will reset the machine and the calibrating cylinders will be at maximum

opening. The starting of flour duster is activated by a simple push-button ON/OFF. On

upper side of the screen it is possible to read the name and program number (4,5) in case

of started program acting on key-button STOP (7) it is possible to stop correctly the

working phase. By pressing on left green key-button (15 – see illustrated drwg chap.2.1

technical description) as indicated on picture, it is possible to operate without any

problem. To start a new program, the operator has only to touch the screen on the picture

located on the left button side (3) in order to enter in datas.

Fig. 3

In this section (fig.3) the operator can find various functions: SETTINGS (9), MANUAL

FUNCTIONS (10), in this case it is possible to operate manually, PROGRAMMING (11)

(which can be quick or slow), PROGRAMS LIST (12) (where the operator will find the preset

user’s programs) VISUALISE/MODIFY (13), DOUBLE PROGRAM (12B), EXIT (14) to return

back at first screening.

2. WORKING METHOD: it is possible to select the way of working desired on the

automatic sheeter SMART: it can be manual or automatic.

3. MANUAL WORKING: the sheeter can work in manual version, meaning the operator can

act directly on the machine.

Technical Assistance Service tel. +39/0444414731

Mod. SMART-AUTOSMART

Revision n°1

date 20.07.2006

18/96

USE AND MAINTENANCE MANUAL

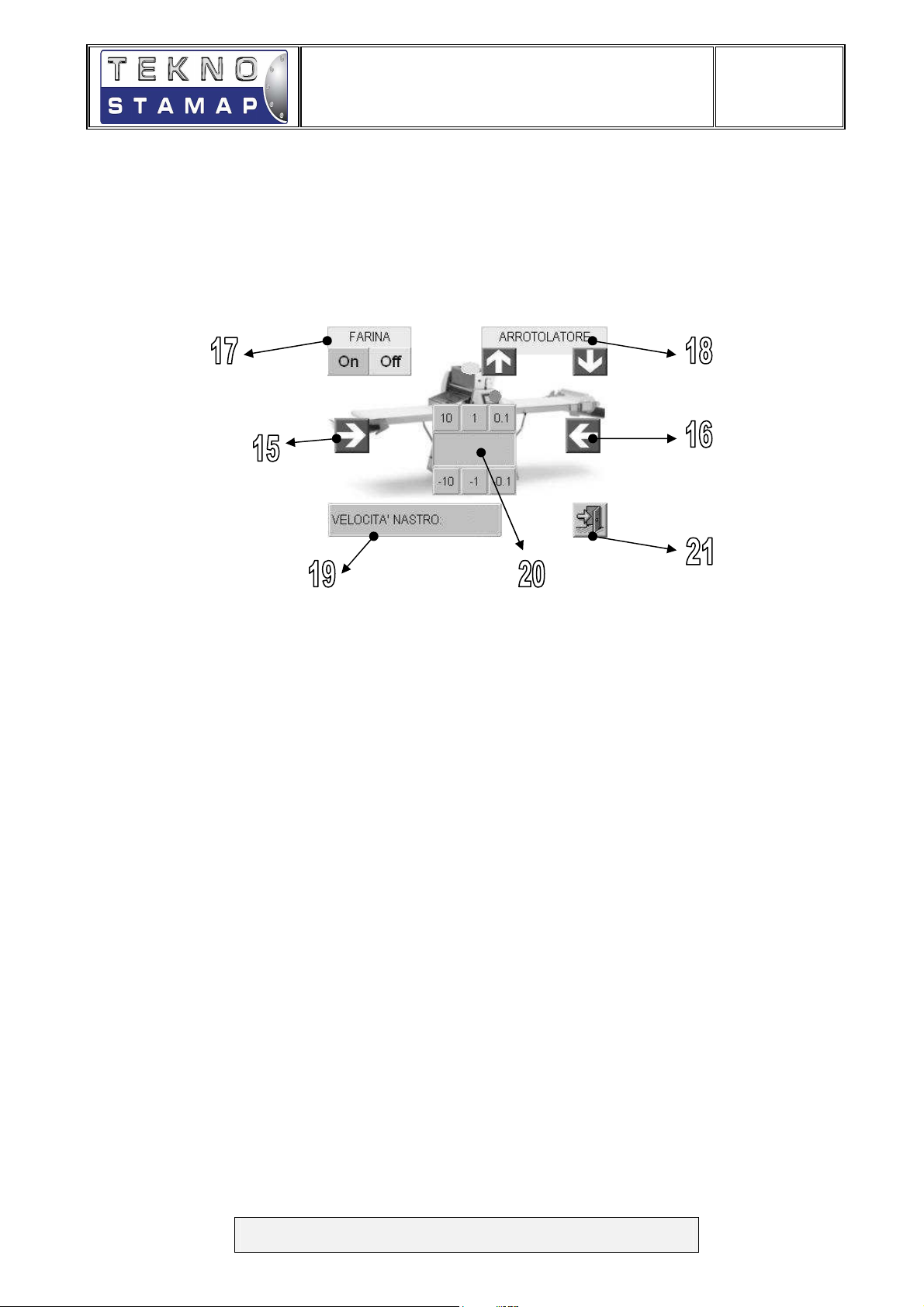

Fig. 4

On the side part of screenning (fig.4) there are 2 arrows → ← (15,16) . By pressing

them it is possible to make the belts revolving on one side or the other or alternatively to

move them through the 2 green key-buttons (14,15 illustrated drwg chap.2.1. technical

description). Pressing the flour duster button on left upper side (17) it is possible to

make it working or not; but it is necessary to verify the position of the key-button on the

flour duster. Anyway, the flour duster working is coordinated with belts movement.

on the upper right side the key-buttons with arrows ↑ ↓ (18) make the dough winder

working up or down (all these movements are done in actual time. On the bottom left

side (19) it is possible to adjust the belt speed from 100mm/sec to 10mm/sec.

At last, the data on centre of screenning (20) indicates the thickness of the dough

(height of cylinders) which can be varied by imputing of dough thickness in mm; the

machine will automatically adjust the height.

To return back to the main screenning, it is necessary only to act on th right bottom keybutton. (21)

Technical Assistance Service tel. +39/0444414731

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

19/96

Revision n°1

date 20.07.2006

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

4. AUTOMATIC WORKING

Fig. 5

The automatic programation allows to proceed with 2 types of programs: quick

programation (22) and manual programation (23) Before selecting one of these 2 options,

the operator has to make sure that the machine has been reset, meaning that cylinders are

fully opened. To do this, it is necessary to go back to initial window per to press reset keybutton.

Once this check is over, it is possible to select in the SETTINGS window the programation

window (11) (fig.13) which will open the window to select the type au automatic

programation (fig.5)

• Quick programation

Fig. 6

Selecting the quick programation the following window (fig.6) will be opened. Here it is

possible to select a set of parameters inside the machine without necessity of inserting

them manually, but having the possibilty to modify them at any moment. First of all it is

Technical Assistance Service tel. +39/0444414731

Mod. SMART-AUTOSMART

20/96

Revision n°1

date 20.07.2006

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

21/96

Revision n°1

date 20.07.2006

necessary to insert the parameters in the column n.1: height of the dough to be sheeted

(25) and the height to be reached at the end of the processus (26), indicating how many

passages the operator wants to do (27). These numbers can be inserted just touching the

value on the screen, and digiting the desired numbers. The running speed of the belt can

be adjusted from 10 to 100mm/sec. (28). The belt speed is set for complete working

cycles.

Under the speed setting button it is possible to see a small window to choose the closing

working phase (29).

FOLDINGS: the machine starts to laminate the dough. During this option the

sheeterstops automatically at the end of the sheeting cycle, allowing the operator to

fold the dough, to turn it on the belt and to start again the working cycle by pressing

on green key-button (14,15 illustrated drwg chap.2.1. technical description). This

cycle is usually used to prepare general puff pastry.

WINDING: the machine is able to feel the height of the dough through a sensor and

once it feels the final thickness the dough is conveyed to the automatic winder with

the roll pin. The winder moves automatically to dough pin on its supports, the dough

follows the belt till it meet the winder which hoists the belt in order to roll the dough on

the pin automatically.

CUTTING-WINDING: this option allows the possibility to save the rejects. At the end

of sheeting phase, the machine stops the belts running before the dough arrives to

the rolling pin, allowing the operator to cut the dough head. To start again the belt

running and the winding cycle it is necessary only to press the green key-button

(14,15 illustrated drwg chap.2.1 technical description).

HEAD-TAIL CUTTING: this phase is pratically the same than previous one, further to

the first stop for head cutting, the machine will stop a second time after the dough is

out of the safety grids for the tail cut. This operation allows to save more rejects

DOUGH CUTTING WITH CUTTING DEVICE: this operation can be done only with

the machine provided with the cutting device. When desired dough height is reached,

the belt running stops, allowing the operator to activate the cutting device. Then to

start again running the operator has only to press the green key-button (14,15

illustrated drwg chap.2.1 technical description).

STOP LAST SHEETING: the machine works on the dough on selected cycle with all

the programmed sheetings, and this cycle will end on one of the two belts following

the number of sheetings selected and the start position of the dough.

MANUAL WINDING: This operation is done when the machine is not supplied with

the automatic dough winder or when working on very special doughs requiring the

operator hands manipulation.

Concerning the position of the dough at the end of cycle in case of manual working, the

machine will work the programmed sheetings and will position the dough consequently.

In case of automatic cycle, with automatic winder or cutting device located on a precise

side of the machine, the machine will work following the preset sheetings, but if the last

sheeting stops on the wrong side, the machine will add automatically a passage with

cylinders fully opened at the beginning of the new working so the dough will be

positioned on the correct side.

Technical Assistance Service tel. +39/0444414731

Fig. 7

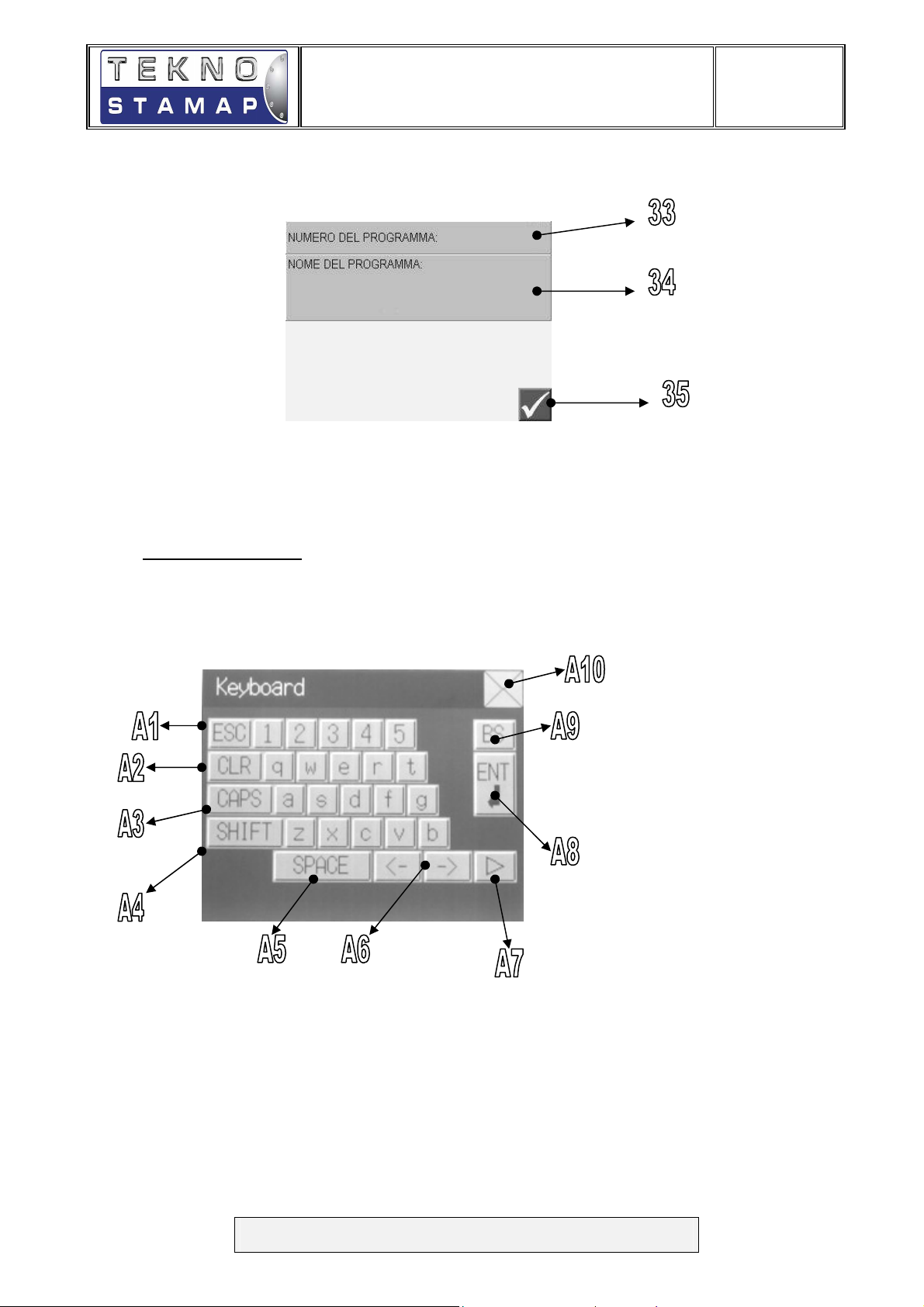

Once the data are confirmed in the machine (24), the program saving window will be

opened. The machine will inform about the first free program starting from nr 1 upto 50.

VERY IMPORTANT: if a new program is saved upon another one, the sheeter will write it

down without informino about the matter.In this case the previous program wil be erased.

With the key-button 34 it is possible to write the name of the program in order to identify it

with a small keyboard divided in 2 parts because of problems of room.

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

22/96

Revision n°1

date 20.07.2006

With keys A1 and A10 it is possibile to close the window without saving the text. With key

A2 it is possibile to erase digited letter. The key A3 writes in small or big size letters.with

key A4 it is possible to change some symbols on the keyboard. Key A5 allows a space.

The 2 arrows A6 allows to move inside the word one letter at a time. With key A7 it is

possible to go on the 2 part of the keyboard. Key A8 will confirm the text and return to the

previous window. Key A9 will erase the letters one at a time. If the information are correct it

is necessary to confirm (35 fig.7) to go on.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Fig. 8

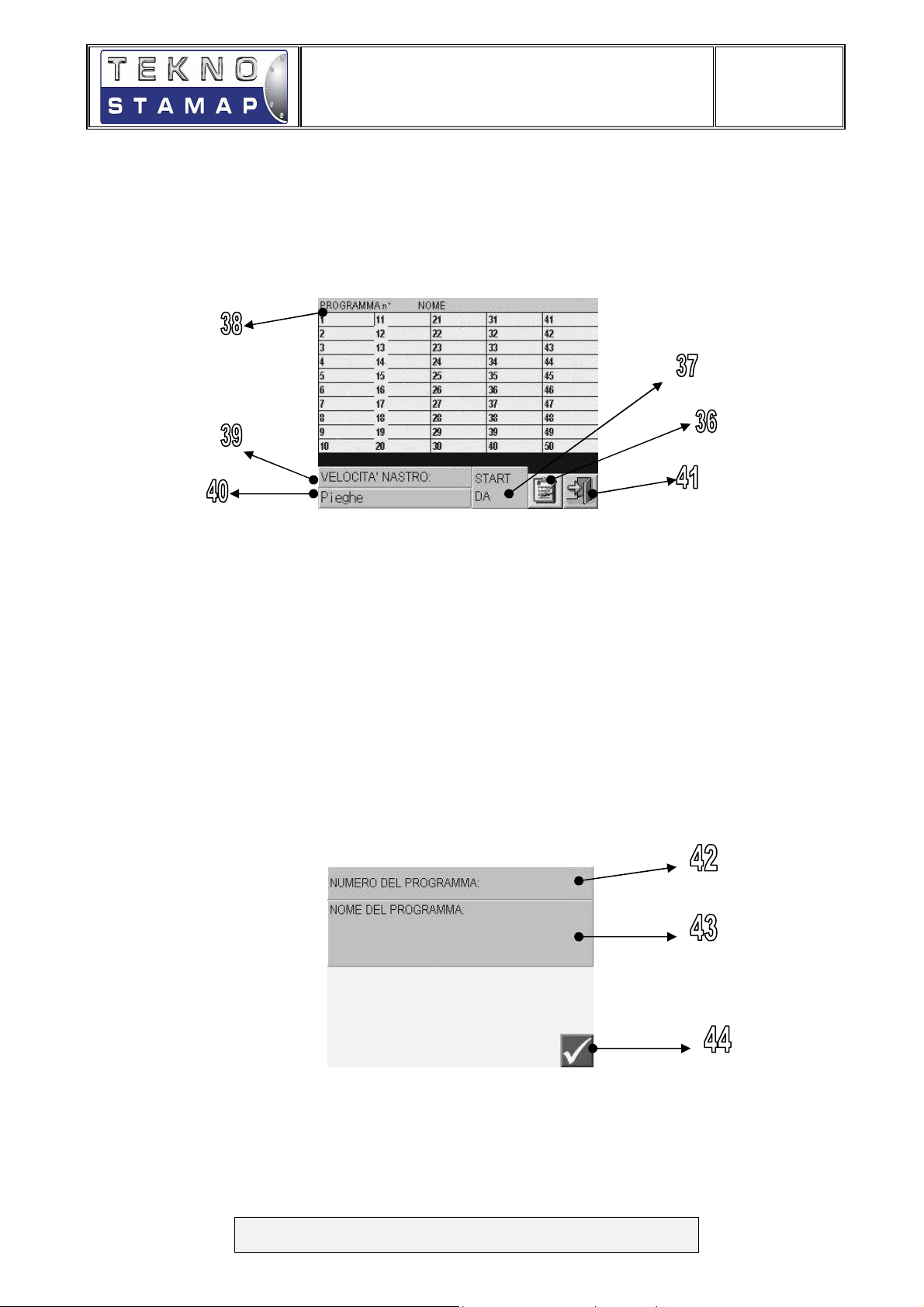

Now the screen will show the working page with the list of the whole sheetings to be done

and the various thickness for each passage (38).

From this window it is possible to decide from which sheeting the operator wants to start

(37). Even from this situation it is possible to modify the name of the program just by

touching the screen near the name.

The key 36 allows to return back to the menu of programation selection (fig 5) and to do

eventual modification (see following chapter fig.10). The window will show all the previous

parameters (39,40) which cannot be varied from here, only through selection menu (36).

In case of correct program, it is possible to start the working pressing one green key-button

(14,15 chap.2.1.technical description). The key 41 allows to start the cycle of initial window.

• Normal programation

Fig. 9

When using the normal programmation (23 fig.5) the first information to insert are the

number to save the cycle (42), the reference name (43) reminding not to use a number

already existing unless to overwriting the program. Once it is confirmed (44), the window as

per fig. 8 will appears. To modify something it is necessary to press the selection keybutton (36) opening thus a window as per fig.7: the option to select quick or slow

Mod. SMART-AUTOSMART

23/96

Revision n°1

date 20.07.2006

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

programation will be required. In case of quick program the situation as per fig.6 will be

opened. The function of slow program is indicated on window 10.

Fig. 10

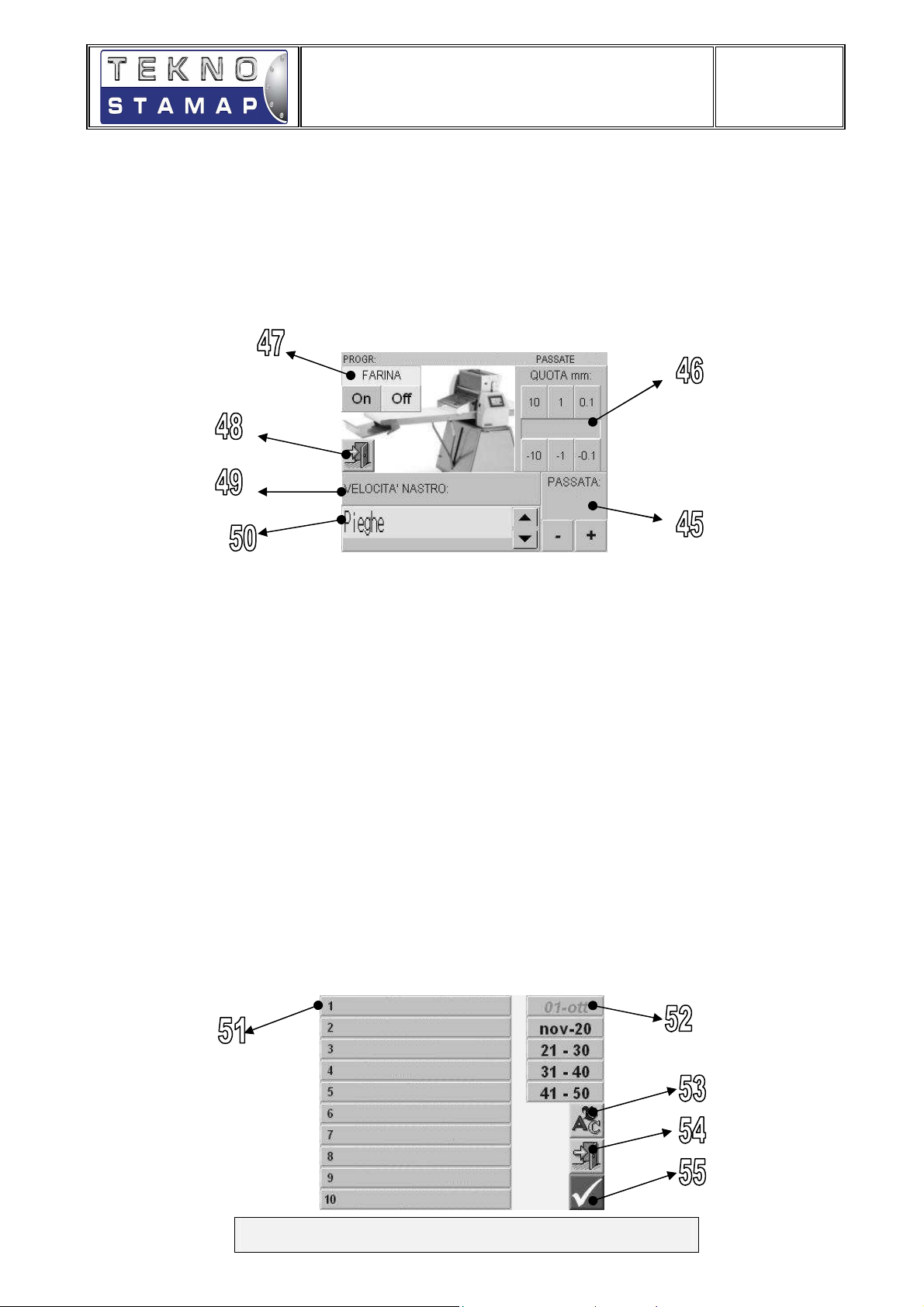

Now it is possibile to start the settings. It is necessari to introduce all the values for each

single phase. In order to choose the sheeting to insert the new datas it is possibile to use

two keysi +/- (45), and inside each single sheeting it is necessari to specify also the other

parameters. To adjust the running speed of the belt it is necessary to press the screen (49)

and to digit the desired value inside the window. To adjust the sheeting dough thickness it

is necessary to vary the value on up right side setting thus the starting thickness to the

finishing one. It is possible to act on key-buttons located above or under the dimensions

expressed in mm. With this type of programation it is possible to decide the use of flour

duster (47) and the sheeter will give automatically the impulse just during the preset

passage (45). It is possible to decide the end of cycle by using the small window located in

the left bottom (50) and the move the arrows ↑↓ on desired option.

When programation is ended it is possible to go back to initial program through key 48 and

restart the working through key (14,15 illustrate drwg chap.2.1 Technical Description). The

activation of flour duster is highlighted on the side.

5. PROGRAM LOADING

Fig. 11

Technical Assistance Service tel. +39/0444414731

Mod. SMART-AUTOSMART

24/96

Revision n°1

date 20.07.2006

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Inside the loading of existing programs (12 fig.3) a dialog window will appear (fig.11). the

cells to be saved (51) are divided in 5 pages which can be visited through keys 52 on right

top side of the creen, and it is possble to save almost 50 different programs.

Through key 53 it is possibkle to activate the function “text modify” to modify the names

and it I necessary to press the key to highlight the name to be modified. To unhighlight the

name press once again on the same key.

In case the operator wants to come out the section it is necessary to press key 54;

otherwise it is possible to go on loading the selected program (55).

The video which will appear is always the working one (fig.8) and from here it is possible to

decide about the variations inside the working cycle.

In order to intervene quickly and directly on loaded program to is necessary to open the

window fig.8 with key 13 fig.13 and to proceed with all the modification listed at priori

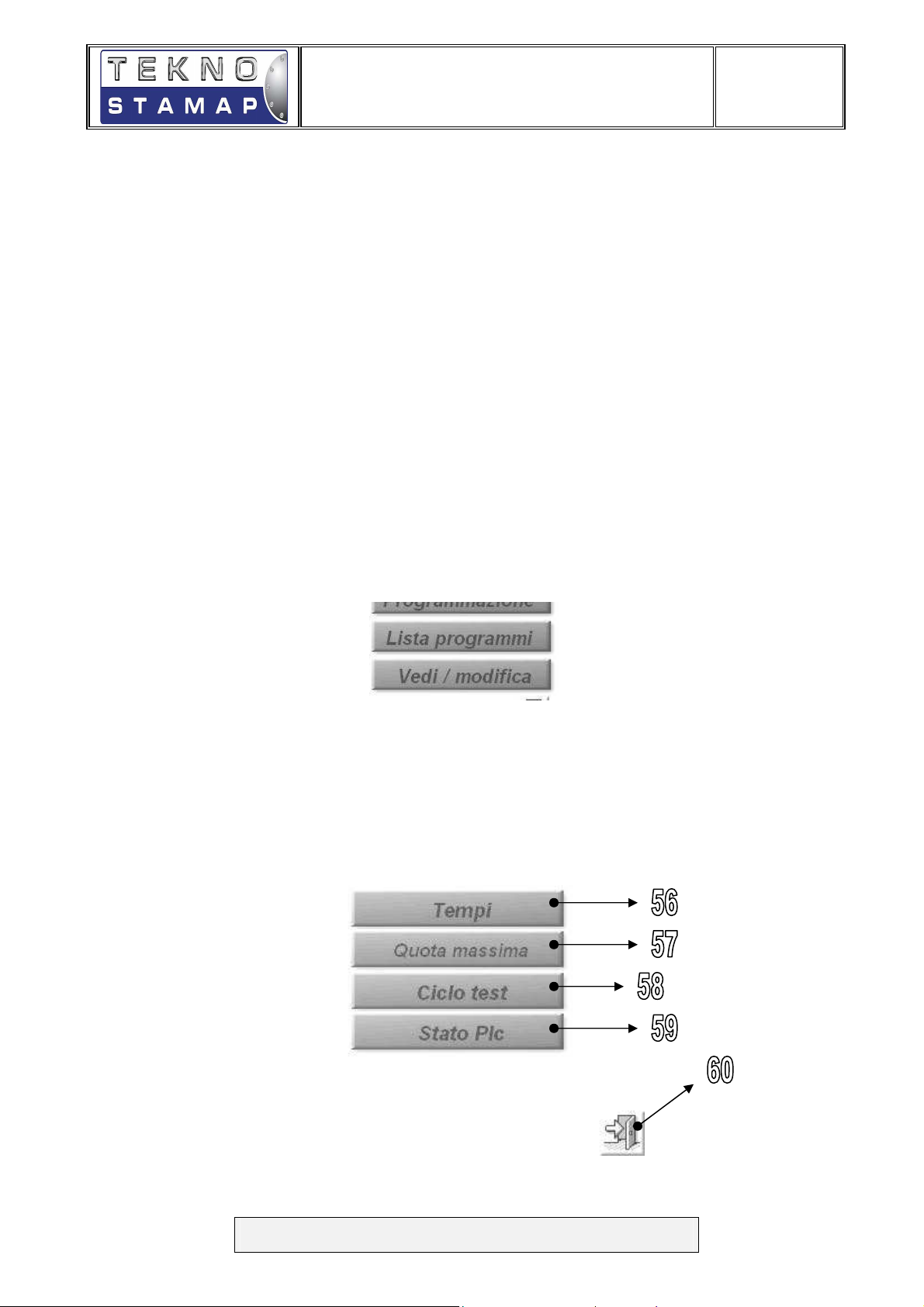

7. SETTINGS

From this window it is possibile to enter in a whole programation and to choose more

specific functions on the sheeter. As those values modify directly the machine settings they

are protected with a password avoiding the modification by the user. But through this

window it is possible to do some modifications in case of necessities

Fig. 12

Technical Assistance Service tel. +39/0444414731

Mod. SMART-AUTOSMART

25/96

Revision n°1

date 20.07.2006

USE AND MAINTENANCE MANUAL

First of all, to enter in the section it is necessari to enter in machine settings on page of

selection (9 fig.3). the first number (56) allows the time settings of few operations done by

the sheeter. Pressing on each option it is possible to enter in a cell and to insert the desired

value. It is possible to visualise all the pages by using the indications on the screen edge

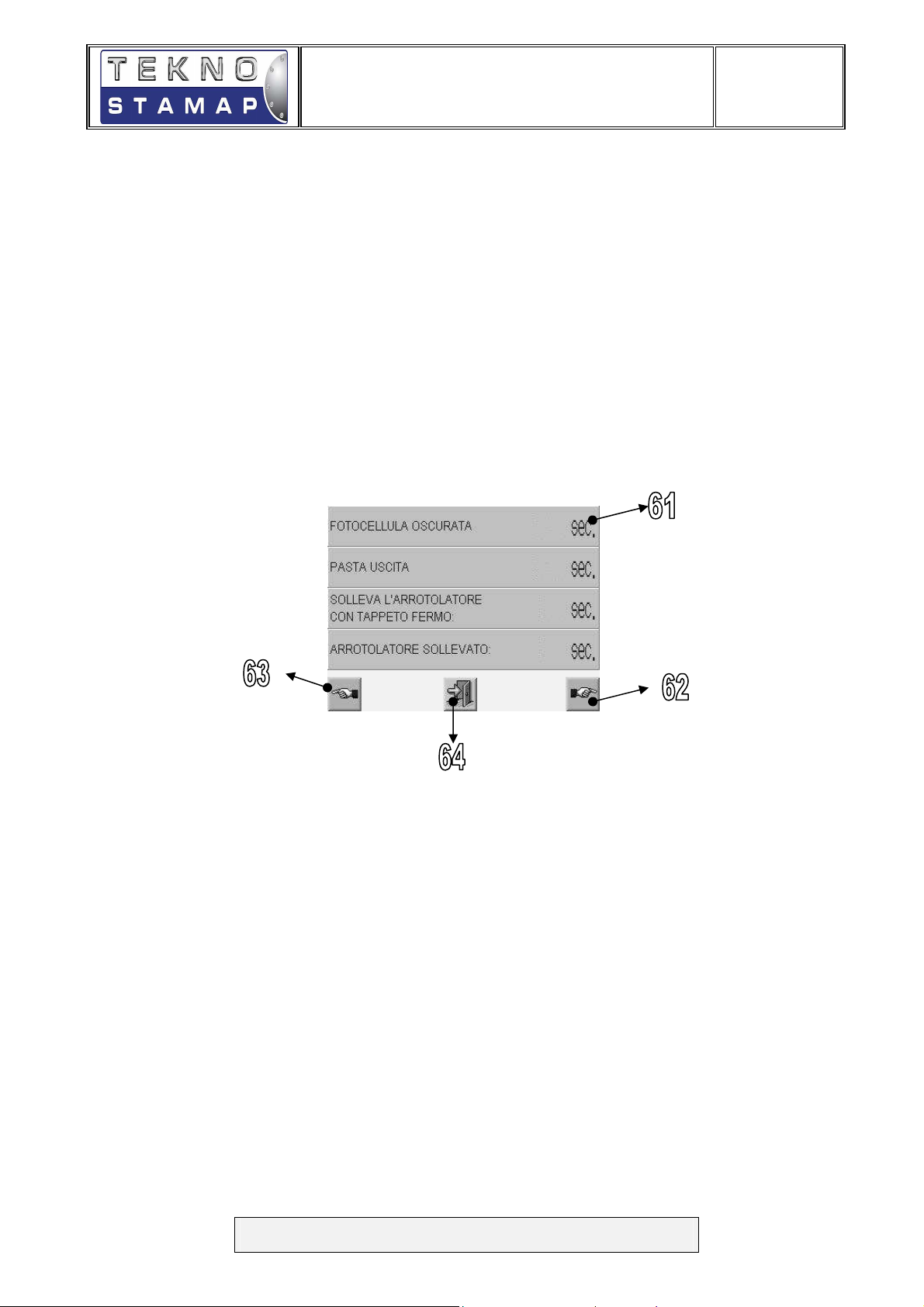

(62,63). To come out of settingspress on key 64.

Fig. 13

It is possibile to modify the following values:

− OBSCURED PHOTOCELL : it is possibile to ad just the min.time of photocel darkening

in order to avoid that sheeter read as beginning or end of the dough some remaining of

dough on the belt.

− DOUGH EXIT: to set out the dough length on the exit of the grids at the end of the last

sheeting.

− WINDER HOISTING WITH BELT STOP: gives the hoisting degree of the winder and

consequently the inclination compared to the belt

− DOUGH WINDER UP: :

− SLOW DOWN THE BELT TO WIND THE DOUGH: indicates the time between the exit

of the beginning of dough from the safety grid (photocell) and the moment when the

dough slow down to allow a correct winding on rolling pin. The last sheeting is

concerned by this adjustment

− FIRST DOUGH WINDING DONE, LOWERS: gives time used by the winder to start

lowering after the dough has done the first rolling on the pin.

− DURATION OF WINDER LOWERING: allows to adjust the opening movement of dough

winder durino lowering phase.

− DOUGH FULLY ROLLED: time used to roll the dough completely on the rolling pin.

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

26/96

Revision n°1

date 20.07.2006

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

27/96

Revision n°1

date 20.07.2006

− DOUGH POSITION TO CUT DOUGH HEAD: allows to adjust manually the dough cut

on the head. Working on this time it is possible to decide how long time it is necessary

to stop the belt after the dough started to pass in front of the photocell, allowing the user

to cut the dough on the most comfortable position.

− DOUGH POSITION TO CUT DOUGH TAIL: the same as above, with difference on belt

stop signal activated when the dough tail is passing in front of the photocell.

− END CUTTING CYCLE SLOW RETARD: This option concerns all the models with

cutting device. It is possible to adjust the time necessary to ch’ange from an usual

sheeting speed to a very defined cutting speed.

− END CUTTING CYCLE SLOW TIME: always concerning the sheeters with cutting

device and allows to decide the quantity of dough coming our of cutting rollers.

− END FINE CUTTING CYCLE: allows to adjust the complete dough exit time from cutting

rollers at the end of cycle.

− WINDING END CYCLE IN MANUAL-DOUGH POSITIONNING: adjusts the quantity of

dough coming out of the safety grid at the end of last sheeting. This time is necessary to

user to lay on the dough the rolling pin and start rolling. To make the belt restart it is

necessary to press back the START BUTTON

− WINDING END CYCLE IN MANUAL IN DELAY:it is the same processus as previously

described, the difference is that after START, the belts don’t begin immediately to run,

giving the user time to position the dough and to wind it.

− END CYCLE WINDING DOUGH: as a matter of fact the position of rolling pin is upto the

user on manual winding, for a complete winding it is possible to decide how long the

belts have to run after the dough is come out of the grids.

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

28/96

Revision n°1

date 20.07.2006

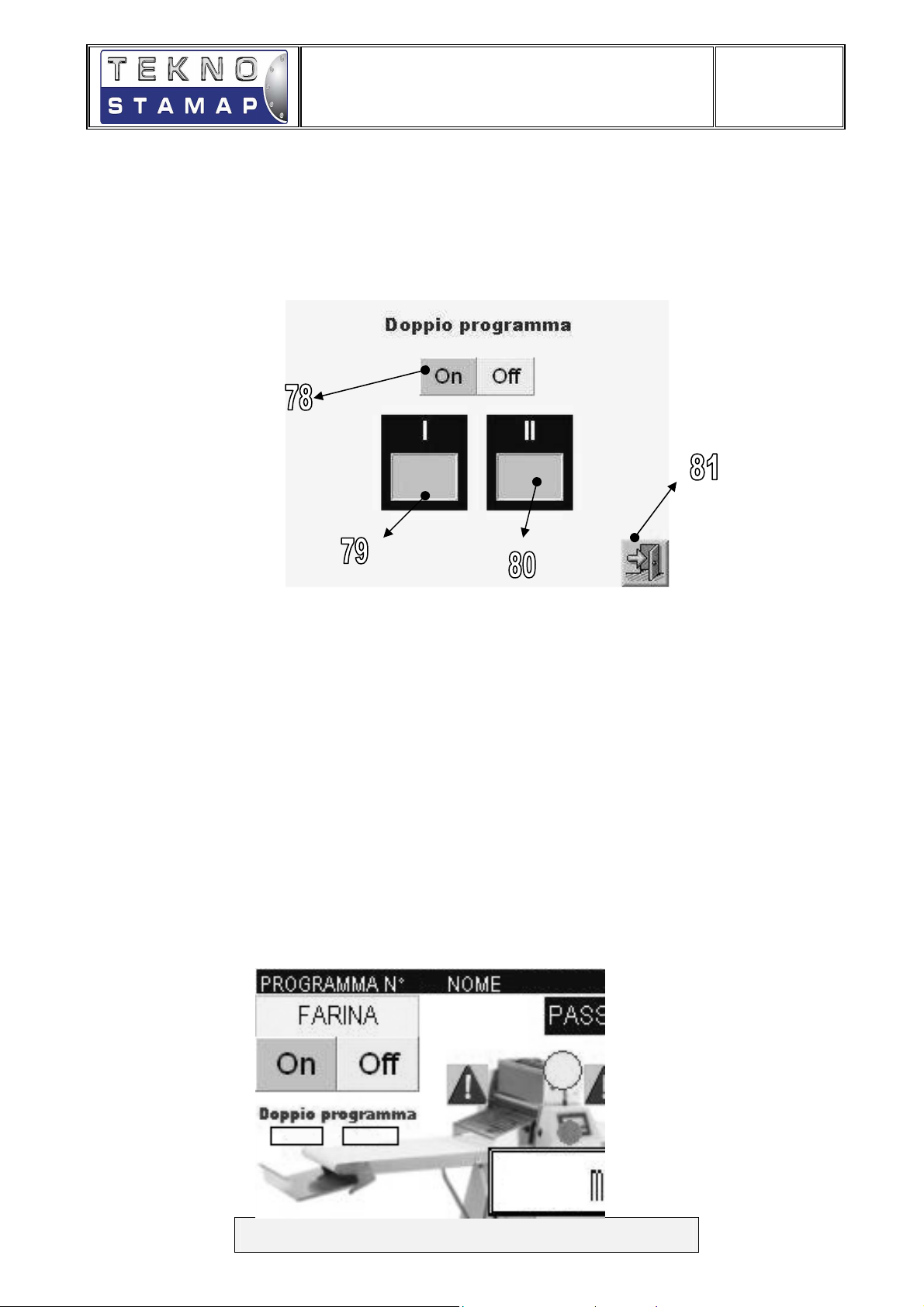

DOUBLE PROGRAM:

with this double program (12B fig.3) it is possible to link 2 different programs in

cascade. The first video is as per fig. 17

Fig. 17

The first step requires insertion of 2 programs 79 and 80 through a dialog window

aloowing to digit the number of a program even not existing; it is necessary to know

previously the programs to be inserted. The key 78 allows the activation for option of

double program which remains actived until the comand is unactivated. The key 81

allows to return back to the main video loading the 2 programs. It is possible to see

that under the indication of flour presence, the numbers of the 2 programs will appear

as confirmation of the oepration. Now it is possible to start working pressing on 1 of the

two green buttons (14,15, illustrated drwg chap.2.1 Technical descrition).

If it is necessary to modify the program, it is possible to enter in settings through menu

of selection and to modify the paramters.

To close the option of double program, it is necessary to come back to selction video

(fig.17 and disactivate the comand through button OFF

Technical Assistance Service tel. +39/0444414731

USE AND MAINTENANCE MANUAL

2

8

1

7

3

4

5

6

AUTOMATIC DOUGH SHEETER

Mod. SMART-AUTOSMART

29/96

Revision n°1

date 20.07.2006

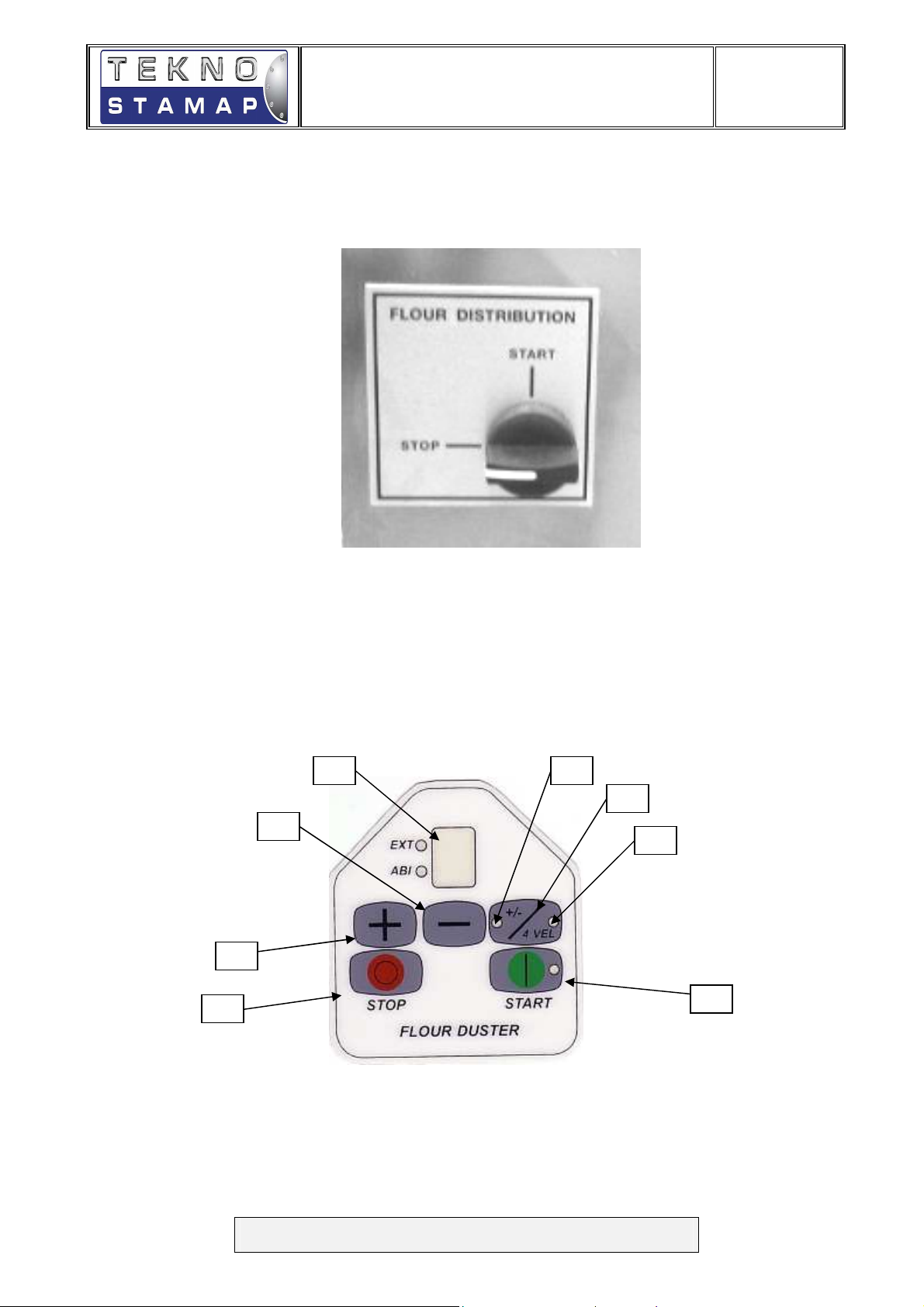

AUTOMATIC FLOUR DUSTER

Fig. 17

The working of the automatic flour duster is simply controlled by a two positions switch and by the

control panel. It is important to keep in mind that this function works only if the button of flour

distribution is on START position. Moreover, its working has to be driven through the control panel,

both for the manual and the automatic operation. In case one of the two switches is not inserted

the flour distribution will not work.

OPTIONAL FLOUR DUSTER :

The flour duster is operated directly through the key 1 which allow to pass from automatic working

to manual working. In order to know if the key 1 is set on +/- or on 4VEL section it is necessary

only to check which red light is on corresponding to one of these functions. If light 7 is ON that

means the flour duster is in +/- function; if light 8 is ON that means 4VEL device is activated; to

change from one function to the other it is necessary only to press once on the key 1.

Technical Assistance Service tel. +39/0444414731

Loading...

Loading...