Erika 10-25 Installation Manual

SEMIAUTOMATIC MANUAL

1

IMPORTANT INSTALLATION NOTICE

ERIKA SEMI-AUTIOMATIC DIVIDER/ROUNDER

FILLING OF OIL RESERVOIR FOR

ROUNDING MECANISIM

MACHINES BUILT IN 1999

AND EARLIER

Add oil to t he machine before beginning

operation. The factory has provided the

right amount and type of oil with the

machine. (see par agraph #4 in the

manual).

If the oil container th at came with the

machine can not be located or is missing;

use 2 Qts. Of SAE #40 motor oil. Do not

use multigrade oil, it will foam and spill

from the reservoir.

• Remove the front and rear plastic

head covers (S009), then remove

the disconnecting pin (S036) and tilt

the machine head assembly to one

side.

• In the center of the rou nding table

(S042) is a large slott ed flathead

screw, remove it by turning

counterclockwise with a large

screwdriver.

• Pour the oil into th e reservoir

through the hole ( it is advisable to

use a small funnel).

• Take the large slotted flathead

screw and insert in the hole, fasten

it with the screwdriver turning it

clockwise until seated firmly.

• Return the machine head assembly

back to the working position. Insert

the disconnecting pin t hrough the

pillow block and arch; and install

the front and rear plastic covers.

DISCLAIMER: The purchaser is responsible for the proper installation and operation of the

machine. Should this equipment be operated without oil, it shall be considered abuse or

misuse of the equipment. Erika Record, LLC will not honor any warranty for parts and/or

labor.

For additional information please contact: Erika Record, LLC

37 Atlantic Way

Clifton, NJ 07012

Tel: 1-800-682-8203

MACHINES BUILT IN 2000

AND LATER

Add oil to t he machine before beginning

operation. The factory has provided the

right amount and type of oil with the

machine. (see par agraph #4 in the

manual).

If the oil container th at came with the

machine can not be located or is missing;

use 2 Qts. Of SAE #40 motor oil. Do not

use multigrade oil, it will foam and spill

from the reservoir.

• The filler plug is located on the to p

rear right hand side of the base of

the machine, it is a black hexagonal

plastic plug.

• Remove the plug by turning it

counterclockwise. Then pour the oil

into the op ening (it is advisable to

use a small funnel to pour the oil

into the reservoir).

• Take the black hexagonal plastic

plug and insert it in the hole, fasten

it by turning it clockwise. Only

hand tighten.

Fax: 973-664-1752

2

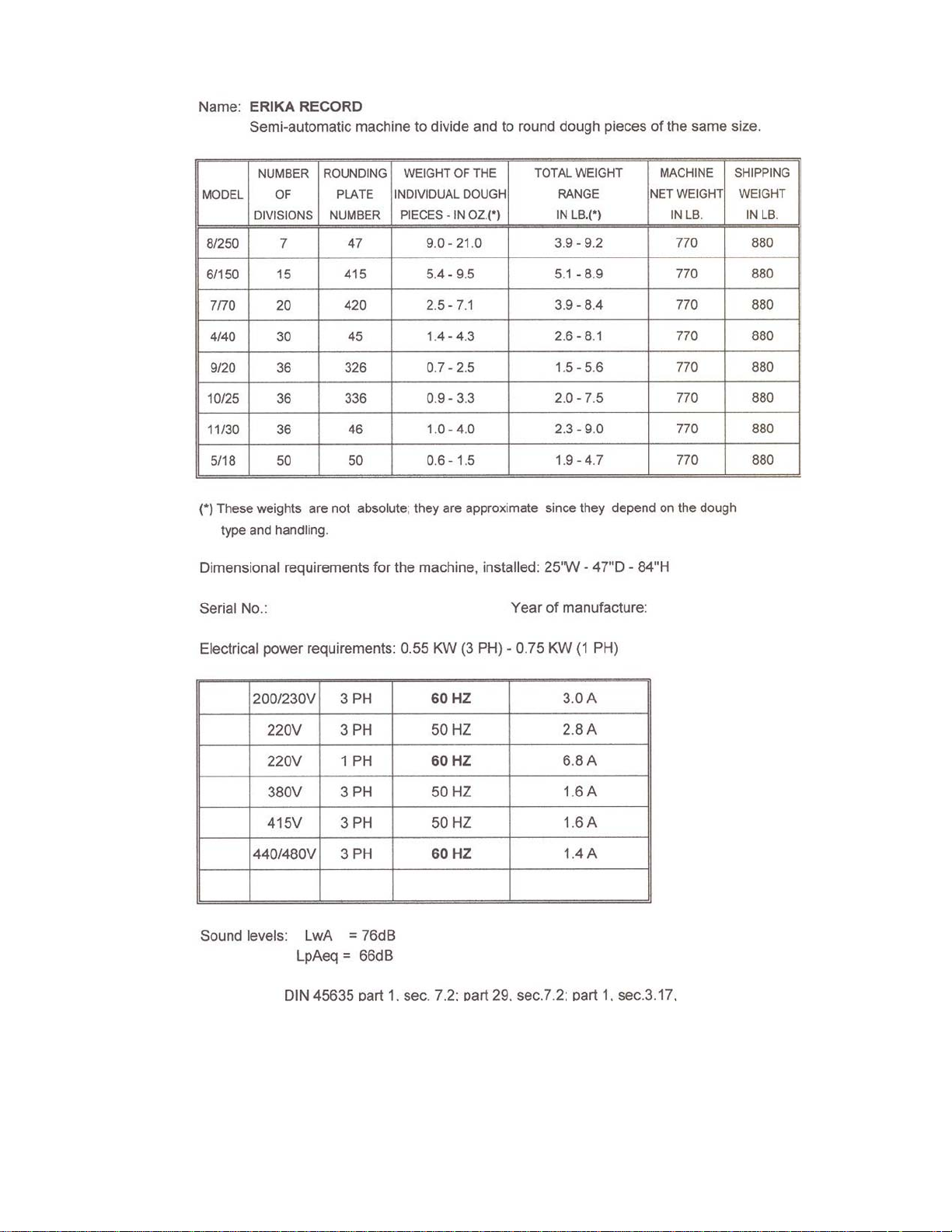

Technical Information

To ensure proper use and to avoid accidents it is

imperative to read the entire instruction manual prior

to use of this machine.

3

1. CAUTION

Please read and familiarize

yourself with the safety instructions

contained in this manual, and the

labels attached to the machine. This

shall be done before you operate,

clean or service the machine.

It is the purchaser’s responsibility

to make sure, that the operators of this

machine are aware of the contents of

this manual.

It is also the responsibility of the

purchaser to translate this manual in

any other language, for non-English

speaking operators.

2. OWNER’S RESPONSIBILITIES

• The owner of this machine, and the

supervisory personnel shall read and

follow the instructions contained in this

manual.

• Make sure that this manual is

readily available for the operators of

this machine.

• All the operators shall be properly

trained and be aware of all the safety

features of the machine, and they shall

be properly supervised while operating

this machine.

• Make sure that the machine is

installed conforming to all applicable

codes and regulations (local, state

and federal) including OSHA

regulations and electrical codes.

• All the warning labels and decals

have to be visible at all times.

• The instruction manual for the

operation of this machine shall be kept

in a safe place next to the machine.

INSTALLATION

3.

• After removing the sides of the

wooden crate, the machine has to be

removed from the wooden pallet, to

which it is bolted with four bolts for safe

transportation.

• Cut open the plastic sleeve in

which the machine is packaged to

avoid moisture problems in transit.

• Remove the base cover that has a

yellow label indicating the storage of

an oil container in the base.

• Remove the oil container.

• Remove the four nuts that hold the

machine to the wooden pallet.

• Now drive the bolts through the

wood with a hammer.

• Gently remove the strings and the

wood piece that holds the rounding

plates in place.

• Get a forklift truck, or 2 or 3

helpers, to remove the machine from

the pallet.

• NEVER attempt to remove the

machine from the pallet on your own.

CAUTION: Remove the pressure

•

lever (S030), which is attached to the

rounding lever (S050).

• The machine has to be placed on a

floor that is level, with sufficient space

around, for a safe and efficient

operation.

• The machine has to be bolted to

the floor with appropriate anchors, and

the gap between the floor and the base

has to be sealed, to prevent water,

flour, etc. from entering the base. We

recommend the use of silicone

caulking. Unless the machine has been

fitted with a set of wheels provided by

the factory.

• NEVER install “off the shelf type”

casters under the machine.

This is dangerous because the unit

•

is top heavy, and the operator could

easily topple the unit over while pulling

the handle.

4.

FILL OIL RESERVOIR - Please refer

to page 2 of this manual for detailed

instructions for first use.

• Add oil to the machine before

putting it in operation. The factory has

provided the right amount and type of

oil with the machine (see paragraph #

3).

• The filler plug is located at the rear

right hand side of the machine; it is a

black hexagonal plastic plug.

4

• Remove by turning

counterclockwise; it is advisable to use

a small funnel to pour the oil in the

reservoir.

• If the oil is missing, use 2 qts. of

SAE 40 weight motor oil.

• Once the oil has been poured in the

reservoir, the machine is lubricated for

life; there is no need to replace or

change the oil.

5. ELECTRICAL

Unless stated otherwise, the machine

has a 190/230 volt, 3 phase, 60 cycle

electric motor. Make sure the machine

is connected to the correct voltage.

This information is printed on the

machine identification label (located on

the base, next to the power cord

connector). Only a qualified electrician

is to connect the machine to the power

source.

6. INITIAL START UP

• The motor is protected by an

overload device, part of the manual

starter; when running the machine for

the first time, make sure the rounding

table (S042) rotates in the right

direction (check arrow on the front of

the unit), the rounding table has to turn

counterclockwise. If this is not the

case, the machine will not function

properly; have an electrician reverse

the rotation of the electric motor.

WARNING: The rounding table (S042)

is secured to the base of the machine

DO NOT TRY TO LIFT OR REMOVE

IT. Serious damage to the rounding

mechanism will result. Only qualified

service people are to remove the

rounding table.

CLEANING – FIRST START-UP

7.

• The machine is shipped with a light

protective grease in the head assembly

to avoid oxidation during transit.

• Remove the front and rear plastic

covers (S009) and the dough ring

(S007), (please read paragraph # 14)

then remove the disconnecting pin

(S036) and tilt the machine head to

one side.

• Clean the grease from the machine

head and rounding table using paper

towels or a soft cloth.

• Bring the machine head back to its

original position, install the

disconnecting pin, dough ring and

plastic head covers.

• Even though you now have cleaned

the product zone, use the first two or

three batches of dough to do the final

cleaning (see paragraph # 9).

8. CHOOSING THE SETTINGS

• The adjustment screw (S032) sets

the height of the rounding chamber of

each dough piece. If the adjustment

screw is in the “up” position (turn

counterclockwise), it will accommodate

a large piece of dough, whereas in its

“down” position (low numbers) it will

accommodate a small weight.

• For example: Setting #2 may

handle approximately 2 to 3 pounds of

dough, whereas setting #7 may handle

approximately 5 pounds of dough on a

model 9/20; 7.5 pounds on a model

10/25; and up to 9 pounds on a model

11/30. If the operator does not choose

the right setting, he will not get a wellrounded product.

• The dough pieces will be flat rather

than round indicating that there is too

much molding space and, therefore the

adjustment screw has to be turned

clockwise for the next batch.

• On the other hand, if the rounded

pieces of dough show a nipple in the

top center, it would indicate that the

rounding chamber is too low and, the

adjustment screw has to be turned

counterclockwise to correct this

problem.

• It is best to retry after giving one or

two full turns to the adjustment screw.

Once the setting is correct, note it on a

piece of paper for future reference.

5

• Please also remember that

settings will differ from one type of

dough to another.

9. OPERATION OF THE MACHINE

• The first batch of dough is to be

used to do the final cleaning of the

machine. Keep using the same dough

several times, before going to the next

piece. Continue this operation until you

no longer see any discoloration of the

dough, and the product zone in the

machine is completely clean.

• A piece of the dough first has to be

weighed within the total weight

parameters of the machine. See page

3 of this manual for the weight ranges.

(They are approximate since they

depend on the dough type and

handling).

• Place the scaled piece of dough

onto the red plastic rounding plate

(S066), with the moist side pressing

against the plate.

• Spread the dough evenly to the

outmost circle of rings, so that it covers

approximately the inner half of the

outer circles.

• Only apply some dusting flour on

top of the dough.

• Never use dusting flour between

the dough and the rounding plate.

• Insert the plate with the dough in

the machine, and make sure that the

plate is properly seated on its locating

peg.

• Make sure that there are no scraps

on the bottom of the plastic plate or on

top of the rounding table, since this will

damage the knives or the red plastic

rounding plate.

• Once the red rounding plate has

been properly placed, pull down the

pressure lever (S030) and compress

the dough evenly by pushing down on

the lever as much as you can.

• (It is easier to push down in short

strokes several times).

• Release the pressure lever

somewhat and press the cutting lever

(S010) to the right.

• Now push the pressure lever

(S030) all the way to its end position,

to cut the dough into pieces.

• Still holding the pressure lever

(S030) down, move the rounding lever

(S050) progressively to the left, this

will start the rounding process.

• Keep the rounding lever engaged

from three to five seconds, depending

of the type of dough.

• Release the rounding lever to

its

position, raise the pressure arm to the

top “up” position, remove the plastic

rounding plate from the machine.

• Check the quality of the finished

pieces; and if necessary, make

adjustments as indicated in paragraph

# 9.

10. DIVIDING ONLY

• Insert one red rounding plate

(S066) face down as a base on the

rounding table (S042).

• Prepare dough on another plate as

described in paragraph # 9 (remembermoist side down).

• Dust with flour only the top side of

the dough.

• Place the plate with the dough, on

top of the rounding plate inserted face

down in the machine.

• Without running the motor, press

and divide the dough as indicated in

paragraph # 9.

MAINTENANCE AND REPAIRS

11.

• The machine has to be inspected

on a regular basis, and maintenance

performed as needed.

• Any repairs are to be done by

authorized service personnel only,

and only original spare parts should

be used.

• The use of non-approved spare

parts may void the manufacturers

warranty.

6

Loading...

Loading...