Eriez E-Z TEC IV, E-Z TEC V Installation, Operation And Maintenance Instructions

Installation, Operation

and Maintenance

Instructions

MM-235F

®

®

E-Z Tec

Metal Detectors

Models IV & V

ERIEZ MAGNETICS HEADQUARTERS: 2200 ASBURY ROAD, P.O. BOX 10608, ERIE, PA 16514–0608 U.S.A.

WORLD AUTHORITY IN ADV ANCED TECHNOLOGY FOR MAGNETIC, VIBRA TOR Y and MET AL DETECTION APPLICA TIONS

Introduction

This manual details the proper steps for installing the Eriez

E-Z Tec® Model IV and V Metal Detectors.

Careful attention to these Installation Requirements will

assure the most efficient and dependable performance of

this equipment.

If there are any questions or comments about the manual,

please call the factory at 814/835-6000 for E-Z Tec

®

Metal

Detector assistance.

CAUTION - ELECTROMAGNETIC FIELDS

• Metal Detectors emit electromagnetic fields. Contact the American

Conference of Governmental Industrial Hygenists, Cincinnati, Ohio,

U.S.A., (www.acgih.org) for additional information.

• If you use a medical implant or similar device, you must never

approach the equipment because your device may malfunction in

the electromagnetic field, with consequences up to and including

death.

Contact Eriez if you have a question regarding these precautions.

© 2005 ERIEZ MAGNETICS ALL RIGHTS RESERVED

®

2

Handling Instructions

PLEASE LEAVE THESE INSTRUCTIONS ATTACHED

TO THE EQUIPMENT UNTIL INSTALLATION IS COMPLETE

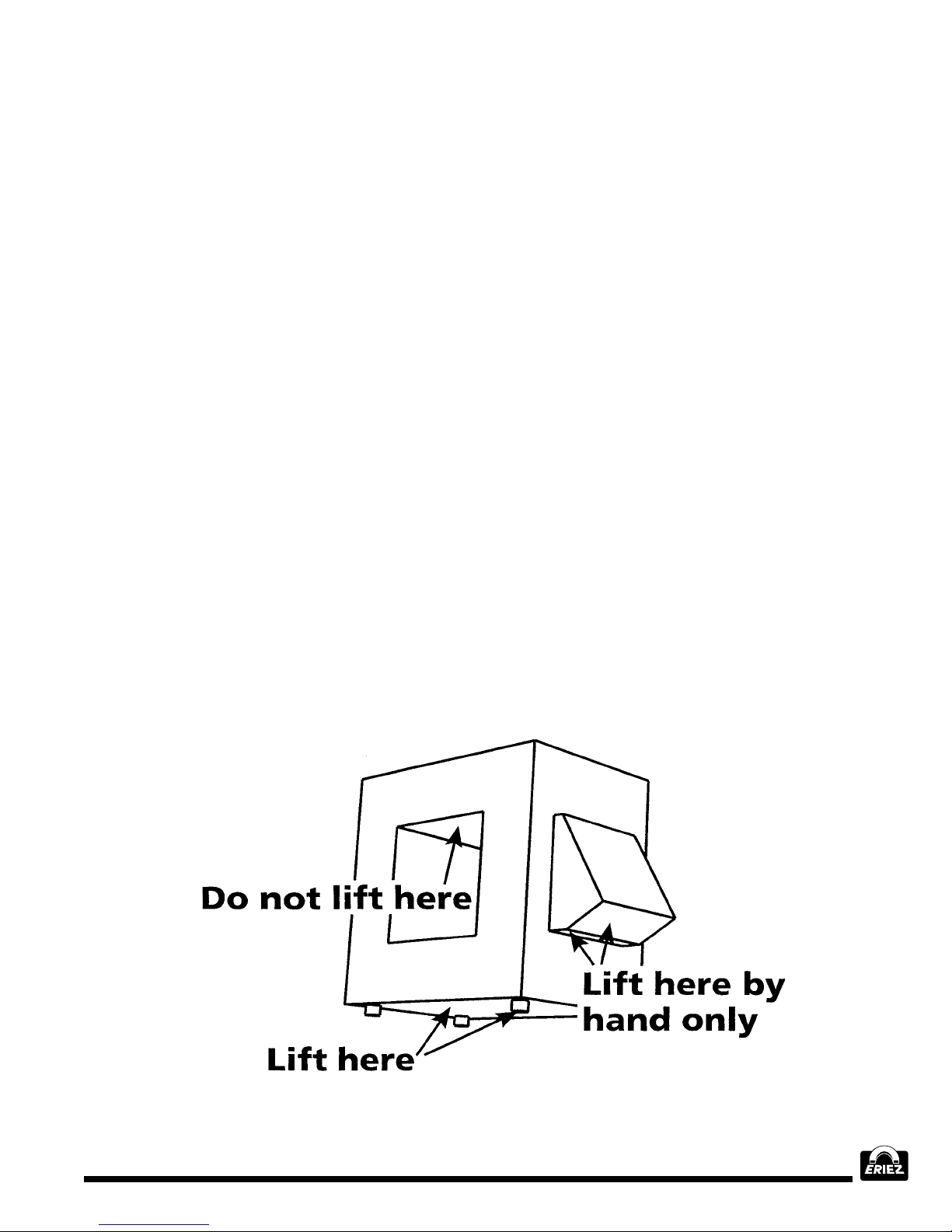

1. DO NOT LIFT THE METAL DETECTOR BY

INSERTING ANYTHING INTO OR THROUGH

THE APERTURE. The inner surface of the

aperture is delicate and is surrounded by a

precisely tuned electronic circuit that must not

be disturbed. Any damage to this surface or

any aperture distortion caused by handling will

invalidate Eriez’ warranty.

2. HANDLE THE SHIPPING PALLET NOT THE

DETECTOR. Keep the metal detector on its

shipping pallet as long as possible.

3. When you must remove the detector from the

shipping pallet, LIFT ONLY ON DETECTOR

HOUSING SERVICES THAT INCLUDE

SUPPORTING “FEET” OR T APPED LUGS, as

supplied by Eriez.

4. LIFT BY HAND IF POSSIBLE, or by using

a crane and soft nylon slings running under

the entire detector housing - NOT

THROUGH THE APERTURE. Block the

slings to prevent rubbing on the remainder

of the detector housing.

5. The metal detector is heavy. Use care

when handling to avoid injury to personnel

or damage to property.

6. Never weld any attachment to the detector

housing. Do not attempt to drill and/or tap

the metal detector housing for lifting or

mounting attachments.

7. Never lift with a crane or fork lift under the “chin”

of the control housing that juts out from the

metal detector housing. Make certain that

lifting straps and other handling equipment do

not contact the control housing.

8. If handling with eye-bolts threaded into pretapped holes supplied by Eriez:

a. Make sure that eye-bolts are strong enough

for the loads that will be applied

b. Never apply loads perpendicular to the

shank of the eye-bolts; they will break.

®

3

Table of ContentsTable of Contents

ERIEZ E-Z TEC METAL DETECTORS - MODELS IV AND V

GENERAL ...........................................................................................................12

PRINCIPLE OF OPERATION .............................................................................12

SPECIFICATIONS ..............................................................................................13

DETECT MODES................................................................................................15

Mode 1 ..........................................................................................................15

Mode 2 ..........................................................................................................15

INSTALLATION CAUTION!! ................................................................................16

MECHANICAL INSTALLATION...........................................................................16

Introduction ...................................................................................................16

Handling ........................................................................................................16

Location of Sensing Head .............................................................................16

Metal Free Area.............................................................................................17

Electrical Current Loops................................................................................17

Insulating the Conveyor Shafts .....................................................................17

Permanent Loops..........................................................................................18

Mounting Base ..............................................................................................18

Belt Splices ...................................................................................................19

Conveyor Slider Bed .....................................................................................19

Product Position ............................................................................................19

Reject Proximity Switch.................................................................................19

ELECTRICAL INSTALLATION............................................................................20

Introduction ...................................................................................................20

Choice of Input Power Source ......................................................................20

Power Supply ................................................................................................20

Relays ...........................................................................................................21

Direct Relay.............................................................................................21

Timed Relay ............................................................................................21

Fault Relay ..............................................................................................21

AC SSR ...................................................................................................21

DC SSR...................................................................................................21

Relay Notes.............................................................................................22

®

4

Table of Contents (cont.)

Inputs ...........................................................................................................22

Tachometer Input (TACH)........................................................................22

Proximity Switch (PROX SW)..................................................................22

Reject Confirmation (REJ CON)..............................................................22

Reject Reset (REJ RESET).....................................................................23

®

Host Computer Port (MPC

Printer Port (MPC only) ...........................................................................23

Conduit..........................................................................................................23

Initial Test (Analog Unit) ................................................................................23

Initial Test (MPC Unit)....................................................................................24

ANALOG CONTROLS AND DISPLAYS .............................................................25

Large Rectangular Status LED’S ..................................................................25

Detect (Red) ............................................................................................25

Fault (Yellow)...........................................................................................25

only) ............................................................23

Monitor Display .............................................................................................25

Sensitivity Control .........................................................................................25

Phase Control ...............................................................................................25

Analog Output Controls.................................................................................25

Travel Time..............................................................................................25

Reject Time .............................................................................................25

Standard Reject Time..............................................................................25

Indexed Reject Time................................................................................25

Programming Switches ...........................................................................26

Fault Indicator..........................................................................................26

Balance LED ...........................................................................................26

Reject LED ..............................................................................................26

Relay Status LEDs ..................................................................................26

Direct .......................................................................................................26

Timed.......................................................................................................26

ACSSR ....................................................................................................26

DCSSR....................................................................................................26

Fault ........................................................................................................26

®

5

Table of Contents (cont.)

Analog Output Controls (cont.)......................................................................26

Window LED............................................................................................26

Index In LED............................................................................................26

Confirm LED............................................................................................26

Clock LED ...............................................................................................27

Detect LED ..............................................................................................27

Analog Circuit Board Switch Programming ...................................................27

SW1-1 .....................................................................................................27

SW1-2 .....................................................................................................27

SW1-3 through SW1-8 ............................................................................27

SW1-9 .....................................................................................................27

SW2-1 .....................................................................................................27

SW2-2 .....................................................................................................27

SW2-3 .....................................................................................................27

SW2-4 .....................................................................................................27

JP1 ..........................................................................................................28

JP2 ..........................................................................................................28

JP3 ..........................................................................................................28

Switch Charts ..........................................................................................28

MPC CONTROLS AND DISPLAYS ....................................................................30

MPC Control Panel .......................................................................................30

LED Bar Graph........................................................................................30

Switch Keys.............................................................................................30

LCD .........................................................................................................30

MPC Software ...............................................................................................30

Flowchart.................................................................................................30

General MPC Operation................................................................................30

Monitor ....................................................................................................30

Reject Reports.........................................................................................31

Product Setup..........................................................................................31

Options ....................................................................................................31

Passwords.....................................................................................................31

Detect / Reject Display..................................................................................31

®

6

Table of Contents (cont.)

Controlling the MPC Display .........................................................................32

Travel Between Menus............................................................................32

Changing Variables .................................................................................32

Detailed MPC Menu Description ...................................................................32

Power Up Display....................................................................................32

Monitor Display........................................................................................32

Change Product Menu ............................................................................33

Identification Display ...............................................................................33

Main Menu...............................................................................................33

Product Setup Menu................................................................................33

Sensitivity ..........................................................................................33

Detect Mode ......................................................................................33

Phase ................................................................................................33

Gain...................................................................................................33

Filter...................................................................................................33

Configure Rejects..............................................................................34

Detailed MPC Menu Description (cont.)........................................................34

Product Description ...........................................................................34

Auto Phase........................................................................................34

Reject Setup............................................................................................34

Detect On Power Up?........................................................................34

Timed Reject .....................................................................................34

Timed Reject, Index Device is not Used............................................34

Timed Reject, Index Device Used .....................................................35

Direct Reject............................................................................................36

Product Description .................................................................................36

Auto Phase..............................................................................................36

Reject Reports.........................................................................................36

Erase All Reports..................................................................................... 37

Fault ........................................................................................................37

Reject Confirmation Fault..................................................................38

Balance Fault ....................................................................................38

Self-Check Fault................................................................................38

Calibration Fault ................................................................................38

®

7

Table of Contents (cont.)

Options ....................................................................................................39

Buzzer ...............................................................................................39

Setup Communication .......................................................................39

Setup Printer .....................................................................................39

Factory...............................................................................................39

Set Time and Date.............................................................................39

Update Passwords ............................................................................39

Print Options............................................................................................39

Diagnostics..............................................................................................39

Troubleshooting.................................................................................39

Self-Check.........................................................................................40

Calibration Check ..............................................................................41

Calibration Check Setup....................................................................41

CONFIGURING ANALOG METAL DETECTOR .................................................42

Analog Adjustment Procedure.......................................................................42

Phasing Out the Product Effect - Analog Units..............................................42

Reject Adjustment - Analog Units ..................................................................43

Direct Reject............................................................................................43

Timed Reject ...........................................................................................44

Timed Reject, Index Device Not Used.....................................................45

Timed Reject, Index Device Used ...........................................................46

CONFIGURING MPC METAL DETECTOR ........................................................48

MPC General Options Menu .........................................................................48

MPC Product Setup ......................................................................................48

MPC Reject Adjustment ................................................................................51

Direct Reject............................................................................................51

Timed Reject ...........................................................................................51

Timed Reject, Index Device Not Used.....................................................51

Timed Reject, Index Device Used ...........................................................52

Obtaining MPC Reject Reports .....................................................................53

LCD .........................................................................................................53

Printer......................................................................................................53

Host Computer ........................................................................................53

®

8

Table of Contents (cont.)

MAINTENANCE ..................................................................................................54

SPARE PARTS....................................................................................................54

Analog Unit Spare Parts................................................................................54

MPC Unit Spare Parts................................................................................... 55

FIGURES ...........................................................................................................56

APPENDIX A - PRINTER OPERATION (MPC ONLY) ........................................77

Introduction ...................................................................................................77

General Description ......................................................................................77

Detailed Description ......................................................................................77

Connector Pinout.....................................................................................77

MPC Printer Setup ..................................................................................77

Data Bits..................................................................................................77

Parity .......................................................................................................77

Transmit Mode.........................................................................................77

End Line With ..........................................................................................78

Baud Rate ...............................................................................................78

Printing Options.............................................................................................78

Printing A Single Report ..........................................................................78

Printing Multiple Reports .........................................................................78

Operating Instructions ...................................................................................78

Configuring Printer Cable ........................................................................78

Setting Up MPC Printer Serial Port .........................................................79

Printing a Single Report Using Manual Mode .........................................79

Printing Reports Automatically ................................................................79

Printing All Stored Reports ......................................................................80

Canceling Print All Reports......................................................................80

APPENDIX B - VARIABLE SPEED TACHOMETER ...........................................81

Tachometer System Design ..........................................................................81

Tachometer Wiring Connections .............................................................82

®

9

Table of Contents (cont.)

APPENDIX C - VARIABLE REJECT UNITS .......................................................83

Introduction ...................................................................................................83

Mechanical ....................................................................................................83

Electrical........................................................................................................84

APPENDIX D - SLIM TEC SINGLE SURFACE UNITS.......................................86

Introduction ...................................................................................................86

Mechanical ....................................................................................................86

Electrical........................................................................................................87

APPENDIX E - SLIM TEC APERTURE UNITS...................................................90

Introduction ...................................................................................................90

Mechanical ....................................................................................................90

Electrical........................................................................................................91

APPENDIX F - VFS PACKAGING MACHINE METAL DETECTORS .................94

Introduction ...................................................................................................94

Mechanical ....................................................................................................94

Electrical........................................................................................................95

®

10

General

The Eriez Magnetics E-Z Tec IV and V Metal

Detectors are state of the art electronic devices

for detecting fine particles of metal in non-metallic

product streams. They are designed for accuracy ,

sensitivity, reliability and simplicity of operation.

Two variants are available: the analog version

(Figure 1) and the MicroProcessor Controlled

(MPC®) version (Figure 2). The performance,

controls, and outputs of the analog version are

ideal for most standalone industrial applications

where a simple detect-reject process is required

and the product stream has consistent

characteristics from day to day. For applications

where the detect-reject procedure may require

more frequent changes, the record keeping

requirements may be more stringent, or a

centrally controlled network of detectors is

required, Eriez provides the MPC versions of the

E-Z Tec IV and V.

This manual covers both the analog and MPC

versions of the E-Z Tec IV and V. Much of the

discussion herein is relevant to either version.

This manual provides all information necessary to

use both the E-Z Tec IV/V Metal Detector (analog

version) and the E-Z Tec IV/V MPC Metal Detector

as standalone systems. For networked or remotely

controlled installations of MPC detectors refer also

to the E-Z Tec III/IV/V MPC Communications

Manual MM-237

NOTE: Throughout this manual, information specific to the analog version of the metal detector is

set off with a gray border.

Information specific to the MPC version of the metal

detector is set off with a gray background.

Generic information—applicable to both analog and

MPC versions—is neither bordered nor shaded.

®

11

Principle of Operation

The E-Z Tec IV/V Metal Detector uses a

differential transformer to detect pieces of metal.

Three coils encircle the detection aperture. The

signal voltage in the primary coil is driven by an

oscillator. Two secondary coils, on a common axis

with the primary , are coupled into the field of the

primary coil in such a manner that the system is

in balance and the induced voltages in the two

secondary coils cancel.

A piece of metal introduced into the detection

aperture will distort the primary field and cause a

difference in induced voltages in the two secondary

coils. This voltage difference constitutes a signal

that is amplified and manipulated to extract the

amplitude and phase angle with respect to the

oscillator input signal. This information is used to

decide whether the signal represents metal or the

user’s product. If it represents the user’s product it

is ignored. If it represents metal, and if the signal

exceeds a pre-set level, the metal detector

generates a detection signal. The detection signal

is manipulated to provide various timing functions

for creating reject actions.

Figures 3 and 4 illustrate conveyor installations

of E-Z Tec analog and MPC metal detectors

respectively.

Separation of P o wer and Signal Wiring

This information is being distributed to

assemblers and electricians about the importance

of proper methods for wiring of controls. These

methods are revised and updated from time to

time as we (Eriez Magnetics) perceive necessary .

This information will cover distances from various

categories of cables and Eriez Metal Detector

wiring standards. The cable categories are:

Use separate machine entry holes for category

1, 2 and 3 cables.

When Eriez Metal Detectors are being installed

in plants using VFC drives, the following

precautions are recommended:

1. Route VFC wiring and Eriez Metal Detector

wiring in to separate metallic conduits.

1. AC power cables

2. DC distribution (thermocouple, power supplies)

3. Signal and Logic

a. Analog (low level)

b. Digital logic

Category 1 cables are to be routed along frame

members and panels. A void open space hanging.

Category 2 cables are routed as in Category 1

but separate from 1.

Category 3 cables are routed separately from

Categories 1 and 2. Category 3b cables are to

be spaced 25 cm (1") from Category 1 for each

meter of run.

®

2. Separate power sources should be used for

VFC drive and Eriez Metal Detectors.

3. The use of a Harmonic Neutralized Constant

Voltage Transformer for the Eriez Metal Detector power is recommended. Use separate

conduits for in and out wiring.

4. Twist AC common circuit run wires tegether to

minimize electromagnetic field interference.

5. Follow cable category separations as detailed

above.

12

Specifications

POWER SOURCE REQUIREMENTS

(TWO RANGES)

105 to 125 VAC 50 to 60 Hz.

Max. surges of 150 V RMS for a period

of 2 seconds.

OR

210 to 230 VAC 50 to 60 Hz.

Max. surges of 300 V RMS for a period

of 2 seconds.

Maximum demand 60 VA (Excluding

externally connected loads).

FUSES

Located in separate NEMA 4(X) enclosure

(See Figure 7).

F1 - Self resetable fuse rated at 200mA DC.

Requires no service.

F2,3,4,5,6 - Bussman GMA-1A 5X20 mm.

F7, F8 - Bussman GMC-1A 5X 20 mm.

TACHOMETER INPUT

Used to monitor variable speed conveyors.

See Appendix B.

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC.

Logic 1 - 3.15 to 50 VDC .

(NPN Open Collector can also be used).

Current

Source N/A.

Sink 1 mA min.

Frequency

50 Hz max maximum.

Minimum Pulse Width

Logic 0 - 5 mSec.

Logic 1 - 5 mSec.

PROXIMITY SWITCH INPUT

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC.

Logic 1 - 3.15 to 50 VDC.

(NPN Open Collector can also be used).

Current

Source N/A.

Sink 1 mA min.

Frequency

50 Hz max maximum.

Minimum Pulse Width.

Logic 0 - 5 mSec.

Logic 1 - 5 mSec.

REJECT CONFIRMATION INPUT

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC.

Logic 1 - 3.15 to 50 VDC.

(NPN Open Collector can also be used).

Current

Source N/A.

Sink 1 mA min.

Frequency

50 Hz max maximum.

Minimum Pulse Width

Logic 0 - 5 mSec.

Logic 1 - 5 mSec

REJECT OUTPUTS

Direct Reject

K1 - Mechanical single pole double throw

relay rated 1A, 250 VAC or 1A, 30 VDC.

Timed Reject

K2 - Mechanical single pole double throw

relay rated 1A, 250 VAC or 1A, 30 VDC.

OPTIONAL SOLID STATE RELAYS

SSR1 - AC solid state relay rated .02 to 1.0 A,

12 to 250 VAC.

SSR2 - DC solid state relay rated .02 to 1.0 A,

5 to 60 VDC.

PRODUCT MEMORY (MPC ONLY)

The MPC is capable of storing all metal

detector adjustments and alphanumeric

descriptions for 99 separate products.

REJECT TIMERS

Direct Reject

Travel Time 0.00 sec.

Reject time 0.05 to 60 sec (these values

approximate on analog version).

Timed Reject

Travel Time 0.05 to 60 sec. (approximate

on analog version).

Reject Time 0.05 to 60 sec. (approximate

on analog version).

Shift Register Resolution 1200.

®

13

Specifications (cont.)

REJECT COUNTER (MPC ONLY)

The MPC stores a running total of the number

of times the Direct Reject output has cycled.

This normally provides a very close approximation of the total number of detections while

preventing multiple counts of the same piece

of tramp metal.

Maximum Count: 9999.

REJECT REPORTS (MPC ONLY)

The MPC stores pertinent data on the most

recent 100 rejects. Report Number, Product

Number, Time, Date, and Peak Signal Level

can be reviewed on the LCD display. The reports can be downloaded to a remote printer.

In this case, Travel Time, Timed Reject Time,

Sensitivity, Gain, and Product Description are

also included in the report. The reports can

be downloaded to a remote computer. The

computer report contains all information mentioned above plus Phase, Filter Frequency,

Detect Mode, Fault Status, Date & Time that

any one of the variables was last changed,

Direct Reject Time, Window Time, and status

of Tach Input, Direct Reject Auto Reset, T imed

Reject Auto Reset, Space Between Products,

Index Device Used?, and Reject Confirmation.

ENCLOSURE RATING

NEMA-4X/IP66.

PRODUCT VELOCITY

The metal detector can be adjusted to scan

products traveling from approximately 2 ft./min.

to 7800 ft./min. (.6 m/min. to 2400 m/min.) depending on the size and type of sensing head.

The unit is set up at the factory for optimal

performance for the customer’s application and

requires no further adjustment.

FREQUENCY

The metal detector operating frequency depends on the aperture size and the characteristics of the product to be inspected. It is adjustable but this is normally not required unless another metal detector in the area causes

interference. In this case consult the factory

for adjustment details.

BATTERY LIFE (MPC ONLY)

Minimum 1.4 years; maximum 5.0 years.

COMMUNICATION (MPC ONLY)

Printer-RS 232 (see Appendix A).

Computer-RS 232/485 (see E-Z Tec MPC

Communications Manual MM-237).

ENVIRONMENT

Ambient Temperature 0° C (32° F) to 50° C

(122° F) during operation.

Storage Temperature -10° C (14° F) to 80° C

(176° F).

Relative Humidity 0 to 95%.

NOTE: When stored at or below 0° C for

longer than six hours and then moved to a

warmer location, the temperature of the unit

should be allowed to stabilize long enough to

allow drying of moisture which may have accumulated on the electronic components (overnight is recommended). DO NOT APPLY

POWER UNTIL ELECTRONIC CIRCUITR Y IS

COMPLETELY DRY.

®

PRODUCT DESCRIPTION (MPC ONLY)

32 alphanumeric characters of description can

be stored for each of 32 separate products.

DIAGNOSTICS (MPC ONLY)

Automatic self-checking for proper operation

of the metal detector electronics at user definable intervals

Detector can show Fault condition when userscheduled calibration procedure is missed.

Receiver and transmitter independently controllable for identification and isolation of external electronic noise sources.

14

Detect Modes

E-Z T ec IV and V metal detectors can operate in either

of two detect modes. The most appropriate mode for

a given application depends largely upon

environmental conditions and upon the likely mix of

tramp metal in the product stream. The discussion

below provides guidelines on selection of the best

detect mode for your operation.

MODE 1

The metal detector control processes an analog signal

from the receiver coils of the metal detector. A typical

example of a metal signal is shown in Figure 5-A. If

the magnitude of the signal rises above a

predetermined detection threshold, the metal detector

will output a detect signal. Note that the analog signal

has a positive and a negative portion. In detect mode

1 the metal detector will detect on both portions of the

signal. The detect signal typically begins with the first

portion of the signal crossing the detection threshold

(at point “A”) and ends after the second portion of the

signal returns through the opposite detection threshold

(at point “B”). Mode 1 is usually the most sensitive

and reliable method of detection and is, therefore,

used in most applications.

MODE 2

Occasionally a metal detector is used in an

environment where significant interference is

experienced. Typical sources of interference are

lightning, static electricity , and nearby equipment with

inductive loads. These types of interference usually

cause analog signals which have only one polarity.

Figure 5-B shows typical unipolar noise signals at “D”,

“E” and “F”. Each of these signals would cause a metal

detector to false detect when operating in Mode 1

because they exceed the detection threshold level.

The metal detector can be adjusted to ignore many

of these signal types by using Mode 2 detection. Refer

again to the analog signal of Figure 5-A. Notice that

the metal signal has both a positive and negative

polarity . Mode 2 detection does not detect a unipolar

signal. It holds off detection until the second polarity

of the signal occurs. For the signal in Figure 5-A the

detection would occur at point “C”. It would last a

predetermined length of time and reset. The noise

signals in Figure 5-B would be ignored because they

are unipolar.

In general, Mode 2 detection may be somewhat

less sensitive than Mode 1 detection. Also Mode 2

detection may allow metal to pass undetected in

certain instances. Figure 5-C shows an analog

signal representing a small piece of metal followed

by a large piece of metal in the product stream.

The beginning of the signal is similar to the

beginning of the signal shown in Figure 5-A; but as

it moves toward the negative detection threshold,

the signal of the small piece of metal is absorbed

by the signal of the larger piece of metal following

it. The larger piece of metal is detected at “G”. Note

that the small piece of metal is not detected.

Extremely large pieces of metal will cause larger

sections of the product stream to be ignored

because the electronics will require more time to

recover. Therefore, the probability of missed metal

increases with the size of the tramp metal. Normally

this area is small because the tramp metal is small.

The probability is low that metal will be missed, but

the possibility exists and must be considered before

one decides to use Mode 2 detection.

If the metal detector works reliably using Mode 1

detection, Eriez recommends use of this mode.

Some applications are electrically noisy and the

number of false trips is high enough that the metal

detector cannot be used in Mode 1. In this case

one must decide whether to use Mode 2 detection

with an increased probability of missing a small

percentage of metal. The unit will ignore most noise

and still detect the overwhelming majority of the

metal. Mode 2 is much better than no protection.

However, Eriez recommends its use only when

absolutely necessary.

Every unit leaves the factory with an Individual Unit

Specifications sheet. This sheet will indicate

whether the unit is set for Mode 1 or Mode 2

detection. Most units will be set for Mode 1

detection. If the detection mode of the unit must be

changed, use switch SW2-1 on the Output Control

panel of an E-Z Tec IV or V analog metal detector

(in the Power Supply housing) or use the Detect

Mode menu option on an E-Z Tec IV or V MPC

metal detector. Detailed instructions for these

procedures are given in later sections.

®

15

Installation Caution!!

E-Z Tec IV and V metal detectors have been

manufactured to very stringent quality control

standards to ensure that they will provide years

of trouble-free service. To achieve this troublefree service, the installer must follow the

installation procedures outlined in this manual.

The details of the procedures are important, and

must be followed precisely for proper metal

detector operation.

A metal detector is by nature extremely sensitive

to very small changes in its electrical and physical

environment. Installed incorrectly, it will be very

likely to display unstable operation. It will appear

Mechanical Installation

INTRODUCTION

The metal detector contains from one to three

components which must be physically mounted to

a conveyor or suitable stand: 1) the sensing head,

2) the control (including the MPC in MPC versions)

if it is not part of the sensing head, and 3) the power

supply which may be integral with the sensinghead

and/or this control. See Figure 6.

The sensing head includes the sensing aperture

and related electronics. The control is either

attached to the sensing head or remote from it. If

the control is remote from the sensing head, its

enclosure must be mounted to a convenient

surface (free of vibration) that is easy to access

so that the metal detector can be adjusted. The

control enclosure is fitted with plastic mounting

feet that must be used to mount it.

The power supply contains all the electrical

connections to the metal detector. It is located

within a NEMA-4X enclosure (see Figure 7). This

enclosure is also fitted with plastic mounting feet

that must be used to mount it.

to be extremely sensitive to vibration and/or will

false trip (generate a false reject signal) when

the conveyor starts and stops. These and other

troubles will be prevented by proper installation

techniques.

The following installation procedures have been

collected over years of experience. Please make

use of them! Problems caused by improper

installation techniques are not covered by

warranty! A little time invested in the installation

process will pay for itself many times over by

providing a smooth trouble-free startup and

continued reliable service.

HANDLING

The metal detector must be handled with care

during installation. Follow the specific handling

guidelines attached to the detector or included in

the shipping materials. For convenience, generic

handling guidelines are included in this manual

immediately inside the front cover.

LOCATION OF SENSING HEAD

The location of the metal detector sensing head

is extremely important. The process of selecting

a location must include consideration of the needs

of the metal detector, the surrounding processing

equipment, and the operator. Product flow

including velocity and rejection of contaminants

is a major concern. Be certain to read and

understand all installation guidelines before the

final location is selected.

®

16

Mechanical Installation (cont.)

METAL FREE AREA

The metal detector monitors an electromagnetic

field to detect metal. This field is predominantly

contained within the metal detector sensing

aperture but some fringing of the field exists at

the entrance and exit openings. The fringing field

will allow the metal detector to detect metal in

the vicinity of the entrance and exit. For this

reason, metal must not be located in this area.

The required metal-free area depends on the size

of the smaller dimension of the aperture. Normally

1.5 times the smaller aperture dimension is

sufficient clearance for non-moving metal. If

space allows, a 1.75 multiplier on the smaller

aperture dimension should be used. Applications

which involve relative movement between the

sensing head and adjacent metal should use a 2.0

multiplier. (For example, stationary metal should not

be located closer than 6 to 7 inches (150 to 175mm)

from either the entrance or exit opening of a metal

detector with a 4 x 8 inch aperture. Moving metal

should not be closer than 8 inches (200mm) from

the entrance or exit of such a detector.) Please refer

to Figure 8 for details.

ELECTRICAL CURRENT LOOPS

By far the most frequent trouble experienced with

metal detector installations is false tripping

caused by electrical current loops. As was

explained in the previous section, some

electromagnetic field extends from the metal

detector aperture. The field dissipates in strength

with distance, to a point that metal contained

outside the metal-free area defined above will not

cause false detections. However, since the field

is time-varying, small electrical currents are set

up in conveyor conduction paths (i.e. metalwork)

quite some distance from the aperture. These

currents and others (e.g. ground currents from

other nearby equipment) are not harmful as long

as they are constant, but if they change, the metal

detector will false trip. Figure 9 shows a simplified

aerial view of a typical metal detector and

conveyor. The arrows located within the conveyor

framework, head pulley, tail pulley and return

idlers represent electrical currents. The bearings

supporting the pulleys and idlers represent

potential switches. As they turn, the bearings

make and break contact with their respective

races through the lubricant within. Likewise the

cross-members of the conveyor framework

represent potential switches if they are attached

to the conveyor with bolts or rivets. Through time,

connections such as these work loose or corrode

and make and break electrical connections as a

result of normal conveyor vibrations. Potential

switches of both these types must be eliminated.

INSULATING THE CONVEY OR

SHAFTS

In the case of pulleys and idlers there is no way

to make the electrical path constant enough to

prevent changes in the currents. These currents

must be eliminated by introducing an insulating

medium within the conduction path. Figure 10

shows two common methods.

The method shown in Figure 10-A is

accomplished by machining the end of the shaft

which rides in the bearing to a small diameter

and inserting an Ultra-High Molecular Weight

(UHMW) plastic sleeve over it. The outside

diameter of the sleeve is the same as the inside

diameter of the bearing. This sleeve breaks the

electrical connection between the bearing and the

shaft, thus permanently preventing current flow.

WARNING: Do not cut through the sleeve when

tightening the bearing set screw.

Figure 10-B shows a method of insulating the

complete bearing block from the conveyor frame.

This requires drilling the bolt holes through the

bearing block to a larger diameter to accept an

insulating shoulder washer. The shoulder washer

wall thickness should be at least 1/32" (1 mm).

Alternatively the shoulder washer can be

replaced with a plastic washer and a length of

plastic pipe or hose. Insulating the bolt with

tape is not recommended. The bearing block

is insulated from the conveyor frame with a

UHMW insulator extending entirely across the

base of the block as shown.

®

17

Mechanical Installation (cont.)

Both insulating methods are reliable. However, it

takes only a small metal shaving or burr to cut

through and short-circuit the insulators. For this

reason the insulation should be tested with an

ohmmeter after the pulley or idler is installed on

the conveyor frame. Obviously insulating either

end of the shaft will prevent current loops.

However, leaving one end uninsulated will prevent

testing with an ohmmeter. For this reason

insulating both ends is recommended.

Sometimes when the humidity is low, static

electricity will form on the conveyor belt. A charge

can build up on pulleys or idlers which are

insulated on both ends. This should be prevented

because static discharge may cause the metal

detector to false trip. After the integrity of the

insulators is checked with an ohmmeter, one end

of each shaft should be electrically reconnected

to the conveyor frame. In the case of the sleeve

insulating method the set screw of one of the

bearings should be used. This may require drilling

a small hole down through the sleeve and

inserting a sharp pointed set screw. In the case

of the bearing block insulating technique simply

remove one of the shoulder washers on one end

of the shaft. Note that in both methods if at any

future time the integrity of the insulators is in doubt

they can be checked again easily.

NOTE: If the conveyor belt drive pulley is driven

with a metal chain, do not defeat the insulators

on either end of the shaft. The metal drive chain

will bleed off any static charge which may accumulate on the pulley.

PERMANENT LOOPS

Permanent conduction paths (such as cross

members) associated with the conveyor frame must

be welded securely . In this way currents flowing in

the loops will remain constant. Bolted construction

is not permissible. Any conduction path which is to

remain removable or is simply not weldable must

be insulated from the conveyor frame.

Figure 11 shows the modified conveyor frame.

Note the potential switches no longer exist and

the only currents in the conveyor frame are

running through welded, permanent connections.

They will be consistent and therefore will not

cause false detections.

IMPORTANT:

It is risky to accept an installation with bolted

conveyor construction, even though tests may

show that no metal detector false trips occur when

bolted structural members are deliberately

shaken or twisted. No matter how good the bolted

connections are initially , there is a high likelihood

that such connections will eventually degrade or

loosen, creating an unstable electrical pathway

that interferes with metal detector operation and

that may be extremely difficult to locate. Use only

welded or insulated construction techniques.

MOUNTING BASE

The base to which the metal detector sensing

head is mounted must be strong, rigid, and as

free as possible from vibration. Although the metal

detector can be set up to be relatively insensitive

to vibration, better sensitivity to metal can often

be obtained by preventing vibration from reaching

the detector head.

Four insulating mounting feet are supplied with

the metal detector. They must be used (refer to

Figure 12). All four must sit flat on the mounting

base. Never draw the feet down to the stand by

tightening the mounting bolts. This will put uneven

stresses on the sensing head and possibly cause

instability. If for any reason the feet do not all sit

flat on the mounting base, shim with appropriate

washers until all four mounting feet are carrying

the same load.

Nothing except the insulating feet and electrical

connections may contact the sensing head.

Conduit attached to the metal detector shell

should utilize plastic fittings (refer to Electrical

Installation).

®

18

Mechanical Installation (cont.)

BELT SPLICES

The metal detector sensing head cannot be

disassembled to be fitted around the conveyor

belt. For this reason the conveyor must be

designed to return the belt through the aperture,

or the belt must be cut and spliced back together.

Splicing the belt with lacing or clamps is not

recommended because foreign materials tend to

collect at the joint, and these eventually cause

false detections.

Vulcanized splices are recommended for best

reliability. Refer to Figure 13 for typical splice

types. If the belt is single-ply, the Finger Splice

configuration should be used. If the belt is multiply, a combination of Step/Finger Splice

configuration is recommended.

Cold bonding is a popular on-site practice. In this

case the splice is usually a Beveled or Step-Lap

type. Adhesives are available which are food or

non-food grade. In either case the splices should

be diagonal rather than straight across the belt.

The cold bond splice is adequate for many

applications as long as the splice is diagonal but

the Vulcanized Finger splice is preferred.

NOTE: During all splicing it is absolutely necessary to ensure that no foreign material (especially

metal) is trapped within the splice. If this happens,

the metal detector will trip every time the splice

passes through the aperture. Since the metal is

trapped inside the splice it cannot normally be located and removed without ruining the belt.

CONVEYOR SLIDER BED

The conveyor belt must be supported as it travels

through the metal detector. This task is performed

by a slider bed, which must be capable of holding

the belt off the aperture liner even when fully loaded.

The slider bed must not contact the metal detector

aperture liner. It should be supported by the

conveyor frame. The slider bed should be made of

static-resistant non-metallic material. Wood and

phenolic are good choices. Plastic should normally

not be used because it tends to generate static

electricity as the conveyor belt slides across it.

PRODUCT POSITION

The product should always be guided through the

center of the aperture, both vertically and

horizontally. This is true whether the product

travels through the metal detector on a conveyor

or flows through a pipe as in a vertical application.

If multiple size products will be inspected by the

same metal detector, design the system to center

the largest product in the aperture.

REJECT PROXIMITY SWITCH

The proximity switch is used to indicate when a

package aligns with a reject device. For example,

a product in a box may need to align with a reject

device, such as a pusher arm, to be rejected

reliably. The proximity switch indicates when the

alignment is achieved. Normally the proximity

switch is positioned just after the reject device

so that it is triggered as the product aligns with

the reject device. If it is difficult to install a switch

in that location, it can be installed upstream from

the reject device. In this case the proximity switch

must contain a delay timer capable of delaying

the output until the product aligns with the reject

device. Be certain not to infringe on metal detector

metal free areas when choosing the location of

the proximity switch.

®

19

Electrical Installation

INTRODUCTION

All electrical connections are intended to be made

within the NEMA-4X power supply enclosure.

Figure 14 shows the enclosure and the electrical

connections to the power supply circuit board.

There are no user serviceable electronics or

electrical connections within the control

enclosure. Never attempt to remove the detector

control from the control enclosure.

CHOICE OF INPUT PO WER SOURCE

The metal detector is equipped with filtering

devices to help eliminate incoming electrical

noise. Noise is usually created by inductive loads

sharing the same power circuit. Even with the

filters there is a limit to what the metal detector

can withstand without false tripping.

The best insurance against electrical noise is to

run a separate circuit from the main power bus.

This circuit should be free of all loads except the

metal detector. The power line should be run in its

own metal conduit. The conduit must be electrically

insulated from the conveyor. This includes any

supporting structure for the metal detector. If this is

impossible or impractical, reliable operation can

often be obtained by powering the metal detector

from a “clean” lighting circuit. This circuit must be

free of inductive loads such as motors, solenoids,

motor starters, variable frequency drives, etc.

If the metal detector must be powered by a less

favorable source, false tripping caused by line noise

can usually be eliminated through the use of a

harmonic neutralized constant voltage transformer.

POWER SUPPLY

Refer to Figure 14 for wiring to the power supply.

The metal detector may be powered at either of

two voltage ranges described in the specifications

section of this manual. Be certain the input power

voltage selection switch is in the proper position to

accept the power supply. The voltage selection

switch is shown in Figure 14 and is labeled SW2

on the circuit board.

CAUTION:

Be careful to distinguish between the input

voltage selection switch and the power (off/on)

switch. Both are located in the lower left corner

of the power supply circuit board. THE VOL TAGE

SELECTION SWITCH IS RED, AND IS LABELED

WITH THE AVAILABLE VOLTAGES, 115V AND

230V . THE POWER SUPPLY SWITCH IS BLACK,

AND IS LABELED WITH 0 AND 1, TO INDICATE

OFF AND ON, RESPECTIVELY. INADVERTENT

USE OF THE IMPROPER SWITCH COULD

LEAD TO CIRCUIT DAMAGE AND/OR

PERSONAL INJURY. See Figure 14 for the

location of these two switches.

The power source attaches to terminals L1 and

L2. If operating in the 115 VAC range, L1 is the

active or high side of the line and L2 is the neutral.

If operating in the 230 V AC range, connect either

supply line to L1 and the other to L2.

Note that L1 and L2 are connected through circuit

board traces to other terminals on the circuit

board as labeled. They are intended to be

conveniently available to the user to power

various ancillary equipment. They are not fused

on the circuit board. It is the user’s obligation to

be certain L1 and L2 lines are adequately fused

external to the metal detector, preferably at the

power source.

The power source must contain a reliable ground.

It must be connected to the “GND” terminal.

NOTE: The metal detector may be grounded at only

one point, through the power supply ground wire.

No other ground connections are permitted. This

includes mounting hardware and conduit.

The metal detector electronics are protected by

1A fuses (GMC-1A). The fuses are located

between the POWER SUPPLY L1 and L2

terminals and the metal detector electronics. Note

there are no fuses between the POWER SUPPL Y

L1 and L2 terminals and the other L1 and L2

terminals on the circuit board.

®

20

Electrical Installation (cont.)

RELAYS

The E-Z Tec IV and V provide three standard and

two optional relays as follows:

DIRECT RELAY

The Direct Relay is a mechanical SPDT (single

pole double throw) relay. The relay contacts are

labeled on the circuit board showing the

respective terminal connections. The relay is

shown energized which is its normal non-reject

state (this provides fail-safe relay operation).

When Direct Reject occurs, the relay changes to

the state opposite that shown (the relay is deenergized which causes the left contacts to close

and the right contacts to open). After the reject

clears, the relay is again energized switching it

back to its original position.

TIMED RELAY

The Timed Relay is a mechanical SPDT (single

pole double throw) relay. The relay contacts are

labeled on the circuit board showing the

respective terminal connections. The relay is

shown energized which is its normal non-reject

state (this provides fail-safe relay operation).

When Timed Reject occurs, the relay changes to

the state opposite that shown (the relay is deenergized which causes the left contacts to close

and the right contacts to open). After the reject

clears, the relay is again energized switching it

back to its original position.

FAULT RELAY

The Fault Relay is a mechanical SPDT (single

pole double throw) relay. The relay contacts are

labeled on the circuit board showing the

respective terminal connections. The relay is

shown energized which is its normal non-fault

state (this provides fail-safe relay operation). If a

fault condition occurs, the relay changes to the

state opposite that shown (the relay is deenergized which causes the left contacts to close

and the right contacts to open). After the fault

clears, the relay is again energized switching it

back to its original position.

AC SSR

The AC SSR is a solid state relay suitable for

switching AC loads only. It functions in parallel

with the Timed Relay described above. The relay

contacts are labeled on the circuit board showing

the respective terminal connections. The polarity

(e.g. normally open or normally closed) is

adjustable using SW1. If the switch is in the right

position, the relay is normally closed. When Timed

Reject occurs, the relay changes state (the relay

is de-energized which causes the relay to open).

After the reject clears, the relay is again energized

switching it back to its original position. If SW1 is

in the left position, the relay operates opposite in

polarity to that just described.

NOTE: This relay is optional. This relay is only

installed in units where the relay was requested

by the customer at the time of manufacture.

DC SSR

The DC SSR is a solid state relay suitable for

switching DC loads only. It functions in parallel

with the Timed Relay described above. The relay

contacts are labeled on the circuit board showing

the respective terminal connections. Note the left

terminal is positive and the right terminal is

negative. The polarity (e.g. normally open or

normally closed) is adjustable using SW1. If the

switch is in the right position, the relay is normally

closed. When Timed Reject occurs, the relay

changes state (the relay is de-energized which

causes the relay to open). After the reject clears,

the relay is again energized switching it back to

its original position. If SW1 is in the left position,

the relay operates opposite in polarity to that just

described.

NOTE: This relay is optional. This relay is only

installed in units where the relay was requested

by the customer at the time of manufacture.

®

21

Electrical Installation (cont.)

RELAY NOTES

As shipped, none of the relays source power. If

switched AC power is needed it must be supplied to

the appropriate relay through a jumper, such as from

one of the L1 or L2 terminals or from an external

source. If switched DC power is needed it must be

supplied from a remote source or from the +5 TACH

terminal (5 volts DC, 100mA max.). All relays are

protected by a 1A fuse (GMA-1A).

Solid state relays cannot be tested with most

ohmmeters. T est the solid state relays by applying an

appropriate power source and load.

INPUTS

The metal detector will accept inputs from external

devices of various types. The terminals for these inputs

are located at the lower edge of the Power Supply

PCB, and are described functionally below.

TACHOMETER INPUT (TACH)

Applications having variable speed product flow and

needing automatic reject timing use this input. A

tachometer is used to allow the metal detector control

to monitor product speed and reject according to the

distance the product has traveled rather than elapsed

time since detection. (Refer to Appendix B for details.)

The electrical specifications are as follows:

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC

Logic 1 - 3.15 to 50 VDC

(NPN Open Collector can also be used)

Current

Source N/A

Sink 1 mA min

Frequency

50 Hz max

Minimum Pulse Width

Logic 0 - 5 mSec

Logic 1 - 5 mSec

PROXIMITY SWITCH (PROX SW)

Sometimes the metal detector is used to scan and

automatically reject packages. A proximity switch

is used to sense the location of the package so it

can be rejected reliably. The device can be a

mechanical switch, photo-eye, or any other device

which is capable of precisely locating the package.

The electrical specifications are as follows:

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC

Logic 1 - 3.15 to 50 VDC

(NPN Open Collector can also be used)

Current

Source N/A

Sink 1 mA min

Frequency

50 Hz max maximum

Minimum Pulse Width

Logic 0 - 5 mSec

Logic 1 - 5 mSec

Note the right terminal of this input is ground. Since

the metal detector is to be grounded only by the

input power supply ground, this terminal must not

be grounded by the proximity device.

REJECT CONFIRMATION (REJ CON)

The reject confirmation input is used to monitor the

function of the reject device. It is usually a limit

switch attached to the reject device which indicates

it is functioning. For example, the device may be a

switch attached to a pusher bar used to reject a

box off a conveyor . The switch is positioned in such

a way that it closes as the pusher bar reaches its

maximum extension. The electrical specifications

are as follows:

Voltage

Logic 0 - 0.0 VDC to 0.9 VDC

Logic 1 - 3.15 to 50 VDC

(NPN Open Collector can also be used)

Current

Source N/A

Sink 1 mA min

Frequency

50 Hz max maximum

Minimum Pulse Width

Logic 0 - 5 mSec

Logic 1 - 5 mSec

Note the right terminal of this input is ground. Since

the metal detector is to be grounded only by the

input power supply ground, this terminal must not

be grounded by the limit switch.

®

22

Electrical Installation (cont.)

REJECT RESET (REJ RESET)

The metal detector has two reject outputs, Direct

and Timed. Either or both can be set to reset

manually following a reject. The Reject Reset input

can be used to reset the rejects. Normally a

momentary close push-button switch is used. The

electrical specifications are as follows:

Voltage

5 VDC

Current

20 mA

Note the right terminal of this input is ground. Since

the metal detector is to be grounded only by the

input power supply ground, this terminal must not

be grounded by the switch.

HOST COMPUTER PORT (MPC ONLY)

The MPC version is capable of communicating with

one or more host computers (typically PCs) through

an RS232 or RS485 link. Please refer to the E-Z

Tec MPC Communication Manual MM-237 for

further information on the use of this port.

PRINTER PORT (MPC ONLY)

The MPC can drive a remote printer through an

RS232 link to print reject reports. This subject is

covered in detail in Appendix A, Printer Operation.

support structure. Metallic conduit fittings must

not be used to attach conduit to the metal detector

housing. Always use a plastic fitting for this

purpose. Conduit for "other" equipment must not

be run along the metal detector conveyor.

Although the conduit serves as shielding, possible

interference could occure.

NOTE: The power on/off switch located inside the

power supply enclosure is intended to be a service

convenience only. It is recommended that the unit

remain on continuously . This will provide best metal

detector performance and enhance the longevity

of the electronic components.

CAUTION:

Be careful to distinguish between the input voltage

selection switch and the power (off/on) switch. Both

are located in the lower left corner of the power

supply circuit board. THE VOLTAGE SELECTION

SWITCH IS RED, AND IS LABELED WITH THE

AVAILABLE VOLTAGES, 115V AND 230V. THE

POWER SUPPLY SWITCH IS BLACK, AND IS

LABELED WITH 0 AND 1, TO INDICA TE OFF AND

ON, RESPECTIVELY. INADVERTENT USE OF

THE IMPROPER SWITCH COULD LEAD TO

CIRCUIT DAMAGE AND/OR PERSONAL INJURY.

See Figure 14 for the location of these two switches.

CONDUIT

It is always wise to run wiring to and from the metal

detector through metal conduit. High voltage wiring

for the power supply and reject devices should not

be installed in the same conduit as low power sensor

wiring (such as wiring for the tachometer and reset

switch). Always keep all metal detector wiring

separate from cables carrying heavy or switched

loads. This is especially true with variable speed

motor control wiring. If these guidelines are followed,

interference from electrical noise will be greatly

decreased.

The use of metal conduit will provide necessary

shielding for the wires within; however, metal conduit

also represents a potential ground path. Metallic

conduit or airlines must be electrically insulated

from the associated components of the metal

detector, such as conveyor, stand or any other

INITIAL TEST (ANALOG UNIT)

a. After all electrical connections are com-

pleted and checked, turn the power switch,

SW4, on. The two center green LED’s in

the bar graph of the metal detector control

panel (Figure 15) should light.

b. Pass a large piece of metal through the

metal detector aperture. The LED bar graph

should respond with positive and negative

excursions of the red LED’s.

c. If the above does not occur, check all in-

stallation instructions, fuses, and input

power. If the fault cannot be located, contact Eriez Magnetics for assistance.

d. Close and latch the power supply enclo-

sure door.

®

23

Electrical Installation (cont.)

INITIAL TEST (MPC UNIT)

a. After all electrical connections are com-

pleted and checked, turn the power switch,

SW3, on. The two center green LED’s in

the bar graph of the MPC control panel (refer to Figure 18) should light. The LCD alphanumeric display should respond with

“ERIEZ MAGNETICS,” address, telephone,

and fax numbers. After approximately 10

seconds, the MONITOR display should appear on the LCD screen showing time, date,

SENSITIVITY ##, and PHASE ##.

b. Pass a large piece of metal through the

metal detector aperture. The LED bar graph

should respond with positive and negative

excursions of the LED’s. The LCD display

top line should register “REJECT” in the top

left corner and “REJECT” in the top right

corner.

c. If any of the above do not occur, check all

installation instructions, fuses and input

power. If the fault cannot be located, con-

tact Eriez Magnetics for assistance.

d. Close and latch the power supply enclo-

sure door.

®

24

Analog Controls and Displays

ANALOG CONTROL PANEL

Figure 15 shows the location of the various front

panel controls and indicators on the E-Z Tec

Version IV and V analog unit. These controls and

indicators are primarily concerned with the

detection performance of the unit.

LARGE RECTANGULAR

STATUS LED’S

The two large rectangular LED’s (Light Emitting

Diodes) in the center of the E-Z Tec control panel

indicate the metal detector status as follows:

DETECT (RED)

Used to indicate that metal has been detected. It

illuminates as metal is detected and extinguishes

soon after detection terminates.

FAULT (YELLOW)

Used to indicate that the coils are unbalanced or

that the reject confirmation failed.

MONITOR DISPLAY

This is an LED bar graph display . The center two

segments are non-extinguishing green LED’s.

They indicate power-on. Red LED excursions to

right and left indicate relative signal intensity. All

red LED’s are off when no signal is present.

SENSITIVITY CONTROL

The sensitivity control is a 100 position switch. A

setting of 99 provides maximum sensitivity. The

adjustment is variable in 01 increments down to

00, at which point the metal detector sensitivity

is very low, and the unit will detect only extremely

large pieces of metal.

PHASE CONTROL

This control is a 1000 position switch. It is used

to make the unit more or less responsive to

various types of materials passing through the

aperture. This control can be used to provide

maximum response to a particular type of metal

or (more often) minimum response to a particular

product. The latter procedure is termed “phasing

out the product effect.”

ANALOG OUTPUT CONTROLS

Figure 16 illustrates the output control panel of

the E-Z Tec Version IV and V analog metal

detector. This panel is located in the power supply

housing. The controls and switches on this panel

are primarily concerned with the rejection

performance of the unit.

TRAVEL TIME

Often contaminated product is automatically

eliminated from the product flow by a suitable

reject device. The reject signal from the metal

detector must be delayed until the contaminated

product travels to the reject device. This delay is

called Travel Time. It is adjustable using the

Travel T ime control knob and the jumper JP2. The

control knob has a range of 0 to 10 units, with

the value of each unit depending on the setting

of JP2. Note that this control is not present in the

MPC metal detector because the relevant function

is controlled by user input at the front panel (or

through the computer interface).

REJECT TIME

The time required for a reject device to perform

its function varies widely depending on the

particular application. The reject time of the timed

relay is controlled by the STANDARD reject

adjustment or the INDEXED reject time

adjustment depending on the setting of SW2-2.

Note that these controls are not present in the

MPC metal detector because the relevant

functions are controlled by user input at the front

panel (or through the computer interface).

STANDARD REJECT

Time The STANDARD REJECT TIME adjustment

determines the amount of time that the TIMED

RELA Y will remain in the detect state when SW22 is set for the standard reject setting. This interval

is adjustable from 0.12 seconds to 9.5 seconds.

INDEXED REJECT TIME

When the INDEXED reject is selected with SW22 the amount of time that the TIMED RELAY will

remain in the detect state is set with the INDEXED

reject adjust. This interval can be adjusted from

0.12 seconds to 9.0 seconds.

®

25

Analog Controls and Displays (cont.)

PROGRAMMING SWITCHES