Page 1

1/153 22-FGC 101 0239/2 Uen Rev J

EDA 2530 Commissioning Procedure fo

r

Cable and Wireless Access

EDA 2530 R4.21 GA EC2

Commissioning Instructions

Page 2

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

2 (200)

Copyright

© Ericsson Limited 2006 - 2010 – All Rights Reserved

Disclaimer

No part may be reproduced, disclosed or used except as authorised by contract or

other written permission. The copyright and the foregoing restriction on reproduction

and use extend to all media in which the information may be embodied.

The information in this work is the property of Ericsson Limited. Except as

specifically authorised in writing by Ericsson Limited, the receiver of this work shall

keep the information contained herein confidential and shall protect the same in

whole or in part from disclosure and dissemination to third parties. Disclosure and

disseminations to the receiver's employees shall only be made on a strict need to

know basis. The information in this work is subject to change without notice and

Ericsson Limited assumes no responsibility for factual inaccuracies or typographical

errors.

Ericsson Limited has used all reasonable endeavours to make sure that the

information contained in this work is accurate at the release date but reserves the

right to make changes, in good faith, to such information from time to time.

Trademarks

Ericsson and the Ericsson logo are trademarks of Telefonaktiebolaget LM Ericsson.

Acrobat(R) Reader copyright (C) 1987-1996 Adobe Systems Incorporated, - All

rights reserved. Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

All trademarks and registered trademarks mentioned in a document of this collection

are the property of their respective holders.

Page 3

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

3 (200)

Contents

1

Introduction............................................................................................ 7

1.1 Objective.................................................................................................. 7

1.2 Scope ...................................................................................................... 7

1.3 Safety Procedures ................................................................................... 7

1.4 Static Sensitive Device Handling Precautions......................................... 8

1.5 Optical Device Precautions ..................................................................... 8

1.6 Inspection/Cleaning Procedure For Optical Connectors.......................... 8

1.7 Commissioning Test Records.................................................................. 8

1.8 Required Information For Commissioning ............................................... 9

1.9 Documentation Change Request ............................................................ 9

2 EDA 2530 MSAN Equipment...............................................................11

2.1 General Equipment Description............................................................. 11

2.2 Equipment Overview ............................................................................. 11

2.3 Rack And Subrack Description.............................................................. 14

2.3.1 Rack ...................................................................................................... 14

2.3.2 EDA 2530 Subrack ................................................................................ 14

2.4 Subrack Composition ............................................................................ 15

2.4.1 Composition Rules ................................................................................ 15

2.4.2 EDA2530E Standard Configuration for CWA Parent and Stand Alone

Shelf ...................................................................................................... 16

2.4.3 Network Interface Units .........................................................................18

2.4.4 Subscriber Interface Units ..................................................................... 20

2.4.5 Subrack Connection Units ..................................................................... 23

2.4.6 Fan Tray (151-2984/02)......................................................................... 32

3 Resources ............................................................................................33

3.1 Documentation ...................................................................................... 33

3.2 Tools......................................................................................................33

3.3 Test Equipment ..................................................................................... 33

3.3.1 PC Connection Cables for Commissioning............................................ 34

3.4 Test Cables ........................................................................................... 35

3.4.1 RS232 Serial Cable Set (151-2502/01) ................................................. 36

3.5 Local Craft Terminal (LCT) Installation.................................................. 37

3.5.1 Removal of Old Issue of EDA Hub Software ......................................... 37

3.5.2 Installation of Local Operator Software on P.C...................................... 37

3.5.3 Install Application Software From CD ROM........................................... 38

3.5.4 LCT 07.02.05 – Known Issue with Java Version 1.6 ............................. 39

4 Commissioning Requirements........................................................... 41

4.1 Description Of Testing Activities............................................................ 41

4.2 Test Records ......................................................................................... 41

4.3 Preliminary Checks................................................................................ 41

4.3.1 Equipment Positioning........................................................................... 41

4.3.2 Card Equipping...................................................................................... 41

4.3.3 Cabling .................................................................................................. 42

4.3.4 Power Supply and Grounding Connections........................................... 43

4.4 Earthing And D.C. Supply Checks......................................................... 44

4.5 Power Supply Connection Unit Check................................................... 45

Page 4

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

4 (200)

4.5.1 Labelling.................................................................................................45

5 Initial Configuration .............................................................................47

5.1 IP Address Configuration Of PC Used As LCT ......................................47

5.2 Common Part Card CF Download..........................................................50

5.3 Subrack Equipping .................................................................................53

5.4 Logon to The EDA 2530 Via LCT...........................................................54

5.5 Reset The Backplane EPROM...............................................................55

5.6 Software Inventory Check ......................................................................57

6 Software Download/Upgrade ..............................................................61

7 Configure IP and Ethernet Management............................................67

7.1 Configure The Optical SFP Modules Gigabit Ethernet...........................69

7.2 Configure CP Ethernet Interfaces ..........................................................72

7.2.1 Configure CP Port 1 ...............................................................................72

7.2.2 Configure CP Port 2 ...............................................................................73

7.2.3 Configure CP Port 3 (If required)............................................................73

7.2.4 Configure CP Port 4 (If required)............................................................73

7.3 Configure EDA 2530 Tag Protocol ID/Bridging Parameters...................74

7.4 ADSL Card Configuration Files ..............................................................75

7.5 SHDSL Card Configuration Files............................................................75

7.6 Configure Static VLANs..........................................................................76

7.7 Adding Interfaces to the Static VLANs ...................................................79

7.7.1 Create S-VLANs for Additional ADSL Cards (If required) ......................81

7.7.2 Create S-VLANs for SHDSL Cards (If required) ....................................83

7.7.3 Create S-VLANs for POTS Cards (If required).......................................85

7.7.4 Complete VLAN Creation.......................................................................88

7.7.5 Create S-VLANs on the “Parent” to Subtend Child#2 (If required).........88

7.7.6 Create S-VLANs on the “Parent” to Subtend Child#3 (If required).........94

7.8 Configuring The IBM Sub-Interface........................................................96

7.9 Assign The IBM IP Address ...................................................................98

7.10 Configure The Default Gateway...........................................................100

7.11 xDSL Bridge Management - Configure xDSL Bridge ...........................101

7.12 xDSL Bridge Management - Configure PVC ........................................104

7.12.1 Download xDSL PVC Management File ..............................................104

7.12.2 Check PVC Management PPPoA Payload & MRU Settings................105

7.12.3 Configure PVC Management ...............................................................106

7.12.4 Configure Additional xDSL Cards.........................................................111

7.13 xDSL Bridge Management – Downstream Flow Assignment...............112

7.14 Configure ADSL Profiles ......................................................................114

7.15 Configure SHDSL Line Profiles............................................................116

7.16 Configure SHDSL Stack Profiles..........................................................118

7.17 Configure POTS Card(s) ......................................................................121

7.17.1 POTS Card Configuration Files............................................................121

7.17.2 Step 1: LCT 07.02.05 – Known Issue with Java Version 1.6 ...............121

7.17.3 Step 2: Add POTS Card(s) Interfaces to Static VLANs........................121

7.17.4 Step 3: Configure UK National Mapping ..............................................122

7.17.5 Step 4: Configure ITAM For Double Play .............................................124

7.17.6 Step 5: Configure RTP Profiles ............................................................126

7.17.7 Step 6: Check TOIP Profiles ................................................................130

7.17.8 Step 7: Configure POTS Cards ............................................................131

Page 5

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

5 (200)

7.17.9 Step 8: Build Voice Configuration........................................................ 135

8 EDA 2530 Equipment Test and Alarm Checks................................147

8.1 Equipment Test ................................................................................... 147

8.1.1 Optical Launch Power Test ................................................................. 147

8.1.2 Unit Status Check................................................................................ 147

8.2 Alarm Checks ......................................................................................148

8.2.1 Common Part Alarm Check ................................................................. 148

8.2.2 Power Supply Alarm Check ................................................................. 148

8.2.3 FAN Unit Extraction/Insertion .............................................................. 149

8.2.4 64 x ADSL2+ Unit Extraction/Insertion ................................................ 150

8.2.5 32 x SHDSL Unit Extraction/Insertion.................................................. 150

8.2.6 64 x POTS/VoIP Unit Extraction/Insertion ........................................... 151

8.3 Set Equipment Time and Date ............................................................ 152

9 Test ADSL2+, POTS, SHDSL & Connection Units.......................... 153

9.1 Configure/Activate/Test 64 Port Adsl2+ Units ..................................... 153

9.1.1 Check 64 x ADSL Cards for ADSL2 + Configuration........................... 153

9.1.2 Configure 64 x ADSL Card for ADSL2 + Configuration Profile............ 155

9.1.3 Test 64 x ADSL2+ Card....................................................................... 161

9.2 Configure/Activate/Test 32 Port SHDSL Units..................................... 163

9.2.1 Configure 32 x SHDSL Card Profiles .................................................. 163

9.2.2 Test 32 x SHDSL Cards ......................................................................168

9.3 Test 64 x POTS/VoIP Cards................................................................ 170

9.3.1 Test 64 x POTS/VoIP Cards................................................................ 170

9.4 Test iTAM Splitter Connection Unit...................................................... 172

9.4.1 Check Test Relay Switching Correctly................................................. 172

9.4.2 Configure ITAM Splitter Unit from LCT ................................................ 174

9.4.3 Continuity Testing LLUT (Line) to LLUL (POTS) Blocks...................... 177

9.5 End Of Stand Alone Configuration/Testing.......................................... 177

10 Appendix - Common Part Unit DIP Setting .....................................179

11 Test Records...................................................................................... 181

11.1 Test Record Procedure ....................................................................... 181

11.2 Certification Of Tests ........................................................................... 184

12 Glossary Of Terms ............................................................................ 187

13 References .........................................................................................191

14 Change Information........................................................................... 193

Page 6

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

6 (200)

This page intentionally blank to facilitate double sided printing.

Page 7

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

7 (200)

1 Introduction

1.1 Objective

The objective of this document is to detail the procedures for commissioning of the

EDA 2530 when used in the Cable and Wireless Access network.

1.2 Scope

This document will be used to commission the EDA 2530 DLE Node on site.

The DLE IP DSLAM EDA 2530 (EDA 0x0x) shelf can be equipped with up to ten 64

x ADSL2+ Cards and ten 64 x POTS/VoIP Cards and up to four 32 x SHDSL Cards

as required. The 64 x POTS/VoIP Card will be configured for H.248 protocol. The

ADSL2+, POTS/VoIP Cards and 32 x SHDSL Cards VLANs will be routed to the

GigaBit Ethernet Port of the EDA 2530 CP-IP Card. The Common Part “Backhaul”

GigaBit Ethernet Port will be connected to the IP network.

The tests in the document are to prove the functionality of the EDA 2530. These

tests will include the set-up and connection of the Local Controller, the loading of

site specific Database and the setting up of circuits through the EDA 2530.

Engineers MUST familiarise themselves with the procedure and be aware of and

observe all safety precautions BEFORE starting the commissioning procedure.

1.3 Safety Procedures

All procedures should be carried out in accordance with the Safety Rules and Safety

Notices as stated in the product handbook.

Page 8

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

8 (200)

1.4 Static Sensitive Device Handling Precautions

Equipment referred to in this document contain static sensitive devices and

therefore an ESP wrist strap MUST be worn and connected to an ESP bonding point

at all times when handling slide-in-units and socketed devices (PROMS).

1.5 Optical Device Precautions

The EDA Subrack may be equipped with Optical Common Part Units containing

laser transmitters. Never look into a laser transmitter port or into a fibre optic cable.

1.6 Inspection/Cleaning Procedure For Optical Connectors

All optical fibre connectors will require inspection for damage and cleanliness.

1.7 Commissioning Test Records

The commissioning test records at the end of this document must be completed as

the commissioning progresses. A complete set of Test Records must be completed

for each EDA 2530 being commissioned. This should be retained on site for the

customer’s use if requested. Any items outstanding after the acceptance testing is

complete are to be listed in the Outstanding Items Summary at the end of this

document.

When all acceptance testing has been completed successfully, both the Ericsson

and Customer’s representatives must complete the Customer Acceptance Form at

the end of this document. If the Customer’s representative is not present on site

enter N/A (Not Available) for the Customer representative.

Page 9

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

9 (200)

1.8 Required Information For Commissioning

The Customer Network Planning Authority shall be responsible for providing the

following information before commissioning can commence.

a. Unit type and location of cards in the subrack.

b. IP over Ethernet Addresses of each EDA 2530 (DLE Node Address).

c. Site/slot specific IP addresses for POTS cards.

d. IP address of the NTP Server.

e. If available, fibre loss figures for the sub-network under test.

f. The SID document, which specifies Configuration information i.e. Site

location, Floor Plan, Rack Layout, Fuse allocations, MDF block locations for

the EDA 2530 Subrack equipment, and Cable Running Out Lists.

g. Alarm Profile list for each unit type that is to be commissioned in the

subrack.

1.9 Documentation Change Request

In order to allow changes to this document to be implemented quickly, site

engineers are requested to use the Document Change Request Form at the end of

this document. The form should be sent by post, fax or e-mail to the author of this

document for the change request to be considered.

End of section

Page 10

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

10 (200)

This page is left intentionally blank to facilitate double sided printing.

Page 11

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

11 (200)

2 EDA 2530 MSAN Equipment

This section provides an overview of the EDA Access Hub equipment. Read this

section if you are not familiar with the EDA 2530.

2.1 General Equipment Description

Within the Access Network, the EDA 2530 fulfils the function of connecting

subscribers through xDSL technology, to provide them with both PSTN telephony

and IP data access.

The data traffic is then forwarded towards the IP Network through IP links. It is

located between the switch/network-side units and the subscriber units.

2.2 Equipment Overview

The EDA 2530 system can be used in four different deployment scenarios:

• Standalone

Cascade

Star

Ring

Standalone Option

Most of the equipment will be commissioned in the “Standalone” scenario, this

procedure only deals with this type of scenario. In this architecture, the equipment

collects user traffic and sends it to the core network via an Ethernet-based uplink.

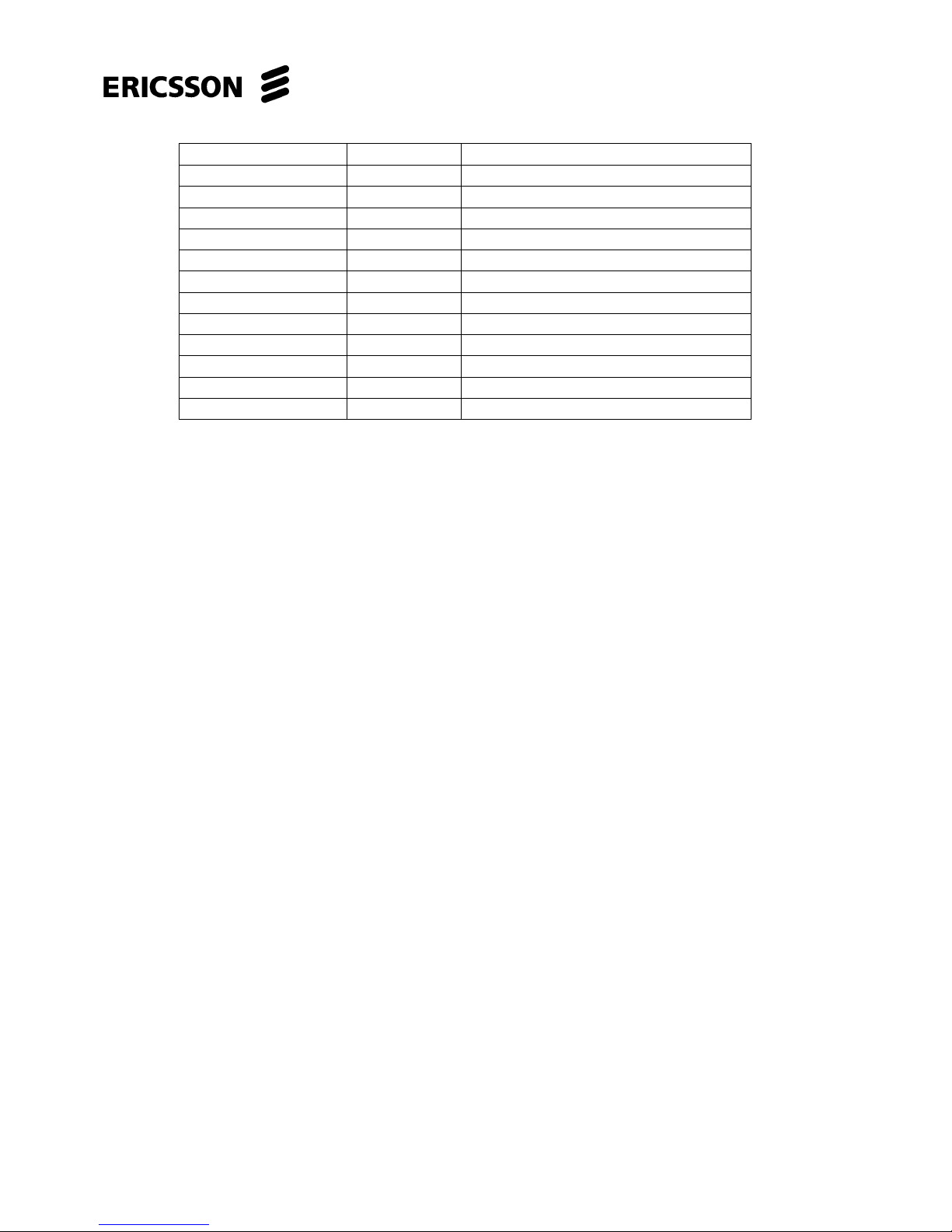

Figure 2.1 – EDA 2530 Subrack Standalone Option

Page 12

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

12 (200)

Star Option

The “Star” scenario is not covered by this procedure, but is mentioned here because

the EDA2530s will be later used to subtend existing C&W EDA2510 equipment,

following the “Migration” (Cut-over) process.

In this architecture, the main equipment collects local user traffic and traffic coming

from the subtended ones. The number of equipment connected towards the main

one depends on the available bandwidth and on the number of interfaces on the

main equipment (available for the subtending).

Figure 2.2 – EDA 2530 Subrack “Star” Option

Note: In the star scenario up to three “Child” EDA2510 or EDA2530 nodes can be

subtended from the “Parent” EDA2530.

Page 13

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

13 (200)

Overview of the most important performance features of equipment:-

Interfaces to IP network

• 4 x 10/100/1000 Mb/s Ethernet Elect/Opt SFP module ports

Subscriber interfaces, (up to 640 xDSL interfaces)

:

• 32 x SHDSL interface (Only available from S/W Release 4.21)

• 32 x VDSL2

• 64 x ADSL2+ interface

• 64 x POTS/VoIP interface

Management through Local Terminal (LCT) via

:

• TCP/IP (802.3)

CP Eth port (Out-Band Management)

Used for on-site commissioning

Management through NMS via “Backhaul” fibre

:

• TCP/IP (802.3)

• A dedicated VLAN (In-Band Management)

Equipment monitoring and management

:

• Network Management system

• Local Terminal

Signalling

:

• In-band via IP

• Out-of-band via LAN

Alarm/Fault management by

:

• Network Management system

• Local Terminal

Doubled power supply to increase reliability:

Independent DC/DC converter on-board on every unit:

"Hot-pluggable" cooling fans:

Page 14

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

14 (200)

2.3 Rack And Subrack Description

2.3.1 Rack

The EDA 2530 equipment is installed in an ETSI type rack with the system alarm

rack lamps being located on the rack top. (If fitted).

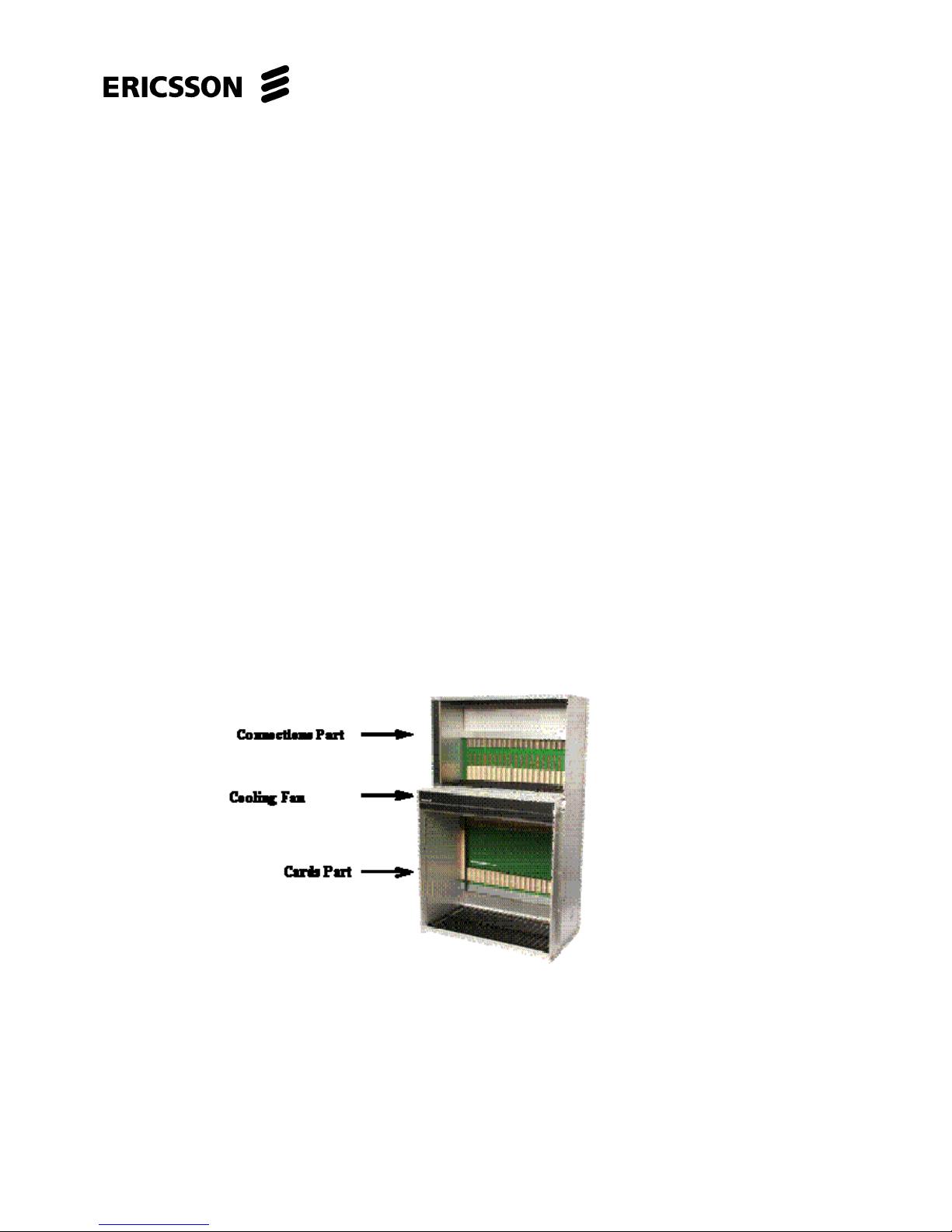

2.3.2 EDA 2530 Subrack

The EDA 2530 subrack comprises 22 slots for the service units and 22 slots for the

interface modules and is divided into three parts:

a. A bottom part (Electronic Part) composed of 22 slots housing the electronic

units – Network Interface Common Parts units and Subscriber Interface

channel units.

b. The top part (Connection Part) comprising the 22 slots for the interface

modules – Power and Alarm Interface (containing the two Power connectors,

the alarm connections and synchronisation connections), and the interface

modules corresponding to the Subscriber Interface units in the Electronic

Part.

c. Between the subrack top and bottom parts is the fan unit (FAN) (151-

2984/02) optimising the air forced circulation within the subrack.

Figure 2.3 – EDA 2530 Subrack

d. The type of subrack deployed for the EDA 2530 is the S20 Chassis, SE

code CA10EM, ME code 133-1555/03.

Page 15

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

15 (200)

2.4 Subrack Composition

2.4.1 Composition Rules

2.4.1.1 Units Composition:-

• Common Part (CP) unit is fitted in position 1 only (slot 22 will not be used) in the

lower part of the subrack (the electronic part).

• 64xADSL2+ and 64xPOTS/VoIP electronic units can be fitted in positions 2 to 21

in the lower part of the subrack.

• 32 x SHDSL electronic units can be fitted in positions 20 and 21 and then 18 and

19 in the lower part of the subrack

• Generally when one electronic unit is inserted in the subrack, one “Connection”

Unit is required in the upper part of the subrack directly above it, with the

exception of the Common Part unit. The type of connection unit is identified in

Section 2.4.5 – Subrack Connection Units.

• Electronic units configured as a protection unit do not require a Connection Unit.

• The Power Supply Connection unit is located in the upper shelf in slot 22.

2.4.1.2 Units Composition with 1+1 Protection (Not used):-

Common Part units can be protected with 1+1 protection. This protection type

requires one worker unit and one protection unit.

This protection scheme is not revertive automatically. When 1+1 Protection is

utilised it is mandatory to insert the protected unit in position 1 and the protection

unit in position 22.

Page 16

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

16 (200)

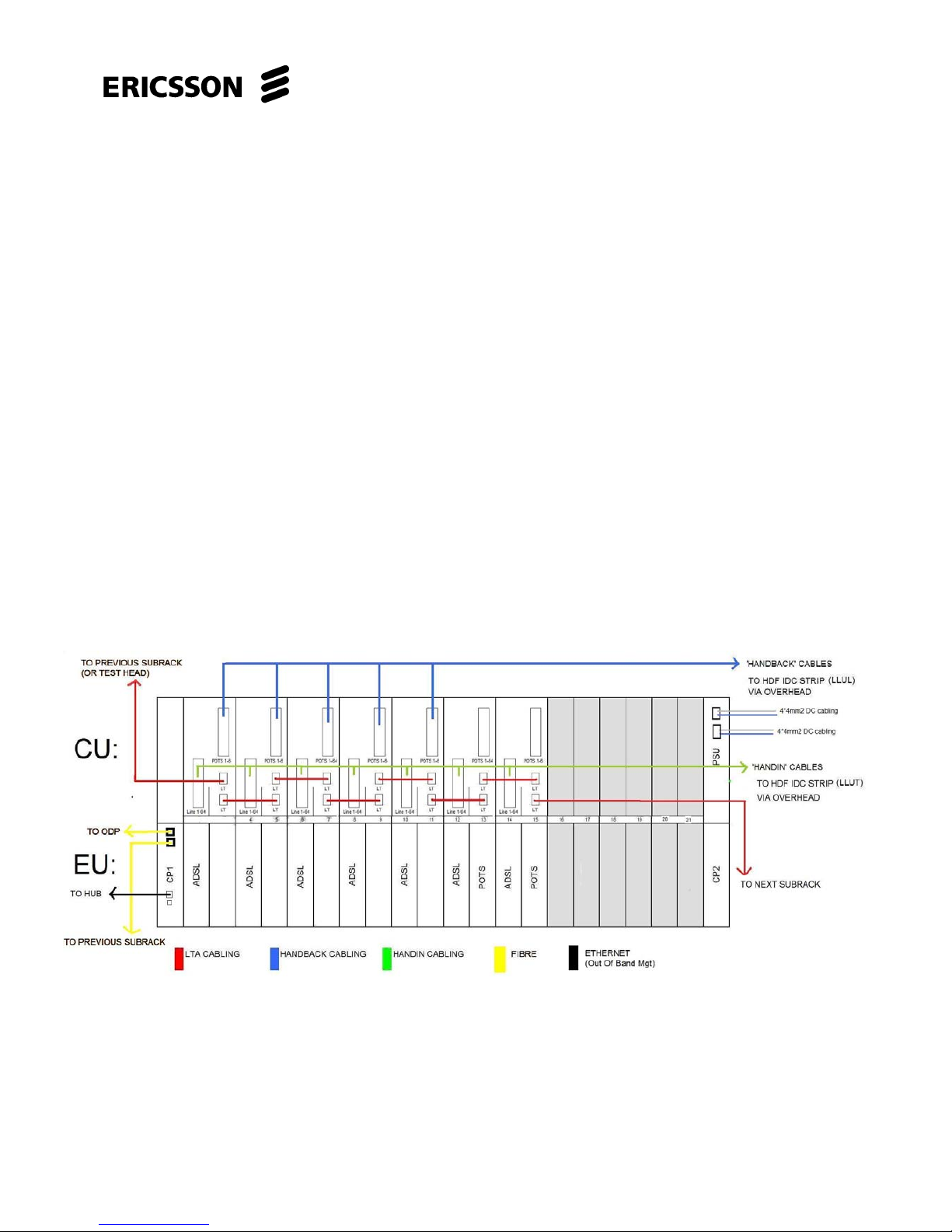

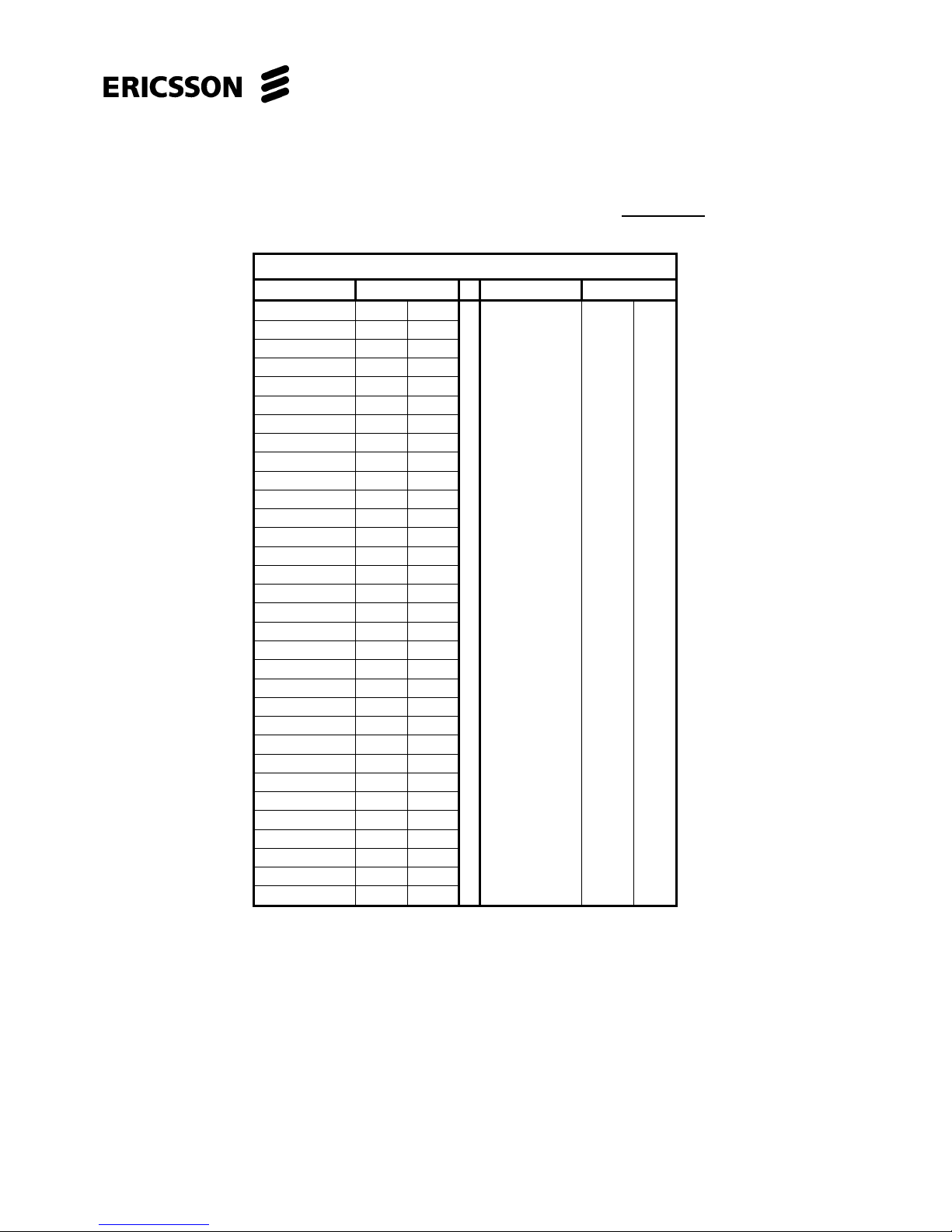

2.4.2 EDA2530E Standard Configuration for CWA Parent and Stand Alone

Shelf

This sub-section describes the standard configuration for CWA EDA2530 DLE

(EDAxx01) Parent and Stand Alone shelves only. The site engineer must refer to

the site specific configuration information for the site being commissioned.

This standard configuration allows for additional units to be provided at a later date

with minimal changes to the existing configuration.

The 64 x ADSL2+ units are inserted in even numbered slots from slot 2 up to slot 18

in increasing order towards the right.

The 64 x POTS/VoIP units are inserted in odd numbered slots from slot 3 up to slot

19 in increasing order towards the right.

Note that each 64 x ADSL and 64 x POTS unit has it’s relevant 64 x COMBI

Interface + I/O POTS + TAM Connection Unit (02HAT 00282 AAQ) fitted above the

pair of units. (A protection unit does not require an associated Connection Unit.)

Each 32 x SHDSL unit has one 32 x TAM Connection Unit (02HAT00136AAR) fitted

directly above the unit.

The 32 x SHDSL units are inserted in slots 20 and 21 and then in slots 18 and 19 if

more than two SHDSL units are required.

Figure 2.4 – EDA 2530 Example Configuration for CWA Shelf

Page 17

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

17 (200)

At present, the standard configuration for 64 x ADSL and 64 x POTS units are not

provided with protection units. This is as specified by the Customer.

From the COMBI cards, 64-pair cables run via Overhead Runways to 100-pair IDC

strips located on the Handover Distribution Frame (HDF).

From the 32 x TAM Connection Unit, 32-pair cables run via Overhead Runways to

100-pair IDC strips located on the Handover Distribution Frame (HDF).

From the HDF blocks, 100-pr cable runs to the BT MDF. HDF blocks and HDF-to-

MDF cabling are provided by BT

HANDIN cabling (from HDF blocks designated LLUT or LLUX) allows connection to

C&W subscribers via the BT ‘last mile’ copper connection. Broadband traffic is

aggregated in the EDA 2530 & routed to the C&W Network via Backhaul fibre from

the Common Part board.

HANDBACK cabling (from HDF blocks designated LLUL) routes POTS telephony

traffic back to the BT Network.

For a pair with a POTS/VoIP card, telephony traffic is routed to the C&W

Network via Backhaul and thus HANDBACK cabling is NOT required.

Where a new EDA2530 Subrack is fitted on a site with an existing EDA2510

Subrack, the new Subrack will become the PARENT & the EDA2510 will become

the CHILD: the existing Backhaul fibre will be re-directed to the EDA2530 & a new

EDA-to-EDA fibre link provided. The EDA2510 will then sub-tend from the

EDA2530.

Page 18

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

18 (200)

2.4.3 Network Interface Units

2.4.3.1 Common Part Unit (02HAT 00103 ACY)

IP 44G + Sync Common Part Unit for EDA 2530.

The Common Parts units contain both the electronics controlling the EDA 2530

(Controller, Matrix, Alarm Unit) and Network Interfaces. The Worker unit is located

in slot 1 and the Protection unit in slot 22 (not used).

The optic fibre cables (Tx and Rx) from the network are terminated on the

Worker network card SFP sockets. If MSP protection is configured optic

fibre/coaxial cables (Tx and Rx) from the network are also terminated on the

Protection network card.

If there is a failure on the Worker network interface then control is automatically

switched to the Protection network interface. If there is no MSP protection the optic

fibre cables (Tx and Rx) will need to be manually disconnected from the Worker unit

(slot 1) and re-connected to the Protection unit (slot 22). When replacing the optical

fibres to the network card, the service will be lost but the Protection card will

maintain the cross-connections and alarm functions.

For line protection, a pair of fibres can be terminated on the Worker card (slot 1) and

another pair on the Protection card (slot 22).

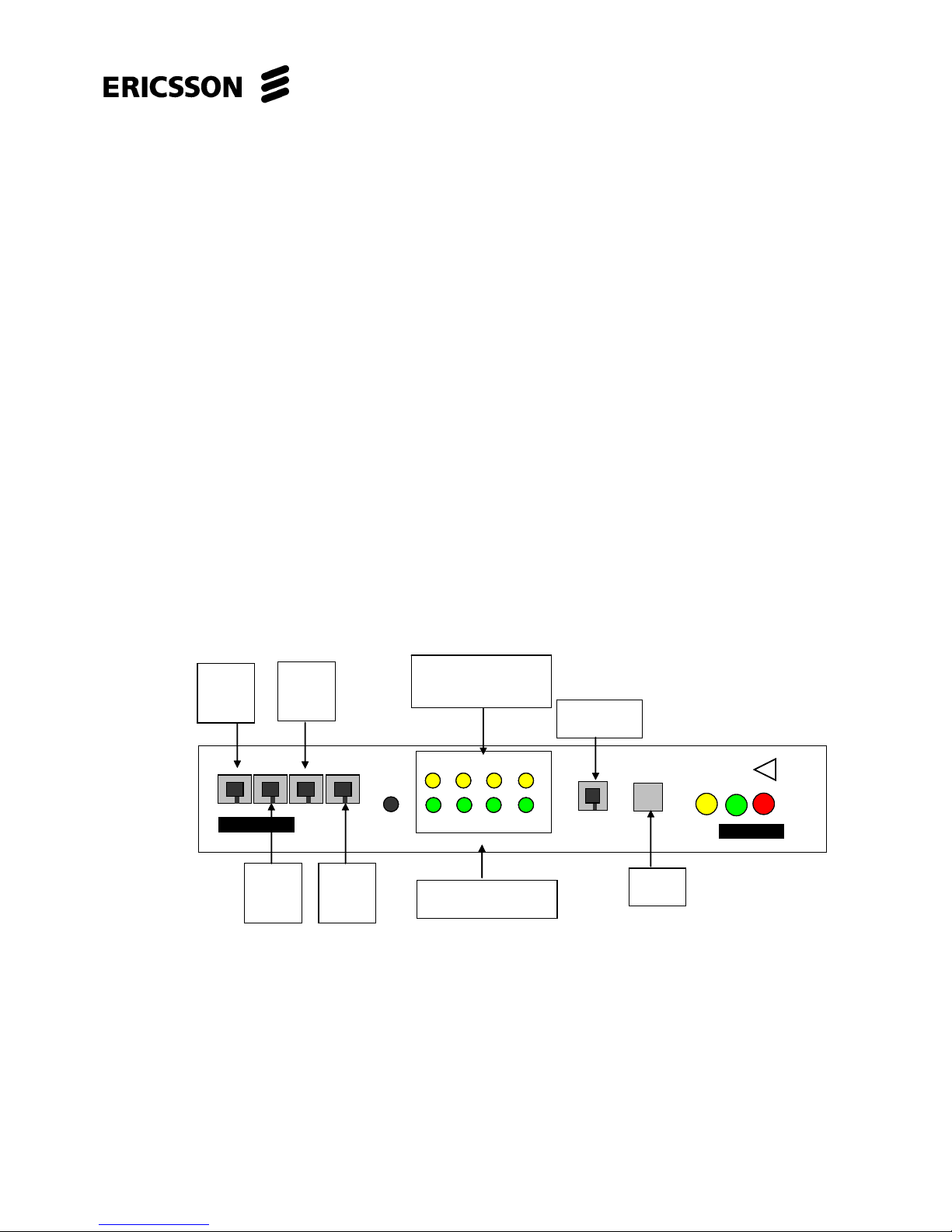

Figure 2.5 – IP 44G + Sync Common Part Unit 02HAT 00103 ACY

T

PWR

RS232

ETH

02HAT 00103 ACY

CP 2530

ETHERNET

RJ45

RS232

RJ12

RESET

PORT

1/1/2/3

Gig Eth

1

2

3

4

LIN

K

ACTIVIT

Y

YELLOW LEDS =

Activity Status of

Ethernet Links

GREEN LEDS =

Ethernet Link Status

PORT

1/1/2/1

Gig Eth

PORT

1/1/2/4

Gig Eth

PORT

1/1/2/2

Gig Eth

T

PWR

RS232

ETH

02HAT 00103 ACY

CP 2530

ETHERNET

RJ45

RS232

RJ12

RESET

PORT

1/1/2/3

Gig Eth

1

2

3

4

LIN

K

ACTIVIT

Y

1

2

3

4

LIN

K

ACTIVIT

Y

YELLOW LEDS =

Activity Status of

Ethernet Links

GREEN LEDS =

Ethernet Link Status

PORT

1/1/2/1

Gig Eth

PORT

1/1/2/4

Gig Eth

PORT

1/1/2/2

Gig Eth

Page 19

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

19 (200)

The front of the card contains the following Interfaces:-

Network Ports - Gigabit Ethernet

There are four Network Gigabit Ethernet sockets, Port 1/1/2/1, Port 1/1/2/2, Port

1/1/2/3, and Port 1/1/2/4, using pluggable SFP modules.

The SFP module types are:-

• 1000Base-SX 850nm Interface (SU57AD), LC connector.

• 1000Base-LX 1310nm Interface (SU57AE), LC connector.

• 1000Base-EX 1310nm Interface (SU57AJ), LC connector.

• 1000Base-ZX 1550nm Interface (SU57AF), LC connector.

Ethernet Port 10Base-T

This RJ45 socket (5102209-0461) is used to connect to the LAN network, for OutBand Management (OBM) and for LCT use during commissioning.

Cabling Note: The Ethernet port can use standard Cat 5 screened cable (Common

Code = 1301042-0019) with standard RJ45 connector (5102169).

Serial Interface Port

This RS-232 RJ12 serial port is not normally used by the on-site engineer for

commissioning, but is utilised in Section 5.2 to download the equipment software to

the CP card’s Compact Flash.

LEDs

The card front is equipped with 3 LED’s whose functions are as follows.

T (yellow) On unit normal activity

Off unit has a protecting role

Blinking configuration is being changed

PWR (green) On unit is powered up

ALARM (red) Off normal activity

On internal alarm.

Blinking external alarm

DIP SWITCH SETTING:-

(Refer to the Section 10 Appendix)

On the Common Part Unit (02HAT00103ACY) check that DIP Switch SW600

(located bottom left near front panel) is set to the default settings, as shown below:-

Pin 1 = OFF

Pin 2 = OFF

Pin 3 = OFF

Pin 4 = OFF

Pin 5 = ON

Page 20

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

20 (200)

2.4.4 Subscriber Interface Units

The EDA 2530 Subrack uses the following Subscriber interface units:-

a. The 64 x ADSL2+ cards can be configured in even slots from 2 to 20.

b. The 64 x POTS/VoIP cards can be configured in odd slots from 3 to 21.

c. The 32 x SHDSL cards can be configured in slots 18, 19, 20 and 21.

2.4.4.1 64 x ADSL2+ Unit (02HAT00162AAD)

EDA 2530 subrack:- The 64 x ADSL2+ card should be equipped in the Even Slots

Only, from slots 2 to slot 20 with up to a maximum of ten cards, providing a

maximum of 640 lines. Each 64 x ADSL2+ card requires its relevant Connection

Unit to be fitted above the 64 x ADSL2+ card. This unit can provide ADSL and

ADSL2+ services.

Note: When used as part of a 64 x ADSL2+ and POTS/VoIP Unit, the Connection

Unit required is the 64 x Combi I/F + In/Out POTS + TAM ETSI Connection Unit

(02HAT 00252 AAU).

Figure 2.6 – 64 x ADSL2+ Unit

The functions of the LEDs are as follows.

T (yellow) On unit normal activity

Off unit has a protecting role

Blinking configuration is being changed.

PWR (green) On unit is powered up

ALARM (red) Off normal activity

On internal alarm.

Blinking external alarm

T

PWR

RS232

02HAT 00162 AAD

ADSL2+ x 64

T

PWR

RS232

02HAT 00162 AAD

ADSL2+ x 64

T

PWR

RS232

02HAT 00162 AAD

ADSL2+ x 64

T

PWR

RS232

02HAT 00162 AAD

ADSL2+ x 64

Page 21

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

21 (200)

2.4.4.2 64 x POTS/VoIP Unit (02HAT00198AAM)

EDA 2530 subrack:- The 64 x POTS/VoIP Unit should be fitted in the Odd Slots

Only, from slots 3 to slot 21 with up to a maximum of ten cards, providing a

maximum of 640 lines. Each 64 x POTS/VoIP card requires its relevant Connection

Unit to be fitted above the 64 x POTS/VoIP card.

Note: When the combination of 64 x ADSL2+ and 64 x POTS/VoIP Units are

used, the Connection Unit required is the 64 x COMBI I/F + IN/Out POTS + TAM

ETSI Connection Unit (02HAT00282AAQ).

Figure 2.7 – 64 x POTS/VoIP Unit

The card front is equipped with 3 LED’s whose functions are as follows.

T (yellow) On unit normal activity

Off unit has a protecting role

Blinking configuration is being changed.

PWR (green) On unit is powered up

ALARM (red) Off normal activity

On internal alarm.

Blinking external alarm

T

PWR

RS232

02HAT 00198 AAM

POTS/VoIPx 64

T

PWR

RS232

02HAT 00198 AAM

POTS/VoIPx 64

Page 22

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

22 (200)

2.4.4.3 32 x SHDSL Unit (02HAT00274AAE)

The 32 x SHDSL card can be equipped in slots 20 and slot 21 with up to a maximum

of two cards per subrack, providing a maximum of 64 lines. Each 32 x SHDSL card

requires its relevant Connection Unit (02HAT00136AAR) to be fitted above the 32 x

SHDSL card.

Figure 2.8 - 32 x SHDSL Unit Front Panel

The functions of the LEDs are as follows.

T (yellow) On unit normal activity

Off unit has a protecting role

Blinking configuration is being changed.

PWR (green) On unit is powered up

ALARM (red) Off normal activity

On internal alarm.

Blinking external alarm

T

PWR

RS232

02HAT 00274 AAE

SHDSL x 32

T

PWR

RS232

02HAT 00274 AAE

SHDSL x 32

Page 23

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

23 (200)

2.4.5 Subrack Connection Units

The EDA 2530 Subrack uses the following Connection Units:-

• Power Supply /Alarms / Sync Connection Unit - 151-2975/53

• 64 x COMBI Interface + I/O POTS + TAM ETSI Connection Unit -

02HAT00252AAU (Double unit width)

• 32 x TAM Connection Unit (02HAT 00136 AAR) - for SHDSL connections.

2.4.5.1 Power Supply Connection and Alarm Unit (151-2975/53)

Required for S20 Chassis 133-1555/03

This unit supplies power to all the devices in the subrack and is required for

Grounding Contacts and Synchronisation.

This unit is inserted in slot 22 in the upper shelf of the subrack.

Figure 2.9 - Power Supply Connection and Alarm Unit (151-2975/53)

Table 2.1 – Power Connector Pinout for Power Supply Connection & Alarm Unit (151-2975/53)

Slot 22 (151-2975/53) VB1 Slot 22 (151-2975/53) VB2

Pin Signal Function Pin Signal Function

1 - B1 Battery 1 negative voltage 1 - B2 Battery 2 negative voltage

2 +B1 Battery 1 positive voltage 2 +B2 Battery 2 positive voltage

3 Not used 3 Not used

4 +B1 Battery 1 positive voltage 4 +B2 Battery 2 positive voltage

5 - B1 Battery 1 negative voltage 5 - B2 Battery 2 negative voltage

5-Way D Type

Connector for

DC Power

Supply 1

25-Way D

Type Male

Connector for

ALARMS

5-Way D Type

Connector for

DC Power

Supply 2

1.0/2.3 Female

Coaxial

Connectors

S

y

nc 1 & 2 IN

ALARMS

151-2975/53

VB1

VB2

VB1

VB2

1

2

PWR

PWR

ALARMS

151-2975/53

VB1

VB2

VB1

VB2

1

2

PWR

PWR

Page 24

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

24 (200)

Description Pin Signal

INT_AC 1 Summarized INTERNAL alarm

------- 2, 4 Not used

PIO1 5 Incoming ground contact nr. 1

PIO3 6 Incoming ground contact nr. 3

PIO5 7 Incoming ground contact nr. 5

PIO4 8 Incoming ground contact nr. 4

PIO8 9 Incoming ground contact nr. 8

PIO6 10 Incoming ground contact nr. 6

PIO7 11 Incoming ground contact nr. 7

PIO2 12 Incoming ground contact nr. 2

GND 13, 14 Ground

------ 15, 25 Not used

Table 2.2 – Alarm Connector Pinout for Power Supply Connection & Alarm Unit (151-2975/53)

Page 25

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

25 (200)

2.4.5.2 64 x COMBI I/F + I/O POTS + TAM ETSI Connection Unit (02HAT00282AAQ)

Front Panel:

Figure 2.10 – 64 x COMBI Interface + I/O POTS + TAM ETSI Connection Unit

(02HAT00282AAQ)

128-Pin DIN Connector

From UNIT Front

02HAT00282AAQ

64 x COMBI I/F + I/O

POTS + TAM ETSI

LINE

1 - 64

POTS

1 - 64

LINE

TEST

ACCESS

32d

1d

1a

32a

TOP

If the POTS connectors are cabled to the existing POTS

exchange then the 60 x POTS VoIP unit MUST NOT

be

fitted.

128-Pin DIN Connector

From UNIT Front

02HAT00282AAQ

64 x COMBI I/F + I/O

POTS + TAM ETSI

LINE

1 - 64

POTS

1 - 64

LINE

TEST

ACCESS

32d

1d

1a

32a

TOP

1d

1a

32a

TOP

If the POTS connectors are cabled to the existing POTS

exchange then the 60 x POTS VoIP unit MUST NOT

be

fitted.

Page 26

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

26 (200)

Note: This unit occupies two slots in the upper shelf and is fitted above the 64 x

ADSL2+ unit (In Even Slot 2) and the optional associated 64 x POTS/VoIP unit (In

Odd Slot 3). This unit will be fitted in slots 2 and 3, 4 and 5, 6 and 7, 8 and 9, 10

and 11, 12 and 13, 14 and 15, 16 and 17, 18 and 19 as required. IMPORTANT: If

the POTS/VoIP unit is fitted then the POTS connectors MUST NOT

be used

COMBO Card DIN Connector Pin Designations

SIGNAL PIN SIGNAL PIN

Line 1 a/b 1a 2a Line 33 a/b 1c 2c

Line 2 a/b 3a 4a Line 34 a/b 3c 4c

Line 3 a/b 5a 6a Line 35 a/b 5c 6c

Line 4 a/b 7a 8a Line 36 a/b 7c 8c

Line 5 a/b 9a 10a Line 37 a/b 9c 10c

Line 6 a/b 11a 12a Line 38 a/b 11c 12c

Line 7 a/b 13a 14a Line 39 a/b 13c 14c

Line 8 a/b 15a 16a Line 40 a/b 15c 16c

Line 9 a/b 17a 18a Line 41 a/b 17c 18c

Line 10 a/b 19a 20a Line 42 a/b 19c 20c

Line 11 a/b 21a 22a Line 43 a/b 21c 22c

Line 12 a/b 23a 24a Line 44 a/b 23c 24c

Line 13 a/b 25a 26a Line 45 a/b 25c 26c

Line 14 a/b 27a 28a Line 46 a/b 27c 28c

Line 15 a/b 29a 30a Line 47 a/b 29c 30c

Line 16 a/b 31a 32a Line 48 a/b 31c 32c

Line 17 a/b 1b 2b Line 49 a/b 1d 2d

Line 18 a/b 3b 4b Line 50 a/b 3d 4d

Line 19 a/b 5b 6b Line 51 a/b 5d 6d

Line 20 a/b 7b 8b Line 52 a/b 7d 8d

Line 21 a/b 9b 10b Line 53 a/b 9d 10d

Line 22 a/b 11b 12b Line 54 a/b 11d 12d

Line 23 a/b 13b 14b Line 55 a/b 13d 14d

Line 24 a/b 15b 16b Line 56 a/b 15d 16d

Line 25 a/b 17b 18b Line 57 a/b 17d 18d

Line 26 a/b 19b 20b Line 58 a/b 19d 20d

Line 27 a/b 21b 22b Line 59 a/b 21d 22d

Line 28 a/b 23b 24b Line 60 a/b 23d 24d

Line 29 a/b 25b 26b Line 61 a/b 25d 26d

Line 30 a/b 27b 28b Line 62 a/b 27d 28d

Line 31 a/b 29b 30b Line 63 a/b 29d 30d

Line 32 a/b 31b 32b Line 64 a/b 31d 32d

Table 2.3 – DIN Connector Pinout for 64 x COMBI Interface + I/O POTS + TAM

ETSI Connection Unit (02HAT00282AAQ)

Page 27

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

27 (200)

Figure 2.11 - 64 Pair COMBO Card to HDF Cable Assembly (RPM251026/10m)

Page 28

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

28 (200)

Figure 2.12 - 64 Pair COMBO to HDF Cable Wiring Diagram (RPM251026/10m)

Page 29

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

29 (200)

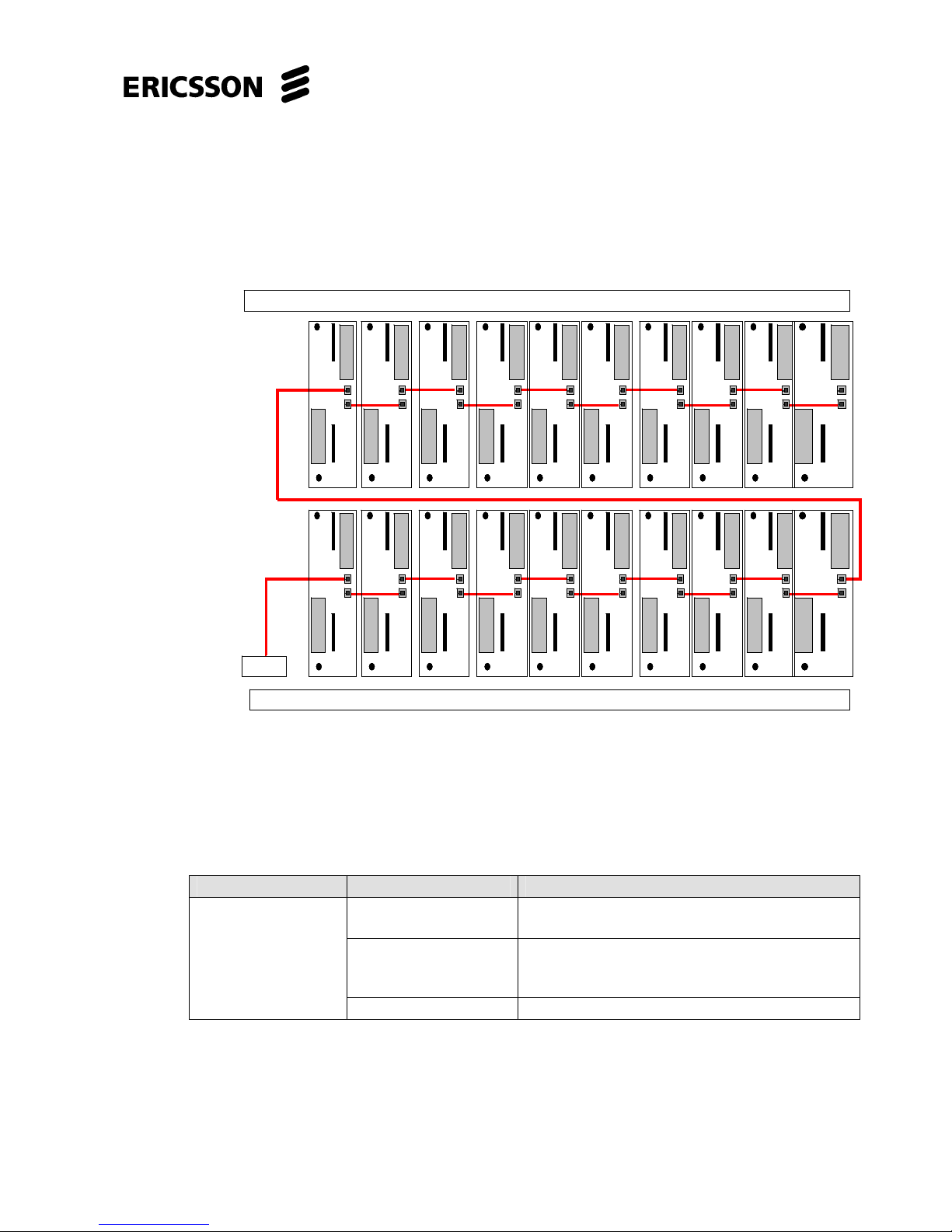

Interconnection Cables for ITAM Connection Unit (02HAT00282AAQ)

Connect the NX Test cable to upper Line Test Access socket on slot 2 and 3 unit.

Connect RJ45 to RJ45 cable from lower Line Test Access socket on slot 2 and 3

unit to lower Line Test Access socket on slot 4 and 5 unit. Connect upper LTA

socket on slot 4 and 5 unit to upper LTA socket on slot 6 and 7 unit and repeat to

daisy chain each unit into the Test Bus.

Figure 2.13 – ITAM Connection Unit (02HAT00282AAQ) Interconnection

On a two EDA shelf site, connect RJ45 to RJ45 cable from the upper LTA socket on slot 20

and 21 unit on the fully equipped Lower shelf, to the upper LTA socket on slot 2 and 3 unit

on the Upper shelf. On the Upper shelf, connect RJ45 to RJ45 cable between the Line Test

Access sockets to daisy chain each unit into the Test Bus.

DESCRIPTION CABLE CODES DESCRIPTION

1HAU62575AAV 50mm LT Bridging cable between adjacent

COMBO cards (terminated with RJ45 plugs)

06ZZ7050 10m STP CAT5E LT cable to connect to

previous subrack (requires terminating with

RJ45 plugs)

LT Cables (ITAM)

2 x 46CJ9002 RJ45 Plugs for LT cable

NxTest

Upper 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Lower 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

NxTest

Upper 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Lower 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Page 30

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

30 (200)

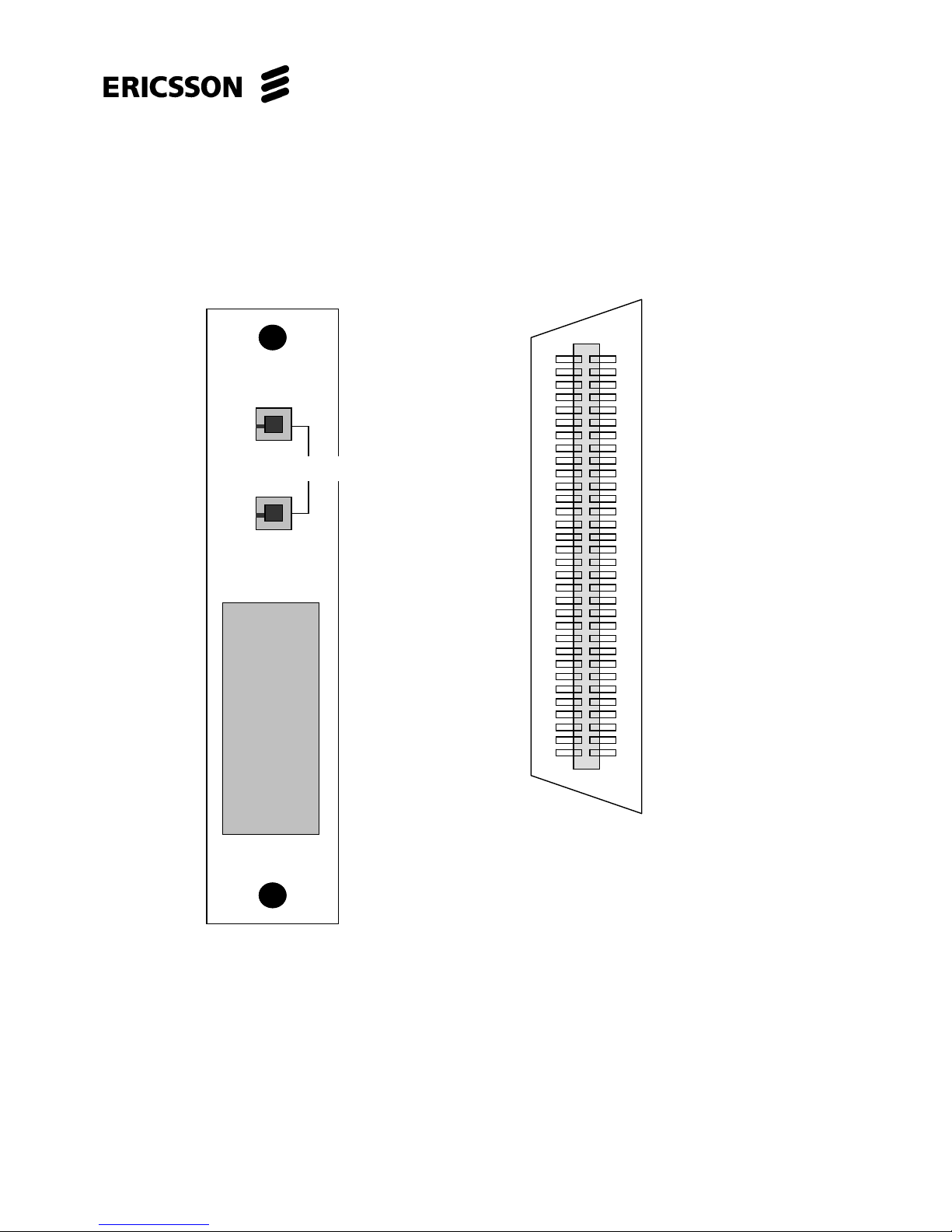

2.4.5.3 32 x TAM Connection Unit (02HAT 00136 AAR)

This unit is a Connection Unit for the 32 x SHDSL line units and is located in the

connection part slot above the 32 x SHDSL unit. It also provides Line Test Access

connections for connection to the TAM equipment.

Figure 2.14 – 32 x TAM Connection Unit

LINE

1 - 32

02HAT 00136 A A R

32 x TAM

LTA

LINE

1 - 32

02HAT 00136 A A R

32 x TAM

LTALTA

32

33 1

64

From UNIT Front

TOP

64-Pin Centronics Connector

Page 31

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

31 (200)

32 x TAM Centronics Connector Pin Designations

SHDSL 2-Wire circuits SHDSL 4-Wire circuits

SIGNAL PIN SIGNAL PIN Interface

Line 1 a/b 1 33 Line 1 a/b 1 33 Interface

Line 2 a/b 2 34 Line 2 a/b 2 34 1

Line 3 a/b 3 35 Line 3 a/b 3 35 Interface

Line 4 a/b 4 36 Line 4 a/b 4 36 2

Line 5 a/b 5 37 Line 5 a/b 5 37 Interface

Line 6 a/b 6 38 Line 6 a/b 6 38 3

Line 7 a/b 7 39 Line 7 a/b 7 39 Interface

Line 8 a/b 8 40 Line 8 a/b 8 40 4

Line 9 a/b 9 41 Line 9 a/b 9 41 Interface

Line 10 a/b 10 42 Line 10 a/b 10 42 5

Line 11 a/b 11 43 Line 11 a/b 11 43 Interface

Line 12 a/b 12 44 Line 12 a/b 12 44 6

Line 13 a/b 13 45 Line 13 a/b 13 45 Interface

Line 14 a/b 14 46 Line 14 a/b 14 46 7

Line 15 a/b 15 47 Line 15 a/b 15 47 Interface

Line 16 a/b 16 48 Line 16 a/b 16 48 8

Line 17 a/b 17 49 Line 17 a/b 17 49 Interface

Line 18 a/b 18 50 Line 18 a/b 18 50 9

Line 19 a/b 19 51 Line 19 a/b 19 51 Interface

Line 20 a/b 20 52 Line 20 a/b 20 52 10

Line 21 a/b 21 53 Line 21 a/b 21 53 Interface

Line 22 a/b 22 54 Line 22 a/b 22 54 11

Line 23 a/b 23 55 Line 23 a/b 23 55 Interface

Line 24 a/b 24 56 Line 24 a/b 24 56 12

Line 25 a/b 25 57 Line 25 a/b 25 57 Interface

Line 26 a/b 26 58 Line 26 a/b 26 58 13

Line 27 a/b 27 59 Line 27 a/b 27 59 Interface

Line 28 a/b 28 60 Line 28 a/b 28 60 14

Line 29 a/b 29 61 Line 29 a/b 29 61 Interface

Line 30 a/b 30 62 Line 30 a/b 30 62 15

Line 31 a/b 31 63 Line 31 a/b 31 63 Interface

Line 32 a/b 32 64 Line 32 a/b 32 64 16

Table 2.4: Centronics Connector Pinout for 32 x TAM Connection Unit

(02HAT00136AAR)

Page 32

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

32 (200)

2.4.6 Fan Tray (151-2984/02)

Figure 2.15 - Fan Unit

The Fan system ensures there is air circulation inside the subrack electronic part by

regulating fan speed as a function of temperature.

In the event of failure of one fan, the remaining ones increase their speed to the

maximum value to ensure proper equipment aeration. The system is located in the

central front part of the EDA 2530 subrack.

WARNING: In a fully equipped subrack, the equipment cannot work for more than

five minutes without the Fans.

End of section

Page 33

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

33 (200)

3 Resources

The following equipment is required to carry out the tests described in this

document.

3.1 Documentation

The following documentation is required to commission the EDA 2530.

No. Description Code Qty

1 This document – EDA 2530 Commissioning

Procedure for Cable and Wireless Access.

2/153 22-FGC 101

0239 Uen

1

2 The EDA 2530 Software and Firmware Release

Note for the release of the EDA 2530 being

commissioned.

1

3 Customer specific Configuration information i.e.

Floor Plan, EDA 2530 Rack Layout, EDA 2530

Subrack equipment allocations, Cable Running Out

Lists.

1

3.2 Tools

No. Description Code Qty

1 Anti Static Wrist Strap and connection cable. 1

2 Anti Static bags for Slide in Units or Anti Static

containers.

As

required

3 Screwdrivers – Flat Blade and Crosshead. 2

4 Side Cutters 1

5 Krone IDC Connection tool see picture CWA013 2

6 Continuity Tester (Buzzer) for checking new cables. 1

7 T-Bar Unit Extraction Tool 151-2765/01 1

3.3 Test Equipment

Record details of the test equipment used on the Record of Test Equipment Form.

Approved equivalents may be used if the items specified are not available.

Page 34

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

34 (200)

3.3.1 PC Connection Cables for Commissioning

Cable for connecting the Local Controller Ethernet Port to the EDA 2530 Common

Part Card. .

RJ45 Crossover Cable - Local Controller Ethernet Port to EDA 2530

Common Part Card

RJ45 Connector RJ45 Connector

Signal Pin Pin Signal

TD+ 1 3 RD+

TD- 2 6 RD-

RD+ 3 1 TD+

RD- 6 2 TD-

TD = Transmit Data RD = Receive Data

No. Description Code Qty

1 A PC to run EDA2530 LCT application (Min specifications

Pentium III 750MHz, 542Mb Ram, 200Mbyte free space,

CD-ROM, resolution 1024x768). Operating System XP or

Vista.

1

2 EDA 2530 Local Controller Software CD for the release of

the EDA 2530 being commissioned. (S38-xxxx/xx.xx.xx)

1

3 RJ45 Crossover cable for connecting the Local Controller

Ethernet Port to the EDA 2530. Refer to Section 3.3.1.

(Q4273) 1

4 RS232 Serial Cable Set, used to connect the Common

Part Unit (CP) RS232 interface to the PC serial COM

port. (Refer to Section 3.4.1 for details)

CWA0002

1

5 Digital Multimeter 1

6 “Golden Modem” multi-level xDSL service tester, with

ADSL /G.SHDSL module interfaces. Capable of ATU-R

and STU-R modem operation modes or an ADSL

modem, Eg. Linksys AM200 ADSL2+ modem.

1

7 SHDSL Modem Eg. Billion BiPAC 8520 up to 4.6Mbps

(4-wire SHDSL) Bridge/Router

1

8 Optical Power Meter with adapter lead for LC connection. 1

9 HDF block 2 pole to RJ11 test cord (Banana plugs) CWA006 1

10 HDF block 2 pole to RJ11 test cord CWA007 1

11 HDF Krone block 2 pole to RJ11 test cord CWA008 1

12 Butt Telephone Test Set with either internal or external

DSL/POTS filtering. Eg. Fluke TS-25D Telephone Test

kit. (Which includes DSL/POTS filtering)

1

13 RJ11 ADSL filter for Test Telephone 1

Page 35

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

35 (200)

3.4 Test Cables

No. Description Code Qty

1 LC to LC single mode optical link. 2

2

Coaxial jumper cables 75Ω terminated with 2 x (1.0/2.3)

(BT Type 54) connectors

(Q4272) 2

3 DDF Loop Back Cables terminated with 2 x Type 43

connectors.

1HAM 10656 ABT

or (Q4232A)

32

4 xDSL line cable (Terminated with RJ12 connector at NT

modem end, with pins 3 and 4 wired to the a and b leg of

the line under test at the MDF).

Note: The “Golden Modem” test equipment includes the

line cable (RJ11), terminated with crocodile clips to

connect to the MDF Line termination (IDC connection).

1

Page 36

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

36 (200)

3.4.1 RS232 Serial Cable Set (151-2502/01)

This cable is required for connection of the Common Part unit (CP) RS232 interface

to the PC serial COM port, for initial configuration.

IMPORTANT WARNING: Connect this cable to the PC before connecting the RJ12

connector to the Common Part. You must disconnect the RJ12 connector from the

Common Part before connecting or disconnecting any 9-Way connector to the PC.

The operator must NOT switch ON or switch OFF power to the PC while it is

connected to the Common Part card.

1

6

RJ12

Sub-D 9pin FEMALE

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Sub-D 9pin FEMALE

SERIAL INTERFACE 1

SERIAL IN TER F ACE 2

Female

Connector

9-Pin Sub-D

Female

Connector

SERIAL INTERFACE 1

SERIAL INTERFACE 2

9-Pin Sub-D

Insertion Key

1

6

RJ12

5

1

9

6

rear view

Code: 151-2502/01

MONITOR

MAINTENANCE

Page 37

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

37 (200)

3.5 Local Craft Terminal (LCT) Installation

With reference to the equipment handbook, install the software packages on the PC

relevant to the EDA Local Craft Terminal. If the correct release of LCT software is

already loaded on your PC ignore this section and go to Section 4.

3.5.1 Removal of Old Issue of EDA Hub Software

If the Access Hub LCT software has been installed previously, follow these steps to

remove it before installing the new version.

a. Close any EDA Local Terminal application, including the PortSrv

(PortServer) program.

b. To remove the EDA Local Craft Terminal software package installed by this

setup procedure, use the "Start -> Settings -> Control Panel ->

Add/Remove Program" utility in the Control Panel to remove the "AXH

Local Terminal xx.yy.zz" software.

c. To remove the EDA Local Craft Terminal Easy On software package

installed by this setup procedure, use the "Start -> Settings -> Control

Panel -> Add/Remove Program" utility in the Control Panel to remove the

"BMS xx.yy.zz" software. EasyOn software is named as “BMS”.

d. From the "Add/Remove Program" utility in the Control Panel, you can also

remove the Java, ITCL, and Acrobat Reader packages, if you need to

remove them.

3.5.2 Installation of Local Operator Software on P.C.

The Local Operator software is supplied on CD-ROM its identification code being

CXP_901_3007_1_R3B_06 [LCT rel. 07.02.06].

The CD ROM provides the following software packages:

• ITCL release 3.3.1

• Java version 5.0 update 15

• Acrobat Reader release 7.0.8

• EDA-AXH LCT release 07.02.06

• LCT EasyOn Addon release R3B06

• LCT 07.02.06 GA EC1 Patch

Page 38

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

38 (200)

a. Insert the CD-ROM into the CD ROM drive of the PC.

b. If the PC is equipped with autorun the file readme.txt will be displayed

otherwise display it by double clicking the readme.txt file.

c. The document readme.txt contains the instructions to be carried out for the

installation of the software.

For further information, refer to the Operator’s Handbook.

3.5.3 Install Application Software From CD ROM

Note: If Windows NT is used, all the applications must be installed as

Administrator user.

a. Remove any previous version of EDA Local Craft Terminal. Refer to section

3.5.1 Removal of Old Issue of Access Hub Software.

b. Open up the Windows Explorer application in order to access the CD

inserted in the CD-ROM drive.

c. Install Java version 1.5.0 update 15, double-click on the "jre-1_5_0_15-

windows-i586-p.exe" file in the Java folder “CXC_172_4901_R2A_01” on

the CD-ROM drive to install it.

Follow the setup wizard to complete the installation, confirming the default

selections when in doubt.

d. If your Windows PC does not have ITCL 3.3.1 installed, double-click on the

"setup.exe" file in the ITCL folder “CXC_172_4904_R1B_01”on the CD-

ROM drive to install it.

Note: ITCL 3.3.1 is installed at the fixed location "C:\itcl3.3" .

e. If your Windows PC does not have Adobe Acrobat Reader release 7.0.8 or

higher installed, double-click on the "AdbeRdr708_en_US.exe" file in the

Acrobat folder “CXC_172_4902_R1A_01” on the CD-ROM drive to install it.

Follow the setup wizard to complete the installation, confirming the default

selections when in doubt.

f. Install the AXH LCT application, double-click on the "setup.exe" file in the

AXH LCT folder “CXC_172_4905_R3B_05”on the CD-ROM drive to install

it.

Follow the setup wizard to complete the installation, confirming the default

selections when in doubt.

g. Install the LCT-EASYON-ADDON application: double-click on the

"setup.exe " file in the LCT-EASYON folder “CXC_172_4906_R3B_06”on

the CD-ROM drive to install it.

Page 39

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

39 (200)

Follow the setup wizard to complete the installation, confirming the default

selections when in doubt. This program will be named as “BMS” when

installed.

h. After completing the installation of LCT-EASYON-ADDON, restart the

computer in order to update the Windows O.S. registry.

i. After the computer has restarted, copy the patch file “p_XdslLineCF.tcl”

from the “LCT 07.02.06 GA EC1 Patch” folder on the CD. Then paste it into

the following folder c:\Mv36bLT\lib\gui, to replace the existing

“p_XdslLineCF.tcl” file.

j. Copy and replace the existing file “setenv80_13.bat” with the latest one

provided, in folder C:\Mv36bLT\Lib\env (you may wish to backup the

existing file before doing so).

Note: If this file is not replaced then when loading the National Mapping file,

Columbia will be selected instead of the United Kingdom.

k. The LCT installation is now complete.

3.5.4 LCT 07.02.05 – Known Issue with Java Version 1.6

LCT 07.02.05 has a known issue with the National Mapping Tool and setting up the

repository location when Java version 1.6 has been installed.

To correct this issue the commissioning engineer must remove Java 1.6, the LCT, &

all of the LCT packages, then re-install them again but with Java version 1.5 before

attempting to configure any POTS card(s).

Perform the following steps:-

a. Uninstall Java 1.6 and all of it’s updates from the Windows Control Panel.

b. Uninstall the LCT then it’s suite of packages including “itcl”, Java 1.5

update 15, & the Easy on Addon known as “BMS”, from the Windows

Control Panel.

c. Delete all of the Java directory(s) in C:\Program Files (ensure you have

removed the Java programs from Windows Control Panel first before you

do this).

d. Reboot the PC.

e. Re-install “itcl”, then “Java 1.5 update 15”, then “LCT 07.02.05”, then Easy

on Addon known as “BMS”.

f. Reboot the PC after Easy on Addon known as “BMS” has been installed.

Page 40

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

40 (200)

g. After the computer has restarted, install the LCT 07.02.05 EC1 correction

patch. Copy the patch file “p_XdslLineCF.tcl” from the “LCT 07.02.06 GA

EC1 Patch” folder on the LCT CD. Then paste it into the following folder

c:\Mv36bLT\lib\gui, to replace the existing “p_XdslLineCF.tcl” file.

End of section

Page 41

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

41 (200)

4 Commissioning Requirements

4.1 Description Of Testing Activities

The testing described in this document is the functional testing on lines chosen by

sampling those present in the system.

During Section 5.2, only the Common Part unit in slot 1 is inserted in the EDA 2530

subrack.

Note: The other units are inserted for configuration from Section 5.3.

4.2 Test Records

The commissioning test records at the end of this document must be completed as

the testing progresses. A complete set of Test Records must be completed for each

EDA 2530 (EDAxx01) Parent and Stand Alone shelf being commissioned.

When all testing has been completed successfully, both the Ericsson representative

and Customer’s representatives must complete the Certification of Tests Form at the

end of this document. If the Customer’s representative is not present on site enter

N/A (Not Available) for the Customer representative.

4.3 Preliminary Checks

4.3.1 Equipment Positioning

Check the equipment positioning corresponds to the implementation plan.

4.3.2 Card Equipping

Check that the correct quantity and type of equipment cards have been supplied to

the contract requirements. The electrical cards should be partially inserted into their

allocated slot positions, ensuring that the unit edge connectors do NOT make

accidental contact with the shelf connectors. Carefully insert the Connection Units

into the start of the shelf runner. Ensure that the unit is exactly level and then gently

slide the unit forward until a resistance is felt. A further gentle push on the unit front

panel will ensure that the unit connector engages with the shelf pin connections. Do

NOT force the unit into the shelf, as this will damage the shelf edge connectors.

Check that the positions not occupied by cards have the appropriate covers fitted.

Refer to Section 2.4.2 for Unit Equipping Rules and Standard Configuration for

Cable and Wireless Parent and Stand Alone shelf.

Page 42

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

42 (200)

4.3.3 Cabling

Check that the positions of service or signal cable terminations on electrical and

optical distribution frames, or on other equipment, comply with the Site

Implementation Plan.

Check that the 64 pair cables (Lines and POTS) are tied on the provided cable

supports. Check that Line cables are linked to the Connection Unit through the

supports supplied with the equipment.

Page 43

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

43 (200)

4.3.4 Power Supply and Grounding Connections

VB1 VB2

Pin Signal Function Pin Signal Function

1

- B1 Negative Voltage of Battery 1

1

- B2 Negative Voltage of Battery2

2 +B1 Positive Voltage of Battery 1 2 +B2 Positive Voltage of Battery 2

3 Not used 3 Not used

4 +B1 Positive Voltage of Battery 1 4 +B2 Positive Voltage of Battery 2

5 - B1

Negative Voltage of Battery 1

5 - B2

Negative Voltage of Battery 2

Note: The 5 Pin D-Type Connector on the Power Cable is Female.

Figure 4.1 - Power Supply Connection Unit (151-2975/53) Pin Allocations

Figure 4.2 Power Supply/Earth Arrangement to Power Supply Connection Unit

Pin 1 2 3 4 5

M

C

B

1

M

C

B

2

-50 V Supply 1

(

Battery 1)

Pin 1 2 3 4 5

M

C

B

3

M

C

B

4

-50 V Supply 2

(

Battery 2

)

Rack Earth Bar

0 V

Power Supply Connection Unit

(151-2975/53) Slot 22 - Socket Vb1

Power Supply Connection Unit

(151-2975/53) Slot 22 - Socket Vb2

Main Earth Bar

0 V

5 Pin D-Type Connector (Male)

on Power Supply Connection

Unit (151-2975/53)

Pin 1 2 3 4 5

Grey Grey Grey Grey

Grey Grey

Blue

Blue Blue

Page 44

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

44 (200)

4.4 Earthing And D.C. Supply Checks

These tests are classified as SAFETY TESTS.

There are different variants of Power Supply Connection Unit available, depending

on the type of subrack and the customer requirements.

SUBRACK

DESCRIPTION

SUBRACK CODE Power Supply - Right

S20 Flexible Connections 133-1555/03 151-2975/53 (Slot 22)

The EDA 2530 Power Supply Connection Unit (151-2975/53 incorporates two 5 pin

D-Type connectors. Each connector allows for connecting two –50 volt and two

earth cables to provide the duplicated power supply to each 5 pin D-Type connector.

The EDA 2530 cabinet will be supplied by two –50 volt power feeds, each protected

by an external circuit breaker rating or fuse of 32 Amps. The two Earth cables will

be connected to the EDA 2530 Earth bar.

Record the external circuit breaker or fuse rating on the Equipment Checks Test

Record.

In the United Kingdom (UK) the main –50v supply (Supply 1) is connected to two

Single-Pole 16 Amp Miniature Circuit Breakers (MCB 1 and MCB 2) fitted on the

circuit breaker panel at the top of the EDA 2530 cabinet. These two 16 Amp MCB’s

are connected to Socket Vb1 on the Power Supply Connection Unit (151-2975/53) in

slot 22. The main –50v supply (Supply 2) is connected to two Single-Pole 16 Amp

Miniature Circuit Breakers (MCB 3 and MCB 4). These two 16 Amp MCB’s are

connected to Socket Vb2 on the Power Supply Connection Unit (151-2975/53) in

slot 22. Other countries may have different types of Isolators or Circuit Breakers

depending on local requirements and regulations.

Check the circuit breakers or fuses in the customer's distribution equipment are

switched OFF or open. Check the EDA 2530 cabinet circuit breakers are switched

OFF. Disconnect the 5 pin D-Type connectors from Socket Vb1 and Socket Vb2 on

the Power Supply Connection Unit in slot 22.

Measurement: Check there is a connection between the EDA 2530 cabinet and

the earth bar. Check the resistance is less than 1 ohm, measured between

cabinet metalwork and an adjacent point on the earth bar. Record the

measured value in the Test Record.

At the customer's DC distribution equipment switch ON the isolators or circuit

breakers, or insert the fuses, for the feeds to the EDA 2530 Cabinet. If the DC

distribution is from an EF80 or similar distribution, insert the two 32 Amp fuses.

Check the supplies at the cabinets are of the correct polarity and lie in the range -

48 V ±20% (-38.4v to -57.6v). Record the measured value on the Main Power

Supply Voltage Check Test Record.

Page 45

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

45 (200)

4.5 Power Supply Connection Unit Check

Switch ON Circuit Breaker MCB 1 at the top of the EDA 2530 cabinet. Check for –

50 volts on Pin 1 of the D-Type connector for Socket Vb1 on Power Supply

Connection Unit in slot 22. Switch OFF MCB 1 and check the –50 volts is removed.

Switch ON Circuit Breaker MCB 2 at the top of the EDA 2530 cabinet. Check for –

50 volts on Pin 5 of the D-Type connector for Socket Vb1. Switch OFF MCB 2 and

check the –50 volts is removed. Check for Earth (0 volts) on Pin 2 and Pin 4.

(Refer to Figure 4.1 for the layout of the 5 pin D-Type connector).

Reconnect the 5 pin D-Type connector to Socket Vb1 on the Power Supply

Connection Unit in slot 22. Secure the connector by tightening the two fixing

screws. Switch ON MCB 1 and MCB 2 and check the Green “VB1” power LED is lit

on the Power Supply Connection Unit in slot 22.

Switch ON Circuit Breaker MCB 3 at the top of the EDA 2530 cabinet. Check for –

50 volts on Pin 1 of the D-Type connector for Socket Vb2 on Power Supply

Connection Unit in slot 22. Switch OFF MCB 3 and check the –50 volts is removed.

Switch ON Circuit Breaker MCB 4 at the top of the EDA 2530 cabinet. Check for –

50 volts on Pin 5 of the D-Type connector for Socket Vb2. Switch OFF MCB 4 and

check the –50 volt is removed. Check for Earth (0 volts) on Pin 2 and Pin 4. (Refer

to Figure 4.1 for the layout of the 5 pin D-Type connector).

Reconnect the 5 pin D-Type connector to Socket Vb2 on the Power Supply

Connection Unit in slot 22. Secure the connector by tightening the two fixing

screws. Switch ON MCB 3 and MCB 4 and check the Green “VB2” power LED is lit

on the Power Supply Connection Unit in slot 22.

4.5.1 Labelling

Check that the Circuit Breakers MCB 1, MCB2, MCB 3 and MCB 4 or alternative

power supply Circuit Breakers are labelled according to the provisions of the

‘Installation Standard for EDA 2530 Equipment’.

Check that the optical links or cable, Customer side and Network side, are labelled

according to the provisions of the ‘Installation Standard for EDA 2530 Equipment’ or

that their terminations can be identified.

Check that the strips of the distribution frames, onto which the equipment is

terminated, are labelled according to the provisions of the ‘Installation Standard for

EDA 2530 Equipment’.

Check that the equipment racks and subracks are labelled according to the

provisions of the ‘Installation Standard for EDA 2530 Equipment’.

End of section

Page 46

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

46 (200)

This page is left intentionally blank to facilitate double sided printing.

Page 47

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

47 (200)

5 Initial Configuration

Prior to testing, the Common Part IP unit requires configuring in accordance with the

parameters assigned to the system.

This section details the process to configure IP addresses/parameters needed for

management of the equipment from LCT and from the appropriate workstation for

network management.

For identification of the IP addresses/parameters assigned to the system, refer to

the Network planning guide.

5.1 IP Address Configuration Of PC Used As LCT

Before connecting the laptop to the Common Part IP unit, the laptop must be

configured to be in the same IP Network Address range as the Out of Band

Management IP Address of the EDA 2530.

Note: For Windows 2000 OS use step a, for Windows XP use step b, and for

Vista OS use step c, all other steps are common to Windows 2000/XP/Vista OS.

a. For Windows 2000

, left click on the Start button, then select Settings >

Control Panel.

Double left click on the Network and Dial-up Connections icon.

b. For Windows XP

, left click on the Start button, then select Control Panel.

Double left click on the Network Connections icon.

c. For Windows Vista

, left click on the Start button, then select Network >

Network and Sharing Center > Manage network connections.

d. Right click on Local Area Connection icon and then click Properties.

e. In the ‘LAN Properties’ window, use the scrollbar to move down the list.

f. For Windows 2000/XP select the ‘Internet Protocol (TCP/IP) entry, but for

Windows Vista select the ‘Internet Protocol Version 4 (TCP/IPv4) option,

then left click on the ‘Properties’ button.

Page 48

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

48 (200)

g. In the ‘Internet Protocol (TCP/IP) Properties’ window, left click in the

~ Use the following IP Address’ radio button.

h. In the ‘IP Address’ field, enter an IP Address for the laptop compatible with

the Out of Band IP Address of all the EDA 2530 shelves. For this project a

suitable laptop IP Address is 150.150.150.16.

Set the Laptop IP Address to 150.150.150.16

Note: The EDA 2530 IP Address is 150.150.150.4

i. In the ‘Subnet Mask’ field, enter the subnet mask for the EDA 2530 node.

This will always be the same for all EDA 2530 shelves.

Enter 255.255.255.0

j. Leave the ‘Default Gateway’ field blank.

k. Left click the OK button to save and close the ‘Internet Protocol (TCP/IP)

Properties’ window.

l. Left click the OK button to save and close the ‘LAN Properties’ window.

Click on Yes to reboot the laptop if prompted.

m. This step only applies to Ericsson personnel running Symantec antivirus

and anti spyware applications on Windows VISTA OS.

Page 49

EDA 2530 Commissioning Procedure for Cable and Wireless Access

1/153 22-FGC 101 0239/2 Uen Rev J 2010-04-01

© Ericsson AB 2010

Commercial in confidence

49 (200)

Disable the antivirus and anti spyware protection by “Stop”ing the

Symantec Endpoint Client and Symantec Management Client, as described

in the follow steps:-

Select Start then right click on Computer, select the path: Manage >

Continue > Services and applications > Services

Right click on Symantec Management Client, and select Stop.

Right click on Symantec Endpoint Protection, and select Stop.

Now close all open windows.