Ericsson 19A704647P11, 19A704647P14, 19A704647P12, 19A704647P1, 19A704647P3 Maintenance Manual

Page 1

LBI-38751C

Maintena n ce Man ua l

13 AMPERE POW ER SUPP LY

19A 704 647P11-P12, P14

19A704647P 1-P3

CAUTION

THESE SER VICING INSTRUCTIONS ARE FOR USE BY QU ALIFIED

PERSONNEL ONLY. TO AVOID ELECTRIC SHOCK DO NOT

PERFORM ANY SERVICING OTHER THAN THAT CONTAINED IN

THE OPERATING INSTRUCTIONS UNLESS YOU ARE QU ALIFIED

TO DO SO. REFER ALL SERVICING TO QUALIFIED SERVICE

PERSONNEL.

WARNING: TO PREVENT FIRE OR ELECTRIC SH OCK HAZARD. DO NOT

EXPOSE THIS PRODUCT TO RAIN OR MOISTURE.

CAUTION: TO PREVENT ELECTRIC SHOCK DO NOT USE THIS

(POLARIZED) PLUG WITH AN EXTENSION CORD, RECEPTACLE OR

OTHER OUTLET UNLESS THE BLADES CAN BE FULLY INSERTED TO

PREVENT BLADE EXPOSURE.

ericssonz

Page 2

LBI-38751

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY INSTRUC TION S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CIRCUIT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Filter And Bridge Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Filter And Output Regu lator Se ction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overtemperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output Overvoltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Internal Bias Voltage Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TROUBLESHOOTI NG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FUSE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TROUBLESHOOTI NG TA BLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

POWER SUPPLY VOLTAGE READING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MODIFICATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ADAPTER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OUTLINE DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page

Repai rs to this equipm ent shoul d be made only by an author ized se rvice tec hnicia n or facili ty desig nated by t he suppl ier . An y

repairs, alter ations or substituti on of rec ommend ed part s made by the user to this equi pment not ap proved by the m anufac turer

could voi d th e user’s authority to opera te th e equi pm e nt i n ad dit io n to the ma nuf ac turer’ s wa rranty.

This manual is published by Ericsson Inc., without any warranty. Improvements and changes to this manual necessitated by

typographical errors, inaccuracies of current information, or improvements to programs and/or e quipment, may be made by

Ericsson Inc., at any time and without not ice . Such c hanges will be incorporated into new e di ti ons of this manu al . No part of

this manual may be reproduced or transmitted in any form or b y any means, electronic or mec hanical, i ncluding p hotocopying

and recordi ng, for a ny pu rpose , without the expre s s writt en pe rm ission of Ericsson Inc.

Copyright © August 1992, Ericsson GE Mobile Communications Inc.

2

NOTE

Page 3

SPECIFICATIONS*

A thermal protection unit will automatically reduce the output voltage if the output is at maximum value for an extended period

of time at 13 amperes.

Part No. Nominal

LBI-38751

Input Voltage (Vac) P11,P12

P14

Input Frequency (Hz) ALL 50/60

Input Current (Amps) P11,P12

P14

Output Voltage (Vdc)

(From 0.5 to 13 Amperes)

Output Ripple (mV P-P)

@ 3 Am ps

@ 13 Amps

Tra nsi e n t Respo nse ( Vd c )

(Except overcurrent condition)

Duty Cycle All 20%: 1 minute ON, 4 minutes OFF

Size All 4.6 X 4.75 X 12 . 5 in c hes

Weight All 13 .1 LBS

* These specifications are intended primarily for the use of the service technician. Refer to the appropriate Specification Sheet for

complete specifications.

All 13.8

All

All

All 11.5 - 16.0

121

240

4

2

50 (Ma xi mum)

100 (Maximum)

19A704 647P1- P3 UL Approv al

19A704 647P11-P12 CSA & U L Ap prov a l (Pe ndi ng)

19A704 647P14 Europe an Approva l (Pending )

NOTE

WARNING

This unit contains dangerous voltage levels. It is strongly recommended that defective units be returned to the manufacturer

for repairs.

If field repair is necessary, remove the input power and then use a load resistor to manually discharge each cap acitor before

servicing the unit.

3

Page 4

LBI-38751

IMPORTANT SAFETY INSTRUCTIONS

1. SAVE THIS MANUAL - It contains important

safety and operating instructions for Power Supply

Models 19A704647 P1, P2, P3 and P11, P12, and

P14.

2. Do not use auxiliary equipment not recommended or

sold by th e ma nufac tur er. To do so may r es ul t in a

risk of fi re, elect ric shock, or injury to personnel.

3. Do not expose unit to rain, snow or other type of

moistu re.

4. To reduce risk of damage to electric plug and cord,

pull by plug rather than cord when d isconnecting

unit.

5. Make sure the cord i s located so t hat it will not be

stepped on, trip ped over, or otherwis e subjec ted to

damag e or stress.

6. An exten sion cord sh ould not be us ed unl ess abs o-

lutely necessary. Use of an improper extension cord

could result in a risk of fire and electric shock. If an

extension cord must be used, make sure:

a. That pins on plug of extension cord are the same

number, size and shapes of those on plug on unit.

b. That extension cord is properly wired, in good

condition, and

c. That wire size is large enough for AC ampere

rating of unit as specified in Tabl e 1.

Table 1 - Recommended Minimum Size For

Extension Cords

10. To reduce ris k of elect ric shock, u nplug unit from

outlet before attem pting any mai nten ance or cleaning.

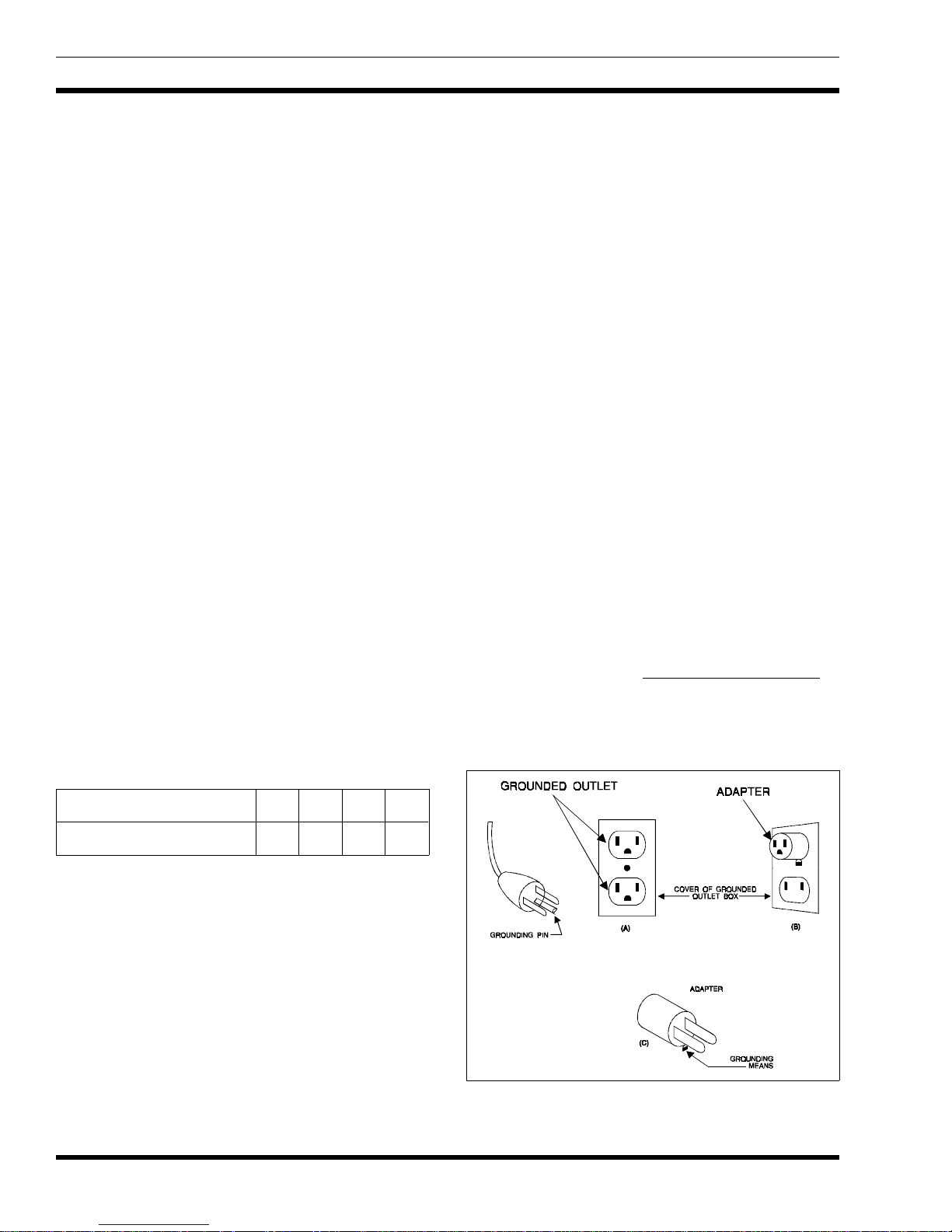

11. GROUNDING AND AC POWER CORD

CONNECTION - To reduce risk of electrical shock

use only a properly grounded output. The unit is

equipped with an electric cord having an equipment

grounding conductor and a grounding plug. Be sure

that t he o ut let i s pr op erly ins talle d and gr ound ed i n

accordance with all local codes and ordinances.

12. DANGER - Never alter AC cord or plug. If it does

not fit t he out le t, hav e a pro per ou tlet in s tall ed by a

qualified electrician. Improper connection can result

in risk of electric shock.

13. This unit is fo r use on a 121 vol t circu it, and ha s a

grounding plug that looks like the plug shown in

Figure 1. A temporary adapter, that looks like t he

adapter shown in sketches B and C, may be u sed to

connect this plug to a two pole receptacle as shown

in sketch B if a properly grounded outlet is not

available. The temporary adapter should be used only

until a pr op erl y gr ou nde d o utl et c an be in stal le d by a

qualified electrician.

14. DANGER - Before using the adapter shown, be

certain that the center screw of the outlet p late is

grounded. The green colored rigid ear or lug extending from the adapter must be connected to a properly

grounded outlet -necessary, replace original ou tlet cover plate screw

with a longer screw that securely fastens the ear or

lug to outlet cover plate and makes a grounded connection to outlet box.

make certain it is grounded. If

Length of Ext e n sio n Cor d( ft .) 25 50 100 150

AWG Size of Exte n sio n C or d 18 18 16 14

7. Do not operate unit with damaged cord or plug replace them immediately.

8. Do not operate unit if it has received a sharp blow,

been dropped, or otherwise damaged in any way.

Return to a qualified service shop.

9. Do not disassemble unit. Return to a qualified service shop when service or repair is required. Incorrect

reassembly may r esult in a r isk of electr ic sh ock o r

fire.

4

Figure 1 - Grounding Methods

Page 5

LBI-38751

15. The P3 and P14 Power Supplies are for use on circuits

of nominal 240 volts AC. They are factory equipped

with an electric cordless plug connector. A terminating connector that meets local electrical codes should

be added.

16. Care shou ld be taken when pla cing the unit in ser vice

to insure proper top and bottom ventilation. A minimum of 1/4 inch is req uir ed b etw een t he bot tom of

the unit and the surface on which it sits.

INTRODUCTION

These power supplies were designed expressly to provide

power for the D elta Des ktop/Wal l sta t ion. Th ey su pp ly th irteen (13) amperes of direct curren t at 13.8 Volts. The output

is protected from both o ve rcurrent and overvo lt age. In addition, built in overtemperature protection prevents damage

from usage outside of the specified temperature range.

The circuit diagrams of these power supplies (part numbers

P11, P12 an d P14) are the s ame, except for pr imary pow er

connections. The applications are:

Part 1, 11 - For rack Mounting (Delta type) - 120V 60Hz

Part 2 , 12 - Table Mo un tin g ( Rubb e r Fee t) - 120V 6 0H z

Part 3 - Table Mounting (Rubber Feet) - 240V 50Hz

Part 4 - For rack Mounting (Delta type) - 240V 50 Hz

CIRCUIT DESCRIPTION

FILTER AND OUTPUT REGULATOR

SECTION

The c urre nt the n f lows t hr ough th e l ine ar reg ula tor sec ti on

of the supply. The linear regulator is compo sed of two functional groups of components. The first group, the series pass

regulator group consists of Q1, Q2, R1, and R2. In order to

control the o ut pu t vo ltag e of the s uppl y, the serie s pas s tr ansistors are operated as variable resistors. If the lo ad on the

supp ly is in crea sed , cau sing a drop in the ou tp ut vo ltag e, the

resistance of the series pass transistors is automatically decreas ed. This dec reas e bal ances th e out put vo lta ge dro p an d

returns the output voltage back to the desired level.

In order to reg ulate the o utput voltag e, tw o pass tr ansist ors

are used. R1 and R2 provide negative feedback to the emitters

of the resp ectiv e tr ansist ors, balan cing them and cau sing e qual

current flow and equal power dissipation.

The second functional group is the series pass control,

consisting of U1 and Q3 in conjunction wit h their ass oc iated

bias r esistors and decoupling capacitors. U1 continuously

monitors the output voltage developed through the interaction

of the load and the series pass transistors. When more output

voltage is required to maintain regulation, U1 increases drive

to transistor Q3. Q3 provides the amount of series pass transistor base drive necessary to d ecrease their r esistance an d

boost t he ou tput volta ge b ack up to the desir ed val ue. Th is

continuous interaction between the control circuitry and series

pass stage for ms a clos ed loop c ontrol g roup prov iding the

regulated output voltage to the power supply load. The closed

feedb ack loop is co mpen sate d by R4 , C6 , and C 7 to provi de

loop stability. Potentiometer R13 varies the amount of output

voltage fed back in the cont rol loop thus allowing precise

adjustment of the output voltage at which regulation is maintained.

INPUT SECTION

Input power to th e supply i s provided f rom a 121 Vo lt,

50/60 Hertz (or 242 V, 50/60 Hz) line source connected

through the main power cord. The line is passed through fuse

F1, that limits the input current to 4 amperes. The input current

also pass es t hrough v aristor RV1, a transient l imiti ng device

that clamps the line at approximately 160 Vrms. This protects

the device from potentially harmful line voltage excursions.

FILTER AND BRIDGE SECTION

After passing through the input protection devices the line

voltage is applied to the p rimary winding to transformer T1.

The stepped down line voltage of approximat ely 35 Vrms, is

appli ed to the d iode bri dge D 1 and filter capacit ors C1, C2,

and C3. These devices convert the alternating current line to

approximately 25 V o lts direct current.

OVERCURRENT P ROTECTION

Overcurrent protection is implemented via a current foldback scheme. Resistor R3 is used as a current sensing element.

The amou nt of voltage developed across this resi stor is direc tly

proportional to the amount of current flowing to the load. This

sense vo ltage is applied to the regulator control integrated

circuit, U1, by means of R5, R6, and R7. As the current

through the sense resistor increases past 13.8 amps, the sense

voltage seen by U1 causes the value of both output voltage and

output current to dec r eas e. Th is fo ld ba ck a p pr oach to ov ercurrent protection decreases the amount of power dissipated

across the series pass transistors during a faulted condition.

The maximum allowable short circuit current is less than five

(5) amps.

5

Page 6

LBI-38751

OVER TEMP ERATURE PROTECTION

In order to protect the supply from abnormal ambient

temperature operating conditions or prolonged radio transmission, overtempera ture protection was added to t he supply. A

thermostat, S2, is attached to th e h eatsink of the supply to

monitor the oper atin g t emper ature of t he s eries pas s tr ansis tors. This thermostat is a normally closed switch type. When

too high an operating temperature is reached, the thermostat’ s

contacts open, thus removing the AC line voltage to the supply .

When t he tem perature of the heatsink returns to a safe value,

the co ntacts of S2 close and oper ation is automatically resumed.

OUTPUT OVERVOLTAGE PROTECTION

To protect the power supply load from possible overvoltage conditions due to failure of the control circuitry, an

overvo ltag e sen sing and shu td own ci rcu it has been incl ud ed.

This cir cuit is compo sed of V R1, VR2, C8 , R10, R11, R12,

Q4, and U1. When the o utput voltage exceeds 15 VDC, VR1

reaches its ZENER voltage and begins to conduct current.

This cur ren t d evelo ps a vol tage a cros s R12, w hi ch th en tr iggers th yristor Q 4 into for ward conduc tion. With Q4 tu rned

ON, a p ortion of th e bias voltage is applied dir ectly to the

shutdown pin of U1. With pin 8 of U1 held high, the drive to

Q3 is disabled, thus turning off the output voltage. Thyristor

Q4 remains ON until AC inpu t power is removed. The removal of AC input power interrupts the holding current

throug h Q4 and t urns i t off. Theref ore, in th e event of an

overvoltage shutdown, the power supply remains OFF

until the AC i nput power is remov ed and then restored either

via the main power swi tch, or d isconnection of the A C li ne

cord.

INTERNAL BIAS VOLTAGE SUPPLY

Internal bias voltage to the power supply is provided by a

separate winding on transformer T1. AC input power is transformed v ia th is wind ing at J 6 and J7 alon g with D2 and C 9

into approximately 30 volts DC at nominal line voltage. This

bias voltage then provides power to all to the internal circuitry

of the supply.

For parts 3 and 14 a connector (cu stomer s upplied )

must be installed on the power cord for connections

to a 240V power source.

3. Place the ON/OFF switch to the ON position to turn

on the supply.

MAINTENANCE

WARNING

This unit contains dangerous voltage levels. It is

strongly recommended that defective units be

returned to the manufacturer for repairs.

If field repairs are necess ary, remove inpu t power

and then use a load resistor to manually disch arge

each capacitor before working on the circuits.

For disassembly, remove 4 screws and lift off top co ver.

When replacing any component be certain to use an identical

compone nt. When r eplaci ng the t hermo stat mou nted on the

heatsink, apply thermal compound between the two. Observe

wire routing when resold ering circuits. Failure to do s o may

lead to excessive ripple or poor regulation.

TROUBLESHOOTING

When troubleshooting is required, use the guides given in

the following table to analyze defects. When a component or

assembly has been identified as defective, replace the defective

compone n t an d al s o check the ass oc iated components before

applying power to the unit in the event that a series of components are defective.

When replacing any component be certain to use an identical component. When replacing the thermostat mounted on

the heatsink, apply thermal compound between the two. Observe wire routing when resolde ri ng c ircuits. Failure to do so

may lead to excessive ripple or poor regulation.

OPERATION

1. Connect 13 Vdc output to the load using the mating

connector .

2. With the ON/OFF switch in the O FF position, connect the AC power cord to a 120V power source for

parts 1, 2, 11, & 12.

6

Recommended test equipment for maintenance or trou-

bleshooting of this power supply includes:

• Digital multimeter

• 50 amp DC meter

• Resi stive load

• Oscilloscope

Page 7

LBI-38751

ADJUSTMENTS

This power supply has an output voltage level adjustment.

Potenti ometer R13 varies the a mount of output volt age fed

back into the control loop, thus allowing precise adjustment of

the output voltage level. This level is to be maintained at 13.8

VDC for use with low power base stations.

INSTALLATION

The power supply can be mounted using mounting holes

found in the c hassis.

NOTE

Insure that ventilation holes in the unit are not obstructed when the unit is mounted or in operation.

The power supply is designed for ope ration from either a

121 VA C (P 1 , P2, P 11, and P12) , o r 242 VA C (P 3 a nd P14)

source. Before connecting the power supply, measure the

source voltage and then connect either the 120V or 240V unit

to match the source voltage. Refer to the Modification Procedures for details.

TROUBLESHOOT ING TABLE

SYMPTOM AREA TO CHECK

FUSE

BLOW S

NO OUTPUT 1) shorted o utp ut

OUTPUT

VOLT A GE

LOW

OUTPUT

VOLT AG E

HIGH

1) shorted output

2) shorted D1, C1, C2, C3, T1, VR1,

RV1, F1

2) output properly connected

3) overt empera t ure shutdown

4) failed Q1, Q2, D1, U1, T 1, S2

1) output overloaded

2) U1 fai lure

1) failed VR1, U1, Q3

2) failed overvoltage protection circuit

POWER SUPPLY VOLTAGE

READING

LOCATION READING

FUSE REPLACEMENT

To replace a defective fuse, use the following procedure:

1. Place ON/OFF switch in the OFF position.

2. R emove cap from fus e holder and replace fus e with

a simil ar type and size [4 amp, 250V(121 V AC inpu t),

2.5 amp, 250V (242 VAC input)].

3. Replace cap and change ON/OFF switch to ON

position.

If trouble persists, check with a qualified service person.

anode D1

C1 plus

cathode D2

OUTPUT

35 Vrms

25 Vdc

30 Vdc

+13.1 TO 14.1 Vdc

APPLICATION

19A704647P12 unit includes mounting feet and omits the

mounting bracket. A mating connector and mating male contacts are provided for the 13 Vdc output connector.

19A704647P14 operates from 242 V ac input. A power cord is

supplied less a power plug (customer to provide).

MODIFICATION PROCEDURES

The modification procedure to change from 120 V olt to 240

Volt operation is described. To change back to 120 Volt,

reverse the procedure. Refer also to the Schematic diagram and

to Figure 2 for an internal view of the power supply.

7

Page 8

LBI-38751

MODIFICATION PROCEDURE

1. Unplug un i t from power source.

2. Cut BRN lead near S1 and cover the short end of wire

to prevent accidental contact.

3. Strip 1/2" of i nsula tion from l ong p ortion of B RN

lead (just cut).

4. Remove wirenut holding BLK/WHT to BRN/WHT

leads.

WIRED FOR 12 0 VOLT

OPER ATION

5. Fasten BRN and BLK/WHT leads together using

wirenut (see Diagram for 240 Volt operation).

6. Cover/i nsu late expo sed BRN/ WHT lea d to pr even t

accidental contact.

7. Move BLACK wire from J7 to J8 .

Power supply can now be used with a 240 Volt, 50/60 Hz,

single phase source.

WIRED FOR 240 VOL T

OPERATION

ADAPTER CABLE

Where the 19A704647P11 unit is used in a desktop station

application, an adapter cable 19B803437P1 must be used

between the power supply DC outp ut jack and the statio n

power cable.

8

Page 9

LBI-38751

Figure 2 - P ower Supply, Internal View

Ericsson Inc.

Private Radio Systems

Mountain View Road

L ynchburg, Virginia 24502

1-800-528-7711 (Outside USA, 804-528-7711) Printed in U.S.A.

9

Page 10

LBI-38751

PARTS LIST

13-AMPERE POWER SUPPLY

M29/19A704647P1, P11 120 VAC 60 Hz

RACK MOUNT

M29/19A704647P2, P12 120 VAC 60 Hz

TABLE TOP

M29/19A704647P3 240 VAC 50 H z

TABLE TOP

M29/19A704647P14 240 VAC 50 Hz

RACK MOUNT

ISSUE 2

SYMBOL PART NO. DESCRIPTION

M29/9103360 PC Board Assembly (P1,P2,P3)

M29/91046800 PC Board Assembly (P11,P12,P14).

M29/83314700 PC Board Insertion Kit (P1,P2,P3)

M29/83325800 PC Board Insertion Kit (P11,P12,P14).

C1,C2 M29/17037900 Capacitor: 18000 µF, 50 VDCW.

C3,C5 M29/17018100 Capacitor: 0.1 µF, 50 VDCW.

C4 M29/17036404 Capacitor: 3900 µF, ±20%.

C6 M29/17018121 Capacitor: 100 pF, 16 VDCW, ±5%.

C7,C8 M29/17018214 Capacitor: 2200 pF. 100 VDCW, ±20%.

C9 M29/17034200 Capacitor: 470 µF, 50 VDCW.

D1 M29/19013900 Diode Bridge Assembly.

D2 M29/18032206 Rectifier 1N4007G.

J1-J11 M29/13048100 FASTON TAB .25", AMP 62650-1.

Q3 M29/91038000 Heatsink

Assembly/Trans istor TIP-31C.

Q4 M29/18031400 SCR 2N5061.

R1,R2 M29/16016800 Resistor: 0.1 ohms, 10w, ±5%.

R3 M29/16013905 Resistor: 0.02 ohms, 5w, ±1%.

R4 M29/16001436 Resistor: 71.5K ohms, ±1%.

R5 M29/16011419 Resistor: 162 ohms, ±1%.

R6,R12 M29/16001525 Resistor: 10K ohms, ±1%.

R7 M29/16001526 Resistor: 100 ohms, ±1%.

R8 M29/16001448 Resistor: 38.3 ohms, ±1%.

R9 M29/16001479 Resistor: 7.15K ohms, ±1%.

R10,R11 M29/16001591 Resistor: 1.27K ohms, ±1%.

R13 M29/16016900 Potentiometer: 1K ohms.

R14 M29/16001449 Resistor: 8.25K ohms, ±1%.

R15 M29/16001698 Resistor: 10M ohms, 0.5w, 10%.

RV1,RV2 M29/18008013 Varistor: 150V, 80J, GEV150LA20A.

U1 M29/19012000 Regulator. IC SG3532

VR1,VR2 M29/18035820 Zener Diode, 15V 1N5245B.

T1 M29/757P2 Transformer.

- - - - MISCELLANEOUS - - - 3 or S1 M29/20003300 Switch.

4 or F1 M29/09019400 Fuse Holder.

5 M29/09019500 Fuse, IEC Fast Blow.

6 M29/11021200 Cord Set (P1,P2,P11,P12).

M29/11029200 Cord Set (P3,P14).

7 M29/11022000 Strain Relief (P1,P2,P11,P12).

M29/11023900 Strain Relief (P3,P14).

8 M29/22049001 Screw: #8-32 x 0.375".

9 M29/22043200 Standoff.

10 M29/22010306 Washer: #8 x 0.333".

11 M29/22041501 Nut: #6-32 KEPS.

13 M29/22043201 Standoff.

14 M29/22041503 Nut: #10-32 KEPS.

15 M29/11003300 TY-WRAP.

or

M29/11024500 TY-WRAP.

16 M29/22039701 Wire Nut.

17 M29/07063200 Case (P2,P3,P12).

SYMBOL PART NO. DESCRIPTION

18 M29/07070400 Cover.

19 M29/35002600 Rubber feet (P2,P3).

20 M29/22010305 Washer: #6, Internal tooth, lock.

21 M29/51060102 Label, warning (P1,P2).

M29/51060100 Label, warning (P3).

M29/51067800 Label, warning (P11,P12,P14).

22 M29/51060200 Label, output (P1,P2,P3).

M29/51067700 Label, output (P11,P12,P14).

23 M29/07070500 Cover/Heatsink Assembly.

24 M29/22027708 Screw .

25 M29/51050900 Date Code Label.

P1 M29/25013900 Output Connector Assembly (P14).

W1 M29/250074290 Side terminal of F1 to Thermostat

(Black).

W2 Lead on T1 Tied to W5 with FASTON term to

(ON) term of S1 (Brown).

W3 Lead on T1 Tied to W4 with wire nut (Item 16)

brown/white.

W4 Lead on T1 Tied to W3 with wire nut (Item 16)

black/white.

W5 Lead on T1 Tied to W2 with FASTON term to (ON)

term of S1 (Black).

W6 On Cordset To end term of F1

(piggyback terminal of W17)(Black).

(Applies to P1,P2,P11,P12).

W7 On Cordset To ground stud. Green (P1,P2,P11,P12).

Green/Yellow (P3,P14).

W8 On Cordset Tied to W15 & W16 with wire nut

(White)(P1,P2,P11,P12). Blue (P3,P14).

W9 Lead on T1 To Tab J4 on PC Board Assembly (Blue).

W10 Lead on T1 To Tab J5 on PC Board Assembly (Blue).

W11 Lead on T1 To Tab J1 on PC Board Assembly (Red).

W12 Lead on T1 To Tab J2 on PC Board Assembly (Red).

W13 Lead on T1 To Tab J3 on PC Board Assembly

(Red/Yellow).

W14 M29/250074290 Thermostat to (OFF) terminal of S1

(Black).

W15 Lead on T1 Tied to W8 & W16 with wire nut

(Item 16)(White).

W16 Lead on PCB Tied to W8 & W15 with wire nut

(Item 16)(Black).

W17 M29/250074288 From Tab J7 on PCB to end tab of fuse

F1 (Black).

W18,W19 M29/250074204 Lead Assembly (Blue).

W20 M29/250074205 Lead Assembly (Brown).

W21,W22 M29/250074206 Lead Assembly (White).

W23 M29/26160311 Lead 2-3/8" lg. Strip " x (Brown).

W24 M29/26160399 Lead 2-3/4" lg. Strip " x (White).

A2 M29/91047000 HEA TSINK ASSEMBL Y.

1 M29/11024100 Heatsink (P1,P2,P3,P11,P12).

M29/11022400 Heatsink (P14).

2 M29/22047800 Screw: #4-40 x 0.25".

3 M29/09017000 Thermostat, TI 1NT01L-1928.

4 M29/13051800 Socket: TO-3 Therm. 8113PF603.

5 M29/31023200 Insulator, Bergquist 1009AC-24.

6 M29/22001109 Screw: #6-32 x 0.625".

7 M29/18030800 Transistor: 2N5885 SGS.

*COMPONENTS ADD ED, DE LETE D OR CHANGE D B Y P RODUC TION CH ANGES

10

Page 11

OUTLINE DIAGRAM

LBI-38751

EARLIER VERSION

HEATSINK ASSEMBLY & P . C. BOARD

13 VOLT POWER SUPPLY

11

Page 12

LBI-38751

OUTLINE DIAGRAM

PC BOARD

12

LA TER VERSION

Page 13

OUTLINE DIAGRAM

13 VOLT POWER SUPPLY

19A70647P1-P3, P11, P12, P14

LBI-38751

13

Page 14

LBI-38751

SCHEMATIC DIAGRAM

13 VOLT POWER SUPP LY

19A70467P1, P2, P11, P12

14

Page 15

SCHEMATIC DIAGRAM

LBI-38751

13 VOLT POWER SUPPLY

19A704647 P3, P14

15

Page 16

LBI-38751

ADAPTER CABLE

19B803437P 1

16

Loading...

Loading...