Ericsson Orion, 136-174 MHz ORION SYNTHESIZED TWO-WAY FM RADIO Service Section

LBI-38993

SERVICE SECTION

136-174 MHz ORION

SYNTHESIZED TWO-WAY FM RADIO

TABLE OF CONTENTS

DESCRIPTION...................................................................................................................... 2

INITIAL MEASUREMENTS................................................................................................. 2

TRANSMITTER....................................................................................................... 2

RECEIVER............................................................................................................... 2

MAINTENANCE................................................................................................................... 3

PREVENTIVE MAINTENANCE............................................................................. 3

DISASSEMBLY PROCEDURE................................................................................ 4

Page

ALIGNMENT PROCEDURES............................................................................................... 7

INTRODUCTION..................................................................................................... 7

TRACKING DATA.................................................................................................. 9

TEST FREQUENCIES............................................................................................. 9

SETTING TRACKING DATA.................................................................................10

TRANSMITTER ALIGNMENT.............................................................................................11

PA TRANSISTOR REPLACEMENT.......................................................................11

RECEIVER ALIGNMENT.....................................................................................................12

TEST EQUIPMENT REQUIRED.............................................................................12

ADJUSTMENT PROCEDURES...............................................................................12

SQUELCH ADJUSTMENT......................................................................................13

TROUBLESHOOTING GUIDE .............................................................................................13

INTRODUCTION.....................................................................................................13

MICROPHONICS.....................................................................................................13

SERVICEABLE PARTS...........................................................................................14

DIAGNOSTIC PROCEDURES..............................................................................................15

ADDITIONAL TOOLS REQUIRED........................................................................16

ERROR CODES.......................................................................................................19

1

L

BI-38993

2

DESCRIPTION

This section contains the information required

to service the ORION VHF two-way FM radio. Included

are disassembly procedures, alignment procedures, and

troubleshooting information (see Table of Contents).

This radio is adjusted by setting personality

parameters stored in the radio's computer memory.

Therefore, all radio alignment procedures require the use

of a Personal Computer (IBM PC or equivalent), along

with an EGE Programming Interface TQ3370, and an

ORION PC Programming Cable TQ3377. EGE PC

Programming Software Version 3.00 or later is also

required.

This radio is designed to be serviced by

replacement of modules and/or circuit boards. As such,

there are very few serviceable component parts contained

on any of the circuit boards within the radio. Normally,

defective boards should be replaced, and returned to an

Authorized EGE Service Center. Any serviceable parts

are listed in the troubleshooting guide for the individual

circuit boards.

INITIAL MEASUREMENTS

After the radio has been installed as described in

the Installation Manual, the following measurements

should be made by a certified electronics technician, an d

recorded for future reference:

TRANSMITTER

• RF Power into 50 ohm resistive load

• Forward Power into antenna

• Reflected Power from antenna

• Carrier Frequency

• Modulation Deviation

RECEIVER

• 12 dB SINAD Sensitivity from FM signal

generator

LBI-3899

3

INTERVAL

MAINTENANCE

PREVENTIVE MAINTENANCE

NOTE

To ensure high operating efficiency, and to prevent mechanical and electrical failures from interrupting system operations,

routine checks should be made of all mechanical and electrical equipment at regular intervals. This preventive maintenance

should include the checks as listed in Table 1, Maintenance Checks.

Table 1 - Maintenance Checks

MAINTENANCE CHECKS

CONNECTIONS - Ground connections and connections to the voltage source

should be periodically checked for tightness. Loose or poor connections to the

power source will cause excessive voltage drops and faulty operation. When

ground connections are not made directly to the battery, the connection from

the battery to vehicle chassis must be checked for low impedance. A high

impedance may cause excessive voltage drops and alternator noise problems.

Every

6

months

ELECTRICAL SYSTEM - Check the voltage regulator and alternator or

generator periodically to keep the electrical system within safe and economical

operating limits. Overvoltage is indicated when the battery loses water

rapidly. Usage of 1 or 2 ounces of water per cell per week is acceptable for

batteries in continuous operation. A weak battery will often cause excessive

noise or faulty operation.

MECHANICAL INSPECTION - Since mobile units are subject to constant

shock and vibration, check for loose plugs, nuts, screws, and parts to make

sure that nothing is working loose. Be sure that all screws are properly

torqued.

ANTENNA INSPECTION - The antenna, antenna base, and all contacts

should be kept clean and free from dirt or corrosion. If the antenna or its base

should become coated or poorly grounded, loss of radiation and a weak signal

will result.

ALIGNMENT - The transmitter and receiver measurements should be

checked periodically. Refer to the applicable Alignment Procedure and

troubleshooting sheet for typical voltage readings.

FREQUENCY CHECK - Check transmitter frequency and deviation, as

required by the FCC. Normally, these checks are made when the unit is first

put into operation, after the first six months, and once a year thereafter.

As

Required

Every 6

months

Every 6

months

As

Required

As

Required

3

L

BI-38993

4

DISASSEMBLY PROCEDURE

To Remove the Unit from the Mounting Bracket

1. Remove Microphone, Power, and Accessory/Remote

Control Cables, as required.

2. Remove the lock screws at the side of the radio unit,

using a No. 20 TORX

3. Pull the radio, and remove the mounting bracket.

To Gain Access to the Circuitry for Servicing

RF Power Amplifier Module

1. Remove the waterproof cover on the bottom of the

module, using #20 TORX

four mounting screws are captive.

2. Remove the inner shield by pulling the attached

handle.

Transceiver (TXRX) Module

1. Remove the waterproof top and bottom covers, using

a #20 TORX

are located on the bottom of the module. The screws

on the bottom cover are captive.

2. To expose the Logic/Audio/455 kHz IF circuitry,

remove the shield on top of the module by pulling

the attached handle.

3. To expose the Exciter/RX Front End circuitry,

remove the shield on the bottom of the module by

pulling the attached handle.

driver.

driver. Note that the

driver. Four cover mounting screws

NOTE

The VCO/Synthesizer circuitry is exposed by removing

the screws from the shield casting, also located on the

bottom of the module. However, this is not

recommended, except on extreme situations. If the shield

is removed, it should be replaced using the exact screw

torque and installation sequence given in LBI-38909.

Control Unit (Front Mounted)

1. Expose the Logic/Audio/455 kHz IF circuitry

according to Steps 1 and 2 in Transceiver (TXRX)

Module section.

2. Disconnect Flex Circuit PC2 from Connector J701,

by carefully disengaging the locking tab from each

side of the connector with a jeweler's screwdriver or

tweezers. Use extreme care to avoid damaging the

plating runs or surface-mounted components on t he

printed wire board (PWB) during this procedure.

3. Turn the radio upside down, and disengage the two

mounting screws, using a #10 TORX

driver. Be

sure to engage the screws in the captivation threads

on the Transceiver chassis. Do this by pulling each

screw upwards with tweezers or needle nose pliers,

while simultaneously turning the screw

counterclockwise with the TORX

driver. See LBI-

38909 for details.

4. Disengage the control unit from the Transceiver

chassis using a pivoting motion about the top edge of

the Transceiver chassis.

5. Disengage the four captive screws on the rear cover,

using a #10 TORX

driver. Slide the rear cover off

the Front Panel Assembly, using care to avoid

damaging the black "O-Ring" moisture gasket

attached to the rear cover. Note that the Flex Circuit

PC2 slides through a slot opening on the rear cover.

Control Head (Remote Mounting)

1. Disconnect Remote Control and Accessory cables,

using a small flat bladed screwdriver.

2. Remove the two side mounting screws from the

mounting bracket. Carefully remove the Control

Head assembly from the bracket.

LBI-3899

3

3. Disengage the four captive screws on the rear half

(also known as the Remote Interface Adapter, or

RIA) of the Control Head. Slide the two halves

apart, using care to avoid damaging the black "ORing" moisture gasket attached to the RIA.

4. Disconnect Flex Circuit PC2 from Connector J2, by

carefully disengaging the locking tab from each

side of the connector with a jeweler's screwdriver or

tweezers. Use extreme care to avoid damaging

plating runs or surface-mounted components in the

PWB during this procedure.

To Re-Assemble Unit after Servicing

Essentially follow the reverse of the preceding

instructions. However, in order to preserve moisture

seals, be sure to follow the EXACT

sequencing specifications for screw engagement during

re-assembly. These specifications are given in LBI-

38909.

torque and

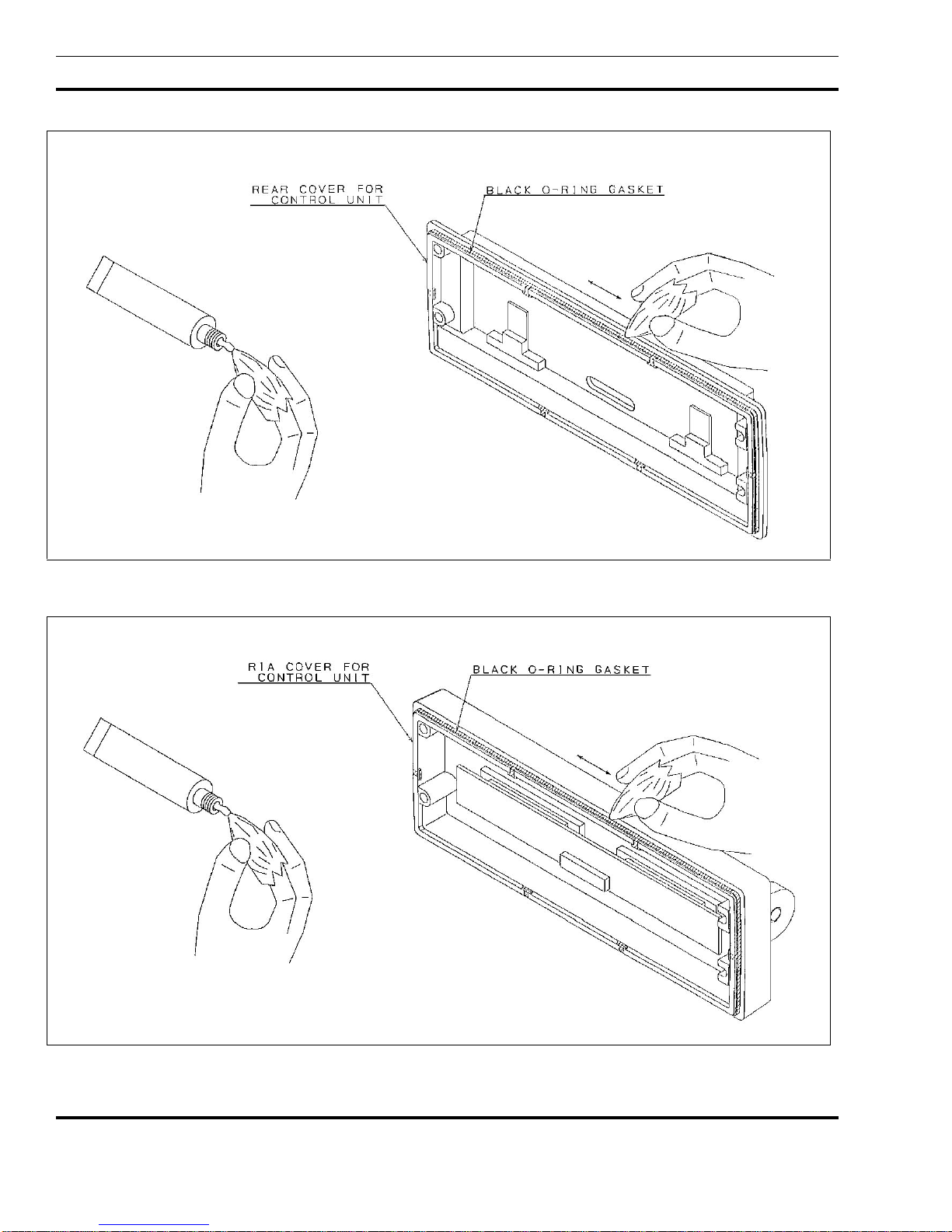

NOTE

For re-assembly of the Control Units (Front and Remote

Mounting) Revision "A" or later, be sure the black "ORing" is lubricated properly with "HIVAC-G" silicone

grease. (See Figures 1A and 1B for intructions.)

Steps:

1. Remove dust and dirt from the black O-Ring

gasket.

2 Apply proper amount of the silicone grease to cloth.

3. Put the silicone grease on throughout the surface of

the black O-Ring gasket evenly. (see Figures 1A

and 1B)

CAUTION

No fibers of the cloth must remain on the gasket after

silicone is applied

4. Wipe out protruded silicone grease from the

Rear/RIA Cover.

5

L

BI-38993

6

Figure 1A - Front Mount Control Unit "O-Ring" Lubrication

Figure 1B - Remote Mount Control Unit "O-Ring" Lubrication

3

ALIGNMENT PROCEDURES

INTRODUCTION

All operations of this radio are controlled by an

embedded digital computer, which is programmed with a

personality unique to the customer. In order to align and

test the radio, it must be programmed with a specific test

personality, which will allow conventional operation on

certain test frequencies. Furthermore, certain commands,

known as Test Mode Commands, cause the radio to

perform specific test functions. These will be noted as

required in the following alignment and troubleshooting

instructions.

In order to program a n ORION personality, the

radio and control unit must first be connected to a

Personal Computer via a PC Programming Cable and

hardware Programming Interface TQ3370 in one of the

configurations shown in Figures 2 and 3. Accessories

may be connected to the appropriate Accessory Cable

19B802554P1-P4 as needed.

The PC must be equipped with the EGE PC

Programming Software Version 4.0 or later. It is

assumed in this manual that the Service Technician is

familiar with the operation of the PC Programming

Software Programs "EDACS3" and "MRKMAINT."

Consult the PC Programming Software manuals for

further details regarding this software.

LBI-3899

CAUTION

Before bench testing the radio, be sure of the output

voltage characteristics of your bench power supply.

To protect the transmitter power output transistors from

possible instant destruction, the following input voltages

must not be exceeded

Transmitter unkeyed: 16.5 Volts

Transmitter keyed 16.3 Volts

(50 ohms resistive load)

Transmitter keyed 14.0 Volts

(no load or non-resistive load):

These voltages are specified at the normal vehicle

battery terminals of the radio and take the voltage drop

of standard cables into account. The voltage limits

shown for a non-optimum load is for "worst case"

conditions. For antenna mismatches likely to be

encountered in practice, the actual limit will approach

the 16.3 Volt figure.

Routine transmitter tests should be performed at EIA

Standard Test Voltages (13.6 VDC for loads of 6 to 16

amperes; 13.4 VDC for loads of 16 to 36 amperes).

Input voltages must not exceed the limits shown, even

for transient peaks of short duration.

Many commonly used bench power supplies cannot

meet these requirements for load regulation and

transient voltage suppression. Bench supplies which

employ "brute force" regulation and filtering (such as

Lapp Model 73) may be usable when operated in

parallel with a 12 Volt automotive storage battery.

7

L

BI-38993

8

Figure 2 - ORION Programming Configurations (USA)

Figure 3 - ORION Programming Configurations (EURO)

Loading...

Loading...