Page 1

INSTRUCTION SHEET

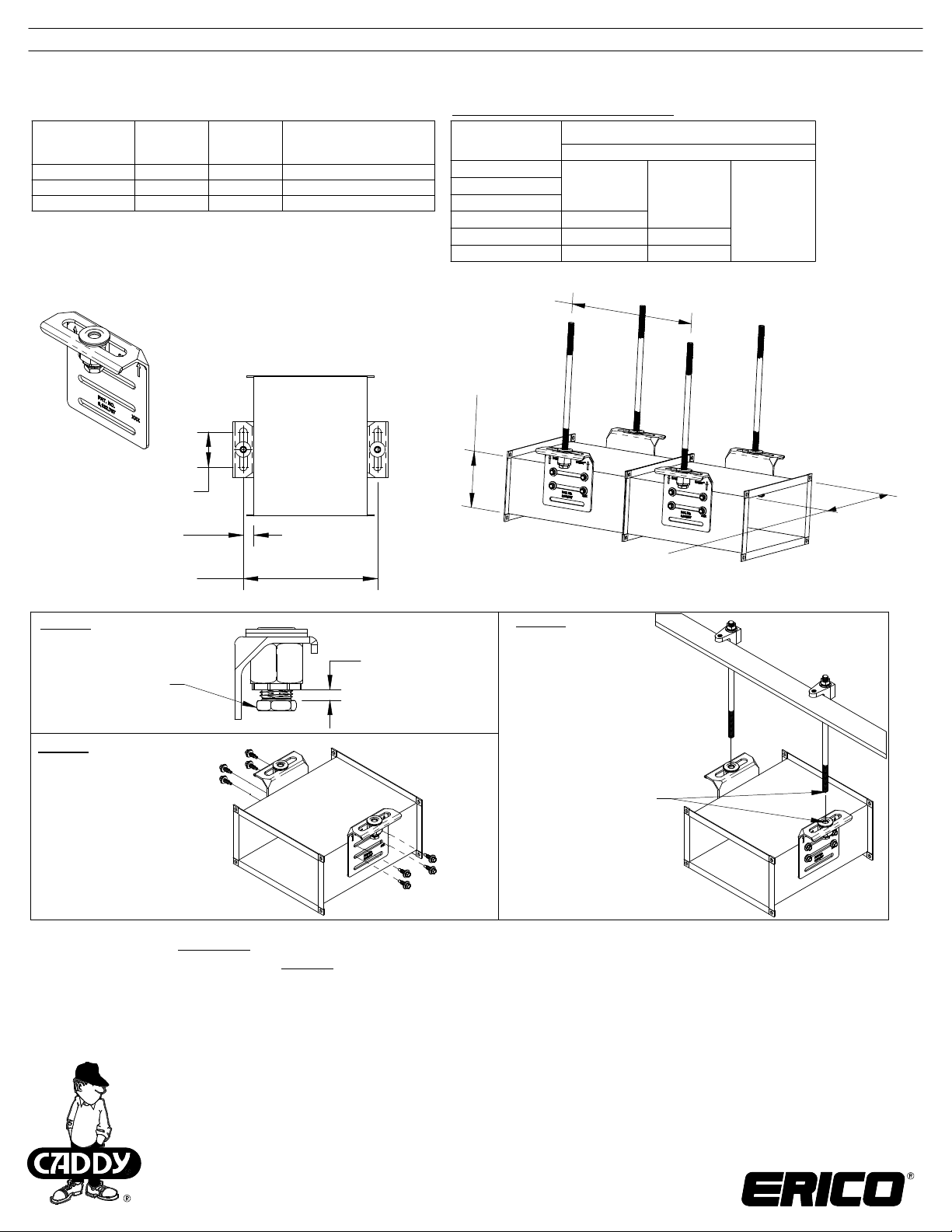

CADDY® ROD LOCK

Top-Mount Duct Bracket

Part Number

CRLD37TEG N/A 3/8" 600 lbs [2,650 N]

CRLDM8TEG 390017 M8 600 lbs [2,650 N]

CRLDM10TEG 390018 M10 600 lbs [2,650 N]

*Note: (4) screws are required for non-duct application.

**CRLD37TEG (3/8") and CRLDM10TEG (M10) were verified by the

SMACNA Testing and Research Institute to be acceptable

alternatives to the duct hanger systems described in the

/SMACNA HVAC Duct Construction Standards (HVAC-DCS)

®

ANSI

3rd edition, Chapter 5, Tables 5-1 and 5-1M

Article

Number

Rod Size

2-1/2" (64mm)

Slot Width

3/4" (19mm)

Typical

Duct Width

+ 1-1/2" (38mm)

Load Rating for

general applications*

(3.0 safety factor)

Rectangular Duct Application

Max. Half of Duct

Perimeter***

P/2 = 30"

P/2 = 72"

P/2 = 96"

P/2 = 120" -P/2 = 168" -- -P/2 = 192" -- --

***P/2 = (Duct Height) + (Duct Width)

3/8", M8, M10 Threaded Rod Sizes**

L = 10ft [3m]

"L" Dimension

Duct Height

Duct Width

60" (1,524mm) Maximum

"L" Dimension

L = 8ft [2.4m]

L = 5ft [1.5m]

Step 0:

Rotate lock nut

counter-clockwise

until reaches

stopping position

Step 1:

Install four (4)

self-drilling screws

(included) for

each bracket.

WARNING:

NOTE: All load ratings are for static conditions and do not account for dynamic loading such as wind, water or seismic loads, unless otherwise noted.

The customer is responsible for:

a. Conformance to all governing codes.

b. The integrity of structures to which the products are attached, including their capability of safely accepting the loads imposed, as evaluated by a qualified

engineer.

c. Using appropriate industry standard hardware as noted above.

SAFETY INSTRUCTIONS:

All governing codes and regulations and those required by the job site must be observed.

Always use appropriate safety equipment such as eye protection, hard hat, and gloves as appropriate to the application.

ANSI is a registered trademark of American National Standards Institute

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

Maximum open

position

ERICO products shall be installed and used only as indicated in ERICO product instruction sheets and training materials. Instruction sheets are available at 1.

www.erico.com and from your ERICO customer service representative.

ERICO products must never be used for a purpose other than the purpose for which they were designed or in a manner that exceeds specified load ratings.2.

All instructions must be completely followed to ensure proper and safe installation and performance. 3.

Improper installation, misuse, misapplication or other failure to completely follow ERICO's instructions and warnings may cause product malfunction, property 4.

damage, serious bodily injury and death.

Products that are manufactured using spring steel components shall be used only in a non-corrosive indoor environment. 5.

All pipe supports, hangers, intermediate components and structural attachments must ONLY be used as described herein and are NEVER to be used for any 6.

other purpose.

Step 2:

Lift duct into place.

Push bracket on

to threaded rod.

both sides

TECHNICA L SUPPORT:

www.erico.com

CFS474_E

1 OF 2

© 2013, 2014 ERICO International Corporation.

Page 2

INSTRUCTION SHEET

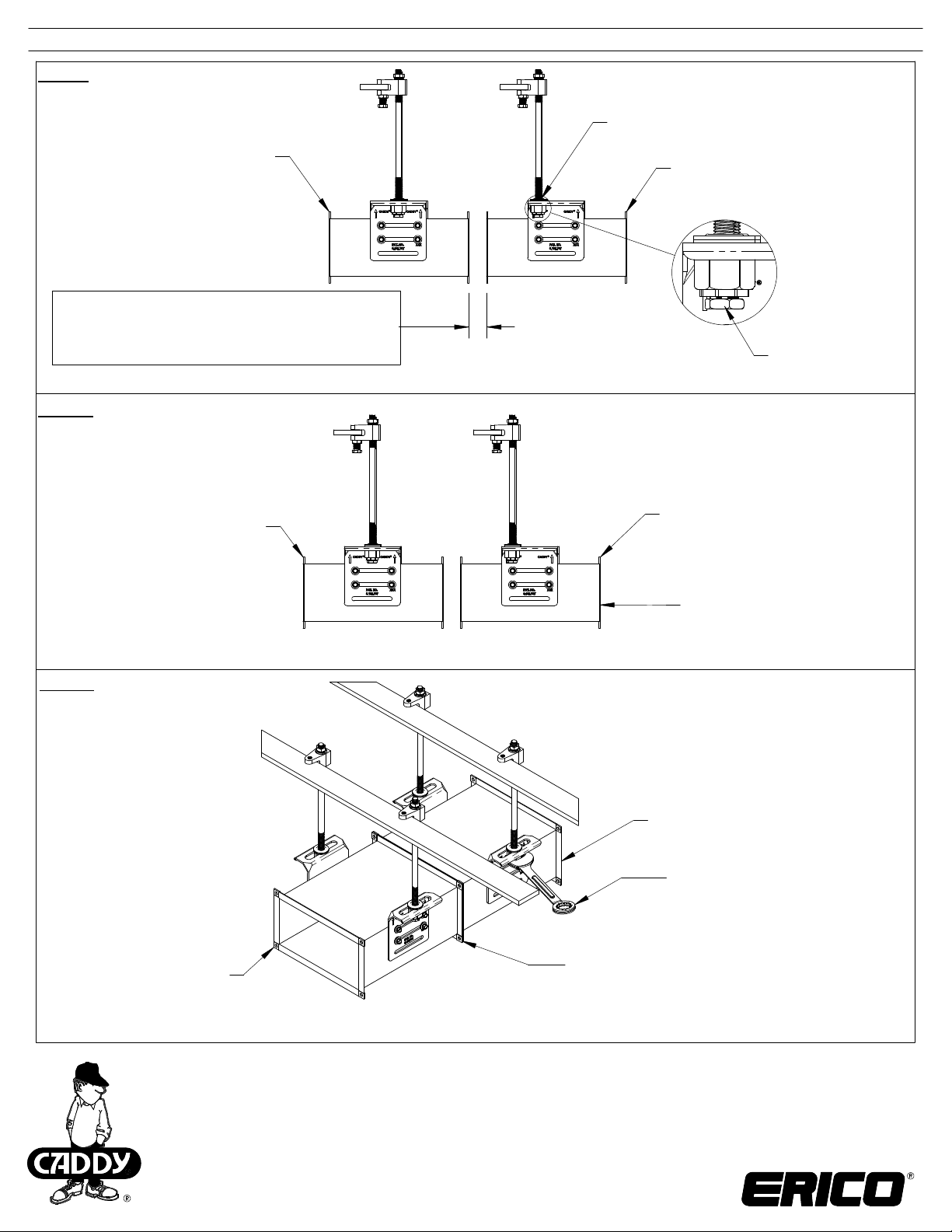

Step 3:

Position duct for assembly

Positioned at nearest end

Previously installed duct

Gap

1-1/2" [38mm] for Flanged duct

or

1/2" - 1" [13mm - 25mm] for Slip & Drive duct

Step 4:

Push duct together.

Previously installed duct

New duct

Tighten lock nut

New duct

Push new duct toward

previously installed duct.

Step 5:

Complete duct joint.

Previously installed duct

New duct

Fine adjust duct height by

wrench:

Clockwise = duct down

Counter-Clockwise = duct up

Complete duct joint for:

Flange connection

or

Slip & Drive connection.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

TECHNICA L SUPPORT:

www.erico.com

CFS474_E

2 OF 2

© 2013, 2014 ERICO International Corporation.

Loading...

Loading...