Page 1

SURGE SUPPRESSOR

Handbook No:

HB-HBCR-109

© Copyright

INSTALLATION INSTRUCTIONS

Includes TDS-AR Alarm Relay

and TDS-SC Surge Counter

www.erico.com

ISSUE: 3 April 2003

Page 2

INSIDE FRONT COVER

(Blank)

Page 3

CONTENTS

Page

Page

1. Warnings ... ... ... ... ... ... ... ... ... ... ... 4

2. Introduction ... ... ... ... ... ... ... ... ... ... 5

3. Quick Installation Guide ... ... ... ... ... ... 5

4. Protection Concepts .. ... ... ... ... ... ... ... 6

5. Mounting ... ... ... ... ... ... ... ... ... ... ... 7

6. Voltage Ratings ... ... ... ... ... ... ... ... ... 8

7. Protection Modes .. ... ... ... ... ... ... ... ... 8

8. Conductor Sizes ... ... ... ... ... ... ... ... ... 10

9. Conductor Length ... ... ... ... ... ... ... ... 11

10. RCD, ELCB ... ... ... ... ... ... ... ... ... ... 14

11. Isolation and Fusing .. ... ... ... ... ... ... 15

12. Status Indication ... ... ... ... ... ... ... ... 17

13. Maintenance & Testing .. ... ... ... ... ... 18

14. Alarm Relay (TDS-AR) .. ... ... ... ... ... 19

15. Surge Counter (TDS-SC) ... ... ... ... ... 26

16. Typical Domestic Installation ... ... ... 29

17. Extended Warranty ... ... ... ... ... ... ... 30

18. Six Point Plan ... ... ... ... ... ... ... ... ... 31

PAGE 3

Page 4

DSD INSTALLATION INSTRUCTIONS

1. WARNINGS

• Prior to installation ensure that the unit is

of the correct voltage and frequency, and is

the type recommended for the local power

distribution, and for the equipment being

protected.

• Hazardous voltages may exist internally to

the modules. The units should be installed

(and replaced) only by qualified personnel

in accordance with all relevant Electricity

Safety Standards.

• Do not power three phase connected units

without the upstream neutral connected.

Failure to do so may damage the units and/

or the load.

• Where the unit has an earth terminal, this

must be connected to a low impedance earth

(<10 Ω) for correct operation.

PAGE 4

• If connecting to the TDS Opto-coupler

alarm outputs do not reverse the +/connections or exceed the maximum

permissible ratings as damage may occur.

• Use only the TDS-AR Alarm Relay with

TDS-DINLINE.

• Use only TDS-SC Surge Counter with TDS

DINLINE.

• Units must be installed in an enclosure or

panel, ensure this does not cause the units

environmental ratings to be exceeded.

• Do not “Megger” or “Flash Test” circuits

with TDS-DINLINE units installed.

• All instructions must be followed to ensure

correct and safe operation.

• Diagrams are illustrative only, and should

not be relied on in isolation.

Page 5

2. INTRODUCTION

This Installation Manual details the preferred

procedure for the installation of TDSDINLINE™ SURGE SUPPRESSORS and

options.

The TDS-DINLINE SURGE SUPPRESSORS

are available in a variety of surge ratings,

which are packaged in the 2M, 4M and 8M

“DIN 43 880” compliant enclosures. They are

designed to suit many distribution systems

including TN-C, TN-S, TN-C-S (MEN) and TT.

They can be selected for use with distribution

systems with nominal RMS voltages of 110/

120, 220/230/240V or 277V at frequencies of

50/60 Hz.

Recommended installation and connection of

the ALARM RELAY (TDS-AR) is detailed in

Section 14. Installation and connection of the

Surge Counter (TDS-SC) is detailed in section

15.

3. QUICK INSTALLATION GUIDE

Install in the following manner:

1. Ensure that power is removed from the area

and circuits to be connected.

2. Install the DIN mounting rail, if not fitted.

3. Snap lock the Surge Suppressor to the rail.

4. Connect wiring to the indicated terminals.

5. Ensure compliance with supplied

instructions.

6. Apply power and observe correct operation

of Status Indicators, and alarm facilities if

utilised.

PAGE 5

Page 6

DSD INSTALLATION INSTRUCTIONS

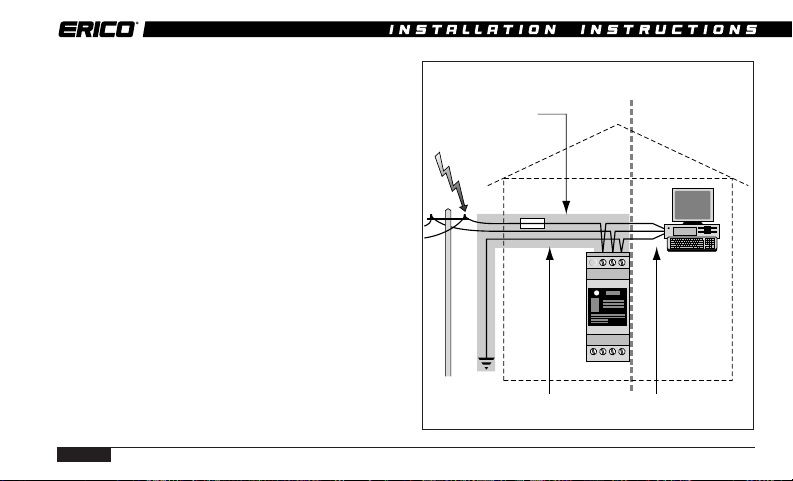

4. PROTECTION CONCEPTS

To optimise effectiveness of installed

protection a concept of “Unprotected” and

“Protected” wiring should be followed. Wiring

from the transient source to the Surge

Suppressor should be considered

“Unprotected” and kept remote from all other

wiring (approximately 300mm) where possible.

Wiring on the equipment side of the Surge

Suppressor should be considered “Protected”.

The separation of “Protected” from

“Unprotected” wiring is recommended in order

to minimise the risk of transients conducted on

“Unprotected” wiring cross coupling on to

“Protected” circuits, thus compromising the

level of protection available from the Surge

Suppressor.

PAGE 6

Keep other cables and

equipment away

from this area.

Unprotected zone Protected zone

Page 7

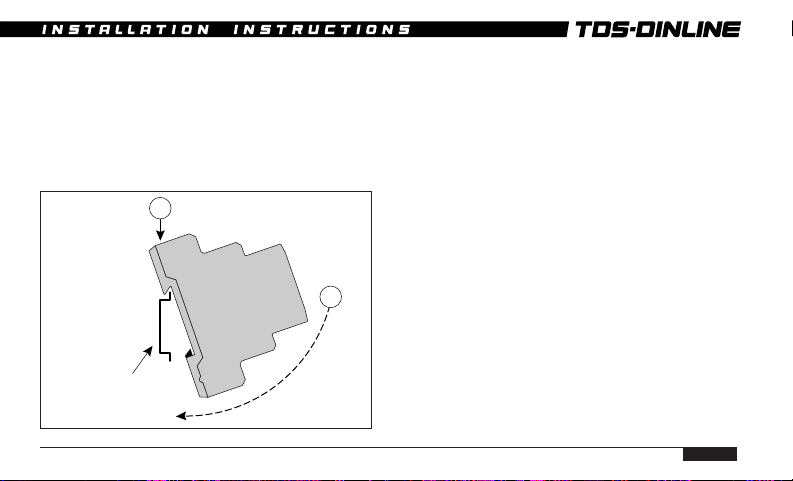

5. MOUNTING

Surge Suppressors are designed to clip to

35mm top hat DIN rails (to Standard

EN50022). Unless otherwise mechanically

restrained, use horizontal DIN rails with the

Surge Suppressor fixing clip to the bottom, ie

label text the correct way up.

Units must be installed in an enclosure or

panel to provide the appropriate degree of

electrical and environmental protection.

35 mm DIN rail

(EN50022)

1

Only use enclosures that:

• Do not cause the internal temperature to

exceed 55 deg C.

• Provide adequate electrical and safety

2

protection.

• Prevent the ingress of moisture and water.

• Allow Surge Suppressor Status Indication

to be inspected.

PAGE 7

Page 8

DSD INSTALLATION INSTRUCTIONS

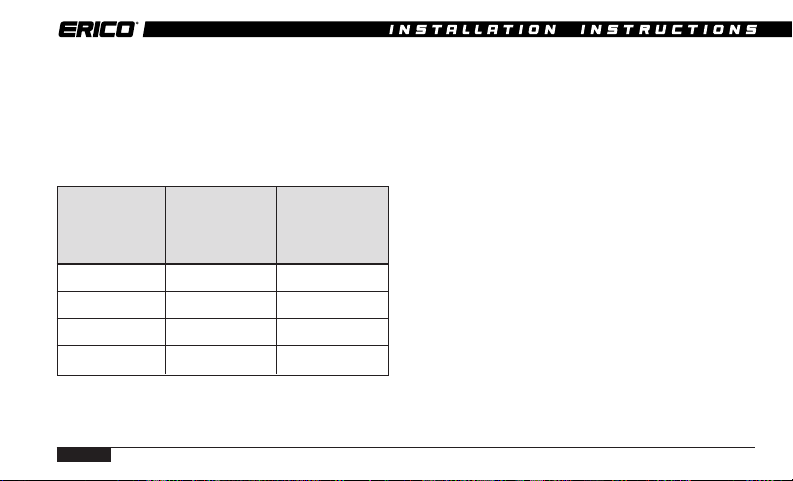

6. VOLTAGE RATINGS

Ensure that the correct voltage rating unit is

installed. Exceeding the nominal voltage

rating under transient conditions may affect

product life. Do not exceed the Maximum

Permissible Abnormal Over Voltage rating.

Model Nominal Voltage Permissible

TDS XXX-120 110-120 Vac 240Vac

TDS XXX-208 208 Vac 260 Vac

TDS XXX-240 220-240 Vac 415 Vac

TDS XXX-277 220-277 Vac 480 Vac

PAGE 8

Maximum

Abnormal

Over Voltage

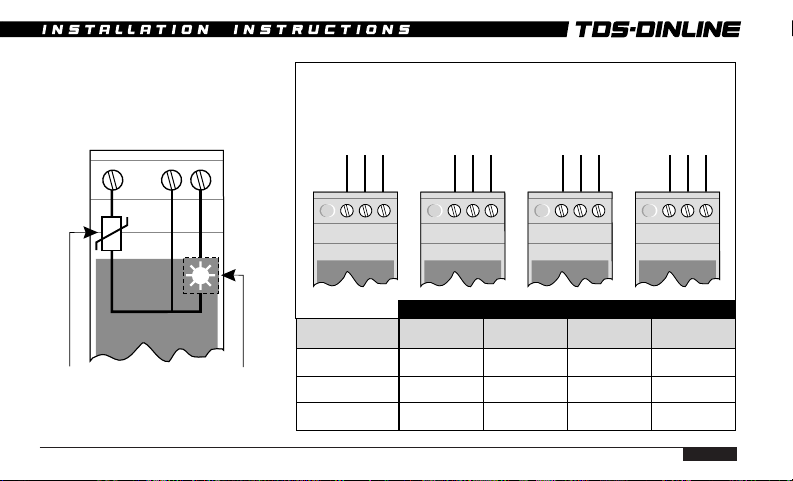

7. PROTECTION MODES

Protection Modes refers to how the internal

protection is arranged and applied to the

circuit to be protected.

TDS-DINLINE Surge Suppressors are Single

Mode units which provide protection between

two conductors connected to the terminals

marked T1 and T2. These units can be

connected to provide protection from PhaseNeutral* or Phase-Earth* or Neutral-Earth.

To allow the status indication and alarm

circuitry to operate, a neutral connection is

required for Phase-Earth* configured units,

and a Phase* connection is required for

Neutral-Earth configured units.

* Note. Some users may be used to the

terminology “Active” or “Line”, in place of

“Phase”. For consistency “Phase” is used

throughout this documentation.

Page 9

SINGLE MODE UNITS

CONNECTION OPTIONS

Protection

T1

T2

X

Status

Electronics

Ph-E ProtectionPh-N Protection N-E Protection Ph-Ph Protection

Ph

NPh

E

Ph N

T1 T2 XT1 T2 X

PROTECTION MODE

Terminals Ph-N Ph-E N-E Ph

T1 Ph E E Ph

T2 NPhNPh

X PhNPhPh

NPh

E

T1 T2 X

Ph

x

T1 T2 X

PhyPh

x - Phy

PAGE 9

x

x

y

x

Page 10

DSD INSTALLATION INSTRUCTIONS

Phase to Phase protection can also be provided

by Surge Suppressors, provided that the

nominal and maximum voltage ratings are not

exceeded.

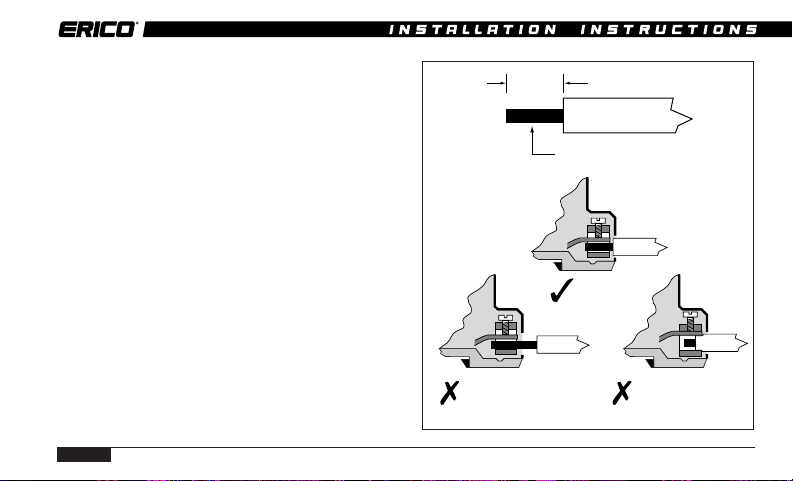

8. CONDUCTOR SIZES

Each Surge Suppressor terminal is designed

to accept wire sizes from 1.5mm2 to 6mm2,

solid or stranded conductor. Insulation should

be stripped back 8mm before terminating into

the tunnel terminal.

Where two conductors require termination in

the same tunnel terminal, conductors should

be limited to a maximum size of 4mm2.

Do not use excessive force when tightening the

terminal.

PAGE 10

8mm

Insulation cut

back too far

1.5-6 mm

Correct

2

conductor

Insulation not cut

back far enough

Page 11

9 CONDUCTOR LENGTH

To optimise transient performance, attempt to

connect units in the “Preferred” fashion as

depicted on pages 11 and 12. Some units have

double terminals to facilitate this. Take care

not to run parallel “protected” and

“unprotected” wiring.

Where this is not possible due to layout or

conductor sizing, use the “Non-preferred” “T”

connection method as depicted on page 13. With

this connection method, the “T” lead length

should be kept as short as practicable (less than

100mm) and wires should be bundled together.

The “T” conductor should be equal in size to the

main conductor, up to a maximum of 6mm2.

PREFERRED CONNECTION METHOD

Separate wires

Ph Ph Ph

Ph

Ph Ph

CORRECT

INCORRECT

NON-PREFERRED CONNECTION METHOD

Keep

Short

Keep Close

T1 T2

T1 T2

CORRECT

INCORRECT

PAGE 11

Page 12

Supply

Ph

N

E

DSD INSTALLATION INSTRUCTIONS

PREFERRED CONNECTION METHOD EXAMPLE FOR Ph-E PROTECTION

Supply

Ph

N

E

Maximum

conductor

size 6mm

T2T

T

1T1

X

2

Maximum

2

conductor

size 2x4 mm

or 1x6 mm

T2T1X

Protected

Equipment

Maximum

conductor

size 4mm

2

Protected

Equipment

2

2

PAGE 12

TD140-2S

TDS1160-8S

Page 13

Supply

Ph

N

E

Bundle

together

NON-PREFERRED "T" CONNECTION METHOD EXAMPLE FOR Ph-E PROTECTION

Supply

Protected

Equipment

Keep as short

as practical

Ph

N

E

Bundle

together

Protected

Equipment

Keep as short

as practical

T2T1X T2T

2

Maximum

conductor

size 6mm

Maximum

conductor

size 6mm

TDS 140-2S

T1T

1

2

TDS1160-8S

X

2

PAGE 13

Page 14

DSD INSTALLATION INSTRUCTIONS

10. RCD, ELCB

Where RCDs/ELCBs (Residual Current

Devices / Earth Leakage Circuit Breakers) are

fitted the Surge Suppressor units should be

installed in the circuit prior to these devices

RCD

ELCB

Protected

Equipment

CORRECT

PAGE 14

(ie upstream). Where this can not be avoided

and RCDs/ELCBs are installed upstream,

nuisance tripping of the RCD/ELCB may occur

during transient activity.

Contact your local representative for advice if

upstream RCDs/ELCBs can not be avoided.

RCD

ELCB

PhPh

INCORRECT

Page 15

11. ISOLATION AND FUSING

Overcurrent and short circuit protection must

be provided to protect the Surge Suppressor

and associated wiring if a fault develops. The

overcurrent protection should be installed in

such a manner to also provide a means of

isolating the TDS-DINLINE module from the

mains supply. This is an important safety

consideration and is required in the event that

any future maintenance or testing is needed.

For Surge Suppressors installed in the

“preferred” connection method (page 12),

upstream overcurrent protection should be

installed based on the maximum current

carrying capacity of the conductors.

Australian regulations AS3000-1991, Table B2

specifies the following upstream protection for

the protection of single phase circuits.

A mm

Ph

2

A mm

Ph Ph

2

Conductor Size Required Fuse

2

CB or Fuse Rewirable Fuse

A mm

2

1.5 mm

2

2.5 mm

2

4.0 mm

2

6.0 mm

Fuse selection based on maximum current carrying capacity of

conductor. Smaller rated fuse may be selected if required.

CB = Circuit Breaker.

16A 12A

20A 16A

25A 20A

32A 25A

PAGE 15

Page 16

DSD INSTALLATION INSTRUCTIONS

For Surge Suppressors installed in the “nonpreferred” connection method (page 13),

depending upon the size and fusing in the

main circuit, the “T” connection may require

independent fusing to be installed.

Circuits with upstream protection rated at

greater than 100A must have a 100A HRC

fuse or circuit breaker installed in the T

connection as detailed by the following

diagram.

Warning:

Isolation/fusing installed in the “T” connection

may disconnect the Surge Suppressor from the

circuit/equipment to be protected. The remote

alarm contacts of the ALARM RELAY (TDSAR) should be used to detect this occurrence.

Operation of the isolation/fuse will remove the

protection from the circuit.

PAGE 16

Supply

A

A mm

2

B

B mm

2

Ph

Supply Upstream* T-Connection Required

Conductor Protection Size T-Connection

Size Fuse

2

A fuse rating B mm2 B fuse rating

A mm

2

1.5 mm

2.5 mm

4.0 mm

6.0 mm

>6.0 mm

>6 mm

* Fuse rating A selection based on maximum current carrying capacity of

conductor. Smaller rating fuse may be selected ir required.

** Short circuit protection selection based on I

16A 1.5 - 6 mm2Nil

2

20A 2.5 - 6 mm2Nil

2

25A 4 - 6 mm

2

32A 6 mm

2

<100A 6 mm

2

>100A 6 mm

2

2

2

2

t rating of cable and fuse.

2

Nil

Nil

Nil**

100 A**

Page 17

The selection of the 100A HRC fuse is not

based on the load carrying capacity of the

main circuit but the “T” connection I2t rating.

The “T” connection under normal conditions

does not carry the load current. Only under

surge or fault conditions does this connection

carry large currents. Under Australian

Standard AS3008.1-1989 it is permissible to

rate the protection for these types of circuits

by the I2t ratings of the cable. For installation

of Surge Suppressor in countries not covered

by these regulations it is recommended that

this practice be followed, unless it conflicts

with the compliance of the local regulations.

12. STATUS INDICATION

A characteristic of all transient and surge

protection devices is that they degrade in

proportion to the magnitude and number of

incident surges to which they have been

subjected. Status indication should be

periodically monitored to determine if

replacement is required.

2S units

These units are identified by the single Status

Indicator provided on the front panel. When

power is applied and full surge capacity is

available the Status Indicator will be

illuminated. Should the indicator fail to

illuminate the Surge Suppressor should be

replaced, as optimum protection is no longer

provided. Note: The Status Indicator will not

operate (regardless of surge capacity) if power

is not available.

4S units

These units are identified by two Status

Indicators which are provided on the front

panel. These Status Indicators monitor

PAGE 17

Page 18

DSD INSTALLATION INSTRUCTIONS

separate protection segments. Each Status

Indicator is illuminated when power is

available and when full surge capacity is

available by that segment. The Surge

Suppressor should be replaced if either

Status Indicator fails to illuminate. Note: The

Status Indicators will not operate (regardless

of surge capacity) if power is not available.

8S units

These units are identified by four Status

Indicators which operate similar to above. The

Surge Suppressor should be replaced if any

two or more Status Indicators fail to

illuminate.

PAGE 18

13. MAINTENANCE & TESTING

Before removing any unit from service

ensure that power to the device is

isolated. Replacement of any Surge

Suppressor should only be undertaken in

accordance with all relevant Electricity

and Safety Standards by suitably

qualified personnel.

TDS-DINLINE units should be inspected

periodically, and also following any periods of

lightning or transient activity. Check the

status indicators and replace if recommended

in Section 12 -STATUS INDICATION.

For high transient exposure sites or those of a

critical operational nature, it is recommended

that the alarm outputs be monitored to

provide an additional warning of reduced

capacity (refer Section 14 - ALARM RELAYTDS-AR).

Page 19

TDS-DINLINE Surge Suppressor units are

designed for optimum performance under

severe transient activity. To provide this

performance, electronic components in the

unit are encased in a patented proprietary,

shock and thermal absorbent compound.

Units cannot be serviced, they must be

replaced.

Do not attempt to open or tamper with the

units in any way as this may compromise

performance and will void warranty.

Do not “Megger” or perform other types of

electrical tests that apply voltages greater

than the nominal operating voltage of the

Surge Suppressor. The Suppressor will

attempt to limit these voltages thereby

affecting the test result. Where these tests

must be performed, remove the Surge

Suppressor from circuit first.

14. ALARM RELAY (TDS-AR)

The Surge Suppressor status monitoring

circuit which provides the visual status

display also provides a low voltage optocoupler alarm output circuit. This should only

be connected to the TDS ALARM RELAY. The

TDS-AR voltage free alarm contacts may then

provide output to external alarm systems or

remote monitoring circuits.

The TDS ALARM RELAY provides fully

isolated potential free change-over alarm

output contacts. One TDS-AR can be used per

Suppressor opto-coupler alarm or Multiple

Suppressor opto-coupler alarms can be

connected in series to the one TDS-AR to

provide a common output.

PAGE 19

Page 20

DSD INSTALLATION INSTRUCTIONS

1 x TDS-AR supports:

20 x TDS140-2S

or 10 x TDS 180-4S

or 5 x TDS 1160-8S

or relative combinations.

It is recommended that the TDS-AR unit be

powered from the same power circuit that

feeds to the Surge Suppressor being

monitored, however it can be powered from

other circuits. This allows for example, one

TDS-AR unit to be connected to separate

Surge Suppressors that are protecting a three

phase circuit.

To satisfy Australian wiring regulations the

phase supply to the TDS-AR needs to be

protected by an overcurrent fuse/circuit

breaker. The overcurrent protection should be

selected according to the wiring size

PAGE 20

connecting to the TDS-AR Phase and Neutral

terminals. For reference a table of values is

given on page 24.

Note. Depending upon the usage of the TDSAR output contacts, failure of power to the

TDS-AR may be interpreted as a failure of one

or more Surge Suppressors. Visual inspection

of all units Status displays would determine

this.

Page 21

STATUS

Protection Operational

Protection Alarm

Fault Mode

DISPLAY

EXPLANATION

Normal

16

Fault

12

14

Normal operation

Normal (green) indicator ON

Red indicator OFF

Relay is energised

Power is supplied

Normal

Normal

16

Fault

12

Fault

14

Surge Suppressor in alarm mode

or power to Suppressor has been

removed

Normal (green) indicator OFF

Red indicator ON

Relay is de-energised

Power is supplied

Power to TDS-AR removed

Protection status unknown

Normal (green) indicator OFF

Red indicator OFF

Relay is de-energised

Power is OFF

16

12

14

PAGE 21

Page 22

Ph

DSD INSTALLATION INSTRUCTIONS

SINGLE ALARM CONNECTION EXAMPLE

To transient

N

E

protected

equipment

TDS140-2S

PAGE 22

T2T1X

NL

TDS-AR

✽

Opto-coupler output

✽

✽

WARNING - Connections are polarity sensitive. Do not reverse.

Voltage free contacts

To remote

alarm

circuit

Page 23

MULTIPLE ALARM CONNECTION EXAMPLE

T1T

1

T2T2X

X

T

2T1

✽✽

TDS180-4S TDS140-2S

✽

WARNING - Connections are polarity sensitive. Do not reverse.

NL

TDS-AR

Voltage free contacts

✽

To remote

alarm

circuit

PAGE 23

Page 24

DSD INSTALLATION INSTRUCTIONS

TDS-AR SPECIFICATIONS:

Output Contact Ratings

Nominal switching capacity

Maximum switching power

Maximum switching voltage

Maximum switching current

Input to output isolation

Note: TDS-AR operates on supply voltages

of 100-480V Vrms.

TDS-AR OVERCURRENT PROTECTION

The power supply to the TDS-AR circuit must

be provided with upstream overcurrent

protection. The fuse rating should be based on

PAGE 24

2A 30VDC

60W 125VA

220VDC, 250VAC

2A

4kV

the wiring size used to connect to the TDS-AR

Ph & N terminals.

Australian regulations AS3000-1991, Table B2

specifies the following upstream protection for

single phase circuits, unenclosed in air.

Cable Size HRC Fuse or CB Rewirable Fuse

2

1.5mm

2.5mm

4mm

6mm

16A 12A

2

20A 16A

2

25A 20A

2

32A 25A

Where overcurrent protection of the

appropriate rating or smaller is already fitted

in the upstream circuit, overcurrent protection

at the TDS-AR will not be required.

Page 25

ALARM TESTING

Testing of the Alarm Relay which is connected

to a fully functional Surge Suppressor unit

can be accomplished by removing power to the

Surge Suppressor only. The Alarm Relay

Status indication and output contacts should

alter from the Normal to Fault condition.

Testing of the Alarm Relay unit alone may be

accomplished by disconnecting the + / connections to the unit. When power is applied

the “Fault” Status Indicator should be

illuminated. By connecting the + / - terminals

together, the “Normal” Status Indicator should

be illuminated. The output contacts should

alter to the appropriate state.

USE OF OTHER INTERFACES

Only ERICO TDS-AR units are recommended

for the interfacing of equipment to the TDSDINLINE opto-coupler alarm output circuit.

The direct connection of other equipment to the

opto-coupler alarm output circuit may not

provide sufficient isolation or exceed the optocoupler specifications. This may damage the

Surge Suppressor and/or the connected

equipment. Warranty may be voided under such

circumstances.

SURGE SUPPRESSOR OPTO-COUPLER ALARM

Opto-coupler

Optocoupler

Protection

diode

Vce = 30V DC

Ic = 150 mA

Note: TDS XXX-4S and

TDS XXX-8S have

respectively 2 and 4

opto-couples connected

internally in series.

PAGE 25

Page 26

DSD INSTALLATION INSTRUCTIONS

15. TDS-SC SURGE COUNTER

The Surge Counter is designed to interface to

the TDS DINLINE units via the supplied CT,

to record the number of surges and impulses

diverted. This is achieved by measuring the

transient current diverted by the TDS

protection device. It is important that the CT

be installed into the circuit where it is

measuring the surge current only, and not

where mains load current is passed through

the core. Method 1 and Method 2 (page 28)

detail the correct connection. Page 27 shows

an incorrect connection as the equipment load

current is passed through the CT core. The

magnetic field from the load carrying

conductor may cause the CT core to saturate.

The surge Counter may fail to record any

transients and additionally dangerously high

voltages may be present on the TDS-SC & CT

terminals.

PAGE 26

WARNINGS

• Do not install CT into load current carrying

circuits.

• CT must be installed into surge current

path only.

• Only install the CT and Surge Counter after

all power and transient sources are

removed and isolated from the equipment

the Surge Counter is to monitor.

• Do not open circuit or disconnect

connections on the secondary of the CT

when monitored circuit is powered or

connected to possible transient source.

Hazardous voltages may exist in the

secondary circuit and in the CT/TDS-SC if

these instructions are not followed.

Page 27

• Only this CT should be used with the TDSSC Surge Counter, other suppliers devices

may not operate correctly or pose a safety

hazard.

• These instructions should only be carried

out by qualified personnel in accordance

with relevant national electrical and safety

codes. Hazardous voltage may exist in the

monitored system.

SURGE COUNTER CONNECTION METHODS*

TDS-SC

0586

LOAD

C1C2

CT

Incorrect Method

* Typical connections only

PAGE 27

Page 28

DSD INSTALLATION INSTRUCTIONS

SURGE COUNTER CONNECTION METHODS*

TDS Surge

Suppressor

PAGE 28

0586

C1C2

TDS-SC

Surge

Current

LOAD

0586

C1C2

TDS-SC

CT

Correct Method 1 Correct Method 2

* Typical connections only

Surge

Current

CT

LOAD

Page 29

14. TYPICAL DOMESTIC INSTALLATION (from 80A fused supply)

A

TDS140-2S-277

N

T2T1X

L

L

I

I

G

H

T

S

RCD

G

ELCB

H

T

S

G

G

G

P

P

O

O

G

P

P

O

O

RCD Protected

Neutral Neutral Earth

MEN Link

PAGE 29

Page 30

DSD INSTALLATION INSTRUCTIONS

17. EXTENDED WARRANTY

This product has a limited warranty to be free

from defects in materials and workmanship for a

period of five (5) years from the date of dispatch

from the Manufacturer. The Purchaser

acknowledges that lightning is a natural event

with statistical variation in behaviour and energy

levels which may exceed product ratings, and 100 %

protection is not offered and cannot be provided

for. Therefore the Manufacturer’s liability is

limited to the repair or replacement of the product

(at the Manufacturer’s sole option) which in its

judgement has not been abused, misused,

interfered with by any person not authorised by

the Manufacturer, or exposed to energy or

transient levels exceeding the Manufacturer’s

specifications for the product. The product must

be installed and earthed (where applicable) in

strict accordance with the Manufacturer’s

specifications and all relevant national Electricity

and Safety Standards. The Manufacturer and the

PAGE 30

Purchaser mutually acknowledge that the

product, by its nature, may be subject to

degradation as a consequence of the number and

severity of surges and transients that it

experiences in normal use, and that this warranty

excludes such gradual or sudden degradation.

This warranty does not indemnify the Purchaser

of the product for any consequential claim for

damages or loss of operations or service or profits.

Customers should contact their nearest

manufacturer’s agent to obtain a Product Repair

Authorisation Number prior to making any claim

under this warranty. This is only a summary of

the warranty given by the Manufacturer. The full

text of the warranty is set out in the

Manufacturer’s Conditions of Quotation and Sale.

The above limited warranty is additional to rights

which arise in respect of the sale of industrial and

technical products and services to knowledgable

buyers under the Australian Trade Practices Act

1974 as amended.

Page 31

18. SIX POINT PLAN

TDS-DINLINE SURGE SUPPRESSORs form

an important part of the much larger ERICO

lightning, surge and transient protection

philosophy (ERICO Lightning Technologies

“Six Point Plan”). The level of protection and

the degree of attention dedicated to each of

the six points will require careful

consideration for each site. The degree of

protection required is determined by the

individual site location/exposure with the aid

of risk management principals.

For further advice on your protection needs

please contact your local representative.

Capture the

lightning strike

Conduct the strike

to ground safely

Dissipate the energy

through a low

impedance earth

system

Eliminate earth

loops and

differentials

Protect equipment

from surges on

power lines

Protect equipment

from transients on

telecommunication

and signal lines

PAGE 31

Page 32

TDS-DINLINE CONNECTION OPTIONS

Ph-E ProtectionPh-N Protection N-E Protection Ph-Ph Protection

Ph

NPh

E

Ph N

E

NPh

Ph

PhyPh

x

x

Terminals Ph-N Ph-E N-E Ph

www.erico.com

T1 T2 XT1 T2 X

PROTECTION MODE

T1 Ph E E Ph

T2 NPhNPh

X PhNPhPh

T1 T2 X T1 T2 X

x - Phy

x

y

x

Loading...

Loading...