Page 1

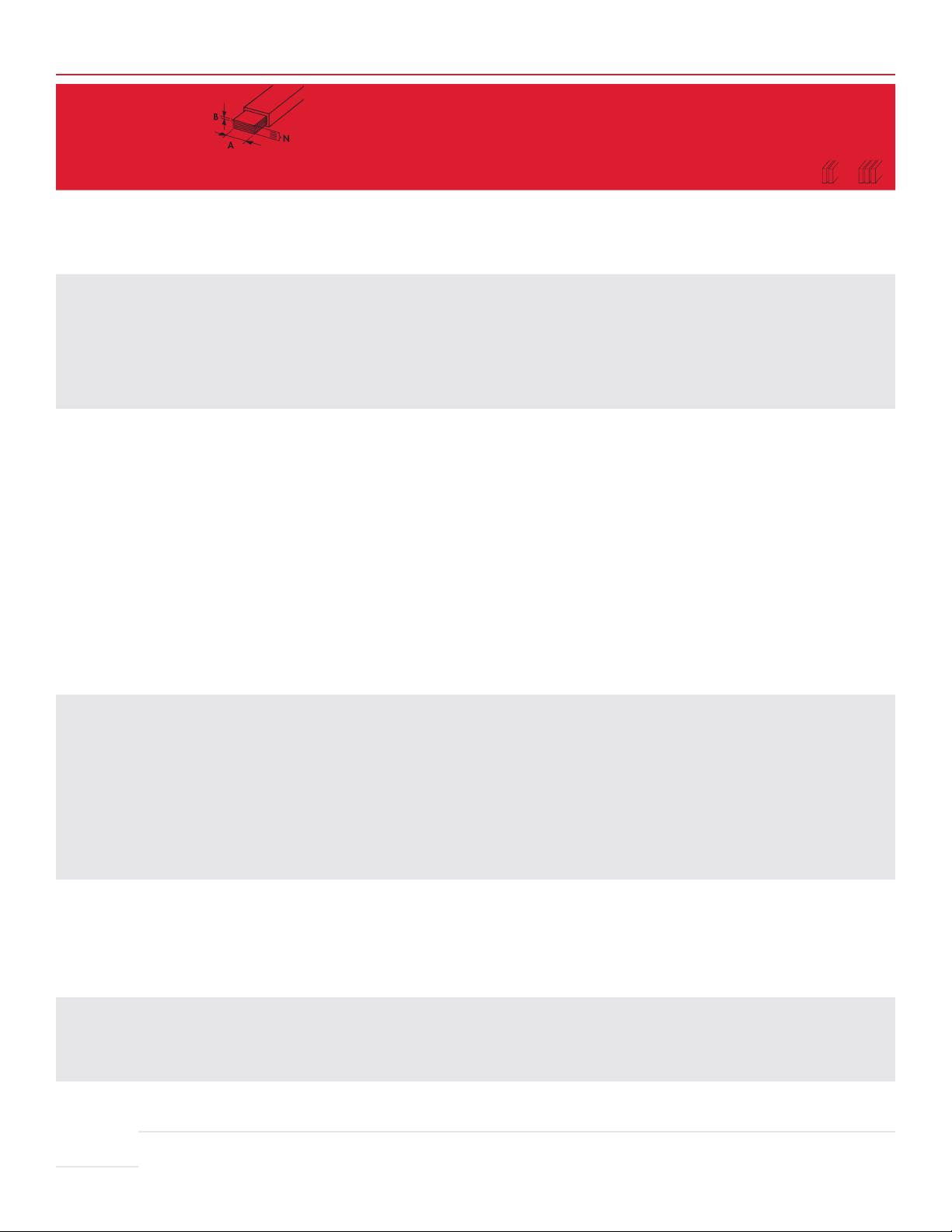

Insulated Flexible Busbar

A COMPLETE RANGE FLEXIBLE BUSBAR

–

ADVANCED

–

STANDARD

–

SUMMUM

THE REFERENCE CONDUCTOR

• nVent ERIFLEX Flexibar is composed of multiple

layers of thin electrolytic copper, available in plain

(

Standard and Summum) or tin plated (Advanced &

Standard

• Flexibar connections are made by punching directly

through the laminates. There are no lugs to purchase,

which eliminates faulty connection problems and makes

installation easier and faster

• The insulation is a high-resistance, self-extinguishing TPE

(

Flexibar Advanced), Silicone (Flexibar Summum) or PVC

(

Flexibar Standard) compound

• Traceability code and designation Part Number

on product

• Easily formed, Flexibar improves assembly flexibility and

aesthetics of panels

• Optimal alternative to large cable & rigid busbar

• Quality: 100% production dielectric tested

• Full range from 24 mm

)

2

up to 1200 mm

2

ENHANCED FLEXIBILITY

nVent’s exclusive manufacturing process offers

superiorflexibility:

• Copper laminates are free to slide within the insulation

• High insulation quality

• Wide variety of bending, twisting & folding possibilities

INNOVATIVE PATE NT I N SUL ATI O N

Flexibar has added grooves on the inner surface of the insulation

sleeve to improve sliding between the central conductor and the

insulation material. The grooves help to reduce the contact surface

between the central conductor and the insulation material. This

results enhances the flexibility of the flexible busbar.

Result: <20% of the inner surface is in contact with the central

conductor.

This nVent ERIFLEX patent idea makes

ever and allows users to optimize the design of their electrical

power connection.

* This patent is applicable for the cross section indication by “*” on

the part number.

Flexibar

more flexible than

FEATURES

• Self-extinguishable/flame retardant

• High mechanical resistance

• High elongation value

• High current withstanding

• High copper quality (99.9% purity

• High conductivity

)

10 |

Page 2

CONNECTION TYPES

–

Between main power and distribution equipment (contactors,

circuit-breakers...

–

Between transformer and busduct

–

Between busduct and electrical cabinet

)

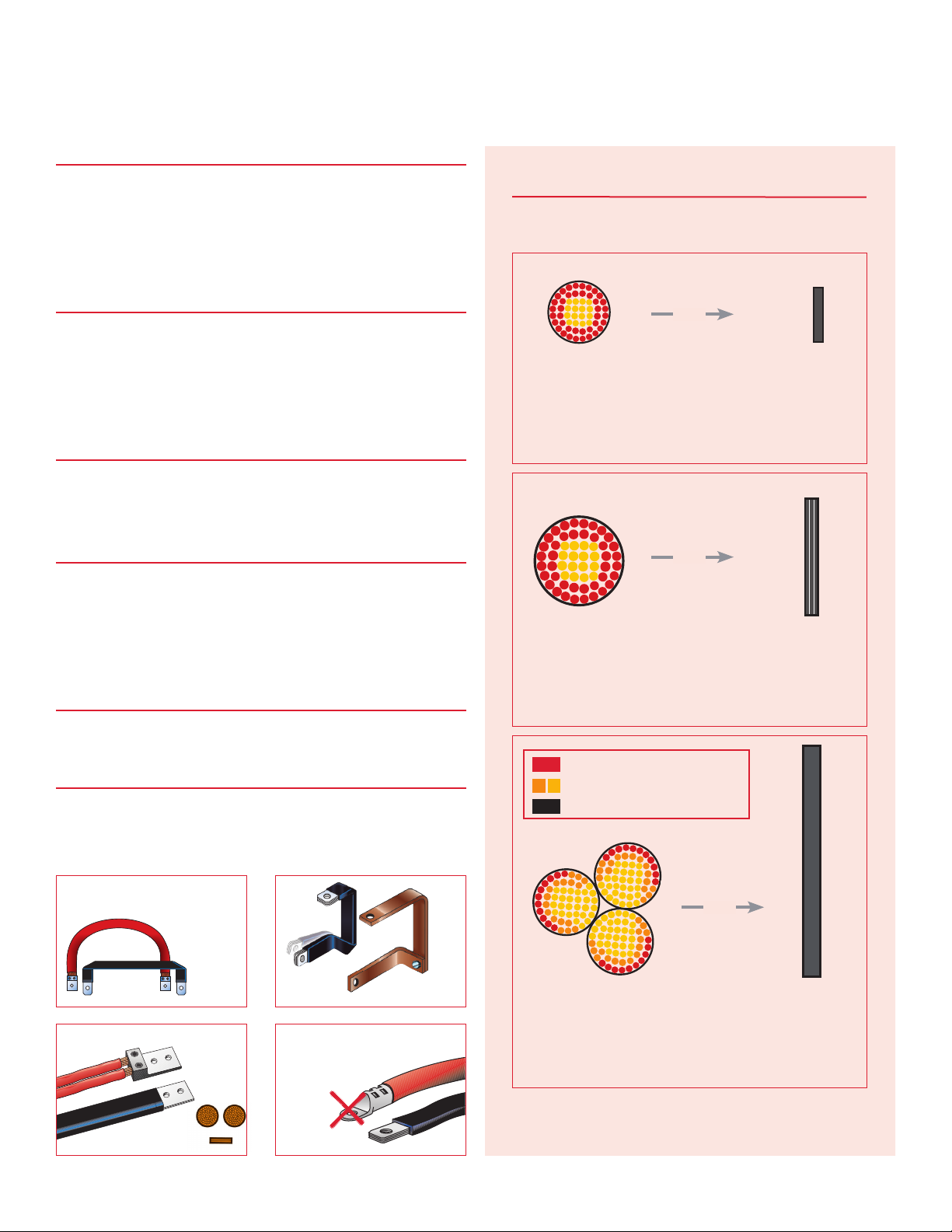

SKIN EFFECT ON A.C. APPLICATION

COPPER CABLE FLEXIBAR

SPACE/WEIGHT SAVINGS

–

Less installation space compared to cable

–

Reduces the length, number of conductors and weight

–

Insulation allows for closer spacing

than traditional busbar designs

COST SAVINGS

–

Eliminates cost and installation of lugs

–

Reduces inventory costs

IMPROVES RELIABILITY

–

ERIFLEX Flexibar is directly connected thus

eliminating the cable lug connection

–

Excellent resistance to vibration

–

No crimping

AESTHETICS

–

Optimal flexibilty for easy access

150 AMPS

1/0

5.35 sq. mm

(.373 In)

380 AMPS

500 MCM

253 sq. mm

(.813 In)

OR

158 AMPS

3 x 9 x 0.8 mm

21.6 sq. mm

60% smaller

OR

379 AMPS

3 x 24 x 1 mm

72 sq. mm

71% smaller

EASY INSTALLATION

–

Thanks to its design Flexibar can be easily bent and shaped for all

sizes

Volume

-25%

CABLE

Flexibar

-40%

Flexibar

Time saving &

improved reliability

BUSBAR

= CONDUCTOR

= REDUCED CONDUCTIVITY

= INSULATION

OR

1140 AMPS

(3) 500 MCM

759 sq. mm

(.813 In)

Representative to scale.

Flexibar ampacity and cable ampacity are based on

(NEC Table 310-16. 75° column) conductor temprature rise of 45°C.

1211 AMPS

4 x 80 x 1 mm

320 sq. mm

58% smaller

| 11

Page 3

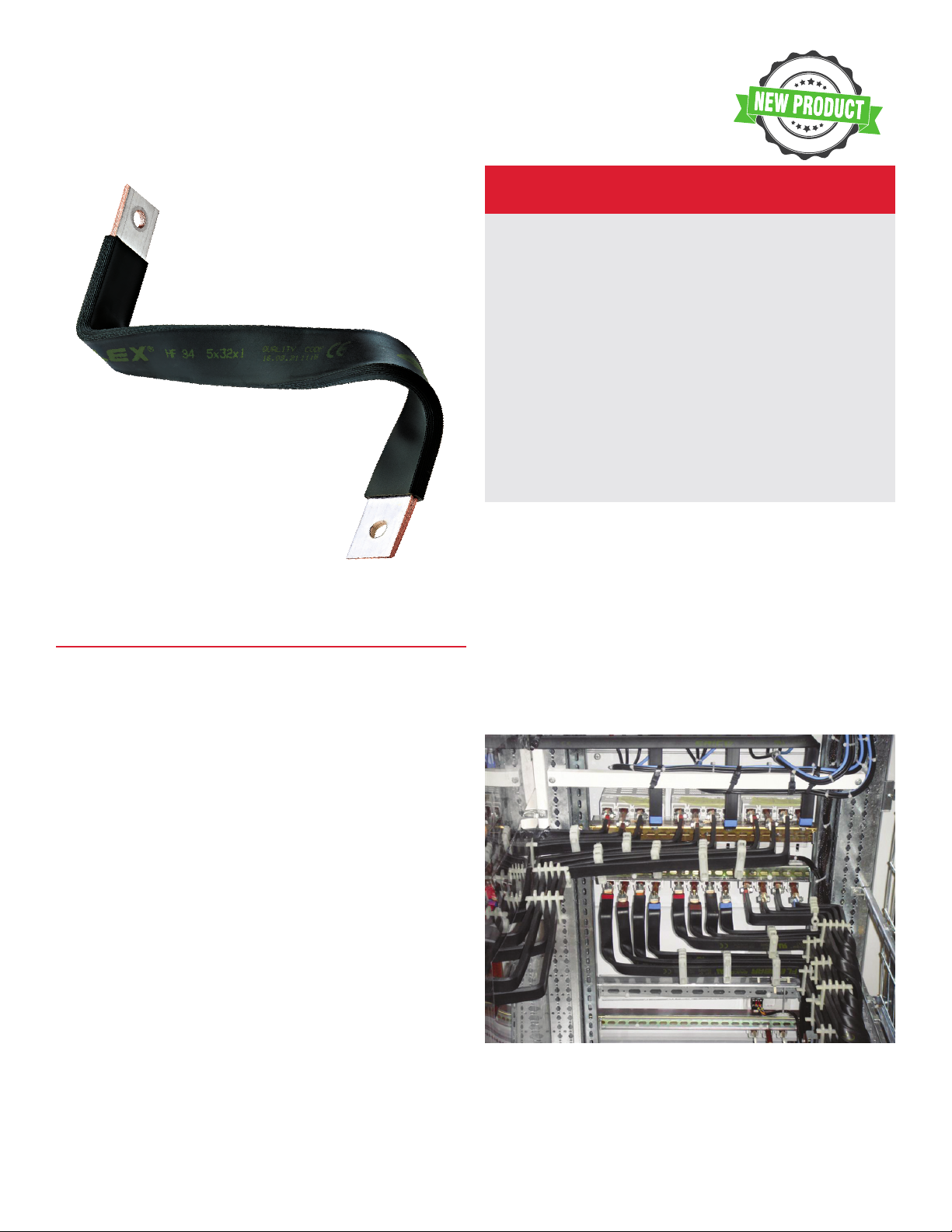

Flexibar Advanced

UNIQUE - SAFER - FLEXIBLE

Flexibar Advanced

Unique – Safer – Flexible

WHY IS FLEXIBAR ADVANCED A

SAFER INSULATION?

Low smoke features:

• Generates less corrosive smoke ISO 5659-2

• Improves visibility for people to be able to easily locate the

emergency exit and also allows rescue workers to better assess

an emergency situation

The halogen–free feature enables:

• Reduction in the quantity of toxic smoke

• Minimum of toxicity with no halogens

(

according to IEC 60754-1

• Use in enclosed spaces for specific applications such as

submarines, switchboards, and other enclosed environments

that require a low emissions solution

The flame retardant portion of the test illustrates the

self-extinguish feature:

• Compliant with the UL 94-V0 Glow wire test @ 960°C

(

IEC 60695-2) testing standard

• Reduces the risk of the spread of fire

• Less damage to your electrical installation

)

• Conductor is electrolytic tinned copper (Cu-ETP

• Insulation is a high-resistance TEP Low Smoke.

Halogen Free and Flame Retardant (LSHFFR).

compound:

–

Typical elongation: 500%

–

Working temperature: -50°C,+115°C

–

Typical thickness: 1.8 mm

–

Self-extinguishing: UL 94 V0

–

Dielectric strength: 20kV/mm

–

Nominal voltage: 1000 V AC/1500 V DC (IEC – UL

–

Dielectric strength: 20kV/mm

Flexibar Advanced has a unique insulation on the market that

combines low smoke, halogen-free and flame retardant features

that improve both the reliability of your electrical installation and

safety for equipment and people.

)

)

Some photographs in the Flexibar Advanced section may actually be using Flexibar

12 |

Page 4

FLEXIBAR ADVANCED TECHNICAL CHARACTERISTICS

ΔT

35°C

(A)

®

Typ i c al

Application

Current

Rating

125 A

250 A

400 A

800 A

1200 A

1600 A

2000 A

ΔT

ΔT

30°C

20°C

(A)

(A)

NEC

Part

Number

N A B

Section

2

mm

310 -16

60°C

534001 3 9 0.8 21.6 101 126 138 14 8 158 167 185 193 201 1.7 2 2.25

534004 3 13 0.5 19.5 102 128 139 150 160 169 187 195 203 1.72 2.25

534006 2 15.5 0.8 24.8 121 152 166 178 190 201 222 232 241 1.72 2.25

534005 6 13 0.5 39 150 188 205 221 235 249 275 287 299 1.72 2.25

534002 6 9 0.8 43.2 15 3 19 2 210 226 241 255 281 293 305 1.72 2.25

53 4010 2 20 1 40 168 2 11 229 247 263 279 307 321 334 1.72 2.25

534007 4 15 .5 0.8 49.6 178 223 24 3 262 279 295 326 340 354 1.72 2.25

53 4 016 2 24 1 48 195 244 266 286 305 323 357 373 388 1.72 2.25

534011 3 20 1 60 210 263 286 308 328 347 383 400 416 1.7 2 2.25

534008 6 15.5 0.8 74.4 225 282 308 331 353 374 412 430 448 1.72 2.25

53 4 017 3 24 1 72 243 304 331 356 379 402 443 463 482 1.72 2.25

53 4012 4 20 1 80 246 308 336 361 385 408 450 470 489 1.72 2.25

534023 2 32 1 64 248 311 338 364 388 411 454 474 493 1.72 2.25

53 4 013 5 20 1 100 280 351 382 411 438 464 512 535 556 1.72 2.25

53 4 018 4 24 1 96 285 356 388 418 445 472 520 543 565 1.72 2.25

534030 2 40 1 80 301 376 409 440 470 497 549 573 596 1.72 2.25

534024 3 32 1 96 308 385 419 451 481 510 562 587 611 1.72 2.25

53 4 014 6 20 1 120 311 390 424 457 487 516 569 594 618 1.72 2.25

53 4019 5 24 1 120 322 403 439 472 504 534 589 615 640 1.72 2.25

534020 6 24 1 14 4 357 448 487 524 559 592 653 682 710 1.72

5

34025 4 32 1 128 359 449 489 526 5 61 594 655 684 712 1.72 2.25

534031 3 40 1 12 0 371 464 505 544 580 614 677 707 736 1.72 2.25

534026 5 32 1 160 405 507 552 594 633 671 740 773 804 1.72 2.25

534015 10 20 1 200 425 532 580 624 661 704 777 811 844 1.72 2.25

534021 8 24 1 192 424 531 578 622 663 702 775 809 841 1.72 2.25

534032 4 40 1 160 432 5 41 589 633 675 7 15 789 824 857 1.72 2.25

534027 6 32 1 192 448 561 611 657 701 742 819 855 889 1.72 2.25

534037 3 50 1 150 449 562 612 658 702 74 3 820 856 891 1.72 2.25

534022 10 24 1 240 484 606 660 710 757 802 885 924 961 1.72 2.25

534033 5 40 1 200 486 608 662 712 759 804 887 926 964 1.72 2.25

534038 4 50 1 200 521 651 709 763 813 861 950 992 10 32 1.72 2.25

534028 8 32 1 256 525 657 715 770 821 869 959 1001 10 42 1.72 2.25

534034 6 40 1 240 535 669 728 784 835 885 976 1019 1061 1.72 2.25

534039 5 50 1 250 583 730 794 855 911 965 1065 1112 1157 1.7 2 2.25

534029 10 32 1 320 595 745 811 873 931 986 10 88 113 6 118 2 1.72 2.25

534035 8 40 1 320 628 786 855 920 981 103 9 114 6 119 7 1246 1.72 2.25

534044 4 63 1 252 633 792 861 927 988 1046 115 5 12 05 1255 1.65 2.12

534040 6 50 1 300 641 802 873 940 1002 10 61 1171 1222 1272 1.72 2.25

534036 10 40 1 400 702 879 956 10 29 1097 1162 1282 13 38 1393 1.72 2.25

534045 5 63 1 315 706 883 961 10 33 110 2 1167 128 8 134 4 139 9 1.65 2 .12

534041 8 50 1 400 741 927 1009 10 85 115 7 1226 1352 1412 1469 1.72 2.25

534046 6 63 1 378 772 966 1051 1130 12 05 1276 1408 1470 1530 1.65 2 .12

534049 4 80 1 320 776 970 105 6 1136 1211 1282 1415 147 7 15 38 1.65 2 .12

534042 10 50 1 500 831 1040 1132 1217 12 98 1375 1517 15 8 4 1648 1.72 2.25

534050 5 80 1 400 861 1077 1172 1260 134 4 1423 15 70 16 40

534047 8 63 1 504 886 1108 1205 1297 138 3 1464 1616 16 87 175 6 1.65 2.12

534051 6 80 1 480 938 1172 1275 1372 1463 15 49 170 9 1785 1858 1.65 2 .12

534048 10 63 1 630 985 123 2 13 41 14 42 15 3 8 1628 1797 1876 1953 1.65 2 .12

534055 5 100 1 500 1041 1301 1416 1523 1624 1719 1898 1982 2062 1.6 2.02

534052 8 80 1 640 1073 1341 14 60 1570 1674 1773 195 6 2043 2126 1.6 5 2.12

534056 6 100 1 600 113 2 1414 153 9 1655 1765 186 9 2062 2153 2241 1.6 2.02

534053 10 80 1 800 1187 1484 1614 173 6 1851 1960 216 4 2259 2351 1.65 2 .12

534057 8 100 1 800 1279 1598 1739 1870 1994 2111 2330 2433 2532 1.6 2.02

534058 10 10 0 1 1000 1413 1765 1921 2066 2203 2332 25 74 2688 2797 1.6 2.02

534059 12 100 1 120 0 1537 192 0 2089 2247 2396 2537 2800 2924 3043 1.6 2.02

534060 10 12 0 1 12 00 164 0 2049 2229 2397 2555 2706 2987 3119 3246 1.6 2.02

ΔT

40°C

(A)

ΔT

45°C

(A)

NEC®

310 -16

75°C

ΔT

50°C

(A)

ΔT

60°C

(A)

NEC®

310 -16

90°C

ΔT

65°C

(A)

ΔT

70°C

(A)

1706 1.

Current

Coefficient

2.25

65 2.12

ADMISSIBLE CURRENTS: This table indicates the temperature rise produced by chosen current in the given section. This calculation does not take

into account the heat dissipation from the switch gear.

| 13

Page 5

Flexibar Advanced

UNIQUE - SAFER - FLEXIBLE

Selection of Flexibar Advanced

according to the internal temperature of the panel

Internal

temperature

of panel (T1)

Temperature of

conductors (T2)

Ambient temperature

TEMPERATURE RISE OF CONDUCTOR =

T2 - T1 = ΔT (K

Ex: For a current of 630A, with: T1 = 40ºC - T2 = 90ºC

1) ΔT = 90 - 40 = 50K

2) In the 50ºK column, find the closest current value to

630A. ERIFLEX Flexibar Advanced 5x32x1 - 534026 160 mm2 - 671A.

3) Select ERIFLEX Flexibar Advanced according to the

terminal width of the equipment being connected.

K = Kelvin degree (temperature calculated,

but not measurable

Flexibar Advanced IN PARALLEL

When using 2 or 3 Flexibar Advanced on edge in parallel for

the same phase, use the coefficient:

Ex: 5 x 32 x 1 - ΔTº = 50 K: 671A

2 bars in parallel > 671 A x 1.72 = 1154 A

3 bars in parallel > 671A x 2.25 = 1509 A

)

)

CERTIFICATION & APPROVALS

• International Commission Electrotechnique (IEC) - Meets

all requirements of IEC 61439.1

• UL 67 Recognized component in the “Panelboard and

Switchboard accessories – component category

(

UL file E125470) for US

• UL 758 Recognized component in the “Appliance wiring

material - component” category style 11681

• CE Conformity

• RoHS compliant

• Class II Conductors (IEC 614 3 9 -1.

Chapter 8.4.4 - Protection by total insulation

• Low Smoke ISO 5659-2

• Halogen-free IEC 60754-1

• Flame retardant UL94-V0

• Glow wire test @ 960°C (IEC 60695-2

)

)

14 |

Page 6

ERIFLEX Flexibar Advanced Part Numbers

2 METERS TINNED COPPER

Part

Number Global Part Number FLEXIBAR ADVANCED Description Kg

534000 FADV2MTC8X6 Flexibar Advanced 2 m Tinned Copper 8X6X0.5 4 0.35

534001 FADV2MTC3X9 Flexibar Advanced 2 m Tinned Copper 3X9X0.8 4 0.43

534002 FADV2MTC6X9 Flexibar Advanced 2 m Tinned Copper 6X9X0.8 4 0.81

534003 FADV2MTC9X9 Flexibar Advanced 2 m Tinned Copper 9X9X0.8 4 1.19

534004 FADV2MTC 3X13 Flexibar Advanced 2 m Tinned Copper 3X13X0.5 4 0.45

534005 FADV2MTC6X13 Flexibar Advanced 2 m Tinned Copper 6X13X0.5 4 0.79

534006 FADV2MTC2X15-5 Flexibar Advanced 2 m Tinned Copper 2X15.5X0.8 4 0.51

534007 FADV2MTC4X15-5 Flexibar Advanced 2 m Tinned Copper 4X15.5X0.8 4 1.02

534008 FADV2MTC6X15-5 Flexibar Advanced 2 m Tinned Copper 6X15.5X0.8 4 1.50

534009 FADV2MTC10X15-5 Flexibar Advanced 2 m Tinned Copper 10X15.5X0.8 4 2.20

53 4010 FADV2MTC2X20X1 Flexibar Advanced 2 m Tinned Copper 2X20X1 3 1.05

534011 FADV2MTC3X20X1 Flexibar Advanced 2 m Tinned Copper 3X20X1 3 1.42

53 4012 FADV2MTC4X20X1 Flexibar Advanced 2 m Tinned Copper 4X20X1 3 1.78

53 4 013* FADV2MTC5X20X1 Flexibar Advanced 2 m Tinned Copper 5X20X1 3 2.15

53 4 014* FADV2MTC6X20X1 Flexibar Advanced 2 m Tinned Copper 6X20X1 3 2.41

534015 * FADV2MTC10X20X1 Flexibar Advanced 2 m Tinned Copper 10X20X1 3 3.9 9

53 4 016 FADV2MTC2X 24X1 Flexibar Advanced 2 m Tinned Copper 2X24X1 3 1.24

53 4 017 FADV2MTC3X24X1 Flexibar Advanced 2 m Tinned Copper 3X24X1 3 1.6 8

53 4 018 FADV2MTC4X24X1 Flexibar Advanced 2 m Tinned Copper 4X24X1 3 2 .12

53 4019 * FADV2MTC5X24X1 Flexibar Advanced 2 m Tinned Copper 5X24X1 3 2.55

534020* FADV2MTC6X24X1 Flexibar Advanced 2 m Tinned Copper 6X24X1 3 2.99

53 4021* FADV2MTC8X24X1 Flexibar Advanced 2 m Tinned Copper 8X24X1 3 3.87

534022* FADV2MTC10X24X1 Flexibar Advanced 2 m Tinned Copper 10X24X1 3 4.75

534023 FADV2MTC2X32X1 Flexibar Advanced 2 m Tinned Copper 2X32X1 2 1.62

534024 FADV2MTC3X32 X1 Flexibar Advanced 2 m Tinned Copper 3X32X1 2 2.20

534025 FADV2MTC4X32X1 Flexibar Advanced 2 m Tinned Copper 4X32X1 2 2.78

534026* FADV2MTC5X32X1 Flexibar Advanced 2 m Tinned Copper 5X32X1 2 3.36

534027* FADV2MTC6X32X1 Flexibar Advanced 2 m Tinned Copper 6X32X1 2 3.94

534028* FADV2MTC8X32X1 Flexibar Advanced 2 m Tinned Copper 8X32X1 2 5.10

534029* FADV2MTC10X32 X1 Flexibar Advanced 2 m Tinned Copper 10X32X1 2 6.27

534030 FADV2MTC2X40X1 Flexibar Advanced 2 m Tinned Copper 2X40X1 2 1.99

534031 FADV2MTC3X40X1 Flexibar Advanced 2 m Tinned Copper 3X40X1 2 2.72

534032 FADV2MTC4X40X1 Flexibar Advanced 2 m Tinned Copper 4X40X1 2 3.44

534033* FADV2MTC5X40X1 Flexibar Advanced 2 m Tinned Copper 5X40X1 2 4.16

534034* FADV2MTC6X40X1 Flexibar Advanced 2 m Tinned Copper 6X40X1 2 4.89

534035* FADV2MTC8X40X1 Flexibar Advanced 2 m Tinned Copper 8X40X1 2 6.33

534036* FADV2MTC10X40X1 Flexibar Advanced 2 m Tinned Copper 10X40X1 2 7. 7 8

534037 FADV2MTC3X50X1 Flexibar Advanced 2 m Tinned Copper 3X50X1 1 3.37

534038* FADV2MTC4X50X1 Flexibar Advanced 2 m Tinned Copper 4X50X1 1 4.27

534039* FADV2MTC5X50X1 Flexibar Advanced 2 m Tinned Copper 5X50X1 1 5.17

534040* FADV2MTC6X50X1 Flexibar Advanced 2 m Tinned Copper 6X50X1 1 6.07

53 4041* FADV2MTC8X50X1 Flexibar Advanced 2 m Tinned Copper 8X50X1 1 7.87

534042* FADV2MTC10X50X1 Flexibar Advanced 2 m Tinned Copper 10X50X1 1 9.68

534044* FADV2MTC4X63X1 Flexibar Advanced 2 m Tinned Copper 4X63X1 1 5.34

534045* FADV2MTC5X63X1 Flexibar Advanced 2 m Tinned Copper 5X63X1 1 6.48

534046* FADV2MTC6X63X1 Flexibar Advanced 2 m Tinned Copper 6X63X1 1 7. 61

534047* FADV2MTC8X63X1 Flexibar Advanced 2 m Tinned Copper 8X63X1 1 9.88

534048* FADV2MTC10X6 3X1 Flexibar Advanced 2 m Tinned Copper 10X63X1 1 12.14

534049* FA DV2MTC4X80X1 Flexibar Advanced 2 m Tinned Copper 4X80X1 1 6.75

534050* FADV2MTC5X80X1 Flexibar Advanced 2 m Tinned Copper 5X80X1 1 8 .19

53 4051* FADV2MTC6X80X1 Flexibar Advanced 2 m Tinned Copper 6X80X1 1 9.62

534052* FADV2MTC8X80X1 Flexibar Advanced 2 m Tinned Copper 8X80X1 1 12.49

534053* FADV2MTC10X80X1 Flexibar Advanced 2 m Tinned Copper 10X80X1 1 15.3 7

534055* FADV2MTC5X100X1 Flexibar Advanced 2 m Tinned Copper 5X100X1 1 10.20

534056* FADV2MTC6X100X1 Flexibar Advanced 2 m Tinned Copper 6X100X1 1 11.9 9

534057* FADV2MTC8X100X1 Flexibar Advanced 2 m Tinned Copper 8X100X1 1 15.5 7

534058* FADV2 MTC10X10 0 Flexibar Advanced 2 m Tinned Copper 10X100X1 1 19.16

534059* FADV 2MTC12X10 0 Flexibar Advanced 2 m Tinned Copper 12X100X1 1 22.74

534060* FAD V2MTC10X120 Flexibar Advanced 2 m Tinned Copper 10X120X1 1 22.9 0

*nVent ERIFLEX Patent insulation

For other length, please contact us.

All ERIFLEX Flexibar

Advanced cross

sections can be bent,

folded or twisted

with a small bending

radius for shorter

and more compact

power connections,

from 125A up to

4500Aapplications.

| 15

Page 7

Flexibar Standard

Flexibar Standard

Selection of Flexibar according to the

internal temperature of the panel

• Conductor is electrolytic copper (Cu-ETP

• Insulation is a high-resistance vinyl compound:

–

Elongation: 370%

–

Operating temperature: -50°C to +105°C

–

Thickness: 2 mm ± 0.2

–

Self-extinguishing: UL 94 VO

–

Dielectric strength: 20kV/mm

–

Nominal voltage = 1000 V AC/1500 V DC (UL & IEC

Ambient temperature

)

)

Internal

temperature

of panel (T1)

Temperature rise of conductor =

T2 - T1 = ΔT (K

Ex: For a current of 650A, with: T1 = 45ºC - T2 = 90ºC

1) ΔT = 90 - 45 = 45ºC

2) In the 45ºC column, find the closest current value to 650A.

Flexibar 8x24x1 - 505511 -

192 mm

3) Select Flexibar according to the terminal width of the

equipment being connected.

K = Kelvin degree (temperature calculated, but not measurable

2

- 663 Amps.

Temperature of

conductors (T2)

)

Flexibar in parallel

When using 2 or 3 Flexibar on edge in parallel for the same

phase, use the coefficient:

Ex: 5 x 32 x 1 - ΔTº = 45 K: 633 A

2 bars in parallel > 633 A x 1.72 = 1088 A

3 bars in parallel > 633 A x 2.25 = 1424 A

)

16 |

Page 8

FLEXIBAR STANDARD TECHNICAL CHARACTERISTICS

UL-rated Ampacity

Part

Number Length

< 400 Amps @ Delta T = 45 C

505051 2 3 9 0.8 126 158 185 Flexibar 2MTC 3x9x0.8 1.72 2.25

505053 2 3 13 0.5 128 16 0 187 Flexibar 2MTC 3x13x0.5 1.72 2.25

505059 2 2 15.5 0.8 152 190 222 Flexibar 2MTC 2x15.5x0.8 1.72 2.25

505054 2 6 13 0.5 188 235 275 Flexibar 2MTC 6x13x0.5 1.72 2.25

505052 2 6 9 0.8 192 241 281 Flexibar 2MTC 6x9x0.8 1.72 2.25

505501 3 2 20 1 211 263 307 Flexibar 3MTC 2x20x1 1.72 2.25

505055 2 4 15.5 0.8 223 279 326 Flexibar 2MTC 4x15.5x0.8 1.72 2.25

505506 3 2 24 1 244 305 357 Flexibar 3MTC 2x24x1 1.72 2.25

505502 3 3 20 1 263 328 383 Flexibar 3MTC 3x20x1 1.72 2.25

505056 2 6 15.5 0.8 282 353 412 Flexibar 2MTC 6x15.5x0.8 1.72 2.25

505507 3 3 24 1 304 379 443 Flexibar 3MTC 3x24x1 1.72 2.25

505503 3 4 20 1 308 385 450 Flexibar 3MTC 4x20x1 1.72 2.25

505513 3 2 32 1 311 385 454 Flexibar 3MTC 2x32x1 1.72 2.25

400 < Ampacity < 800 A @ Delta T = 45 C

505504 3 5 20 1 351 438 512 Flexibar 3MTC 5x20x1 1.72 2.25

505508 3 4 24 1 356 445 520 Flexibar 3MTC 4x24x1 1.72 2.25

505514 3 3 32 1 385 481 562 Flexibar 3MTC 3x32x1 1.72 2.25

505505 3 6 20 1 390 487 569 Flexibar 3MTC 6x20x1 1.7 2 2.25

505509 3 5 24 1 403 504 589 Flexibar 3MTC 5x24x1 1.72 2.25

505510 3 6 24 1 448 559 653 Flexibar 3MTC 6x24x1 1.72 2.25

505 515 3 4 32 1 449 561 665 Flexibar 3MTC 4x32x1 1.72 2.25

505521 3 3 40 1 464 580 677 Flexibar 3MTC 3x40x1 1.72 2.25

505516 3 5 32 1 507 633 740 Flexibar 3MTC 5x32x1 1.72 2.25

505 5 11 3 8 24 1 531 663 775 Flexibar 3MTC 8x24x1 1.72 2.25

505522 3 4 40 1 541 675 789 Flexibar 3MTC 4x40x1 1.72 2.25

505517 3 6 32 1 561 701 819 Flexibar 3MTC 3x32x1 1.72 2.25

505527 3 3 50 1 562 702 820 Flexibar 3MTC 3x50x1 1.72 2.25

50 5512 3 10 24 1 606 757 885 Flexibar 3MTC 10x24x1 1.72 2.25

505523 3 5 40 1 608 759 887 Flexibar 3MTC 5x40x1 1.72 2.25

800 < Ampacity < 1200 A @ Delta T = 45 C

505528 3 4 50 1 651 813 950 Flexibar 3MTC 4x50x1 1.72 2.25

505518 3 8 32 1 657 821 959 Flexibar 3MTC 8x32x1 1.72 2.25

505524 3 6 40 1 669 835 976 Flexibar 3MTC 6x40x1 1.7 2 2.25

505533 3 3 63 1 687 857 10 02 Flexibar 3MTC 3x63x1 1.65 2.12

505529 3 5 50 1 730 911 10 65 Flexibar 3MTC 5x50x1 1.72 2.25

505551 3 6 45 1 736 919 1074 Flexibar 3MTC 6x45x1 1.72 2.25

50 5519 3 10 32 1 745 931

505525 3 8 40 1 786 981 1146 Flexibar 3MTC 8x40x1 1.72 2.25

505534 3 4 63 1 792 988 1155 Flexibar 3MTC 4x63x1 1.65 2.12

505530 3 6 50 1 802 1002 1171 Flexibar 3MTC 6x50x1 1.72 2.25

505526 3 10 40 1 879 1097 1282 Flexibar 3MTC 10x40x1 1.72 2.25

505535 3 5 63 1 883 1102 1288 Flexibar 3MTC 5x63x1 1.65 2 .12

505531 3 8 50 1 927 1157 1352 Flexibar 3MTC 8x50x1 1.72 2.25

1200 < Ampacity < 1600 A @ Delta T = 45 C

505536 3 6 63 1 966 1205 140 8 Flexibar 3MTC 6x63x1 1.65 2 .12

505540 3 4 80 1 970 1211 1415 Flexibar 3MTC 4x80x1 1.6 5 2 .12

505532 3 10 50 1 104 0 1298 1517 Flexibar 3MTC 10x50x1 1.72 2.25

505541 3 5 80 1 1077 1344 15 70 Flexibar 3MTC 5x80x1 1.65 2 .12

505537 3 8 63 1 110 8 1383 1616 Flexibar 3MTC 8x63x1 1.65 2.12

505542 3 6 80 1 117 2 1463 1709 Flexibar 3MTC 6x80x1 1.65 2 .12

505538 3 10 63 1 123 2 1538 1797 Flexibar 3MTC 10x63x1 1.65 2 .12

1600 < Ampacity < 2000 A @ Delta T = 45 C

505546 3 5 10 0 1 1301 1624 1898 Flexibar 3MTC 5x100x1 1.60 2.02

505543 3 8 80 1 1341 1674 195 6 Flexibar 3MTC 8x80x1 1.65 2.12

505547 3 6 100 1 1414 1765 2062 Flexibar 3MTC 6x100x1 1.60 2.02

505544 3 10 80 1 1484 1851 216 4 Flexibar 3MTC 10x80x1 1.65 2.12

2000 < Ampacity @ Delta T = 45 C

505548 3 8 10 0 1 15 98 1994 2330 Flexibar 3MTC 8x100x1 1.60 2.02

505549 3 10 100 1 1765 2203 2574 Flexibar 3MTC 10x100x1 1.60 2.02

505550 3 12 100 1 1920 2396 2800 Flexibar 3MTC 12x100x1 1.60 2.02

ADMISSIBLE CURRENTS: This table indicates the temperature rise produced by chosen current in the given section. This calculation does not take

into account the heat dissipation from the switch gear.

N A B 30°C 45°C 60°C

Temp. Rise of

1088 F

Description

lexibar 3MTC 10x32x1 1.72 2.25

Current

Coefficient

| 17

Page 9

Flexibar Standard

CERTIFICATION & APPROVALS

• International Commission Electrotechnique (IEC) - Meets

all requirements of IEC 60439.1 & IEC 61439.1

• UL 67 Recognized component in the “Panelboard and

Switchboard accessories - component” category (UL file

E125470) for US and Canadian territory

• UL 758 Recognized component in the “Appliance wiring

material - component” category style 10531 (UL file

E316390) and category style 11343 (UL file E316390

• Bureau Veritas Certified - No. 02859/DOBV.

Ship application

• Canadian Standards Association - CSA certified as

appliance wiring material for a maximum of 1000 volts.

File Nº 090005 (CAN/CSA - C22.2

• American Bureau of Shipping (ABS) - Certificate

No. 08-HS365878-1-PDA-DUP - Marine & Offshore

Applications

• CE Conformity

• EAC compliant

• RoHS compliant

• Class II Conductors (IEC 61439-1. Chapter 8.4.4 Protection by total insulation

)

)

)

18 |

Page 10

Flexibar Standard Part Numbers

2 METERS TINNED COPPER

Part

Number Flexibar Description

505051 Flexibar 2MTC 3x9x0.8 0.95

505052 Flexibar 2MTC 6x9x0.8 1.79

505053 Flexibar 2MTC 3x13x0.5 1.00

505054 Flexibar 2MTC 6x13x0.5 1.74

505055 Flexibar 2MTC 4x15x0.8 2.25

505056 Flexibar 2MTC 6x15x0.8 3.31

505059 Flexibar 2MTC 2x15x0.8 1.12

3 METERS TINNED COPPER

Part

Number Flexibar Description lbs

505501 Flexibar 3MTC 2X20X 13.47

505502 Flexibar 3MTC 3X20X1 4.92

505503 Flexibar 3MTC 4X20X1 5.88

505504* Flexibar 3MTC 5X20X1 7.11

505505* Flexibar 3MTC 6X20X1 8.33

505506 Flexibar 3MTC 2X24X1 4.1

505507 Flexibar 3MTC 3X24X1 5.56

505508 Flexibar 3MTC 4X24X1 6.99

505509* Flexibar 3MTC 5X24X1 8.44

505510* Flexibar 3MTC 6X24X1 9.9

505 5 11* Flexibar 3MTC 8X24X1 12.81

50 5512 * Flexibar 3MTC 10X24X1 15.7

505513 Flexibar 3MTC 2X32X1 5.34

505514 Flexibar 3MTC 3X32X1 7. 2 8

505 515 Flexibar 3MTC 4X32X1 9 .19

505516* Flexibar 3MTC 5X32X1 11.11

505517* Flexibar 3MTC 6X32X1 13.0 3

505518* Flexibar 3MTC 8X32X1 16.87

50 5519 * Flexibar 3MTC 10X32X1 20.72

505521 Flexibar 3MTC 3X40X1 8.99

505522 Flexibar 3MTC 4X40X1 11. 3 8

505523* Flexibar 3MTC 5X40X1 13.78

505524* Flexibar 3MTC 6X40X1 16.16

505525* Flexibar 3MTC 8X40X1 20.9 4

505526* Flexibar 3MTC 10X40X1 25.73

505551* Flexibar 3MTC 6X45X1 18 .15

505527 Flexibar 3MTC 3X50X1 11.13

505528* Flexibar 3MTC 4X50X1 14 .11

505529* Flexibar 3MTC 5X50X1 17. 0 9

505530* Flexibar 3MTC 6X50X1 20.08

505531* Flexibar 3MTC 8X50X1 26.04

505532* Flexibar 3MTC 10X50X1 32.01

505533 Flexibar 3MTC 3X63X1 15.04

505534* Flexibar 3MTC 4X63X1 17. 6 8

505535* Flexibar 3MTC 5X63X1 21.43

505536* Flexibar 3MTC 6X63X1 25 .18

505537* Flexibar 3MTC 8X63X1 32.65

505540* Flexibar 3MTC 4X80X1 22.33

5055 41* Flexibar 3MTC 5X80X1 2 7.07

505542* Flexibar 3MTC 6X80X1 31.81

505543* Flexibar 3MTC 8X80X1 41. 31

505546* Flexibar 3MTC 5X100X1 33.73

505547* Flexibar 3MTC 6X100X1 39.65

505548* Flexibar 3MTC 8X100X1 51.5

505549* Flexibar 3MTC 10X100X1 63.36

505550* Flexibar 3MTC 12X100X1 75.2

* nVent ERIFLEX patent insulation

lbs

All Flexibar cross sections can be bent, folded or

twisted with a small bending radius for shorter and

more compact power connections, from 125A up to

4500A applications.

| 19

Page 11

Flexibar Summum

On request: Tinned Flexibar Summum

Flexibar Summum

HALOGEN FREE - HIGH TEMPERATURE

• Halogen-free

• High current density

• High ambient temperature

• High flexibility

• High insulation value

Flexibar Summum

• Conductor in electrolytic copper

–

Laminates thickness 1 mm

• Insulation in silicone compound

–

Working temperature: -50ºC up to 280ºC

(

315ºC short time

–

Low smoke

–

High UV & ozone withstanding

–

Self-extinguishing: UL 94 V O

–

Elongation: 400% minimum

–

Tear resistance: 20 KN/m minimum

–

Thickness: 2 mm ± 0.2 mm

–

Dielectric strength: 20 KV/mm

–

Maximum continuous voltage: 1000 V AC/ 1500 V DC

–

American Bureau of Shipping (ABS) -

Certificate No. 08-HS365878-1-PDA-DUP -

Marine & Offshore Applications

–

IEC 60439.1

–

IEC 614 3 9 .1

)

20 |

Page 12

2 METER RED COPPER

)

Coefficient

Part

Number Flexibar Description Kg

Section

2

mm

IEC® Ampacity ΔT (ºk

70 60 50 40 30

566490 Flexibar Summum 2 M 2 x 20 x 1 5 1.05 40 326 300 275 246 214 1.72 2.25

566500 Flexibar Summum 2 M 3 x 20 x 1 5 1.42 60 428 395 360 323 280 1.72 2.25

566510 Flexibar Summum 2 M 4 x 20 x 1 5 1.78 80 476 440 402 360 312 1.72 2.25

566520 Flexibar Summum 2 M 5 x 20 x 1 5 2.15 100 498 460 420 376 326 1.72 2.25

566550 Flexibar Summum 2 M 2 x 24 x 1 5 1.24 48 450 416 380 340 295 1.72 2.25

566560 Flexibar Summum 2 M 3 x 24 x 1 5 1.68 72 490 453 413 370 320 1.72 2.25

566570 Flexibar Summum 2 M 4 x 24 x 1 5 2 .12 96 550 540 465 416 360 1.72 2.25

566580 Flexibar Summum 2 M 5 x 24 x 1 5 2.55 120 608 563 514 460 398 1.72 2.25

566590 Flexibar Summum 2 M 6 x 24 x 1 5 2.99 14 4 670 620 566 506 438 1.72 2.25

566630 Flexibar Summum 2 M 3 x 32 x 1 5 2.2 96 570 525 480 430 372 1.72 2.25

566640 Flexibar Summum 2 M 4 x 32 x 1 5 2.78 12 8 648 600 548 490 425 1.72 2.25

566650 Flexibar Summum 2 M 5 x 32 x 1 5 3.36 16 0 758 702 640 573 496 1.72 2.25

566660 Flexibar Summum 2 M 6 x 32 x 1 5 3.94 19 2 846 783 715 640 555 1.72 2.25

566670 Flexibar Summum 2 M 8 x 32 x 1 5 5.1 256 1018 943 860 770 667 1.7 2 2.25

566720 Flexibar Summum 2 M 5 x 40 x 1 5 4.16 200 900 832 760 680 590 1.72 2.25

566730 Flexibar Summum 2 M 6 x 40 x 1 5 4.89 240 1018 943 860 770 667 1.72 2.25

566750 Flexibar Summum 2 M 10 x 40 x 1 5 7.7 8 400 140 0 1295 1181 1055 915 1.72 2.25

566780 Flexibar Summum 2 M 5 x 50 x 1 5 5.17 250 1100 1016 930 830 718 1.72 2.25

566800 Flexibar Summum 2 M 8 x 50 x 1 2 7.87 400 1393 1290 1175 1050 912 1.72 2.25

566810 Flexibar Summum 2 M 10 x 50 x 1 2 9.68 500 1650 1525 1395 124 5 108 0 1.72 2.25

Product not available in all location – on demand

ADMISSIBLE CURRENTS: This table indicates the temperature rise produced by chosen current in the given section. This calculation does not take into

account the heat dissipation from the switch gear.

Current

Some photographs in the Flexibar Summum section may actually be using Flexibar

| 21

Loading...

Loading...