ERICO IBS, IBSB Catalog

IBS & IBSB Advanced

Power Conductor

Halogen-Free – Low Smoke – Flame Retardant

Insulated Braided Conductor for Circuit Breakers

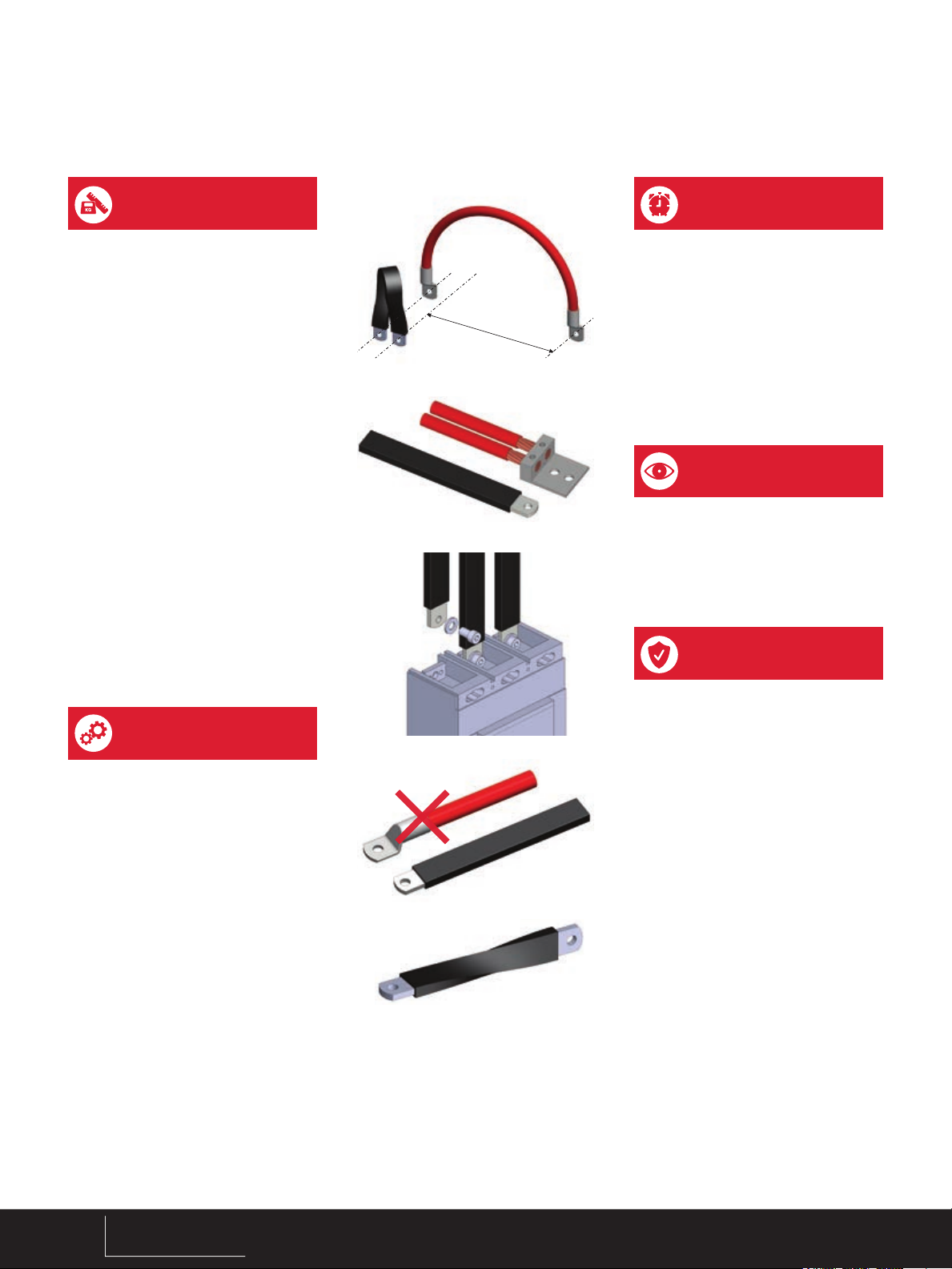

SPACE AND WEIGHT

ADVANTAGE

• nVent ERIFLEX IBS & IBSB

Advanced require less wire

bending space than traditional

cable with greater flexibility.

• With greater ampacities, a

single piece of IBS & IBSB

Advanced can replace multiple

runs of cable.

• Protective sleeve and flexibility

allows IBS & IBSB Advanced

to be mounted in tight areas

where rigid busbar or rigid cables

can not be used.

• No clearance distance needed

around IBS & IBSB Advanced vs other

phases or metallic parts due

to Class II insulation characteristics.

• Integral solid palm without lugs

or terminals reduces material

and assembly weight.

TIME ADVANTAGE

• IBS & IBSB Advanced is a ready

to use conductor that does not

require lug or tools to fabricate the

conductor, reducing installation

time and cost.

• Easier to bend and shape

than large cables, making

installation quicker.

AESTHETIC

ADVANTAGE

• Increases design flexibility.

• Neatly organizes hard-to-make

connections.

RELIABILITY &

SAFETY ADVANTAGE

OPERATING

ADVANTAGE

• IBS & IBSB Advanced are able

to connect on the front access

connection of the main molded

case circuit breakers.

• Ring terminals or lugs are no longer

needed as IBS & IBSB Advanced

is already punched. No additional

crimping operation is needed.

• The high working temperature

115°C is better than a standard

cable that allow reducing the risk

of hot point at the connecting area.

• IBS & IBSB Advanced are directly

connected thus eliminating the

cable lug connection and other

source of heating point.

• IBS & IBSB Advanced have

tinned protected palms for better

corrosion resistance.

• Excellent resistance to vibration.

• No crimping.

• Less human error.

• Insulation sleeve manufactured

from high-resistance low smoke,

halogen-free and flame retardant

Thermoplastic (LSHFFR), with

a 115°C maximum temperature.

2 |

The Advanced Technology insulation is a high-resistance

low smoke, halogen-free and flame retardant Thermoplastic

(LSHFFR), with 115°C high working temperature.

IBS & IBSB Advanced does not

generate corrosive gases and

produces a relatively low smoke

opacity in accordance with IEC

61034-2 and UL 2885. The low

smoke features improves visibility

conditions for people to be able to

easily locate the emergency exit and

also allows rescue workers to better

assess an emergency situation. IBS

& IBSB Advanced means greater

safety for individuals, less damage

for your electrical equipment and less

environmental impact.

The halogen–free feature enables

a reduction in the quantity of toxic

smoke. IBS & IBSB Advanced contain no

halogens, according to IEC 60754-1 and

UL 2885, minimizing toxicity and making

it the ideal product for use in enclosed

spaces such as data centers, rail and

spaces where people are present such

as hospitals and schools. This feature

also facilitates the use of IBS & IBSB

Advanced in specific applications such

as submarines, switchboards and other

enclosed environments that require a low

emissions solution.

In addition to the above features,

IBS & IBSB Advanced are compliant

with the UL 94-V0 testing standard

and Glow wire test 960°C. The

flame retardant portion of the

test illustrates self-extinguishing

capabilities. This feature is also

shown by the Limiting Oxygen

Index (LOI) at 30%. In the case

of a fire, IBS & IBSB Advanced

generates a limited quantity of

smoke that is less damaging to

your electrical equipment.

|

3

Loading...

Loading...