Page 1

How to select nVent Eriex IBS & IBSB Advanced?

When sizing a conductor, the air temperature around the

conductor is a very important parameter, mainly affected by

factors such as convection type, protection level of enclosure

or the temperature rise. Based on IEC 61439 standards, the

ambient air temperature does not exceed +40°C and its

average over a period of 24h does not exceed +35°C.

For IBS & IBSB Advanced, we provided an ampacity

table under different temperature rise, a lower temperature rise

maybe used when the ambient temperature is higher than usual.

TEMPERATURE RISE OF THE CONDUCTOR.

Temperature rise of the conductor (ΔT) = Temperature of the

conductor – Internal temperature of the panel.

• Temperature rise of conductor = T2 – T1 = ΔT (C°

Example:

For a requested current of 630A, with: T1 = 40ºC and T2 = 90ºC

• ΔT = 90 – 40 = 50°C

• in the ΔT 50ºC column, find the closest current value

to 630A.

Result: IBSB Advanced 240 mm² – 718A (IEC & UL).

)

For IBS & IBSB Advanced, we recommend the maximum

temperature rise does not exceed 50°C for a normal

application. Generally, 50°C is chosen as the default

temperature rise considering the ambient temperature

inside the panel is below 40°C. But when the connected

section is an electrical component which may dissipate

heat (for example circuit breaker) or the ventilation inside

the enclosure is not efficient, it may be necessary to choose

lower temperature rise.

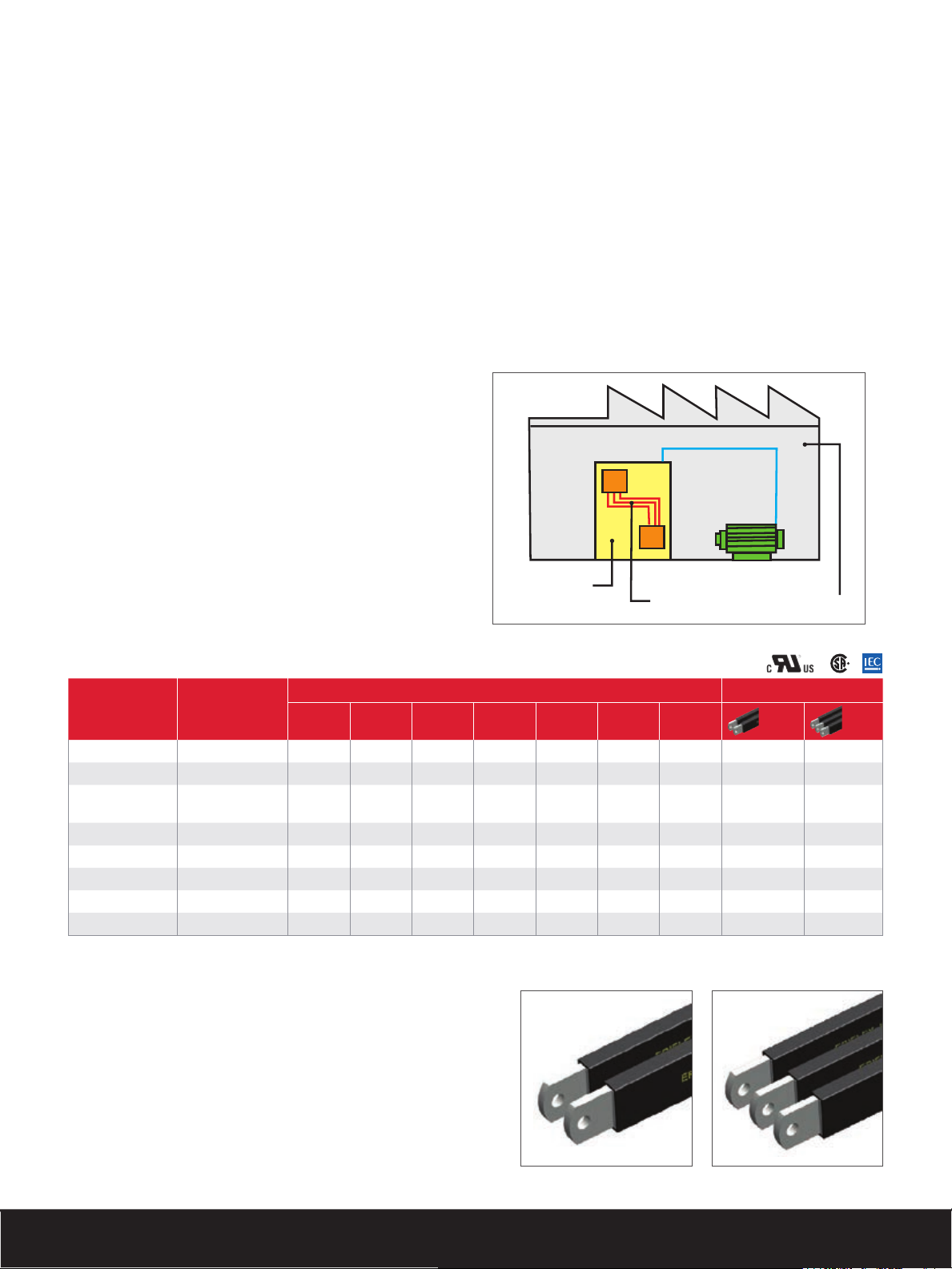

Internal

Temperature of

Panel (T1)

Temperature of

Conductors (T2)

Ambient

Temperature

Insulated

Braided

conductor type

IBSB ADV 25 25 (49.34

IBS ADV 25 25 (49.34

IBS ADV 50

IBSB ADV 50

IBSB ADV 70 70 (13 8 .15

IBSB ADV 100 100 (19 7. 3 5

IBSB ADV 120 120 (236.82

IBSB ADV 185 185 (365.1

IBSB ADV 240 240 (473.65

Admissible currents: This table indicates the tempe rature rise produced by chosen current in th e given section. This calculation does not take into ac count the heat dissipation from the

switch gear.

Cross Section

mm² (kcmil

)

)

50 (98.68

)

)

)

Maximum Ampacity Ratings Current Coefficient

ΔT 30°

)

C (A

116 134 142 150 157 16 4 17 7 1.6 2

137 15 8 167 177 185 19 3 209 1.6 2

213 246 260 274 288 301 325 1.6 2

226 261 277 291 306 319 345 1.6 2

)

298 344 365 385 404 422 456 1.6 2

)

363 419 444 468 491 513 554 1.6 2

416 480 509 537 563 588 635 1.6 2

)

556 642 681 718 753 786 849 1.6 2

ΔT 40°

)

C (A

ΔT 45°

)

C (A

ΔT 50°

)

C (A

ΔT 55°

)

C (A

ΔT 60°

)

C (A

ΔT 70°

)

C (A

)

IBS & IBSB ADVANCED IN PARALLEL

When using 2 or 3 IBS & IBSB Advanced in parallel for the

same phase, use the current coefficient showed on the next

IEC & UL ampacities table.

Example:

IBSB Advanced 240 mm² – ΔT = 50°C: 718 A (IEC & UL

• 2 Braids in parallel: 718 A x 1,6 = 1149 A

• 3 Braids in parallel: 718 A x 2 = 1436 A

)

Loading...

Loading...