Page 1

The ERICO CADWELD Process

nVent ERICO Cadweld

Installation and

Inspection Guide

Page 2

WARNING

1. nVent ERICO pr oducts shall be ins talled and used o nly as indicated in nVent E RICO product

instruc tion sheets and tr aining materials . Instruction s heets are availabl e at nVent.com/ERI CO and

from your nVent E RICO customer s ervice repre sentative.

2. nVent ERICO pr oducts must neve r be used for a purpos e other than the pur pose for which they we re

designe d or in a manner that exc eeds specifi ed load ratings.

3. All instru ctions must be co mpletely followe d to ensure proper an d safe installation an d performanc e.

4. Improper i nstallation, mi suse, misapplic ation or other fail ure to completely fol low nVent ERICO’s

instruc tions and warning s may cause produc t malfunction, p roperty dam age, serious bo dily injury

and death.

GENERAL AND SAFETY INSTRUCTIONS:

A. Only nVent ERICO ma nufactured equi pment and materia ls should be used to ma ke nVent ERICO

Cadweld connections.

B. Do not connect i tems except as detai led in instructi on sheets. Failu re to comply with the se

instruc tions may result in i mproper and unsafe c onnections , damage to items bei ng connected,

bodily in jury and

property damage.

C. Do not use worn or bro ken equipment whi ch could cause le akage.

D. D o not alter equipm ent or material wit hout nVent ERICO aut horization.

E. When using C adweld do not use weld ing material pack age if damaged or no t fully intact. Wh en using

Cadweld Pl us, do not tamper wi th or disassembl e the welding mater ial unit.

F. Make connec tions in conform ance with Cadweld i nstructions a nd all governing co des.

1. Personn el should be prop erly trained in th e use of this product a nd must wear safety gl asses

and gloves.

2. Avoid conta ct with hot material s.

3. Advise ne arby personnel o f welding operati ons in the area.

4. Remove or pr otect fire hazard s in the immediate are a.

5. Provide ad equate ventilatio n to the work area.

6. Do not smoke w hen handling sta rting material .

7. Avoid direc t eye contact with “ flash” of light fro m ignition of star ting material.

G. Weld ing material is an exoth ermic mixture a nd reacts to produc e hot molten materia l with

temperat ures in excess of 1400 °C (2500°F) a nd a localized rele ase of smoke. These m aterials are not

explosiv e. Ignition temp eratures are in exces s of 900°C (1650°F ) for welding mater ial.

H. Adhe ring to the Cadweld we lding procedu res will minimize risk o f burns and fire cau sed by hot molten

material sp illage. In case of fi re, use of water or CO

quantiti es of water will aid in con trolling a fire sho uld the exothermi c materials becom e involved.

Water shoul d be applied from a di stance.

1. Make sure the re is proper mold f it and assembly of e quipment.

2. Avoid moistur e and contaminan ts in mold and materia ls being welded. C ontact betwe en hot molten

metal and m oisture or contam inants may result in s pewing of hot materi al.

3. Base materi al thickness mus t be sufficien t for the size and type o f connection be ing made to prevent

melt-th rough and leakag e of hot molten metal.

I. Applicat ions or conditi ons may exist which re quire special co nsiderations . The following are

examples , but are not intende d to be a complete list ing of applicatio ns/conditions.

CONNECTIONS TO PIPE/VESSELS

For use wit h cast iron pipe or he avy casting mee ting ASTM A47- 84, A48 -83, A126-84 , A278-85 , or

A377- 89. DO NOT USE ON CA ST IRON SOIL PI PE (ASTM A74-9 3). Evaluate possibl e effects of Cadwel d

connec tions to structur al members and th in-wall materi als; vessels/pipin g systems that are pre ssurized,

closed or containing (or having contained) flammable/explosive/hazardous materials. Evaluation

should be m ade prior to use, bas ed on condition s of use and applicab le codes, and sho uld incorpora te

as a minimum , effects of melt- through of hot mater ial; structural /metallurgical e ffects of Cadweld

connec tions, pressure ( temperature) build -up and fire/ch emical decom position hazard s.

CONNECTIONS TO REBAR

Applic ation of the Cadweld c onnection may hav e an effect on the reb ar’s structura l integrity. The re bar’s

chemist ry and the locat ion of the weld should b e considered be fore making any welds to t he rebar.

For lappe d rebar splices, i t is recommend ed that the connec tions be made near t he bar end at an area

of minimum s tress. If Cadweld Re bar Splices are us ed, the groundi ng connection c an be made to the

splice sl eeve with minimal ef fect on the struc tural character istics of the splic e.

SAFET Y INSTRUC TIONS:

All gover ning codes and reg ulations and thos e required by the job si te must be observ ed. Always

use appro priate safety equip ment such as eye prote ction, hard hat , and gloves as approp riate to the

application.

WARRANTY

Cadweld pr oducts are warran ted to be free from defe cts in material and wo rkmanship at the ti me of

shipmen t. NO OTHER WARR ANTY, WHE THER EXPRE SS OR IMPLIE D (INCLUDING A NY WARRANT Y

OF MERC HANTABILIT Y OR FITNES S FOR A PARTICUL AR PURPOS E), SHALL E XIST IN CON NECTION

WITH TH E SALE OR USE O F ANY nVent ERICO P RODUCTS. Cla ims for errors, sh ortages, defe cts or

nonconfo rmities ascer tainable upon i nspection mus t be made in writing wi thin 5 days after Bu yer’s

receipt of p roducts. All oth er claims must be ma de in writing to nVent ERI CO within 6 months f rom the

date of shipm ent or transpor t. Products cla imed to be nonconfo rming or defecti ve must, upon nVent

ERICO ’s prior written ap proval in accorda nce with its stand ard terms and proce dures governing r eturns,

promptly b e returned to nVent ERI CO for inspectio n. Claims not made a s provided above and w ithin the

applica ble time period wi ll be barred. nVent ERI CO shall in no event b e responsible if th e products have

not been s tored or used in acco rdance with its sp ecification s and recommend ed procedures . nVent

ERICO wil l, at its option, ei ther repair or rep lace nonconfor ming or defective p roducts for which i t is

responsi ble or return the pu rchase price to the B uyer. THE FOREGO ING STATES BUYER’ S EXCLUSIV E

REMEDY FO R ANY BREAC H OF NVENT ERI CO WARRANT Y AND FOR AN Y CLAIM, WH ETHER

SOUND ING IN CONTR ACT, TORT OR NEGLIGE NCE, FOR LOS S OR INJURY CAU SED BY THE SAL E OR

USE OF A NY PRODUCT.

LIMITATION OF LIABILIT Y

nVent ERICO e xcludes all liabili ty except such lia bility that is dire ctly attribu table to the willful or g ross

neglige nce of nVent ERICO’s em ployees. Shou ld nVent ERICO be hel d liable its liabili ty shall in no

event exce ed the total purchas e price under the c ontract. NVE NT ERICO SHA LL IN NO EVEN T BE

RESPO NSIBLE FOR A NY LOSS OF BUS INESS OR PRO FITS, DOWN TIME OR DELAY, LA BOR, REPAIR OR

MATERIA L COSTS OR AN Y SIMILAR OR D ISSIMIL AR CONSEQU ENTIAL LOS S OR DAMAGE INC URRED

BY BUYE R.

will aid in co ntrol of burning co ntainers. Lar ge

2

Page 3

The nVent ERICO Cadweld Process

The nVent ERICO Cadweld process is a method of making

electrical connections of copper-to-copper or copper-to-steel in

which no outside source of heat or power is required.

In this process, conductors are prepared, placed in a purposedesigned graphite mold, and exothermically welded to produce a

permanent electrical connection.

The steps outlined below are a general demonstration of a typical

welded connection.These basic steps are used for all Cadweld

electrical connections. Be sure to read and follow the instructions

included with every mold before making a connection.

The Cadweld exothermic process is a system. Materials from

other manufacturers should not be mixed or matched with

Cadweld molds or welding material.

The Cadweld Plus Process ........................................... 11

The Cadweld Exolon Process ......................................19

The Cadweld One Shot Process ................................. 28

The Cadweld Plus One Shot Process ........................ 33

Cadweld Quality Standards ......................................... 38

nVent.com/ERICO | 1

Page 4

The Cadweld Process

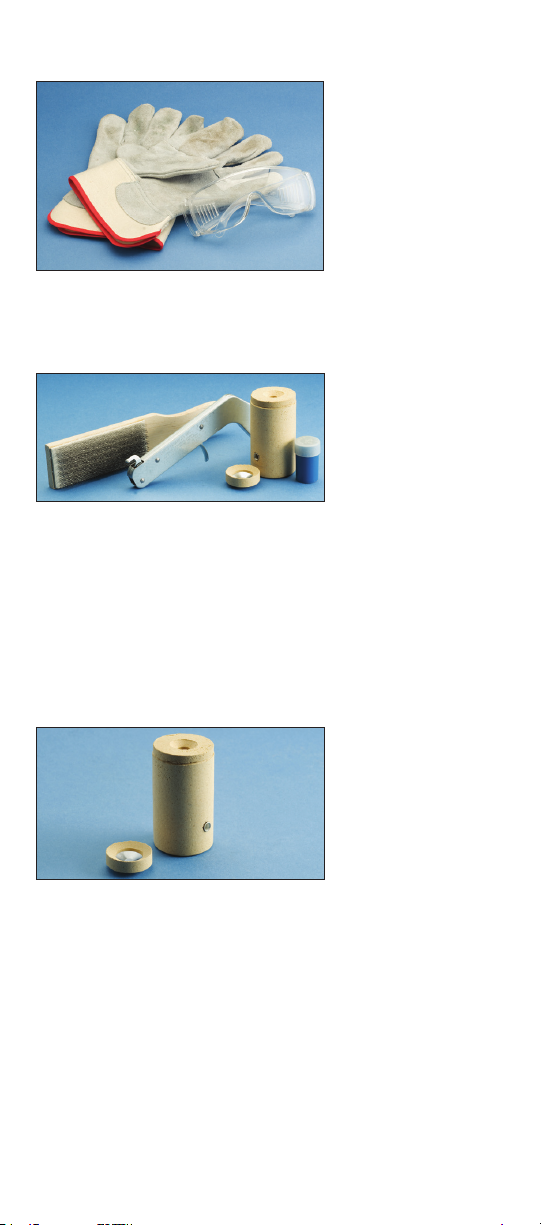

Fig. 1

Always wear protective safety glasses and gloves

while working with Cadweld

exothermic welding products.

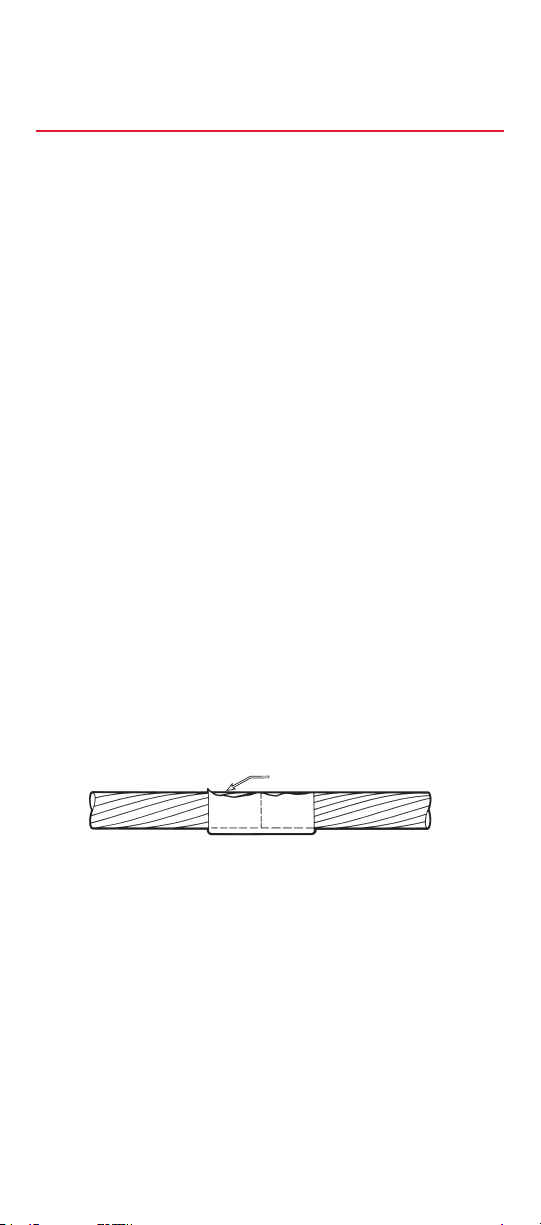

Fig. 2

Gather the proper materials and equipment for the type of

connection you are making. The typical Cadweld system requires

a graphite mold, handle clamp, welding material, natural bristle

brush for mold cleaning, wire brush for cleaning/preparing

conductors, flint igniter, and propane torch.

NOTE: Additional materials may be required for your specific

application. Refer to your mold instructions. Advise nearby

personnel of welding operations in the area prior to ignition.

Fig. 3

Check to ensure the graphite mold is not worn or broken, which

could cause leakage of molten weld metal during the reaction.

2 | nVent.com/ERICO

Page 5

The Cadweld Process

Fig. 4

Inspect the mold ID tag to ensure that it corresponds to the

application, indicated by the:

1. mold part number

2. conductor size

3. welding material required

4. other materials required

The mold must be correct for the conductor size and application.

DO NOT MODIFY MOLDS.

Fig. 5

Remove the small wire bracket which is used to temporarily hold

the mold together before using. Set the bracket aside.

Fig. 6

Slide the handle clamp into the pre-drilled holes with the proper

orientation for the thumbscrews.

nVent.com/ERICO | 3

Page 6

The Cadweld Process

Fig. 7

Tighten the clamp thumbscrews onto the mold.

Fig. 8

Close the grips to tightly lock the mold. Check for an appropriate

seal on the mold.

Fig. 9

If the mold does not seal properly, make adjustments to tighten/

loosen the handle clamp.

4 | nVent.com/ERICO

Page 7

The Cadweld Process

Fig. 10

Graphite absorbs moisture. Ignite the propane torch and dry out

the inside of the mold thoroughly on both sides, heating the mold

to approximately 250 degrees Fahrenheit (120 degrees Celsius).

Fi g . 11

The conductors should be clean and dry before the connection

is made. Use a propane torch to dry wire conductors and remove

remaining cleaning residue, solvent, or water before making the

Cadweld connection.

Fig. 12

Next, use a wire brush to further prepare the surface of the

conductors (nVent ERICO T-313 or T-314 brush). Scrape the outer

surface to remove dirt and oxidation. You will notice a slight color

change.

nVent.com/ERICO | 5

Page 8

The Cadweld Process

Fig. 13

Insert the conductors and position them for the connection.

Fig. 14

Close the clamp tightly once the conductors are properly

positioned.

Fig. 15

Steel disk found inside the packaging box of welding material.

6 | nVent.com/ERICO

Page 9

The Cadweld Process

Fig. 16

Insert the steel disk (concave side up) into the mold. Hold the

steel disk on the side of the mold and let it slide into place.

Fig. 17

Ensure that the steel disk is properly seated.

Fig. 18

Next, take a tube of properly sized welding material

(as identified on the mold ID tag) out of the box.

nVent.com/ERICO | 7

Page 10

The Cadweld Process

Fig. 19

Remove the lid over the mold crucible.

Fig. 20

Quickly pour the loose welding material powder into the mold.

Fig. 21

The bottom of the tube contains compressed material

(starting material). Tap the bottom of the tube a couple of times

to loosen this material.

8 | nVent.com/ERICO

Page 11

The Cadweld Process

Fig. 22

Pour 1/4 to 1/3 of the starting material over the welding material

in the mold crucible.

Fig. 23

Close the lid and pour the remaining 3/4 to 2/3 of the starting

material into the slot on the mold cover.

NOTE: Welding material is an exothermic mixture and reacts

to produce hot molten material with temperatures in excess

of 2500 degrees Fahrenheit (1400 degrees Celsius) and a

localized release of smoke. Avoid looking directly at the “flash”

of light from ignition of starting material. Avoid inhalation of

smoke/fumes.

Fig. 24

Aiming the flint igniter from the side, ignite the starting material

on the mold cover. Withdraw the igniter quickly to prevent fouling.

Allow approximately 30 seconds for completion of the reaction

and solidification of the molten material.

nVent.com/ERICO | 9

Page 12

The Cadweld Process

Fig. 25

Open the mold and remove the connection. Use care to prevent

chipping the mold. Avoid contact with hot materials. See the

“Cadweld Quality Standards” section to see whether a quality

connection has been made.

Fig. 26

Completed Cadweld connection.

Fig. 27

Cadweld graphite molds will last approximately 50 connections.

Use a soft cotton cloth or a soft bristle brush (nVent ERICO part

#T394) to clean inside the mold cavity and cover.

Fig. 28

Ready to make another Cadweld connection.

10 | nVent.com/ERICO

Page 13

The Cadweld Plus Process

Fig. 1

Always wear protective safety glasses and gloves

while working with Cadweld Plus exothermic products.

Fig. 2

Prepare the proper materials and equipment for the type of

connection you are making. The Cadweld Plus system requires a

graphite mold, mold clamp, Cadweld Plus welding material cup,

natural bristle brush for mold cleaning, wire brush for cleaning/

preparing conductors, control unit, and propane torch.

NOTE: Additional materials may be required for your specific

application. Refer to your mold instructions. Advise nearby

personnel ofwelding operations in the area prior to ignition.

Fig. 3

Check to ensure the graphite mold is not worn or broken, which

could cause leakage of molten weld metal during the reaction.

nVent.com/ERICO | 11

Page 14

The Cadweld Plus Process

Fig. 4

Inspect the mold ID tag to ensure that it corresponds to the

application, indicated by the:

1. mold part number

2. conductor size

3. welding material required

4. other materials required

The mold must be correct for the conductor size and application.

DO NOT MODIFY MOLDS.

Fig. 5

Remove the small wire bracket which is used to temporarily hold

the mold together before using. Set the bracket aside.

Fig. 6

Slide the handle clamp into the pre-drilled holes with the proper

orientation for the thumbscrews.

12 | nVent.com/ERICO

Page 15

The Cadweld Plus Process

Fig. 7

Tighten the clamp thumbscrews onto the mold.

Fig. 8

Close the grips to tightly lock the mold. Check for an appropriate

seal on the mold.

Fig. 9

If the mold does not seal properly, ake adjustments to tighten/

loosen the handle clamp.

nVent.com/ERICO | 13

Page 16

The Cadweld Plus Process

Fig. 10

Graphite absorbs moisture. Ignite the propane torch and dry out

the inside of the mold thoroughly on both sides, heating the mold

to approximately 250 degrees Fahrenheit (120 degrees Celsius).

Fi g. 11

The conductors should be clean and dry before the connection

is made. Use a propane torch to dry wire conductors and remove

remaining cleaning residue, solvent, or water before making the

Cadweld connection.

Fig. 12

Next, use a wire brush to further prepare the surface of the

conductors (nVent ERICO T-313 or T-314 brush). Scrape the outer

surface to remove dirt and oxidation. You will notice a slight color

change.

14 | nVent.com/ERICO

Page 17

The Cadweld Plus Process

Fig. 13

Insert the conductors and position them for the connection.

Fig. 14

Close the clamp tightly once the conductors are properly

positioned.

Fig. 15

Remove the proper Cadweld Plus welding material cup from the

plastic container. Inspect the cup to ensure it is tightly sealed and

the ignition strip is securely attached to the seal.

nVent.com/ERICO | 15

Page 18

The Cadweld Plus Process

Fig. 16

Place the cup into the top of the mold. Make sure the ignition strip

nests into the recess on the top edge when the cover is closed.

Fig. 17

Battery powered control unit.

Fig. 18

Place the ignition strip into the control unit connector. Remove or

protect fire hazards in close proximity to the connection.

16 | nVent.com/ERICO

Page 19

The Cadweld Plus Process

Fig. 19

Close the graphite mold lid. Advise nearby personnel of welding

operations in the area.

Fig. 20

Using the control unit, press the button and hold, while you

observe the “ready” indicator light. A green light will blink for a few

seconds and then will change to a constant light. At this time, the

unit will send a charge to the ignition strip. The ignition strip will

spark inside the metal cup, initiating the Cadweld Plus exothermic

reaction.

Allow approximately 30 seconds for completion of the reaction

and solidification of the molten material.

Fig. 21

Remove the control unit connector from the ignition strip.

Open the lid and remove the used Cadweld Plus cup

from the mold.

nVent.com/ERICO | 17

Page 20

The Cadweld Plus Process

Fig. 22

Open the mold and remove the connection. Use care to prevent

chipping the mold. Avoid contact with hot materials. See the

“Cadweld Quality Standards” section to see whether a quality

connection has been made.

Fig. 23

Completed Cadweld connection.

Fig. 24

Cadweld graphite molds will last approximately 50 connections.

Use a soft cotton cloth or a soft bristle brush (nVent ERICO part

#T394) to clean inside the mold cavity and cover.

Fig. 25

Ready to make another Cadweld connection.

18 | nVent.com/ERICO

Page 21

The Cadweld Exolon Process

Fig. 1

Always wear protective safety glasses and gloves while working

with Cadweld exothermic products.

Fig. 2

Prepare the proper materials and equipment for the type of

connection you are making. The Cadweld Exolon system requires

a Cadweld Exolon graphite mold, handle clamp, welding material,

wire brush for cleaning/preparing conductors, battery pack, and

propane torch.

NOTE: Additional materials may be required for your specific

application. Refer to your mold instructions. Advise nearby

personnel of welding operations in the area prior to ignition.

Fig. 3

Check to ensure the graphite mold is not worn or broken, which

could cause leakage of molten weld metal during the reaction.

nVent.com/ERICO | 19

Page 22

The Cadweld Exolon Process

Fig. 4

Inspect the mold ID tag to ensure that it corresponds

to the application, indicated by the:

1. mold part number

2. conductor size

3. welding material required

4. other materials required

The mold must be correct for the conductor size and application.

DO NOT MODIFY MOLDS.

Fig. 5

Remove the small wire bracket which is used to temporarily hold

the mold together before using. Set the bracket aside.

Fig. 6

Slide the handle clamp into the pre-drilled holes with the proper

orientation for the thumbscrews.

20 | nVent.com/ERICO

Page 23

The Cadweld Exolon Process

Fig. 7

Tighten the clamp thumbscrews onto the mold.

Fig. 8

Close the grips to tightly lock the mold. Check for an appropriate

seal on the mold.

Fig. 9

If the mold does not seal properly, make adjustments to the

handle clamp.

Fig. 10

Graphite absorbs moisture. Ignite the propane torch and dry out

the inside of the mold thoroughly on both sides, heating the mold

to approximately 250 degrees Fahrenheit (120 degrees Celsius).

nVent.com/ERICO | 21

Page 24

The Exolon Process

Fi g . 11

The conductors should be clean and dry before the connection

is made. Use a propane torch to dry wire conductors and remove

remaining cleaning residue, solvent, or water before making the

Cadweld connection.

Fig. 12

Next, use a wire brush to further prepare the surface of the

conductors and ground rod (nVent ERICO T-313 or T-314 brush).

Scrape the outer surface to remove dirt and oxidation.

You will notice a slight color change.

Fig. 13

Weld metal package (includes welding material, discs, filters and

ignitors for 4 connections).

22 | nVent.com/ERICO

Page 25

The Exolon Process

Fig. 14

Each Exolon package contains 2 filters for a low emission

connection. Insert the white ceramic and black graphite

filters into the mold cover. (Filters must be changed every

4 connections.)

NOTE: If using XL200 welding material or higher, 3 filters

(1 white, 2 black) are included in the weld metal package.

Insert the white filter between the black filters.

Fig. 15

Insert the conductors and position them for the connection.

Fig. 16

Close the clamp tightly once the conductors are properly

positioned.

nVent.com/ERICO | 23

Page 26

The Cadweld Exolon Process

Fig. 17

Steel disk found inside the packaging box of welding material.

Fig. 18

Insert the steel disk (concave side up) into the mold. Hold the

steel disk on the side of the mold and let it slide into place.

Fig. 19

Ensure that the steel disk is properly seated.

Fig. 20

Next, take the tube of welding material included in the

Cadweld Exolon package and remove the lid over

the mold crucible.

24 | nVent.com/ERICO

Page 27

The Cadweld Exolon Process

Fig. 21

Quickly pour the loose welding material powder into the

Cadweld Exolon mold.

NOTE: Welding material is an exothermic mixture and reacts

to produce hot molten material with temperatures in excess

of2500 degrees Fahrenheit (1400 degrees Celsius) and a

localized release of smoke. Avoid direct eye contact with “flash”

of light from ignition of starting material. Avoid inhalation of

smoke/fumes.

Fig. 22

Place the graphite Cadweld Exolon cover onto the mold, with the

larger side facing down.

Fig. 23

Next, take an igniter pin and place it halfway into the small hole

on the side of the mold, with the loop side facing into the hole.

Spread the wire leads.

nVent.com/ERICO | 25

Page 28

The Cadweld Exolon Process

Fig. 24

Cadweld Exolon battery pack.

Fig. 25

Take the alligator clips and clip them onto the wire leads. Remove

or protect fire hazards in close proximity to the connection.

Advise nearby personnel of welding operations in the area.

Fig. 26

Using the Cadweld Exolon battery pack, press the button. At this

time, the unit will send a charge to the igniter pin. The igniter pin

will initiate the Cadweld Exolon exothermic reaction.

Allow approximately 30 seconds for completion of the reaction

and solidification of the molten material.

Fig. 27

Remove the alligator clips from the igniter pin. Remove the

graphite cover of the Cadweld Exolon mold.

26 | nVent.com/ERICO

Page 29

The Cadweld Exolon Process

Fig. 28

Open the mold and remove the connection. Use care to prevent

chipping the mold. Avoid contact with hot materials. See the

“Cadweld Quality Standards” section to see whether a quality

connection has been made.

Fig. 29

Completed Cadweld connection.

Fig. 30

Cadweld Exolon graphite molds will last approximately 50

connections. Use a soft cotton cloth or a soft bristle brush (nVent

ERICO part #T394) to clean inside the mold cavity and cover;

remove any slag left from the exothermic reaction.

Fig. 31

Ready to make another Cadweld connection.

nVent.com/ERICO | 27

Page 30

The Cadweld One Shot Process

Fig. 1

Always wear protective safety glasses and gloves while working

with Cadweld exothermic products.

Fig. 2

Gather the proper materials and equipment for the type of

connection you are making. The Cadweld One Shot system

requires a Cadweld One Shot ceramic mold, welding material, wire

brush for cleaning/preparing conductors, flint igniter, and propane

torch.

NOTE: Additional materials may be required for your specific

application. Refer to your mold instructions. Advise nearby personnel of

welding operations in the area prior to ignition.

Fig. 3

Check to ensure the ceramic mold is not broken, which could

cause leakage of molten weld metal during the reaction.

Inspect the Cadweld One Shot box label to ensure that it

corresponds to the application, indicated by the:

1. Cadweld One Shot part number

2. conductor size

3. welding material required

4. other materials required

The mold must be correct for the conductor size and application.

DO NOT MODIFY MOLDS.

28 | nVent.com/ERICO

Page 31

The Cadweld One Shot Process

Fig. 4

The conductors should be clean and dry before the connection

is made. Use a propane torch to dry wire conductors and remove

remaining cleaning residue, solvent, or water before making the

Cadweld One Shot connection.

Fig. 5

Next, use a wire brush to further prepare the surface of the

conductors and ground rod (Cadweld T-313 or

T-314 brush).

Scrape the outer surface to remove dirt and oxidation.

You will notice a slight color change.

Fig. 6

Each Cadweld One Shot contains a rubber grommet

at the bottom of the mold.

Gently turn the Cadweld One Shot onto the ground

rod until the ground rod reaches the stopper and cannot go

any fur ther.

nVent.com/ERICO | 29

Page 32

The Cadweld One Shot Process

Fig. 7

Insert the conductors and position them for the connection.

Fig. 8

Place the steel disk into the Cadweld One Shot

with the concave side facing up.

Fig. 9

Ensure that the steel disk is properly seated inside the

Cadweld One Shot.

Fig. 10

Next, take the tube of welding material included in the

Cadweld One Shot package and remove the lid

over the crucible.

30 | nVent.com/ERICO

Page 33

The Cadweld One Shot Process

Fi g. 11

Quickly pour the loose welding material powder into the

Cadweld One Shot mold.

Fig. 12

Place the cover on the top of the Cadweld One Shot.

Fig. 13

The bottom of the tube contains compressed material

(starting material). Tap the bottom of the tube a couple of

times to loosen this material.

Fig. 14

Pour the starting material onto the Cadweld One Shot cover.

NOTE: Welding material is an exothermic mixture and reacts to produce

hot molten material with temperatures in excess of 2500 degrees

Fahrenheit (1400 degrees Celsius) and a localized release of smoke.

Avoid direct eye contact with “flash” of light from ignition of starting

material. Avoid inhalation of smoke/fumes.

nVent.com/ERICO | 31

Page 34

The Cadweld One Shot Process

Fig. 15

Aiming the flint igniter from the side, ignite the starting material

on the mold cover. Withdraw the igniter quickly to prevent fouling.

Allow approximately 30 seconds for completion of the reaction

and solidification of the molten material.

Fig. 16

Break the ceramic Cadweld One Shot mold off of the connection.

Avoid contact with hot materials. See the “Cadweld Quality

Standards” section to see whether a quality connection has been

made.

Fig. 17

You are ready to make another Cadweld One Shot connection.

32 | nVent.com/ERICO

Page 35

The Cadweld Plus One Shot Process

Fig. 1

Always wear protective safety glasses and gloves while working

with Cadweld exothermic products.

Fig. 2

Prepare the proper materials and equipment for the type of

connection you are making. The Cadweld Plus One Shot system

requires a Cadweld One Shot ceramic mold, Cadweld Plus

welding material, wire brush for cleaning/preparing conductors,

control unit, and propane torch.

NOTE: Additional materials may be required for your specific

application. Refer to your mold instructions.

Fig. 3

Check to ensure the ceramic mold is not worn or broken, which

could cause leakage of molten weld metal during the reaction.

Inspect the Cadweld Plus One Shot box label to ensure that it

corresponds to the application, indicated by the:

1. Cadweld Plus One Shot part number

2. conductor size

3. welding material required

4. other materials required

The mold must be correct for the conductor

size and application. DO NOT MODIFY MOLDS.

nVent.com/ERICO | 33

Page 36

The Cadweld Plus One Shot Process

Fig. 4

The conductors should be clean and dry before the connection

is made. Use a propane torch to dry wire conductors and remove

remaining cleaning residue, solvent, or water before making the

Cadweld connection.

Fig. 5

Next, use a wire brush to further prepare the surface of

the conductors and ground rod (nVent ERICO T-313 or

T-314 brush).

Scrape the outer surface to remove dirt and oxidation.

You will notice a slight color change.

Fig. 6

Each Cadweld Plus One Shot contains a copper wire at the

bottom of the mold.

Place the mold onto the ground rod until the ground rod reaches

the wire stopper and cannot go any further.

34 | nVent.com/ERICO

Page 37

The Cadweld Plus One Shot Process

Fig. 7

Insert the conductors and position them for the connection.

Fig. 8

Inspect the cup to ensure it is tightly sealed and the ignition strip

is securely attached to the seal.

Fig. 9

Place the welding material cup into the top of the mold. Make sure

the ignition strip nests into the recess on the top edge.

Fig. 10

Place the ceramic lid onto the mold.

nVent.com/ERICO | 35

Page 38

The Cadweld Plus One Shot Process

Fi g. 11

Battery powered control unit.

Fig. 12

Place the ignition strip into the control unit connector. Remove or

protect fire hazards in close proximity to the connection. Advise

nearby personnel of welding operations in the area.

Fig. 13

Using the control unit, press the button and hold, while you

observe the “ready” indicator light. A green light will blink for a

few seconds and then will change to a constant light. At this

time, the unit will send a charge to the ignition strip. The ignition

strip will spark inside the metal cup, activating the Cadweld Plus

exothermic reaction.

Allow approximately 30 seconds for completion of the reaction

and solidification of the molten material.

36 | nVent.com/ERICO

Page 39

The Cadweld Plus One Shot Process

Fig. 14

Remove and dispose of the used Cadweld Plus weld metal cup.

Fig. 15

Break the ceramic Cadweld One Shot mold off of the connection.

Avoid contact with hot materials. See the “Cadweld Quality

Standards” section to see whether a quality connection has been

made.

Fig. 16

You are ready to make another Cadweld connection.

nVent.com/ERICO | 37

Page 40

Cadweld Quality Standards

All Cadweld materials are produced to high standards under

stringent quality control. All Cadweld connections are designed and

tested using Cadweld molds, welding materials, and accessories.

In the absence of any standards, national or international, we

cannot accurately predict the individual product standards of

our competition, either known or unknown. Therefore, mixing of

one manufacturer’s molds with another manufacturer’s welding

materials can predictably lead to finished welds that do not

meet the standards of either manufacturer. After all, one of the

advantages of exothermic welding as a welding process is the

fact that it is pre-engineered.

Specifications for Cadweld Connections

All grounding system connections shall be made by the Cadweld

process. Connections shall include, but not be limited to, all cable

to cable splices, T’s, X’s, etc.; all cable to ground rods, ground rod

splices, cable to steel and cast iron; and cable lug terminations.

Procedures listed in all Cadweld instructions shall be followed.

Molds shall not be altered in the field.

All materials used (molds, welding material, tools, accessories,

etc.) shall be Cadweld materials, manufactured by nVent ERICO.

Materials of different manufacturers shall not be mixed.

A Cadweld mold is designed to last for an average of 50

connections. This will vary according to the care given the mold

during use.

Inspect the mold regularly. Check the following items to

determine if a mold should be replaced:

38 | nVent.com/ERICO

Page 41

Cadweld Quality Standards

CADWELD MOLD INSPECTION

Chip in mold

parting face

Mold par ting

face smo oth

Tap hole

well dened

Weld cavity

well dened

Good

Replace

Disk seat worn

Mold par ting

face has

erosion lines

Chip in weld

cavity

Cable opening

worn

Cable Opening

• The conductor should fit snugly. A loose fit will cause leakage.

• The opening should not be chipped or worn.

Weld Cavity

• The cavity should be well defined.

• There should be no chips or gouges.

Tap Hole

• The tap hole should be well defined.

Disk Seat

• The seat should not be worn or chipped; the disk must seat

properly.

Mold Parting Face

• The parting face should not be chipped.

• The parting face should always be cleaned properly. Use a clean

shop towel or newspaper and wipe clean. Using a wire brush to

clean the mold will cause erosion and quickly destroy the mold.

nVent.com/ERICO | 39

Page 42

Cadweld Quality Standards

INSPECTION OF CADWELD CONNECTIONS GENERAL

INDICATORS

Proper inspection of a Cadweld connection relies on the judgment

of the field personnel. Look closely at the size, color, surface

finish, and porosity of the connection.

Following the guidelines below will assist in making meaningful

inspections. Photographs of good, acceptable, and reject

connections appear on pages 14 – 17.

SIZE

1. No portion of the conductor within the confines of the weld

should be exposed.

2. Maximum depression under the riser on horizontal

connections (after the slag has been removed) should be no

lower than the top of the conductor.

A low fill indicates:

(a) Not enough welding material was used.

(b) Excessive leakage of molten metal.

(c) Improper positioning of the conductor inside the mold.

(d) Movement of conductor.

3. Excessively high fill (tall riser) indicates:

(a) Too large welding material size was used (connection is

still acceptable).

(b) Apparent volume increase due to contaminants in

conductor or mold (see “Porosity” on page 12).

40 | nVent.com/ERICO

Strands showing

(below weld level)

Unacceptable

Page 43

Cadweld Quality Standards

Higher than normal

Normal

Minimum acceptable

Typ e VS

Higher than normal

Normal

Minimum acceptable

Typ e GT

Typ e SS

Higher than normal

Normal

Minimum acceptable

nVent.com/ERICO | 41

Page 44

Cadweld Quality Standards

INSPECTION OF

CADWELD CONNECTIONS

GENERAL INDICATORS (CONTINUED)

Color

The color of a Cadweld connection is best seen after a light wire

brushing of the connection. It should normally be gold to bronze

in color. Occasionally, it may be silvery at the top. This silver color

indicates “tin sweat” of the surface, a normal condition.

A Cadweld connection to cast iron or galvanized surfaces is often

silvery due to alloying with the metals.

Surface Finish

The surface of a Cadweld connection should be reasonably

smooth and free of major slag deposits. If slag deposits cover

more than 20% of the connection surface, or if any cable strands

are exposed after slag has been removed, the connection must

be rejected.

Porosity

The connection should be essentially free from porosity.

Excessive porosity is normally the result of contaminants

(water, oil, dirt, etc.) in the conductor and/or mold. A few small

pinholes may be present on the surface of the riser. The depth of

a pinhole must never extend beyond the center of the conductor.

To check the depth, probe the pinhole with a 1/32-in.-diameter

wire (paper clip). Reject the connection if the depth of the pinhole

extends beyond the center of the conductor.

42 | nVent.com/ERICO

Page 45

Cadweld Quality Standards

INSPECTION OF

CADWELD CONNECTIONS

VISUAL INSPECTION

Photographic Guides

Like all electrical connections, a visual inspection is no guarantee

of performance. Crimped or bolted connections cannot be

inspected visually, but Cadweld connections can be visually

inspected and provide an indication of the quality of the weld.

Visual inspection is recommended as a practical minimum.

Use the photographs on the following pages as a guide to visual

inspection. Cadweld connections are normally rated as good,

acceptable or reject.

A good connection is a normal weld with only minor surface

imperfections.

An acceptable connection is a less than normal weld, but a good

performing weld. Imperfections indicate that 1) a new mold is

required, 2) a change in procedure is necessary, or 3) the proper

mold conductor and/or welding material should be used.

A reject connection shows inadequate fill or an extra high

riser due to 1) use of incorrect procedure, 2) use of incorrect

equipment and/or equipment worn beyond its useful life, or 3)

use of incorrect material.

nVent.com/ERICO | 43

Page 46

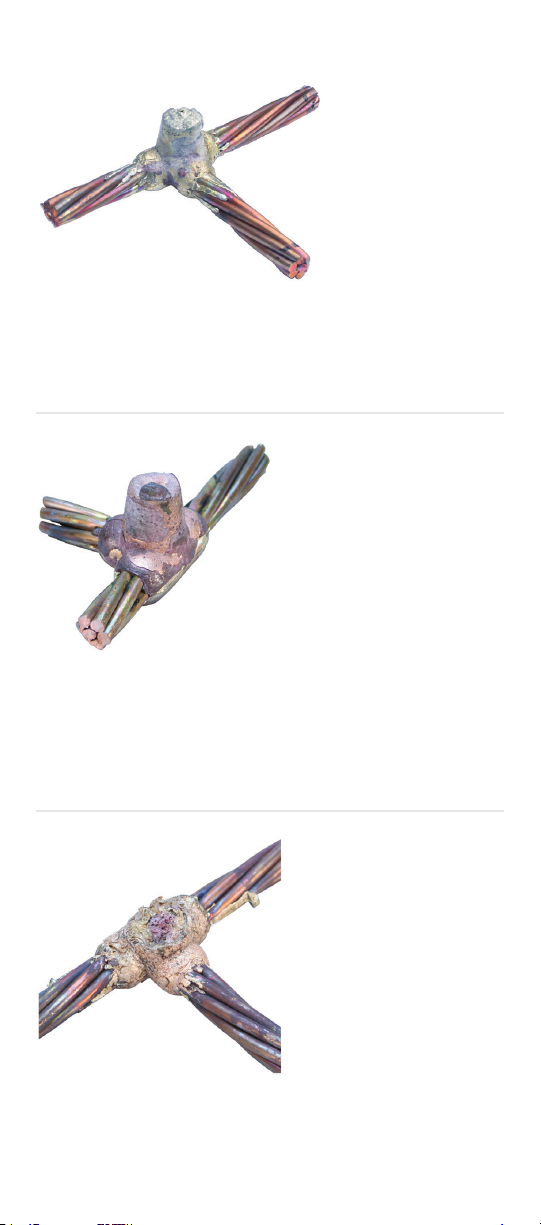

Cadweld Quality Standards

INSPECTION OF

CADWELD CONNECTIONS

PHOTOGRAPHIC GUIDES

Good.

A solid weld with only minor surface imperfections.

Acceptable.

Fill is lower than normal, but still sufficient.

Reject.

A worn or incorrect mold was used, allowing leakage around

conductor. The fill in this connection is insufficient to allow it as

acceptable. Replacement of mold is required prior to making next

connection.

44 | nVent.com/ERICO

Page 47

Cadweld Quality Standards

Acceptable.

The presence of water/moisture in conductor strands or mold

indicates that one or both were not properly dried. Although the

riser is porous, the weld is solid. The degree of porosity is not

sufficient to reject this connection.

Reject.

Extreme amounts of slag on surface are caused by welding

material leaking past disk or complete lack of disk. Inspect the

condition of mold disk seat and check disk positioning prior to

making the next connection.

Reject.

Excessive water in cable strands and/or mold.

nVent.com/ERICO | 45

Page 48

Cadweld Quality Standards

INSPECTION OF

CADWELD CONNECTIONS

PHOTOGRAPHIC GUIDES (CONTINUED)

Reject.

Light carbon traces on cable and connection are evidence of oil

on cable strands. Oily cables must be cleaned with safety solvent.

Reject.

Heavy carbon coating on cable and connection is evidence of large

amounts of oil or grease on cable. Cable must be cleaned with

safety solvent.

46 | nVent.com/ERICO

Page 49

Cadweld Quality Standards

Reject.

Fill too low. Weld cavity was not filled over cable strands. “Fins”

indicate that the mold was not closed tightly due to incorrect

mold, incorrectly adjusted handle clamp, or presence of foreign

material in mold parting line. Before making the next connection,

check the mold for each of the above.

Reject.

Fill too low. Weld cavity was not filled over cable strands.

Absence of leakage indicates that welding material size was

incorrect (too small) or thru conductor moved.

nVent.com/ERICO | 47

Page 50

Cadweld Quality Standards

FIELD SITUATION GUIDE

Most field difficulties can be overcome by checking the

following problems.

PROBLEM A

The mold doesn’t close tightly.

Check for:

1. Adjustment of handle clamps.

2. Cables out of round or bent.

3. Dirt or slag in mold parting line.

4. Correct cable size.

NOTE: Use “C” clamp if necessary.

PROBLEM B

The connection is covered with excessive slag.

Check for:

1. Welding material leaking past the disk, caused by:

(a) Chipped graphite at tap hole.

(b) Disk moved when welding material was dumped.

(c) Disk not properly seated.

(d) Disk was not installed.

NOTE: A small amount of slag on the surface is not abnormal.

PROBLEM C

Molten metal “spits” out of the crucible when making a

connection.

Remedy:

1. See Problem D.

48 | nVent.com/ERICO

Page 51

Cadweld Quality Standards

PROBLEM D

The connection is porous

Check for:

1. Presence of moisture either in conductor or mold.

Remedy:

(a) Dry the conductor by wiping and heating.

(b) Heat mold with torch (to above 212°F) or by igniting

welding material in mold without any conductors, taking

care to prevent burns from the hot material running out

of the mold.

NOTE: Do not use the second method of heating if the mold

has wear plates.

Check for:

2. Other contaminants (oil, insulation, etc.) present in

conductors.

Remedy:

(a) Use a safety solvent to wash the conductor, then dry it.

(b) If insulation is present between strands, remove it.

Check for:

3. Mold packing material in weld cavity of mold.

Remedy:

(a) Always apply mold packing material to conductor after

mold is closed.

PROBLEM E

The conductors do not weld

Check for:

1. Conductors were not properly cleaned and dried.

Remedy:

(a) Remove oxides with a wire brush. If heavily oxidized, have

fresh-cut conductor end and use Cadweld Heavy Duty

molds.

(b) Dry conductors with a torch.

Check for:

2. Conductors not properly positioned in the mold.

Remedy:

(a) Check for proper gap or butting as required (see the mold

tag and read the instructions packaged with mold).

nVent.com/ERICO | 49

Page 52

Cadweld Quality Standards

Field Situation Guide (continued)

(b) Check to be sure gap is centered under tap hole.

NOTE: In some cases, the run (thru) conductor must be cut

and gapped. Follow instructions for same or use Cadweld

Heavy Duty molds.

PROBLEM F

The welding material leaks around the conductor.

Remedy:

1. Use packing material around the conductor after the mold is

closed.

2. Use molds with wear plates (which also act as chill plates).

3. Check for the proper mold. Mold must be sized for the cable

being welded.

4. If the mold is excessively worn, replace with a new mold.

PROBLEM G

The connection has “fins”— metal is lost.

Check for:

1. Mold not completely closed.

2. Mold worn beyond useful life and needs replacement.

PROBLEM H

The cables pull out of the mold during welding.

Remedy:

1. Use a clamp (Cadweld B-265) or other means to prevent

movement of conductors when welding.

PROBLEM I

Insufficient fill material to cover conductors

Check for:

1. Use of proper welding material size (see mold tag).

2. Too large a gap between conductors (see positioning

instructions).

3. Mold leakage.

50 | nVent.com/ERICO

Page 53

Cadweld Quality Standards

Remedy:

(a) See Problem F.

(b) See Problem G.

(c) See Problem H.

4. Conductor movement.

PROBLEM J

The riser is too high.

Check for:

1. Use of proper welding material size (see mold tag).

2. Moisture in mold or conductor.

Remedy:

(a) See Problem D.

PROBLEM K

The mold wears out quickly.

(Molds should produce an average of 50 connections.)

Remedy:

1. Use Cadweld B-265 cable clamp for hard-drawn copper or

DSA Copperweld

2. Clean the mold with a soft brush, clean cloth, or newspaper.

DO NOT USE A WIRE BRUSH.

3. Use care in removing the mold from a finished connection to

prevent chipping of mold.

®

.

PROBLEM L

When welding to steel, the weld does not “stick” to the steel.

Remedy:

1. Clean the steel with a rasp or grinder to bright metal.

When grinding, use an nVent ERICO approved grinding

wheel only. All mill scale, paint, and/or other coating must

be removed. Wire brushing will NOT suffice. Grease must be

removed with safety solvent before cleaning.

2. Clean galvanized surfaces with a wire brush or emery cloth.

However, extra heavy galvanized steel must be cleaned with

a rasp.

3. If the steel is moist, heat with a torch (from the back side

if possible). Any carbon deposit from the flame must be

removed.

4. If conductors are not in proper position, check the

instruction sheet.

nVent.com/ERICO | 51

Page 54

Cadweld Quality Standards

Field Situation Guide (continued)

PROBLEM M

When welding to ductile iron or cast iron, the weld does not

“stick” to the surface.

Remedy:

1. Remove all coatings before cleaning.

2. Clean the surface with a rasp or grinder to bright metal. When

grinding, use an nVent ERICO-approved wheel only.

3. Clean the surface with a safety solvent after grinding or

rasping.

4. Use Cadweld XF-19 alloy welding material (orange cap).

52 | nVent.com/ERICO

Page 55

Page 56

Our powerful portfolio of brands:

CADDY ER ICO HO FFMA N RAYCHEM SCHROF F TRAC ER

nVent.com/ERICO

©2018 nVent. All nVent marks and logos are owned or licensed by nVent Ser vices

GmbH or its affiliates. All other trad emarks are the prop erty of their respective owners.

nVent reser ves the right to change specifications without notice.

ERICO-CAT-E1294W-E297LT17WW-EN-1805

Loading...

Loading...