Page 1

ERIFLEX® FLEXIBAR - Flexible Wire Replacement

NEW Generation Flexible Wire Replacement

Patent pending insulation on ERIFLEX FLEXIBAR

ERIFLEX FLEXIBAR Flexible

Wire Replacement - a preferred

conductor

• ERIFLEX FLEXIBAR is formed with multiple

layers of thin electrolytic copper, available in

plain or tin plated

• ERIFLEX FLEXIBAR connections are made by

punching and bolting directly through the

laminates or by clamping or welding (using

CADWELD®). There are no lugs to purchase,

helping to eliminate faulty connection problems

and making installation simpler and faster

• The insulation is a high-resistance, self-

extinguishing PVC or silicone compound

Superior Flexibility

ERICO’s exclusive manufacturing process offers superior

flexibility:

• Copper laminates are free to slide within the insulation

• High insulation quality

• Wide variety of bending, twisting & folding possibilities

NEW

Innovative patent pending insulation*

ERIFLEX FLEXIBAR has added grooves on the inner surface of

the insulation sleeve to improve sliding between the central

conductor and the insulation material. The grooves help

reduce the contact surface between the central conductor

and the insulation material. This results in improved flexibility

of the flexible busbar. Result: <20% of the inner surface is

in contact with the central conductor. This ERICO patentpending idea makes ERIFLEX FLEXIBAR more flexible than

ever, and allows users to optimize the design of their

electrical power connection.

• Traceability code and designation Part Number

on product

• Easily formed, ERIFLEX FLEXIBAR improves

assembly flexibility and aesthetics of panels

• Ideal alternative to large cable & rigid busbar

• Quality: 100% production dielectric tested

• Full range from 27 mm² up to 1200 mm²

Diverse Applications

• Working Temperature -25°C up to 105°C

(-13°F up to 221°F) ERIFLEX FLEXIBAR

• Nominal voltage = 1000 V AC/1500 V DC

(IEC & UL®)

• Self-extinguishable

• High mechanical resistance

• High elongation value

• High current withstanding

• High copper quality (99.9% purity)

• High conductivity

* This patent is applicable for the cross section indication by “*” on the part number.

Refer to table on page 14”

8

Page 2

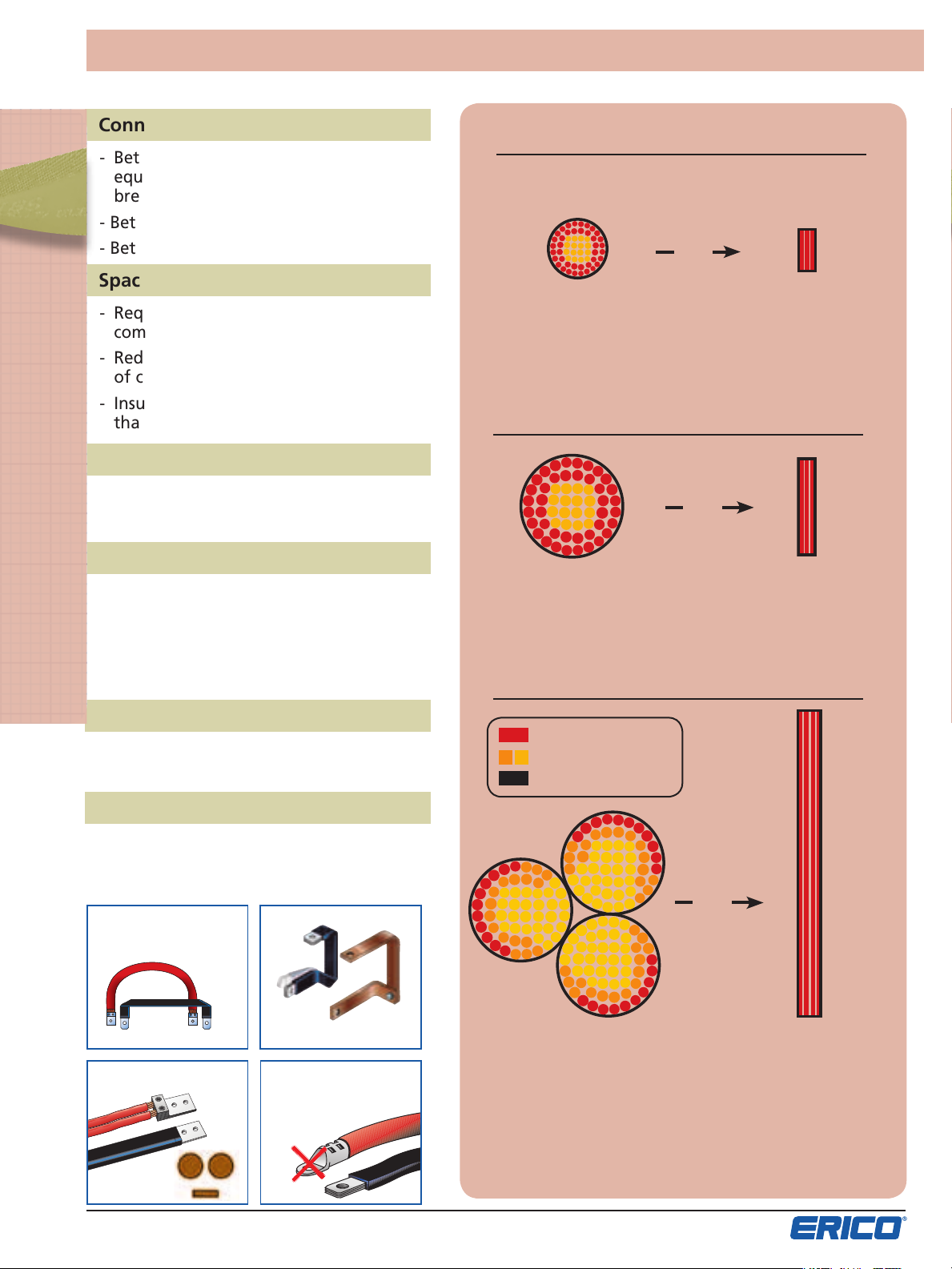

Connection Types

- Between main power and distribution

equipment (contactors, circuit-

breakers...)

- Between transformer and busduct

- Between busduct and electrical cabinet

Space/Weight Savings

ERIFLEX® FLEXIBAR

Skin Effect on A.C. Application

COPPER CABLE ERIFLEX FLEXIBAR

OR

- Requires less installation space when

compared to cable

- Reduces the length and number

of conductors, reducing weight

- Insulation allows for closer spacing

than traditional busbar designs.

Cost Savings

- Eliminates cost and installation of lugs

- Reduces inventory costs

Improves Reliability

- Connection is made directly to

ERIFLEX FLEXIBAR thus eliminating

the cable lug connection

- Excellent resistance to vibration

- No crimping

Aesthetics

- Improves design flexibility and

panel access

150 AMPS

1/0

53.5 sq. mm

(.373 in.)

380 AMPS

500MCM

253 sq. mm

(.813 in.)

= Conductor

= Reduced Conductivity

= Insulation

158 AMPS

3 x 9 x 0.8 mm

21.6 sq. mm

60% smaller

OR

379 AMPS

3 x 24 x 1 mm

72 sq. mm

71% smaller

Ease of Installation

- Installation is facilitated through the

ease of bending and shaping even

large sizes

Volume

-25%

CABLE

ERIFLEX

ERIFLEX FLEXIBAR

-40%

FLEXIBAR

Time saving &

improved reliability

BUSBAR

OR

1140 AMPS

(3) 500MCM

759 sq. mm

(.813 in.)

Representative to scale.

ERIFLEX FLEXIBAR ampacity and cable ampacity are based on

(NEC Table 310-16, 75º column) conductor temperature rise of 45ºC.

9

1211 AMPS

4 x 80 x 1 mm

320 sq. mm

58% smaller

Loading...

Loading...