Page 1

Instruction Manual

CADWELD®for Rebar Splicing System

Page 2

IMPORTANT

General and Safety Information

A. Only ERICO®manufactured equipment and materials should be used to make CADWELD®rebar splices.

1. Do not splice except as detailed in the instructions.

2. Do not use worn or broken equipment that could cause leakage.

3. Do not alter equipment or material without factory authorization.

4. Do not substitue for specified ERICO manufactured equipment and materials.

Failure to comply with the above may result in hazards to the individual, improper splices, or damage to items being spliced.

B.

Make splices in accordance with described splicing procedures and in consideration of surrounding conditions and personnel.

Refer to ANSI Z-49.1 SAFETY IN WELDING AND CUTTING and your local safety procedures.

1. Personnel should be properly trained in the use of this product.

2. Avoid breathing concentrations of smoke, as it may be hazardous to health.

3. Avoid contact with hot materials.

4. Advise nearby personnel of splicing operation in the area.

5. Remove or protect fire hazards in the immediate area.

6. Do not smoke when handling starting material.

C. Adhering to the recommended splicing procedures will minimize risk of burns and fire caused by hot molten material

spillage.

1. Make sure there is proper fit and assembly of equipment.

2. Avoid moisture and decomposable contaminants on splicing equipment and rebar.

Contact of hot molten metal with moisture or contaminants may result in spewing of hot material.

D. Unusual applications or conditions may exist which require special considerations.

1. Provide adequate ventilation where natural air flow is not sufficient to prevent personnel breathing concentrations of

smoke.

E. Storage of CADWELD filler material should be in a clean, dry, “No Smoking” area and should be restricted to access by

authorized personnel only.

1. Starting material and filler material are exothermic mixtures and react to produce hot molten materials with

temperatures in excess of 2200°C (4000°F) and a localized release of smoke. These materials are NOT explosive.

Ignition temperatures are in excess of 450°C (850°F) for starting material and 900°C (1650°F) for filler material.

2. In case of fire, water or CO

2

will aid in control of burning containers. Large quantities of water will aid in controlling

a fire should the exothermic materials become involved. Water should be applied from a distance.

F.

CADWELD filler material in the work area should be protected from spatter and hot materials to prevent accidental ignition.

Use a covered wood or metal gang box for storage of materials not for immediate use.

G. Dispose of slag from the CADWELD splicing process in a steel container that has a layer of dry sand in the bottom.

The sand is necessary to prevent burn through.

H. See splicing instructions enclosed for additional information.

Page 3

1

www.erico.com

Table Of Contents

General Safety Information...............….............................................................................IFC

Rebar Cleaning Procedure (Preparation) …………............................................................... 2

Instructions for Vertical Splicing (Bar-to-Bar) .................................................................... 3-4

Instructions for Horizontal Splicing …………....................................................................5-6

Filler Material Remixing and Placement Procedures............................................................. 7

Venting CADWELD

®

Horizontal Splices ……….................................................................... 8

Inspection …….................................................................................................................. 9

Eccentricity and Cocking of Rebars ……………................................................................. 9

Rejection of a Splice and Its Causes................…................................................................10

Void Limits.........................................................................................................................11

Additional Instructions for B-Series.................................................................................... 12

Welding of Splice Sleeves to Structural Steel......................................................................12

Care of Finished Assemblies...............................................................................................12

Addenda ...........…........................................................................................................... 13

External Bar Reference Marks ...........….............................................................................13

Bar End Gap ……..............................................................................................................13

B-Series Sleeve Repair........................................................................................................ 13

Tap Hole Relocation...........................................................................................................14

Use of Sleeves Out of Their Normal Position..................................................................... 15

Repair of Bar-to-Bar Production Splice Samples or Rejected Splices....................................15

Traceability....................................................................................................................... 15

Page 4

2

www.erico.com

Rebar Cleaning Procedure (Preparation)

1. Rebar ends to be spliced must be dry and free of

excessive rust, loose mill scale, dirt, paint, concrete, etc.

Clean back from bar end at least one-half sleeve length.

2. Cleaning Procedure

2.1 Torch and Power Brushing (See notes)

2.1.1 Flame dry ends to remove moisture and/or

burn away any other foreign contaminants.

Flame should be soot free and not leave any

residue or deposits on bar ends. A “rosebud”

torch tip is recommended.

2.1.2 Remove excessive rust and all loose mill scale,

dirt, paint, concrete, etc. with a power wire

brush.

2.1.2.1 Heavy duty, low speed (200-350 rpm),

reversible drill is recommended for

use with ERICO

®

brand of cleaning

brushes (Series RBW343). See catalog

for additional information.

2.1.2.2 1000 rpm or higher is recommended

for wire wheel and cup brushes

2.1.3 Repeat steps 2.1.1 and 2.1.2 on extremely bad

bar surfaces.

2.2 Torch and Sandblasting

2.2.1 Sandblast bar ends clean.

2.2.2 Flame dry ends to remove moisture.

Flame should be soot free and not leave any

residue or deposits on bar ends. A “rosebud”

torch tip is recommended.

2.3 Torch and Hand Wire Brushing

(See notes)

2.3.1 Flame dry ends to remove moisture and/or

burn away any other foreign contaminants.

Flame should be soot free and not leave any

residue or deposits on bar ends. A “rosebud”

torch tip is recommended.

2.3.2 Should lack of power or clearance restrictions

prevent the use of power-driven equipment,

remove excessive rust and all loose mill scale,

dirt, paint, concrete, etc. with a hand wire brush.

2.3.3 Repeat steps 2.3.1 and 2.3.2 on extremely bad

bar surfaces.

2.3.4 Wipe bar ends with a clean, dry rag to remove

any dust.

3. Badly deformed bar ends may require cutting to assure

easy fit of the sleeve. Bar end shear “drags” may be

flame cut or ground off. Oversize longitudinal ribs

should only be ground as flame cutting may damage the

bar, especially on higher strength steels. The longitudinal

ribs should not be ground below the height of the bar

deformations.

4. Cleaned bar ends that must be left out overnight should

be protected (use empty plastic filler material bags) and

must be re-dried and re-cleaned if necessary.

NOTES:

1. Brushes must be kept free of grease, oil, and/or

other contaminants that could evolve gas and

cause porosity in filler material.

2. Eye protection should be worn when using

power-driven cleaning brushes.

3. Do not reverse the rebar cleaning brush

while it is engaged with the rebar.

Page 5

3

www.erico.com

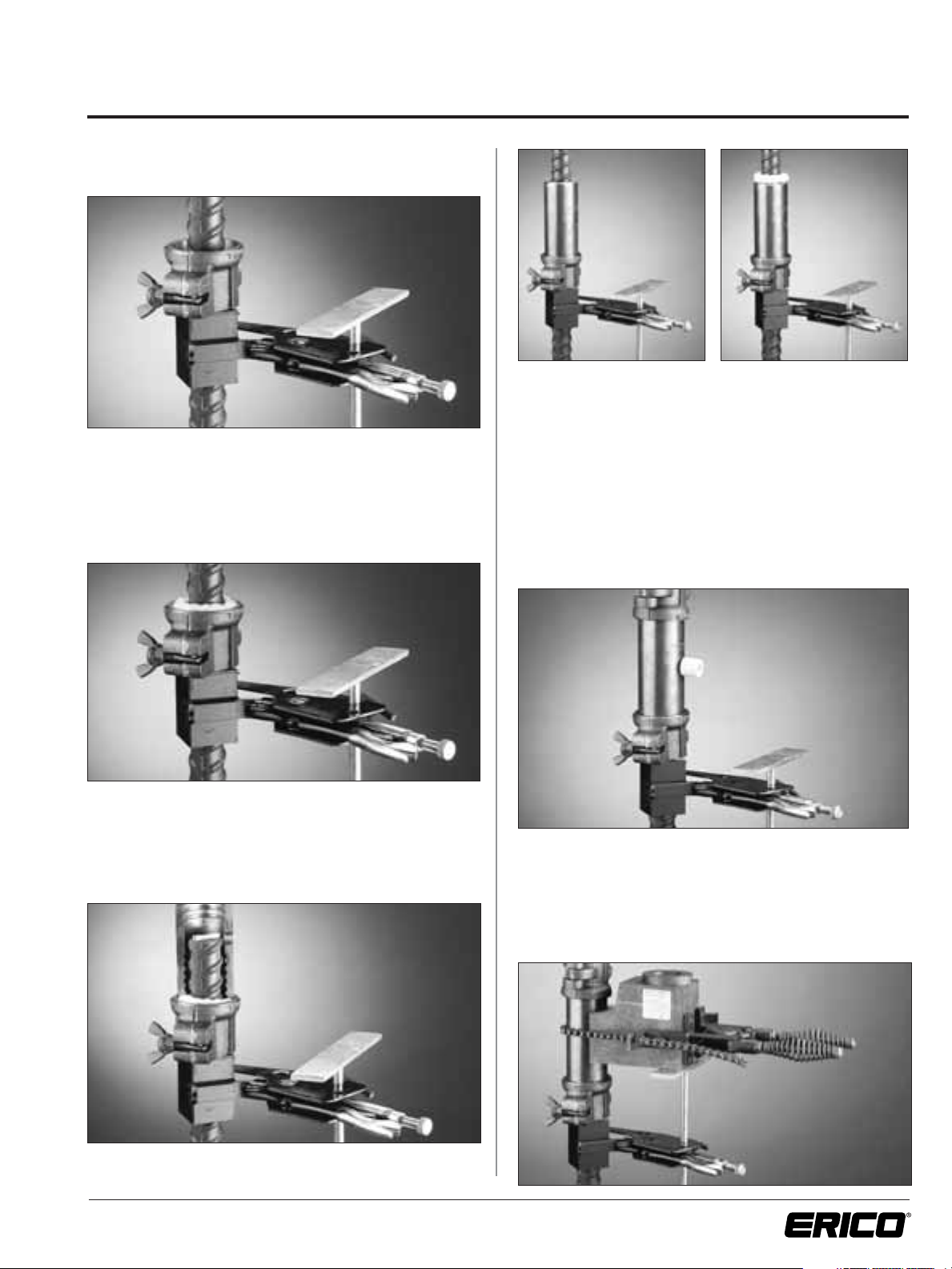

Instructions For Vertical Splicing (Bar-to-Bar)

1. Clean rebar ends as per “Rebar Cleaning Procedure”

on page 2, as required.

2.

Position bottom support clamp and end alignment fitting

so end of rebar will be at tap hole opening of sleeve.

“T” shaped support rod on bottom support clamp

should be in line with the sleeve tap hole so that

support will be directly beneath the pouring basin.

3. Place a double wrap of packing material into position in

the lower end alignment fitting. Using a blunt screwdriver,

place the first wrap around the bar into the space

between the bar and end alignment fitting. The second

wrap around the bar is placed loosely above the first.

4. Place splice sleeve into lower fitting and seat firmly

against the packing to seal lower end of sleeve.

5. Lower top rebar into position. The average gap

between bar ends should not exceed 1/4-in. (6mm).

If a natural gap is not provided by the shape of the

reinforcing bar ends, a spacer can be used.

Spacers are enclosed in an envelope in each carton of

CADWELD

®

ferrous filler material.

Both bar ends should be visible through the sleeve tap

hole.

6. Place a single wrap of packing material loosely around

bar on top of splice sleeve; DO NOT PACK.

7. Place end alignment fitting on top of splice sleeve;

position ceramic insert guide tube assembly firmly into

taphole, making sure it is completely seated inside the

hole.

8. Flame dry pouring basin and crucible before using.

As a check, a drop of water should boil off rapidly.

Page 6

4

www.erico.com

Instructions For Vertical Splicing (Bar-to-Bar)

9.

With pouring basin frame handles unlocked and pouring

basin slightly open, place the pouring basin around the

ceramic insert and against the splice sleeve. Close pouring

basin frame handles and lock. Place chain around the

sleeve and finger tighten thumb nut. Be sure to support

the pouring basin while securing chain to prevent

unseating of the sleeve against the bottom packing.

Adjust “T” shaped support rod against bottom of pouring

basin. Support rod should just touch and support levelled

pouring basin DO NOT force pouring basin up.

NOTE: A crucible should not be reused until allowed to

cool for 15 minutes or more. If more frequent use

is desired, several crucibles complete with frames

should be used alternately to allow sufficient cooling

time. Clean crucible thoroughly inside. Empty the

crucible completely, see Note 15 & 16 on this page for

additional information. DO NOT use a wire brush.

10. Place crucible ceramic insert assembly in bottom of

crucible. All crucibles use the same ceramic insert.

11. The crucible ceramic insert assembly is supplied with a

steel disk pre-installed into it as a one-piece assembly.

If the steel disk is not present in the ceramic insert,

place the steel disk on the crucible ceramic insert and

check for proper seating. Remix bag of CADWELD

®

filler

material

and fill crucible according to the instructions on

page 7.

12. Position crucible on the pouring basin and secure the

tiedown chain, keeping it just loose enough to allow

swivelling of the crucible without tipping.

13. Open the starting material container. Evenly distribute

the starting material over the filler material in the crucible,

saving a small amount to be placed on the tab of the

crucible extension. Place the crucible extension on the

crucible and put the remainder of starting material on

the tab. Place the crucible cover on the extension.

Standing off to the side of the opening and up wind,

ignite the starting material on the tab.

14. Keep the tiedown chain secured at all times.

Immediately after the sleeve has filled, slowly swivel

the crucible back and forth to break the slag between

the base of the crucible and top of the pouring basin.

Repeat after 15 or 20 seconds as necessary.

After the slag has solidified, release the tiedown chain

and remove the crucible. All other parts can then be

removed.

15. Clean the crucible by turning upside down and placing

a metal rod (#5 [16mm] rebar) against the ceramic and

lightly tapping the rod end to discharge the slag and

ceramic into a suitable waste container.

16. Break off riser with hammer. Clean slag from crucible

and pouring basin as soon as possible to promote cooling.

Use a whisk broom, rag or wooden wedge for cleaning.

Do not use a wire brush. Cover and crucible extension

need not be cleaned every time.

NOTE: Clean flash or debris from all mating surfaces as debris

can

cause springing of the equipment clamps and hinges.

Page 7

5

www.erico.com

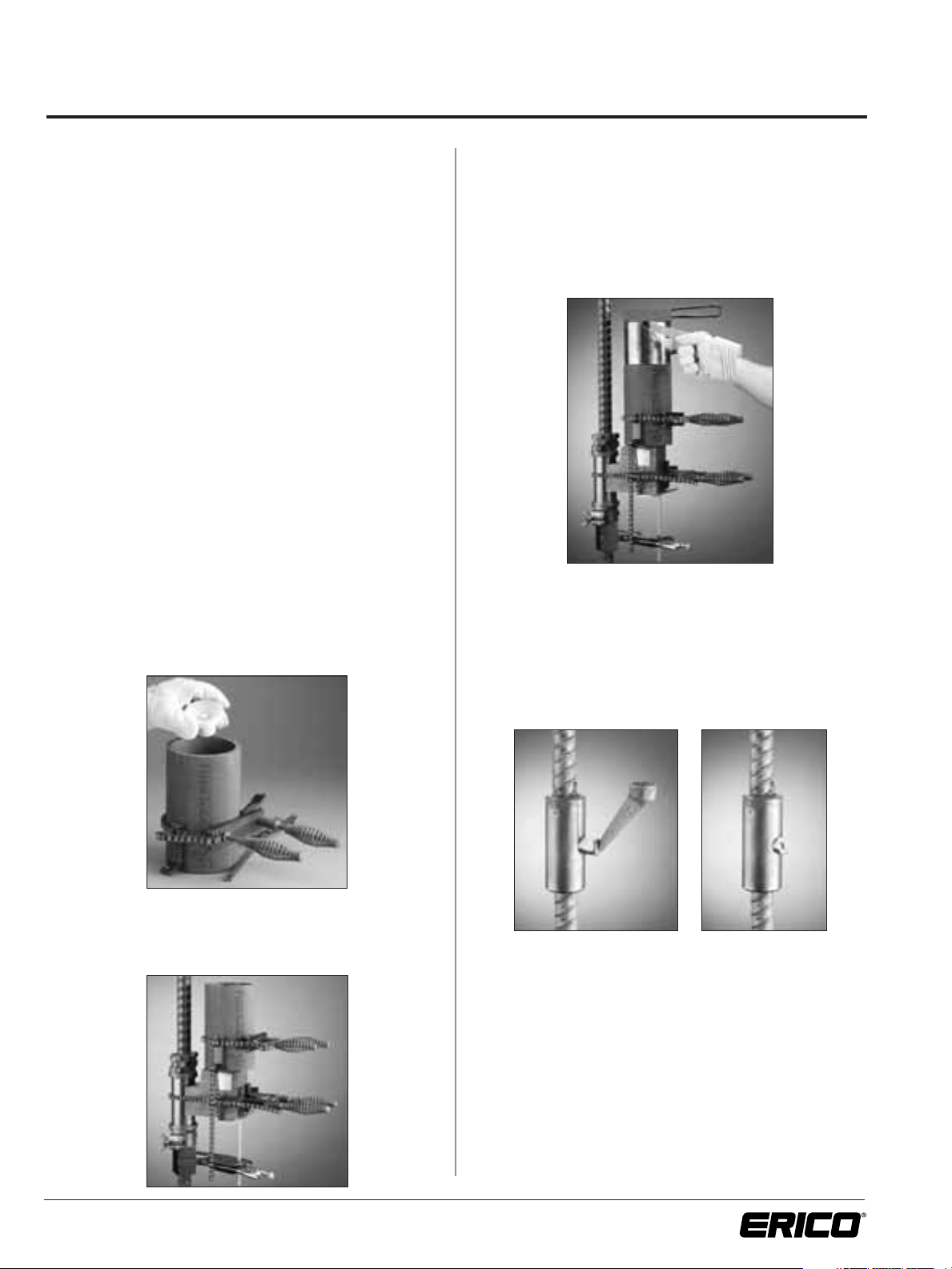

Instructions For Horizontal Splicing

1. Clean rebar ends as per “Rebar Cleaning Procedure” on

page 2.

2. Slide splice sleeve over bar before placing rebar into

position for splicing.

The average gap between bar ends should not exceed

1/4-in. (6mm). If a natural gap is not provided by the

shape of the reinforcing bar ends, a spacer can be used.

The spacer is not required to remain in position.

Spacers are enclosed in an envelope in each carton of

CADWELD

®

filler material. For certain conditions, a

spacer may be omitted. Contact ERICO

®

for additional

information.

3. Position splice sleeve by placing tap hole directly in line

with the gap between the bar ends.

Lift the splice sleeve completely and drive down the

vent pins. The splice sleeve need not be concentric with

the rebar.

For sleeves without vent pins, please see page 8.

4. Place a double wrap of packing material around rebar,

against both ends of sleeve. The second wrap of packing

should be placed alongside the first. DO NOT force

packing into splice sleeve.

5. Place end alignment fitting around rebar. Lock and slide

into position against packing and sleeve. Be sure that

the fittings slide over the ends of the sleeve.

6. Place horizontal packing clamp in position. (Normally it

will hang from the rebar.) Draw bar must not block

access to the sleeve tap hole.

Tighten hand knob on end of clamp to draw end

alignment fittings firmly into position over sleeve ends.

This action wedges the packing against the sleeve and

rebar to prevent leakage of filler material.

7. Position ceramic insert guide tube assembly firmly into

tap hole, making sure it is completely seated in the tap

hole.

8. Flame dry pouring basin and crucible before using.

As a check, a drop of water should boil off rapidly.

9. Place pouring basin into position on the sleeve.

Place chain around sleeve and finger tighten thumb

nut. Do not over tighten thumb nut.

Spacer

Page 8

6

www.erico.com

Instructions For Horizontal Splicing

NOTE: A crucible should not be reused until allowed to

cool for 15 minutes or more. If more frequent use

is desired, several crucibles complete with frames

should be used alternately to allow sufficient cooling

time.

Clean crucible thoroughly inside. Empty the crucible

completely. See Note 13 & 14 on this page for

additional information. Do not use a wire brush.

Place crucible ceramic insert in bottom of crucible.

All crucibles use the same ceramic insert.

The crucible ceramic insert assembly is supplied with a

steel disk pre-installed into it as a one-piece assembly.

If the steel disk is not present in the ceramic insert, place

the steel disk on the crucible ceramic insert and check for

proper seating.

Remix bag of CADWELD

®

filler material and fill crucible

according to the instructions on page 7.

10. Position crucible on the pouring basin and secure the

tiedown chain. Keeping it just loose enough to allow

swivelling of the crucible without tipping.

11. Open the starting material container. Evenly distribute

the starting material over the filler material in the crucible,

saving a small amount to be placed on the tab of the

crucible extension. Place the crucible extension on the

crucible and put the remainder of starting material

on the tab. Place the crucible cover on the extension.

Standing off to the side of the opening and up wind,

ignite the starting materials on the tab.

12. Keep the tiedown chain secured at all times.

Immediately after the sleeve has filled, slowly swivel

the crucible back and forth to break the slag between

the base of the crucible and top of the pouring basin.

Repeat after 15 to 20 seconds as necessary. After the

slag has solidified, release the tiedown chain and remove

the

crucible. All other parts can then be removed.

13. Clean the crucible by turning upside down and placing

a metal rod (#5 [16mm] rebar) against the ceramic and

lightly tapping the rod end to discharge the slag and

ceramic into a suitable waste container.

14. Break off riser with hammer. Clean slag from crucible

and pouring basin as soon as possible to promote cooling.

Use a whisk broom, rag or wooden wedge for cleaning.

Do not use a wire brush. Cover and crucible extension

need not be cleaned every time.

NOTE: Clean flash or debris from all mating surfaces as this

causes springing of the equipment clamps and hinges.

Page 9

7

www.erico.com

Filler Material Remixing And Placement Procedures

1. Cut off top of bag just below closure tie. This will allow

enough remaining bag length to permit remixing.

2. Open bag and then reclose to entrap air. (Starting

material container may be removed if it is convenient.)

3. Fold over cut end of bag, leaving enough open space

within the bag to allow free tumbling of filler material.

4. Using both hands, flip-flop the bag several times,

allowing the filler material to remix.

5. Unfold bag and pour enough filler material into a

prepared crucible to completely cover the crucibleceramic and steel-disk assembly. Lift crucible up to

ensure filler material is not leaking. (If it is leaking,

carefully pour the filler material back into the bag and

reseat the steel disk or replace if bent.)

6. Dump the remainder of the filler material into the

crucible, taking care to remove the container of starting

material if it is still in the filler material.

Page 10

8

www.erico.com

Instructions For

Venting CADWELD

®

Horizontal Splices*

The use of wire or nails for venting is two-fold. Primarily,

they raise or lift the sleeve from the top of the rebar, creating a gap between the sleeve and bar. The gap is necessary

for proper fill at the top of a horizontal splice. Gravity takes

care of filling the bottom of the sleeve.

The second purpose of the wires or nails is to provide a

path for the escape of air from the inside of the sleeve.

During splicing, air inside the sleeve is greatly expanded by

the incoming molten metal. If this air is trapped in the

sleeve, it takes up volume and will not allow the metal to

fill correctly. Creating an avenue of escape (with the wires

or nails) allows the metal to adequately fill the splice sleeve.

Venting with vent pins. Raise sleeve until it touches the

bottom of the bar and firmly drive down vent pins with a

hammer.

Venting with twisted tie wire. Place uncoated steel wire

on top of bar. Wire should be long enough to protrude

approximately 2-in. (50 mm) into sleeve and out beyond

End Alignment Fitting as shown above.

Venting with nails. Place uncoated steel nail on top of

bar. Nail should be long enough to protrude approximately

2-in. (50mm) into sleeve and out beyond End Alignment

Fitting as shown above.

Venting of B-Series structure splice with twisted tie

wire. Place uncoated steel wire on top of bar. Wire should

be long enough to protrude full length of sleeve and out

beyond End Alignment Fitting as shown above.

*Formerly Bulletin 101

Page 11

9

www.erico.com

Inspection

Inspection of a CADWELD®splice is a visual process.

Properly made splices will have filler metal visible at both

ends of the sleeve and at the Tap Hole.

Due to the gasket action of the packing, the filler metal will

not always flow to the very edge of the sleeve. This condition is most prominent in splices that require use of the

Horizontal Packing clamp which, when tightened, forces

the packing into the sleeve. The bottom of a vertical splice

will exhibit the same tendency due to the weight of the

equipment forcing the packing into the sleeve.

This indent caused by the packing will vary from 1/8-in.

(3 mm) to 1/4-in. (6 mm) in depth. Occasionally, where

a loose end of the packing has been forced into the sleeve,

the indent can vary from 3/8-in. (9.5 mm) to 1/2-in.

(12.7 mm) in depth. See Figures 1 and 2 for illustrations.

NOTES:

1. Do not manually force packing into sleeve. As described

above, the packing will be forced into the sleeve by

either the Horizontal Packing Clamp or by the weight of

the splicing equipment.

2. When making vertical splices, it is important that the

proper length packing be used at both the top and the

bottom of the sleeve. The longer bottom packing (2-1/2

wraps) is used to seal the bottom of the sleeve while the

shorter top packing (1-1/4 wraps) is loosely placed around

the top of the sleeve in order to permit expanding air to

escape and allow proper fill. Top packing should never

be forced inside the sleeve.

Due to the loose top packing, filler metal will often

flow above the top of the sleeve. This overflow is not

detrimental to the splice and should not be a cause for

rejection. In fact, an overflow is evidence of complete

fill. It is not necessary to remove filler metal flash

(collars) at the end(s) of the splice sleeves.

Adequate venting is essential for proper fill in all splice

positions. See page 8 for recommended

venting

procedures on horizontal splices.

3. When the riser is removed, a shrinkage bubble may be

exposed in the Tap Hole area. This bubble should not

be distinguished from general porosity and shall not

constitute cause for rejection.

Eccentricity And Cocking Of Rebars

If the splice sleeve is filled with sound metal, eccentricity,

cocking and contact of rebars within the sleeve will have

no effect on splice performance and are not cause for

rejection. Standard splicing procedures for horizontal splices

require lifting of the splice sleeve until contact is made with

the bottom of the rebar.

Figure 1

Figure 2

Filler Metal

Reinforcing Bar

Splice Sleeve

End Alignment

Fitting

Packing

Note How It Bulges Into

Opening Between Splice

Sleeve And Reinforcing Bar

(See Note 1.)

Spacer

Reinforcing Bar

Splice Sleeve

Filler Metal

Shrinkage

Bubble

(See Note 3.)

Page 12

10

www.erico.com

Rejection Of A Splice And Its Causes

Improper Fill

Filler metal not visible at ends of sleeve –

See “Void Limits.”

1. Filler metal leakage due to faulty use of packing or

misalignment of equipment.

2. Excessive gap between the ends of the rebars or

between the rebar end and the plate or structure to

which a B-Series splice sleeve is welded. (Requires more

filler metal to fill this space.)

3. Use of a smaller cartridge than called for or use of only

part of the correct cartridge due to spillage when loading.

4. Undersize rebar requiring more filler metal to completely

fill the sleeve. (Check the latest ASTM specification.)

5. Packing forced into the sleeve beyond the acceptable

void limits.

6. If rebars are not clean and dry, gas or steam will be

generated by the heat of the molten filler metal. This

gas or steam can cause a blowout or general porosity

and produce voids.

7. Improper placement of rebar ends in sleeve causing

blockage of incoming filler metal at the Tap Hole.

8. Inadequate venting of Splice Sleeve. For vertical splices

refer to Splice Kit Sheet for proper length of top packing

(approximately 1-1/4 wrap around top bar). See page 8

for recommended venting procedures on horizontal

splices.

9. Sound splices often have pin holes, shrinkage fissures

and cold joints. These are usually visible at the ends of

completed splices and are not cause for rejection.

Slag at Taphole

1. Omission of Steel Disk at bottom of Crucible.

2. Any one or more of items 1, 2, 3, and 4 under

“Improper Fill.”

NOTE: When checking for filler metal at the sleeve Tap

Hole, you cannot rely on color alone. When a hot

riser is broken off, the exposed filler metal will

oxidize almost immediately and discolor. If there is

any doubt as to whether filler metal or slag is present

in the Tap Hole, use a coarse file, prick punch or

hammer to test. Filler metal will shine while slag will

remain dull and crumble. Breaking off the riser may

pull metal out of the sleeve Tap Hole. This should

not be construed as an unfilled Tap Hole and is not

cause for rejection.

Blowouts indicate that the cleaning practice

for rebar ends should be reviewed

Power wire brushing and torch drying (as called for in

standard instructions “Rebar Cleaning Procedure”) will help

eliminate blowouts and severe voids.

Blowouts also can be caused by Splice Sleeves and other

equipment being damp. This most commonly occurs when

material is left out overnight or in the rain.

Page 13

11

www.erico.com

Void Limits

Splices shall be acceptable if the void per end does not exceed the limit listed below. Void areas

are approximated as shown in the illustrations below. More exact void measurements should be

made only when necessary.

SUMMARY

The inspection of a CADWELD®rebar splice is visual. Occasional checking of the workmanship of the splicer to make sure

that

he or she is following the correct splicing procedure will

serve to reinforce the judgement of the inspector on the job.

ERICO

®

standard instructions

should be consulted for additional information.

NOTES:

1. Allowable accumulative void

is shown for each end. For

example, a splice of #18 bar

in RBT-1891 is acceptable

with a spot void 1

1

/2-in.

(38.1 mm) wide, 1

1

/2-in.

(38.1 mm) deep, and 5/16-in.

(7.9

mm) low fill around

remaining

perimeter

of bar.

(Cumulative void are = 1.50

(1

1

/2 -5/16) + 7.09 (5/16 –

3/16) =

2.66 square inches

[17.2 cm

2

].)

The width (W)

of any void is

measured at

the bar perimeter.

There is a

3/16 in. (5 mm) allowance

for packing.

2.

Use this column for all

standard splices; vertical,

horizontal, horizontal side

fill, angled splices, and

B-series structure splices

with spot voids.

3. Use this column for vertical

splices only with low filler

metal around entire circumference (for spot voids, use

Column A). Applicable also

for vertical B-Series Structure

Splices with low filler metal

around entire circumference.

NOTE:

Void dimensions can be

established by use of a

probe of tie wire.

Bar Size Sleeve Number Allowable Void

Column A (1) (2) Column B (3)

Spot Voids Full Circumference Low

(in

2

) (cm2) (in) (cm)

#4 RBT5101A (HA) or RBB592JA 0.47 3.03 0.500 1.27

#5 RBT5101A (HA) or RBB592JA 0.53 3.41 0.500 1.27

#6 RBT6101A (HA) or RBB692JA 1.05 6.77 0.625 1.58

#7 RBT7101A (HA) or RBB792JA 1.03 6.64 0.562 1.42

#8 RBT8101A (HA) or RBB8101JA 1.02 6.58 0.500 1.27

#9 RBT9101A (HA) or RBB992JA 1.02 6.58 0.500 1.27

#10 RBT1091A (HA) or RBB1092JA 1.03 6.64 0.437 1.11

#11 RBT11101A (HA) or RBB11101JA 1.53 9.87 0.562 1.42

#14 RBT14101A (HA) or RBB14101JA 2.15 13.8 0.625 1.58

#18 RBT1891A (HA) or RBB1892JA 3.00 19.3 0.625 1.58

#6 to #7 RBT7101A (HA) 1.05 / 1.03 6.77 / 6.64 0.625 / 0.562 1.58 / 1.42

#7 to #8 RBT8101A (HA) 1.03 / 1.02 6.64 / 6.58 0.562 / 0.500 1.42 / 1.27

#8 to #9 RBT9101A (HA) 1.02 / 1.02 6.58 / 6.58 0.500 / 0.500 1.27 / 1.27

#9 to #10 RBT10901A (HA) 1.02 / 1.03 6.58 / 6.64 0.500 / 0.437 1.27 / 1.11

#10 to #11 RBT11101A (HA) 1.58 / 1.53 10.1 / 9.87 0.625 / 0.562 1.58 / 1.42

#11 to #14 RBT1114101A (HA) 1.53 / 1.52 9.87 / 9.80 0.625 / 0.625 1.58 / 1.58

#11 to #18 RBT1118101A (HA) 1.53 / 1.99 9.87 / 12.8 0.562 / 0.500 1.42 / 1.27

#14 to #18 RBT1418101A (HA) 2.15 / 1.99 13.8 / 12.8 0.625 / 0.500 1.58 / 1.27

= T-Series and B-Series = T-Series Transition

Void Limits

Page 14

12

www.erico.com

Additional Instructions For B-Series

1. Leave protective wrappers on sleeves until ready to arc

weld.

2. When removing protective wrappers, avoid tearing as

wrappers must be inserted in sleeves after welding and

before caplugs are installed as shown.

3. Cut or fold protective wrapping paper same length as

the sleeve (splice sleeve original wrapping.)

4. Insert paper into sleeve with unprinted side out.

5. Place O.D. sleeve cap caplug over sleeve and tap hole

caplug in tap hole (and vent hole plug in vent hole if

required). See table in catalog for proper part number.

6. Caplugs must be kept tightly in place until removed for

splicing bar in sleeve.

7. As an additional precaution against moisture, it is

suggested that polyethylene sheet, tarpaulins, building

paper or other protective cover be used to cover sleeves

after welding and until they are spliced.

8. If CADWELD

®

splicing of the welded assembly will not

occur for a week or more, it is recommended that the

metal O.D. end cap be placed over the end of the sleeve

and secured with all weather pipe tape to hold it in

position. The metal end cap will protect against dislodging

or puncturing of the plastic O.D. caplug.

9. When ready to complete the connection of rebar to the

sleeve, remove end caps, plugs, paper and flame dry

sleeve thoroughly.

NOTES:

1. O.D. sleeve cap caplug, tap hole caplug, and paper must

be placed in sleeve as soon as sleeve has cooled after

welding to effectively prevent internal rusting.

2. Part numbers for these accessories are listed in the

catalog. See catalog for additional information.

Welding of Splice Sleeves to Structural Steel

Splice sleeves are generally arc welded to the structural steel in

a fabricating shop. The design of the weld, the selection of

the electrode, etc. depend on the chemical and physical

properties of the structural steel to which the splice sleeves

are welded. The engineer designing the assemblies should

refer to the pertinent codes and recommended practices of

the American Concrete Institute, American Welding Society,

etc.

Care of Finished Assemblies

Following the instructions on this page, CADWELD®B-Series

sleeves welded to the finished assemblies are covered to inhibit

rusting and foreign contaminants from entering the sleeve

interior.

Page 15

13

www.erico.com

Addenda

External Bar Reference Marks

Each bar should be marked some known distance from the

end to provide an external means of checking the location of

the bar ends within a completed splice. Any convenient distance may be used so long as the marks are visible outside of

the splice sleeve. As an example, we have used the dimension

of 12 in. (30.5 cm).

For inspection purposes, we recommend a plus or minus tolerance of 1/4-in. (6 mm) on each reference mark.

To prevent damage to the bar, we recommend using either

permanent ink or paint as a marking material, blunt nose

punch or draw file at the option of the engineer. Do not use

prick punch or chisel.

Using our recommendations, the procedure would be as

follows:

1. Prior to making the splice, an external reference mark shall

be applied to each bar at a distance of 12 in. (30.5 cm) plus

or minus 1/4-in. (6 mm) from the end of the reinforcing bar.

2. After the splice is completed, the distance between external

reference marks shall not exceed 24

3

/4

-in. (62.9 cm).

3. The midpoint of the distance between external reference

marks shall lie within the diameter of the sleeve tap hole.

NOTE: When distance between reference marks is less than

231/2

-in. (59.7 cm), marks may not be within tolerance.

A random check on reference mark locations should

be made.

Bar End Gap

If a natural gap is not provided by the shape of the reinforcing

bar ends, such as the tapered nature of shear cut bar ends or

the tapered and uneven surface of flame cut ends, a spacer

can be used to obtain a 3/16-in. (5 mm) to 1/4-in. (6 mm)

average gap between the bar ends. An average gap is not

restricted to a uniform gap.

In the horizontal position, a spacer can be used to set the

average gap and then it can be removed. The spacer is not

required to remain in position.

In the vertical position, when a natural gap is not formed by

the shape of the reinforcing bar ends, a spacer may be used to

provide a gap.

B-Series Sleeve Repair

Piggy-Back Repair

Repair of low filled structure splices can be accomplished by

stacking or “Piggy-Backing” a second sleeve on to the end of

the original sleeve. Depending upon construction conditions,

the piggy-back sleeve may be a standard bar-to-bar splice

sleeve, standard J-Groove structure splice sleeve, split bar-tobar splice sleeve, or a split J-Groove structure splice sleeve.

(Please see sketches on page 14.)

The principle behind the use of a bar-to-bar splice sleeve as

the piggy-back repair is to completely fill the void in the initial

sleeve and the new sleeve. Doing this only requires the use

of a tack weld between sleeves. However, the filler metal

cartridge must be adjusted each time to allow for the extra

volume created by the voids in the initial splice.

The use of a J-Grooved structure splice sleeve enables the

voids in the initial splice to be packed with inert packing

material, eliminating having to calculate the void areas and

adjusting the filler metal cartridge accordingly. A standard

cartridge can be used each time. However, a structural weld

between the initial and piggy-back sleeve is required to transmit the tension stress from the repair sleeve through the initial

sleeve and into the structural plate or shape.

When it is not possible to slide a new sleeve over the loose

end of the reinforcing bar, a split sleeve can be placed around

the reinforcing bar and welded together forming a closed

sleeve. This can be done using either a split bar-to-bar or a

split structure splice sleeve, depending on which method of

repair is used. When welding the split sleeve, care should be

taken to prevent striking an accidental arc on the reinforcing

bar.

Page 16

Addenda (continued)

Tap Hole Relocation

Due to unforeseen clearance restrictions, B-Series sleeves are

sometimes welded to structure assemblies with their tap hole

oriented in the wrong directions, preventing the splicing

equipment from fastening to the sleeve. In some instances

the only method of correction is to redrill a new tap hole in

a different location. This can be accomplished without altering

the function of the splice sleeve as long as the following conditions are met.

1. The new tap hole should be the same size and distance

from the end of the sleeve as the original tap hole.

2. When splicing a standard grade 60 (420 MPa) reinforcing

bar, the abandoned tap hole should be plug welded using

at least an E70XX electrode or equivalent.

3.

Drilling of the new tap hole should always be accomplished

without the assistance of cutting oils or other lubricants to

prevent contamination of the splice sleeve and subsequent

cleaning.

Erroded Tap Hole Repair

Improper seating of the pouring basin against the sleeve

can cause filler metal or slag leakage to occur, eroding small

amounts of the external splice sleeve surface. When it is

impractical to remove the sleeve, strength integrity can be

restored by building up the eroded area with at least an

E70XX electrode or equivalent.

Cleaning Rusty Sleeves

To clean B-Series sleeves that are welded to structural assemblies and have become rusty, we recommend the following

procedures:

1. Flame dry sleeves with torch to remove all moisture

and/or burn away any other foreign matter. Flame should

be soot free and not leave any residue or deposits on

the inside sleeve surface. A “rose-bud” torch tip is

recommended.

2. Using a solid end brush (contact ERICO

®

for brush size

and information), and a pencil grinder with compatible

revolutions per minute capacity, clean the inside sleeve

and plate surfaces.

3. Any pitting in the grooves not cleaned by the end brush

can be cleaned using a radial end brush (wheel brush).

The wheel brush can be attached to an arbor and used in

the pencil grinder.

4. Clean tap hole using a tube brush.

5. All brushes must be run dry. Lubricants or other abrasives

should not be used.

14

www.erico.com

Rebar

CADWELD Bar-to-Bar

Splice Sleeve

Fillet Weld

CADWELD

Structure

Splice Sleeve

(TYP)

Void filled with

filler metal

Packing

Material

Void packed with

packing material

CADWELD

Structure

Splice Sleeve

Structural

Weld

Structural

Weld full

length of

sleeve

Void filled with

filler metal

CADWELD

Bar-to-Bar

Split Splice

Sleeve

Fillet Weld

Structural

Weld full

length of

sleeve

Packing

Material

CADWELD

Split Structure

Splice Sleeve

Structural

Weld

Void packed with

packing material

Page 17

15

www.erico.com

Addenda (continued)

Use of Sleeves out of their Normal Position

The only difference between vertical and horizontal sleeves

are the vent pins added to the horizontal sleeves. For this

reason, horizontal sleeves can be used in the vertical position and vertical sleeves can be used in the horizontal position without losing splice integrity, providing the following

procedures are followed:

1. Horizontal sleeves used in the vertical position require

plugging of the vent pins to eliminate filler metal leakage.

This can be accomplished by bending the vent pin over

or bubbling the bent pin closed with a torch.

2. Vertical sleeves used in the horizontal position require

the use of tie wire or nails to protrude underneath the

packing material and out beyond the end alignment

fitting. This will raise the sleeve off the bar surface and

also create an avenue for the air inside the sleeve to

escape. (Please see Venting Section on page 8.)

Repair of Bar-to-Bar Production Splice Samples or

Rejected Splices

Following the requirements of Regulatory Guide 1.10 for

removal of production splice test samples, it is necessary to

replace the removed test piece with one or two additional

splices. If the bar from which the sample was taken can be

conveniently moved, the bar ends should be repositioned and

spliced with a replacement splice. However, if the bar cannot

be conveniently moved, the test sample will have to be

replaced with two splices and a replacement bar the same

length as that which was removed. The same procedures can

be used for replacing rejected splices.

In congested areas, or for splices to short dowel lengths, it

may not be practical to cut the reinforcing bar to remove the

rejected splice. The only practical method may be to split the

original splice sleeve with a cutting torch, remove the sleeve

and filler metal and install another splice over the same length

of bar. When splitting the splice sleeve, care should be taken

to prevent damaging the reinforcing bar.

Traceability

ERICO®provides for material traceability of splice sleeves and

filler metal. When required, splice sleeves are traceable to the

manufacturer’s original material certification.

Splice sleeves and their boxes and the filler metal cartridge

boxes are marked to provide traceability.

WARNING

ERICO products shall be installed and used only as indicated in ERICO’s product instruction sheets and training materials. Instruction sheets are available at www.erico.com and from your ERICO customer service

representative. Improper installation, misuse, misapplication or other failure to completely follow ERICO’s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death.

WARRANTY

ERICO products are warranted to be free from defects in material and workmanship at the time of shipment. NO OTHER WARRANTY, WHETHER EXPRESS OR IMPLIED (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF ANY ERICO PRODUCTS. Claims for errors, shortages, defects or nonconformities ascertainable upon inspection

must be made in writing within 5 days after Buyer's receipt of products. All other claims must be made in writing to ERICO within 6 months from the date of shipment or transport. Products claimed to be nonconforming or defective must, upon ERICO's prior written approval in accordance with its standard terms and procedures governing returns, promptly be returned to ERICO for inspection. Claims not made as provided above and

within the applicable time period will be barred. ERICO shall in no event be responsible if the products have not been stored or used in accordance with its specifications and recommended procedures. ERICO will, at its

option, either repair or replace nonconforming or defective products for which it is responsible or return the purchase price to the Buyer. THE FOREGOING STATES BUYER’S EXCLUSIVE REMEDY FOR ANY BREACH OF

ERICO WARRANTY AND FOR ANY CLAIM, WHETHER SOUNDING IN CONTRACT, TORT OR NEGLIGENCE, FOR LOSS OR INJURY CAUSED BY THE SALE OR USE OF ANY PRODUCT.

LIMITATION OF LIABILITY

ERICO excludes all liability except such liability that is directly attributable to the willful or gross negligence of ERICO's employees. Should ERICO be held liable its liability shall in no event exceed the total purchase price

under the contract. ERICO SHALL IN NO EVENT BE RESPONSIBLE FOR ANY LOSS OF BUSINESS OR PROFITS, DOWNTIME OR DELAY, LABOR, REPAIR OR MATERIAL COSTS OR ANY SIMILAR OR DISSIMILAR CONSEQUENTIAL LOSS OR DAMAGE INCURRED BY BUYER.

Page 18

Page 19

Page 20

Copyright ©2004, 2009 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

PDF088_B C1329IS09WWEN 3M0510

AUSTRALIA

Phone 1-800-263-508

Fax 1-800-423-091

BELGIUM

Phone 0800-757-48

Fax 0800-757-60

CANADA

Phone +1-800-677-9089

Fax +1-800-677-8131

CHILE

Phone +56-2-370-2908

Fax +56-2-369-5657

DENMARK

Phone 808-89-372

Fax 808-89-373

FRANCE

Phone 0-800-901-793

Fax 0-800-902-024

GERMANY

Phone 0-800-189-0272

Fax 0-800-189-0274

HONG KONG

Phone +852-2764-8808

Fax +852-2764-4486

HUNGARY

Phone 06-800-16538

Fax +39-0244-386-107

INDONESIA

Phone +62-21-575-0941

Fax +62-21-575-0942

ITALY

Phone 800-870-938

Fax 800-873-935

MEXICO

Phone +52-55-5260-5991

Fax +52-55-5260-3310

NETHERLANDS

Phone 0800-0200-135

Fax 0800-0200-136

NORWAY

Phone 800-100-73

Fax 800-100-66

SINGAPORE

Phone +65-6-268-3433

Fax +65-6-268-1389

SPAIN

Phone 900-993-154

Fax 900-807-333

SWEDEN

Phone 020-790-908

Fax 020-798-964

SWITZERLAND

Phone 0800-55-86-97

Fax 0800-55-96-15

THAILAND

Phone +66-2-267-5776

Fax +66-2-636-6988

UNITED KINGDOM

Phone 0808-2344-670

Fax 0808-2344-676

UNITED STATES

Phone 1-800-753-9221

Fax +1-440-248-0723

POLAND

Phone +48-71-349-04-60

Fax +48-71-349-04-61

BRAZIL

Phone +55-11-3623-4333

Fax +55-11-3621-4066

www.erico.com

CHINA

Phone +86-21-3430-4878

Fax +86-21-5831-8177

UNITED ARAB

EMIRATES

Phone +971-4-881-7250

Fax +971-4-881-7270

Loading...

Loading...