Page 1

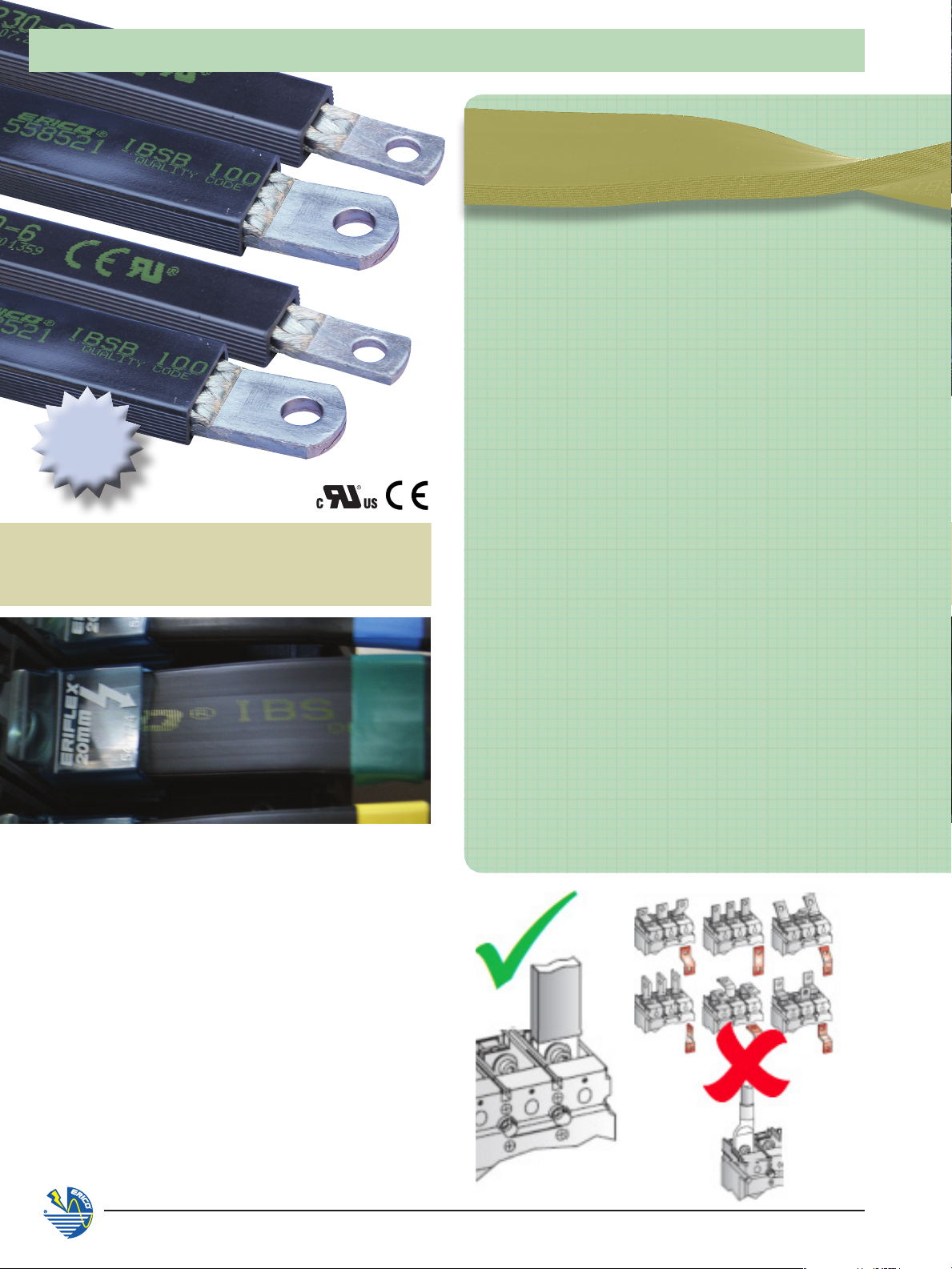

Insulated Braided Conductor (IBSB & IBSBR)

Insulated Braided Conductor

Technical Characteristics

• IBSB and IBSBR are specially designed and

developed to be suitable and connectable for

molded case circuit breaker ranges, including

most compact breakers on the market

• IBSB and IBSBR are formed with high-quality

electrolytic copper wire (diameter 0,15 mm for

maximum flexibility)

• Material savings: Integral palm without lugs

or terminals

NEW

Insulated braided conductors suitable for

all the main molded case circuit breakers

worldwide.

Ideal connection for molded case circuit breakers

• Quick and easy to install: Ready to use. No

cutting, stripping, crimping or punching.

Less labor time for installation

• Weight savings: A flat braid weighs less than a

cable (with insulation) and lugs.

Offers better copper usage (Skin Effect)

• The insulation is a high-resistance selfextinguishing PVC – 105°C working

temperature maximum

• Full application range: 80 A to 630 A

(section 25, 50, 70, 100, 120, 185 and

240 mm2), with 230 up to 1030 mm length

• Reliability – No extra contact due to the lugs

being crimped at the extremities of the cables.

Integral palm without tin addition or crimped

lug for an excellent electrical contact.

• Resistant to vibration - ideal alternative to cable

The IBSB and IBSBR range can be used as an alternative

to cable for all low-voltage applications. It is suitable

and connectable for molded case circuit breaker ranges,

including most compact breakers on the market. From

80 A up to 630 A circuit breakers, you can directly

connect the IBSB/IBSBR on the front access terminals

breaker without additional accessories, such as angular

connectors, spreaders, ring terminal connectors

or extenders. No lugs and no cutting, stripping, or

crimping are necessary.

Very simple! Very quick! Ready to use!

24

Direct connection

No spreader,

no extender

needed

No lug

needed

www.erico.com

Page 2

Insulated Braided Conductor (IBSB & IBSBR)

The optimised alternative to cable - Ready to use.

ERICO has developed a unique, state-of-the-art

manufacturing line to massivate directly the palms of

IBSB and IBSBR braids.

The innovative manufacturing process provides an

effective electrical contact, due to the integral palms,

without the addition of tin or crimped lugs. This

process welds the flexible braid and brings back a

solid tinned or red copper block as a palm. Unlike

the traditional press-welded palms process, ERICO’s

process is suitable for red copper, but also for tinned

plated copper. The electrical contact between each

wire is optimized.

www.erico.com

This ERICO process also helps eliminate moisture

issues in the palms. By using crimped lugs in a severe

environment, moisture can enter in the lug (often by

capillarity) and create corrosion between each wire.

After several years, the electrical contact between

each wire can deteriorate and alter the electrical

conductivity of the equipment. The corrosion in the

palm is impossible to remove without changing the

element.

This process produces RoHS products; no additional

substances are added to the tinned-plated wires

during the manufacturing process.

25

Page 3

Insulated Braided Conductor (IBSB & IBSBR)

AA

+5

Comparison of tensile strength

Solidified

Palms

Traditional

Braid

Displacement

Nominal clamping force

Technical data

• Excellent electrical contact with integral palm construction

• Good tensile strength

• High resistance: vinyl compound

• Maximum working temperature:

105º C

• Self-extinguishable: UL 94 V0

• Dielectric strength: 20 kV/mm

• Max. working voltage:

1000 V AC-1500 V DC-IEC & UL 758

• Max. working voltage:

600V AC/DC – UL 67

• Class II Conductors (IEC 61439-1,

Chapter 8.4.4 Protection by total

insulation)

• Tinned (IBSB 25-50-70-100) or red

(IBSBR 120-185-240) electrolytic

copper

• Wire diameter: 0.15 mm for

maximum flexibility - According to

EN 13602

• Very good resistance to vibration

0

L

Certification & ApprovalsInsulation Braid

• IEC 60439.1 & IEC 61439.1

•

cRUus per UL67 & CAN/CSA

C22.2 No. 29 (File E125470)

• RU per UL758 (File E316390)

• CE conformity

• RoHS compliance

• American Bureau of

Shipping (ABS®) Certificate

No. 13-HS1070074-PDA

Marine & Offshore Applications

21

1

K

J

1

26

2

2

J

K

M

www.erico.com

Page 4

Insulated Braided Conductor (IBSB & IBSBR)

Use with

circuit breaker

IBSB - Tinned Copper

125/160A

IBSB 25IBSB 50IBSB 70IBSB 100IBSBR 120IBSBR 185IBSBR 240

250A

300A

350A

IBSBR - Red Copper

400A

500A

630A

Part

Number

558500 IBSB 25-230-6 25 230 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.08

558501 IBSB 25-330-6 25 330 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.11

558502 IBSB 25-430-6 25 430 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.15

558503 IBSB 25-530-6 25 530 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.18

558504 IBSB 25-630-6 25 630 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.22

558505 IBSB 25-830-6 25 830 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.28

558506

558507

558508 IBSB 50-330-8-10 50 330 8.5 10.5 9 11 20 3 9 27 10 0.21

558509 IBSB 50-430-8-10 50 430 8.5 10.5 9 11 20 3 9 27 10 0.27

558510 IBSB 50-530-8-10 50 530 8.5 10.5 9 11 20 3 9 27 10 0.33

558511 IBSB 50-630-8-10 50 630 8.5 10.5 9 11 20 3 9 27 10 0.39

558512 IBSB 50-830-8-10 50 830 8.5 10.5 9 11 20 3 9 27 10 0.52

558513

558514

558515 IBSB 70-330-8-10 70 330 8.5 10.5 9 11 20 4.3 11 27 10 0.28

558516 IBSB 70-430-8-10 70 430 8.5 10.5 9 11 20 4.3 11 27 10 0.362

558517 IBSB 70-530-8-10 70 530 8.5 10.5 9 11 20 4.3 11 27 10 0.444

558518 IBSB 70-630-8-10 70 630 8.5 10.5 9 11 20 4.3 11 27 10 0.527

558519 IBSB 70-830-8-10 70 830 8.5 10.5 9 11 20 4.3 11 27 10 0.692

558520

558521

558522 IBSB 100-330-8-10 100 330 8.5 10.5 9 11 24 5 13 31 10 0.39

558523 IBSB 100-430-8-10 100 430 8.5 10.5 9 11 24 5 13 31 10 0.50

558524 IBSB 100-530-8-10 100 530 8.5 10.5 9 11 24 5 13 31 10 0.62

558525 IBSB 100-630-8-10 100 630 8.5 10.5 9 11 24 5 13 31 10 0.73

558526 IBSB 100-830-8-10 100 830 8.5 10.5 9 11 24 5 13 31 10 0.96

558527

558528

558529 IBSBR 120-330-10 120 330 10.5 10.5 11 11 32 4.4 12 39 2 0.47

558530 IBSBR 120-430-10 120 430 10.5 10.5 11 11 32 4.4 12 39 2 0.6

558531 IBSBR 120-530-10 120 530 10.5 10.5 11 11 32 4.4 12 39 2 0.74

558532 IBSBR 120-630-10 120 630 10.5 10.5 11 11 32 4.4 12 39 2 0.88

558533 IBSBR 120-830-10 120 830 10.5 10.5 11 11 32 4.4 12 39 2 1.15

558534

558535

558536 IBSBR 185-430-10-12 185 430 10.5 12.5 12 14 32 7.1 16 39 2 0.9

558537 IBSBR 185-530-10-12 185 530 10.5 12.5 12 14 32 7.1 16 39 2 1.1

558538 IBSBR 185-630-10-12 185 630 10.5 12.5 12 14 32 7.1 16 39 2 1.3

558539 IBSBR 185-830-10-12 185 830 10.5 12.5 12 14 32 7.1 16 39 2 1.7

558540

558541

558542 IBSBR 240-430-10-12 240 430 10.5 12.5 12 14 32 9.2 18.5 39 2 1.14

558543 IBSBR 240-530-10-12 240 530 10.5 12.5 12 14 32 9.2 18.5 39 2 1.4

558544 IBSBR 240-630-10-12 240 630 10.5 12.5 12 14 32 9.2 18.5 39 2 1.65

558545 IBSBR 240-830-10-12 240 830 10.5 12.5 12 14 32 9.2 18.5 39 2 2.16

558546 IBSBR 240-1030-10-12 240 1030 10.5 12.5 12 14 32 9.2 18.5 39 2 2.67

Description

IBSB 25-1030-6 25 1030 6.5 6.5 7.5 7.5 12 2.8 9 18 10 0.35

IBSB 50-230-8-10 50 230 8.5 10.5 9 11 20 3 9 27 10 0.15

IBSB 50-1030-8-10 50 1030 8.5 10.5 9 11 20 3 9 27 10 0.64

IBSB 70-230-8-10 70 230 8.5 10.5 9 11 20 4.3 11 27 10 0.197

IBSB 70-1030-8-10 70 1030 8.5 10.5 9 11 20 4.3 11 27 10 0.857

IBSB 100-230-8-10 100 230 8.5 10.5 9 11 24 5 13 31 10 0.27

IBSB 100-1030-8-10 100 1030 8.5 10.5 9 11 24 5 13 31 10 1.19

IBSBR 120-230-10 120 230 10.5 10.5 11 11 32 4.4 12 39 2 0.33

IBSBR 120-1030-10 120 1030 10.5 10.5 11 11 32 4.4 12 39 2 1.43

IBSBR 185-330-10-12 185 330 10.5 12.5 12 14 32 7.1 16 39 2 0.7

IBSBR 185-1030-10-12 185 1030 10.5 12.5 12 14 32 7.1 16 39 2 2.1

IBSBR 240-330-10-12 240 330 10.5 12.5 12 14 32 9.2 18.5 39 2 0.89

L mmØ1 mmØ2 mmA1 mmA2 mmJ mmM

S

2

mm

mm

K1

mm

K2

mm

Kg

www.erico.com

27

Loading...

Loading...