Page 1

IBS/IBSB Advanced Insulated Braided Conductor, Halogen Free–IBSBADV50-330 (534408)

IBS/IBSB Advanced Insulated Braided Conductor, Halogen Free is the ideal ready-to-install flexible wire replacement solution that

is specifically designed for connections to all molded case circuit breakers, including the most compact breakers on the market.

IBS/IBSB Advanced connects to the front access terminals of the breakers without any additional accessories, such as angular

connectors, spreaders, ring terminal connectors or extenders. IBS/IBSB Advanced is available in cross sections of 25 to 240 mm²

(49.34 to 273.65 kcmil), lengths from 230 to 1,030 mm (9.06" to 40.55"), and 80 to 700 A.

Manufactured in an ISO 9001 certified automated facility, IBS/IBSB Advanced is formed by weaving high-quality electrolytic copper

wire to form a durable low voltage connector with maximum flexibility which allows for more compact power connections to

circuit breakers. The IBS/IBSB Advanced allows users to reduce the total size and weight of the installation, improving both design

flexibility and assembly aesthetics.

The unique manufacturing process of integral pre-punched palms make IBS/IBSB Advanced ready to connect out of the box. There

are no lugs to purchase or install, making connections simpler and faster and eliminates faulty connections due to vibration or

fatigue.

IBS/IBSB Advanced is compatible with all major brand molded case circuit breakers.

The advanced technology insulation is a high-resistance low smoke, halogen-free and flame retardant thermoplastic.

IBS/IBSB Advanced does not generate corrosive gases and produces a relatively low smoke opacity in accordance with IEC 61034-2

and UL 2885. The low smoke characteristic improves visibility conditions for people to be able to easily locate the emergency exit

and also allows rescue workers to better assess an emergency situation. IBS/IBSB Advanced means greater safety for individuals,

less damage for your electrical equipment and less environmental impact.

The halogen–free feature enables a reduction in the quantity of toxic smoke. IBS/IBSB Advanced does not contain any halogens,

according to IEC 60754-1 and UL 2885, minimizing toxicity and making it the ideal product for use in enclosed spaces such as

data centers, rail, and public facilities such as hospitals and schools. This also facilitates the use of IBS/IBSB Advanced in specific

applications such as submarines, switchboards and other enclosed environments that require a low emissions solution.

In addition to the above features, IBS/IBSB Advanced is compliant with the UL 94-V0 testing standard and glow wire test 960 °C.

The flame retardant portion of the test illustrates the self-extinguish feature. This superior feature of IBS/IBSB Advanced is also

shown by the Limiting Oxygen Index (LOI) at 30%. In case of fire, IBS/IBSB Advanced generates a limited quantity of smoke that is

less damaging to your electrical equipment.

Page 2

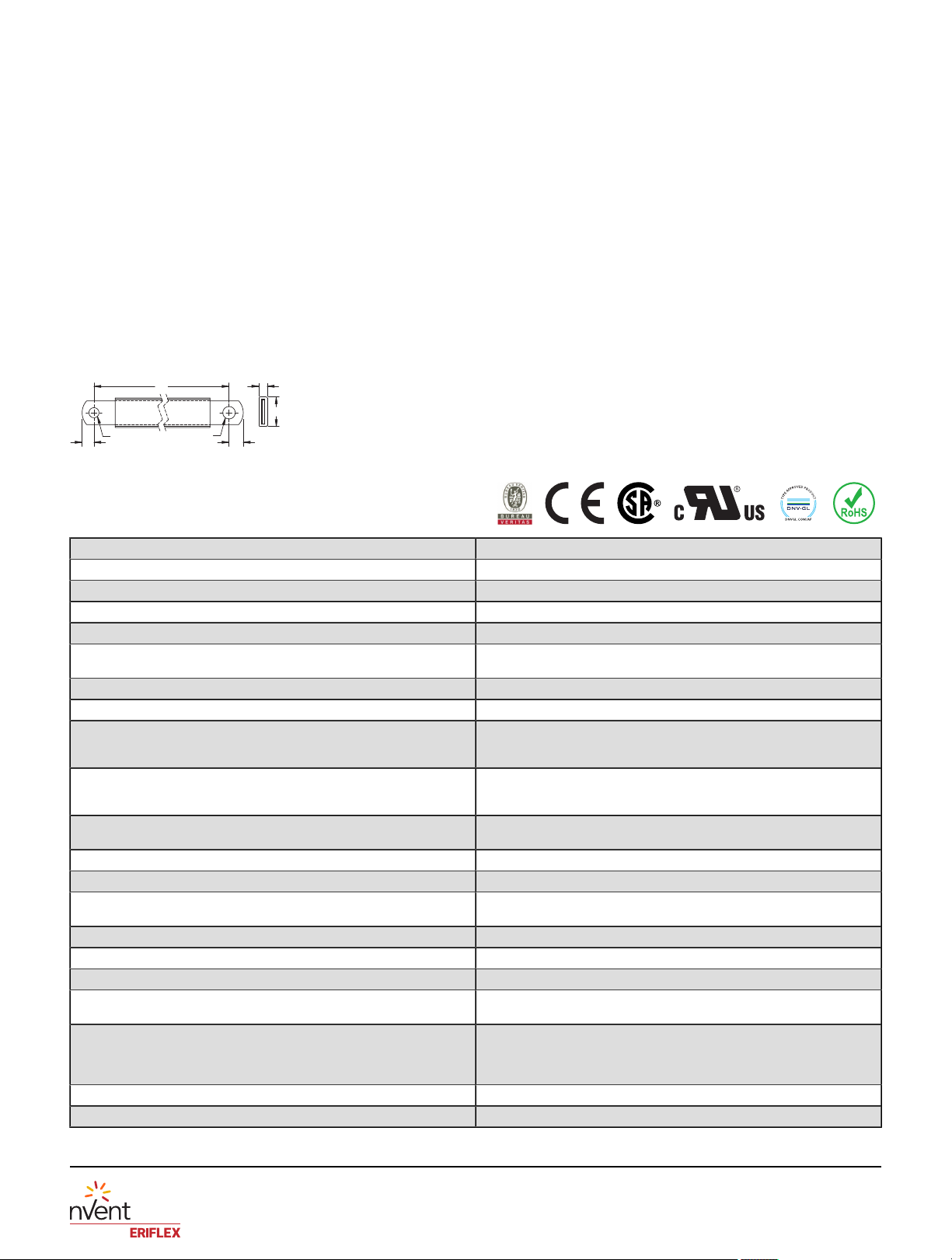

• Suitable for all main molded case circuit breakers

A

L

B

HS1

HS2

C

D

• Resistant to vibration, improving reliability and performance

• Insulated by high-resistance, halogen free, flame retardant and low smoke material

• Tinned copper provides superior corrosion resistance

• Improves assembly flexibility and aesthetics

• Quick and easy installation

• No additional cutting, stripping, crimping and punching needed

• Integral palm without lugs or terminals reduces material and assembly weight

• Conforms to NF EN 45545 obtaining an HL2 classification for chapters R22 and R23

• DNV GL® and Bureau Veritas certified for marine and offshore applications

• Small wire diameter provides maximum flexibility

• Dramatically smaller and more flexible than comparable cable based on ampacity

• Better power density than cable with lower skin effect ratio

• Reduces total installation cost

• RoHS compliant

• Tinned copper allows for copper or aluminum conductor connections

Part Number IBSBADV50-330

Article Number 534408

Typical Application Current Rating 250 A

Peak Short Circuit Current (Ipk) 30 kA

Finish Tinned

Material Copper

Dielectric Strength 20 kV/mm

Flammability Rating UL® 94V-0

Halogen Free Rating UL® 2885

Low Smoke Rating IEC® 61034-2

UV Resistance Rating UL® 854

Insulation Elongation 500 %

Insulation Thickness 0.07"

Max Working Voltage, IEC/UL 758 1,000 VAC

Max Working Voltage, UL 67 600 VAC/DC

Working Temperature -58 to 239 °F

Wire Diameter 0.006"

Certification Details UL® 67

Complies With IEC® 60439.1

Cross Section 98.68 kcmil

Conductor Width 0.79"

Thermoplastic Elastomer

IEC® 60754-1

IEC® 62821-1

ISO 5659-2

UL® 2885

UL® 2556

1,500 VDC

UL® 758

IEC® 60695-2-11 (Glow Wire Test 960 °C)

IEC® 61439.1

IEC® 61439.1 Class II

Page 3

Part Number IBSBADV50-330

Conductor Thickness 0.12"

Length (L) 12.99"

A 0.35"

B 0.43"

C 1.06"

D 0.35"

Hole Size 1 (HS1) 0.33"

Hole Size 2 (HS2) 0.41"

Certifications Bureau Veritas 41939 BV

Standard Packaging Quantity 10 pc

UPC 78285696089

EAN-13 0782856960898

Maximum Ampacity Ratings

Cross Section

(mm²/kcmil)

25/49.34 116 134 142 150 157 164 177 1.6 2

50/98.68 213 246 260 274 288 301 325 1.6 2

70/138.15 226 261 277 291 306 319 345 1.6 2

100/197.35 298 344 365 385 404 422 456 1.6 2

120/236.82 363 419 444 468 491 513 554 1.6 2

185/365.1 416 480 509 537 563 588 635 1.6 2

240/473.65 556 642 681 718 753 786 849 1.6 2

ΔT 30° C (A) ΔT 40° C (A) ΔT 45° C (A) ΔT 50° C (A) ΔT 55° C (A) ΔT 60° C (A) ΔT 70° C (A)

CE

CSA 90005

cURus

DNV GL IBS/IBSB Advanced, TAE00003B8

IEC 61439-1 Class II IBSB_ADV

IEC 61439-1 IBSB_ADV

RoHS

2 Bar Current

Coefficient

3 Bar Current

Coefficient

Circuit Breaker Compatibility

Circuit

Breaker

Current Rating

Part Number IBSBADV25x IBSADV25x IBSBADV50x IBSADV50x IBSBADV70x IBSBADV100x IBSBADV120x IBSBADV185x IBSBADV240x

Schneider

Electric®

Compact®

(IEC)

Square D®

PowerPact®

(UL)

ABB®

Tmax® (IEC)

ABB®

Tmax® (UL)

GE® Record

Plus®

(IEC/UL)

Siemens®

Sentron®

(IEC/UL)

125/160 A 250 A 300 A 350 A 400 A 500 A 630 A

NSA

NG 125

H-Frame J-Frame J-Frame J-Frame L-Frame L-Frame L-Frame - -

T1

T2

XT1

XT2

T1

T2

XT1

XT2

FD 160 FD 160 FE 250 FE 250 FG 400 FG 400 FG 400 FG 630 FG 630

VL160X

3VL1

VL160

3VL2

NSX 100

NSX 160

-

T3

-

NSX 250 NSX 250 NSX 400 NSX 400 NSX 400 NSX 630 NSX 630

T3

XT3

XT4

T4

XT3

XT4

VL250

3VL3

T3

XT3

XT4

T4 T5 T5 T5 - -

VL250

3VL3

T4 T4 T5 T5 T5

VL400

3VL4

VL400

3VL4

VL400

3VL4

- -

Page 4

Circuit Breaker Compatibility

Circuit

Breaker

125/160 A 250 A 300 A 350 A 400 A 500 A 630 A

Current Rating

Part Number IBSBADV25x IBSADV25x IBSBADV50x IBSADV50x IBSBADV70x IBSBADV100x IBSBADV120x IBSBADV185x IBSBADV240x

Moeller®

xEnergy®

NZM1 - NZM2 NZM2 NZM3 NZM3 NZM3 NZM3 NZM3

(IEC)

Cutler

Hammer®

EG Frame JG Frame JG Frame JG Frame LG Frame LG Frame LG Frame LG Frame LG Frame

Series G (UL)

Legrand®

(IEC)

DPX 160

DPX3 160

-

DPX 250

DPX3 250

DPX 250

DPX3 250

DPX 630 DPX 630 DPX 630 DPX 630 DPX 630

Hager® (IEC) h3 160 - h3 250 h3 250 h3 630 h3 630 - - -

Rockwell/Allen

Bradley (UL)

G-Frame

H-Frame

-

I-Frame

J-Frame

I-Frame

J-Frame

I-Frame

J-Frame

- K-Frame K-Frame -

NF125

Mitsubishi

Electric (IEC)

-

NF160

DSN125

NF250

DSN250

NF250

DSN250

-

NF400

DSN400

- - -

DSN160

OEZ (IEC) BC160N -

∆T = Temperature of conductors – Internal temperature of panel.

This table indicates the temperature rise produced by chosen current in the given section. This calculation does not take into account the heat dissipation from the switch gear.

IBSB Advanced Insulated Braided Conductor with a cross section of 240 mm² (473.65 kcmil) is constructed of red copper strands with tinned palms.

Distance between supports must not exceed 630 mm (17.8") according to IEC 61439-1.

BD250N

BD250S

-

BH630B

BH630S

BH630B

BH630S

BH630B

BH630S

BH630B

BH630S

BH630B

BH630S

ABB is a registered trademark of ABB Asea Brown Boveri Ltd. CSA, CSA-US and C-CSA-US are registered trademarks of Canadian Standards Association. DNV GL and the Horizon

Graphic are trademarks of DNV GL AS. GE and Record Plus are registered trademark of General Electric Company. Hager is a registered trademark of the Hager Group. IEC is a

registered trademark of the International Electrotechnical Commission. Legrand is a registered trademark of Legrand North America, Inc. Moeller, xEnergy, and Cutler Hammer are

registered trademarks of Eaton Corporation. Schneider Electric and Compact are registered trademarks of Schneider Electric SA. Siemens and Sentron are registered trademarks

of Siemens Aktiengesellschaft. Square D and PowerPact are registered trademarks of SNA Holdings Inc. Tmax is a registered trademark of ABB SACE Spa. UL, UR, cUL, cUR, cULus

and cURus are registered certification marks of UL LLC.

WARNING

nVent products shall be installed and used only as indicated in nVent's product instruction sheets and training materials. Instruction sheets are available at www.erico.com and from

your nVent customer service representative. Improper installation, misuse, misapplication or other failure to completely follow nVent 's instructions and warnings may cause product

malfunction, property damage, serious bodily injury and death and/or void your warranty.

© 2019nVentAll rights reserved

nVent, nVent CADDY, nVent ERICO, nVent ERIFLEX and nVent LENTON are owned by nVent or its global affiliates.

All other trademarks are the property of their respective owners. nVent reserves the right to change specifications without prior notice.

Loading...

Loading...