Page 1

ERITECH® SYSTEM 3000

Installation, Operation and

Maintenance Manual

Page 2

ERITECH® SYSTEM 3000 Installation,

Operation and Maintenance Manual

EDITION 14

Copyright © 2009, 2012 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERITECH, ERIFLEX and LENTON are registered

First printed 1988

trademarks of ERICO International Corporation.

IP79131_B

REVISION 2

Page 3

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The ERITECH® SYSTEM 3000

Installation, Operation

and Maintenance Manual

IP79131_B

www.erico.com

1

Page 4

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Table of Contents

Pre-Installation Requirements ................................................................................ Page 4

Grounding Systems ................................................................................................. Page 5

Downconductors ..................................................................................................... Page 5

Structural Bonding Braid & Conductive Structural Points ...................................... Page 6

Lightning Event Counters ....................................................................................... Page 6

ERITECH

Masts ........................................................................................................................ Page 7

Checking Lightning Protection Components on Receipt ................................. Page 8

ERITECH

Grounding Systems Installation ............................................................................. Page 9

Ground Resistance Lowering Compounds ......................................................... Page 12

Insulation of Grounding Systems Page ............................................................... Page 12

Bonding the Lightning Protection Ground to other Service Grounds .................. Page 12

Labelling ............................................................................................................ Page 13

Downconductors .................................................................................................. Page 14

Downconductor Hauling .................................................................................... Page 14

Penetrations ....................................................................................................... Page 16

Routing ............................................................................................................. Page 16

Securing the Downconductor ............................................................................ Page 18

Use of Mast or Conventional Cable as the Downconductor ............................... Page 19

Labelling ............................................................................................................ Page 20

Structure Bonding Braid .................................................................................... Page 20

Terminating the ERITECH

Terminating the ERITECH

Terminals and Masts ............................................................................................. Page 40

Terminals ........................................................................................................... Page 40

Masts ................................................................................................................ Page 40

Mast Bases .........................................................................................................Page 41

Mast Couplings & Guying Points ....................................................................... Page 42

Guying .............................................................................................................. Page 44

Raising of Mast .................................................................................................. Page 45

Lightning Event Counter ................................................................................ Page 48

Long Lengths of ERITECH ERICORE Downconductor ........................................ Page 49

Parallel ERITECH

Series connected ERITECH ERICORE cable sections ............................................. Page 52

Practical Examples for long lengths of ERITECH ERICORE ............................. Page 54

Certification .............................................................................................................. Page 55

Operation & Maintenance ..................................................................................... Page 55

Maintenance Records ........................................................................................... Page 58

Specifications ............................................................................................................ Page 59

Glossary ....................................................................................................................... Page 62

Certificate of Compliance and Warranty Registration .................... Inside Back Cover

®

DYNASPHERE Terminals ......................................................................... Page 6

®

SYSTEM 3000 Installation ...................................................................... Page 9

®

ERICORE Lower End ................................................. Page 24

ERICORE Upper End .................................................. Page 28

®

ERICORE cables ......................................................................... Page 51

2

www.erico.com

Page 5

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

ERITECH® SYSTEM 3000

THE ERITECH® SYSTEM 3000

Installation, Operation

and Maintenance Manual

Due to ongoing research into the phenomena of lightning and lightning

protection technology and product improvement, ERICO reserves the right to

alter any information and specifications contained herein at any time without

notice. Users should check with ERICO to ensure they have the latest edition.

Warning:

1. ERICO products shall be installed and used only as indicated in ERCIO product instruction

sheets and training materials. Instruction sheets are available at www.erico.com and from

your ERICO customer service representative.

2. ERICO products must never be used for a purpose other than the purpose for which they

were designed or in a manner that exceeds specified load ratings.

3. All instructions must be completely followed to ensure proper and safe installation and

performance.

4. Improper installation, misuse, misapplication or other failure to completely follow ERICO’s

instructions and warnings may cause product malfunction, property damage, serious bodily

injury and death.

SAFETY INSTRUCTIONS: All governing codes and regulations and those required by the job site

must be observed. Always use appropriate safety equipment such as eye protection, hard hat,

and gloves as appropriate to the application.

®

The ERITECH

International patents on the ERITECH SYSTEM 3000 are existing.

Local Distributors should be the user’s first point of contact with supply, delivery, installation,

limited warranty, and checking of the system for compliance with Manufacturer’s instructions.

www.erico.com

SYSTEM 3000 is manufactured by ERICO.

3

Page 6

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Pre-Installation Requirements

This manual is a guide to the Installation,

Operation and Maintenance of the ERITECH

SYSTEM 3000 Lightning Protection System.

It assumes that the system to be installed

has been designed by an authorized ERICO

representative. The system design will

include:

t

Grounding system design - a

configuration should be designed as

a result of soil resistivity analysis.

®

t Downconductor routes - chosen to

avoid other services, maintain

minimum bending radii and minimize

downconductor run length.

t Downconductor securing requirements.

t Terminal types - operating environment.

t CAD analysis design software which

determines terminal placement, mast &

height requirements as well as protection

level calculation.

All of the above are recommended for a

successful installation. If there is any doubt

about any of the points mentioned, please

contact ERICO or your nearest Distributor

for clarification.

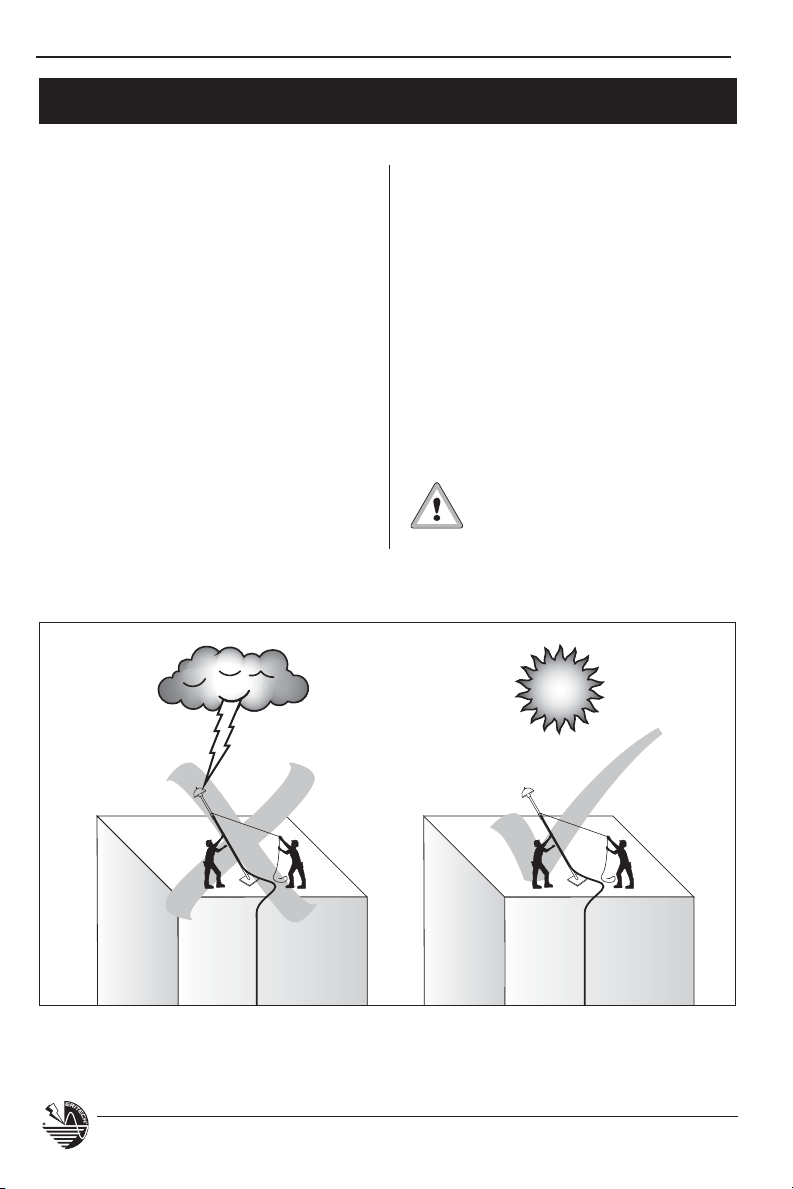

Only attempt to install the

ERITECH SYSTEM 3000

during storm-free periods.

Figure 1.

4

www.erico.com

Page 7

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The recommended order of installation is as follows:

1. Full installation of the grounding system.

2. Full installation of the downconductor.

3. Termination of the downconductor to the grounding system.

4. Upper termination of the downconductor (may already have been completed

by ERICO) and connection to the ERITECH

5. Termination of bonding cable from upper termination to structure

(if required).

6. Raise mast into position and secure.

®

DYNASPHERE air terminal.

Grounding Systems

The grounding system is critical to the

integrity of any lightning protection

installation and should include

consideration of:

t Local Standards compliance

(IEC 61024-1, BS 6551, AS1768-1991,

®

780, C22.1-98, NEC® etc.)

NFPA

t Available space / location.

t Natural soil conditions - resistivity of

soil, soil moisture content, soil

temperature range, etc.

t Location of underground services -

Power, Communications, Fuel, Gas,

Water, etc.

t Corrosive environments, ie: salt

water, acid / alkaline contaminated

ground mass.

t Use of suitable grounding rods such

as ERITECH

®

rods.

t Minimization of risk to personnel.

Contact an ERICO office or Distributor if you

require further advice on grounding systems.

Downconductors

The ERITECH® ERICORE downconductor

or other recommended downconductor

should have been selected during the design

stage, as should the route, length and any

preterminations of the downconductor.

Re-check intended route of

downconductor immediately

prior to installation to ensure

that:

t There are no structural changes or

additions that may effect the initial

design.

t Most direct route possible to the

grounding system with minimal

number of bends and as flush with

the structure as possible.

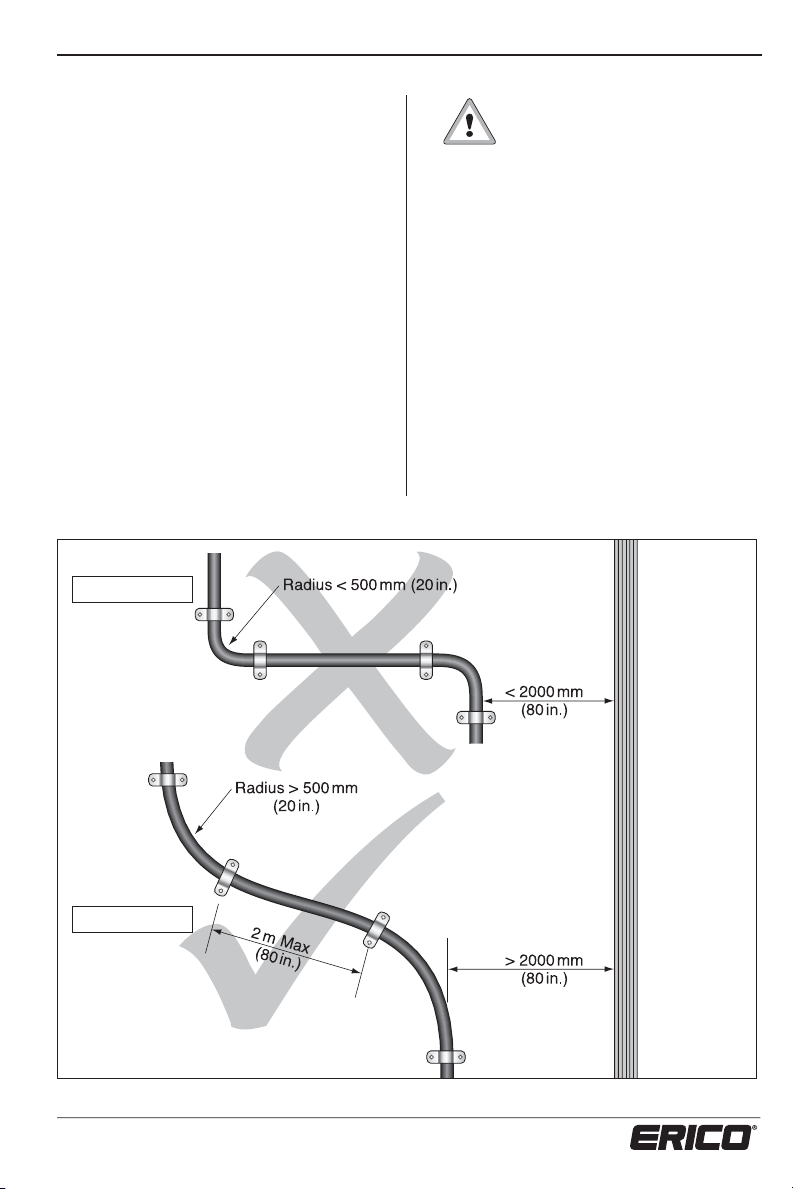

t Minimum bending radii maintained

(500 mm, 20 in.).

t Parallel routing with other services -

minimum separation = 2 m (80 in.).

t Attachment to the structure is at a

maximum of every 1 m (40 in.) for the top

10% of the downconductor route and

2 m (80 in.) from then on.

t Pipe installations follow the instructions

given on page 17.

www.erico.com

5

Page 8

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Re-check:

t Securing of downconductor - saddles,

cable ties, beam clamps, cable hangers,

etc, are appropriate.

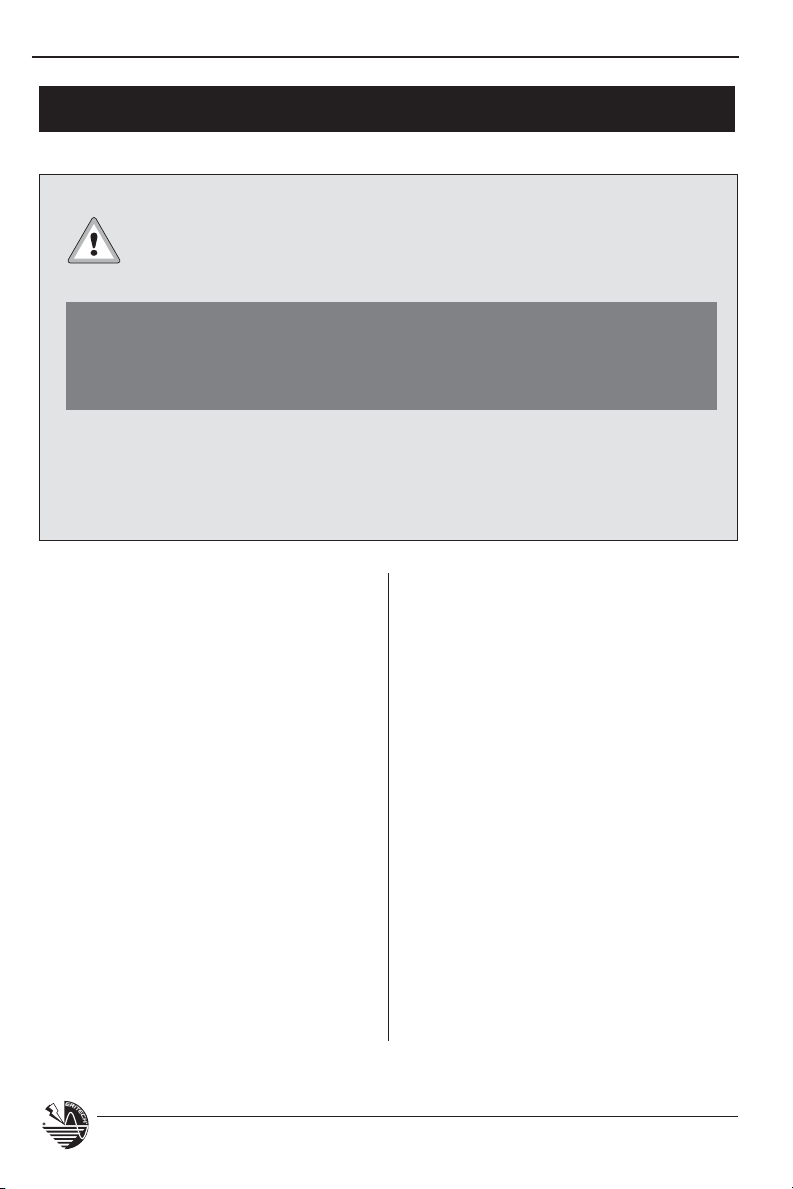

t Method of cable installation, ie. cable

upper terminated on the outside of the

drum - to be rolled off from the base of

the structure, or cable upper terminated

on the inside of the drum - to be rolled

off from the top of the structure,

(refer Figure 6 on page 15).

t The outer sheath of the downconductor

must be electrically bonded to a

conductive structural point within 5 m

(17 ft) of the upper termination kit.

Structural Bonding Braid & Conductive

Structural Points

When installing the upper end of

the downconductor on a masonry

structure (concrete panels, brick,

etc), the downconductor should be secured

directly to the structural steel work. In

addition, the bonding cable (supplied in the

termination kit) must be connected via

2

(8 AWG) insulated copper cable to

6 mm

the nearest conductive structural point. This

point should be where the downconductor

first comes into contact with the structure

and may be either structural steel work or

the reinforcing within concrete panels or

slabs.

See Pages 18 to 24, figures 10-17 for more

details and diagrams.

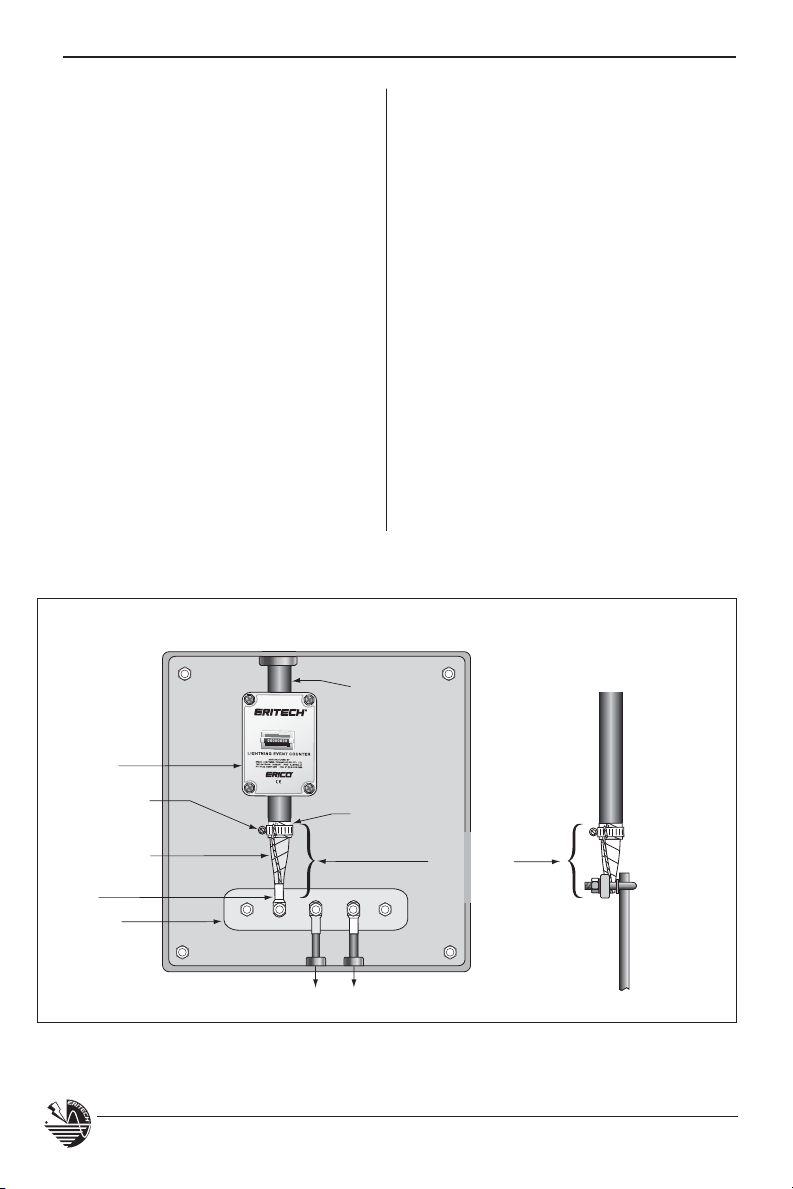

Lightning Event Counters

The Lightning Event Counter (LEC IV) is

a device for registering and recording

the number of strikes that the ERITECH

SYSTEM 3000 has intercepted. The design

of this counter allows many installation

alternatives on the downconductor

as discussed in later text. Also, see

Specifications on page 60.

The following should be considered prior to

installation of the Lightning Event Counter:

®

t It is advisable to locate the LEC IV in

a secure area that is not prone to

contact with moving objects, theft,

or vandalism.

t If the LEC IV is to be encased in an

additional enclosure, ensure that it is

mounted to enable easy access to the

display, (see figure 32 on page 48).

ERITECH® DYNASPHERE

Terminals

The ERITECH® DYNASPHERE is the air

terminal of the ERITECH SYSTEM 3000.

Ensure that the appropriate air terminal has

been provided.

It is recommended that this point be

determined prior to the installation to allow

for any site work or equipment that may be

required prior to the installation.

2

The 6 mm

and the length of the cable will need

to be determined and obtained before

commencing the installation.

(8 AWG) cable is not supplied

Suitable for use in:

t General purpose applications

t High temperature environments

t Corrosive environments (salt or acid

atmosphere)

6

www.erico.com

Page 9

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

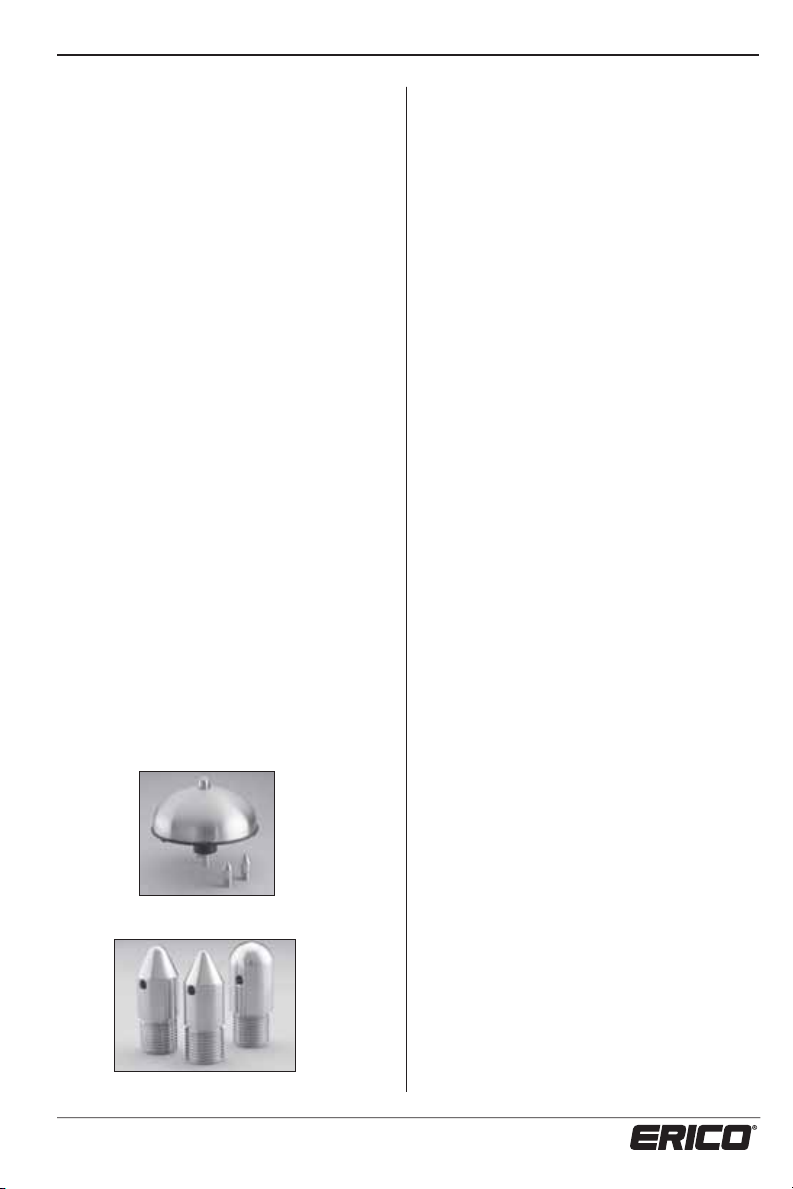

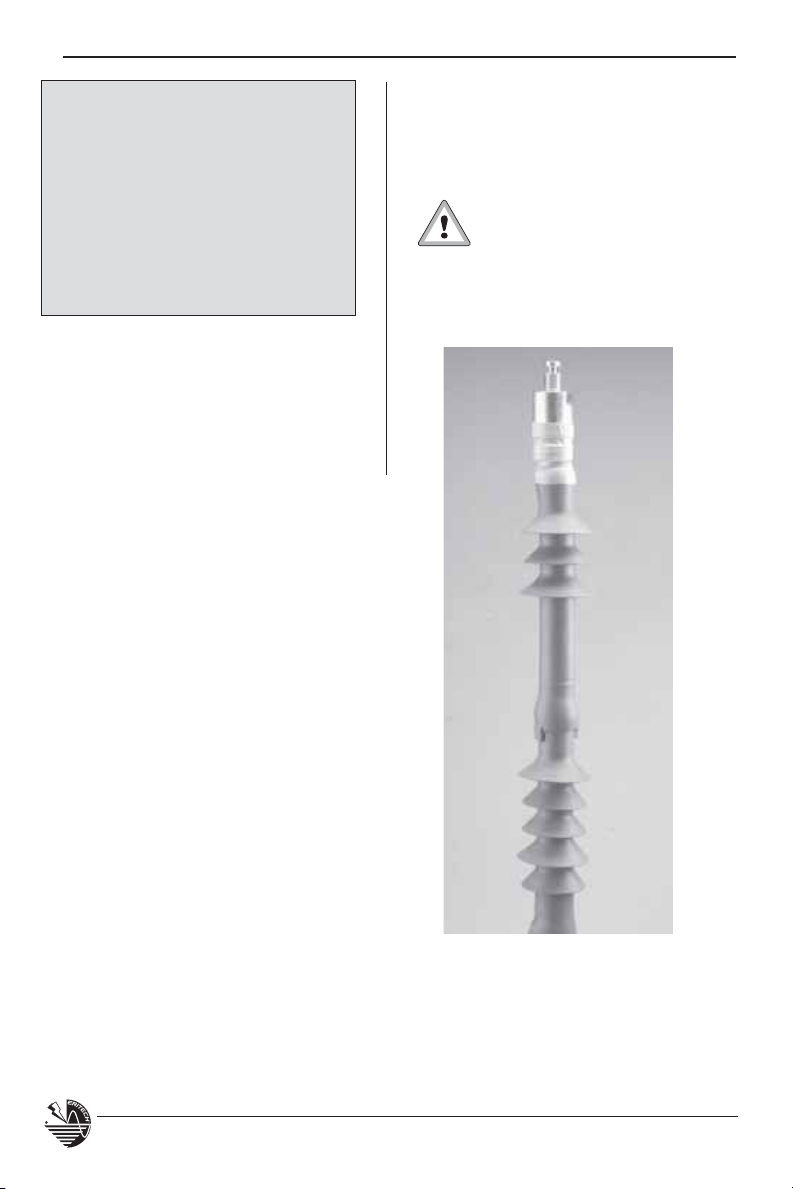

Ensure the air terminal is supplied with the

finial tip secured in place. The air terminal

is supplied with three different finial tip

configurations (two separate, and one

secured in place), similar to that shown

in photo 1. It is important that the

correct finial tip is installed, specific

to the application. Photo 2 shows the

three different finial tip

sharp to blunt in dimension.

(middle), medium tip (left) and rounded tip

(right). The application of each of these tips

is detailed below:

sizes, ranging from

The sharp tip

Masts

There are three main types of mast

configurations:

t Guyed - generally required for mast

t Sharp Tip – Terminal heights less than

20 m (65 ft)

t Medium Tip – Terminal heights less

50 m (165 ft), greater than 20 m

than

(65 ft)

t Cantilevered - the lower third of the

t Rounded Tip – Terminal heights greater

than 50 m (165 ft)

Note: heights listed refer to the actual terminal height above ground

level

If required, replace the finial tip supplied

with the appropriate tip for the application,

and tighten firmly.

Warning – Do not install the ERITECH®

DYNASPHERE

correct finial tip.

without installing the

t Free-standing - base support only.

Ensure that the configurations and

heights for your specific installation

conform to the design and consultation

directives.

Specific advice for each mast configuration is provided on pages 40 to 47.

When all of the components for the

ERITECH

received, they should be checked against

the design “Bill of Materials” and for any

possible shipping loss or damage.

heights of over 3 m (10 ft) or for

climatic conditions where wind gusts

may exceed 160 km/h (100 mph).

Always consult with a local civil

engineer if in doubt. The mast is

anchored at the base and then guyed

using one or two guy sets, depending

on the mast height and configuration,

each with 3 lengths of non conductive

guying material.

mast is secured to a vertical surface

to provide support. These may also

require guying depending on mast

height.

®

SYSTEM 3000 have been

1 – ERITECH DYNASPHERE with two spare finial tips.

2 – Three (3) ERITECH DYNASPHERE finial tip sizes.

www.erico.com

7

Page 10

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Checking Lightning Protection Components

on Receipt

Before installation, in particular, check the

following:

Terminal(s)

t ERITECH

not been dented in any way.

®

DYNASPHERE terminals have

t The correct finial tip has been installed,

based on the overall height of the air

terminal above ground.

®

ERITECH

ERICORE Downconductor(s)

t The cable drum (if supplied) is in a

serviceable condition.

t Correct length(s)

t That there is no obvious damage to the

cable.

t Is terminated as required. If the

downconductor has been preterminated before shipment, check that

the termination is still intact and in

good order. See note on Page 14 on

removing protective covers.

t If the Upper Termination Kit has been

supplied separately, check that the

Cold-Shrink tube in the kit is in good

order, has no tears or cuts and has

not collapsed.

This information along with downconductor lengths and quantities (if

more than one length on the one

drum), will be printed on a label on the

side of the Cable Drum(s).

8

www.erico.com

Page 11

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

ERITECH® SYSTEM 3000 Installation

During the installation of the ERITECH® SYSTEM 3000, all site restrictions

and safety requirements must be followed.

It is important to follow the recommended order of installation:

1. Full installation of the grounding system.

2. Full installation of the downconductor.

3. Termination of the downconductor to the grounding system.

4. Upper termination of the downconductor (may already have been completed

by ERICO®) and connection to the ERITECH® DYNASPHERE air terminal with

correctly sized finial tip.

5. Termination of bonding cable from upper termination to structure.

6. Raise mast into position and secure.

Only attempt to install the

ERITECH SYSTEM 3000

storm-free periods.

If the terminal must be raised before

being connected to the ground system, or

cannot be immediately connected, then

attempt to connect the lower end of the

down-conductor to either the structure

steel reinforcing or some other reasonable

ground point.

during

Grounding Systems

Installation

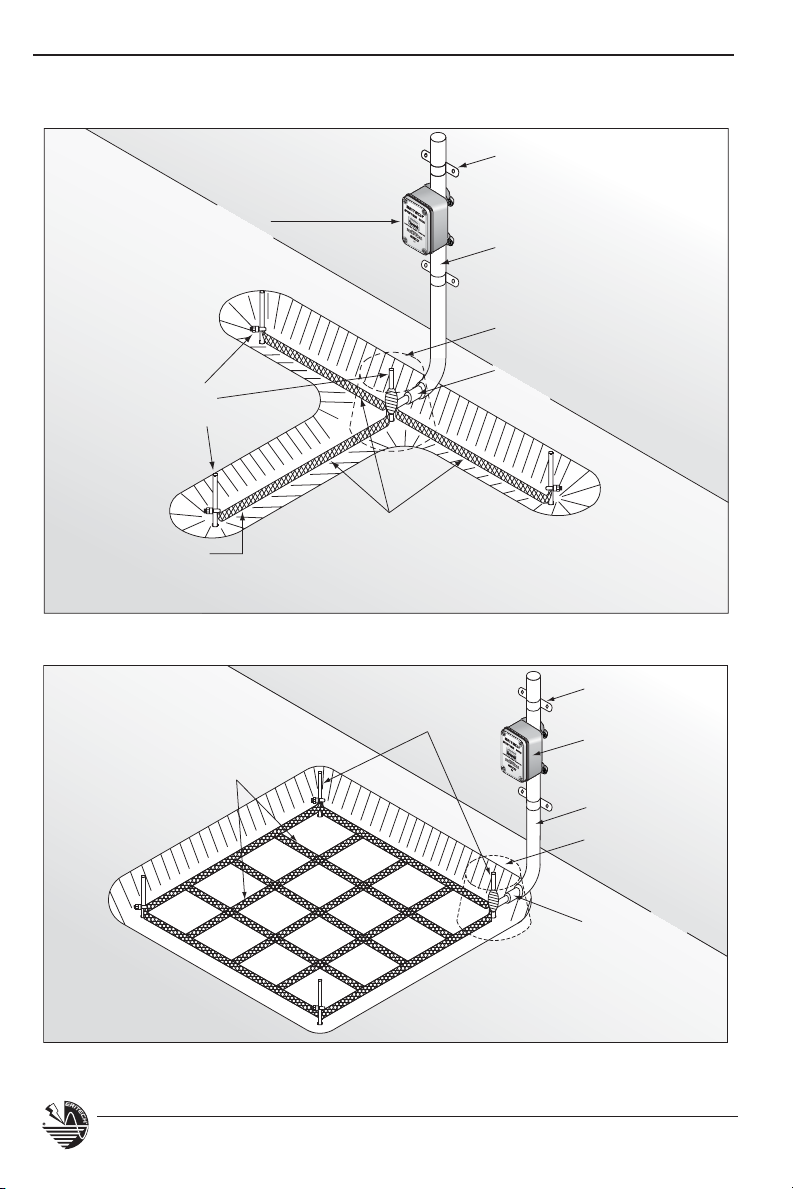

Prior to the installation of the

lightning protection grounding

systems, it is important to refer

to site drawings of all underground

www.erico.com

services to ensure that these are

avoided and not interrupted during

trenching, excavation, boring or

driving ground rods, (see figure 4 on

page 11).

Care must be taken to follow the

ground survey design. Ensure the

correct materials have been provided

and are used to achieve an acceptable

Ground DC resistance (typically <10Ω).

Examples of typical grounding systems

that may be used (Note: these may or may

not be relevant to the specific ERITECH

SYSTEM 3000 design) are shown in figures

2 and 3 on page 10.

9

Page 12

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

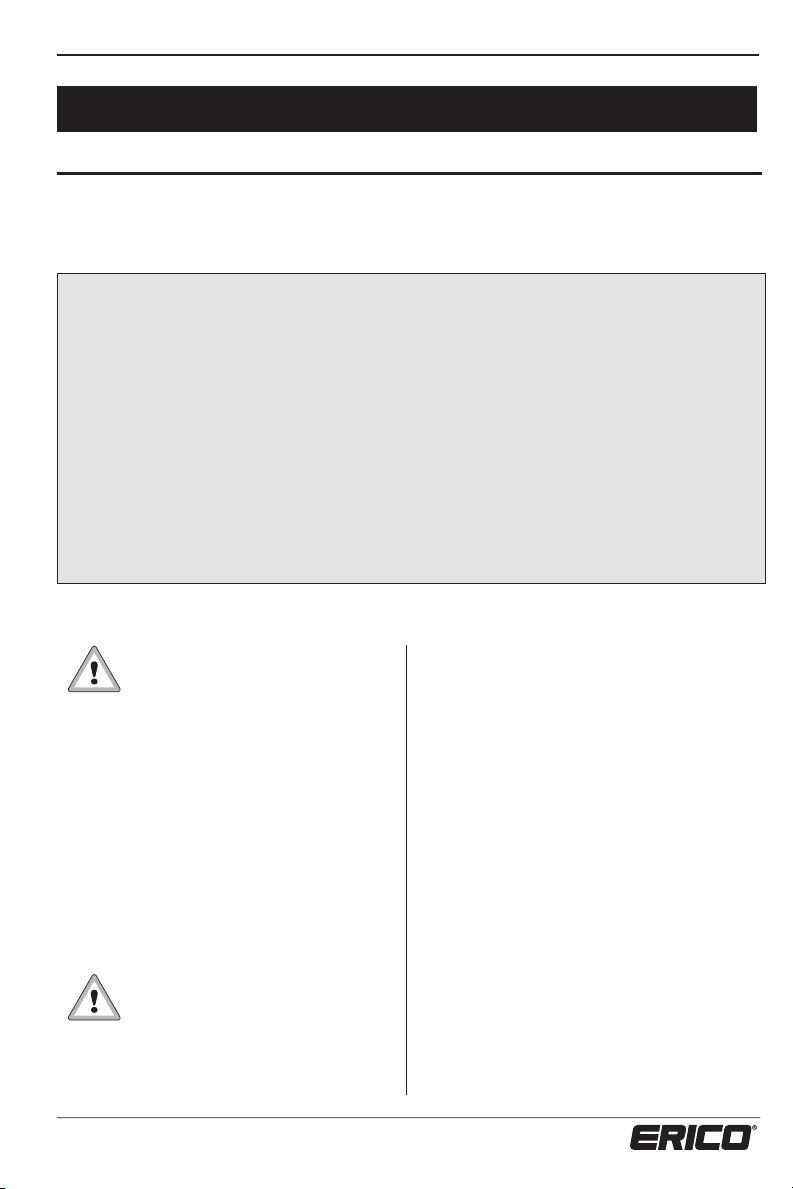

Lightning Event

Counter - LEC IV

Ground rods

clamped or

welded to

copper ground

tape using

CADWELD

Each trench is treated

with GEM or ERITECH

Enhancing Compounds

®

Conductive Saddles

ERITECH

®

ERICORE

Ground Pit

Lower Termination

(Bound in Waterproofing

Mastic)

Copper Ground Tape

Typical lengths, minimum of 5 m (17 ft). (Lengths are dependant

upon soil resistivity reading) @ 600 mm (24 in.) depth or greater if

required, to ensure that it is below the frost line.

Figure 2: Radial Ground.

Copper ground tape grid

5000 x 5000 mm (17 x 17 ft.)

@ 600 mm (24 in.) depth or

greater if required to ensure

that it is below the frost line.

Figure 3: Grid Ground.

ERITECH ground rods

clamped or welded to

copper ground tape,

using CADWELD.

10

Conductive

Saddles

Lightning Event

Counter - LEC IV

ERITECH ERICORE

Ground Pit

Lower Termination

(Bound in

Waterproofing

Tape)

www.erico.com

Page 13

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

POWER

GAS

WATER

IRRIGATION

COMMUNICATIONS

SEWERAGE/STORMWATER

Figure 4: Precautions required for ground pit excavation and lower termination corrosion protection.

It is advised that a ground pit is installed

where the end of the downconductor

This provides a convenient access point for

disconnection and future testing.

terminates to the ground system.

www.erico.com

11

Page 14

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

When using ground rods it is advisable to:

t Use driving heads to prevent

mushrooming on top of the rod.

t Use driving heads when using

coupled rods.

tUse a post or picket driver.

When bonding the grounding system

components, try to use the recommended

methods suggested below:

t CADWELD

used to provide permanent electrical

bonding, corrosion resistance and

mechanical strength between

conductors, including most types

of copper cable, bar, rod, tape,

structural steel work, reinforcing

steel and pipe.

t Supplied ground rod clamps should

be used for termination of ERITECH

ERICORE downconductors directly

to ground rods. This allows later

disconnection for maintenance

requirements.

®

connections must be

®

t Use of aluminum lugs or couplings is

prohibited.

t Waterproofing mastic tape should be

used for waterproofing corrosion

vulnerable connections.

Ground Resistance Lowering

Compounds

Ground enhancing compounds, (such as

GEM) are recommended and supplied when

the existing soil mass has a high resistivity.

These compounds can be used to increase

the total surface area of grounding

conductors,

resistance / impedance.

Compounds may require water and a

mixing container.

thereby reducing the ground

When applying these compounds, be sure

to take necessary handling precautions

as advised by the product instructions,

and ensure that the directions for use are

followed correctly.

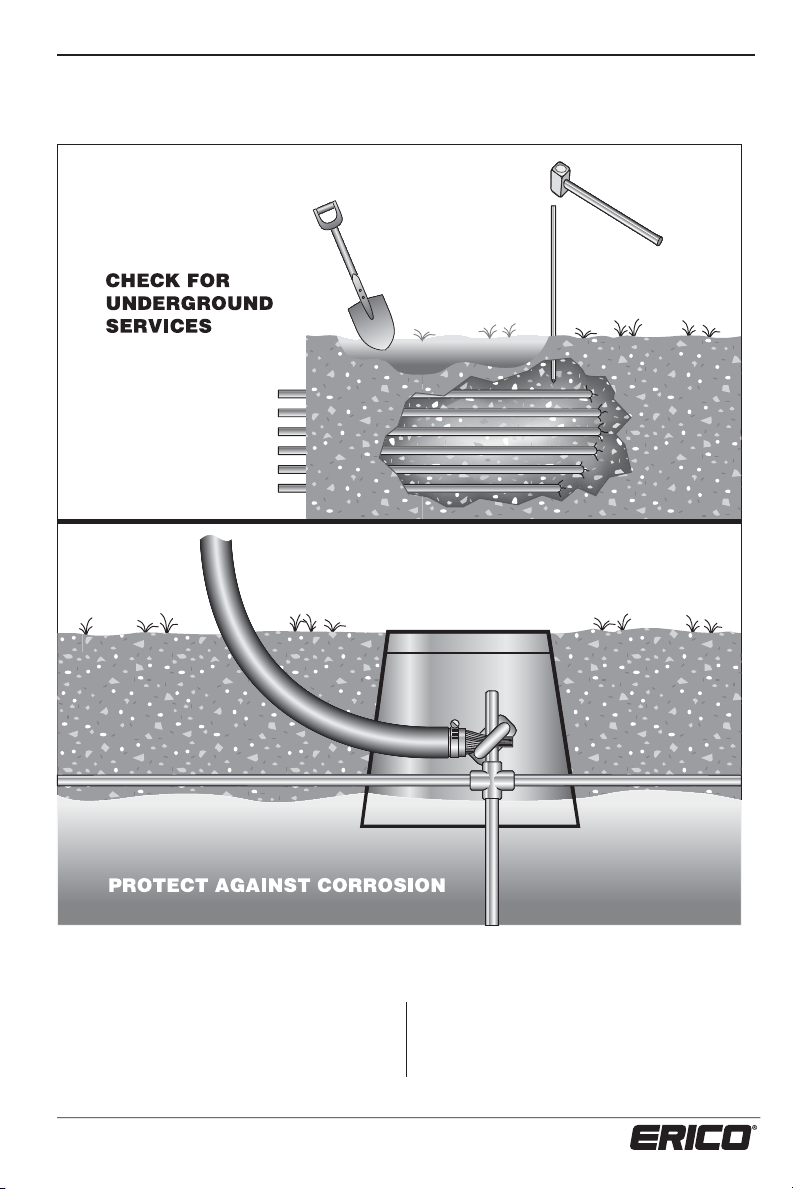

Insulation of Grounding

Systems

In some installations, it may be necessary

to insulate part of the ground system from

an area of the surface, for the purposes of

safety or isolation, (pedestrian walkways,

proximity to other services, etc.). In this

situation, it is recommended that a

minimum of 70 mm

copper cable is run in PVC conduit to the

connection point (start) of the intended

ground system. This conduit should be at

a depth of at least 600 mm (24 in.), or

greater if required, to ensure that it is below

the frost line to the start of the intended

ground system.

Another possible design method for

reducing surface step-potentials may be to

insulate the ground system for the first few

meters of depth from the surface. This is

done by isolating the initial injection point

of the downconductor from the surface

of the ground mass by running it through

PVC conduit to the required depth before

exposing it to the ground mass.

2

(2/0 AWG), insulated

Bonding the Lightning

Protection Ground to Other

Service Grounds

Where separate grounds exist eg: Structure,

Power, Communications and Lightning

Protection, they should be bonded

to form an equipotential ground plane.

This will eliminate the possibility of

loops and potential differences arising

under transient conditions.

together

ground

12

www.erico.com

Page 15

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Surface Area of Isolation

Downconductor

Lower Termination

Ground Pit

600 mm (24 in.) or greater to ensure

it is below the frost line.

2 m (80 in.)

2

2/0 (AWG)

Insulated

Conduit

70 mm

Insulated Copper

Cable

Start of

Grounding

System

ERITECH

Ground Rod

Figure 5: Various methods of isolating the ground system.

Authorization may be required by the

particular service providers before bonding

of these grounds takes place.

2

Bonding cable must be 70 mm

(2/0 AWG)

minimum depending on local standards. In

some circumstances, it may be necessary

to use a Transient Earth Clamp (ERICO

Part No. TEC100C) which effectively bonds

all grounds to the same potential under

transient conditions, to satisfy service

providers.

For further information, it is advised that

local applicable standards are consulted, ie

IEC 61024-1, BS 6551, AS1768, NFPA

C22.1-98 and NEC

www.erico.com

®

.

®

780,

13

®

Labelling

The labelling of ground pits or grounding

systems to local requirements is the

responsibility of the customer / installer.

Page 16

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Downconductors

Depending on site requirements, the downconductor(s) may have their

upper terminations completed at a pre-specified end of the cable by

ERICO before shipment. These terminations will be protected by a short

length of flexible PVC tube.

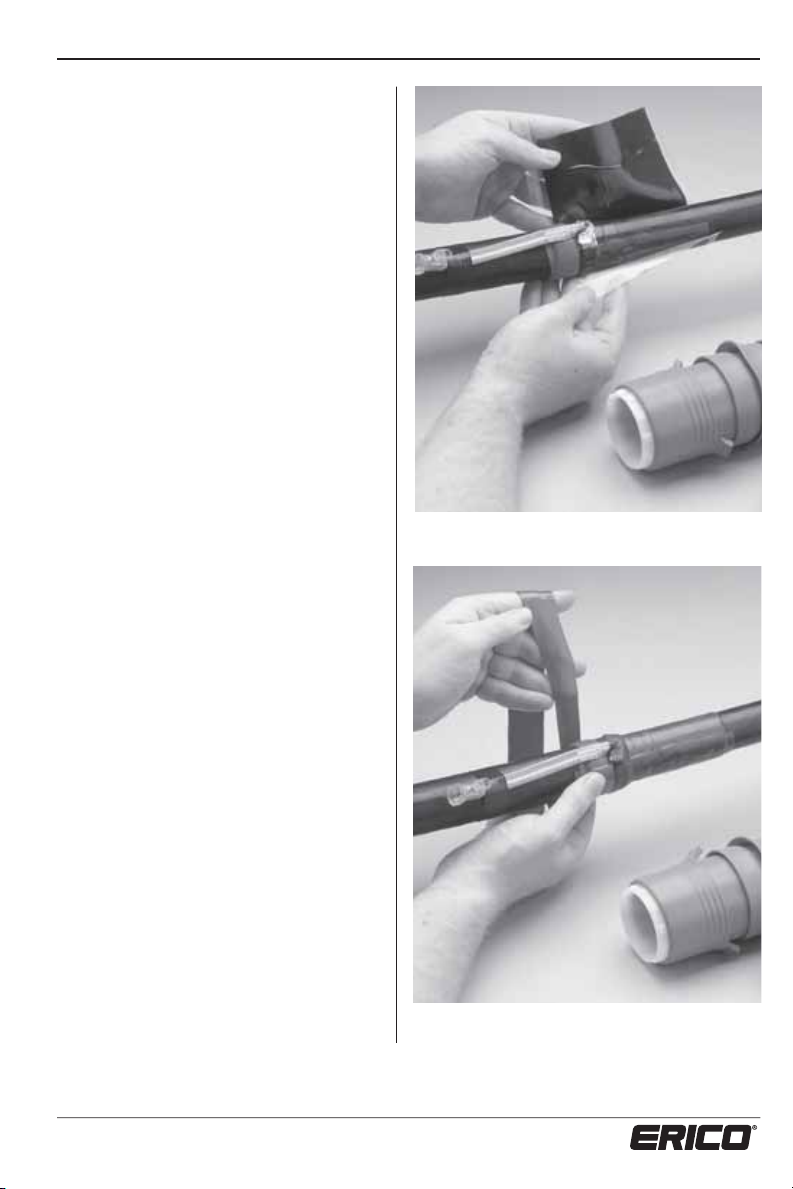

It is VERY IMPORTANT that when removing these tubes, they are not

removed with a knife or cut in any way as this will damage the outer

layer of the termination. It is suggested that the tape and cover are best

removed by hand. (See figure 6)

All ERITECH® purpose-designed downconductors have a semi-conductive outer

sheath which is approximately 2 mm (0.08 in.) thick. Rough or careless handling

of the downconductor can damage this sheath and compromise its performance.

Downconductor Hauling

Locate the downconductor cable drum at

the appropriate location, (refer to figure 6).

When hauling the downconductor, use the

following guide points:

t Ensure that the cable drum, if supplied, is

in a serviceable condition.

t If the downconductor has been upper

terminated on the outside of the drum,

then the downconductor must be hauled

off the drum from the ground.

t If the downconductor has been upper

terminated on the inside of the drum,

then the drum must be at or near the

of the structure, so that the down-

top

conductor

drum towards the base, (see figure 6).

can be unwound from the

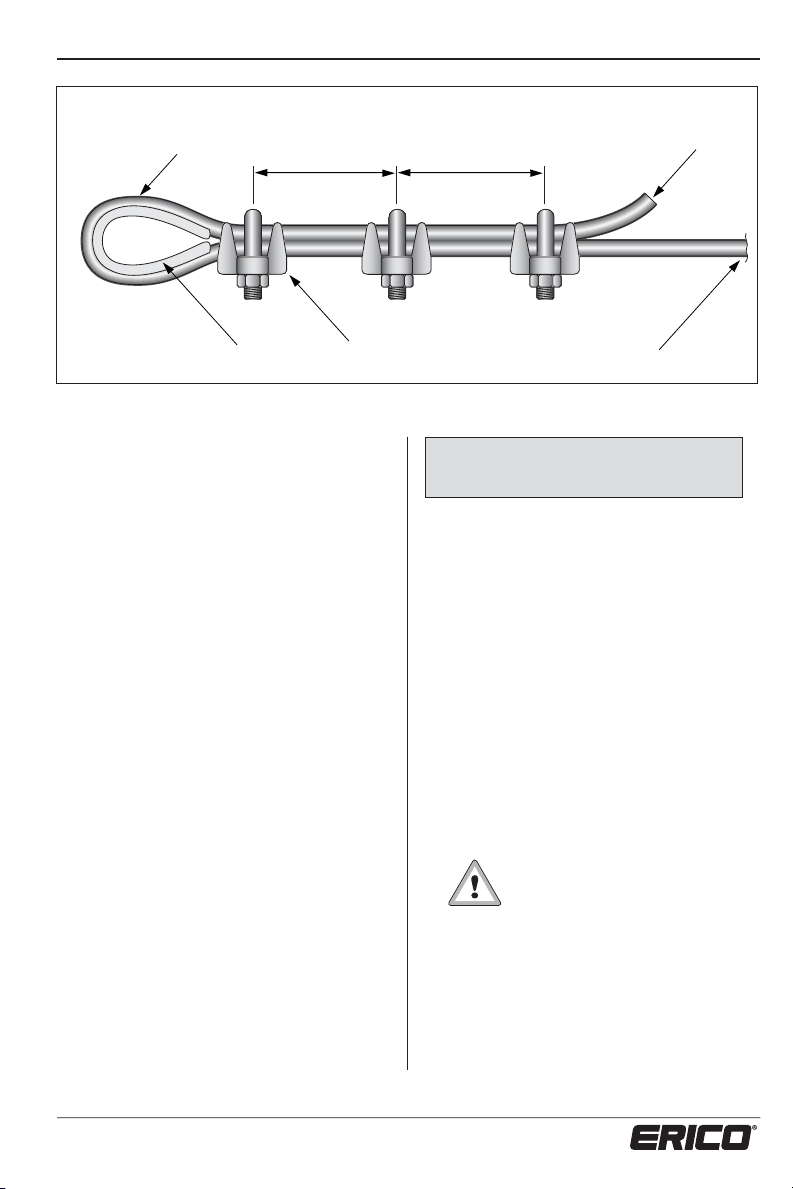

t When using slings or ropes to haul

downconductors, use MULTIPLE hitches

around the cable.

t DO NOT sling from the termination

coupling or cold-shrink section of the

terminated downconductor.

t DO NOT use cable stockings over

TERMINATED downconductor ends.

t Protect the downconductor from

abrasion and tearing when hauling over

rough surfaces, at all times, especially

around corners or through penetrations.

14

www.erico.com

Page 17

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Downconductor pre-terminated

on the OUTSIDE end when

wound on the cable drum

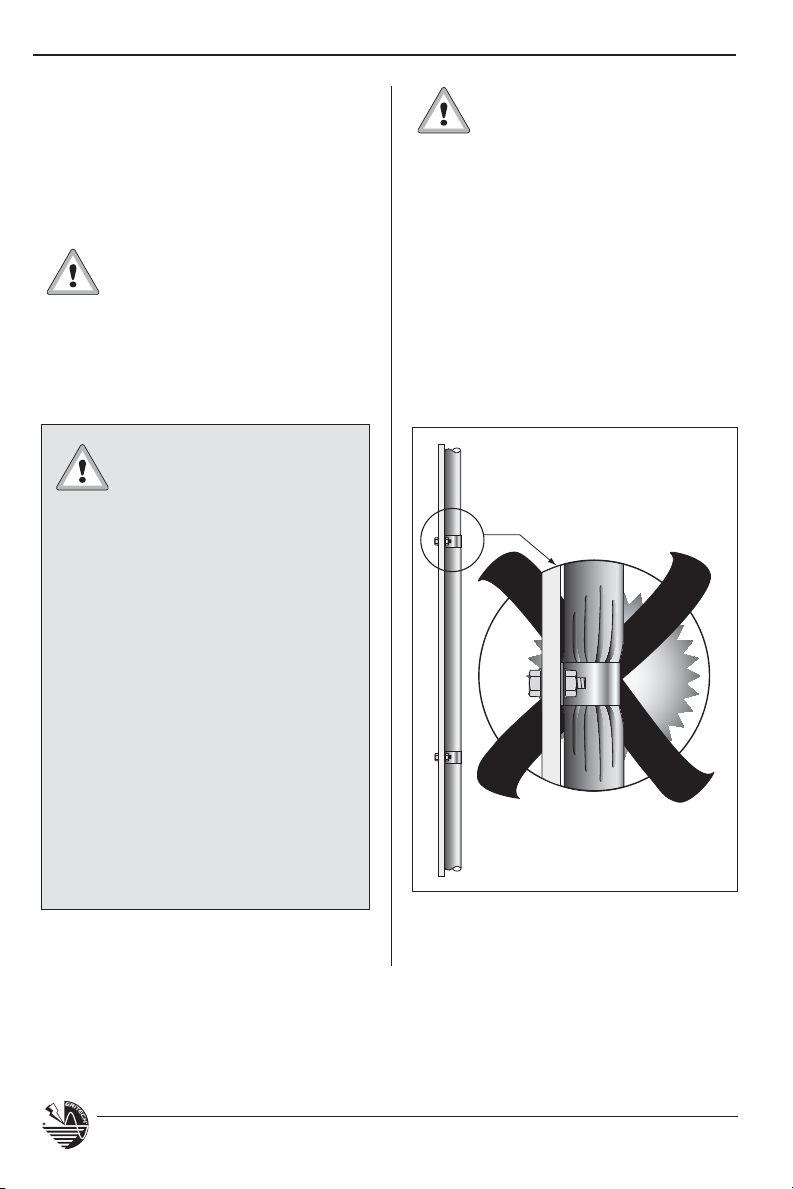

Figure 6: Cable pre-termination and drum locations.

INCORRECT

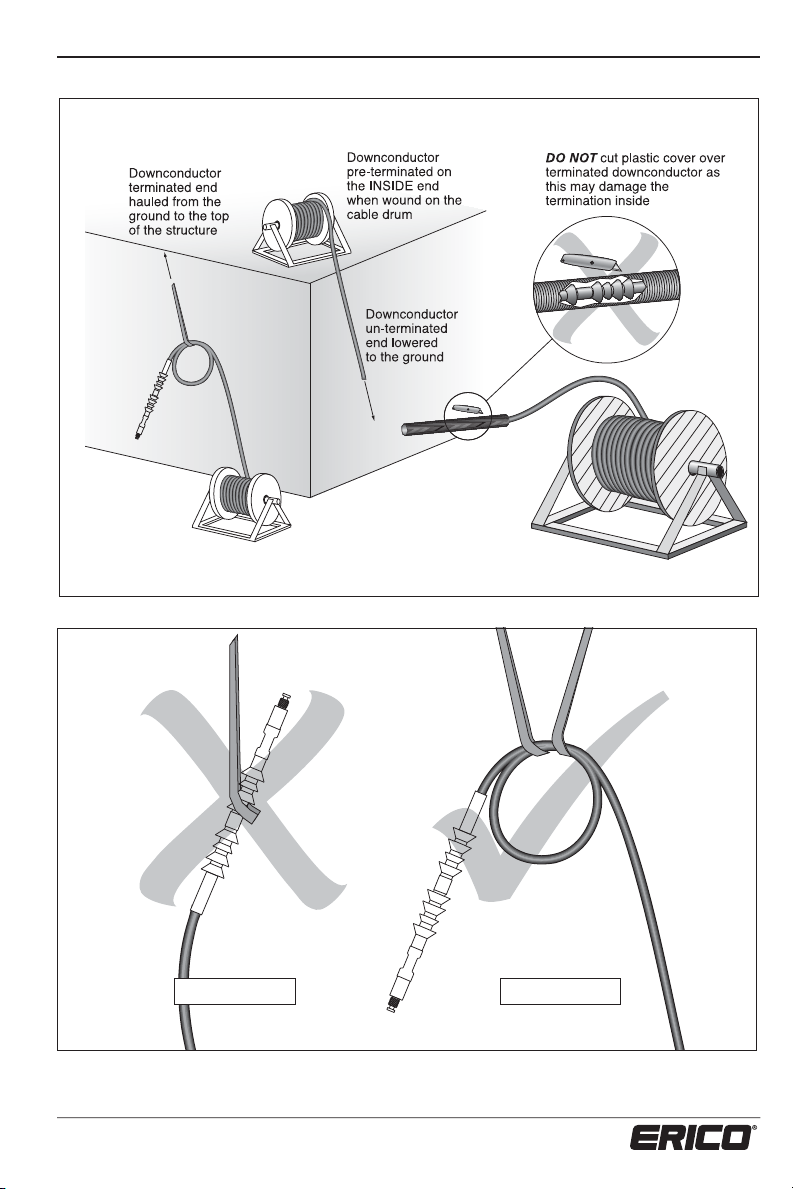

Figure 7: Incorrect and correct cable hoisting methods.

www.erico.com

CORRECT

15

Page 18

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Penetrations

Before routing the downconductor through

any penetrations, ensure that:

t If un-terminated, a minimum hole

diameter of 50 mm (2 in.) is provided.

t If terminated, a minimum hole diameter

of 60 mm (2

3

⁄8 in.) is provided.

t Enough physical protection (conduit

or similar) is provided to stop the

downconductor from being damaged

when being fed through the penetration.

t When feeding the upper termination

of the downconductor through any

penetrations, the termination sheds

(flanges) should be temporarily wrapped

in insulation tape to reduce their

diameter and protect them against

abrasion. This is very important as the

cold-shrink tubes are susceptible to

tearing if nicked or scuffed.

If either side of the penetration requires

environmental protection ie: waterproofing,

air-con pressure seal, etc., use a suitable

sealant or deck sealing gland.

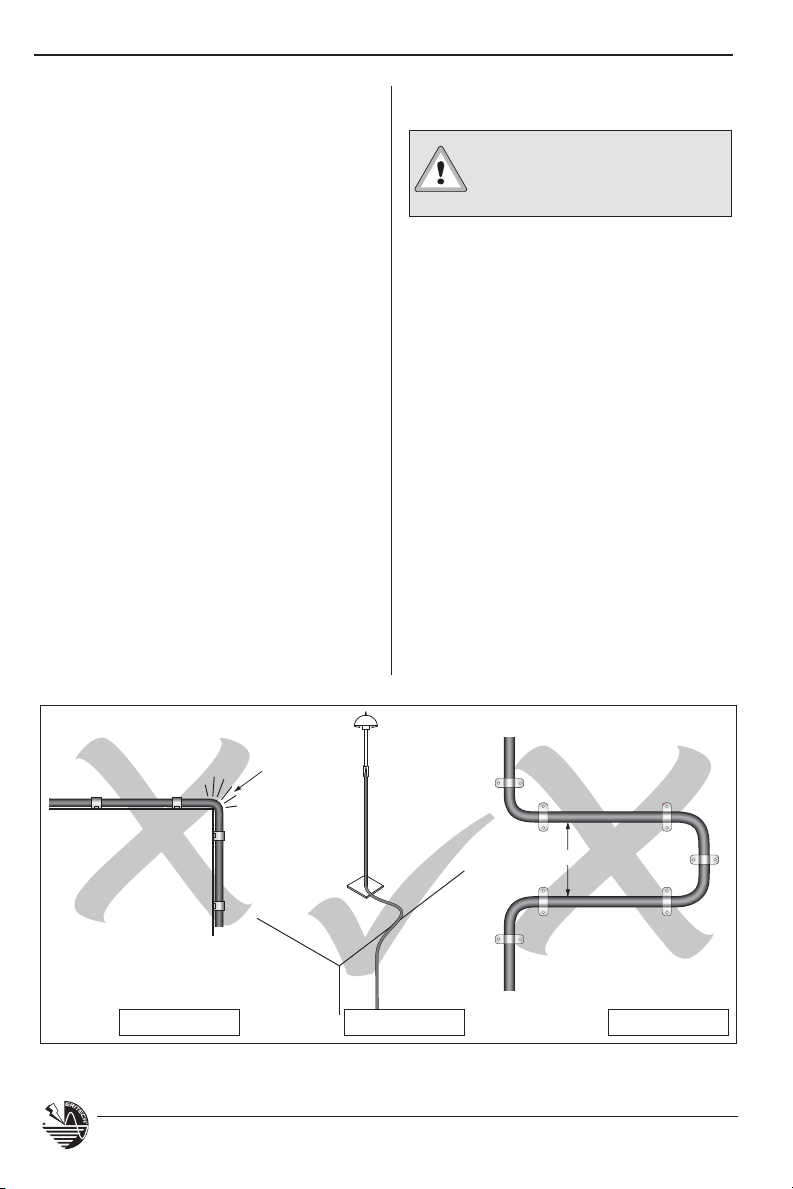

Routing

The route taken by the downconductor is very important

and must follow these rules:

t Carefully survey the intended route

of the downconductor immediately

prior to the installation to check for

any alterations that may effect the

original design, ie: structural changes,

new antenna or mast installations, air

conditioning towers or ducting, etc.

t Use the most direct route practical to

minimize the downconductor length.

t To minimize the risk of side-flash,

DO NOT route the downconductor back

beside itself after change of direction,

ie: 180º.

t Minimize number of bends.

t Minimize strain on the downconductor

during installation.

Radius

< 500 mm

(20 in.)

INCORRECT

Figure 8: Correct & incorrect cable routing methods.

CORRECT

16

< 2000 mm (80 in.)

INCORRECT

www.erico.com

Page 19

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

t Ensure bend radius maintained >500 mm

(20 in.).

t Parallel routing with other services -

Minimum separation = 2 m (80 in.). Try

to isolate as much as possible from other

services.

t If the downconductor must cross other

services, ensure that it crosses at right

angles to minimize any inductive effect.

t The lower end of the downconductor

must terminate as close as possible to the

initial injection point of the grounding

system.

INCORRECT

t Allow 500 mm (20 in.) of slack

in the length of downconductor

at the upper end of the cable

to facilitate mast erection and correct

seating of the ERITECH

terminal in the top of the FRP mast.

t

Where isolation of the downconductor

required, (for physical or proximity safety

reasons) install the cable in a

insulating conduit with a min

thickness of 3 mm (

NOTE: This is the only time that the

downconductor should be isolated from the

structure and generally only for 2.4 m

(8 ft.) maximum. DO NOT route the entire

length of downconductor in insulated

conduit.

®

DYNASPHERE

1

imum wall

⁄8 in.).

is

suitable

CORRECT

Figure 9: Correct & incorrect cable routing.

www.erico.com

COMMUNICATIONS / POWER

17

Page 20

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

t To seat the terminal correctly in the top

of the FRP mast, any cable slack will

have to be removed from the mast while

also minimizing any stress on the upper

termination sheds (flanges) by twisting the

FRP mast against the terminal for at least

one turn.

If the downconductor is damaged

during installation, it must be

checked by an ERICO

representative to see if the damage will

effect its safe operation.

Securing the Downconductor

Securing of the downconductor not only provides a

mechanical attachment to the

structure, but also an Electrostatic connection to the structure via

the semiconductive outer sheath of

the downconductor cable.

It is important that the downconductor is both physically and

electrically secured to the entire

length of the structure to relieve both

physical and electrical stresses along

the downconductors’ length.

The electrical bonding of the downconductor is especially important for

at least the first 10% of the downconductor route from the upper

termination, and for this reason the

downconductor must be secured at

least every 1 m (40 in.).

ERITECH® brand of saddles

and conductive clamps are

recommended for the purpose

of securing the downconductor. These

have been specifically designed and

manufactured to mechanically secure and

electrically bond the ERITECH

®

ERICORE

to the structure, while minimizing stress

points on the cable.

Use of a brand of saddles other than

ERITECH can compromise the outer sheath,

creating high stress points which can lead

to flashover, (see figure 10).

Use ERITECH clamps only

Figure 10: Detail shows the need to use ERITECH

Clamps.

18

www.erico.com

Page 21

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

t For brick and concrete walls or roofs,

use the ERITECH

saddles. These have two 6 mm (

®

brand of stainless steel

1

⁄4 in.)

diameter holes on either side and are

suitable for use with masonry anchors.

These saddles can also be used with other

suitable fastenings against wood, fiberglass

and metallic surfaces.

t When securing externally to round section

structures such as pipes, tower legs,

masts, etc, stainless steel cable ties are

recommended. Ensure that these are

firmly secured.

t For securing to other structures such as

angle iron, ie: radio towers, structural

beams etc., use CADDY

clamps and suitable cable clamps from

ERICO.

®

brand of beam

t If the downconductor is to be routed

above a false ceiling, ensure that it is

fixed to the underside of the concrete

floor slab.

t Use of exothermic fastening methods

on ERITECH brand of saddles is NOT

recommended.

t Use of CADDY

strut system) is recommended where

suitable, (see figure 11).

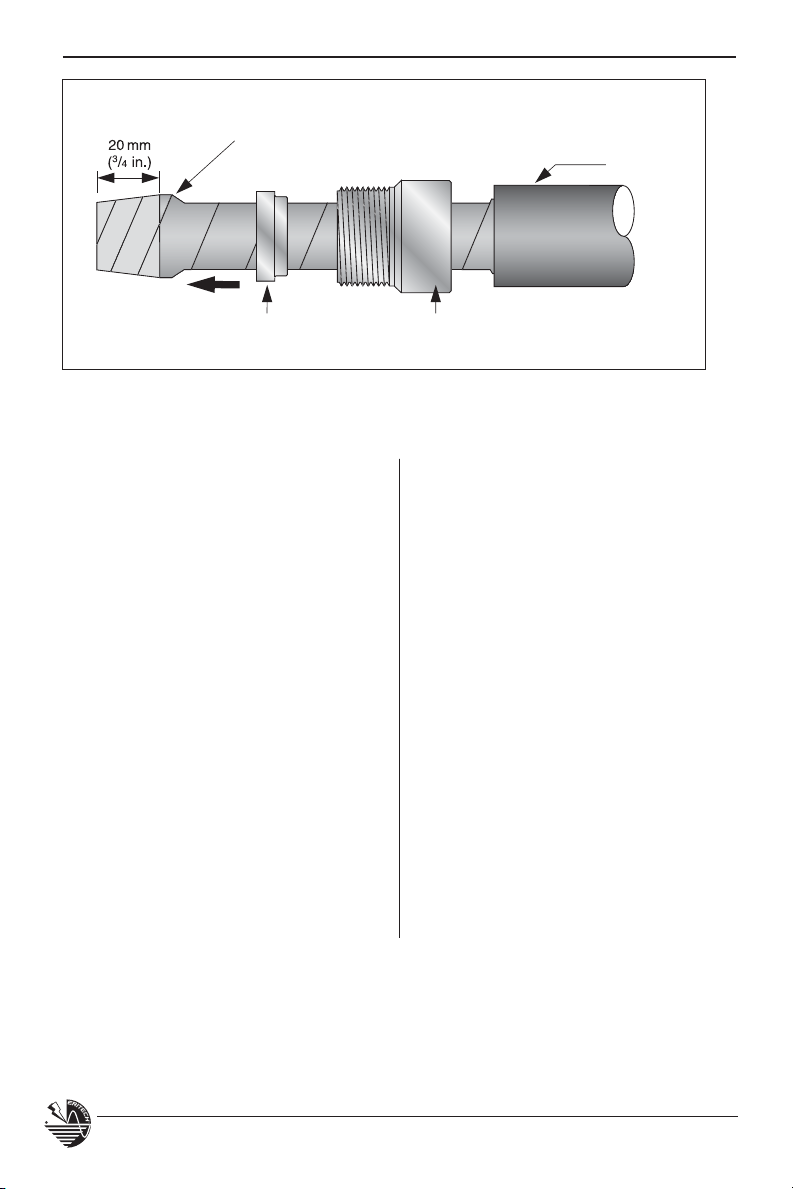

Use of Mast or Conventional

Cable as the Downconducto

In some installations, the mast may be used

as the downconductor or alternatively, in

short-run installations, conventional cable is

sometimes used. In these cases, a Terminal

Lug Coupling Adaptor will be supplied

to allow a lugged 50 mm

2

(2/0 AWG) (depending on local

70 mm

minimum standards) cable termination to

the base of the ERITECH

(see figure 12).

®

ERISTRUT (or other similar

r

2

(1/0 AWG) or

®

DYNASPHERE,

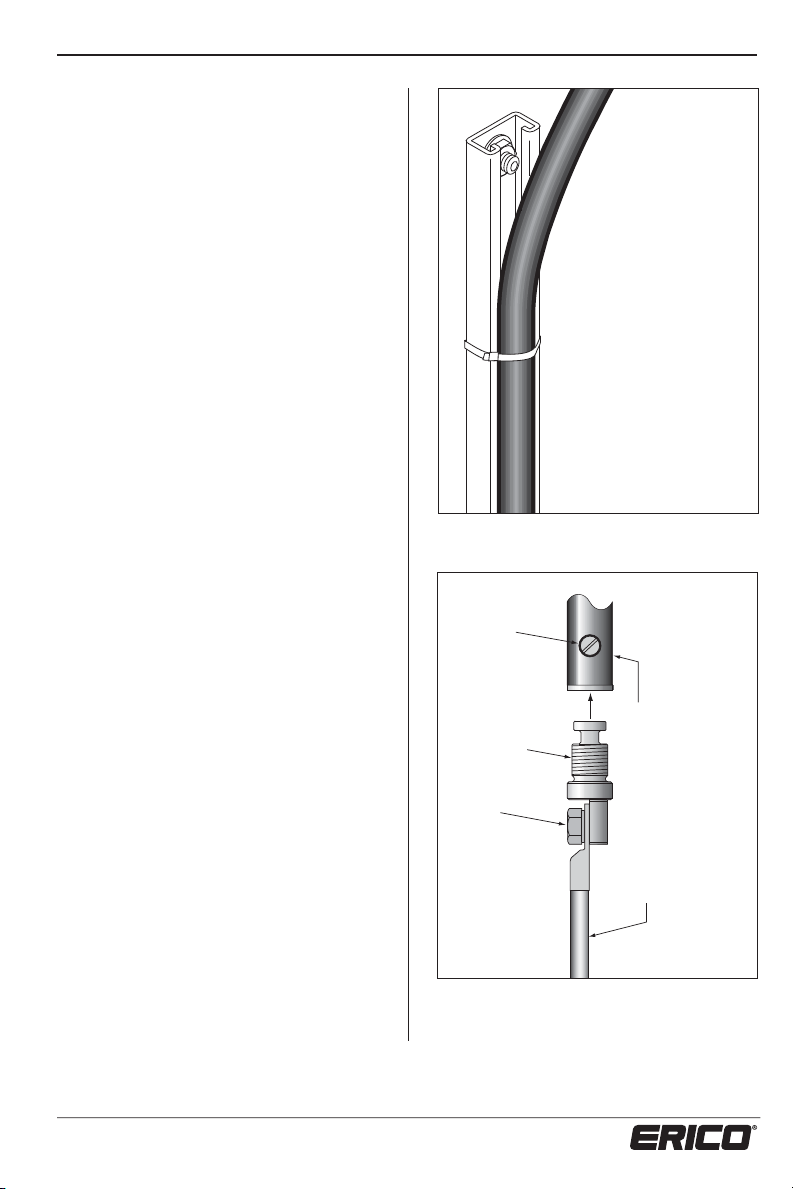

Use of CADDY® ERISTRUT

to anchor downconductor

with S/S cable ties

Figure 11: Downconductor anchored to strut.

Lock Screw

Lightning Protection

Lug Coupling

M10 Bolt

Figure 12: Lug Coupling for non-ERITECH

ERICORE

downconductors.

Terminal Base

2

50 mm

(1/0 AWG)/

2

70 mm

(2/0 AWG)

minimum

downconductor

(or as per local

standards)

®

www.erico.com

19

Page 22

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Labelling

Vital Warning Labels must be located at

eye level:

t Where there is the possibility of

personnel being in close proximity to

the cable.

t Where the downconductor terminates

to the grounding system.

t At the mast base.

There is a VITAL WARNING LABEL

supplied in the front cover of this manual

and also one supplied in each of the

upper and lower termination kits.

If more labels are required, contact your

nearest ERICO

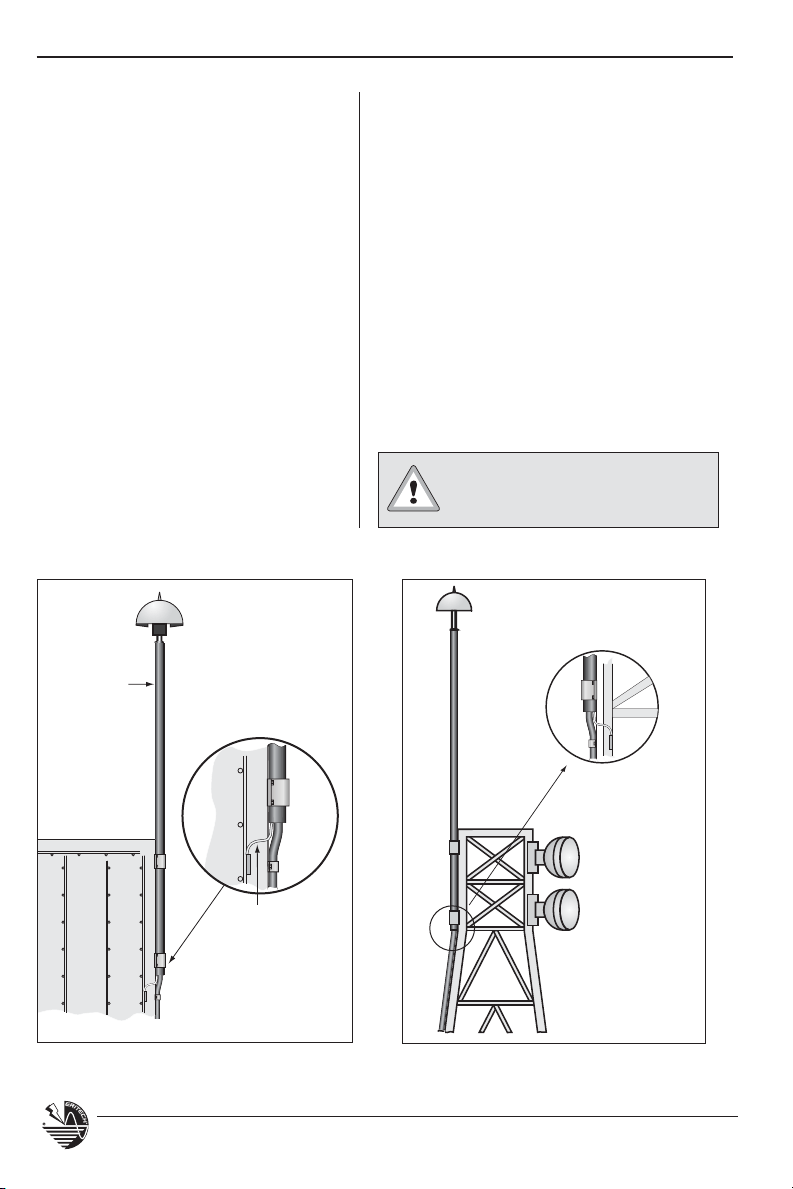

4.6 m (15 ft.)

FRP Mast

®

Distributor.

Structure Bonding Braid

To help ensure that the upper end of the

downconductor can be adequately electrically

bonded to the structure, a Structure Bonding

Braid has been provided at the base of the upper

termination of the downconductor. This braid is

a 75 mm (3 in.) tail which exits from under the

termination coldshrink and is

connector to allow connection

(8 AWG) copper cable (as mentioned in the

following text). This must be connected to a

conductive structural point to relieve the electrical

stresses on the downconductor and masonry

surfaces.

The use of the Structure

Bonding Braid is NOT optional,

and MUST always be used.

supplied with a

to a 6 mm2

Structure bonding

cable connected

to structural steel

Figure 13(a): Cantilevered FRP section on building.

Figure 13(b): Cantilevered FRP section on Radio Tower.

20

www.erico.com

Page 23

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

After routing the downconductor,

it must be kept in constant physical

contact with the structure via

conduc

tive fixings as follows:

t The top 10% of the downconductor

from the terminal must be secured at

least every 1 m (40 in.). This includes

metallic mast sections.

t The lower 90% of the downconductor

must be secured at least every 2 m (80

in.).

t This includes routing inside any type of

conductive pipe or conduit, (see Fig. 17).

t When mechanical fastening of the

cable every 2 m (80 in) is not possible,

a maximum unsupported length of

35 m (114 ft) is allowed as long as the

installation adheres to the electrical

bonding requirements (see use of cable

ties in figure 17).

When using metallic lower

sections of mast (ie: aluminum),

then the downconductor MUST

be secured with ERITECH

of saddles to the mast at 1 m

(40 in.) intervals (max.). The

mast in turn must be electrically

bonded to the nearest conductive

structural point. In this case, the

structure bonding braid must

connect to the inline coupling,

(see Fig. 14).

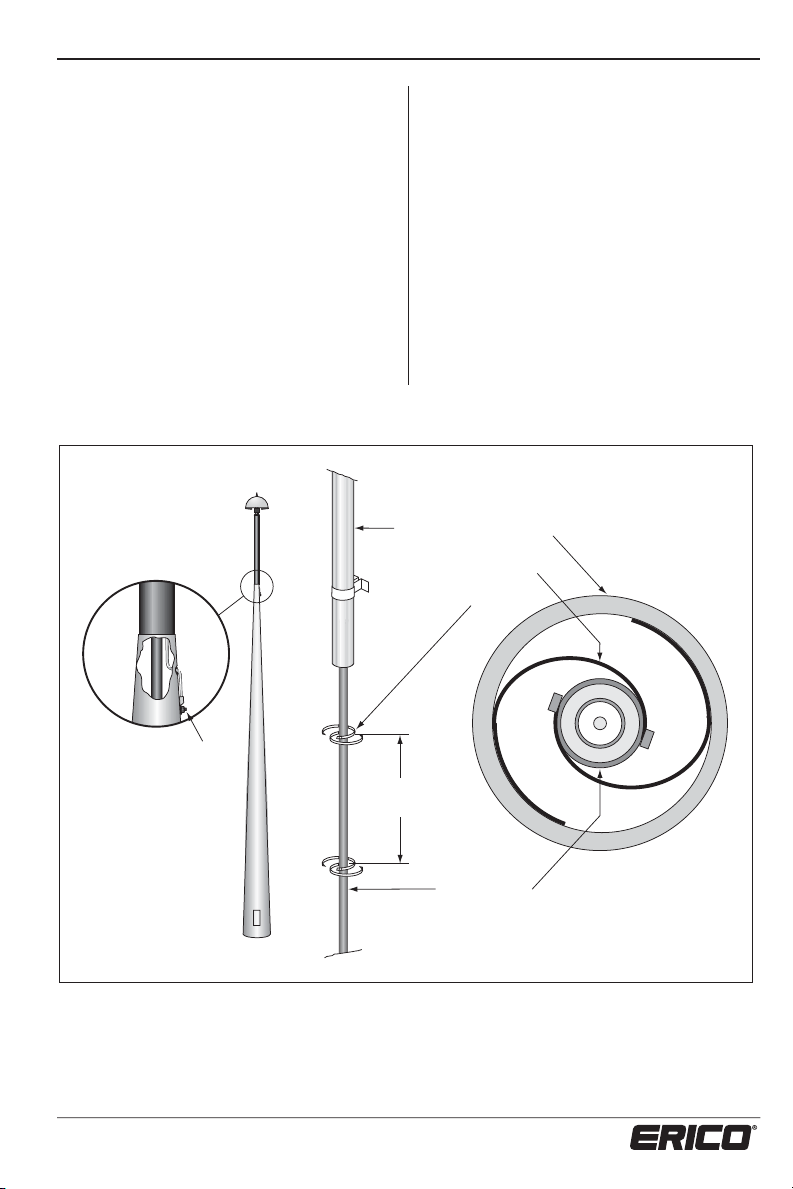

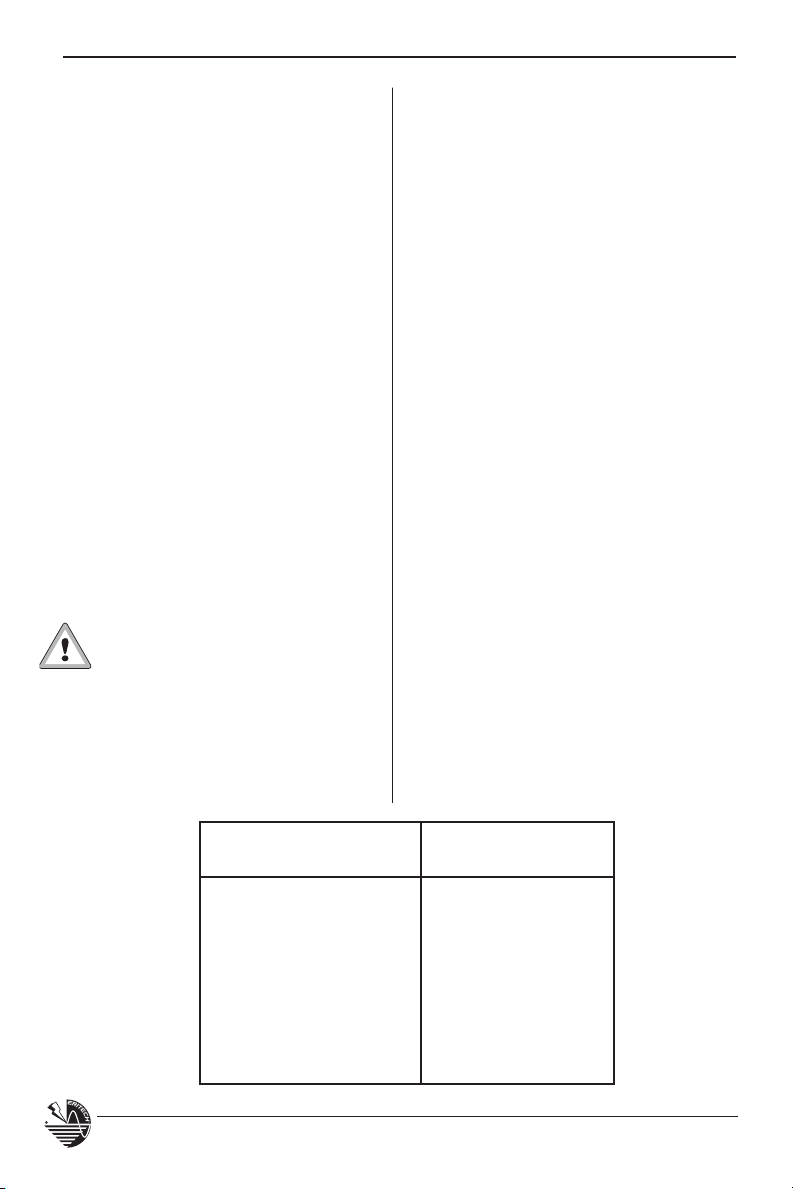

Aluminum Mast

ERITECH

Saddles at

1 m (40 in.)

intervals

(max.)

®

brand

ERITECH

ERICORE

®

www.erico.com

To nearest conductive

structural point (steel

Figure 14: Connection of Structure Bonding

Braid in FRP and F.S. masts.

21

work, concrete

re-inforcing, etc)

Page 24

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Structural Steel Work

Figure 15: Connection of bonding cable to structural steel work.

Concrete Panel

To upper termination

kit bonding braid or

mast base

CADWELD®, bolted, or

other suitable electrically

bonded method

To upper termination kit

bonding braid or mast base

Structure bonding cable

CADWELD, bolted, or

other suitable electrically

bonding method

Figure 16: Connection of bonding cable to concrete reinforcing.

22

Reinforcing Steel

www.erico.com

Page 25

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

2

The 6 mm

(8 AWG) copper cable used to

connect the structure bonding braid to the

structure must be one continuous length.

Joins in this cable would represent a

potential maintenance issue.

Any metallic surfaces that the downconductor may be secured to, if possible,

should be electrically connected to the

structural steel work.

Also, when using a metallic mast (ie: free

standing light pole), the structure bonding

braid must be connected to the top of the

metallic mast using 6 mm

2

(8 AWG)

insulated copper cable, (see figure 17).

To bond the downconductor inside a

conductive non-ferromagnetic mast pipe

or conduit, secure two stainless steel cable

ties around the downconductor at every

1 m (40 in.) or at 2 m (80 in.) intervals

with their tails left on, alligned at 180°

to each other so that when fed into

the pipe, they maintain contact with

the inside wall of the pipe, (see figure

17). The maximum length of the cable

installed inside the mast pipe or conduit

should not exceed 35 m (114 ft).

Metallic mast pipe or conduit

2 x stainless steel

cable ties at 180°

with tails left on

tructure bondin

cable attached to

top of freestandin

mast

reestandin metallic

mast where

downconductor

cannot be secured

to inside of mast

Figure 17: Electrical bonding of downconductor within metallic mast section or pipe.

www.erico.com

1 to 2 m (40-80 in.)

intervals as appropriate

Downconductor

23

Page 26

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

®

Terminating the ERITECH

ERICORE Lower End

Instructions for ERITECH ERICORE Downconductor

The downconductor has been

specifically designed to cope

with extremely high impulse

voltages and currents. Due to the nature

of the downconductor construction, and

working environment, it is Very

its

Important

and carried out exactly as per the

following instructions.

that each step be followed

Tools required for Terminating Lower End of ERITECH ERICORE

1. Sharp Knife

2. Tape Measure

3. Flat Blade Screwdriver

4. Hacksaw

5. 150 mm (6 in.) Adjustable Spanner / Wrench

6. Roll Spring - (supplied with Upper Termination Kit)

7. Insulation Cutting Tool - (supplied with Upper Termination Kit)

8. Crimper (90 mm

2

) (only required if the cable lug is to be used)

The downconductor can be lugged, (as

detailed overleaf) and then connected

to the ground rod using the ground rod

clamp, or alternatively, it can simply be

connected to the ground rod using only

the ground rod clamp.

The Lower Termination Kit Consists of:

1 x Hose Clamp

2

1 x 90 mm

1 x 2.5 mm

1 x ‘U’ Bolt type Ground Rod Clamp (13-15 mm,

Lug

2

x 105 mm (12 AWG x 4 1⁄8 in.) Bare Copper Wire

1

1 x Water Proofing Mastic

1 x Vital Warning Label

2 x Rubber Gloves

1 x Instructions

24

⁄2 - 5⁄8 in. Rod Diameter.)

www.erico.com

Page 27

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Refer to Figure 18 for the following

instructions (1 to 10).

1. With the hacksaw (or appropriate

cutters), cut the downconductor cable to

length, leaving enough cable to be able to

easily and directly route it to the ground

termination.

2. At a distance of 100 mm (4 in.) from

the end of the cable, carefully cut a shallow

notch into the black outer insulation, no

deeper than 1 mm, (

3

⁄64 in.). Using the

insulation cutting tool, cut around the

circumference of the black outer insulation

until the copper screen underneath is

exposed.

Important! The insulation

cutting tool uses friction to cut

into the sheath and is less likely

to damage the layers underneath than using a knife.

3. Use a knife to carefully cut along the 100

mm (4 in.) length of black outer insulation

to a depth of no more than 1 mm. (

3

⁄64 in.).

Be careful not to cut too deeply so that the

copper layer underneath is not exposed

or damaged. Starting from the end of the

cable, carefully remove the outer insulation

and discard.

4. Carefully clean up the insulation

friction cut, removing any burrs for a neat

finish.

5

5. Fit the roll spring 15 mm (

⁄8 in.) from

the end of the outer insulation over the

exposed copper tape (roll spring supplied

with upper termination kit).

6. Remove the copper tape up to the roll

spring (exposing black triple extrusion

layers) by unrolling, then tearing the tape

up and back over the edge of the roll

spring at about a 45º angle. If necessary,

cut about 6 mm (

1

⁄4 in.) of the copper

tape up against the roll spring with a

knife and then tear over the spring.

2

7. Wrap one end of the 2.5 mm

105 mm (12 AWG x 4

1

⁄8 in.) bare copper

x

wire (supplied with the kit) around the

hose clamp, then fix the hose clamp over

the exposed copper screen of the downconductor and tighten with a screwdriver.

3

8. At 85 mm (3

⁄8 in.) from the end of

the cable, carefully cut around the

circumference of the black triple extrusion

layers with a knife, then, from the first

cut, along the length of the insulation to

the end of the cable. Remove the layers

and discard.

85 mm (33/8 in.) 15 mm (5/8 in.)

Copper Strands

and Double Tape Layer

Figure 18: Stripping lengths downconductor.

www.erico.com

Copper Tape Black

Outer Sheath

Compression Lug

25

2

2.5 mm

Copper Wire

Copper Strands and

Double Tape Layer

Hose Clamp

Copper Tape Black

Outer Sheath

Page 28

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

9. Lay back all of the copper strands and

tape cut off the filler core with a hacksaw

or knife as close to the strands and tape

as possible without damaging them. Lay

the copper strands and tape neatly and

uniformly back in place.

10. If using the compression lug, combine

the end of the 2.5 mm

2

(12 AWG) bare

copper wire from the hose clamp with the

downconductors’ copper strands and then

fit ALL conductors into the 90 mm

2

lug

supplied with the kit. Make sure that it is

fitted correctly before crimping with an

appropriate crimper.

11. S

ecurely connect the lugged down-

conductor to the grounding system.

12. If the ‘U’ bolt ground rod clamp (or

other method) is to be used, then ensure

that the 2.5 mm

2

(12 AWG) bare copper

Lower termination shown lugged and

bolted to bus bar within enclosure

System 3000

ERITECH

wire from the hose clamp is bonded with

the final grounding connection and all of

the other downconductor copper strands

and tape. Then securely tighten the whole

connection.

Note: The ground rod clamp supplied in

this kit must be tightened to 44Nm

(32 lbf.ft.).

13. Make sure the lower termination is

free of moisture. Using rubber gloves,

shape the waterproofing mastic (supplied)

around all of the exposed areas of the

lower termination.

Note: Depending on the environment of

the lower termination, it may be necessary

to wrap a sealing tape or mastic around

the waterproofing mastic to stop it from

drying out over time.

Lower termination

shown connected

to rod with clamp

®

ERICORE

ERITECH ERICORE

LC

Hose Clamp

2.5 mm

(12 AWG)

Copper Wire

Compression

Lug

Copper

Bus Bar

To Grounding System

Figure 19: Termination to bus bar and ground rod.

Copper Tape

26

ntire loer

termination

to e ound

in aterprooing

masti

od Clamp

Ground od

www.erico.com

Page 29

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

It is important to cover all

exposed metallic surfaces

(copper, hose clamp, lug,

ground rod clamp, etc.) To

avoid the risk of corrosion.

14. Place the ‘VITAL WARNING’ label

(supplied in the kit) in a suitable place near

the downconductor.

Note: If an upper termination has

already been performed on the cable,

then start with STEP 23 on page 37.

ERITECH

conductor cable has been

specifically designed to cope

®

ERICORE down-

with extremely high impulse

voltages and currents. Due

to the nature of the cable

construction, and its working

environment, it is very

important that each step

is followed and carried out

exactly as per the following

instructions.

The special insulation cutting tools have

been supplied to facilitate the cutting

of the cable’s insulation layers, while

preventing damage to other layers, such as

the copper foil.

Ground Pit

System 3000

LEC IV

Figure 20: Completed termination for downconductor.

www.erico.com

27

Downconductor

lower termination

bound in

waterproofing

mastic

ERITECH

Ground Rod

®

Page 30

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Terminating the ERITECH® ERICORE Upper End

Instructions for ERITECH® ERICORE Downconductor

Photo 2: Contents of upper termination kit and the tools required to complete the termination procedure.

Tools required for terminating upper end of ERITECH® ERICORE

1. Sharp Knife

2. Tape Measure

3. 2 x 375 mm (15 in.) Shifting Spanner / Wrench

4. PVC Electrical Tape

5. Roll Spring - supplied with termination kit

6. Insulation Cutting Tool - supplied with termination kit

The Upper Termination Kit consists of:

1 x Coldshrink Tube (red) 1 x Vital Warning Label 1 x Mastic Tape

1 x ERITECH ERICORE Coupling 1 x Structure Bonding Braid 1 x Instructions

(4 pieces when dismantled) 1 x Insulation Cutting Tool 1 x Crimp Lug

1 x Silicone Tape - 1.3 m (93 in.) 1 x Semi Conductive Tape 1 x Roll Clip

28

www.erico.com

Page 31

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The Insulation Cutting Tool uses

friction to cut into the sheath and is

less likely

under

to damage the layers

neath than using a knife. When

the instructions call for the knife to be

used, be sure not to cut any deeper

than instructed.

If the instructions are not followed correctly,

or if any of the insulation layers or the copper

foil are incorrectly cut, then the integrity of

the lightning protection is affected.

Refer to Figure 21 on page 36 for the

following instructions (1 to 11).

5

1. At a distance of 600 mm (23

⁄8 in.) from

the end of the cable, carefully cut a shallow

notch into the black outer insulation no

deeper than 1 mm, (

3

⁄64 in.). Then, using

the insulation cutting tool, cut around the

circumference of the black outer insulation

until the copper screen underneath is

exposed, (see photo 3).

2. Using a knife, carefully cut the outer

insulation of the cable to a depth of no

more than 1 mm (

600 mm (23

3

⁄64 in.), for the full

5

⁄8 in.), in the direction of the

end of the cable. Be sure not to cut so deep

as to expose or damage the copper layer

underneath. Starting from the end of the

cable, carefully remove the outer insulation

and discard.

Photo 3: Use of the insulation cutting tool to

cut the insulation without damaging the layers

beneath.

3. Carefully clean up the friction cut,

removing any burrs for a neat finish.

6

4. Fit the roll spring 20 mm (

⁄8 in.) from the

end of the outer insulation over the exposed

copper tape.

5. From the end of the cable, remove the

copper tape up to the roll spring, exposing

the black semi-conductive material by

unrolling, then tearing the tape up and back

over the edge of the roll spring at about a 45˚

angle. (If necessary, carefully cut about 6 mm

of the copper tape up against the roll spring

with a knife and then tear over the spring).

www.erico.com

29

Photo 4: Using the roll clip to cut and remove the

copper screen.

Page 32

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

6. Carefully remove the roll spring, then

tape up the last 6 mm (

1

⁄4 in.) of the copper

tape with a piece of PVC tape, to stop

further unravelling.

7. Clean and degrease the outer sheath

for a distance of 100 mm (4 in.) from the

cut position. Using slight tension, wrap

one layer of sealant tape (red) around the

black outer insulation with a small overlap

of 5 mm (

1

⁄5 in.) over the copper tape

screen, (see photo 5).

8. Place the structure bond braid over

the cable so that it sits over the copper

screen and up against the sealant tape

(red). Ensure that the braid loops are tight

around the copper screen. Tape the bond

braid into place with PVC tape, (see

photo 6). (Ultimately, this braid may

require electrical bonding to the structure.)

3

9. At a distance 70 mm (2

⁄4 in.) from the

end of the cable, carefully cut a notch in

triple layered insulation no deeper than

3

⁄64 in.). Then using the insulation-

1 mm (

cutting tool, cut around the circumference

of the triple layered insulation until the

copper underneath is exposed.

Photo 5: Red sealant tape applied over overlap.

10. With a knife, carefully cut along the

70 mm (2 3⁄4 in.) length of triple layered

insulation

more than 1 mm

on the cable to a depth of no

(3⁄64 in.). Be sure not to

cut too deep, as to expose or damage the

copper layer underneath. Starting from

the end of the cable, carefully remove the

triple layered insulation and discard.

Photo 6: Bonding braid secured in place.

30

www.erico.com

Page 33

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

11. Remove one release foil from the

stress control patch (green) and apply it

level with the outer insulation cut, against

the red sealant tape, (see photo 7). Wrap

the entire patch around the cable as

shown and remove the release foil during

installation. Avoid air pockets, wrinkles or

creases.

12. Wrap one layer of sealant tape (red)

with a small overlap and slight

over the braid wire and previously

tension

applied

sealant tape, below and level with the

(green) stress control patch, (see photo 8).

®

13. Take apart the ERITECH

ERICORE

coupling, ensuring there are 4 pieces.

There should be:

t"$PNQSFTTJPO/VU

t"$PNQSFTTJPO3JOH

t"$PNQSFTTJPO$POF

t".BJO$PVQMJOH1JFDF

14. Place the compression nut and

compression ring of the coupling set over

the strands and copper tape layer. Check

the order and orientation of the nut and

ring against Figure 22 on page 36.

Photo 7: Applying the stress control patch. In line with

initial outer layer cut and over the bonding braid.

15. Unwrap the material double tape layer

back to the compression ring. Place the

compression cone between the filler core

and the copper strands as shown in Figure

22. The cone should be “pushed on” until

it is flush with the end of the filler core.

Neatly form the copper strands back over

the cone in their original order.

www.erico.com

Photo 8: Apply the sealant tape below the stress

control patch.

31

Page 34

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Wind Back Layers of Copper Tape

Over Copper Strands to the End

Compression Ring Compression Nut

Figure 23: The termination coupling is fitted to the downconductor

ready for the main coupling body to be fitted.

Coldshrink

16. Rewrap the outer double layer of

copper tape into place over the copper

strands. Push the compression ring back up

over the wrapped copper strands and up

against the cone, (see figure 23).

17. Fit the main coupling piece from the

coupling set carefully over the end of the

cable ensuring the cable is pushed up as

far as it will go into the coupling. Ensure

the copper strands are kept in place and

order. Screw the compression nut into

the coupling piece and tighten, using the

correct size spanners / wrenches.

18. At a distance of 100 mm (4 in.) from

the end of the cable, wrap one half-lapped

layer of semi-conductive tape around

the triple layer insulation with an overlap

towards the copper tape / copper strand

center conductor up to, but not over, the

compression coupling.

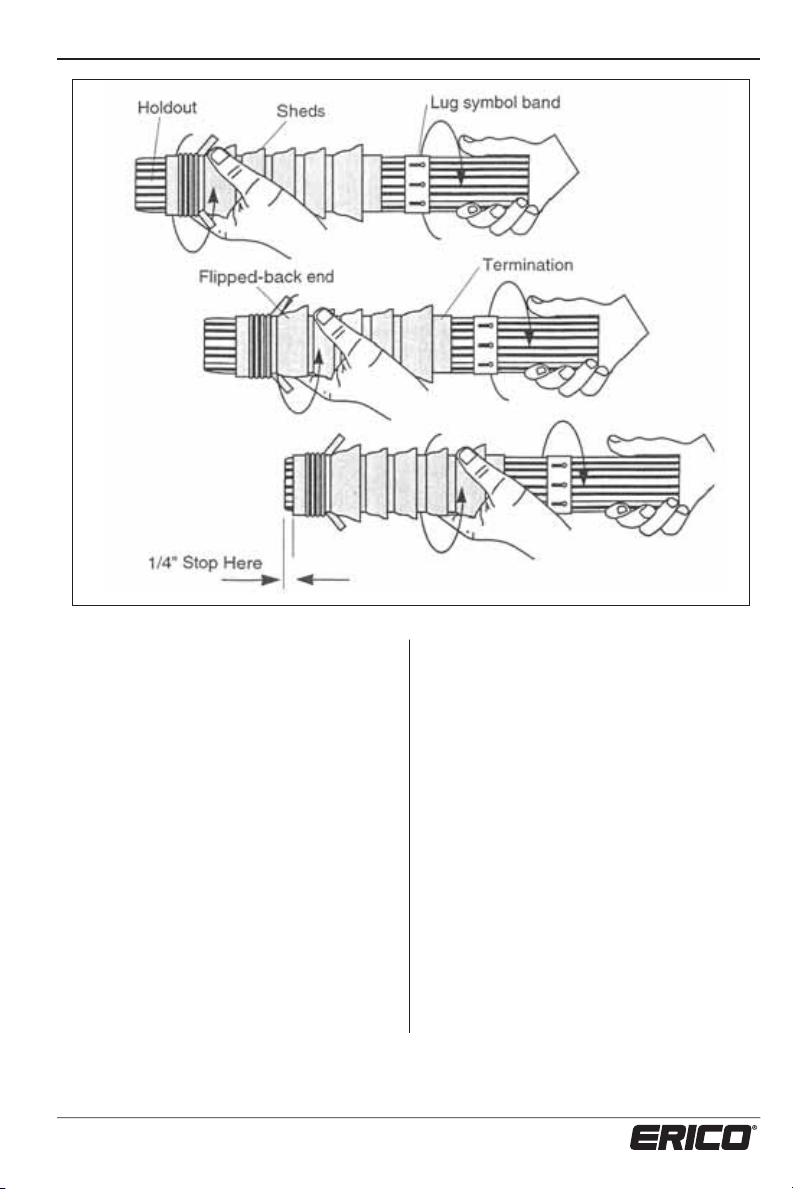

19. Loosening Termination

This operation is vital to the simple

installation of the product.

There are two terminations in this

kit, (one with three sheds, the other

with five). Loosen both in the manner

shown on page 33. Install the five

shed termination first.

Hold the termination in one hand and

the holdout in the other. Gripping

firmly, twist the termination and

holdout in opposite directions. Repeat

twisting the termination and holdout,

moving the hand in short increments

up the termination until the entire

termination is felt to move on the

holdout. Slide the termination until it

lines up with the end of the holdout

tube as shown. Note: Take care not

to slide the termination off the end

of the holdout. Stop the termination

about 6 mm (

1

⁄4 in) from the end of

the holdout.

32

www.erico.com

Page 35

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

20. Installing the termination.

Position the holdout over the cable until

it meets the jacket cutback. Twist the

termination and slowly push it to the end

of the holdout.

Slide the termination off the holdout with

a twisting motion, holding the termination

that is on the holdout in one hand and

pulling the holdout with the other.

Note: Do NOT stretch the termination.

Do NOT hold the termination that is

partially installed and attempt to pull the

remaining termination off the holdout,

as this will stretch the termination and

generate an improperly installed termination

if not repositioned.

www.erico.com

Using the pull tabs, pull the flip-back

portion away from the main termination, at

the same time working the first two fingers

of each hand between the flip-back and

main termination. Pull the stretched out

flip-back over the cable jacket and sealant.

Make sure the termination length is in

accordance with the dimensions shown.

Having positioned the termination, now

wrap one layer tape sealant (red) over the

end of the termination and 6 mm (

onto the cable insulation as shown.

33

1

⁄4 in)

Page 36

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

381 mm (15 in)

6 mm (1/4 in)

34

32 mm (1-1/4 in)

www.erico.com

Page 37

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

21. Installing the termination (continued).

Slide the three-shedded termination over the cable until it meets the leading edge of the

sealant strip as shown. Twist the termination and slowly push it to the end of the holdout.

Slide the termination completely off the holdout using a twisting and pulling motion as shown.

Using the pull tabs, pull the flip-back portion away from the main termination, at the same time

working the first two fingers of each hand between the flip-back and main termination.

Pull the stretched out flip-back over the sealant.

www.erico.com

35

Page 38

70 mm (2

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

600 mm (23 5/8 in.)

3

/4 in.)

380 mm (15 in.)

20 mm

6

(

/8 in.)

Copper

Conductor

Copper Strands and

Double Tape Layer

Figure 21: Cutting dimensions

Compression Cone Compression Ring

Copper Strands Splayed

Out to Allow Fitting of

Compression Cone

Filler Core (Black)

Figure 22: Positioning the compression coupling.

Triple Layered

Insulation Layer

PVC Tape to Stop Copper Tape from Unravelling

Compression Nut

Double Copper Tape Layer

Copper

Tape

Black Outer

Sheath

Wind Back Layers of Copper Tape

Over Copper Strands to the End

Compression Ring Compression Nut

Coldshrink

Figure 23: The termination coupling is fitted to the downconductor

ready for the main coupling body to be fitted.

36

www.erico.com

Page 39

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

The coupling must be tightened

using spanners / wrenches, as

tightning by hands will not be

adequate.

22. Using the roll of silicone tape (grey),

overwrap half layers from 20 mm (

the end of the coldshrink to 30 mm (1

3

⁄4 in.) over

1

⁄8 in.)

over the coupling so that it covers the joint

between the main coupling and compression

nut, (refer to figure 24 on page 39).

Wrap with moderate tension (10 to 100%

stretch). Apply one final layer with no stretch.

Press down, to avoid the end lifting before

fusion of the tape takes place.

The finished termination must be

protected against any abrasion

and sharp edges during transport

or installation, as the coldshrink

tubes are susceptible to ripping or

tearing if nicked or scuffed.

23. The structure bonding braid MUST be

electrically connected via a 6 mm

2

(8 AWG)

length of insulated copper cable to the

specified conductive structural point, as

described in the ERITECH® SYSTEM 3000

Installation, Operation & Maintenance

Manual.

®

Connecting the ERITECH

DYNASPHERE

24. Feed the downconductor (and

structure bonding cable) through the

FRP mast so that the entire termination

is protruding from the top of the mast.

Remove

ERITECH

the lock screw in the base of the

®

DYNASPHERE

terminal, then

screw the terminal all the way onto the

termination coupling thread. Replace the

lock screw back into position so that it

locks the thread into place and will stop

the terminal from unscrewing.

25. Carefully pull the downconductor

(and structure bonding cable) back down

through the FRP mast so that the terminal

base sits correctly in the top of the mast.

Twist the FRP mast at least one complete

turn at the base of the terminal to remove

any stress on the termination sheds

(flanges) and to seat the terminal correctly.

www.erico.com

Photo 11: Installed compression coupling.

37

Page 40

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Note: It may be necessary to

pull back any slack of ERITECH

®

ERICORE downconductor through

the FRP support mast to achieve a

properly seated fit for the ERITECH

®

DYNASPHERE.

The ERITECH DYNASPHERE must

not be skewed and the base of the

terminal must be fully inserted into

the top of the mast.

2

26. Connect the 6 mm

bonding cable as detailed in the ERITECH

(8 AWG) structure

®

SYSTEM 3000 Installation, Operation

and Maintenance Manual. After bonding

the cable, ensure that the connection is

waterproof and resealed if required.

27. Place the Vital Warning Label in a

prominent position at the base of the mast,

or beside the downconductor at eye level,

if the installation is in an area where it is

possible for persons to gain access.

These termination procedures

should be strictly adhered to

since an incorrect termination

will result in failure of the

system.

38

Photo 12: Completed termination.

www.erico.com

Page 41

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

30 mm

(1 1/4 in.)

Double Wrap Silicon Tape

Half Lapping Over Entire Length - Ensure Tape Covers Join in Coupling

40 mm

(1 1/2 in.)

20 mm

(3/4 in.)

Figure 24.

Photo 13: Once the ERITECH® DYNASPHERE has been

fitted to the termination coupling, ensure the locking

screw is tightened securely.

www.erico.com

Photo 14.

39

Page 42

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Terminals and Masts

Terminals

Once the terminal has been checked and

found to be in an acceptable condition

for installation, it can be attached to the

terminated downconductor as shown in the

Upper Termination instructions on page 37.

Please note, the serial number of each unit

will have been recorded in the Certificate

Of Compliance (inside back cover) in this

manual.

Masts

The selected mast configuration chosen must:

t

Elevate the terminal to the required

height as determined by the design

process (minimum height of 3 m

(10 ft.) above the highest point of the

structure).

t

Include a minimum of 2 m (80 in.) of

insulated mast material (FRP) immediately

below the air terminal.

t

Be suitably rated for local weather

conditions. It is advisable that guidance

from a local civil engineer be sought.

t

Be securely attached to the selected

mounting point(s).

t

Be guyed if applicable.

If the lower section of the mast

is conductive, ie. aluminum or

galvanized iron; then:

t *UNVTUCFFMFDUSJDBMMZCPOEFEUP

the nearest conductive structural

point. This may be either

structural steel work or concrete

reinforcing. Refer to page 20 for

details.

t 5IFEPXODPOEVDUPSNVTUCF

secured to the mast at 1 m (40

in.) intervals (max.).

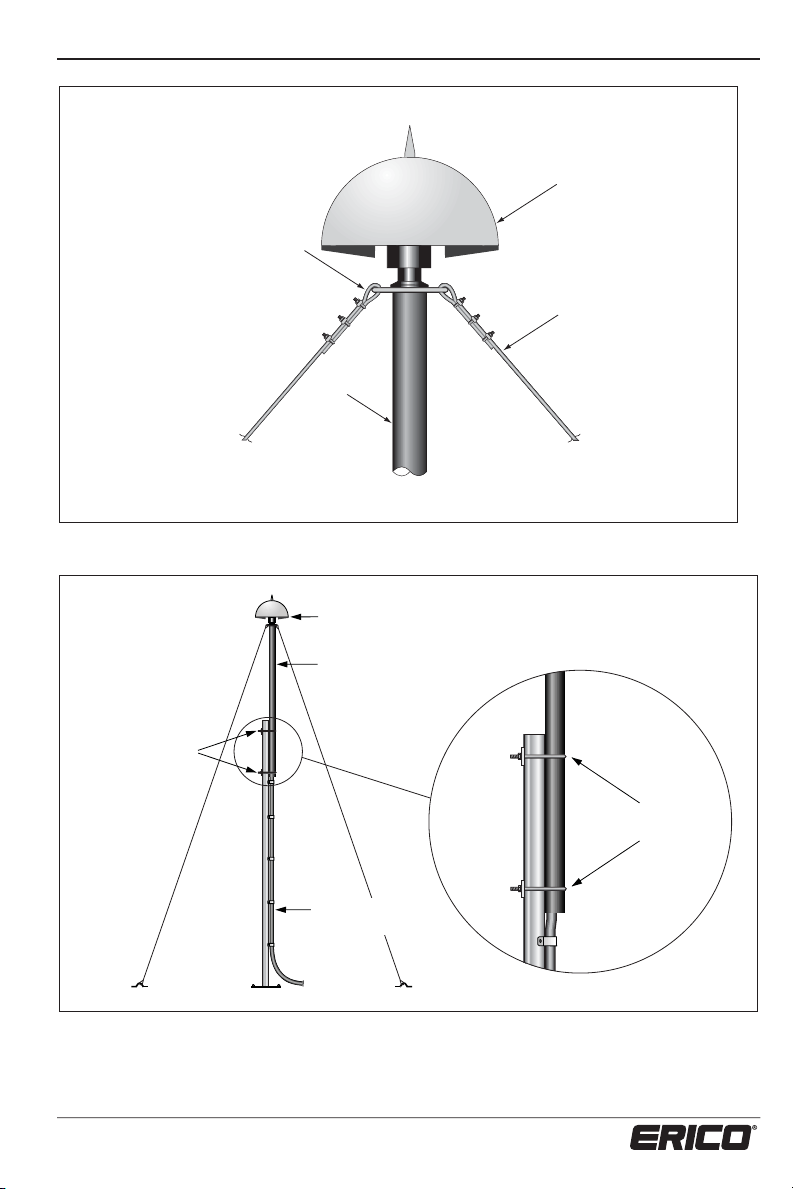

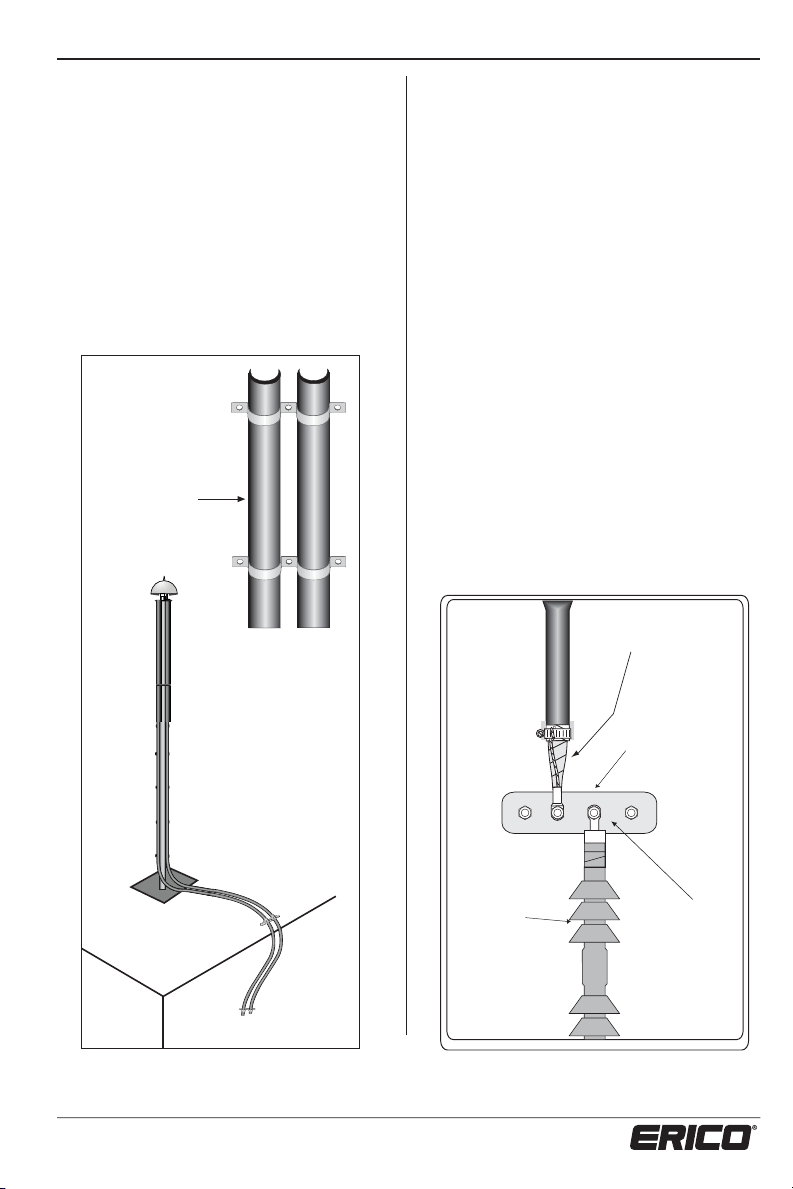

Three basic types of mast configuration

include:

Guyed

t

Single length guyed - one section of

FRP (Fiberglass Reinforced Plastic)

mast material guyed at the top.

t

Double length guyed - two sections of

mast material, usually aluminum lower

and FRP upper, guyed between the two

sections and at the top.

Cantilevered

Used in situations where it is more practical

to mount without a base, eg: radio towers.

t At least one third of the lower mast

should be secured against the structure.

t Cantilevered masts can either be free

standing or guyed for extra stability.

Freestanding

Often used where the terminal, down-

conductor and grounding system are

isolated from volatile areas by installing the

ERITECH

away from those areas.

40

®

SYSTEM 3000 at least 5 m (17 ft.)

www.erico.com

Page 43

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Before the installation of the mast, ensure

that:

t

The free standing mast is supplied with

an appropriate spigot, suitable for either

internal or external mounting of the FRP

mast.

t

The downconductor is to be routed

internally or externally.

t

Provision is made for external or internal

mounting of LEC IV and access.

t

The downconductor is able to exit

through the base of the free standing

mast.

The free standing mast requirements for

foundations and erection are generally

handled by the mast manufacturers.

®

ERITECH

DYNASPHERE

2.0 m (81 in.) FRP

Inline Coupling

Mast Bases

ERICO supplies a range of aluminum bases

to suit:

t

ERITECH

base with an internal mast spigot).

t

Aluminum masts (welded directly onto

the required length of mast).

Both base types have downconductor

exit holes in the base, required if the

downconductor is to be routed inside of

the mast. They also have identical mounting

hole dimensions which are shown overleaf.

ERITECH

DYNASPHERE

4.6 m (15 ft.)

FRP (1/3 of

Mast Mounted

to Structure)

®

brand of FRP masts (aluminum

ERITECH

DYNASPHERE

2.0 m (81 in.) FRP

orge

Tn

ree ning

s

1.5 m (5 ft.)

luminum

s

Comms Tower

Figure 25: Guyed, Cantilevered and Free Standing Mast examples.

www.erico.com

41

5 m (1 ft.)

Page 44

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Figure 26: Base and mounting dimensions.

If an aluminum mast and

base are used and can not

be directly attached to the

structural steel work, or are

anchored to a concrete roof,

then they need to be directly

electrically bonded to the

closest structural steel work

or conductive structural point.

Refer to page 20.

Mast Couplings and Guying

Points

There are two different methods of

coupling two sections of mast:

1. The U-Bolt set, which uses two stainless

steel U-bolts to clamp the two sections

of mast together, (see figure 28).

2. The Inline Coupling is designed to fit

between the upper and lower sections

of the masts and also provides three

guying anchor points, and, a downconductor exit point if required. The

maximum mast diameter that the Inline

Coupling is able to clamp onto is 70 mm

7

⁄8 in.) OD.

(2

On both the U-Bolts and Inline

Couplings, the nuts must not

be tightened to any more than

55kg/cm (45 in.lb).

Additional guying is

required at the top of 4.6 m

1

⁄2 ft.) FRP masts (if not

(15

mounted in a cantilevered

fashion). A guying ring is

supplied for guy anchor

points. This is installed

between the ERITECH

®

DYNASPHERE terminal and

the top of the mast, (see

figure 27).

42

www.erico.com

Page 45

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Guying Ring fitted

between ERITECH

DYNASPHERE

& FRP Mast

Figure 27: Use of Guying Ring.

U Bolts

®

FRP

Mast

ERITECH

DYNASPHERE

4.6 m (15 ft.) FRP

ERITECH

®

DYNASPHERE

Insuated Guying

®

Figure 28: Use of U-Bolts.

www.erico.com

5 m (1 ft.)

Amm t

43

U Bolts

Page 46

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Guying

1

ERICO has standard 4 m (13

7 m (24

of a

appropriate

1

⁄2 ft.) guying kits. If the guying

fiberglass mast is required, then the

guying kit should be selected

to suit the application. The guying material

is made up of light weight plastic coated

fiberglass, which is non-conductive.

If a customized guy kit has been supplied,

then the actual guy length can be

determined from the following:

Guy Length = 1.41 X

Where X = the vertical height between the

upper and lower guying points and the

assumed angle from horizontal is 45˚.

Important recommendations:

t 8IFOHVZJOHBOZNBTUJUJTBEWJTBCMF

that the guying angle be no greater

than 60° from horizontal.

t *UJTSFDPNNFOEFEUIBUNN

diameter stainless steel guying saddles

are used for the base guy anchor

points. If these are to be anchored to

a concrete surface, then 6 mm (

diameter x 40 mm (1

(minimum) masonry anchors or similar

should be used.

⁄2 ft.) and

5

⁄16 in.)

1

5

⁄8 in.) depth

⁄4 in.)

t &BDIPGUIFHVZJOHLJUTDPNFTXJUITJY

stainless steel thimbles to relieve stress

on the guys at the anchor points. These

thimbles MUST be used when guying,

(see figure 29).

3

t 8IFOVTJOHTIBDLMFTNN

⁄16 in.)

minimum), ensure that the shackle

pins are secured with nichrome wire.

When securing the fiberglass guys, use

the guying grips supplied in the guying

kit, carefully following the instructions

provided. Use of alternative wire rope

grips is acceptable but ensure that:

t (SJQTBSFNBEFPGBTVJUBCMFNBUFSJBMUP

PREVENT corrosion.

t 5IFSFBSFBNJOJNVNPGHSJQTQFSHVZ

end.

t (SJQTBSFTQBDFEBUBNJOJNVNPG

30 mm (1

1

⁄4 in.) on guys (or 6 x guy

diameter).

t (SJQTBSFDPSSFDUMZPSJFOUBUFEHSJQ

base (saddle) on the ‘Live’ side of the

guy and ‘U-bolt’ over the ‘Dead’ side or

tail of the guy.

t /PNPSFUIBOD/NMCGJOPG

torque is applied to the grip.

The above recommendations should also

be used for any other guying, ie: stainless

steel, when used on any mast.

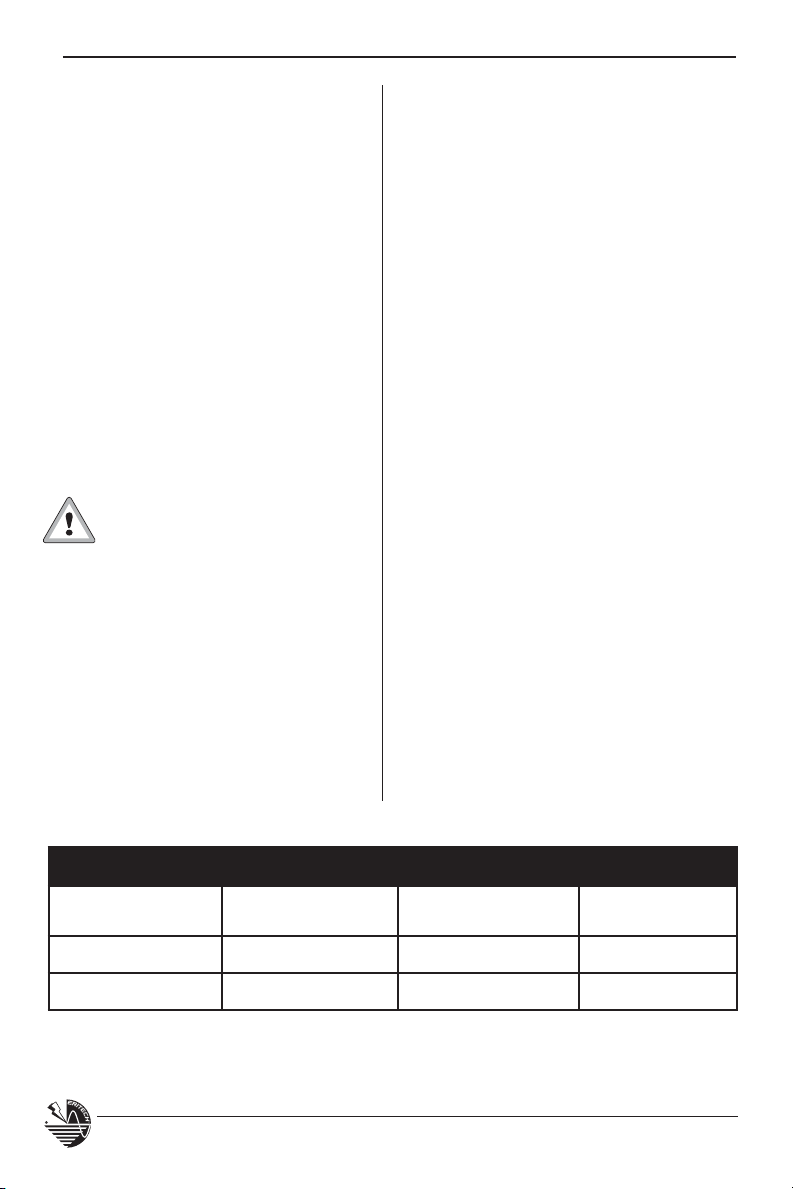

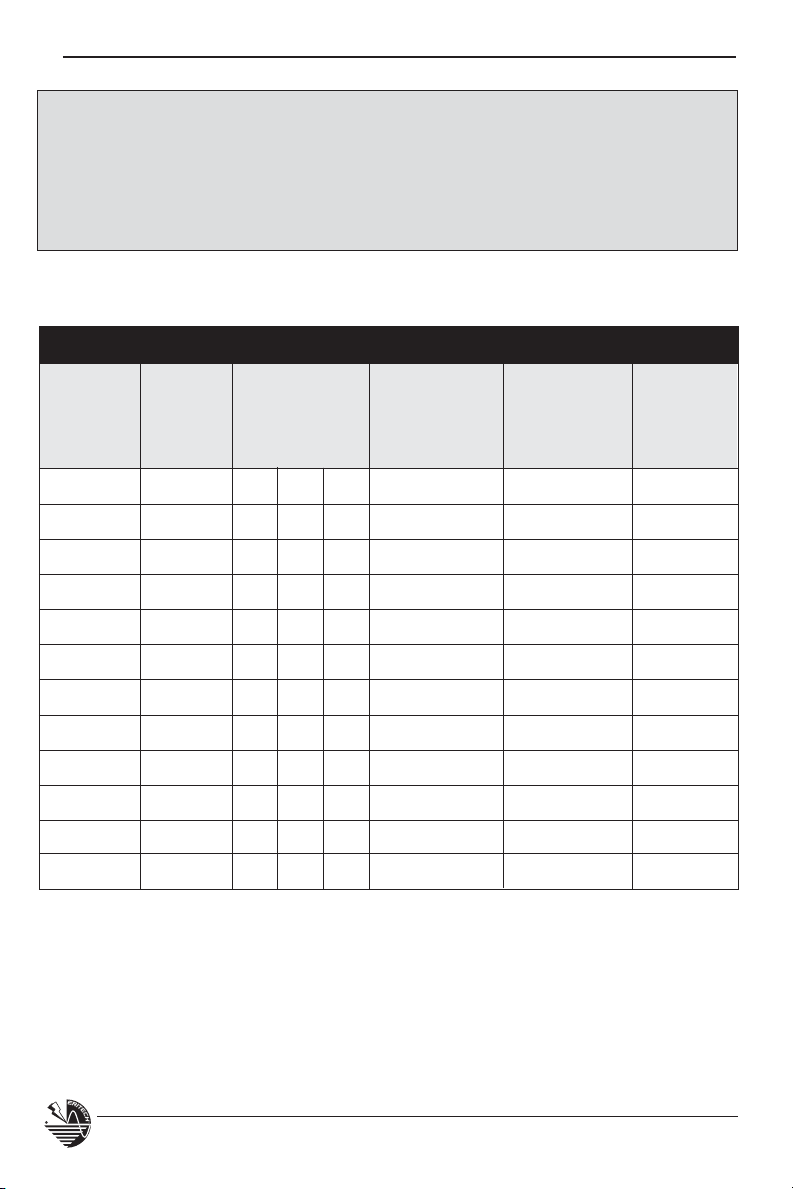

Guy Kit Specifications

Guying Kit Guy Diameter

4 m Guy Kit 4 mm -

7 m Guy Kit 5 mm -

5

/32 in. 6 m - 20 1/2 ft. 430 Kg - 946 lb

3

/16 in. 10 m - 34 ft. 560 Kg - 1232 lb

44

Actual Guy

Length

Guy Tensile

Strength

www.erico.com

Page 47

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Minimum spacing

Fiberglass

30 mm (1

between Saddles

1

/4 in.) 30 mm (1 1/4 in.)

"Dead" End

Thimble

Figure 29: Correct methods of guying.

Saddle Base on "Live" End

Raising of Mast

When ready to raise the mast, check the

following:

t

Guys to the inline coupling, guying ring

or other mast anchor points are properly

secured.

t

Ensure the guys are not twisted, kinked

or damaged in any way.

t

Ensure that each guy can be easily

secured at the base when the mast has

been raised.

Turnbuckles or rigging screws are recommended at the base anchor points of the

guys to enable easy vertical alignment of

the mast and correct tensioning of the guys.

If using turn-buckles, ensure that they are

wired securely with nichrome wire.

Using conductive guying, such as stainless

steel, is acceptable as long as it is NOT

used for guying to the top of sections of

insulated FRP mast. Guying to the top of an

aluminum section of mast is acceptable.

"Live" Side

Remember to always Plan the Lift

before attempting it.

If the mast is to be raised by hand, ensure

that it can be safely and easily managed

manually.

It is recommended that the use of a crane

or other suitable equipment be used for

anything over 6 m (20 ft.) in height, or for

hazardous area installations such as high

elevations (towers).

To minimize the possibility of the mast

becoming bent or damaged, it is very

important to keep the mast straight during

the lift.

Ensure that:

t There are no overhead AC

power lines.

t There is nothing overhead that will

obstruct the lift.

t There is enough man-power available to

safely conduct the lift.

www.erico.com

t

There is only ONE person in control of

the lift.

45

Page 48

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

n

t

Everyone involved in the lift knows

what has been planned and how the

lift is to be performed.

t

The mast is securely footed and cannot

move out of control during the lift.

t

Any guying has been properly secured

at the mast anchor points.

t

The downconductor has been correctly

terminated and the structure bonding

cable has been attached to the