Page 1

testing equipment for quality management

Adhesion and

Resistance Tester

Model 435 S

Mar Tester

Model 435

3 Test Ranges:

0 - 3 N

0 - 10 N

0 - 20 N

Model 435

Model 435 S

Technical Description and Operating Instructions

Page 2

Mar Tester, Model 435

Purpose and Application

Scars on surfaces are unsightly, especially on

smooth, glossy surfaces. Surfaces can be ruined so

easily - for example marks on the matt polished

surface of a table, by a fingernail, or on the shiny

bodywork of a Cadillac, by a twig. Great annoyance

can result from such small causes.

Marks can also be caused by metallic objects. The

culprits may be metal particles from coins, cutlery or

rings on fingers. Any of these can mar surface

finishes.

The traditional test for the resistance of surfaces to

such damage was to try to mark the surface with a

fingernail. With the Mar Tester, Model 435, the

quality of the surface can be measured accurately.

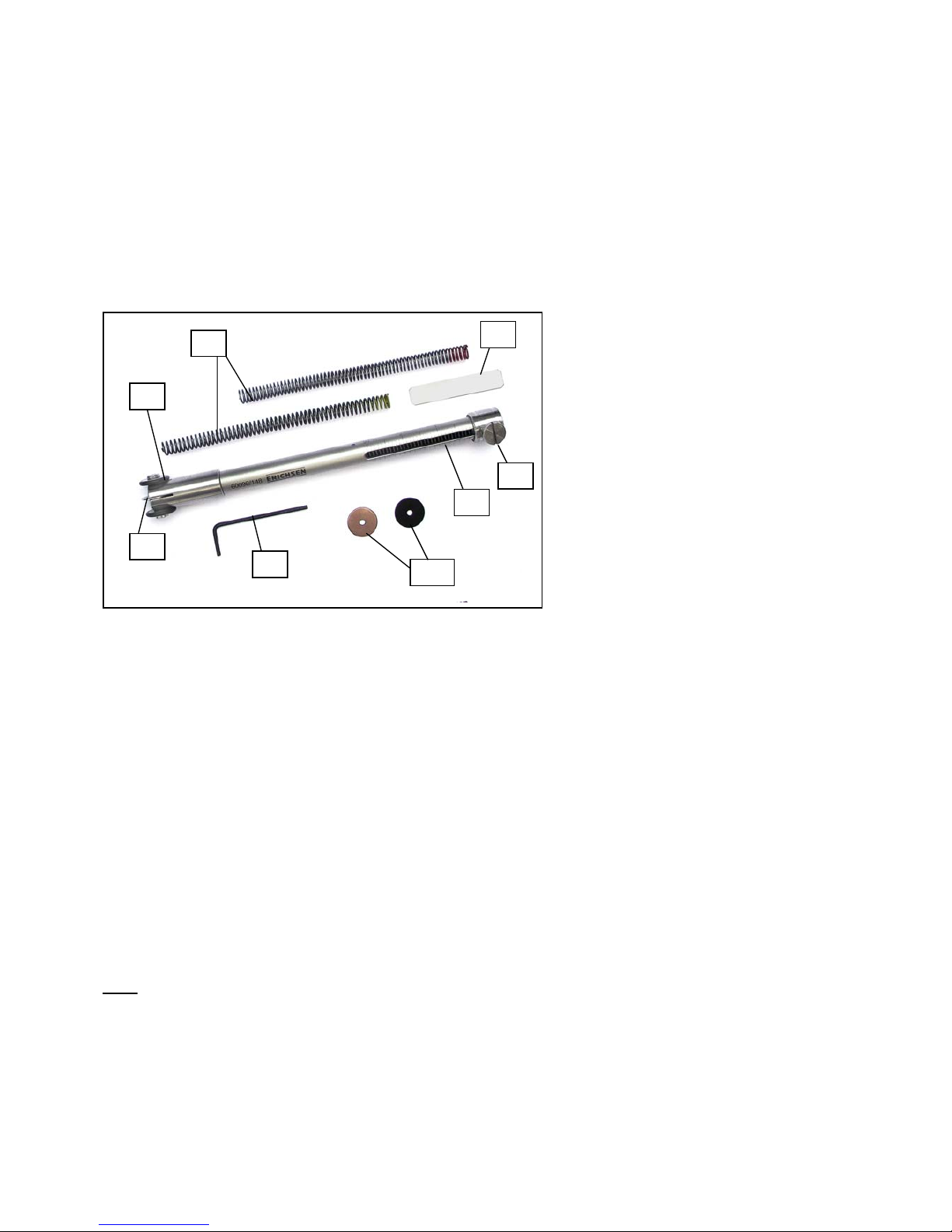

1. Rotating guide rolls

2. Fixed marking disc

3. Test force scale

4. Alternatives test dics

5. Force springs

6. Allen key

7. Locking screw slider

8. Help aid for fixing the locking

screw slider

Design and Function

The scaring tool in the form of a disc, with locking

facility, made of special plastic or metal, is mounted

on a screw and is under pressure from a helical

spring. This applies to a force which is adjustable

from 0 to 20 N. The instrument is placed onto the

surface so that it rests on the two guide wheels and

the marking wheel which is locked in position then

presses onto the surface with the pre-set force from

the spring. The range of spring forces available is

divided into three sections, each covered by one of

three exchangeable springs:

Test range 1: 0 - 3 N - Sensitivity 0,1 N

Test range 2: 0 - 10 N - Sensitivity 0,5 N

Test range 3: 0 - 20 N - Sensitivity 1,0 N.

Note:

The test discs will wear at the point at which they are

used. After 100 tests the discs should therefore be

moved round so as to bring a point about 2 mm

further along on the periphery into operation. The

point at which the marking disc is first used should be

marked by a scratch.

Method of Operation

First set up the selected test wheel depending on the

test required, i. e.

- the plastic disc for scar-resistance tests;

- the copper disc or other special disc for metal

marking.

After tightening the screw it must not be possible to

turn the marking disc. The spring is then set to

provide what is anticipated to be a suitable force and

the instrument is placed perpendicularly onto the test

surface and pressed down so that the guide wheels

touch the surface.

In this way the preset pressure of the test disc is fully

effective on the test surface.

The instrument is then moved a distance of a few cm

so that the wheels roll over the surface, in a rapid

motion appropriate for the scaring effect. The test

result is the spring force in Newton which is just

sufficient to produce a clear surface scar visible with

the naked eye but not a crack or scratch.

If the interest is in the so-called metal marking effect,

the result is expressed in terms of the spring force at

which the surface just shows a black or grey mark.

Page 3

Adhesion and Scratch Resistance Tester, Model 435 S

Purpose and Application

At first developed from the Mar Tester 435, Model

435 S has been adjusted, in cooperation with a well-

known manufacturer of – among others - scaled

indication fittings for vehicle cockpits, especially to

tests of this product group.

When used as an adhesion tester e.g. the coloured

coating applied to the dial of a speedometer in the

shape of raised numbers, points or scale lines, is

tested concerning its adhesion to the substrate, by

lateral slipping with a defined “blunt” test body

geometry, with a preselected test force.

In principle the Model 435 S is feasible for testing the

adhesion of almost all printed scales, numbers,

letters and marks “lying“ on the scale plates’ surface!

When used as a scratch resistance tester for

testing surfaces against “blunt” effects, it is

recommended for testing surfaces on which the

Hardness Test Rod 318 is still too “aggressive” –

even using the largest tip diameter of 1 mm available

for this purpose.

1. Rotating guide rolls

2. Test disc made of steel

3. Test force scale

4. Force springs

5. Allen key

6. Locking screw slider

7. Help aid for fixing the locking srew

slider

Design and Function

The main difference between the Mar Tester 435 and

the new Model 435 S is the direction in which the

test body is moved. While the test body of Model 435

(a disc with locking facility) is moved relatively fast in

longitudinal direction in order to produce a “scar”, the

test direction in which the test body of Model 435 S

is guided, is rotated by 90°.

The part of the test body relevant for the test,

corresponds in its shape exactly to that of Model 435

and is basically, for the time being, only available in

the version made of steel which is most useful within

the scope of products tested up to now.

As the diameter of the test head of Model 435 S is

considerably smaller compared with the steel disc of

Model 435, a central sector of the disc of Model 435

has been chosen as test body for reasons of space

saving. The test body is mounted on a bolt and is

preloaded by an internal helical spring to a force

adjustable from 0 to 20 N. When placing Model 435 S

with the two guide wheel perpendicularly onto the

surface, the rigidly arrested test body acts (with the

preset force) upon the surface. The test force can be

varied – as for Model 435 – by means of 3

exchangeable springs covering three different test

ranges.

Method of Operation

After checking the tight fixing of the test body at the

end of the load transmission bolt, the required force

is adjusted on the scale using the locking screw

slider. Then the Model 435 S is placed

perpendicularly onto the surface to be tested resp.

beside the applied raised coating to be tested, and is

pressed down so that the guide wheels touch the

surface. In this way the preset force acting upon the

test disc is fully effective on the test surface. The

instrument is now moved into the rolling direction the

wheels over the specimen to be tested e.g. against,

for example, scale lines.

The user selects the speed that is adequate for the

product to be tested. When testing e.g. raised

inscriptions, the test result is expressed by the test

force in Newton (N) at which the adhesion of the

coating failed.

For scratch resistance tests of surfaces against

“blunt” effects the test result is the maximum force in

Newton (N) at which the test body does not leave any

trace on the test surface.

Page 4

Order Information

Ord.-No. Product Description

0096.01.31

Mar Tester according to

Oesterle, Model 435

Including

♦ 3 test discs

(duroplast, copper, steel)

♦ 3 force springs

♦ 1 case

Spare Parts

Ord.-No. Product Description

0430.01.32 Duroplast test disc

(per 10 pcs.)

0430.02.32

Test disc made of copper

(per 10 pcs)

0430.03.32

Test disc made of steel

(per 10 pcs.)

Order Information

Ord.-No. Product Description

0268.01.31

Adhesion and Resistance

Tester, Model 435 S

Including:

♦ 1 test disc made of steel

♦ 3 force springs

♦ 1 case

Spare Part

Ord.-No. Product Description

0796.01.32 Test disc made of steel

The right of technical modifications is reserved.

Gr. 14 - TBE/BAE 435/-435 S - IV/2007

Loading...

Loading...