BA43E000

Operating Instructions

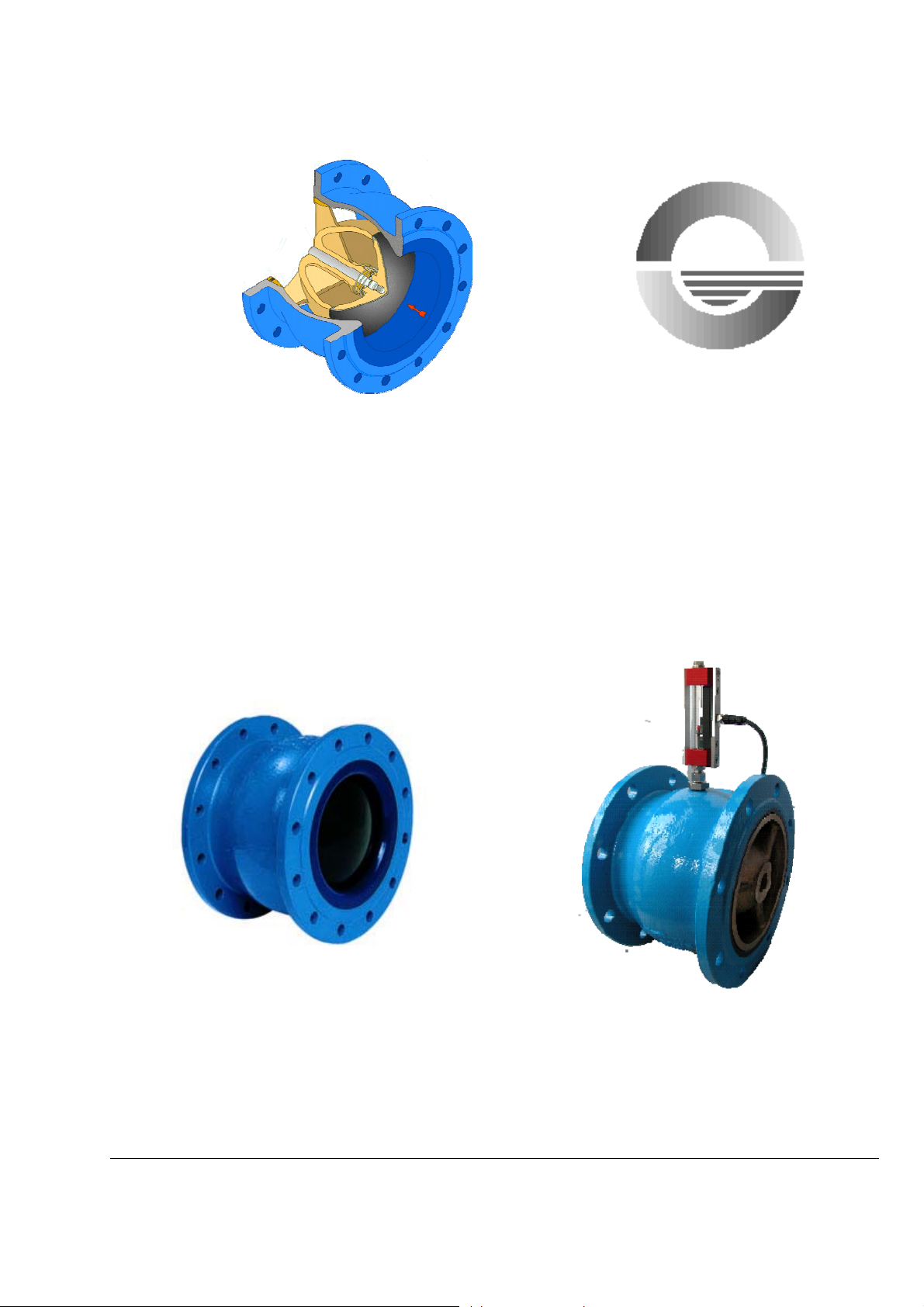

ERHARD NON SLAM

Nozzle Check Valve

ERHARD NON SLAM

Nozzle Check Valve

ERHARD NON SLAM

Nozzle Check Valve (option)

You are requested to follow operating

instructions BA43D001.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: http://www.erhard.de

(07321) 320 491 E-Mail: info@erhard.de

Page 1 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Index of contents

These operating instructions must always be used in combination with operating

instructions BA01E001!

1. Description of product and performance 3

1.1 ERHARD NON SLAM Nozzle Check Valves 5

DN 80 - 600, PN 10 – PN 40 prod. No. 435...00

1.2 Design Features – Technical Data 5

1.2.1 ERHARD NON SLAM Nozzle Check Valves

DN 80 – 300 1.2.2 5

1.2.2 ERHARD NON SLAM Nozzle Check Valves

DN 350 – 600 7

1.3 Performance and mode of operation 8

1.4 Application according to the rules 9

1.5 Transport and storage 9

1.5.1 Transport 9

1.5.2 Storage 10

1.6 Installation into the pipeline 10

2. Maintenance 14

2.1 Maintenance 15

2.2 Spare parts 15

2.3 Replacement of spare parts / necessary devices 16

2.4 Trouble during operation and remedies 18

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 2 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

1 Description of Product and Performance

ERHARD NON SLAM Nozzle Check Valves (EDRV)

DN 80 – 600, PN10 – PN40 Product No. 435...00

The ERHARD NON SLAM Nozzle Check Valve is a non-return valve of compact design

and short pattern, with central rubber-coated valve disc (DN 80-300) or valve ring (DN

350-600) which opens and closes in axial direction, the closing movement being springassisted.

Thanks to the materials and the sealing and corrosion protection systems, the

ERHARD NON SLAM Nozzle Check Valve is suitable for application in the water

industry (mechanically neutral water up to a max. temperature of 60° C) and for pretreated sewage.

In case of hot flow media, there is the risk of burns and the valve has to be heatinsulated by the user.

The normal range of flow velocity of the ERHARD NON SLAM Nozzle Check Valve is

0,5 – 5 m/s (referred to the nominal size DN). At a velocity of 2 m/s (referred to DN) the

ERHARD NON SLAM Nozzle Check Valve is used in a fully economical way. With

these velocities, all nominal sizes are in fully open position.

For opening the ERHARD NON SLAM Nozzle Check Valve , according to DN, 0,5 – 0,9

mWC (50 – 90 mbar) as minimum differential pressure is necessary. The valve opens at

this differential pressure and the medium begins to flow. For tight closure, a minimum

back pressure of approx. 4.0 mWC (400 mbar) is necessary for DN 80 – 300 and of

approx. 8 mWC (800 mbar) for DN 350 – 600.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 3 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

]

r

p

Pressures:

Nominal size

DN [bar] [bar] [bar]

PN PFA PMA PEA

Hydr. test pressure [bar

fo

body seat

80 - 300

10 10 12 17 15 10

350 - 600

80 - 300

24 1616 16 20 25

350 - 600

80 - 300 25 25 30 35 37,5 25

80 - 300 40 40 48 56 60 40

The ERHARD NON SLAM Nozzle Check Valves are tested at the manufacturers' works

for strength and tightness according to DIN EN 12266 / 1074.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 4 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

1.2 Design Features – Technical Data

1.2.1 ERHARD NON SLAM Nozzle Check Valve DN 80 – 300

Fig. 1.1

Dimensions of ERHARD NON SLAM Nozzle Check Valve DN 80 – 300:

PN10 PN16

DN

Døk d4b

80

200 160 132 200 160 132 200 160 19 132 200 160 19 132 3 180

100

220 180 156 220 180 156 235 190 23 156 235 190 23 156 3 190

125

250 210 184 250 210 184 270 220 184 23,5 270 220 184 23,5 3 200

150

285 240 211 285 240 211 300 250 211 26 300 250 211 26 3 210 -

200

340 295 266 20 340 295 266 20 360 310 274 22 375 320 31 284 30 3 230 -

250

400 350 319 22 400 355 319 22 425 370 330 24,5 450 385 345 34,5 3 250 -

300

455 400 370 24,5 455 410 370 24,5 485 430 16 389

d2 d2 d2 d2

d4 b D øk D øk D økd4 b

øz øz øz øz

19

23

12

8

19

19

819

23

12

28

PN25

28

31

12

PN40

19

8

28

515 450 16 409 39,5 4 270 20

27,5

34

*Attention: For nominal size DN 300 the guiding stem protrudes by 20 mm

when the valve disc is open!

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

d4 b L l*

19

8

12

Page 5 of 18

f

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Parts list for ERHARD NON SLAM Nozzle Check Valves DN 80 – 300

with standard materials

Description Qty. Notes

Item

Body 80-125

Body 150 - 300 EN-JS1030 EN-JS1025

2 Internal body 1 zinc-free bronze

3 Threaded pin 3 stainless steel

4Bush 2

5,8,9 Valve disc 1

6 Guiding stem 1 stainless steel

7 Pressure spring 1

Mate ri al / Sta nd ar d

PN 10/16 PN25/40

EN -JS1025

2.1050.01

A4

High-performance polymer

2.1050.01/NBR or

2.1050.01/EPDM

1.4057.05

1.4310

ductile cast iron11

vulcanized NBR or EPDM

rubber-coating

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 6 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

1.2.2 ERHARD NON SLAM Nozzle Check Valves DN 350 – 600

Fig. 1.2

Dimensions of ERHARD NON SLAM Nozzle Check Valve DN 350 – 600:

PN10 PN16

DN

Døk d4 b

505 460 23 429 26,5 520 470 28 429 26,5 290 8

350

565 515 480 28 580 525 31 480 28 310 10

400

670 620 582 31,5 715 650 34 609 31,5 350 15

500

780 725 31 682 30 840 770 37 720 36 5 390 9

600

d2 d2

øz øz

16

28

20

bDøk

d4 L l*

16

20

f

4

*Attention: DN 350 – 600: the guiding stems protrude over the face-to-face dimension when the valve ring

is open!

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 7 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Parts list for ERHARD NON SLAM Nozzle Check Valves DN 350 – 600

with standard materials

Item Description Qty. Material Notes

Body 350 - 400 EN-JS1030

Body 500 - 600 EN-JS1025

2 In ternal body 1 2.1050.01 zinc-fr ee bronze

3 Threaded pin 4 A4 stainless steel

4 Bush 8 High-performance polymer

5 Piston ring 1 1.4404/EPDM

6 Guide rod 4 1.4057.05 stainless s teel

7 Pressure spring 4 1.4310.07 s tainless steel

8 Threaded bush 4 A4 stainless steel

9 Washer 4 NBR or EPDM

10 Cover 1 2.1050.01 zinc-free bronze

ductile cast iron11

vulcanised EPDM rubbercoating

Corrosion protection for DN 80 – 600:

The body is internally vitreous-enamelled and externally EKB coated (synthetic epoxy

coating). All other parts are made of stainless materials.

Recesses are provided at the centering of the internal body in the main body so that the

transitions between the uncoated and coated surface can be filled with sealing agent.

This protects and seals these critical areas against the flow medium.

1.3 Performance and Mode of Operation

The ERHARD NON SLAM Nozzle Check Valve is a flow-controlled non-return valve

with centrally and axially moved obturator. This obturator with the shape of a valve disc

(DN 80 – 300) or a valve ring (for DN 350 and larger) is guided by means of one (four) a

guiding stem(s) in an internal body. The closing movement of the valve is springassisted (one or four springs).

The ERHARD NON SLAM Nozzle Check Valve is resilient-seated, with tight closure

according to DIN EN 12266 / 1074 – leakage rate 1 (0 drop per minute), at a minimum

back pressure of 4.0 mWC (400 mbar) and larger for DN 80 – 300 and a minimum back

pressure of 8.0 mWC (800 mbar) and larger for DN 350 – 600.

The valve starts opening at incipient velocity and is fully open at a velocity of approx. 2

m/s. The opening process can be influenced by a special spring which is designed for

special cases of application.

The standard design is suitable for installation in horizontal pipeline and for vertical

pipeline and for vertical upward flow. When the valve is installed in a vertical pipeline

with downward flow, the ERHARD NON SLAM Nozzle Check Valve has to be equipped

with a special spring. Moreover, a remachined internal body is used which is designed

with additional bores for drainage of the internal body (see fig. 1.1 and 1.2).

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 8 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

1.4 Application according to the rules

Thanks to their design, the ERHARD NON SLAM Nozzle Check Valves are applied

according to the General Instructions BA01E001 Section 1.1.

1.5 Transport and storage

1.5.1 Transport

It is not allowed to attach the lifting gears in the flange holes or to roll the valve on the

outside diameter of the flanges which would damage the corrosion protection.

Weights of the ERHARD NON SLAM Nozzle Check Valves:

DN 80 100 125 150 200 250 300 350 400 500 600

PN

10

16

25

40

The ERHARD NON SLAM Nozzle Check Valves DN 300 and smaller should be

transported by means of belts which are to be placed around the flange necks and to

be suspended at the lifting gear (see fig. 1.3).

The ERHARD NON SLAM Nozzle Check Valves DN 350 to 600 are provided with

threaded holes (M16) at the flanges. Thus, it is possible to transport the ERHARD

Check Valves by means of eyebolts.

----50,070,0100,0 130,0 160,0 260,0 420,0

14,0 19,0 27,0 32,5 50,0 70,0 100,0 135,0 16 5,0 275,0 480,0

14,0 19,0 27,0 40,0 56,5 81,5 113,0 - - - 14,0 19,0 27,0 40,0 67,5 101,0 145,5 - - - -

in kg

Weight approx.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 9 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Fig. 4.2: Installation in vertical

Fig. 1.3: Installation in horizontal pipeline

pipeline

(left hand: Check Valve DN 80 – 300, right

hand: Check Valve DN 350 – 600)

For installation into vertical pipeline insert two bolts of appropriate material and strength

into two opposite flange holes to which the belts are fixed at the flange back (see fig.

1.4). Please provide protective devices at the bolts (e.g. sleeves of plastic material ...)

for protecting the coating of the flange holes.

1.5.2 Storage

The ERHARD NON SLAM Nozzle Check Valves are to be secured by means of wedges

or belts (fig 1.5) against rolling off, or good stability has to be ensured by putting them

horizontally on the flange (fig. 1.6).

BA43E000

Juli 2009

Rev.9

Fig. 1.5 Fig.1.6

1.6 Installation into the Pipeline

Remove all packing material from the valve. Prior to installation, check the pipeline

for impurities and foreign bodies and clean it if necessary.

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 10 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Attention !

Follow direction of installation

according to the cast-on arrow!

The valve opens in case of flow from A to

B and closes in reverse direction from B to

A, thus preventing backflow!

Fig. 1.7

There must be free access all around the valve for operation and maintenance.

Prior to installation into the pipeline the function of the ERHARD NON SLAM Nozzle

Check Valve can be checked by pressing the obturator onto the stop of the internal

body. When releasing the obturator, the obturator must be pressed into the seat by the

spring, completely and automatically. (Check installation position accordingly.)

ERHARD NON SLAM Nozzle

Check Valve

Serial No.: 000000/00/00

Admiss.work.pressure PFA __bar

Flanges PN ??

Sealing material: NBR

Spring: standard

Position of installation: →↑

Fig. 5.2 Standard nameplate

During installation of the valve, the distance between the pipe flanges should exceed

the valve face-to-face dimension by at least 20 mm. Thus, the raised faces will not be

damaged and the gaskets can be inserted. Up to PN 16 textile reinforced rubber seals

are recommended for use as flange gaskets. Steel-reinforced rubber seals are

recommended for PN 25 and higher. For slip-on flanges, they are absolutely

necessary. (Consider resistance to flow medium and temperature.)

The mating pipe flanges must be plain-parallel and concentric.

Tighten the connecting bolts evenly (without distortion) and crosswise. The pipeline

mustn't by any means be pulled up to the valve.

Installation in horizontal and vertical pipeline is

possible. For installation in vertical pipeline with

upward flow a standard spring is used as for

installation in horizontal pipeline. The installation

position is marked on the nameplate (5.2). The

springs for the standard case (→ ↑) are marked

accordingly – like all the other springs.

A special spring is used for installation in vertical

pipeline with downward flow (↓). In this case, the

internal body has an additional bore.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 11 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Warning

Follow the applicable safety rules according to

VGB 9a and wear the

Warning

necessary personal protective equipment.

Risk of injury!

During transport or installation of the

ERHARD NON SLAM Nozzle Check

Valves, there may be the risk of

Attention! Risk of bruises!

Risk of penetration of flow medium!

Prior to putting into operation and after carrying out maintenance work, check

tightness of the flange connections and screwed connections if any or replace the

seals.

Attention: For DN 300 – 600, the guiding stems exceed the face-to-face

dimension of the valve in fully open position (see Tables

"Dimensions of ERHARD NON SLAM Nozzle Check Valves DN 80 -

300" and "Dimensions of ERHARD NON SLAM Nozzle Check Valves

350 – 600". Consider corresponding valves or fittings downstream of

the valve!

Installation directly upstream or downstream of bends, T-pieces or valves has

to be avoided.

bruising the fingers by uncontrolled

movement of the obturator.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 12 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Note concerning installation:

We recommend to design the non-return

valve in the nominal size DN of the

delivery side of the pump. (DN of pump =

DN of ERHARD NON SLAM Nozzle

Check Valve.)

Thus, there will be – referred to the

nominal size – a higher flow velocity and

thus an optimum operating performance

(opening degree, economic efficiency). If

the ERHARD NON SLAM Nozzle Check

Valve is mounted directly on the delivery

side of the pump, irregular flow and

vibrations of the ERHARD Check Valve

might have negative effects (releasing

screwed connections, damaging the

seals, spring breaking, and increased

wear and tear of the mobile valve and

bearing components).

Therefore we recommend a distance of

min. 5 – 7 x DN (especially for speedcontrolled pumps) or a minimum velocity

of 2 – 3 m/s for the ERHARD NON SLAM

Nozzle Check Valve in order to ensure

that the valve is fully open.

BA43E000

Juli 2009

Rev.9

Fig. 1.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 13 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

2 Maintenance

Control of the performance and tightness of the ERHARD NON SLAM Nozzle Check

Valve is to be done at regular intervals according to DVGW print W390. Inspection or

repair of the valve must not be carried out before the pipe section in which the valve is

installed has been isolated and made pressure-less.

Warning

In case of penetration of dangerous liquids, substances, gases, and

steams, immediately the plant has to be shut down, the responsible

supervisor must be informed and appropriate repair work has to be

Danger

The personal protective equipment according to the rules of the

employer's liability insurance association must be used. Depending

on the flow medium, there is the risk of poisoning, causticization,

scalding, and danger due to biological and microbiological

substances as well as the risk of fire and explosion!

WARNING

Before carrying out maintenance work on the

valve, any pressurised pipeline has to be

made pressure-less and to be secured

against re-starting!

After finishing the maintenance work, any

connection has to be checked for tightness

and close fit.

DANGER

carried out.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 14 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

2.1 Maintenance

ERHARD NON SLAM Nozzle Check Valves are maintenance-free.

Recommended intervals for inspection and maintenance:

Continuous 2 x per year Yearly

ERHARD NON SLAM Nozzle Check

Valve installed in plants

• performance test (Open – Closed)

• tightness test

• head loss measurement

♦

♦

♦

Other checks

• external leakage

• damages

• contamination / ease of operation

• noise

♦

♦

♦

♦

2.2 Spare parts

When spare parts are required, it is necessary to specifiy the serial number of the valve.

The serial number is specified on the name plate (fig. 1.8). All data required for

selecting the appropriate spare parts are assigned to the serial number.

For 2 and 5 years‘operation wearing parts are not necessary.

The following spare parts for the ERHARD NON SLAM Nozzle Check Valve are defined

as wearing parts:

ERHARD NON SLAM Nozzle Check Valves DN 80 – 300:

1. Completely mounted unit (if necessary):

rubber-coated valve disc (1) with

guiding stem (2) and washer (5).

2. Spring (3)

(if necessary)

3. Bush (4) 2 pieces

Fig. 2.1

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 15 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

ERHARD NON SLAM Nozzle Check Valves DN 350 - 600:

1. Completely mounted unit (if

necessary): rubber-coated valve

ring (1) with 4 guiding stems (2) and

washers (5).

2. Springs (3)

(if necessary) 4 pieces

4. Bushes (4) 4 or 8 pieces

Fig. 2.2

2.3 Replacement of the spare parts / necessary tools

For replacing above mentioned wearing parts, the ERHARD NON SLAM Nozzle Check

Valve has to be removed from the pipeline after having depressurized the pipeline. The

internal body (2) is secured in the body (3) in the following manner:

- for sizes DN 80 to 300 with 3 threaded pins M6 with internal hexagon 3 mm (1),

- for sizes DN 350 to 500 with 4 threaded pins M6 with internal hexagon 3 mm (1) and

- for size DN 600 with 4 threaded pins M8 with internal hexagon 4 mm.

These pins must be screwed off.

DN 80 – 300:

For removing the internal body (2) from

the body (3), a force of approx. 20 kN

is required. This force can be applied

by means of a press, an auxiliary

mounting tool or similar device as

shown in fig. 2.3.1.

The tool is centrally placed on the

pushed back valve disc, both bolts are

tightened in two opposite flange holes

with washers and nuts, parallel to the

raised face. The internal body is

pressed out of the main body by means

of the central bolt (4). When pressing

the internal body out of its position, it

should be held in order to avoid

damage to the coating.

BA43E000

Juli 2009

Rev.9

Fig. 2.3.1

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 16 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

DN 350 – 600:

For removing the internal body (2) from

the body (3), a force of approx. 40 kN

is required. This force can be applied

by means of a press, an auxiliary

mounting tool or similar device as

shown in fig. 2.3.2.

The tool is centrally placed on the

pushed back valve ring so that the

bolts (4) required for expulsion are

centrally arranged on the width of the

valve ring. The two fastening bolts are

tightened in two opposite flange holes

with washers and nuts, parallel to the

raised face.

The internal body is pressed out of the

main body, screwing-in the bolts (4) in a

slow and uniform manner. When

screwing-in, the corresponding nuts

have

to be secured against following the

bolts. When pressing the internal

body out of its position, it should be

held

in order to avoid damage to the coating.

Fig. 2.3.2

Assembly DN 80 – 600:

During assembly, internal body, valve disc (ring), spring(s), and guiding stem(s) are

pushed into the internal body. The valve disc (ring) can be fixed in its rear limit position

by means of bolt(s) including washer(s) (5), screwed into the guiding stem(s). The fitting

surface (fig. 2.4) of the internal body, has to be cleaned. The body’s fitting surface which

must also be cleaned has to be covered with sealing agent BA51 on the two transitions

to vitreous enamel as well as in the groove in which the threaded pins are engaged.

After having pushed the internal body into the main body, the threaded pins have to be

secured with BA5, too, and screwed into the groove. The internal hexagon of the

threaded pins is filled with BA5 in order to ensure further screwing off. Excessive

sealing agent must be removed from both transitions and be smoothed. For mounting

the internal body in the main body, see also fig. 2.4.

1

Sealing agent BA5 Loctite Deutschland GmbH Type: screw locking, medium strength

Art.-No. 24374

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 17 of 18

Operating Instructions for ERHARD NON SLAM Nozzle Check Valve

p

Fig. 2.4:

Curing of the sealing agent takes about 5 hours.

2.4 Troubles during operation of the ERHARD NON SLAM Nozzle Check Valve

and remedies

Trouble Possible Causes Remedy

Leakage in the seat

High head loss

Valve blocked

Increased noise

(closing shocks)

Valves installed in a

wrong way,

contrary to the specified

direction of installation

Deposits or dirt in the seating zone In case of firm incrustations, clean

seating zone and valve disc/ring

Damage to the coating of the valve

disc/ring

Clogging and seizing of the spring Clean spring, in case of very dirty

Deposits on guiding stem Open valve manually several times

Foreign bodies between valve

disc/ring and internal body

Foreign bodies jammed in the

seating zone at v (referred to DN)

<2 m/s

Foreign bodies jammed in the

seating zone at v (referred to DN)

>2 m/s

Return spring broken

Deposits in the guiding device due

to low flow velocity

Pump discharges against closed

valve.

The direction arrow has not been

followed during installation.

Replace valve disc/ring, see

paragraph 2.3

medium: provide spring protecting

device, for dismantling see

paragraph 2.3

until valve can be operated easily

again or dismantle according to

paragraph 2.3 and clean guiding

stem and bore

Manually remove foreign body,

dismantling acc. to 2.3

Increase flow velocity and flush out

foreign bodies

Manually remove foreign bodies

Replacement of spring, see

paragraph 2.3

Cleaning of the bore.

For dismantling, see paragraph

2.3.

Removal of the valve from the

pipeline

Installation into the pipeline, see

1.6.

BA43E000

Juli 2009

Rev.9

ERHARD GmbH & Co. KG x D-89502 Heidenheim x Postfach 1280

Telefon: (07321) 320-0

Internet: htt

(07321) 320 491 E-Mail: info@erhard.de

://www.erhard.de

Page 18 of 18

Loading...

Loading...