ERGOMART LEVERLIFT Instruction Manual

LEVERLIFT

READ BEFORE INSTALLATION - SAFETY INFORMATION

INSTRUCTIONS MANUAL

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

WARNING – READ FIRST

• Carefully read and understand warnings and instructions before assembly and/or

installation.

• Check all local codes and ordinances regarding mounting locations and fastening

methods.

• Local codes may supersede Ergomart instructions.

• Always retain warning statements and instructions for future reference.

• Ensure all product users read and understand the User Safety Precautions and the

instructions for safe and proper usage.

• Contact Ergomart service at 888 420 3200 with any questions prior to installation.

• Installation of this product requires basic mechanical skills and aptitudes and should

never be undertaken by someone uncertain about the terms and procedures described

in the accompanying instructions for safe use and installation.

• Use only correct tools and serviceable equipment to ensure personal safety and to

prevent damage to components, fasteners and product.

• Determine the load capacity of the wall, ceiling, member, surface or structure you intend

to use before installation. Consult a professional installer, Ergomart technical support

or an engineer if the material to which you plan to attach is not specifically described

in the installation manual.

• Never alter products or assemble in a fashion not described within the instructions

without consulting an installation professional, engineer or Ergomart technical support

at 888 420 3200.

• Never exceed the Maximum Load for any device or component. If you are unsure about

any weight rating on any given component within a modular system provided by Ergomart,

contact Ergomart service at 888 420 3200.

• Never introduce or add additional components into an existing modular system without

consulting Ergomart technical support at 888 420 3200.

• Never attempt to open, service or disassemble any Ergomart component where no

written Ergomart instructions are available for disassembly and repair.

• Never use harsh chemicals or abrasives to clean Ergomart products. Use mild, dilute

cleaners and test before widespread use on an inconspicuous location or surface.

• Use best practices before and during installation:

o Always use the correct tool for the specified procedure or job.

o Always use assistance and lifting devices wherever indicated within the

instructions.

o Avoid shortcuts and always measure twice before drilling, cutting or changing

things that cannot be altered.

o When penetrating walls or surfaces, determine that no wiring, gas, ductwork or

plumbing exist beneath the surface.

o Consult an installation professional, facility manager or engineer before starting

an installation project involving materials with properties that are not evident

from experience or described as acceptable medium for attachment within the

Ergomart documentation.

1

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

DISCLAIMER

Ergotect Corporation and its subsidiaries and brands, hereafter referred to as (EC), strive

to create broadly comprehensible, complete and accurate information regarding our product installation documentation. Ongoing changes in suppliers, materials, designs, components, product upgrades, and other variables inhibit our ability to guarantee document

accuracy. Furthermore, EC reserves the right to make changes and updates to product

documentation and/or product design without notifying existing and new users. EC therefore does not guarantee completeness, accuracy or suitability of documentation and will

not be held liable due to incomplete documentation, editorial errors, improper translation

from English, or the comprehensibility of language or images or the ability of a user to

understand any particular written instructions or interpret images contained herein and

below.

EC disclaims any liability for damage to EC provided product, customer or user owned

devices and equipment affixed to, used on or in conjunction with EC provided product,

other property, or personal injury resulting, in whole or in part, from improper installation,

modification, use or misuse of its products. EC disclaims all other warranties, express or

implied, including warranties of merchantability and fitness for a particular purpose. EC

is not responsible for incidental, special or consequential damages, including but not limited to, inability to use EC products or costs incidental to the installation or removal of

defective or serviceable EC products or components.

2

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

LEVERLIFT USER SAFETY PRECAUTIONS

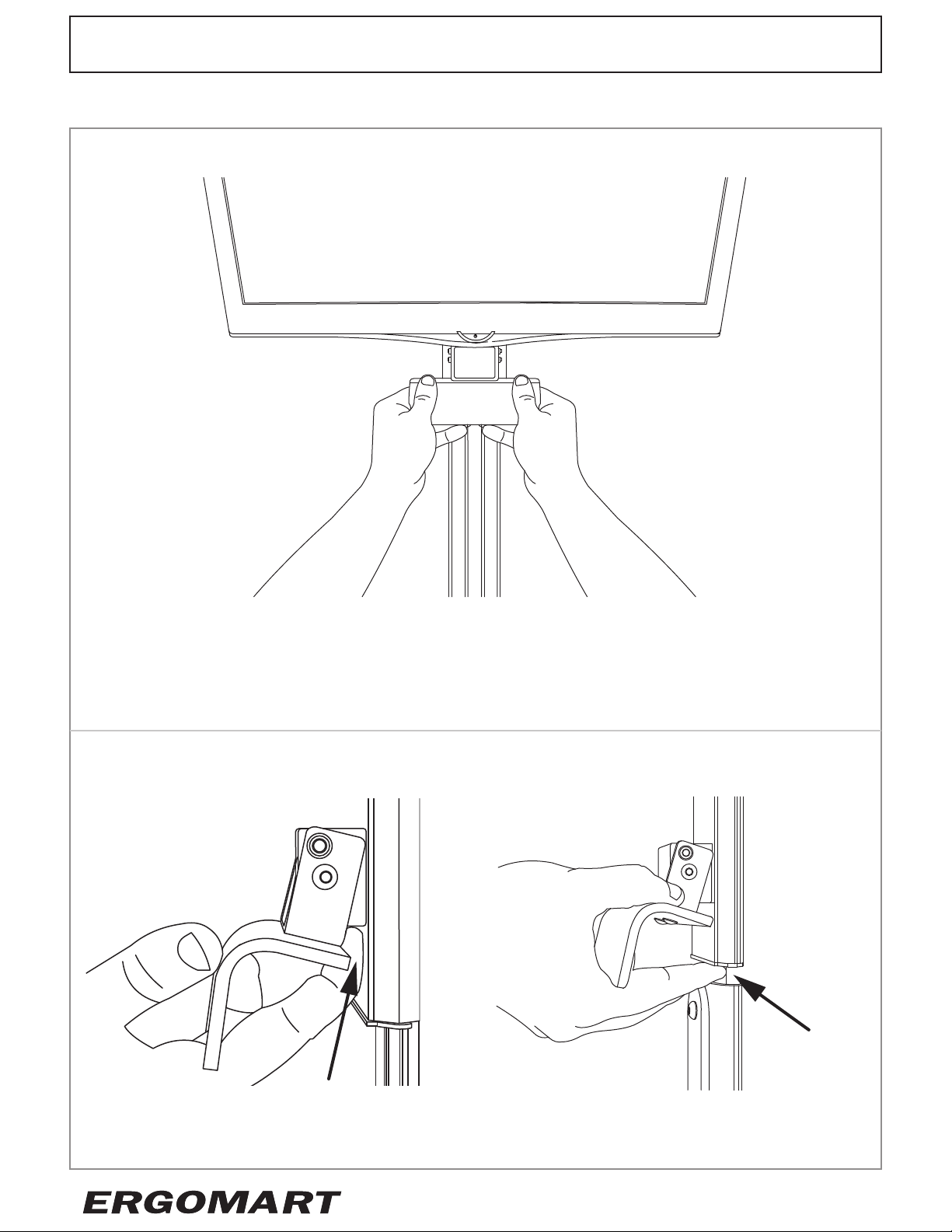

OPERATE LEVER WITH BOTH HANDS

To raise or lower a LeverLift, grasp with both hands as illustrated and pull up slightly to

release the brake. Once disengaged, the device may be lifted up to raise the height or

allowed to slide down to a lower position. Once the desired height is achieved, release the

handle. Returning the handle to the rested position causes the LeverLift mechanism to

brake immediately and securely.

AVOID PINCH POINTS

PINCH POINT

PINCH POINT

Always use two hands to raise and lower the LeverLift to avoid pinch points.

3

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

LEVERLIFT USER SAFETY PRECAUTIONS (Continued)

• Do not remove safety and warning labels and stickers from the LeverLift System.

• Always use two hands when lifting or lowering monitors, touch screens or any heavy

component.

• The LeverLift is suitable for use by individuals who have a full range of motion and use

of both hands and both arms and are able to lift 20 lb above the head using both hands

simultaneously. Not all individuals will be able to move components vertically and may

require assistance.

• Maximum payload per LeverLift is 12 lb (5.4 kg).

• All users must receive instruction on the safe and correct, two handed

method of lifting and lowering loaded LeverLift mechanism.

• This product is intended for users age 18 and above.

• This product is intended for indoor use.

• Keep fingers and hands away from pinch points.

ATTENTION:

MAKE OPERATING INSTRUCTIONS AVAILABLE TO ALL LEVERLIFT OPERATORS.

4

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

M-TRACK INSTALLATION AND INSTALLER SAFETY OVERVIEW

• Pre-Installation Preparation:

o Clear installation space of clutter and items that could create a hazardous work area.

o Remove end stops and any other components that are attached to the track.

o Determine the optimal vertical position of the rail and the correct fastener components

for the surface using the tables in Appendix A. Select the appropriate table for

your application.

o It is critical that the dimensions of all LeverLift components and devices be known

and taken into consideration before installation to eliminate interference.

o When mounting any type of wall track to a wall it is always best practice to affix it

into a wood stud or backer. The LeverLift System and M-Track, however, is designed

to work where an immovable support structure is unavailable.

o C

walkways, furniture, fixtures, and electrical panels are some of many potential

obstructions and hazards.

o Make note of wire management needs such as locations of networking ports and

outlets so that device wiring does not cause interference.

heck for operational clearance for all components and users. Doors, adjacent walls,

• Unbacked Sheetrock:

o Sheetrock must be 1/2” or thicker and must be serviceable. The age, condition, and

capacity of the sheetrock must be considered. Inspect fasteners for secureness and

o Snaptoggle® BA-10-24 will be used with 3/16”-24 machine screw fasteners.

o Ensure that sheetrock is correctly attached to the framing/structure with sufficient

fasteners connected at properly spaced intervals.

o Ensure that sheetrock is not warped or bent as it may cause bowing or bending of

the Leverlift track leading to difficult slider use. For minor deviations of flatness

of less than .25” use shims available from Ergomart.

• Sheetrock backed with a thin gage metal stud:

o Sheetrock must be at least 1/2” and serviceable. The age, condition, and capacity

of the sheetrock must be considered. Inspect fasteners for secureness and sheet rock for integrity initially and on a periodic basis once the track has been installed.

o Snaptoggle® brand BA-10-24 will be used with 3/16”-24 machine screw fasteners.

o Ensure that sheetrock is not warped or bent as it may cause bowing or bending of

the Leverlift track leading to difficult slider use. For minor deviations of flatness

of less than .25” use shims available from Ergomart.

sheetrock for integrity initially and on a periodic basis once the track has been

installed.

• Sheetrock that is directly backed with a wood stud:

o Stud must be in good condition.

o Pre-drill fastener locations with 3/32” pilot holes to prevent splitting the stud.

o Ensure that sheetrock is not warped or bent as it may cause bowing or bending of

the Leverlift track leading to difficult slider use. For minor deviations of flatness

of less than .25” use shims available from Ergomart.

5

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

M-TRACK INSTALLATION AND INSTALLER SAFETY OVERVIEW (Continued)

• The LeverLift track may be affixed to a variety of additional surfaces including CMU,

metal, masonry bricks, and concrete as well as many piers and poles. Work

with an installation professional or other qualified person to determine the best

attachment method for your specific application.

• Other materials and substrates require specific solutions. Due to the abundance of wall

materials and building methods, Ergomart can only specifically recommend attachment

methods for the above described conditions. In all other instances, determine the correct

fastener for the job and if you are unsure, consult with a professional installer, home

improvement store specialist or engineer. Prior to installation, ensure the surface,

material, structure or member you wish to use for fixing will support the entire payload.

ADDRESSING WALL FLATNESS ISSUES WITH SHIMS

Suitable wall mount locations must be generally flat and uniform surfaces.

Irregularities will hinder the correct installation of the M-Track and result in

difficult operation of LeverLift Sliders. Conditions with irregularities that may or

may not be correctable with shims:

o Wall joints that do not abut flatly and cleanly

o Surfaces that are bowed or warped

o Surfaces that have bulges or crowns

o Sheet rock improperly installed or not attached to stud

o Wall materials or surfaces that are not rigid

• The Leverlift is designed for use with surfaces that are flat over the length of the

mounting area beneath the track. Before purchasing the Leverlift system utilize a straight

edge that spans the intended mounting location. Surfaces with minor depressions or

bumps will require shims. Surfaces with bulges or crowns that are greater than .25” are

not suitable for the LeverLift System. Surfaces with valleys or depressions greater than

.25” are also not suitable for the Leverlift system. Experienced Installers may use various

techniques to correct an irregular surface.

• If you are currently installing your M-Track and have discovered you require shims,

you may fashion shims using poster board and sizing them into 2” x 3.5” pieces and then

stacking them into the appropriate thickness.

LEVERLIFT COMPONENT INSTALLATION SEQUENCE

When installing your M-Track and LeverLift, always ensure the M-Track is properly and

securely attached to the wall before installing any LeverLift or other components. Install

components from the bottom of the track, starting with the item that will ultimately rest

at the top of the track. Ensure sliders with set screws are tightly secured before installing

devices. Begin installing devices with thin clients/CPUs first where applicable, followed by

monitors, wire managers, keyboards, mice, and any other peripherals. Finish your installation by inspecting your components/devices for possible errors during installation. If no

error is found, reattach M-Track end caps.

6

©2016 All rights reserved.

LEVERLIFT

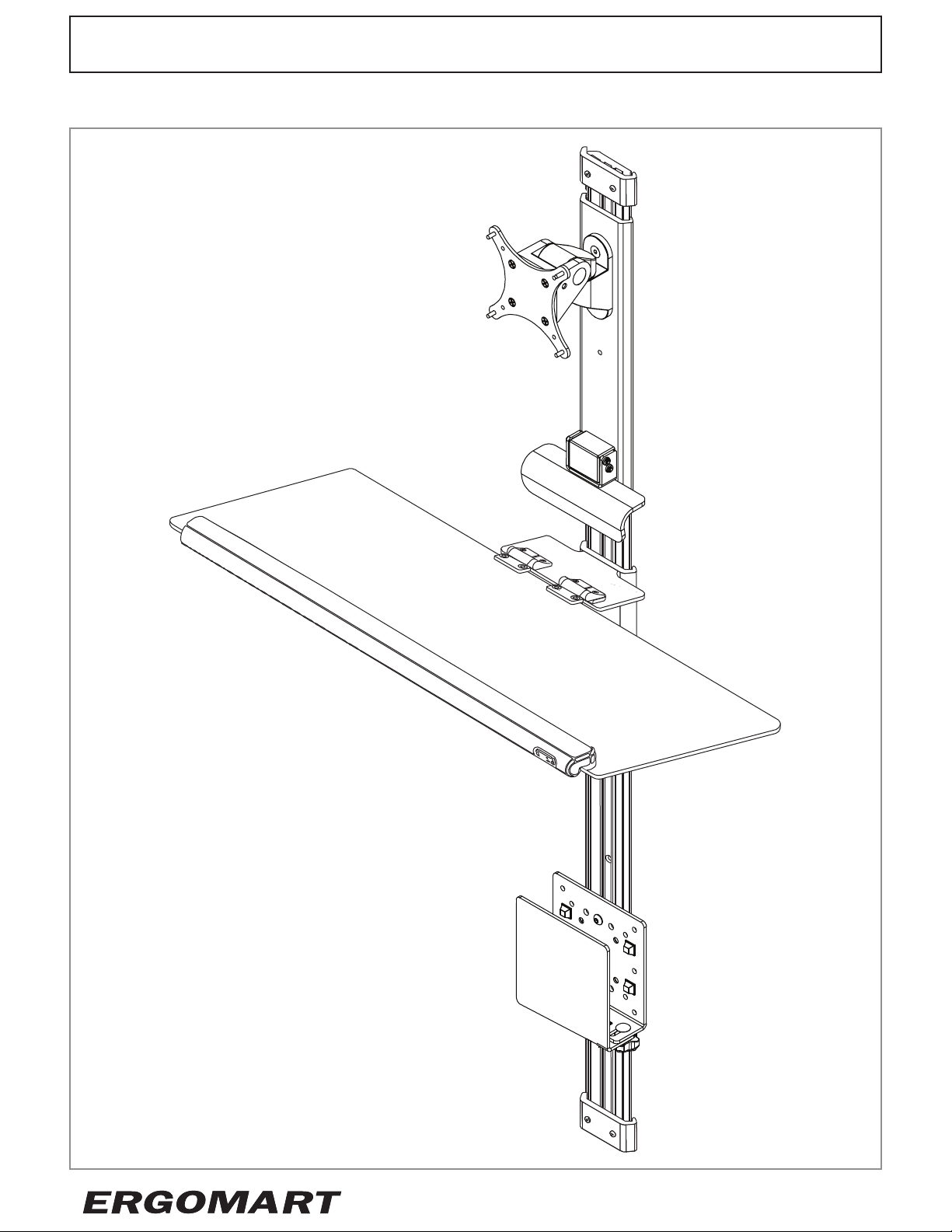

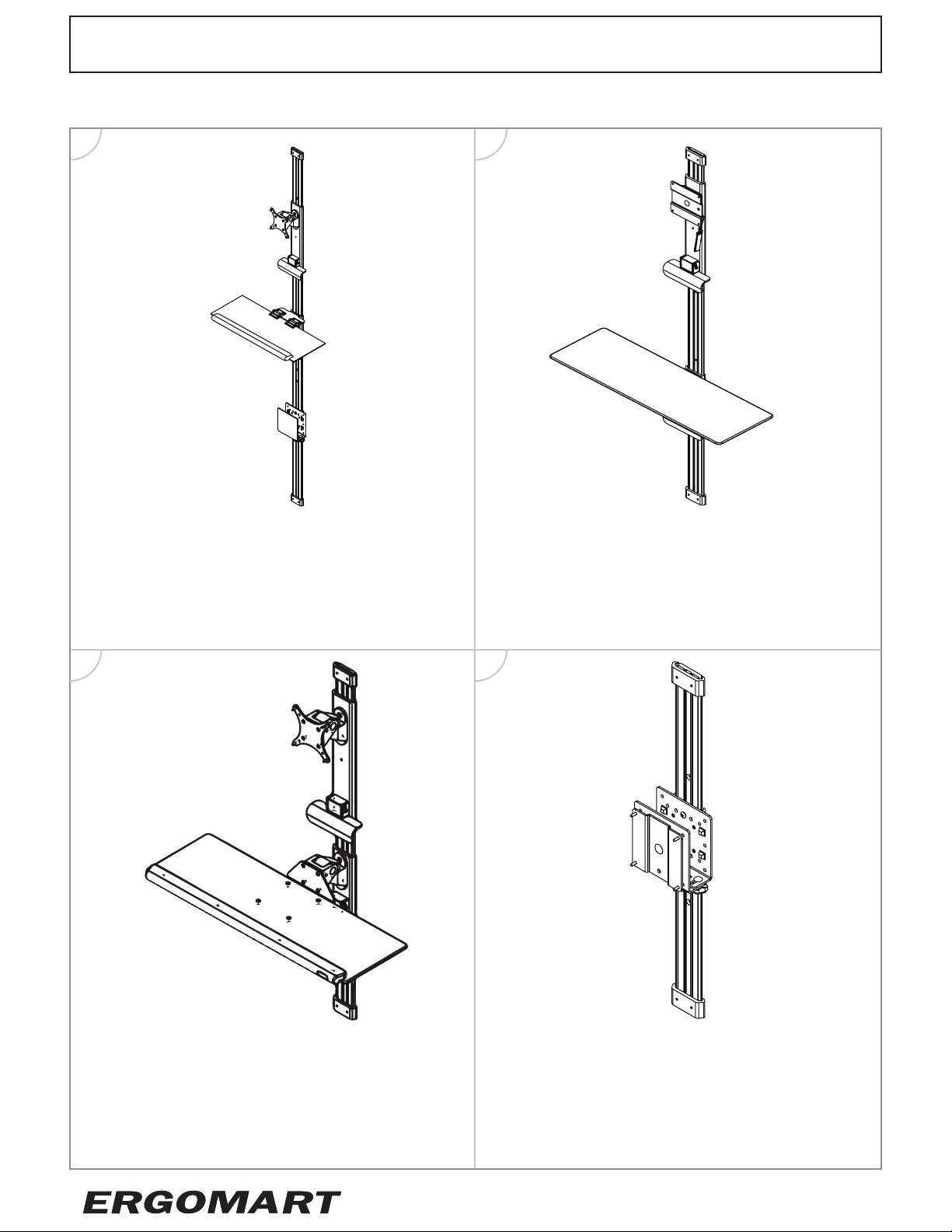

SAMPLE CONFIGURATIONS

1 2

INSTRUCTIONS MANUAL

75/100mm VESA with Articulating Mount

on 14” low profile LeverLift and 26” Folding

Keyboard LeverLift with a Thin Client Bracket

on 77” M-Track.

3 4

26” Fixed Tray LeverLift and 14” Low Profile

VESA 100 LeverLift on 51” M-Track.

75/100mm VESA with Articulating Mount on

14” low profile LeverLift and an Articulating

20” Keyboard Tray LeverLift on 39” M-Track.

Rotating 100mm VESA Slider Plate mounted

in front of a Thin Client Bracket on 27” MTrack.

7

©2016 All rights reserved.

LEVERLIFT

ASSEMBLY INSTRUCTIONS:

SECTION 1 | TRACK INSTALLATION: RIGIDLY BACKED/HOMOGENEOUS SURFACES

SECTION 2 | TRACK INSTALLATION: SHEETROCK AND/OR METAL STUD

SECTION 3 | LEVERLIFT COMPONENT INSTALLATION

SECTION 4 | LOW PROFILE QUICK RELEASE INSTALLATION

SECTION 5 | ARTICULATING MOUNT INSTALLATION

SECTION 6 | PLAIN THIN CLIENT HOLDER INSTALLATION

SECTION 7 | THIN CLIENT HOLDER WITH VESA PLATE INSTALLATION

INSTRUCTIONS MANUAL

SECTION 8 | FIXED KEYBOARD TRAY INSTALLATION

SECTION 9 | FIXED SHELF INSTALLATION

SECTION 10 | FOLDING KEYBOARD TRAY INSTALLATION

SECTION 11 | WIRE MANAGER INSTALLATION

TOOL KIT

These items will typically be needed for correct installation:

• Pencil

• Level

• Cordless power drill with appropriate driver bits (Phillips, square, etc.)

• Drill bit set

• Mallet (soft)

• Tape measure

• Ladder or stepstool

• Adequate lighting

• Safety goggles

• Stud finder

• Appropriate Fasteners (Snap toggles, #10 wood screws, etc.)

• Assistant

8

©2016 All rights reserved.

LEVERLIFT

INSTRUCTIONS MANUAL

SECTION 1 | M-TRACK INSTALLATION: RIGIDLY BACKED/HOMOGENEOUS SURFACES

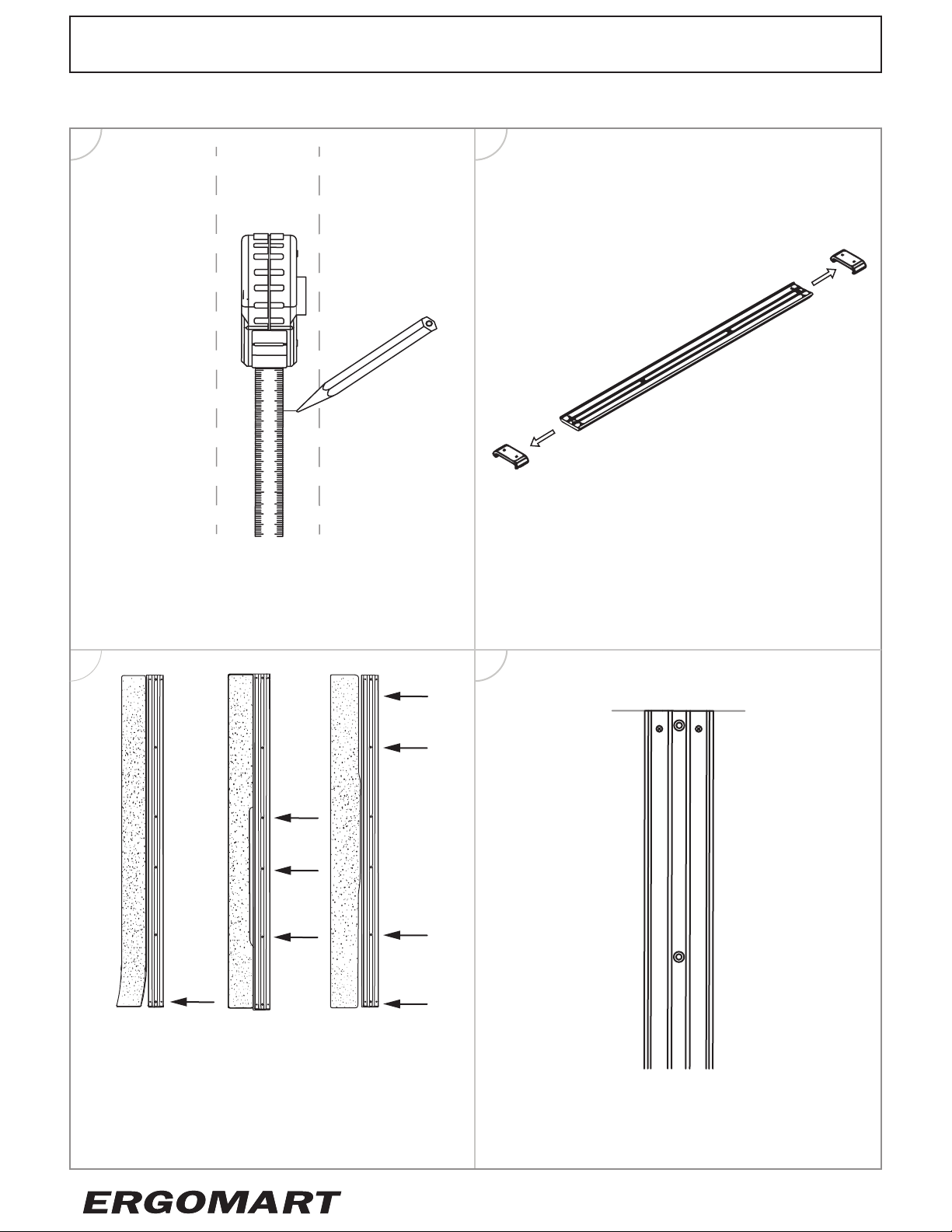

1.1 1.2

Determine location and height of track in

front of stud. Consult tables on page 28 for

vertical placement and mark the location of

the top of the track.

1.3 1.4

Remove end stops by loosening set screws

and sliding them off the track.

WARNING: Inspect location for flatness. If

a credit card easily slides beneath any point

under the edge of the track proceed to

Appendix B on page 29, do not proceed

onward to 1.4.

Align the top of the track with the location

marking from Step 1.

9

©2016 All rights reserved.

Loading...

Loading...