Stellar/160

Stand-aid lifter

User instruction

Important information

This user instruction must be read

before the mobile lifter is used.

This user instruction is intended

for technicians, installers,

therapists and other personnel, in

connection with the use, servicing

and maintenance of the Stand-aid

lifter.

Date: 01.10.2013 - Version 02

!

Scan the QR-code for further information

2

3

Contents

1. Aim and use

1.1 Purpose 4

1.2 Safety instructions 4

1.3 Daily check 5

1.4 Terminology 5

1.5 Unpacking 6

1.6 Assembling instruction 6

1.7 Mounting of lifting slings 8

2. Functions

2.1 Pictograms and functions – control box 9

2.2 Pictograms and functions – hand control 10

2.3 Safety functions 11

2.4 Charging 12

2.5 Transport 12

3. Use

3.1 Adjusting the knee support 13

3.2 Using the lifting slings 13

3.3 Using the control box 15

4. Maintenance

4.1 Cleaning 16

4.2 Storage 16

4.3 Special environments 16

5. Check and trouble shooting

5.1 Annual check 16

5.2 Trouble shooting 17

6. Technical data and dimensions

6.1 Technical specifications 18

6.2 Dimensions 19

7. Environment and quality

7.1 Disposal 20

7.2 Battery 20

7.3 Quality 20

7.4 Symbols and abbreviations 21

8. Accessories 22

4

1. Aim and use

1.1 Purpose

Stellar/160 is a mobile stand-aid lifter designed to transfer persons in institutions such as

nursing homes, hospitals, care centres and in home care. Stellar can be used for transfer

between bed and chair/wheelchair, from chair to another chair and from wheelchair to a

toilet/commode.

Stellar is approved to transfer with a maximum load on 160 kg.

Before using the Stellar please follow these instructions:

Personnel have received qualified instruction by Ergolet in using the stand-aid lifter.

The stand-aid lifter has been assembled correctly and according to this user instruction.

NEVER use the stand-aid lifter for other purposes than described in this user instruction.

Ensure the user cannot be squeezed or restricted in the lifting situation.

The stand-aid lifter has been developed for use with Ergolet lifting slings and other sling

products authorized by Ergolet. See Ergolet’s user instruction for slings for specific

information about which models that can be used.

The stand-aid lifter is intended for indoor use under normal temperatures (+2 – +40 C°)

and relative humidity (40-90%).

1.2 Safety instructions

This user instruction must be read thoroughly before the stand-aid lifter is taken into use.

All parts must be mounted correctly according to this user instruction.

There must be no indication of wear and tear on the stand-aid lifter or the lifting sling.

NEVER begin lifting if there is suspicion of any defect (abnormal sound, loose brackets

etc.). In such cases it is important to find the cause and to take the stand-aid lifter out of

service and your dealer or Ergolet contacted.

The lifting capacity must never be exceeded. When using the stand-aid lifter in

connection with other components e.g. slings it is always the component with the

LOWEST weight capacity that decides the maximum lifting capacity.

Ensure that neither carers/helpers nor patients/users can be hurt during the lifting.

Using the lifter may not run on uneven surfaces or threshold.

Never lift higher than necessary in the actual lifting situation.

See section 5.1 (annual check) for further information.

!

Important – Warning!

5

1.3 Daily check

The carer/helper is responsible for ensuring that a daily check is carried out BEFORE the

stand-aid lifter and accessories are used, including the following:

1) Check that the stand-aid lifter is complete and no parts are missing.

2) Check that there are no signs of rust, wear and tear or other defects. If there is any sign

of a defect the stand-aid lifter must be taken out of service.

3) If any abnormal sound is heard from the stand-aid lifter, the lifter must not be used

before personnel authorised by Ergolet have carried out a safety check on the unit.

4) Check the lifting slings for any damages especially as regards to the lifting straps for

tears in the material. The slings must not be used if defects are detected.

5) If in any doubt concerning the use of stand-aid lifter or lifting slings, contact Ergolet for

advice and guidance.

1.4 Terminology

Fig. 1.4

Hand control

Actuator (lifting motor)

Mast

Handles

Lifting arms

Leg / electrical leg spreading

Control box, emergency stop

and battery

Knee support

6

1.5 Unpacking

Check that all the parts are present and undamaged. Any suspicion of damage or shortage

should be reported to your dealer or Ergolet. We recommend that the box packaging is kept if

the stand-aid lifter is to be used on other sites or for return shipment in case of repair or annual

check.

Content of the box:

1. Leg with base for leg spreading

2. Mast and lifting arm

3. Actuator

4. Hand control with battery

5. Control box

6. Handles

7. Knee support

8. Tools (Allen key, spanner)

9. User instruction

1.6 Assembling instruction

Following step by step the assembly guidance:

1. Place the leg part on the floor and brake the

wheels. Fig. 1.6A

2. Assembly the mast/lifting arm with the leg part

and tighten the hand screw. (Fig 1.6B + 1.6C)

Fig. 1.6C

Fig. 1.6B

Fig. 1.6A

7

Fig. 1.6F

3. Mount the foot plate into the corresponding

holes on the leg base.(Fig. 1.6D)

4. Fit the actuator piston rod to the lifting arm.

Use the Allen key and the spanner to tighten

the bolt/nut. (Fig. 1.6E). Put the cap on the

nut.

5. Fit the handle on the mast with a screw and

tighten with the Allen key. (Fig 1.6F)

6. The hand control, lifting arm and electrical leg

spreader are connected to the control box.

(Fig 1.6G)

(See section 2.1 – functions / connection).

Fig. 1.6D

Fig. 1.6G

Fig. 1.6E

(a)

8

( 1 )

Fig. 1.7A

1.7 Mounting of lifting slings

The stand-aid lifter is equipped with lifting arms where there in the end is a hook, which is

designed for use with Ergolet lifting slings. Ergolets lifting slings have 4-6 lifting straps and are

designed for lifting hooks larger than ø8mm.

If using non-authorized slings Ergolet will have no responsibility for faults and accidents.

Ergolet can assist in choosing slings and their correct use.

Fitting slings on the Ergolet lifting hook

Ergolet accepts no responsibility if slings are placed incorrectly, it is always the onus of the

carer/helper to ensure that the sling is correct for the situation needs and is correctly fitted.

(1) The sling strap is placed over the hook in its open position.

(Fig. 1.7A)

(2) The strap is pulled downwards so that the hook closes.

(Fig. 1.7B)

The design of the lifting hook is such that the weight of the

patient/user will help close the hook.

To release the strap after lifting simply pull upwards to open

the hook.

Note: Risk of finger entrapment - ensure that patients’ fingers cannot get trapped.

(2)

Fig. 1.7B

9

2. Functions

2.1 Pictograms and functions – control-box

(1) Connecting plug - hand control

(2) Connecting plug - lifting actuator

(3) Connecting plug - electrical leg spreading

(4) Connecting plug - power supply

(5) Battery

(6) Emergency stop – See section 2.3

(7) Lift up/down – Press and the lifting arm

is lifted up. Press and the lifting arm is

lowered. Stop movement by releasing the

button.

(8) Leg spreading in/out – Press and the

leg spreading move together. Press and the

leg spreading will spread. Stop movement by

releasing the button.

(9) Charge – indicates charging on the battery

(see section 2.4).

(10) ON – indicates that main supply is on.

(11) Display – (See section 3.3)

(5)

(6)

(7)

(8)

(9)

(10)

(1)

(2)

(3)

(4)

(11)

10

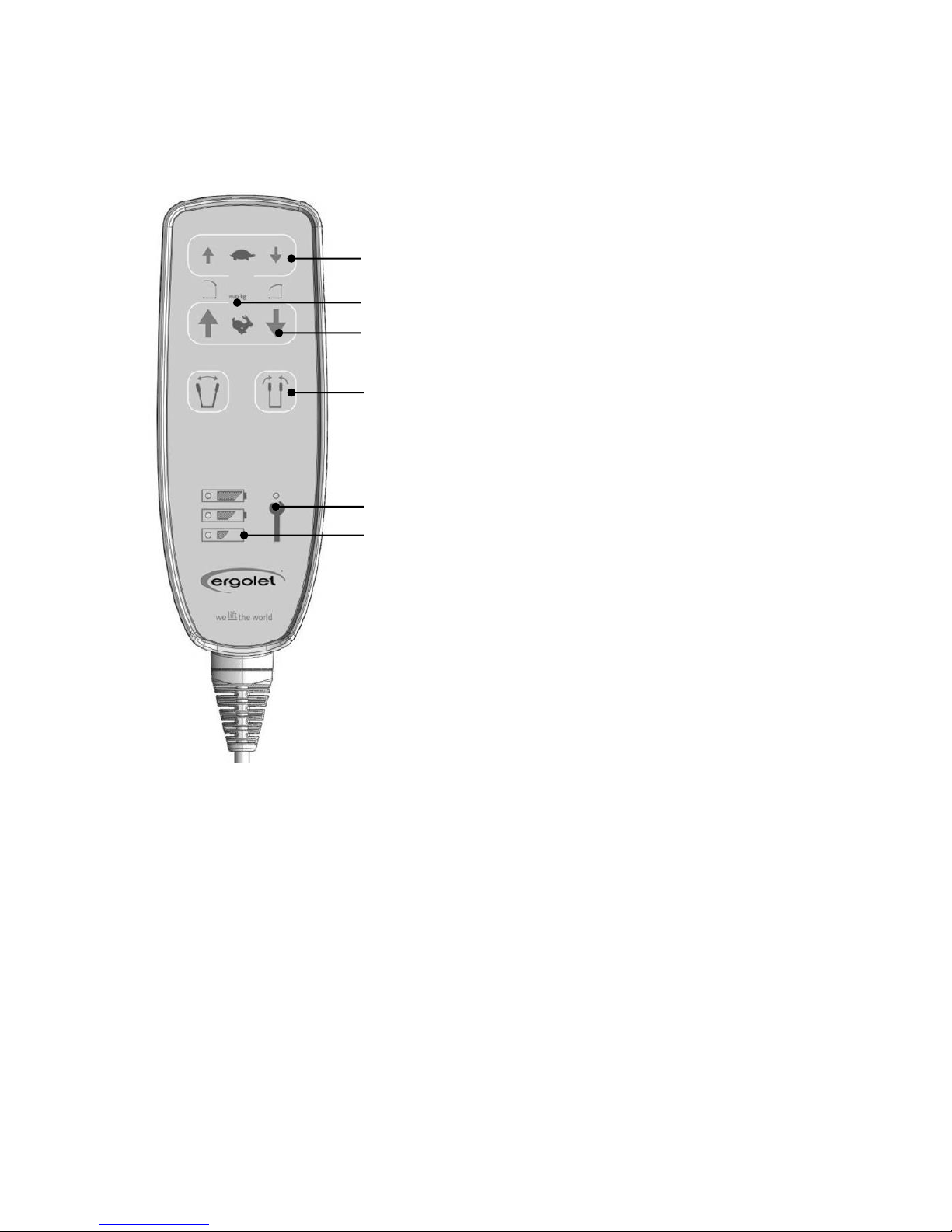

2.2 Pictograms and functions – hand control

(1) Turtle – This function operates the lifting arm

up/down in a low speed.

(2) Max Kg – indicates an overload (see section

3.3)

(3) Hare – This function operates the lifting arm

up/down in a high speed.

(4) Leg spreading – Press and the leg

spreading move together. Press and the leg

spreading will spread.

(5) Service – See section 3.3

(6) Battery – indicates the state of the battery

(see section 2.4)

(1)

(2)

(3)

(4)

(5)

(6)

11

2.3 Safety functions

Emergency stop: This function is only to be used in an

emergency e.g. if the stand-aid lifter does not react or

does not stop after releasing the hand control operation.

If the emergency button has been activated all functions

immediately stops. The emergency stop can be released

by turning the red button a ¼ turn to the right. (Fig 2.3A)

Emergency lowering: This function is only to be used in

an emergency, where it is necessary to safely lower a

patient. The emergency lowering is placed on the lifting

actuator and is activated by pulling in the red handle and

the lifting arm is lowered slowly. (Fig 2.3B)

For both functions; If the emergency button/lowering has been activated due to an

emergency the stand-aid lifter must not be used again before a check has been made and any

defect repaired.

In any doubt, please contact Ergolet.

Fig. 2.3A

Fig. 2.3B

12

2.4 Charging

The stand-aid lifter is equipped with a battery that requires regular charging. Ergolet

recommends that the battery is charged when the stand-aid lifter is not in use or every

night. The stand-aid lifter can be charged from the mains (wall outlet).

There are 3 batteries symbols on the hand control, which indicate the power level of the

battery.

Low battery

The battery must IMMEDIATELY be put on charge. In this situation

remain on charge for 24 hours.

Battery 25%

An audible battery alarm will alert when there is a 25% capacity

remaining in the battery.

Battery 50%

Recommend charging to avoid low battery.

Full battery

The lifter is ready for use.

Note: The stand-aid lifter cannot be overcharged.

Charge directly from the wall outlet

1) Remove the plug, placed on the side of the control box and

plug into the mains.

2) The cable from the charger to the mains must be loose.

3) The “charge” diode lights yellow on the control box and the

display shows a plug symbol during charging.

2.5 Transport

The stand-aid lifter is most safely transported using the original packing.

Symbols are printed on the packaging to ensure the best information to carrier companies.

Fig. 2.4

13

3. Use

Stellar/160 is ready for use if all assembly instructions have been followed and the

emergency stop has been released.

3.1 Adjusting the knee support

Height adjustment:

The knee support is adjusted by loosening the hand screw (1).

The knee support adjusted up or down. The upper edge

of the knee support should be under the user’s

kneecap.

Tighten the hand screw when settings fit.

Note: The knee support must never press on the knee-caps.

Angle adjustment:

The angle of the knee support can be adjusted in 5 positions.

Pull the click lock (2) out and set the angle to the user

when the user stands up.

Release the click lock and ensure that the mechanism is

locked.

Note: As additional support, the calf belt (3) can be tightened around the knee support.

3.2 Using the slings

Lifting from sitting position:

Place the sling behind the user by pushing the back

support as low down on the users back as possible.

Close the safety belt. Lock the clasps on the belt

and pull the straps tight. Straps must be pulled

tight.

Note: Be aware that the clasps located under the

user’s ribs.

Fig. 3.1A

(1)

(2)

(3)

14

Fit the side pieces under the user’s arms and fasten the

sling loops on the sling hooks on the lifting arm.

The user may have their arms outside as illustrated or if

the user is semi-paralyzed, it may be necessary to keep

the arm inside the lifting arm/sling.

Apply the brakes on the wheelchair. Move the stand-aid

lifter to the user and place the user’s feet on the foot

plate.

Start lifting until the sling sits tightly around the back. Re-

tighten the sling belt around the waist once more if it is

not tight enough.

The user may hold the foam padded part of the handle

and is asked to participate (co-operate) in the lifting

action, as much as possible.

Ensure that the patient feels no discomfort.

Ask the user to press their feet down onto the plate and

to stretch both knee-and hip-joints.

The carer may help by placing a hand on to the knee and

press the knee lightly downwards. Continue the lifting

process according to the user’s ability, until he stands as

upright as possible. Never lift higher than is necessary.

From standing to sitting position:

Move the lifter to the secured (braked) wheel chair.

Note: Do not apply the brakes on the stand-aid lifter

when lifting the user.

The user is best lowered with his buttocks placed on the

bottom half of the chair’s back-rest. This will tilt the chair

slightly backwards and the user will then slide down into

the back of the chair when lowered. This movement

demands the utmost care and attention from the carer.

15

3.3 Using the control box

Display information’s:

To activate the display press up and down at the same time on the hand control

Total cycles – lifting actuator

Total work (Amp/sec)

Number of overloads

Day since last service/days between services

Service indicator:

When it is time for a service on the lifting actuator the diode lights

on the hand control and the wrench symbol will be shown on the

display. Service interval is 8000 cycles/12months by default, this

interval can be adjusted.

Resetting of service is done by pressing up/down on the hand

control at the same time for 5 sec. The counter will reset to zero and

start counting a new service period.

Overload:

The safety working load (SWL) on 160kg has been exceeded!

Charge:

See description in section 2.4.

Battery:

See description in section 2.4

16

4. Maintenance

4.1 Cleaning

The stand-aid lifter may be cleaned using a slightly damp cloth with a standard household

cleaning agent. Chemicals and other strong/abrasive agents must not be used.

The stand aid lifter cannot under any circumstance be autoclaved.

It is recommended that the stand-aid lifter be cleaned after each use to avoid infection. The

stand-aid lifter can be disinfected with household alcohol.

4.2 Storage

The stand-aid lifter must be stored in a dry environment with relative humidity under 90%.

If the stand-aid lifter is not to be used over a longer period of time it is best to fully charge

the unit and activate the emergency button to save battery before putting in storage.

4.3 Special environments

The stand-aid lifter is not intended for use in aggressive environments e.g. leisure centres or

swimming pools. For these situations please contact your local dealer or Ergolet.

5. Check and trouble shooting

5.1 Annual check / inspection

The stand-aid lifter must always be maintained by qualified and authorised personnel who

have been approved by Ergolet.

The manufacturer Ergolet stipulates that this lifter MUST be checked by a qualified and

authorised person at least once a year. This annual check is also recommended in the

Standard (EN/ISO 10535) for lifters.

It is the customer’s / dealer’s responsibility to ensure that the annual service inspection is

carried out.

If it is necessary to replace any parts due to wear or damage these must be

obtained/purchased from Ergolet or your local dealer.

17

5.2 Trouble shooting

Fault:

The lifter does not

react when the hand

control buttons

UP/DOWN are used.

Possible cause:

Emergency stop is activated.

Solution:

Release the emergency stop (see section 2.3)

Possible cause:

Defect hand control.

Solution:

Try using another hand control. Alternative is

to get a new hand control from the dealer.

Possible cause:

Flat battery.

Solution:

Charge battery (see section 2.4).

Fault:

The lifting arm can

travel up or down not

both.

The electrical leg

spreading can only

move in or out not

both.

Possible cause:

Fault in the control box.

Solution:

Replace the control box.

Possible cause:

Defect hand control.

Solution:

Try using another hand control. Alternative is

to get a new hand control from the dealer.

Fault:

The lifting actuator is

noisy or vibrates

abnormally

Possible cause:

Lifting actuator is defective.

Solution:

Replace the lifting actuator.

Fault:

Does not charge

Possible cause:

Charger is not connected to the main supply.

Solution:

Connect charger.

Possible cause:

Defective control box.

Solution:

Try another control box. Order a new control

box from Ergolet or your dealer.

Possible cause:

Defective battery.

Solution:

Replace battery.

18

6. Technical data and dimensions

6.1 Technical specifications

Lifting properties:

Load capacity: 160 kg

Number of lift movements: 60-80 lift with 80kg / 0,5 m

Duty cycle: 10%, max, 2 min/18 min

Manually emergency lowering: Yes

Electronically lowering: Yes

Electrical details:

Power supply (Input): 100-240 VAC 50/60 Hz, max 0,35 A

Output voltage: 24V

Control box (Output): 250 VA

Battery capacity: 2,9Ah

IP-class: IPx4

Noise:

Lwa during lifting/lowering without load is 49dB(A)

Lwa during lifting/lowering at maximum load is 52dB(A)

Material:

Powder coated steel

More test results may be available by contacting Ergolet.

19

1. Highest point

2. Maximum reach point

3. Lowest position

a) Maxi. reach at 600 mm

(reference height): 89mm

b) Maxi. reach from base 553mm

c) Reach from base with

legs spreading to 700 mm 232mm

d) Min. Dist. from wall to CSP*

at maxi. height 616mm

e) Min. Dist. from wall to CSP*

at maxi. reach (legs spread) 98mm

f) Min. Dist. from wall to CSP*

at min. height (legs spread) 136mm

i) Min. Height of CSP* 697mm

k) Maxi. height of CSP *: 1683mm

m) Hoisting range 986mm

p) Maxi. internal width 828mm

q) Internal width at maxi.

reach: 893mm

r) Min. internal width 535mm

* CSP = Central suspensions point

Turning radius: 1060mm

Weight:

Weight in total: 54 kg

Mast incl. battery: 21 kg (battery 2,8kg)

Base/legs: 23 kg

Foot plate: 10 kg

6.2 Dimensions

20

7. Environment and quality

Stellar/160 has an expected life time of minimum 10 years under the assumption that all

recommended service checks have been carried out and that the normal maintenance and

care instructions have been followed.

7.1 Disposal

Disposal of this stand-aid lifter can be made through Ergolet. After useful lifetime Ergolet will

receive the stand-aid lifter back and dispose of the individual parts in an environmentally

friendly way either through reuse or recycling.

Parts that contain aluminum, lead acid batteries, electrical component, ABS plastic, steel

may damage the environment if not handled in an environmentally responsible way.

7.2 Battery

The stand-aid lifter is equipped with one battery which may be returned either to a local

recycling station or to Ergolet at the end of their lifetime.

7.3 Quality

Ergolet is certified according to the quality standard ISO 9001 and ISO 13485.

These certifications mean that the products and the company comply with international

standards for quality management and standards for traceability of medical products.

Stellar/160 is classified as a Medical device class 1 product.

21

Direct current

Double insulated

The patient is not separated from the ground and the chassis

The product should be reused where possible

Refer to user instruction

Safe working load (user + sling)

7.4 Symbols and abbreviations

SWL

22

8. Accessories

Stellar/160

011-01310EU

011-01310UK

011-01310US

011-01310AUS

011-01615CN

Stellar/160

Hand control

018-08021

Standard hand control

Foot plate

722-11100

722-11099

017-00010

Foot platform, 50mm

Foot platform, 100mm

Angle handle

Battery

018-08014

Battery module

A complete list of spare parts is available. Please contact Ergolet for details.

23

24

Phone: + 45 70 27 37 20

Fax: + 45 70 27 37 19

Email: ergolet@ergolet.dk

www.ergolet.com

Manufacturer:

Ergolet

Taarnborgvej 12 C

4220 Korsoer

Denmark

9 3 / 4 2 / E Ø F C L A S S I

E N I S O 1 0 5 3 5

910-00760UK

Loading...

Loading...