Ergodyne 17393, 17392, 17396, 17394, 17372 User Manual

...

PROFLEX® GLOVES

COLLECTION

TRADES • DORSAL IMPACT-REDUCING • THERMAL • ANTI-VIBRATION

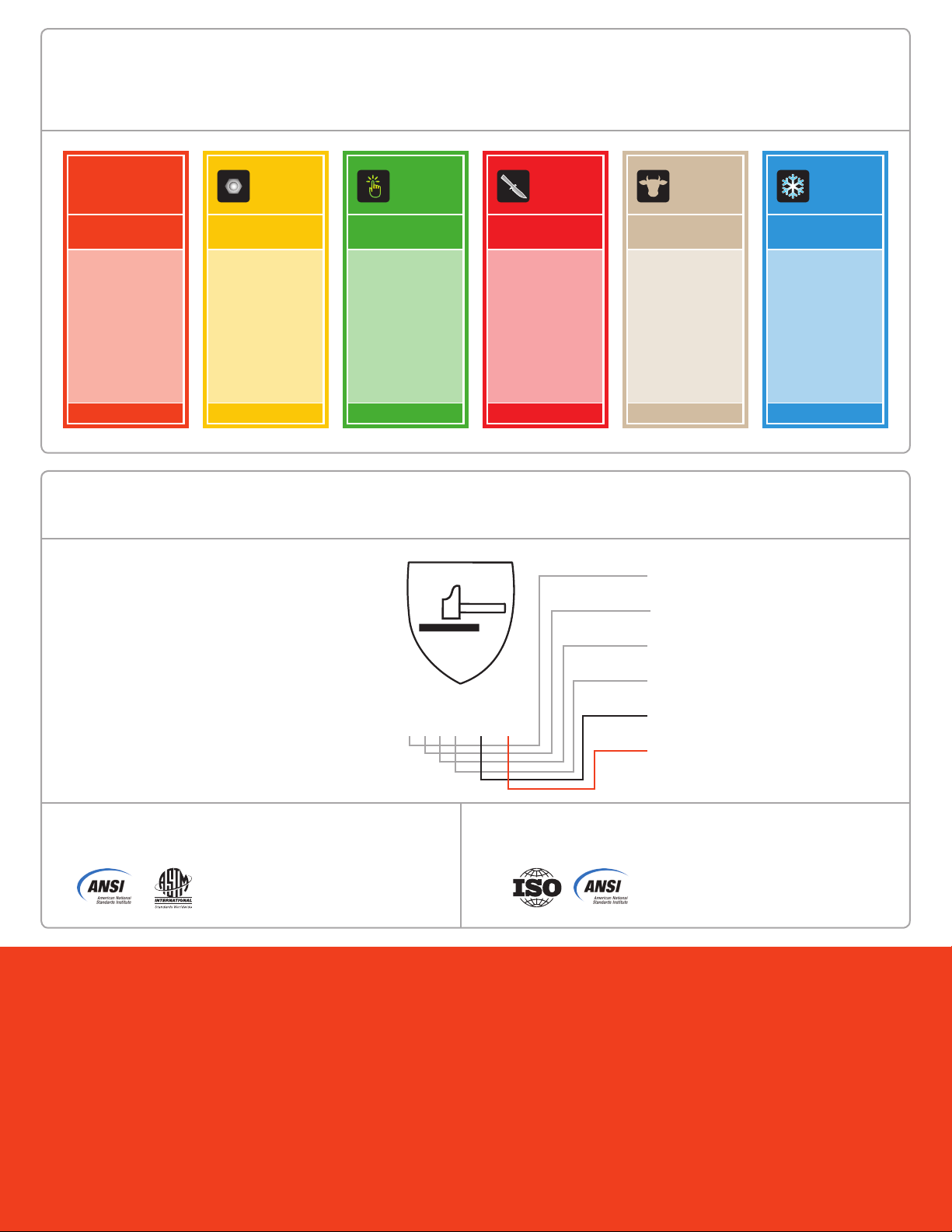

TASTE THE RAINBOW: COLOR-CODED FUNCTIONALITY

#### X P

All ProFlex® Gloves are designed to perform and built to last. But sometimes, the job requires that little extra somethin’ to help handle your specific hazard.

Technical adds like + Touch Screen and + Cut Resistance are found across the line with a color-coded system to show you the way.

ORIGINAL

MODELS

The tried and true originals. Whether standard

or heavy-duty, you know

you’re getting the latest

in design, materials,

and technology. Look

for orange accents and

know you’ve got the best

of the basics.

+HI-DEX +TOUCHSCREEN +CUT

RESISTANCE

It’s all about control and

feel. A super-thin palm,

50% thinner in fact,

provides maximum dexterity while maintaining

abrasion resistance

and durability. Look for

yellow accents when no

job is too small.

In today’s workplace,

the touchscreen device

has become another

tool of the trade. Touchscreen-capable palms

and fingertips allow you

swipe, tap, and type

while staying protected.

Look for green accents

and you’re money …

Silicon Valley money.

When sharp edges and

cut hazards crank up

the intensity level, so do

ProFlex

palms featuring stateof-the-art materials

like Armortex

protection in the toughest applications. Look for

red accents for no red

accidents.

®

Gloves. Glove

®

provide

+GENUINE

LEATHER

Want a softer, natural

feel without sacrificing

protection? ProFlex

Gloves with genuine

leather reinforcements

deliver all the features

of their Original Model

counterparts but with

supple genuine leather

reinforcements. Look

for tan accents for an

old-school look that still

packs a punch.

®

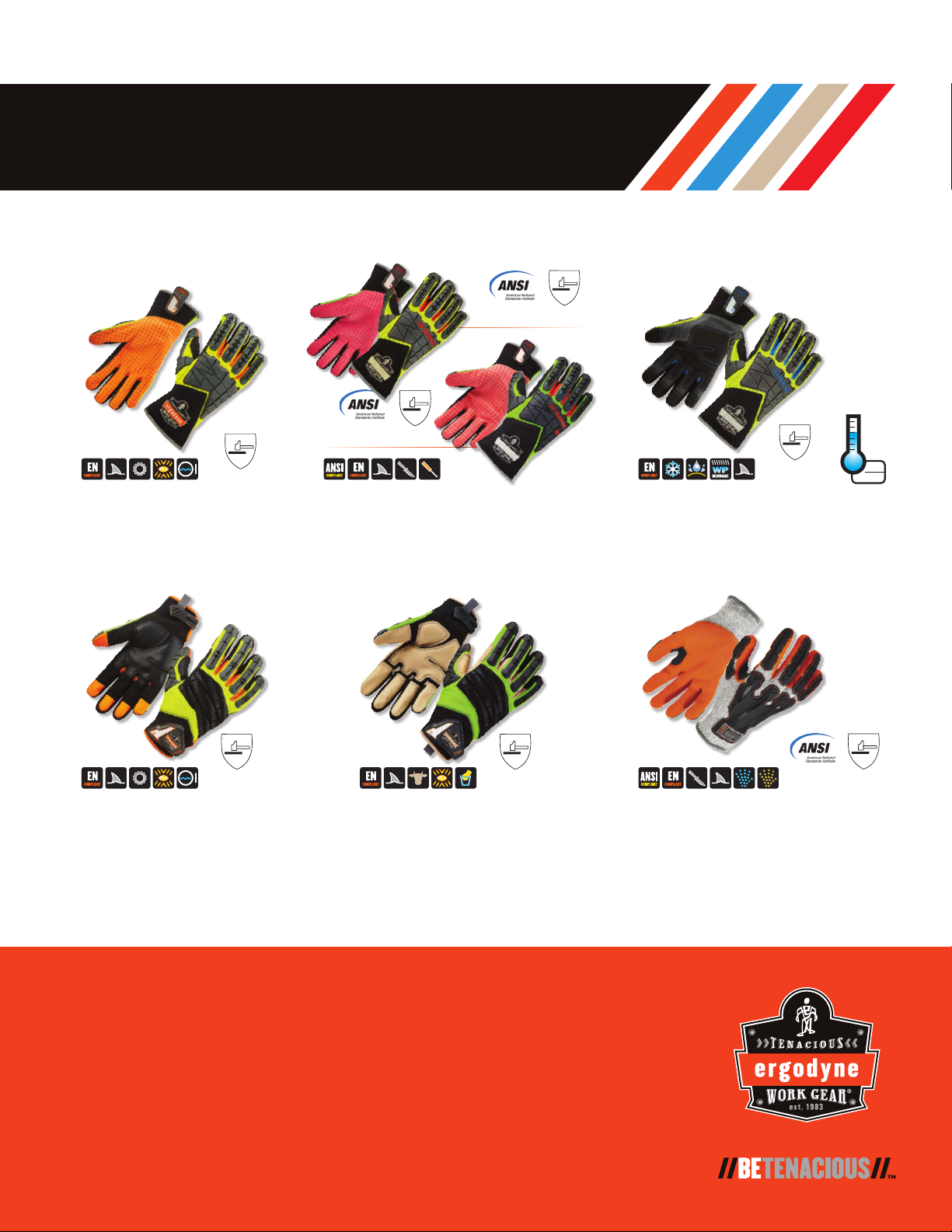

LABELING 101: THE HANDBOOK ON HAND PROTECTION

EN388:2016

All ProFlex® Gloves are tested to EN 388,

measuring and scoring four “mechanical

risks”: abrasion, cut, tear and puncture.

Gloves engineered to provide enhanced cut

protection are also tested to cut-resistant

standards ISO 13997 and ANSI/ASTM F2992.

Select Dorsal Impact-Reducing Series Gloves

meet the impact protection criteria of EN 388.

Select Vibration-Reducing Series Gloves meet

ISO 10819/ANSI S2.73, the global standard for

anti-vibration. All this info can be found on

the interior label.

Confused? Read on!

EN388

Abrasion Resistance (0-4)

Blade Cut Resistance (0-5)

Tear Resistance (0-4)

Puncture Resistance (0-4)

ISO Cut Resistance (A-I; X = Not tested)

Impact Protection (P = PASS)

+TH ERM AL

Because work doesn’t

stop when the

temperature drops,

there’s ProFlex

Gloves. With or without

waterproof tech, in black

or hi-vis and even a fliptop mitten option, look

for blue accents so your

winters don’t have to be,

well…blue.

®

Thermal

ANSI 105-2016 // ASTM F2992-2015

ANSI/ASTM Cut Protection is noted as:

ISO 10819:2013 // ANSI S.2.73-2014

ANSI/ASTM

CUT LEVEL A#

(Levels A1-A9)

Compliance with the ISO 10819:2013 Vibration-Reducing standard is noted as:

ISO 10819:2013

ANSI S.2.73-2014

THE EVOLUTION OF

PROFLEX® GLOVES:

DORSAL IMPACT-REDUCING SERIES

EN388

4121 X P

925F(x) // STANDARD DIR

Maximum impact protection

and full coverage.

ANSI/ASTM

CUT A3

925CR

ANSI/ASTM

CUT A6

925CR6

EN388

4443 F P

925CR/925CR6 // PERFORMANCE DIR + CUT

Armortex

®

-backed palm for two

levels of enhanced cut protection.

EN388

4443 C P

EN388

3323 X P

925WP // PERFORMANCE DIR + THERMAL WP

Insulated and waterproof for

cold weather work.

TEMP

RANGE

COLD

EN388

3122 X

924 // HYBRID DORSAL IMPACT-REDUCING

Full finger coverage and

foam knuckle padding.

GLOVE.

EN388

2122 X

92 4LTR // LEATHER-REINFORCED HYBRID DIR

Full finger coverage with genuine

leather palm and fingers.

This is not a drill – this is a quantum leap forward into the

21st century. Three years in the making. Borne of research,

listening, design, testing, blood, sweat, tears and a whole

lotta love. Brimming with technical options and features

delivering the functionality and protection you have come

to expect and trust. Taste the rainbow and never look back.

922CR // CUT RESISTANT NITRILE-DIPPED DIR

13-guage HPPE knit with sandy

foam nitrile palm.

ANSI/ASTM

CUT A3

EN388

4543

Loading...

Loading...