Page 1

INSTALLATION INSTRUCTIONS

BOOST / VACUUM GAUGES/KITS

PREPARATION FOR INSTALLATION

1

© 2004 IEC - All Rights Reserved MRP #93-0033

1. Read instructions completely before installation.Seek the advice of

a professional if you are not familiar with the installation of vehicle

instrumentation or the functions of related vehicle systems.

2. Install gauges only when engine is cool and ignition is off.

3. Make sure all necessary tools, materials, and parts are on hand.

4. Always read the vehicle's service manual and follow it’s safety pre-

cautions.

5. Disconnect negative (-) battery cable before installing gauges (do

not forget to reconnect battery after installation is complete).

NOTE:It may be necessary to reprogram your radio, cloc k, etc.after

reconnecting the battery.

NOTE: Additional mounting options (pillar mount, console mount, etc.)

and hardware are available for some gauges. For information on

optional mounting configurations, mounting hardware and prices, visit

us on the web at www.iequus.com

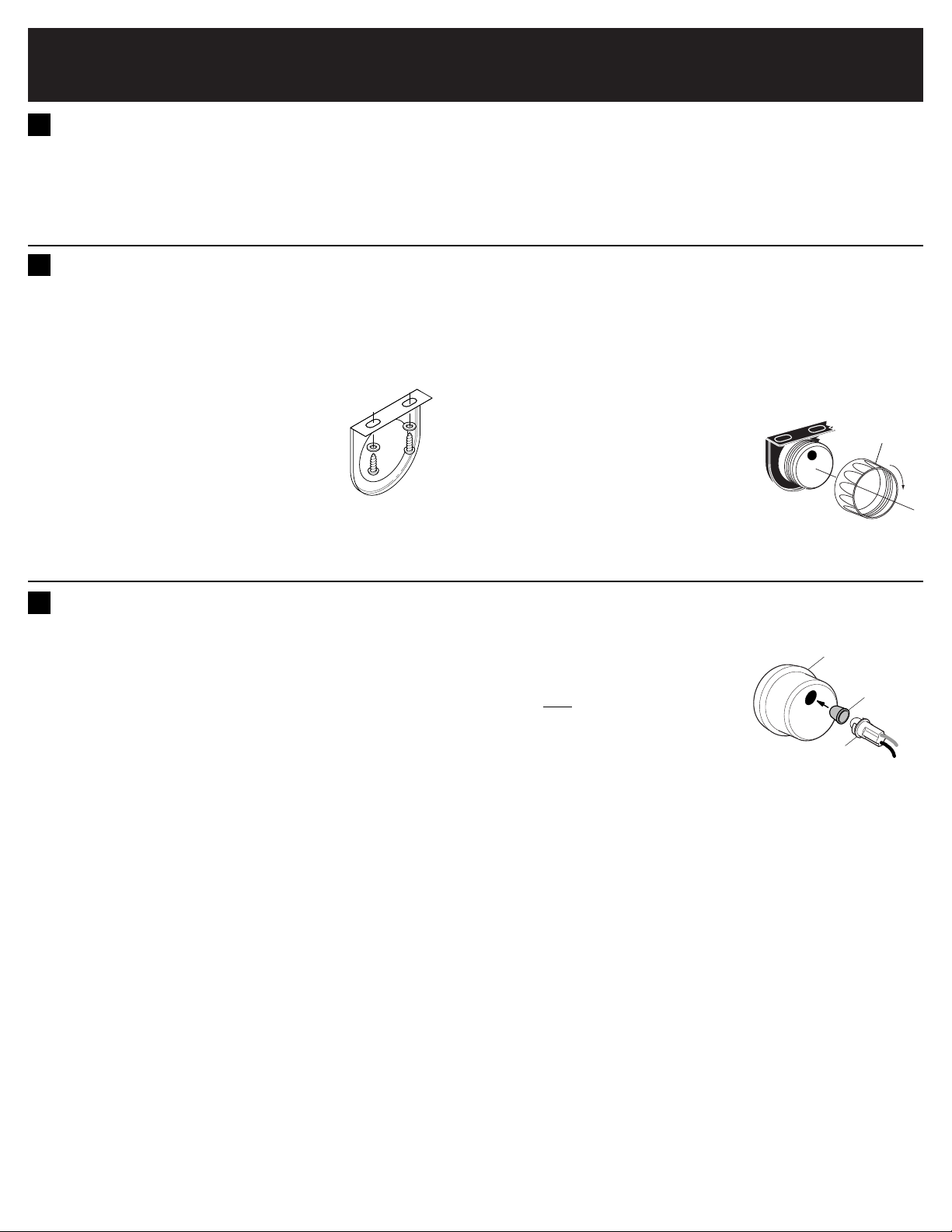

A. PANEL INSTALLATION

For On-Dash or Under-Dash mounting

(panel is optional with some gauge models

and must be purchased separately).

1. Determine the mounting location for the

gauge.

2. Using gauge panel as a template, mark

locations for screws.

3. Drill small holes for the screws and secure

panel with screws and flat washers provided.

MOUNTING AND INSTALLATION

2

B. IN-DASH MOUNTING OPTION

1. Determine a location on the dashboard that can be cut out without

striking any objects behind the dash.

2. Using a hole template, cut out a 1-1/2" (3,8 cm), 2" (5,1 cm) or

2-5/8"(6,7 cm) hole, as necessary, through the dashboard.

3. Using a round file, smooth out the rough edges around the drilled

hole.

C. INSTALLING GAUGE INTO GAUGE PANEL OR IN-DASH

1. Insert gauge through front of panel or

hole in dashboard.

2. Hold gauge case and rotate gauge, as

needed, until gauge dial face is properly positioned in front of dashboard/

panel.

3. Tighten locking ring on gauge in clock-

wise direction until gauge is tight

against dashboard/panel. Tighten

locking ring HAND TIGHT ONLY.

Figure 1. Gauge Panel

Figure 2. Gauge Equipped

with Locking Ring

NOTE: Depending on the model of gauge, backlighting color may be

changed to either red, green or blue by installing the optional color filter over the bulb (not available for all gauge kits).

1. Insert the light bulb and socket assemblies into the light receptacles on the back of the gauge and press firmly to snap/lock into

place.

NOTE: Wire for gauge lights must be purchased separately. Use

size 18-20 AWG stranded copper wire.

2. Splice the RED or WHITE wire from the gauge light(s) into the

vehicle's lighting circuit, between the dimmer control switch and the

dash lights (consult the vehicle's service manual for proper wire).

GAUGE LIGHT INSTALLATION AND CONNECTION

3

3. Connect light socket BLACK wire to a good chassis ground.

4.

Insulate all splices and connections with

shrink tubing to prevent shorting.

WARNING: For bulb replacement

use onl

y part # 161 Instrument/

Indicator wedge type bulbs available at most auto parts stores. DO

NOT USE ANY OTHER PART NUMBER SINCE THE HEAT PRODUCED

BY A HIGHER WATTAGE BULB

WILL MELT THE GAUGE CASE

AND CREATE A FIRE HAZARD.

Figure 3. Light Bulb

Installation

5.0

5.0

LOCKING

RING

GAUGE

OPTIONAL COLOR

FILTER

BULB AND

SOCKET ASSEMBLY

Page 2

© 2004 IEC - All Rights Reserved

GAUGE CONNECTION

4

Install Vacuum/Boost gauge as descr ibed in Section 2, MOUNTING

AND INSTALLATION.

Determine routing for pressure line. Use an existing firewall grommet

or drill a 3/8" (9,5 mm) diameter hole through firewall to accommodate

pressure line.Install a rubber grommet (purchased separately) in hole,

to protect lead wires from chaffing or other damage. Use Teflon tape

(purchased separately) on all adapter threads to prevent leaks.

NOTE: The pressure fitting instructions that follow are for the installation of gauges that have a BOOST function. If the gauge you are

installing does not have a BOOST function, simply connect the vacuum tubing to the back of the gauge fitting, and then to an existing

intake manifold vacuum hose using the "T" fitting. No pressure tubing

is needed for vacuum gauges that do not ha v e a BOOST function, and

the section of the instructions describing pressure fitting connections

can be disregarded.

MAKING CONNECTION TO GAUGE

1. Connect nylon pressure tubing to gauge using compression sleeve

and compression nut provided.Tighten compression nut until tubing is secure. See Figures 4 and 5.

2. Route nylon tubing through grommet in firewall.

MAKING CONNECTION TO VEHICLE

■■

Some vehicles are factory equipped with a tapped hole on the

intake manifold that is suitable for the Boost/Vacuum gauge nylon

tubing connection. If your vehicle is equipped with a suitable tap

on the intake manifold f ollo w the directions for "Option One - Intake

Manifold Connection" (Figure 4).

NOTE: Make sure this is a vacuum port, and not a coolant por t.

■■

On vehicles without a tap on intake manifold, locate an existing vacuum line where a "T" fitting can be utilized and follow the directions

for "Option Two - Existing Vacuum Line Connection" (Figure 5).

■■

IF YOUR VEHICLE DOES NOT HAVE A TAPPED HOLE ON THE

INTAKE MANIFOLD, AND A SUITABLE VACUUM LINE IS NOT

AVAILABLE, CONSULT A PROFESSIONAL FOR INSTALLATION

OF THIS TYPE OF GAUGE.

Option One - Intake Manifold Connection

See Figure 4 and follow the instructions below:

1. Remove plug from tapped hole on intake manifold and install 1/8" 27 NPT or 1/4" - 18 NPT adapter, as required, in tapped hole.

NOTE: Additional adapters must be purchased separately.

2. Connect nylon tubing to the installed adapter using compression

sleeve and compression nut provided. Tighten compression nut

until tubing is secure.

Option Two - Existing Vacuum Line Connection

See Figure 5 and follow the instructions below:

1. Connect nylon tubing to the 5/16" (7,9 mm) vacuum nipple using

compression sleeve and compression nut provided. Tighten compression nut until tubing is secure.

2. Insert vacuum nipple into one end of the 5/16" X 4" (7,9 mm X 10,2

cm) hose (provided);insert the vacuum "T" fitting into the other end

of the hose.

3. Cut the selected vacuum hose on the vehicle and install "T" fitting

in line with this hose. Use hose clamps (purchased separately) as

needed to secure "T" fitting.

FINISHING THE INSTALLATION

1. Secure tubing along its route to prevent damage from sharp edges,

moving parts or hot engine components.

2. Reconnect negative (-) battery cable. Start and run engine for

approximately 30 seconds and check gauge installation for leaks.

Tighten or reseal joints as needed and retest.

Figure 4. Boost/Vacuum Gauge - Intake Manifold Connection

The Manufacturer warrants to the original purchaser that this unit is free of defects in

materials and workmanship under normal use and maintenance for a period of one (1)

year from the date of original purchase.If the unit fails within the one (1) year period, it

will be repaired or replaced, at the Manufacturer's option, at no charge, when returned

prepaid to the Technical Service Center with Proof of Purchase. The sales receipt may

be used for this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or re-manufactured, assume as their warranty

period for only the remaining time of this warranty. This warranty does not apply to

damage caused by improper use, accident, abuse, improper voltage, service, fire,

flood, lightning, or other acts of God, or if the product was altered or repaired by anyone other than the Manufacturer's Technical Service Center.Consequential and incidental damages are not recoverable under this warranty. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. No por tion of this warranty may be copied or duplicated without the expressed written permission from the Manufacturer.

Obtaining Warranty Service:

Products requiring service should be returned as follows:

1. Call the Technical Service Center to obtain a Return Reference Number:

USA & Canada = 1-800-544-4124

Other = 714-241-6805

2. Package the product carefully to prevent shipping damage

3. Include your name, return address, and a day contact phone

4. Enclose a copy of the dated sales receipt

5. Describe the problem

6. Ship prepaid to: Technical Service Center, 17291 Mt.Herrmann Street, Fountain

Valley, CA 92708 U.S.A.

Phone: 1-800-544-4124 or 714-241-6805 Fax: 714-432-7910

Web: www

.iEQUUS.com Email: service@iEQUUS.com

LIMITED WARRANTY AND SERVICE PROCEDURES

Figure 5. Boost/Vacuum Gauge “T”Fitting Option Connection

COMPRESSION

NUT

1/8"

GAUGE

PORT

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

*

COMPRESSION

*

GROMMET

SLEEVE

NYLON

TUBING

COMPRESSION

SLEEVE

COMPRESSION

NUT

1/8"

CONNECTOR

TUBE

ADAPTER

*

*

INTAKE

MANIFOLD

VACUUM

TEE

NUT

OPTIONAL

GROMMET

COMPRESSION

SLEEVE

NYLON

TUBING

COMPRESSION

NUT

COMPRESSION

1/8"

GAUGE

PORT

*

USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

*

COMPRESSION

SLEEVE

1/8"

VACUUM

NIPPLE

HOSE 5/16" x 4"

*

VACUUM

HOSE

FROM

MANIFOLD

Page 3

INSTRUCTIONS D'INSTALLATION

JAUGES/TROUSSES D’AMPLIFICATION/VIDE

PRÉPARATION POUR L'INSTALLATION

1

© 2004 IEC - All Rights Reserved MRP #93-0033

1. Lisez les instructions en entier avant de commencer l'installation.

Consultez un mécanicien professionnel si vous n'êtes pas familier

avec l'installation d'instruments dans les véhicules ou avec les

fonctions des systèmes connexes des véhicules.

2. Installez les jauges uniquement lorsque le moteur est froid et que

l'allumage est en positon «OFF».

3. Assurez-vous que vous avez tous les outils, les matériaux et les

composants à portée de la main.

4. Lisez toujours le manuel de service du véhicule et observez les

mesures de sécurité.

5. Débranchez le câble de la borne négative (-) de la batterie avant

d'installer les jauges. N'oubliez pas de rebrancher la batterie une

fois que vous avez terminé votre installation.

REMARQUE : Vous devrez peut-être reprogrammer votre radio,

votre horloge, etc. après avoir rebranché la batterie de votre

véhicule.

REMARQUE : D'autres options d'installation (montant avant, console,

etc.) et des trousses additionnelles d'installation sont disponibles pour

les jauges.Pour avoir des renseignements sur les différentes configurations d'installation, les trousses de montage et les prix, consultez

notre site Internet à www.Iequus.com.

A. INSTALLATION DU PANNEAU

Pour les installations sur le tableau de

bord ou sous celui-ci (le panneau soit facultatifs pour certains modèles de jauges

et ils doivent être achetés à part).

1. Déterminez l'endroit où la jauge sera

installée.

2. Utilisez le panneau comme gabarit et

marquez l'emplacement des vis.

3. Perforez des orifices pour les vis et fixez le

panneau à l'aide des vis et des rondelles

plates fournies.

MONTAGE ET INSTALLATION

2

2. À l'aide d'un gabarit à orifices, découpez un orifice de 1 ½ po (3,8

cm), 2 po (5,1 cm)ou 2 5/8 po (6,7 cm) , selon le cas, dans le

tableau de bord.

3. À l'aide d'une lime ronde, adoucissez les arêtes rugueuses autour

de l'orifice perforé.

C. INSTALLATION DE LA JAUGE DANS LE PANNEAU OU DANS

LE TABLEAU DE BORD

1. Insérez la jauge par l'avant du pan-

neau ou par l'orifice pratiqué dans le

tableau de bord.

2. Tenez le bâti de la jauge et tournez

cette dernière, selon les besoins,

jusqu'à ce que le devant de la jauge

soit bien placé sur le devant du panneau/tableau de bord.

3. Serrez l'anneau de verrouillage sur la jauge en le tournant en sens

horaire jusqu'à ce que la jauge soit serrée sur le tableau de bord/

panneau. Serrez l'anneau de verrouillage À LA MAIN SEULEMENT.

Figure 1. Panneau pour le

jauge

Figure 2. Jauge avec

anneau de verrouillage

REMARQUE :Selon le modèle de jauge, il est possible de changer la

couleur de l'éclairage par l'arrière des jauges pour passer du rouge,

au vert et au bleu en installant un filtre facultatif de la couleur sur l'ampoule (non disponible pour toutes les trousses de jauges).

1. Insérez l'assemblage de l'ampoule et la douille dans le logement à

l'arrière de la jauge, et pressez fermement jusqu'à qu'il s'emboîte en

place.

REMARQUE : Le fil électrique alimentant l'éclairage de la jauge

doit être acheté à part. Utilisez un fil électrique de jauge 18-20

AWG à brins toronnés en cuivre.

2. Connectez le fil ROUGE ou BLANC de la jauge au circuit d'éclairage du tableau de bord du véhicule, entre le gradateur et l'éclairage (consultez le manuel de service de la véhicule pour plus

d'informations sur le fil correcte.)

INSTALLATION ET RACCORDEMENT DE L'ÉCLAIRAGE DE LA JAUGE

3

3. Raccordez le fil électrique NOIR de la douille d'éclairage sur une

bonne mise à la masse du châssis.

4. Isolez les connexions à l'aide de gaine

thermorétrécissable pour prévenir les

court-circuits.

AVERTISSEMENT : Utilisez unique

ment l'ampoule de rechange #161

(instruments / indicateurs) fournie

par les vendeurs de pièces d'auto.

LA CHALEUR PLUS INTENSE DES

AMPOULES PLUS FORTES FERA

FONDRE L'EXTÉRIEUR DE LA JAUGE;

ELLE PRÉSENTE UN RISQUE D'INCENDIE.

Figure 3. Installation de

l'ampoule d'éclairage

5.0

5.0

B. INSTALLATION DANS LE TABLEAU DE BORD

1. Déterminez l'endroit où le tableau de bord peut être découpé sans

toucher à rien qui se trouve derrière le tableau de bord.

ANNEAU DE

VERROUILLAGE

Ampoule et douille

Filtre facultatif

de la couleur

Page 4

© 2004 IEC - All Rights Reserved

RACCORDEMENT DES JAUGES

4

Installez la jauge de vide/amplification tel que décrit à la section 2,

MONTAGE ET INSTALLATION.

Déterminez l'acheminement du conduit de pression.Utilisez un passefil déjà pratiqué dans la cloison pare-feu ou perforez un orifice de 3/8

po (9,5 mm) de diamètre dans cette cloison pour y faire passer le conduit de pression. Installez un passe-fil (acheté à par t) dans l'orifice

pour protéger les fils électriques contre tous les dommages. Utilisez

du ruban de Teflon (acheté à part) sur tous les filets de l'adaptateur

pour prévenir les fuites.

REMARQUE : Les instructions s'appliquant au raccord à pression qui

suivent s'appliquent à l'installation des jauges ayant une fonction

d'AMPLIFICATION. Si la jauge que vous installez n'a pas de fonction

d'AMPLIFICATION, raccordez tout simplement le tube de vide à l'arrière du raccord de la jauge puis ensuite sur le tuyau de vide du collecteur d'admission à l'aide d'un raccorde en té. Aucun tuyau à pression n'est requis pour les jauges de vide qui n'ont pas de fonction

d'AMPLIFICATION et vous n'avez pas à suivre les instructions présentées à la section décrivant les instructions sur le raccordement des

raccords de pression.

RACCORDEMENT SUR LA JAUGE

1. Raccordez le tube à pression (tube de nylon) sur la jauge à l'aide du

manchon et de l'écrou à compression fournis. Serrez l'écrou à compression jusqu'à ce que le tube soit bien fixé.Voir les Figures 4 et 5.

2. Passez le tube en nylon dans le passe-fil installé dans la cloison

pare-feu.

RACCORDEMENT SUR LE VÉHICULE

■■

Certains véhicules ont déjà un orifice fileté sur le collecteur d'admission et qui peut être utilisé pour y installer le conduit à pression

de la jauge d'amplification/vide. Si votre véhicule a un tel point de

raccordement, suivez les instructions décrites à l'«Option un Raccordement au collecteur d'admission» (Figure 4).

REMARQUE : Assurez-vous qu'il s'agit d'un point d'accès au vide

et non d'un point d'accès au liquide de refroidissement.

■■

Si votre véhicule n'a pas de point de raccordement de ce genre sur

le collecteur d'admission, trouvez le conduit de vide existant où un

raccord en té peut être installé et suivez les instructions décrites à

l'«Option deux - Raccordement sur un conduit de vide existant»

(Figure 5).

■■

SI VOTRE VÉHICULE N'A PAS D'ORIFICE FILETÉ SUR LE COLLECTEUR D'ADMISSION ET QUE VOUS N'AVEZ PAS DE CONDUIT DE VIDE ACCEPTABLE, CONSULTEZ UN MÉCANICIEN

PROFESSIONNEL POUR INSTALLER CE TYPE DE JAUGE.

Option un - Raccordement au collecteur d'admission

Consultez la Figure 4 et suivez les instructions ci-dessous.

1. Retirez le bouchon installé sur l'orifice fileté pratiqué sur le collecteur d'admission et installez l'adaptateur de 1/8 po 27 NTP ou

de ¼ po - 18 NTP, selon le cas, dans l'orifice fileté.

REMARQUE : Les autres adaptateurs doivent être achetés à part.

2. Raccordez le tube à pression (tube de nylon) sur l'adaptateur que

vous venez d'installer;utilisez le manchon et l'écrou à compression

fournis. Serrez l'écrou à compression jusqu'à ce que le tube soit

bien maintenu.

Option deux - Raccordement sur un conduit de vide existant

Consultez la Figure 5 et suivez les instructions ci-dessous.

1. Raccordez le conduit à pression (tube de nylon) sur le raccord droit

de vide de 5/16 po (7,9 mm) en utilisant le manchon et l'écrou à

compression fournis. Serrez l'écrou à compression jusqu'à ce que

le conduit soit bien fixé sur le raccord droit.

2. Insérez le raccord droit de vide sur l'une des extrémités du tuyau

de 5/16 po x 4 po (7,9 mm X 10,2 cm) (fourni). Insérez le raccord

en té de vide sur l'autre extrémité du conduit.

3. Coupez le tuyau de vide choisi sur le véhicule et installez le raccord en té sur le tuyau. Utilisez des serre-tuyaux (achetés à part)

selon les besoins pour fixer le raccord en té.

FIN DE L'INSTALLATION

1. Fixez le tube ici et là le long de son parcours afin de prévenir les

bris sur les arêtes vives, les pièces mobiles et les composants

chauds du moteur.

2. Rebranchez la borne négative (-) de la batterie. Démarrez le

moteur laissez-le en marche pendant 30 secondes environ;vérifiez

l'installation de votre jauge pour voir s'il y a des fuites. Serrez et

installez des joints étanches sur les joints qui fuient, le cas

échéant, et refaites la vérification.

Figure 4. Jauge d’amplification/vide - Raccordement au collecteur

d'admission

Le fabricant garantit à l'acheteur d'origine que cet appareil ne comporte aucun

défaut, ni au niveau des matériaux ni de l'exécution;cette garantie vaut pendant un

(1) an à partir de la date d'achat d'origine et à condition que l'appareil fasse l'objet

de conditions normales d'utilisation et d'entretien. Si l'appareil connaît des problèmes au cours de la première (1) année, il sera réparé ou remplacé, au choix du

fabricant, sans frais, à condition d'être renvoyé en port payé au Centre de service

technique avec la preuve d'achat.Le reçu de caisse peut être utilisé à cette fin. Les

frais de main-d'œuvre pour l'installation ne sont pas couverts par la présente

garantie.Toutes les pièces de rechange, qu'il s'agisse de pièces neuves ou refaites,

ne sont garanties que pendant la période de garantie résiduelle de la présente

garantie. La présente garantie ne s'applique pas aux dommages découlant d'une

mauvaise utilisation, d'un accident, d'un usage abusif, d'une tension anormale, de

problèmes de service, d'un incendie, d'une inondation, de la foudre ou d'autres cas

de force majeure ou si le produit est modifié ou réparé par une autre personne que

le Centre de service technique du fabricant. On ne peut pas réclamer de dommages

indirects et consécutifs en vertu de la présente garantie. Cer tains états ne permettent pas l'exclusion ou la limitation des dommages indirects ou consécutifs; par conséquent, les limites ou les exclusions ci-dessus pourraient ne pas s'appliquer dans

votre cas. Cette garantie vous confère des droits légaux spécifiques et vous pourriez également avoir d'autres droits qui peuvent varier d'un état à l'autre.Aucune par-

tie de ce document ne peut être copiée ou reproduite sans l'autorisation écrite

expresse du fabricant.

Obtention du service sous garantie:

Pour obtenir le service, envoyez le produit en procédant comme suit :

1. Téléphonez au Centre de service technique pour obtenir un numéro de

référence pour le renvoi.

États-Unis et Canada : 1-800-544-4124

Ailleurs : (714) 241-6805

2. Emballez le produit avec soin pour éviter les dommages pendant le transport.

3. Indiquez votre nom, votre adresse et un numéro de téléphone où l'on peut vous

rejoindre le jour.

4. Annexez une copie du reçu de vente montrant la date d'achat.

5. Décrivez le problème.

6. Expédiez le produit en por t payé à l'adresse suivante : Centre de service tech-

nique, 17291 Mt. Herrmann Street, Fountain Valley, CA 92708 U.S.A.

Tél : 1-800-544-4124 or 714-241-6805 Télécopieur : 714-432-7910

Internet : www.iEQUUS.com Courriel : service@iEQUUS.com

GARANTIE LIMITÉE ET PROCÉDURE DE SERVICE

Figure 5. Jauge d’amplification/vide - Raccordement sur un conduit

de vide existant

ÉCROU DE

COMPRESSION

1/8"

*

MANCHON DE

COMPRESSION

POINT D'ACCÈS

DE LA JAUGE

UTILISEZ DU RUBAN DE SCELLEMENT EN TEFLON SUR LES JOINTS FILETÉS INDIQUÉS

*

PASSE-FIL

TUBE DE

NYLON

MANCHON DE

COMPRESSION

ÉCROU DE

COMPRESSION

1/8"

CONNECTEUR

DU TUBE

ADAPTATEUR

*

*

COLLECTEUR

D'ADMISSION

ÉCROU DE

COMPRESSION

1/8"

POINT D'ACCÈS

DE LA JAUGE

*

UTILISEZ DU RUBAN DE SCELLEMENT EN TEFLON SUR LES JOINTS FILETÉS INDIQUÉS

*

PASSE-FIL

MANCHON DE

COMPRESSION

TUBE DE

NYLON

ÉCROU DE

COMPRESSION

MANCHON DE

COMPRESSION

1/8"

RACCORD DROIT

TUYAU DE 5/16 PO X 4 PO

DE VIDE

TÉ DE VIDE*

TUYAU DE

VIDE EN

PROVENANCE

DU COLLECTEUR

Page 5

INSTRUCCIONES DE INSTALACIÓN

CONJUNTOS / MANÓMETROS DE VACÍO / SOBREPRESIÓN (BOOST)

PREPARACIÓN PARA LA INSTALACIÓN

1

© 2004 IEC - All Rights Reserved MRP #93-0033

1. Lea completamente las instrucciones antes de la instalación. Si

usted no está familiarizado con la instalación de instrumentos en

vehículos o las funciones de los sistemas relacionados en el

vehículo, busque la ayuda de un profesional.

2. Instale indicadores sólo cuando el motor esté frío y la ignición esté

apagada.

3. Asegúrese que estén disponibles todas las herramientas, partes y

materiales necesarios.

4. Siempre lea el manual de servicio del vehículo y siga sus precauciones de seguridad.

5. Desconecte el cable negativo (-) de la batería antes de instalar los

indicadores (no se olvide de conectar la batería después de ter-

minar la instalación).

NOTA: Puede ser necesario reprogramar el radio, ajustar el reloj,

etc. después de conectar de nuevo la batería.

NOTA: Hay disponibles opciones adicionales de montaje (en pilar,

sobre la consola, etc.) y sus herrajes de montaje correspondientes

para algunos indicadores. Para obtener información sobre las configuraciones opcionales de montaje, los herrajes y los precios, visítenos

en nuestro sitio en internet al www.iequus.com

A. INSTALACIÓN EN PANEL

Para montaje sobre el tablero o debajo del

tablero de instrumentos (el panel es

opcionales con algunos modelos de indicadores y deben comprarse por separado).

1. Determine la ubicación de montaje desea-

da para el indicador.

2. Utilice el panel de indicadores como plantilla para marcar la ubicación de los tornillos.

3. Taladre or ificios pequeños para los tornillos

y sujete el panel del indicador con los tornillos y arandelas planas suministradas.

MONTAJE E INSTALACIÓN

2

C. INSTALACIÓN DEL INDICADOR EN UN PANEL DE INDI-

CADORES O EMPOTRADO EN EL TABLERO

1. Introduzca el indicador a través del panel frontal en el hueco en el

tablero.

2. Sujete la caja del indicador y gírela

según sea necesario, hasta que el dial

del cuadrante del indicador quede

debidamente colocado al frente del

tablero o panel.

3. Apriete el anillo de sujeción en el

indicador en sentido horario hasta

que el indicador esté apretado en el

tablero o panel. Apriete el anillo de

sujeción SÓLO CON LA FUERZA

DE LA MANO.

Figura 1. Panel de

indicadores

Figura 2. Indicador equipado

con anillos de sujeción

NOTA: Dependiendo del modelo de indicador, la iluminación de fondo

del indicador se puede cambiar a rojo, verde o azul mediante la instalación del filtro de color opcional sobre la bombilla (no está disponible

para todos los juegos de indicadores).

1. Inserte el conjunto del foco y receptor en el agujero detras del indicador y presione hasta que trabe en su lugar.

NOTA: Es necesario comprar por separado el alambre para las

luces del indicador. Use cable de cobre entorchado de calibre

AWG 18-20.

2. Empalme el cable ROJO o BLANCO del indicador al circuito de iluminación del tablero de borde, entre el control de graduación y las

luces. (Consulte el manual de ser vicio para el cable correcto.)

3. Conecte el cable NEGRO del receptor de la luz a una conexión a

tierra apropiada en el chasis.

INSTALACIÓN Y CONEXIÓN DE LA LUZ DEL INDICADOR

3

4. Aisle las conexiones con tubería termoencogible para prevenir los cor-

tocircuitos.

ADVERTENCIA: Para lámparas de

reemplazo solamente utilize el tipo

Instrumento/Idicador modelo # 161

disponibles en la mayoría de los

almacenes de auto partes. NO UTILICE NINGÚN OTRO NÚMERO DE

PIEZA PUESTO QUE El CALOR PRODUCIDO POR UNA LAMPARA DE

MÁS ALTA POTENCIA DERRETIRÁ

LA CAJA DEL INDICADOR Y

CAUSARÁ UN PELIGRO DE FUEGO.

Figura 3. Instalación

de la bombilla

5.0

5.0

2. Con ayuda de una plantilla de orificios, corte un orificio de 1-1/2"

(3,8 cm), 2" (5,1 cm) ó 2-5/8" (6,7 cm), según sea necesario, a

través del tablero.

3. Con una lima circular, alise los bordes ásperos alrededor del orificio taladrado.

B. OPCIÓN DE MONTAJE EN EL TABLERO DE INSTRUMENTOS

1. Determine un lugar en el tablero de instrumentos en que se pueda

hacer un corte sin tocar ninguno de los objetos detrás del tablero.

ANILLO DE

SUJECIÓN

BOMBILLA Y RECEPTÁCULO

COLOR OPCIONAL

CONJUNTO DE

FILTRO DE

Page 6

© 2004 IEC - All Rights Reserved

CONEXIÓN DEL INDICADOR

4

Instale el indicador de vacío/sobrepresión como se ha descrito en la

sección 2, MONTAJE E INSTALACIÓN.

Determine la ruta a seguir con la tubería de presión. Use un ojal existente en el cortafuegos o taladre un orificio de 3/8" (9,5 mm) de

diámetro a través del cortafuegos para pasar la línea de presión.

Instale un ojal de goma (comprado por separado) en el orificio para

proteger los conductores contra el roce u otros tipos de daños. Use

cinta de teflón (comprada por separado) en todas las juntas roscadas

de los adaptadores para evitar fugas.

NOTA: Las instrucciones para conexiones de presión a continuación son

para la instalación de manómetros que tienen una función de sobrepresión. Si el manómetro que usted está instalando no tiene función de

sobrepresión, simplemente conecte la tubería de vacío en la conexión

trasera del manómetro y después al múltiple de admisión usando una

"T". No se requiere manguera de presión para los manómetros de vacío

que no tienen una función de sobrepresión y no es necesario observar

las instrucciones de la sección de conexiones de presión.

PARA HACER LAS CONEXIONES AL MANÓMETRO

1. Conecte la tubería de presión (tubo de nylon) al manómetro usan-

do un manguito y tuerca de compresión suministrados. Apriete la

tuerca hasta que la tubería quede sujeta.Véanse las Figuras 4 y 5.

2. Pase la tubería de nylon por el ojal en el cortafuegos.

PARA HACER LA CONEXIÓN AL VEHÍCULO

■■

Algunos vehículos vienen equipados de fábrica con un orificio

roscado en el múltiple de admisión que se puede usar para conectar la línea de presión del manómetro de vacío/sobrepresión.Si su

vehículo tiene este orificio roscado en el múltiple de admisión, siga

las instrucciones denominadas "Opción Uno - Conexión roscada

en el múltiple de admisión" (Figura 4).

NOTA: Asegurese que el orificio es un puerto del vacio y no del agua.

■■

En vehículos que no tengan esta conexión roscada de fábrica en el

múltiple de admisión, será necesario localizar una línea de vacío en

la que se pueda conectar una "T", y se deben seguir las instrucciones

denominadas "Opción Dos - Conexión a línea de vacío existente"

(Figura 5).

■■

SI SU VEHÍCULO NO TIENE UN ORIFICIO ROSCADO EN EL

MÚLTIPLE DE ADMISIÓN, NI TAMPOCO UNA LÍNEA DE VACÍO

DISPONIBLE PARA CONEXIÓN, DIRÍJASE A UN PROFESIONAL

PARA LA INSTALACIÓN DE ESTE TIPO DE MANÓMETRO.

Opción Uno - Conexión roscada en el múltiple de admisión

Véase la Figura 4 y siga las instrucciones a continuación:

1. Saque el tapón de la conexión roscada del múltiple de admisión e

instale un adaptador de rosca 1/8"- 27 NPT ó 1/4" - 18 NPT, según

se requiera, en el orificio roscado.

NOTA: Los adaptadores adicionales se compran por separado.

2. Conecte la tubería de presión (tubo de nylon) al adaptador instal-

ado usando un manguito y tuerca de compresión suministrados.

Apriete la tuerca hasta que la tubería quede sujeta.

Opción Dos - Conexión a línea de vacío existente

Véase la Figura 5 y siga las instrucciones a continuación:

1. Conecte la tubería de presión (tubo de nylon) al niple de vacío de

5/16" (7,9 mm) usando un manguito y tuerca de compresión suministrados. Apriete la tuerca hasta que la tubería quede sujeta.

2. Introduzca el niple de vacío en un extremo de la manguera de

5/16" x 4" (7,9 mm X 10,2 cm) (suministrada); introduzca la "T" en

el otro extremo de la manguera.

3. Corte la manguera de vacío seleccionada en el vehículo e instale

la "T" entre los dos extremos cortados de esta manguera. Use

abrazaderas para manguera (compradas por separado) según sea

necesario para sujetar la "T".

PARA TERMINAR LA INSTALACIÓN

1. Sujete la tubería a lo largo de su trayectoria para prevenir daños

causados por bordes filosos, partes en movimiento o componentes

calientes del motor.

2. Vuelv a a conectar el cab le negativo (-) de la batería.Ponga en marcha el motor aproximadamente 30 segundos y revise que no haya

fugas en la instalación del manómetro.Apriete o vuelva a sellar las

juntas según sea necesario y pruébelas de nuevo.

Figura 4. Opción de conexión roscada en el múltiple de admisión

El fabricante garantiza al comprador original que esta unidad está exenta de defectos en materiales y mano de obra por un período de un (1) año a partir de la fecha

de compra original. Si la unidad falla en un período de un (1) año, se reemplazará

o se reparará, a opción del Fabricante, sin cargo adicional alguno, cuando se

devuelva con porte prepagado al Centro de Servicio Técnico acompañada del comprobante de pago.El recibo de compra puede usarse para este propósito.La mano

de obra no tiene cobertura en virtud de esta garantía.

Todas las partes de repuesto, sean nuevas o reconstruidas, asumirán como su

período de garantía sólo el plazo restante de esta garantía. Esta garantía no cubre

daños causados por uso indebido, accidental, abusivo, o si el producto fue modificado o reparado por alguien ajeno al Centro de Servicio Técnico del Fabricante.Los

daños consecuentes o incidentes no son recuperables en virtud de esta garantía.

Algunos estados no permiten la exclusión o la limitación de los daños incidentes o

consecuentes, así que la limitación o exclusión anterior quizá no sea aplicable a su

caso.

Esta garantía le otorga derechos legales específicos, y usted quizá pueda tener

otros derechos, los cuales varían de estado a estado. No se permite copiar ni

duplicar porción alguna de esta garantía sin el consentimiento expreso y escrito del

Fabricante.

Asistencia técnica y Servicio de garantía

Los productos que requieran servicio deberán devolverse de la manera siguiente:

1. Llame al Centro Servicio Técnico para obtener un Número de Referencia de

Devolución.

2. Embale cuidadosamente el producto para evitar daños durante el envío.

3. Incluya su nombre, el remitente y un teléfono disponible en horas hábiles.

4. Adjunte una copia del recibo de compra fechado.

5. Describa el problema.

6. Envíe el producto con porte pagado a: Technical Service Center, 17291 Mt.

Herrmann Street, Fountain Valley, CA 92708 U.S.A.

Para recibir Asistencia técnica y/o Servicio de garantía, sírvase dirigirse a:

Teléfono: EE.UU. y Canadá 1-800-544-4124; otros países: 714-241-6805 (E.U.A.);

Fax 714-432-7910 (E.U.A.); Internet: www.iEQUUS.com; correo electrónico: service@iEQUUS.com

Para garantía en México ver con distribuidor.

GARANTÍA LIMITADA Y PROCEDIMIENTOS PARA OBTENER SERVICIO

Figura 5. Opción de conexión con un adaptador en T

TUERCA DE

COMPRESIÓN

1/8"

PUERTO DEL

INDICADOR

USE CINTA SELLADORA DE TEFLON® EN LAS JUNTAS ROSCADAS INDICADAS.

*

MANGUITO DE

COMPRESIÓN

*

OJAL

TUBO DE

NYLON

MANGUITO DE

COMPRESIÓN

TUERCA DE

COMPRESIÓN

1/8"

CONECTOR

DEL TUBO

ADAPTADOR

*

COLLECTEUR

D'ADMISSION

TUERCA DE

COMPRESIÓN

1/8"

PUERTA DEL

MANÓMETRO

*

USE CINTA SELLADORA DE TEFLON® EN LAS JUNTAS ROSCADAS INDICADAS.

*

MANGUITO DE

COMPRESIÓN

OJAL

TUBERÍA DE

NYLON

TUERCA DE

COMPRESIÓN

MANGUITO DE

COMPRESIÓN

1/8"

NIPLE DE

VACÍO

MANGUERA

5/16" x 4"

EN T

*

ADAPTADOR

*

MANGUERA DE

VACÍO DEL

MÚLTIPLE

DE ADMISIÓN

Loading...

Loading...