Page 1

INSTALLATION INSTRUCTIONS

AIR / FUEL RATIO GAUGE KITS

PREPARATION FOR INSTALLATION

2

© 2004 IEC - All Rights Reserved MRP #93-0038

1. Read instructions completely before installation.Seek the advice of

a professional if you are not familiar with the installation of vehicle

instrumentation or the functions of related vehicle systems.

2. Install gauges only when engine is cool and ignition is off.

3. Make sure all necessary tools, materials, and parts are on hand.

4. Always read the vehicle's service manual before any test or serv-

ice is performed, and follow it’s safety precautions.

5. Disconnect negative (-) battery cable before installing gauges (do

not forget to reconnect battery after installation is complete).

NOTE:It may be necessary to reprogram your radio, cloc k, etc.after

reconnecting the battery.

When selecting a location to install the gauge, take into consideration

that the gauge’s signal wires must be routed through the fire wall when

making the gauge connections. Choose a location that will allow routing of the gauge wiring through an existing firewall grommet.

If an existing firewall grommet is not accessible, drill a 3/8” (9,5 mm)

diameter hole through the firewall. Install a rubber grommet (purchased separately) in drilled hole to protect lead wires from chaffing or

other damage.

A. PANEL INSTALLATION

For On-Dash or Under-Dash mounting

(panel is optional with some gauge models

and must be purchased separately).

1. Determine the mounting location for the

gauge.

2. Using gauge panel as a template, mark

locations for screws.

3. Drill small holes for the screws and secure

panel with screws and flat washers provided.

MOUNTING AND INSTALLATION

3

B. IN-DASH MOUNTING OPTION

1. Determine a location on the dashboard that can be cut out without

striking any objects behind the dash.

2. Use a hole template to cut out a 1-1/2", 2" or 2-5/8" (3,81 mm, 5,08

mm or 6,67 mm) hole, as necessary, through the dashboard.

3. Use a round file to smooth out the rough edges around the drilled hole.

C. INSTALLING GAUGE INTO GAUGE PANEL OR IN-DASH

1. Insert gauge through front of panel or

hole in dashboard.

2. Hold gauge case and rotate gauge, as

needed, until gauge face is properly

positioned in front of dashboard/panel.

3. Tighten locking ring on gauge in clockwise direction until gauge is tight

against dashboard/panel. Tighten locking ring HAND TIGHT ONLY.

Figure 1. Gauge Panel

Figure 2. Gauge Equipped

with Locking Ring

Install Air/Fuel Ratio Gauge as described in Section 3, MOUNTING

AND INSTALLATION.

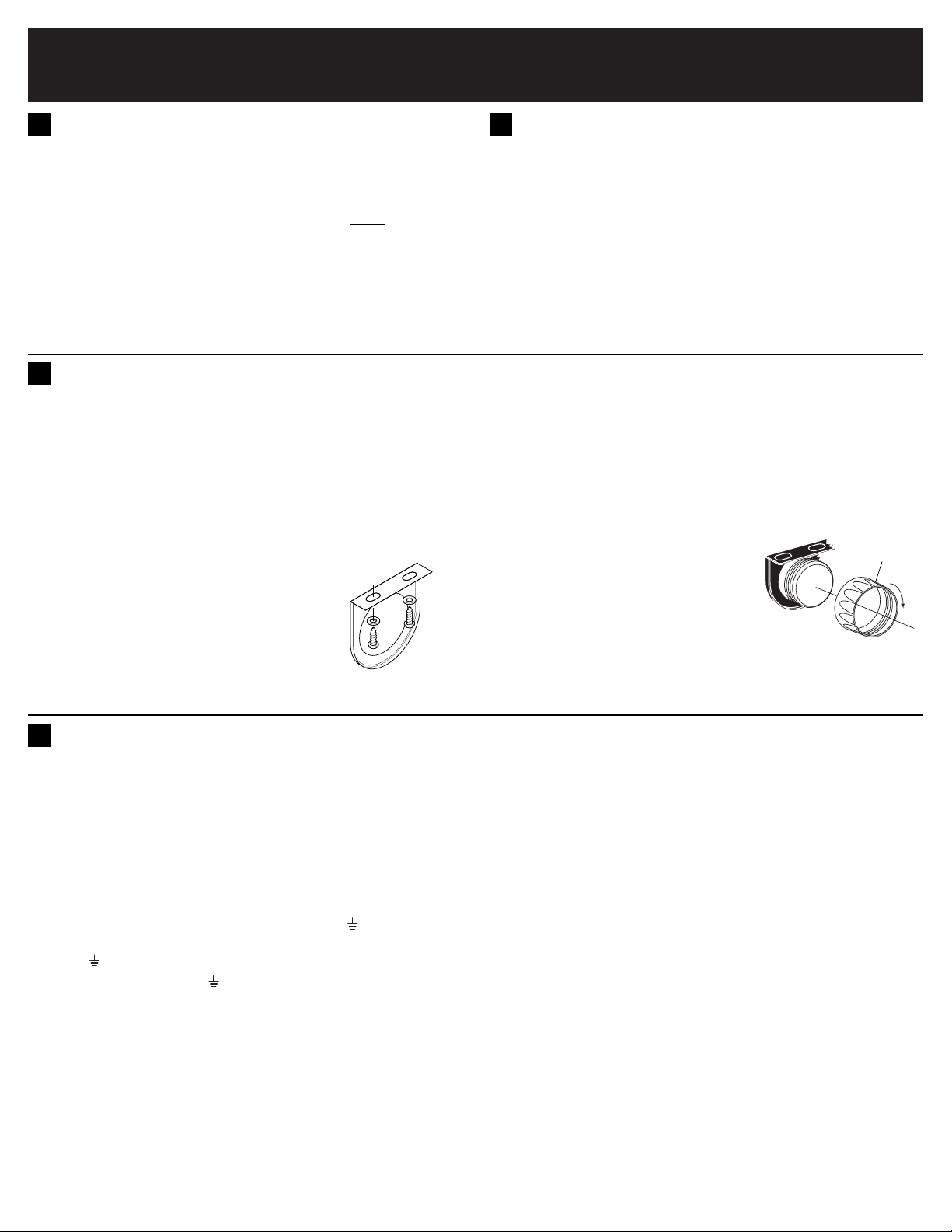

Refer to Figure 3 (on back page) and make gauge connections as follows.

NOTE: Wiring is not provided with gauge kit.Wire and connectors to

suit your particular installation must be purchased separately. Use 2022 AWG stranded copper wire.

1. After determining the wire length needed,

2. Crimp or solder ¼" (6,35 mm) female spade terminals (included)

on one end of gauge positive (+) and negative ( ) wires.

3. Connect gauge positive and negative wires to positiv e (+) and negative ( ) spade posts.

4. Connect the negative ( ) lead wire to a good (bare metal)

chassis ground.

5. Connect the positive (+) lead wire into a switched (hot only when

the ignition key is turned to the On position) 12 volt positive source .

6. Connect the signal wires (see figure 3) to the Air/Fuel Ratio Gauge

and the vehicle's oxygen sensor(s) SIGNAL circuit(s) as follows:

GAUGE CONNECTION

4

■■

If your vehicle has

only one

pre-catalytic converter oxygen sensor, crimp or solder a wire to the large female spade terminal

(included with gauge kit) and connect the terminal over the two

small male spade signal posts on back of the gauge. Connect

the other end of the wire to the oxygen sensor signal circuit.

This allows the LEDs on both sides of the gauge to display the

air/fuel ratio for one oxygen sensor.

■■

If your vehicle is equipped with two pre-catalytic converter

Oxygen sensors, crimp or solder two wires to the two small

female spade terminals (included in gauge kit), and connect the

terminals to the two small male spade signal posts on back of

the gauge. Splice one of the loose ends of the gauge signal

wires to the signal circuit of the oxygen sensor on Bank 1 of the

engine, splice the other signal wire to the oxygen sensor signal

circuit on Bank 2 of the engine.This allows the LEDs on the right

side of the gauge to display the air/fuel ratio for Bank 1 oxygen

sensor and the LEDs on the Left side of the gauge to display the

Air/Fuel Ratio for Bank 2 oxygen sensor (see figure 3).

CAUTION: Some oxygen sensors use shielded wires. Make your

SIGNAL wire connections on the signal circuit, away from the

shielded wire and after the oxygen sensor connector. DO NOT

make connections on the shielded wire itself.

INTRODUCTION

1

The Air/Fuel Ratio Gauge reads and interprets the voltage output signals from the vehicle’ s oxygen sensor(s) to giv e an indication of air/fuel

ration while driving; either Optimal, Lean or Rich.

IMPORTANT: The Air/Fuel Ratio Gauge is designed to work with the

vehicle’ s existing o xygen sensor.The gauge will work ONL

Y with oxygen

sensors that generate voltage output signals from 0 to 1 volt.See your

vehicle’s service manual for oxygen sensor operating voltage specifications.

If your vehicle is not equipped with this type of sensor , or is not equipped

with

any

oxygen sensor, it may be possible to install an after-market

heated oxygen sensor .See a professional to determine if a suitable o xygen sensor can be installed on your vehicle.

7.0

7.0

LOCKING

RING

Page 2

© 2004 IEC - All Rights Reserved

GAUGE CONNECTION (continued)

4

The Manufacturer warrants to the original purchaser that this unit is free of defects in

materials and workmanship under normal use and maintenance for a period of one (1)

year from the date of original purchase.If the unit fails within the one (1) year period, it

will be repaired or replaced, at the Manufacturer's option, at no charge, when returned

prepaid to the Technical Service Center with Proof of Purchase. The sales receipt may

be used for this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or re-manufactured, assume as their warranty

period for only the remaining time of this warranty. This warranty does not apply to

damage caused by improper use, accident, abuse, improper voltage, service, fire,

flood, lightning, or other acts of God, or if the product was altered or repaired by anyone other than the Manufacturer's Technical Service Center.Consequential and incidental damages are not recoverable under this warranty.Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. No por tion of this warranty may be copied or duplicated without the expressed written permission from the Manufacturer.

Obtaining Warranty Service:

Products requiring service should be returned as follows:

1. Call the Technical Service Center to obtain a Return Reference Number:

USA & Canada = 1-800-544-4124

Other = 714-241-6805

2. Package the product carefully to prevent shipping damage

3. Include your name, return address, and a day contact phone

4. Enclose a copy of the dated sales receipt

5. Describe the problem

6. Ship prepaid to: Technical Service Center, 17291 Mt. Herrmann Street, Fountain

Valley, CA 92708 U.S.A.

Phone: 1-800-544-4124 or 714-241-6805 Fax: 714-432-7910

Web: www

.iEQUUS.com Email: service@iEQUUS.com

LIMITED WARRANTY AND SERVICE PROCEDURES

Figure 3. Air/Fuel Ratio Gauge Connections

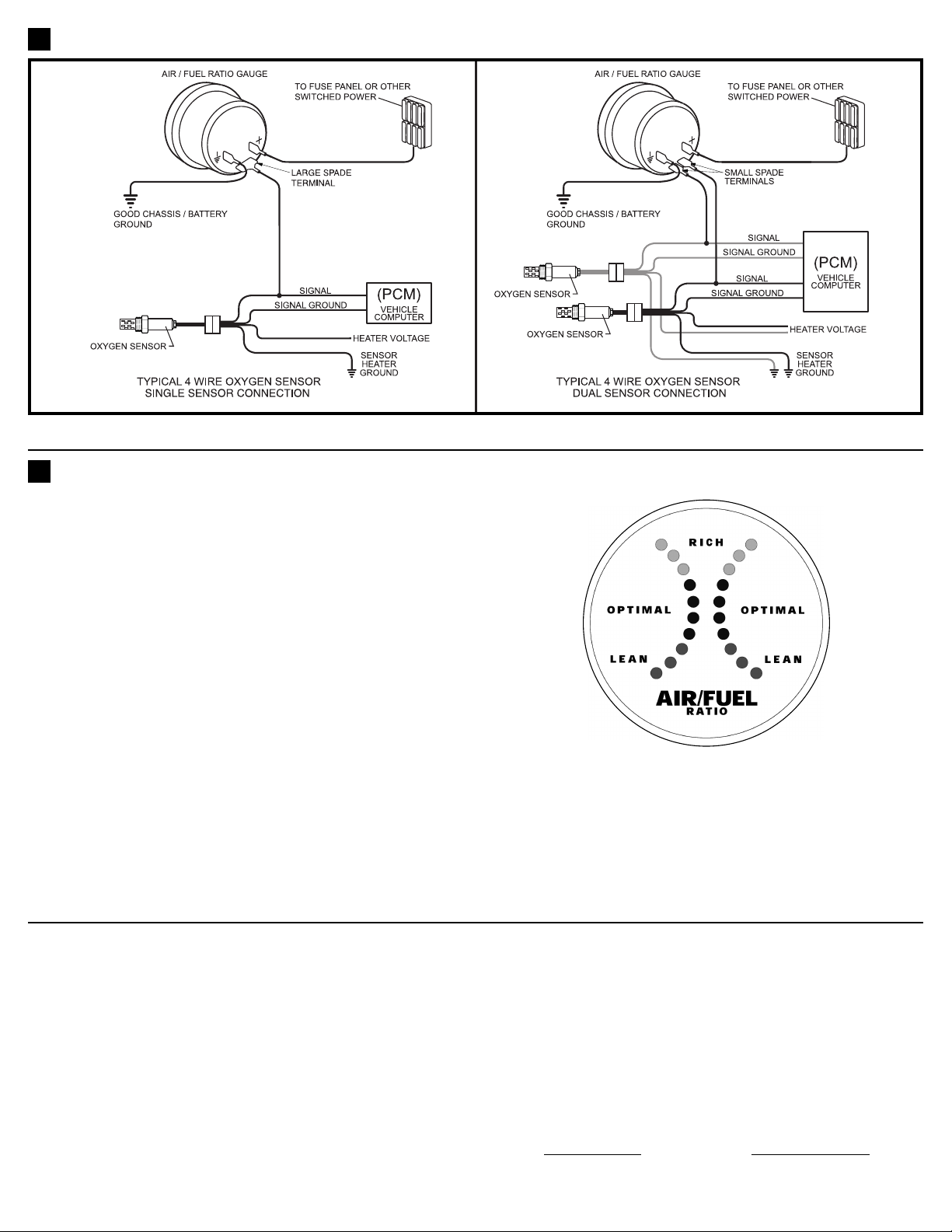

The Air/Fuel Ratio Gauge face has two columns of 10 colored LEDs.

Each LED lights in response to a specific output voltage signal level

from the oxygen sensor(s). The LED colors represent the current

air/fuel ratio condition; Red to indicate a LEAN condition, Green to

indicate OPTIMAL, and Yellow to indicate a RICH condition.

The Air/Fuel Ratio Gauge indication should change, depending on the

current driving conditions, as described below:

■■

At engine warm up, the engine runs in a RICH mode until the oxygen sensor reaches operating temperature. The oxygen sensor

does not operate until it reaches a minimum of 600° F.

■■

At cruising speed, the oxygen sensor output voltage continually

fluctuates up and down.The gauge LEDs light accordingly, cycling

between slightly lean and slightly rich.This condition is considered

OPTIMAL (normal) operation.

■■

When the vehicle is accelerated rapidly, the vehicle’s computer

enriches the air/fuel mixture. The gauge indicates this very rich

condition by gravitating mostly into the RICH (Yellow LEDs) area..

■■

On deceleration, the computer cuts most of the fuel to the engine.

The gauge indicates this very lean condition by gravitating towards

the LEAN (Red LEDs) area.

IMPORTANT: The four operating conditions described above represent a normally operating engine and engine management system. These conditions are considered normal. If a condition

GAUGE OPERATION (See Figure 4)

5

exists where the engine runs in the RICH or LEAN area most of

the time, even at cruising speed, a problem may be indicated.

Visually inspect components in the engine compartment for

defective or disconnected vacuum hoses, or broken components. See your vehicle’s repair manual to conduct appropriate

tests related to that particular condition.

Figure 4. Gauge Operation

S

S

Page 3

INSTRUCTIONS D'INSTALLATION POUR LES JAUGES /

TROUSSES DE MÉLANGE D'AIR/CARBURANT

PRÉPARATION POUR L'INSTALLATION

2

© 2004 IEC - Tous droits réservés MRP #93-0038

1. Lisez toutes les instructions en entier avant de commencer l'installa-

tion. Consultez un professionnel si vous n'êtes pas familier avec l'installation des instruments de votre véhicule ou les fonctions des systèmes connexes de votre véhicule.

2. Installez les jauges uniquement lorsque le moteur est froid et que l'allumage est en position «OFF».

3. Assurez-vous que vous avez tous les outils nécessaires en main ainsi

que les matériaux et les pièces.

4. Lisez toujours le manuel de service de votre véhicule avant de faire

des tests ou des travaux de service et suivez les précautions de sécurité.

5. Débranchez le câble négatif (-) de la batterie du véhicule avant d'installer les jauges (n'oubliez pas de rebrancher la batterie une fois

que l'installation est terminée).

REMARQUE : Vous devrez peut-être reprogrammer votre radio, votre

horloge, etc. lorsque vous rebrancherez votre batterie.

Lorsque vous choisissez l'endroit où installer la jauge, tenez compte que

le câblage de la jauge doit passer à travers la cloison pare-feu lorsque

vous raccordez la jauge. Choisissez un endroit permettant de passer le

câblage de la jauge dans un passe-fil existant de la cloison pare-feu existante.

Si aucun passe-fil n'est disponible dans la cloison pare-feu, perforez un

orifice de 3/8 po (9,5 mm) de diamètre dans la cloison. Installez le passefil en caoutchouc (acheté à part) dans l'orifice pour protéger le câblage

contre l'usure et les dommages par la friction.

A. INSTALLATION DU PANNEAU

Pour le montage sur le tableau de bord ou

sous ce dernier, le panneau est optionnel

pour certains modèles de jauges et il faut l'acheter à part.

1. Déterminez l'endroit où installer le jauge.

2. Utilisez le panneau de la jauge comme

gabarit et marquez l'emplacement de vis.

3. Perforez de petits orifices pour les vis et fixez

le panneau à l'aide des vis et des rondelles

plates fournies.

MONTAGE ET INSTALLATION

3

B. MONTAGE OPTIONNEL DANS LE TABLEAU DE BORD

1. Déterminez l'emplacement sur le tableau de bord qui peut être

découpé sans rien toucher derrière le tableau de bord.

2. Utilisez un gabarit pour découper un or ifice de 1-1/2 po, de 2 po ou de

2-5/8 po (3,81 mm, 5,08 mm ou 6,67 mm), selon le besoin, dans le

tableau de bord.

3. Utilisez une lime ronde pour adoucir les bordures rugueuses des or ifices.

C. INSTALLATION DE LA JAUGE DANS LE PANNEAU DE LA JAUGE

OU LE TABLEAU DE BORD

1. Insérez la jauge par l'avant du panneau

ou de l'orifice pratiqué dans le tableau de

bord.

2. Tenez la jauge et tournez-la, au besoin,

jusqu'à ce qu'elle soit bien placée dans

le tableau de bord / panneau.

3. Serrez la bague de verrouillage sur la

jauge en tournant en sens horaire

jusqu'à ce que la jauge soit bien serrée

dans le tableau de bord/panneau.Serrez

la bague À LA MAIN SEULEMENT.

Figure 1. Panneau de

la jauge

Figure 2. Jauge avec

bague de verrouillage

Installez la jauge de mesure du rapport d'air/carburant tel que décrit à la

section 3, MONTAGE ET INSTALLATION.

Consultez la Figure 3 (au verso) et faites les raccordements en conséquence.

REMARQUE : Le câblage n'est pas fourni avec la jauge.Le câblage et les

connecteurs convenant à votre installation particulière doivent être

achetés séparément. Utilisez un câblage de 20-22 AWG torsadé en cuivre.

1. Déterminez la longueur du câblage nécessaire.

2. Sertissez ou brasez une borne femelle de ¼ po (6,35 mm) (fournie) sur

l'une des extrémités des fils positif (+) et négatif ( ) de la jauge.

3. Branchez les conducteurs positif et négatif de la jauge sur les bornes

positive (+) et négative ( ).

4. Branchez le conducteur négatif ( ) sur une bonne mise à la masse

(métal nu) du châssis.

5. Banchez le conducteur positif (+) sur un conducteur positif de 12 volts

commuté (sous tension uniquement lorsque la clé d'allumage est en

position «ON»).

6. Branchez le câblage du détecteur sur les conducteurs produisant les

SIGNAUX des détecteurs d'oxygène du véhicule comme suit :

■■

Si votre véhicule n'a qu'une seul détecteur d'oxygène en amont du

convertisseur catalytique, sertissez ou brasez un conducteur sur la

RACCORDEMENT DE LA JAUGE

4

grande borne femelle (fournie dans la trousse) et branchez la borne

sur les deux petites tiges mâles de réception des signaux qui se

trouvent à l'arrière de la jauge. Branchez l'autre extrémité du conducteur sur le circuit produisant le signal à partir du détecteur

d'oxygène. Cela permet aux DEL des deux côtés de la jauge d'afficher le rapport d'air et de carburant pour un détecteur d'oxygène.

■■

Si votre véhicule a deux détecteurs d'oxygène en amont du con-vertisseur catalytique, sertissez ou brasez deux conducteurs sur les

petites bornes femelles (fournies avec la jauge) et branchez les

bornes sur les deux petites tiges mâles de réception des signaux

situées à l'arrière de la jauge. Épissez l'une des extrémités libres

des conducteurs de la jauge sur le circuit du détecteur d'oxygène du

premier groupe du moteur; épissez l'autre conducteur sur le circuit

du détecteur d'oxygène du deuxième groupe du moteur. Cela permet aux DEL du côté droit de la jauge d'afficher le rapport d'air et de

carburant pour le détecteur d'oxygène du premier groupe; les DEL

du côté gauche de la jauge affichent le rapport d'air et de carburant

pour le détecteur d'oxygène du deuxième groupe (voir la figure 3).

MISE EN GARDE : Certains détecteurs d'oxygène utilisent des conducteurs blindés.Faites v otre r accordement du câb lage des SIGNAUX

sur le circuit du signal, et non sur le conducteur blindé, et en aval du

connecteur du détecteur d'oxygène.NE FAITES PAS le raccordement

sur le conducteur blindé lui-même.

INTRODUCTION

1

La jauge de mélange d'air et de carburant lit et interprète les signaux de

sortie de la tension des détecteurs d'oxygène du véhicule pour donner une

indication du rapport d'air et de carburant lorsque le véhicule est en

marche; les trois réglages sont les suivants : Optimal, pauvre ou riche.

IMPORTANT: La jauge est conçue pour utiliser les détecteurs actuel

d'oxygène du véhicule. La jauge fonctionne UNIQ

UEMENT avec les

détecteurs d'oxygène qui produisent des signaux de sortie de tension oscillant entre 0 et 1 volt.Consultez le manuel de service de votre véhicule pour

avoir les fiches techniques et la tension d'utilisation des détecteurs

d'oxygène.

Si votre véhicule n'a pas de détecteurs de ce genre ou s'il n'a pas de

détecteur d'oxygène, il sera peut-être possible d'installer un détecteur

d'oxygène chauffé qu'on trouve sur le marché secondaire.Consultez un professionnel pour déterminer quel détecteur d'oxygène doit être installé sur

votre véhicule.

7.0

7.0

BAGUE DE

VERROUIL-LAGE

Page 4

© 2004 IEC - Tous droits réservés

RACCORDEMENT DE LA JAUGE (suite)

4

Le fabricant garantit à l'acheteur d'origine que cet appareil ne contient aucun défaut,

que ce soit au niveau des matériaux ou de la fabrication; cette garantie vaut à condition que l'appareil soit soumis à des conditions normales d'utilisation et d'entretien;

cette garantie vaut pendant un (1) an à partir de la date d'achat d'origine. Si l'appareil fait défaut pendant cette période d'un (1) an, il sera réparé ou remplacé, au

choix du fabricant, sans frais, lorsqu'il est renvoyé en port payé au centre de service technique avec sa preuve d'achat.Le reçu de vente peut être utilisé à cette fin.

La main-d'œuvre pour l'installation n'est pas couverte en vertu de cette garantie.

Toutes les pièces de rechange, qu'elles soient neuves ou remises à neuf, ne sont

garanties que pour la période résiduelle de garantie.Cette garantie ne vaut pas pour

les dommages découlant d'une mauvaise utilisation, d'un accident, d'un usage abusive, d'une tension inacceptable, de travaux de service, d'un incendie, d'une inondation, de la foudre, d'une autre calamité naturelle ou si l'appareil a été modifié ou

réparé par une personne autre qu'un spécialiste du centre de service technique du

fabricant.Les dommages secondaires et accidentels ne peuvent pas être récupérés

en vertu de la présente garantie.Certains états ne permettent pas l'exclusion ou les

limites imposés aux dommages accidentels ou secondaires; par conséquent, les

limites et les exclusions ci-dessus pourraient ne pas s'appliquer dans votre cas.

La présente garantie vous donne des droits particuliers et vous pourriez avoir

d'autres droits qui peuvent varier d'un état à l'autre. Aucune partie de la présente

garantie ne peut être copiée ou reproduite sans la permission écrite expresse du

fabricant.

Service sous garantie :

Les produits qui doivent recevoir des travaux de service doivent être renvoyés en

procédant comme suit :

1. Téléphonez au centre de service technique pour obtenir un numéro de

référence pour le renvoi :Etats-Unis et Canada = 1-800-544-4124

Ailleurs = 714-241-6805

2. Emballez le produit avec soin pour éviter les dommages pendant le transport.

3. Indiquez le nom, l'adresse de retour et un numéro de téléphone avec lequel on

peut communiquer pendant la journée.

4. Endossez une copie de votre reçu de vente montrant la date.

5. Décrivez le problème.

6. Expédiez l'appareil en por t payé à l'adresse suivante : Centre de service tech-

nique, 17291, Mt. Herrmann Street, Fountain Valley, CA 92708 U.S.A.

Téléphone : 1-800-544-4124 ou 714-241-6805 Télécopieur : 714-432-7910

Internet : www.iEQUUS.com Courriel: service@iEQUUS.com

GARANTIE LIMITÉE ET SERVICE

Figure 3. Raccordement de la jauge indiquant le rapport d'air et de carburant

La devanture de chaque jauge de mesure du rapport d'air et de carburant a

deux colonnes de 10 DEL de couleur. Chaque DEL réagit à un signal de tension de sortie particulier en provenance du détecteur d'oxygène. Les couleurs

des DEL représentent l'état de rapport actuel d'air et de carburant; le rouge

indique une condition «LEAN» (pauvre); le vert indique une condition OPTIMALE et jaune indique une condition RICHE.

La jauge indiquant le rapport d'air et de carburant devrait changer suivant les

conditions de conduite (voir ci-dessous) :

■■

Au moment où le moteur se réchauffe, il f onctionne en mode RICHE jusqu'à

ce que le détecteur d'oxygène parvienne à sa température de fonctionnement. Le détecteur d'oxygène ne se met pas en marche avant de parvenir à 600 ° F au moins.

■■

Aux vitesses de croisière, la tension de sortie du détecteur d'oxygène

change constamment. Les DEL de la jauge s'allument en conséquence,

passant d'un mode légèrement pauvre à un mode légèrement riche. Ce

mode de fonctionnement est considéré comme OPTIMAL (normal).

■■

Lorsque le véhicule accélère rapidement, l'ordinateur du véhicule enrichit le

mélange d'air et de carburant. La jauge indique cet état d'alimentation très

riche en passant principalement dans le secteur RICHE (DEL jaune).

■■

Au moment de la décélération, l'ordinateur coupe la plus grande partie du

carburant parvenant au moteur. La jauge indique un état très pauvre en

passant vers le secteur «LEAN» (pauvre) (DEL rouges).

IMPORTANT: Les quatre modes de fonctionnement décrits ci-dessus

représentent un moteur fonctionnant normalement et le système normal

de gestion du moteur.Ces conditions sont considérées comme normales.

FONCTIONNEMENT DE LA JAUGE (voir la Figure 4)

5

Si le moteur fonctionne en mode RICHE ou PAUVRE la plus grande partie du temps, même aux vitesses de croisière, cela peut révéler la

présence d'un problème. Faites une inspection visuelle des composants

du moteur pour voir si des tuyaux de vide seraient débranchés ou

défectueux ou si des composants seraient brisés. Consultez votre

manuel de réparation du véhicule pour faire les vérifications appropriées

concernant l'état en question.

Figure 4. Fonctionnement de la jauge

JAUGE DE RAPPORT D'AIR

ET DE CARBURANT

S

BONNE MISE À LA MASSE

SUR LE CHÂSSIS/BATTERIE

MISE À LA MASSE DU SIGNAL

DÉTECTEUR

D'OXYGÈNE

RACCORDEMENT TYPIQUE À 4 CONDUCTEURS DANS UN

SYSTÈME À UN SEUL DÉTECTEUR D'OXYGÈNE

VERS LE PORTE-FUSIBLES ET

L'ALIMENTATION COMMUTÉE

GROSSE BORNE

SIGNAL

TENSION DE LA

CHAUFFERETTE

MISE À LA

MASSE DE LA

CHAUFFERETTE

DU DÉTECTEUR

(PCM)

ORDINATEUR

DU VÉHICULE

JAUGE DE RAPPORT D'AIR

ET DE CARBURANT

S

BONNE MISE À LA MASSE

SUR LE CHÂSSIS/BATTERIE

DÉTECTEUR

D'OXYGÈNE

DÉTECTEUR

D'OXYGÈNE

RACCORDEMENT TYPIQUE À 4 CONDUCTEURS DANS UN

SYSTÈME À DEUX DÉTECTEURS D'OXYGÈNE

MISE À LA MASSE DU SIGNAL

VERS LE PORTE-FUSIBLES ET

L'ALIMENTATION COMMUTÉE

PETITES BORNES

SIGNAL

MISE À LA MASSE

DU SIGNAL

SIGNAL

TENSION DE LA

CHAUFFERETTE

(PCM)

ORDINATEUR

DU VÉHICULE

MISE À LA

MASSE DE LA

CHAUFFERETTE

DU DÉTECTEUR

Page 5

INSTRUCCIONES DE INSTALACIÓN

INDICADOR DE RELACIÓN AIRE / COMBUSTIBLE

PREPARACIÓN PARA LA INSTALACIÓN

2

© 2004 IEC - Derechos Reservados MRP #93-0038

1. Lea completamente las instrucciones antes de la instalación. Busque con-

sejo profesional si no está familiarizado con la instalación de instrumentos

de vehículos o con las funciones de los sistemas relacionados del vehículo.

2. Instale calibradores sólo cuando el motor esté frío y la ignición esté apa-

gada.

3. Asegúrese que estén disponibles todas las herramientas, partes y materi-

ales necesarios.

4. Siempre lea el manual de servicio del vehículo y siga las precauciones de

seguridad antes de realizar cualquier procedimiento de prueba o de servicio.

5. Desconecte el cable negativo (-) de la batería antes de instalar los indi-

cadores (no se olvide de conectar la batería después de terminar la

instalación).

NOTA: Después de volv er a conectar la batería quizá sea necesario v olver a

programar el radio, el reloj, etc.

Al seleccionar una ubicación para instalar el indicador, tome en cuenta que los

cables de señales del indicador deben pasarse a través del mamparo contra

incendios al efectuar las conexiones del indicador. Elija una ubicación que

permita pasar el cableado del indicador a través de un ojal existente en el

mamparo contra incendios.

Si no hubiese accesible un ojal existente en el mamparo contra incendios, taladre un orificio de 3/8" (9,5 mm) a través del mamparo.Instale un ojal de goma

(se compra por separado) en el orificio taladrado, para proteger los cab les conductores contra la fricción u otro tipo de daño.

A. INSTALACIÓN EN PANEL

Para montaje sobre el tablero o debajo del

tablero de instrumentos (el panel es opcional

con algunos modelos de indicadores y se debe

comprar por separado).

1. Determine la ubicación de montaje para el indi-

cador.

2. Utilice el panel de indicadores como plantilla

para marcar la ubicación de los tornillos.

3. Taladre or ificios pequeños para los tornillos y fije

el panel con los tornillos y arandelas planas suministradas.

MONTAJE E INSTALACIÓN

3

B. OPCIÓN DE MONTAJE EMPOTRADO EN EL TABLERO DE INSTRU-

MENTOS

1. Determine una ubicación en el tablero de instrumentos que pueda cortarse

sin hacer contacto con objeto alguno detrás del tablero.

2. Con ayuda de una plantilla de orificios, corte un orificio de 1-1/2", 2" ó 25/8" (3,81 mm, 5,08 mm o 6,67 mm), según sea necesario, a través del

tablero.

3. Con una lima circular, alise los bordes ásperos alrededor del orificio taladrado.

C. INSTALACIÓN DEL INDICADOR EN UN PANEL DE INDICADORES O

EMPOTRADO EN EL TABLERO

1. Introduzca el indicador a través del panel

frontal o en el hueco en el tablero.

2. Sujete la caja del indicador y gire el indicador según sea necesario, hasta que el

indicador quede debidamente colocado al

frente del tablero o panel.

3. Apriete el anillo de sujeción en el indicador

en dirección horario hasta que el indicador

esté apretado en el tablero o panel.Apriete

el anillo de sujeción SÓLO CON LA

FUERZA DE LA MANO.

Figura 1. Panel de

indicadores

Figura 2. Indicador

equipado con anillos

de sujeción

Instale el Indicador Aire/Combustible según se describe en la Sección 3, MONTAJE E INSTALACIÓN.

Consulte la Figura 3 (en la contraportada) y efectúe las conexiones del indicador de la siguiente manera.

NOTA: No se suministra el cableado con el conjunto del indicador. Es necesario comprar por separado el cable y los conectores que se adapten a su

instalación particular. Use cable de cobre entorchado AWG calibre 20-22.

1. Después de determinar la longitud necesaria del cable,

2. Engarce o solde los terminales hembra de bayoneta de 1/4" (6,35 mm)

(incluidos) en un extremo de los cables de positivo (+) y negativo ( ) del

indicador.

3. Conecte los cables positivo y negativo a los postes de ba y oneta positivo (+)

y negativo ( ).

4. Acople el cable del conductor negativo ( ) a un buen sitio de conexión a tierra en el chasis (metal descubierto).

5. Conecte el cable conductor positivo (+) a una fuente eléctrica positiva de

12 V conmutada (energizada únicamente cuando la llave de la ignición se

coloca en la posición On).

6. Conecte los cables de señal al indicador y al cicuito de SEÑAL del sensor

de oxígeno en el vehículo .Consulte la Figura 3 (en la contraportada) y efectúe las conexiones del indicador de la siguiente manera.

CONEXIÓN DEL INDICADOR

4

■■

Si su vehículo tiene únicamente un sensor de oxígeno pre-convertidor

catalítico, engarce o solde un cable al terminal de bayoneta grande

(incluido con el conjunto del indicador) y conecte el terminal sobre los

dos postes de señal pequeños de bayoneta, machos, en la parte posterior del indicador. Conecte el otro extremo del cable al circuito de

señal del sensor de oxígeno.Esto permite que los LED en ambos lados

del indicador muestren la relación aire/combustible para un sensor de

oxígeno.

■■

Si su vehículo está equipado con dos sensores de oxígeno pre-convertidor catalítico, engarce o solde dos cables a los dos terminalespequeños de bayoneta hembra (incluidos en el conjunto de indicador),y

conecte los terminales a los dos postes de señal pequeños de bayoneta,hembra, en la parte posterior del indicador. Empalme uno de los

extremos flojos de los alambres de señal del indicador al circuito de la

señal del sensor del oxígeno en el banco #1 del motor, empalme el otro

alambre de la señal al circuito de la señal del sensor del oxígeno enel

banco #2 del motor.Esto permite que los LEDs al lado derecho del indicador exhiban la proporción de aire/combustible para el sensor de

oxígeno del banco 1 y los LEDs en el lado izquierdo del indicador

exhiban la proporción de aire/combustible para el sensor de oxígeno

del banco 2 (véase la figura 3).

PRECAUCIÓN: Algunos sensores de oxígeno utilizan cables apantallados.Efectúe sus conexiones de cable de SEÑAL en el circuito de señales,

lejos del cable apantallado y después del conector del sensor de oxígeno.

NO efectúe conexiones en el cable apantallado mismo.

INTRODUCCIÓN

1

El Indicador de Relación Aire/Combustible lee e interpreta las señales de salida de voltaje desde los sensores de oxígeno del vehículo para ofrecer una

indicación de la relación aire/combustible al conducir; ya sea Optimal (Ópti-

ma), Lean (Pobre) o Rich (Rica).

IMPORTANTE: El indicador de Relación Aire/Combustible está diseñado para

funcionar en combinación con el sensor de oxígeno existente en el vehículo. El

indicador funcionará SÓLO con los sensores de oxígeno que generan señales

de salida de voltaje de 0 a 1 volt.Consulte en el manual de servicio de su vehículo las especificaciones de voltaje de funcionamiento del sensor de oxígeno.

Si su vehículo no está equipado con este tipo de sensor, o no está equipado con

ningún tipo de sensor, quizá sea posible instalar un sensor de oxígeno calentado de posventa. Consulte a un profesional para determinar si se puede instalar

en su vehículo un sensor de oxígeno compatible.

7.0

7.0

ANILLO DE

SUJECIÓN

Page 6

© 2004 IEC - Derechos Reservados

CONEXIÓN DEL INDICADOR (Continuación)

4

El fabricante garantiza al comprador original que esta unidad está exenta de

defectos en materiales y mano de obra por un período de un (1) año a partir de

la fecha de compra original. Si la unidad falla en un período de un (1) año, se

reemplazará o se reparará, a opción del Fabricante, sin cargo adicional alguno,

cuando se devuelva con porte prepagado al Centro de Servicio Técnico acompañada del comprobante de pago. El recibo de compra puede usarse para este

propósito.La mano de obra no tiene cobertura en virtud de esta garantía.

Todas las partes de repuesto, sean nuevas o reconstruidas, asumirán como su

período de garantía sólo el plazo restante de esta garantía. Esta garantía no

cubre daños causados por uso indebido, accidental, abusivo, o si el producto

fue modificado o reparado por alguien ajeno al Centro de Servicio Técnico del

Fabricante.Los daños consecuentes o incidentes no son recuperables en virtud de esta garantía. Algunos estados no permiten la exclusión o la limitación

de los daños incidentes o consecuentes, así que la limitación o exclusión anterior quizá no sea aplicable a su caso.

Esta garantía le otorga derechos legales específicos, y usted quizá pueda

tener otros derechos, los cuales varían de estado a estado. No se permite

copiar ni duplicar porción alguna de esta garantía sin el consentimiento expreso y escrito del Fabricante.

Asistencia técnica y Servicio de garantía

Los productos que requieran servicio deberán devolverse de la manera siguiente:

1. Llame al Centro Servicio Técnico para obtener un Número de Referencia de

Devolución.

USA & Canada = 1-800-544-4124

Otro = 714-241-6805

2. Embale cuidadosamente el producto para evitar daños durante el envío.

3. Incluya su nombre, el remitente y un teléfono disponible en horas hábiles.

4. Adjunte una copia del recibo de compra fechado.

5. Describa el problema.

6. Envíe el producto con porte pagado a: Technical Service Center, 17291 Mt.

Herrmann Street, Fountain Valley, CA 92708 U.S.A.

Para recibir Asistencia técnica y/o Servicio de garantía, sírvase dirigirse a:

Teléfono: EE.UU. y Canadá 1-800-544-4124; otros países: 714-241-6805

(E.U.A.); Fax 714-432-7910 (E.U.A.); Inter net: www.iEQUUS.com; correo electrónico: service@iEQUUS.com

Para garantía en México ver con distribuidor.

GARANTÍA LIMITADA Y PROCEDIMIENTOS DE SERVICIO

Figura 3. Conexiones del Indicador de Relación Aire/Combustible

El cuadrante del Indicador de Aire/Combustible tiene dos columnas de 10 LED

de colores. Cada LED se ilumina en respuesta a un nivel de señal de voltaje

de salida específico de los sensores de oxígeno.Los colores en el LED representan la condición actual de la relación aire/combustible; el Rojo indica una

condición de mezcla LEAN (POBRE), el Verde indica OPTIMAL (ÓPTIMO), y

el Amarillo indica una condición RICH (RICA).

Las lecturas en el Indicador de Relación Aire/Combustible deben cambiar,

dependiendo de las condiciones de manejo existentes, según se describe a

continuación:

■■

Durante el calentamiento del motor, el motor funciona en modo RICH hasta

que el sensor de oxígeno alcanza la temperatura de funcionamiento. El

sensor de oxígeno no funciona antes de alcanzar una temperatura mínima

de 600 °F (315 ºC).

■■

A velocidad de crucero, el voltaje de salida del sensor de oxígeno fluctúa

continuamente. Los LED del indicador se iluminan proporcionalmente,

efectuando ciclos entre mezcla levemente pobre y levemente rica. Esta

condición se considera como funcionamiento ÓPTIMO (normal).

■■

Cuando se acelera rápidamente el vehículo, la computadora del vehículo

enriquece la mezcla aire/combustible. El indicador muestra esta condición

muy rica al gravitar principalmente en el área RICH (LED Amarillo).

■■

Al desacelerar, la computadora corta la mayoría del combustible al motor.

El indicador muestra esta condición muy pobre al gravitar hacia el área

LEAN (LED Rojo).

IMPORTANTE: Las cuatro condiciones de funcionamiento descritas anteriormente representan un motor funcionando normalmente y un sistema

FUNCIONAMIENTO DEL INDICADOR (Ver la figura 4)

5

de manejo del motor. Estas condiciones se consideran normales. Si

existe una condición en la que el motor funcione en las áreas RICH o

LEAN la mayor parte del tiempo, incluso a velocidad de crucero, puede

ser indicativo de un problema.Inspeccione visualmente los componentes

en el compartimiento del motor para verificar que no haya mangueras de

vacío defectuosas o desconectadas, o componentes rotos. Consulte el

manual de reparación del vehículo para realizar las pruebas apropiadas

relacionadas con esa condición particular.

Figura 4. Funcionamiento del Indicador

INDICADOR DE RELACIÓN

AIRE / COMBUSTIBLE

S

BUENA CONEXIÓN A TIERRA EN

EL CHASIS O EN LA BATERÍA

CONEXIÓN A TIERRA DE LA SEÑAL

SENSOR DE

OXÍGENO

SENSOR DE OXÍGENO TÍPICO DE 4 CABLES

CONEXIÓN DE UN SOLO SENSOR

AL PANEL DE FUSIBLES U OTRA FUENTE

DE ALIMENTACIÓN ELÉCTRICA CONMUTADA

TERMINAL GRANDE DE BAYONETA

SEÑAL

COMPUTADORA

DEL

VEHÍCULO

(PCM)

VOLTAJE DEL

CALENTADOR

CONEXIÓN A TIERRA

DEL CALENTADOR

DEL SENSOR

INDICADOR DE RELACIÓN

AIRE / COMBUSTIBLE

S

BUENA CONEXIÓN A TIERRA EN

EL CHASIS O EN LA BATERÍA

SENSOR DE

OXÍGENO

SENSOR DE

OXÍGENO

SENSOR DE OXÍGENO TÍPICO DE 4 CABLES

CONEXIÓN DE SENSOR DOBLE

CONEXIÓN A TIERRA DE LA SEÑAL

AL PANEL DE FUSIBLES U OTRA FUENTE

DE ALIMENTACIÓN ELÉCTRICA CONMUTADA

TERMINALES DE BAYONETA PEQUEÑOS

SEÑAL

CONEXIÓN A TIERRA

DE LA SEÑAL

SEÑAL

COMPUTADORA

DEL

VEHÍCULO

(PCM)

VOLTAJE DEL

CALENTADOR

CONEXIÓN A TIERRA

DEL CALENTADOR

DEL SENSOR

Loading...

Loading...