Page 1

INSTALLATION INSTRUCTIONS

PERFORMANCE T A CHOMETER

PREPARATION BEFORE INSTALLATION

1

This section contains important preliminary information. Read this section

FIRST before proceeding with installation.

Safety Precautions

To prevent personal injury, damage to the vehicle and/or the tachometer, read

these instructions completely and observe the following safety precautions:

■ Always consult the vehicle's service manual and follow its safety precau-

tions before installing this gauge.

■ To prevent burns, install the tachometer only when the engine is cool.

■ The vehicle's exhaust is very toxic , to pre vent serious injury or death always

run the vehicle in a well ventilated area.

■ When an engine is running, cooling fans, pulleys, belts, etc.rotate at a very

high rate of speed.ALWAYS be aware of moving/rotating parts, and keep a

safe distance away from these items.

■ Disconnect the negative (-) battery cable before installing and/or making

tachometer connections.

NOTE:It may be necessary to reprogram your radio, clock, etc.after reconnecting the battery.

■ ALWAYS insulate wire splices with shrink tubing to prevent shorting.

Applications

This tachometer is compatible with 12 volt negative (-) ground systems ONLY,

and will work on most of the following ignition systems:

■ DISTRIBUTOR EQUIPPED - 4 cycle ignition systems

■ DISTRIBUTORLESS (DIS) and other 2 cycle Ignition Systems - these

type of systems are no longer equipped with distributors.

NOTE:This tachometer may not work on some vehicles with the following ignition systems:

■ Multiple Spark Ignition Systems: Consult manufacturer and/or instruc-

tions on how to connect a tachometer to these systems.

■ Direct (coil on plug) Ignition Systems: Consult the vehicle’s service

manual to determine if an adequate tachometer signal connector is available for connecting an aftermarket tachometer.

■ Determine a mounting location for the tachometer.Choose a location that

does not impair visibility, or interfere with driving. Check behind the

mounting location for any wiring or components before drilling.Ensure that

all the tachometer wires can be routed properly to their specific locations

from the mounting location chosen.

On-Dash or Under-Dash

Mounting

1. Install the base mount and secure

with screws, washers and nuts provided.

2. Install the ring clamp type mount to

the tachometer body.

3. Using the spacer and bolts provided,

secure the tachometer and ring clamp

type mount assembly to the base

bracket.SEE FIGURE 1.

4. Proceed to section 3 for tachometer

connection.

MOUNTING THE T A CHOMETER

2

Figure 1

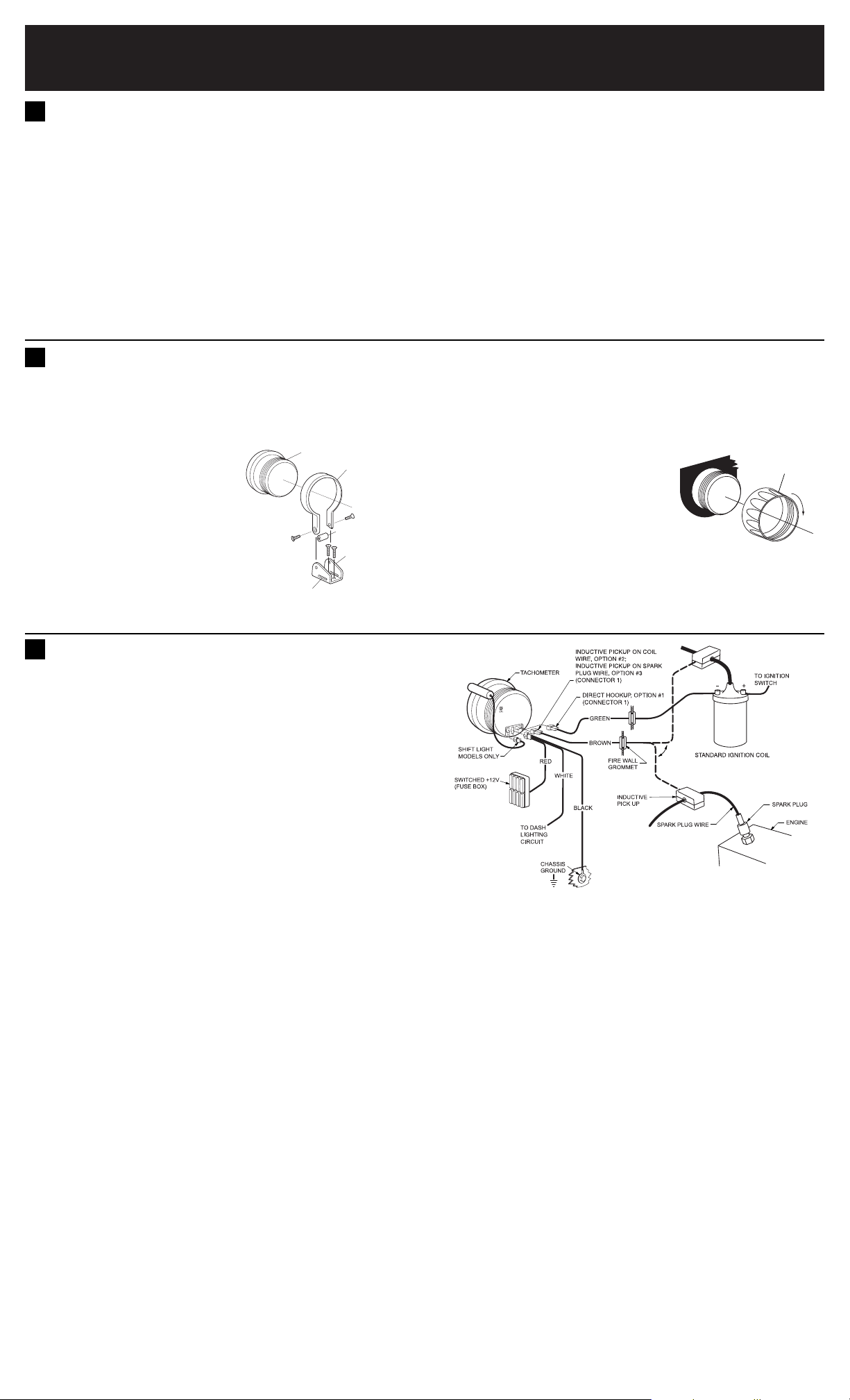

TACHOMETER CONNECTIONS

3

Power and Ground Connections (Figure 3)

1. Plug the 3-pin power connector (RED, BLACK and WHITE wires) into the

#2 connector on back of the tachometer.

2. Connect the tachometer's power (RED) wire to a switched +12 volt circuit

at fuse box, or splice into a vehicle harness wire that has voltage ONLY

when the ignition key is turned to the "ON" (RUN) position.

3. Crimp or solder a terminal lug on the ground (BLACK) wire, and connect to

a clean, bare spot on the vehicle's metal frame.

4. Connect the tachometer's lighting (WHITE) wire to the instr ument panel

light circuit (consult vehicle's repair manual for wiring diagrams). Proceed

to tachometer signal hookup.

NOTE:To install the light bulbs, use needle nose pliers to insert the bulb in the

bulb receptacle on back of gauge, then twist clockwise ¼ turn to lock into place .

Gauge backlighting color may be changed to RED, GREEN or BLUE by

installing the desired color filter over the bulb (not available for all gauge kits).

Tachometer Signal Hookup

This Performance Tachometer lets you use one of three options (described

below) to pick up a tachometer signal from the vehicle's ignition system.

Choose the option best suited for your vehicle/system and proceed to the

appropriate "Connection Instructions".

NOTE: Due to the various ways the tachometer signal on this type of system is

processed; this tachometer is compatible with some but not all "Coil On Plug"

systems.

1. OPTION #1 - Direct Hookup with GREEN Wire - the GREEN tachometer

wire is connected directly to the vehicle's "Ignition System Tachometer

Signal Port".

■ Use this option on any vehicle/ignition system where a suitable

tachometer port is available (including Conventional, Distributorless,

and Coil-on-Plug ignition systems).

2. OPTION #2- Inductive Pick-Up on Ignition Coil Wire - the Inductive Pick-

Up is clamped around the "Ignition Coil Wire" to pickup a tachometer signal inductively.

■ Use this option on any vehicle with a Conventional(distributor-equipped)

ignition system with an exposed coil wire where a suitable tachometer

signal port is not available or not easily accessible.

3. OPTION #3- Inductive Pick-Up on Spark Plug Wire - the Inductive Pick-

Up is clamped around one of the "Spark Plug Wires" to pickup a tachometer signal inductively.

■ Use this option on vehicles with Conventional (distributor equipped) or

Distributorless Ignition Systems-DIS where the Direct Hookup Option

cannot be used because a suitable tachometer signal port is not available or not easily accessible.

Connection Instructions for OPTION #1 - Direct Hookup

with GREEN Wire

1. Connect the GREEN wire to the negative side of the ignition coil, or to a

suitable tachometer signal port as follows (see Figure 3):

A. Plug the tachometer signal GREEN wire 4-pin female connector into the

4-pin connector #1 on back of tachometer.

B. Use an existing firewall grommet, or drill a 3/8-inch (9,5 mm) hole through

firewall.Install a grommet in hole and route the GREEN lead wire from the

tachometer through grommet and into the engine compartment.

C. For conventional 4-cycle and Coil on Plug ignition systems, connect the

GREEN wire to the negative side of the ignition coil (on Coil-On-Plug

Systems, make the connection to the negative side of oneof the coils only).

D. For Distributerless ignition systems make the connection to a suitable

tachometer signal port.

2. Proceed to the "CYLINDER SETTING INSTRUCTIONS" section to adjust

the tachometer to the proper Cylinder/RPM setting for the "Direct Hookup

with GREEN Wire” option.

Connection Instructions for OPTION #2 - Inductive Pick-Up

on Ignition Coil Wire

1. Connect the Inductive Pick-Up to the Ignition Coil Wire as follows (see

Figure 3):

A. Use an existing firewall grommet, or drill a 3/8-inch (9,5 mm) hole

through firewall. Install a grommet in hole and route the Inductive PickUp 4-pin female connector from the engine compartment side through

grommet and to the tachometer.

NOTE: The Inductive Pick-Up lead wire is a special shielded wire. DO

NOT cut the wire.

B. Plug the 4-pin Inductive Pick-Up connector into the 4-pin connector #1

on back of tachometer.

C. Remove the screw and nut from the Inductive Pick-Up Clamp.

D. Find the Ignition coil wire, and clamp the Inductive Pick-Up around the

wire.Make sure that the arrow stamped on the Inductive Pick-Up clamp

points toward the distributor.

E. Re-install the screw and nut to secure the inductive pick up clamp on to

the ignition coil wire.

2. Proceed to the "CYLINDER SETTING INSTRUCTIONS" section to adjust

the tachometer to the proper Cylinder/RPM setting for the "Inductive PickUp on Ignition Coil Wire” option.

© 2004 IEC - All Rights Reserved MRP #93-0012 Rev. B

Figure 3

In-Dash Mounting

1. Determine a location on the dashboard that can be cut out without striking

any objects behind the dash.

2. Using a hole template, cut out a 1-1/2" (3,8 cm), 2" (5,1 cm) or 2-5/8"(6,7

cm) hole, as necessary, through the dashboard.

3. Using a round file, smooth out the rough

edges around the drilled hole.

4. Insert gauge through in dashboard.

5. Hold gauge case and rotate gauge, as

needed, until gauge dial face is properly

positioned in front of dashboard.

6. Tighten locking ring on gauge in clockwise

direction until gauge is tight against dashboard. Tighten locking ring HAND TIGHT

ONLY.SEE FIGURE 2.

Figure 2

1.0

1.0

Tachometer

Ring Clamp Type Mount

Threaded Spacer

Base Mount

Opening for Steering Column Mount

LOCKING

RING

--or--

Page 2

TACHOMETER CONNECTIONS (Cont)

3

Connection Instructions for OPTION #3 - Inductive Pick-Up

on Spark Plug Wire

1. Connect the Inductive Pick-Up to a spark plug wire as follows (see Figure 3):

A. Use an existing firewall grommet, or drill a 3/8-inch (9,5 mm) hole

through firewall. Install a grommet in hole and route the Inductive PickUp 4-pin female connector from the engine compartment side through

grommet and to the tachometer gauge.

NOTE: The Inductive Pick-Up lead wire is a special shielded wire. DO

NOT cut the wire.

B. Plug the 4-pin Inductive Pick-Up connector into the 4-pin connector #1

on back of tachometer.

C. Remove the screw and nut from the Inductive Pick-Up Clamp.

D. Find a spark plug wire, and clamp the Inductive Pick-Up around the

wire.Make sure that the arrow stamped on the Inductive Pick-Up clamp

points toward the spark plug.

E. Re-install the screw and nut to secure the inductive pick up clamp on to

the spark plug wire.

2. Proceed to the "CYLINDER SETTING INSTRUCTIONS" section to adjust

the tachometer to the proper Cylinder/RPM setting for the "Inductive Pick- Up

on Spark Plug Wire” option.

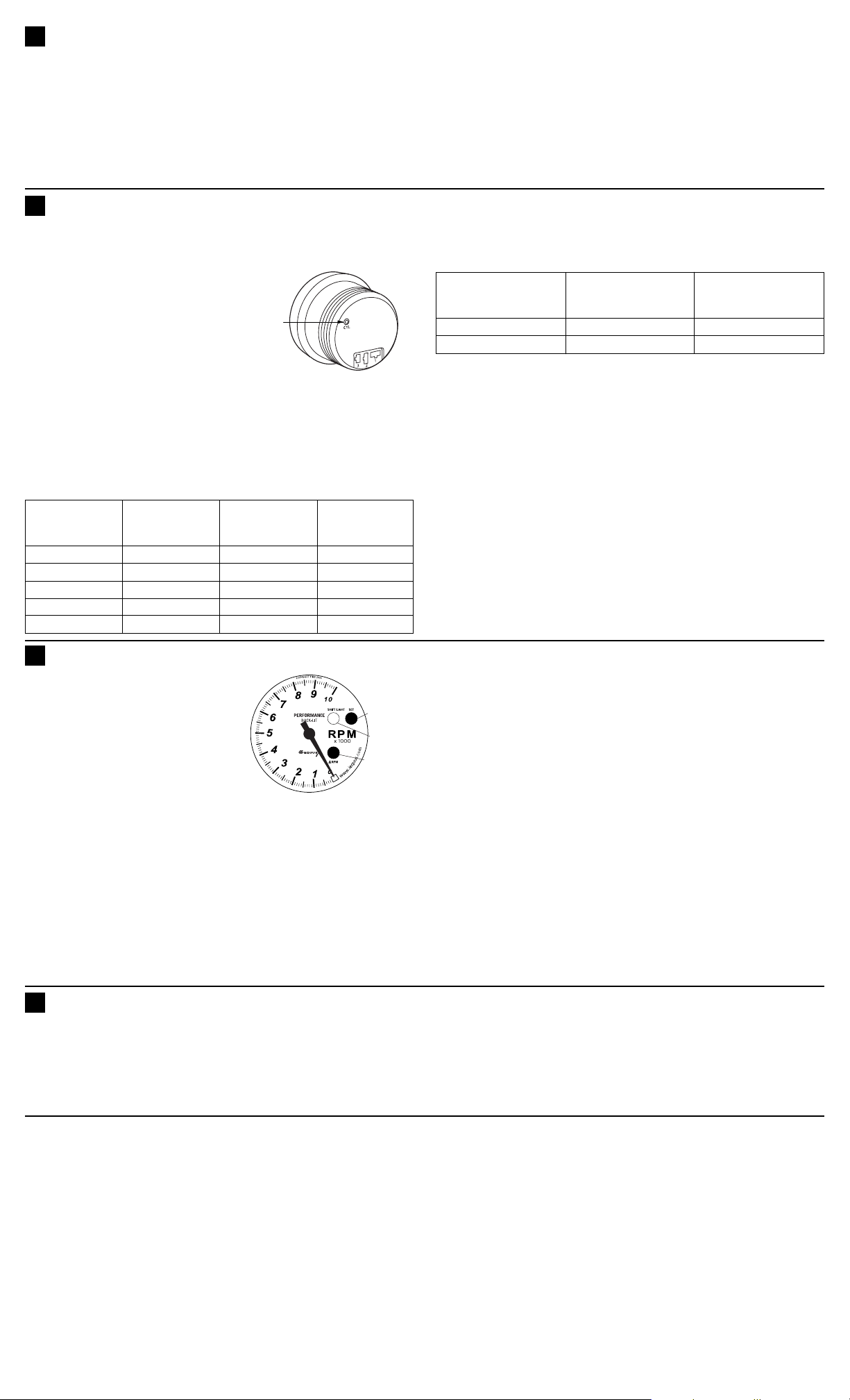

Shift Light Operation and Setting

The shift light can be used to provide a visual indication of engine "Red Line" (maximum

safe engine speed) or optimum gear shifting

engine speed (to improve vehicle performance when shifting gears). See Figure 5.

Setting Shift RPM

1. With the ignition key in the "ON" posi-

tion and the engine "OFF" (not running), press and hold down the shift

light set button.After about 4~5 seconds, the needle will start moving up the

display. Continue holding the shift button down and proceed to step 2.

2. When the tachometer’s needle indicates the desired "shift RPM speed" on

the display, release the shift light set button. The "shift RPM " is now set in

the tachometer's memory, and the shift light will illuminate every time the

needle reaches or exceeds the set "shift RPM ".

3. After the "shift RPM " is set, press and release the shift light set button to

return to the normal tachometer operating mode.

4. To check the shift light RPM setting, press and release the shift light set button. Press and release again to retur n to normal tachometer operation. If

the "shift RPM setting" needs to be changed, repeat steps 1~3.

SHIFT LIGHT/RPM RECALL OPERATION (For Shift Light/RPM Recall Tachometers Only)

5

Peak RPM Recall Function

This function saves the highest (peak) RPM that was achieved during a trip in

the tachometer's memory and gives the operator the ability to recall this information at any time.

To view the peak RPM value stored in recall memory, press and release the

RPM recall button. Press and release again to return to normal operation.

NOTE: The Peak (highest) RPM achieved during a trip will remain in the

tachometer’s memory until overwritten by a higher RPM valu, or until the memory is cleared by the operator.

Clearing Peak RPM from Tachometer's Memory

1. Press and release the RPM recall button to place the tachometer in RPM

recall mode. The needle should r ise and remain at whatever value is in

Recall Memory.

2. While tachometer is in RPM Recall mode, press and hold the RPM Recall

button. Within 3 ~ 4 seconds, the tachometer’s needle will begin to move

down.Wait until the needle reaches zero, then release the RPM Recall b utton.The RPM Recall memory is now cleared, and the tachometer will begin

saving the highest (peak) RPM reached during the next trip.

Figure 5

If the tachometer does not function, or functions erratically , perf orm the follo wing:

■ Ensure that the ignition system is in good working order in accordance with

the vehicle manufacturer’s specifications. If the ignition system is in good

working order but you still experience erratic readings, the tachometer may

be picking up Electromagnetic Interference (EMI).Try re-routing the Inductive

Pick-Up lead wire or the GREEN tachometer signal wire (whichever is applicable) away from all other spark plug wires, ignition coils and the alternator.

TROUBLESHOOTING

6

■ If the Inductive Pick-Up option is being used, reverse the direction of the

Inductive Pick-Up clamp on the spark plug wire so the arrow points away

from the spark plug. If this is unsuccessful, tr y moving the Inductive PickUp clamp to a different location on the spark plug wire, or to a different

spark plug wire.

For further assistance, contact the Technical Service Center.

The Manufacturer warrants to the original purchaser that this unit is free of defects

in materials and workmanship for a period of one (1) year from the date of original

purchase.If the unit fails within the one (1) year period, it will be repaired or replaced,

at the Manufacturer's option, at no charge, when returned prepaid to the Technical

Service Center with Proof of Purchase. The sales receipt may be used for this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or re-manufactured, assume as their warranty

period for only the remaining time of this warranty. This warranty does not apply to

damage caused by improper use, accident, abuse, or if the product was altered or

repaired by anyone other than the Manufacturer's Technical Service Center.

Consequential and incidental damages are not recoverable under this warranty.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights,

which vary from state to state. No portion of this warranty may be copied or duplicated without the expressed written permission from the Manufacturer.

Technical Assistance and Warranty Service:

Products requiring service should be returned as follows:

1. Call the Technical Service Center to obtain a Return Reference Number:

2. Package the product carefully to prevent shipping damage

3. Include your name, return address, and a day contact phone

4. Enclose a copy of the dated sales receipt

5. Describe the problem

6. Ship prepaid to: Technical Service Center, 17291 Mt. Herrmann Street, Fountain

Valley, CA 92708 U.S.A.

For Technical Assistance/Warranty Service, contact us at:

Phone: USA & Canada 1-800-544-4124, Others 714-241-6805; Fax:

714-432-7910; Web: www.iEquus.com;Email: service@iEquus.com

LIMITED WARRANTY AND SERVICE PROCEDURES

© 2004 IEC - All Rights Reserved

CYLINDER SETTING INSTRUCTIONS

4

The tachometer's CYL setting must be adjusted to match the tachometer's

internal settings to the RPM signal received from the vehicle's ignition system.

Adjust the settings as follows:

1. Make sure the tachometer power and

ground wires are connected to the vehicle, and the 3-pin connector is plugged

into the #2 connector on back of the

tachometer.

2. Remove power from the tachometer

(turn ignition switch off). Press and hold

the CYL button (small RED button on

rear of tachometer, see Figure 4), then

apply power to the tachometer (turn ignition switch on).

3. Press and release the CYL button as many times as required until the

tachometer's needle points to the correct RPM for the signal hookup option

used.

■ Use the settings in Table 1 if "OPTION #1- Direct Hook Up with GREEN

Wire" or "OPTION #2 -Inductive Pick-Up on Coil Wire” is being used.

Figure 4

Table 1.Tachometer Cylinder Setting Table (OPTION #1 and #2)

Set tachometer Set tachometer

No. of Cylinders needle to read No. of Cylinders needle to read

on vehicle (RPM) on vehicle (RPM)

1 500 6 3000

2 1000 8 4000

3 1500 10 5000

4 2000 12 6000

5 2500 Coil on Plug 500

■ Use the settings in Table 2 if "OPTION #3 - Inductive Pickup on Spark

Plug Wire" is being used.

4. When the correct cylinder setting is obtained, turn the ignition off.The cylin-

der setting is now saved in the tachometer's memory, and will remain until

changed.To change the setting, repeat steps A through D.

5. Proceed to "Tachometer Operational Checkout" to finish installation.

Tachometer Operational Checkout

1. Turn on ignition. DO NOT START ENGINE.Tachometer pointer should rotate

to "0" when ignition is turned on.

NOTE: This tachometer utilizes an "Air Core Movement".With this type of

movement, the needle will remain (point) at whatever position it was in (not

necessarily zero) at the time the power to the tachometer was removed.

This behavior is normal for this type of needle movement. The needle

should return to zero when power is reapplied to the tachometer.

2. Start and run engine. Rev engine se veral times and verify tachometer indication changes as RPM increases and decreases. If tachometer fails to operate, or operates erratically, consult the Troubleshooting section for troubleshooting details.

Table 2.Tachometer Cylinder Setting Table (OPTION #3)

Set tachometer

No. of Cylinders needle to read

Ignition Type on vehicle (RPM)

Conventional All 500

DIS All 1000

CYL

BUTTON

Shift Light

Set Button

Shift Light

RPM Recall

Button

Page 3

INSTRUCTIONS D'INSTALLATION

TACHYMÈTRE DE RENDEMENT

PRÉPARATION ANTÉRIEURE À L'INSTALLATION

1

Cette section contient des renseignements préliminaires importants. Lisez cette section EN PREMIER, avant d'entreprendre l'installation.

Mesures de sécurité

Pour prévenir les b lessures et les dommages au véhicule et (ou) au tach ymètre ,lisez

ces instructions en entier et observez les mesures de sécurité décrites ci-dessous :

■ Consultez toujours le manuel de service du véhicule et observez les mesures

de sécurité qui y sont présentées avant d'installer cette jauge.

■ Pour prévenir les brûlures , installez le tachymètre uniquement lorsque le moteur

est froid.

■ Les émanations en provenance du véhicule sont très toxiques;pour prévenir les

blessures graves , v oire un décès , ne laissez jamais le moteur en marche si l'aire

de travail n'est pas très bien ventilée.

■ Lorsque le moteur est en marche, le ventilateur du système de refroidissement, les

poulies, les courroies, etc.tournent à très grande vitesse. Il faut TOUJOURS être vigilant face aux pièces mobiles/rotatives et se ternir à distance sûre de ces composants.

■ Débranchez le câble de la borne négative (-) de la batterie avant d'installer et

(ou) de raccorder le tachymètre.

REMARQUE: Vous devrez peut-être reprogrammer votre radio, votre horloge,

etc. lorsque le câble de la batterie est rebranché.

■ Isolez TOUJOURS les épissures de câbles électriques à l'aide de tubes à rétré-

cissement pour éviter tout court-circuit.

Applications

Ce tachymètre est compatible avec les systèmes de mise à la terre négative (-) de

12 volts UNIQUEMENT; il peut être utilisé sur la plupart des véhicules et (ou) des

systèmes d’allumage :

■ VÉHICULES À DISTRIBUTEUR - Système d'allumage à quatre temps

■ Allumages SANS DISTRIBUTEUR (DIS) et autres systèmes à deux temps -

Ces systèmes n'ont plus de distributeur.

REMARQUE : Ce tachymètre pourrait ne pas fonctionner sur certains véhicules

ayant les systèmes d'allumage suivants :

■ Systèmes d'allumage à étincelles multiples - Consultez le fabricant et (ou)

les instructions pour savoir comment raccorder le tachymètre sur ces systèmes.

■ Systèmes à allumage direct (bobine sur la bougie) - Consultez le manuel de

service du véhicule pour déterminer si un connecteur de signal adéquat pour le

tachymètre est disponible pour raccorder un tachymètre en provenance du

marché secondaire.

■ Déterminez l'emplacement de montage du tachymètre. Choisissez un endroit

qui ne nuira pas à la visibilité ni à la conduite.Vérifiez derrière l'emplacement

choisi pour le montage pour voir s'il y a des fils électriques ou des composants

avant de percer l'orifice. Assurez-vous que tous les fils du tachymètre peuvent

être acheminés comme il se doit jusqu'à leur emplacement particulier à partir de

l'endroit choisi pour faire le montage.

Installation sur ou sous le tableau de

bord

1. Installez le base de montage et fixez-le à l'aide

des boulons, des rondelles et des écrous.

2. Installez le bague de montage sur le corps du

tachymètre.

3. Utilisez la cale et les boulons fournis. Installez le

tachymètre et la bague sur le base de montage

(VOIR LA FIGURE 1).

4. Passez à la section 3 pour faire le raccordement

du tachymètre.

MONTAGE DU TACHYMÈTRE

2

Figure 1

RACCORDEMENT DU TACHYMÈTRE

3

Raccordement de l'alimentation et de la masse (Figure 3)

1. Branchez le connecteur d'alimentation à 3 broches (CONDUCTEURS ROUGE,

NOIR et BLANC) sur le 2e connecteur situé à l'arrière du tachymètre.

2. Branchez le conducteur d'alimentation (ROUGE) sur un circuit commuté positif

de +12 volts au niveau du porte-fusibles ou faites une épissure sur le faisceau

de câblage du véhicule qui est sous tension UNIQUEMENT lorsque la clé d'allumage est en position «ON» (fonctionnement).

3. Sertissez ou brasez une cosse sur le conducteur de mise à la terre (NOIR) et rac-

cordez cette cosse sur une pièce métallique nue et propre du châssis du véhicule.

4. Branchez le conducteur d'éclairage du tachymètre (BLANC) sur le circuit d'é-

clairage du tableau de bord (consultez le manuel de réparation du véhicule pour

avoir le schéma de câblage).Raccordez le tachymètre.

REMARQUE : Pour installer les ampoules électriques, utilisez des pinces à bec

effilé pour insérer l'ampoule dans la douille qui se trouve à l'arrière du tachymètre,

puis tournez de ¼ tour en sens horaire pour verrouiller l'ampoule en place. La

couleur de l'éclairage par l'arrière peut être ROUGE, VER TE ou BLEUE en installant

un filtre de couleur sur l'ampoule (non disponible sur toutes les trousses).

Raccordement sur le signal du tachymètre

Ce tachymètre de performance vous permet d'utiliser l'une de trois méthodes (voir

ci-dessous) pour capter le signal destiné au tachymètre à partir du système d'allumage du véhicule. Choisissez l'option qui convient le mieux à votre véhicule/système et suivez les instructions appropriées de raccordement.

REMARQUE : Compte tenu des différentes façons utilisées par ce tachymètre pour

traiter les signaux en provenance de ce système, ce tach ymètre est compatib le av ec

certains systèmes où la bobine est intégrée aux bougies, mais pas tous.

1. OPTION #1 - Raccordement direct avec le conducteur VERT - Le conducteur

VERT du tachymètre est branché directement sur le point du système d'allumage du véhicule produisant le signal destiné au tachymètre.

■ Utilisez cette option sur n'importe quel véhicule/système d'allumage où un

point convenable est disponible pour le tachymètre (y compr is les systèmes conventionnels, sans distributeur et à bobine sur la bougie).

2. OPTION #2- Capteur inductif sur le conducteur de la bobine d'allumage -

Le capteur inductif est installé sur le conducteur de la bobine d'allumage pour

recevoir le signal inductif destiné au tachymètre.

■ Utilisez cette option sur tout véhicule ayant un système d'allumage conven-

tionnel (avec distributeur) et un conducteur exposé menant à la bobine

lorsqu'aucun point producteur convenable de signal destiné au tachymètre

n'est disponible ou facilement accessible.

3. OPTION #3- Capteur inductif sur le câble de la bougie - Le capteur est instal-

lé sur un câble de bougie pour recevoir le signal inductif destiné au tachymètre.

■ Utilisez cette méthode sur les véhicules à système d'allumage convention-

nel (avec distributeur) ou sans distributeur où le raccordement direct ne peut

pas être utilisé parce qu'il n'y a pas de point producteur de signal convenable ou qu'il n'est pas facile d'accès.

Instructions de raccordement - OPTION #1 - Branchement direct

à l'aide du conducteur VERT

1. Branchez le conducteur VER T sur le côté négatifde la bobine d'allumage ou sur

un point producteur de signal convenable pour le tachymètre (voir la Figure 3).

A. Branchez le connecteur femelle à 4 broches du conducteur VERT du signal destiné

au tachymètre dans le connecteur #1 à 4 broches situé à l'arrière du tachymètre.

B. Utilisez un passe-fil existant de la cloison pare-feu ou perforez un trou de 3/8

po (9,5 mm) à travers la cloison pare-feu.Installez un passe-fil dans l'orifice et

insérez-y le conducteur VERT en direction du logement où se trouv e le moteur .

C. Pour les systèmes d'allumage conventionnels à 4 temps et les systèmes à

bobine sur la bougie, branchez le conducteur VERT sur le côté négatif de

la bobine d'allumage (système à bobine sur la bougie et faites le raccordement sur le côté négatif d'une des bobines uniquement).

D. Pour les systèmes sans distributeur, faites le raccordement sur un point pro-

ducteur de signaux convenable destinés au tachymètre.

2. Passez à la section «INSTRUCTIONS POUR LE RÉGLAGE DES PISTONS»

pour régler le tachymètre en fonction des pistons/régime du moteur dans le cas

d'un raccordement direct à l'aide du conducteur VERT.

Instructions de raccordement - OPTION #2 - Capteur inductif sur

le câble de la bobine d'allumage

1. Branchez le capteur inductif sur le câble de la bobine d'allumage tel que décrit

ci-après (voir la figure 3):

A. Utilisez un passe-fil existant à travers la cloison pare-feu ou perforez un trou

de 3/8 po (9,5 mm) dans la cloison pare-feu.Installez un passe-fil dans l'orifice et passez le connecteur femelle à 4 broches du capteur inductif en

provenance du logement où se trouve le moteur pour parvenir au

tachymètre en passant à travers la cloison pare-feu.

REMARQUE : Le conducteur du capteur inductif est un conducteur spécial

blindé. IL NE FAUT PAS couper le conducteur.

B. Branchez le connecteur du capteur inductif à 4 broches dans le connecteur

à 4 brochez #1 situé à l'arrière du tachymètre.

C. Retirez le boulon et l'écrou de la pince du capteur inductif.

D. Trouvez le conducteur de la bobine d'allumage et installez le capteur induc-

tif sur le conducteur.Assurez-vous que la flèche estampillée sur la pince du

capteur inductif est orientée vers le distributeur.

E. Réinstallez le boulon et l'écrou pour fixer la pince du capteur inductif sur le

câble de la bobine d'allumage.

2. Passez à la section «INSTRUCTIONS POUR LE RÉGLAGE DES PISTONS»

pour régler le tachymètre en fonction des pistons/régime du moteur pour le capteur inductif de l'option du conducteur d'allumage.

Instruction de raccordement - OPTION #3 - Capteur inductif sur

le câble d'une bougie

1. Branchez le capteur inductif sur le câble d'une bougie en procédant comme suit

(voir la Figure 3) :

A. Utilisez un passe-fil existant à travers la cloison pare-feu ou perforez un trou

de 3/8 po (9,5 mm) à travers la cloison pare-feu.Installez un passe-fil dans

l'orifice et insérez-y le connecteur femelle à 4 broches du capteur inductif en

provenance du compartiment du moteur pour aller au tachymètre.

© 2004 IEC - All Rights Reserved MRP #93-0012 Rev. B

Figure 3

Installation dans le tableau de bord

1. Déterminez l'endroit où le tableau de bord peut être découpé sans toucher à rien

qui se trouve derrière le tableau de bord.

2. À l'aide d'un gabarit à orifices, découpez un orifice de 1 ½ po (3,8 cm), 2 po (5,1

cm)ou 2 5/8 po (6,7 cm) , selon le cas, dans le tableau de bord.

3. À l'aide d'une lime ronde, adoucissez les arêtes rugueuses autour de l'orifice

perforé.

4. Insérez la jauge par l'orifice pratiqué dans le

tableau de bord.

5. Tenez le bâti de la jauge et tournez cette

dernière, selon les besoins, jusqu'à ce que le

devant de la jauge soit bien placé sur le

devant du tableau de bord.

6. Serrez l'anneau de verrouillage sur la jauge

en le tournant en sens horaire jusqu'à ce que

la jauge soit serrée sur le tableau de bord.

Serrez l'anneau de verrouillage À LA MAIN

SEULEMENT (VOIR LA FIGURE 2).

Figure 2

1.0

1.0

Tachymètre

Bague de montage

Ouverture pour colonne de direction

Cale filetée

Base de

montage

ANNEAU DE

VERROUILLAGE

Capteur inductif sur le câble de

la bobine d'allumage - Option #2

(Connecteur 1)

Capteur inductif sur le câble

Modèles à voyant

de changement des

vitesses uniquement

Circuit commuté(+12V)

(Porte-fusibles)

Vers le circuit d'éclairage

Tachymètre

du tableau de board

Rouge

Blanc

Mise à la masse

du châssis

d'une bougie - Option #2

(Connecteur 1)

Branchement direct à l'aide du

conducteur VERT - Option #1

(Connecteur 1)

Vert

Brun

Passe-fil à travers

la cloison pare-feu

Noir

Capteur

inductif

Bobine d'allumage normale

--ou--

Fil de bougie

Vers L'interrupteur

d'allumage

Bougie

Moteur

Page 4

RACCORDEMENT DU TACHYMÈTRE (suite)

3

REMARQUE : Le conducteur du capteur inductif est un conducteur spécial

blindé. IL NE FAUT PAS le couper.

B. Branchez le connecteur du capteur inductif à 4 broches dans le connecteur

à 4 broches situé à l'arrière du tachymètre.

C. Retirez le boulon et l'écrou de la pince du capteur inductif.

D. Trouvez un câble de bougie et installez le capteur inductif sur le câble.

Assurez-vous que la flèche estampillée sur la pince du capteur inductif est

orientée vers la bougie.

E. Réinstallez le boulon et l'écrou sur la pince du capteur inductif installé sur le

câble de la bougie.

2. Passez à la section «INSTRUCTIONS POUR LE RÉGLAGE DES PISTONS»

pour régler le tachymètre en fonction des pistons/régime du moteur pour l'option

«Capteur inductif sur le câble de la bougie».

Fonctionnement et réglage du voyant de changement des

vitesses

Le voyant de changement des vitesses

peut être utilisé pour fournir une indication

visuelle du «régime maximum» du moteur

(régime que le moteur peut atteindre en

toute sécurité) ou du régime optimum que

le moteur atteint avant le changement des

vitesses (pour optimiser le rendement du

véhicule lors du changement des

vitesses).VOIR LA FIGURE 5.

Réglage du régime (tr/min) pour

le changement des vitesses

1. Placez la clé en position «ON» et ne faites pas démarrer le moteur; enfon-

cez le bouton de réglage de changement des vitesses et tenez-le ainsi.

Après 4-5 secondes, l'aiguille commence à se déplacer. Tenez le bouton

enfoncé et passez à l'étape 2.

2. Lorsque l'aiguille du tachymètre indique le régime désiré pour le changement des vitesses sur l'afficheur, relâchez le bouton de réglage du voyant

de changement des vitesses. Le régime de changement des vitesses est

maintenant entré dans la mémoire électronique du tachymètre; le voyant

s'allumera chaque fois que l'aiguille atteint ou dépasse ce régime de

changement des vitesses.

3. Lorsque le régime de changement des vitesses est réglé, appuyez sur le

bouton de réglage du voyant de réglage du régime et relâchez-le pour

revenir au mode de fonctionnement normal du tachymètre.

4. Pour vérifier le réglage du voyant du régime (tr/min) de changement des

vitesses, appuyez sur le bouton de réglage du voyant de changement des

VOYANT DE CHANGEMENT DE VITESSE/RAPPEL DU NOMBRE DE TOURS/MINUTE (pour les

tachymètres à voyant de changement de vitesse/rappel du nombre de tr/min seulement)

5

vitesses et relâchez-le. Appuyez sur le bouton de nouveau et relâchez-le

pour revenir au fonctionnement normal du tachymètre. Si le réglage du

régime de changement des vitesses doit être changé, répétez les étapes

1à 3.

Fonction de rappel du régime (tr/min) de pointe

Cette fonction sauvegarde dans la mémoire du tachymètre le plus haut régime

(tr/min) atteint pendant un voyage en plus de donner au conducteur la possibilité de rappeler cette information à n'importe quel moment.

Pour voir la valeur du régime maximum atteint sauvegardée dans la mémoire

du tachymètre, appuyez sur le bouton de rappel du régime et relâchez-le.

Appuyez sur le bouton de nouveau et tenez-le enfoncé pour revenir au mode

normal de fonctionnement.

REMARQUE: Le régime (tr/min) de pointe (le plus élevé) relevé pendant un

voyage restera inscrit dans la mémoire du tachymètre jusqu'à ce qu'il soit remplacé par une valeur plus élevée ou jusqu'à ce que la mémoire soit vidée par

l'opérateur.

Suppression du régime le plus élevé sauvegardé dans la

mémoire du tachymètre

1. Appuyez sur le bouton de rappel du régime pour mettre le tachymètre en

mode de rappel du régime. L'aiguille devrait monter et rester à la valeur

contenue dans la mémoire du tachymètre.

2. Pendant que le tachymètre est en mode de rappel du régime, appuyez sur

le bouton de rappel du régime et tenez-le ainsi. En 3 à 4 secondes, l'aiguille du tachymètre commencera à baisser. Attendez que l'aiguille soit revenue à zéro puis relâchez le bouton de rappel du régime. La mémoire de

rappel du régime est maintenant vidée et le tachymètre commencera à

sauvegarder la nouvelle valeur maximale du régime atteint au cours du

prochain voyage.

Figure 5

Si le tachymètre ne fonctionne pas ou s'il fonctionne de manière erratique, faites ce

qui suit :

■ Assurez-vous que le système d'allumage est en bon état et qu'il respecte les

fiches techniques du fabricant du véhicule.Si le système d'allumage est en bon

état mais que vous avez encore des lectures erratiques, le tachymètre pourrait

capter des interférences électromagnétiques (IEM). Changez l'endroit où passe

le fil du capteur inductif ou le fil VERT (suivant le cas) et éloignez-le de tous les

autres fils de bougie, des bobines d'allumage et de l'alternateur.

PROBLÈMES ET SOLUTIONS

6

■ Si vous utilisez le capteur inductif, inversez la direction de la pince du capteur

inductif sur le fil de la bougie de sorte que la flèche soit orientée de façon à

s'éloigner de la bougie. Si cela ne donne pas de résultats, changez l'emplacement de la pince du capteur inductif sur le fil de la bougie ou installez-la sur un

autre fil de bougie..

Pour avoir de l’aide, communiquez avec le Centre de Service Technique.

Pendant un (1) an à partir de la date de premier achat, le fabricant garantit à l'acheteur d'origine que

cet appareil ne comporte aucune défaut au niveau des matériaux et de l'exécution.Si l'appareil tombe

en panne au cours de cette première année, il sera réparé ou remplacé, au choix du fabricant, sans

frais, lorsqu'il est renvoyé en port payé au centre de service technique av ec une preuve d'achat.Le reçu

de caisse peut être utilisé à cette fin.La main-d'œuvre pour l'installation n'est pas couverte en vertu de

la présente garantie.

T outes les pièces de rechange , qu'elles soient neuv es ou ref aites , sont garanties uniquement pour la

période de garantie résiduelle de l'appareil. Cette garantie ne s'applique pas aux dommages causés

par une mauvaise utilisation, un accident, un usage abusif, ou si le produit a été modifié ou réparé

par une autre personne que le centre de service technique du fabricant. Les dommages indirects ou

accessoires ne sont pas couverts par cette garantie.Certains états ne permettent pas l'exclusion ou

l'imposition de limites aux dommages indirects ou accessoires;les limites ou les exclusions indiquées

ci-dessus pourraient donc ne pas s'appliquer à vous.

La présente garantie vous donne des droits légaux particuliers et vous pourriez en avoir d'autres

qui pourraient varier d'un état à l'autre.Aucune partie de la présente garantie ne peut être copiée

ou reproduite sans le consentement spécifique écrit du fabricant.

Aide technique et service sous garantie

Les produits qui doivent faire l'objet de travaux de service doivent être renvoyés en procédant

comme suit :

1. Téléphonez au centre de service technique pour obtenir un numéro de référence pour le renvoi.

2. Emballez le produit avec soin pour prévenir les dommages pendant le transport.

3. Indiquez votre nom, votre adresse de retour et un numéro de téléphone où l'on peut vous

rejoindre pendant la journée.

4. Annexez une copie du reçu de caisse montrant la date d'achat.

5. Décrivez le problème.

6. Expédiez l'appareil en port payé à l'adresse suivante : Centre de service technique,

17291 Mt. Herr mann Street, Fountain Valley, CA 92708, États-Unis.

Pour recevoir une aide technique ou pour profiter du service sous garantie, communiquez avec

nous comme suit :

Téléphone :États-Unis et Canada : 1-800-544-4124; ailleurs : 714-241-6805;télécopieur :714-4327910; Inter net : www.iEQUUS.com;courriel : service@iEQUUS.com

GARANTIE LIMITÉE ET SERVICE

© 2004 IEC - All Rights Reserved

INSTRUCTIONS POUR LE RÉGLAGE DES PISTONS

4

Le réglage des pistons sur le tachymètre doit

être fait de manière à assurer la concordance

entre les réglages internes du tachymètre et le

signal de régime en provenance du système

d'allumage du véhicule. Faites les réglages

suivants.

1. Assurez-vous que les conducteurs de

masse et l'alimentation du tachymètre

sont branchés sur le véhicule et que le

connecteur à 3 broches est branché dans

le connecteur à 3 broches #2 à l'arrière du

tachymètre.

2. Coupez l'alimentation parvenant au tachymètre (placez la clé d'allumage en position «OFF»). Appuyez sur le bouton «CYL» et tenez-le enfoncé (petit bouton

ROUGE situé à l'arrière du tachymètre (voir la Figure 4); mettez ensuite le

tachymètre sous tension (tournez la clé d'allumage en position «ON»).

3. Appuyez sur le bouton «CYL» et relâchez-le autant de fois que nécessaire pour

que l'aiguille du tachymètre pointe vers le bon régime suivant l'option de raccordement au signal que vous avez utilisé.

■ Utilisez les réglages présentés au Tableau 1 si vous avez utilisé l'option 1

«Raccordement direct à l'aide du conducteur VERT» ou l'option 2

«Capteur inducteur sur le câble de la bobine».

■ Utilisez les réglages du Tableau 2 si vous utilisez l'option 3 «Capteur induc-

tif sur le câble d'une bougie»

4. Lorsque vous parvenez au bon réglage, Placez l'allumage en position «OFF».

Le réglage est maintenant sauvegardé dans la mémoire du tachymètre et il

restera ainsi jusqu'à ce que vous le changiez de nouveau. Pour changer le

réglage, répétez les étapes A à D.

5. Passez à la section «Vérification du fonctionnement du tachymètre» pour

terminer l'installation.

Figure 4

Vérification du fonctionnement du tachymètre

1. Placez la clé d'allumage en position «ON» mais SANS DÉMARRER LE MOTEUR.

L'aiguille du tachymètre devrait pointer vers «0».

REMARQUE : Ce tachymètre fait appel à un «déplacement pneumatique du

noyau». L'aiguille restera donc à la position qu'elle avait (pas nécessairement

zéro) au moment où l'alimentation électrique du tachymètre a été coupée.C'est

normal pour ce genre de déplacement. L'aiguille devrait revenir à zéro lorsque

l'alimentation électrique du tachymètre est rétablie.

2. Démarrez le moteur et laissez-le tourner. Faites augmenter le régime à plusieurs

reprises et voyez ce que le tach ymètre indique à mesure que le régime augmente

et diminue. Si le tachymètre ne fonctionne pas ou s'il fonctionne de manière erratique, consultez la section Problèmes et solutions pour avoir les instructions

nécessaires pour corriger le problème.

Table 2.Tachometer Cylinder Setting Table (OPTION #3)

No. de pistons Réglez l'aiguille

Type d'allumage sur le véhicule du tachymètre à (régime)

Conventionnel Tous 500

DIS Tous 1000

Tableau 1. Réglage des pistons (OPTIONS #1 et #2)

Réglez l'aiguille Réglez l'aiguille

No. de pistons du tachymètre No. de pistons du tachymètre

du véhicule à (régime) du véhicule à (régime)

1 500 6 3000

2 1000 8 4000

3 1500 10 5000

4 2000 12 6000

5 2500 Coil on Plug 500

Bouton

de CYL

Bouton de réglage

du voyant de

changement des

vitesses

Voyant de

changement

des vitesses

Bouton de rappel

du régime (tr/min)

Page 5

INSTRUCCIONES DE INSTALACIÓN

TACÓMETRO INDUCTIVO DE ALTO DESEMPEÑO

PREPARACIÓN ANTES DE LA INSTALACIÓN

1

Esta sección contiene información preliminar importante. Léase esta sección

PRIMERO antes de proceder con la instalación.

Precauciones de seguridad

Para evitar lesiones personales y daños al vehículo o al tacómetro, lea estas

instrucciones por completo y observe las siguientes precauciones de seguridad:

■ Siempre consulte el manual de servicio del vehículo y cumpla con sus precau-

ciones de seguridad antes de instalar el tacómetro.

■ Para evitar quemaduras, instale el tacómetro sólo cuando el motor esté frío.

■ Los gases de escape del vehículo son muy tóxicos.Para evitar lesiones serias

o muerte, siempre opere el motor en un ambiente bien ventilado.

■ Cuando el motor está en marcha, hay elementos tales como el ventilador,

poleas, etc., que giran a altas velocidades.Esté SIEMPRE consciente de estos

elementos en movimiento y manténgase alejado de ellos.

■ Desconecte el cable negativo (-) de la batería antes de instalar o hacer las

conexiones del tacómetro.

NOTA: Puede ser necesar io reprogramar el radio, ajustar el reloj, etc., después

de reconectar la batería.

■ SIEMPRE aísle las conexiones de los cables con tubo de contracción térmica

para evitar cortos circuitos.

Aplicaciones

Este tacómetro es compatible SOLAMENTE con sistemas eléctricos de 12 volts con tierra

negativa (-), y puede operar con la mayoría de los v ehículos y/o sistemas de encendido:

■ EQUIPADOS CON DISTRIBUIDOR - sistemas de encendido de 4 ciclos

■ SISTEMAS DE ENCENDIDO SIN DISTRIBUIDOR (DIS) y otros sistemas de

encendido de 2 ciclos - este tipo de sistema no usan distribuidor.

NOTA: El tacómetro puede no funcionar correctamente con algunos vehículos con

los siguientes sistemas de encendido:

■ Sistemas de encendido de chispa múltiple: Consulte al fabricante y/o las

instrucciones sobre cómo conectar el tacómetro a estos sistemas.

■ Sistemas de encendido con la bobina directo a la bujía: Consulte el manu-

al de servicio del vehículo para determinar si existe un conector apropiado de

señal de tacómetro para conectar un tacómetro accesorio.

■ Determine la ubicación en que se desea montar el tacómetro. Seleccione un

lugar en que no impida la visión ni interfiera con la conducción del vehículo. Antes de comenzar a taladrar, revise detrás del sitio seleccionado para ase-

gurar que no haya cables u otros componentes. Asegúrese de que todos los

cables del tacómetro puedan pasarse desde la posición del tacómetro hasta los

puntos de conexión necesarios en el vehículo.

Montaje sobre o debajo del panel de

instrumentos

1. Instale la base del soporte y asegúrela con los

tornillos, arandelas y tuercas suministradas.

2. Acoplar el montaje tipo abrazadera de anillo al

cuerpo del tacómetro.

3. Usando el espaciador y los tornillos suministrados, asegurar el tacómetro y la

abrazadera al soporte como se ilustra en la

FIGURA 1.

4. Proceder a la sección 3 para efectuar las

conexiones al tacómetro.

MONTAJE DEL TACÓMETRO

2

Figura 1

CONEXIONES AL TACÓMETRO

3

Conexión de Alimentación Eléctrica y a Tierra (Figura 3)

1. Enchufe el conector eléctrico de 3 clavijas (alambres ROJO, NEGRO y BLAN-

CO) en el conector 2 de la parte posterior del tacómetro.

2. Conecte el alambre de alimentación eléctrica (ROJO) a un circuito conmutado

de +12 voltios en la caja de fusibles, o empálmelo al alambre del arnés del

vehículo que está energizado ÚNICAMENTE cuando la llave de la ignición se

encuentra en la posición de encendido "ON" (MARCHA).

3. Engarce o suelde con estaño una orejeta terminal en el alambre de conexión a

tierra (NEGRO), y conéctelo a un área limpia y con metal descubierto en el

bastidor metálico del vehículo.

4. Conecte el alambre de iluminación del tacómetro (BLANCO) al circuito de ilu-

minación del panel de instrumentos (consulte en el manual de reparación del

vehículo los diagramas de cableado).Proceda a conectar la señal de tacómetro.

NOTA: Para instalar las bombillas, utilice pinzas de cuello largo para insertar la

bombilla en el receptáculo correspondiente en la parte posterior del indicador,

después gírela a la derecha ¼ de vuelta para fijarla en posición. La luz de iluminación de fondo del indicador se puede cambiar a ROJO , VERDE o AZUL mediante

la instalación del filtro de color opcional sobre la bombilla (no está disponible para

todos los juegos de indicadores).

Conexión de la Señal del Tacómetro

Este Tacómetro de alto desempeño le permite utilizar una de tres opciones

(descritas a continuación) para captar una señal de tacómetro del sistema de ignición del vehículo.Elija la opción que mejor se adapte a su vehículo / sistema y proceda con las "Instrucciones para la Conexión".

NOTA: Siendo que hay varias maneras que la señal del tacómetro en este tipo de

sistemas es procesado;este tacómetro es compatible con algunos pero no todos los

systemas de "Coil On Plug" (Bobina en Bujia).

1. OPCIÓN 1 - Conexión Directa con el Alambre VERDE - el alambre VERDE

del tacómetro se conecta directamente al "Puerto de Señales del Tacómetro del

Sistema de Ignición del vehículo".

■ Utilice esta opción en cualquier vehículo / sistema de ignición donde haya

disponible un puerto de tacómetro adecuado (incluso en sistemas de ignición convencionales, sin distribuidor y de bobina con bujías [Coil-on-Plug]).

2. OPCIÓN 2 - Captación Inductiva en el Cable de la Bobina de Ignición - el

captador inductivo se engancha alrededor del "Cable de la Bobina de Ignición"

para captar por inducción la señal del tacómetro.

■ Utilice esta opción en cualquier vehículo con un sistema de ignición conven-

cional (equipado con distribuidor) que tenga un cable de bobina expuesto

cuando no haya un puerto de señales de tacómetro adecuado o cuando no

esté accesible.

3. OPCIÓN 3 - Captación Inductiva en el Cable de la Bujía - el captador inductivo se engancha alrededor de uno de los "Cables de Bujías" para captar por

inducción la señal del tacómetro.

■ Utilice esta opción en vehículos con Sistemas de Ignición Convencionales

(equipados con distribuidor) o Sin Distribuidor (DIS) donde no se pueda utilizar la opción de Conexión Directa porque no hay disponible un puerto de

señales del tacómetro o cuando no esté fácilmente accesible.

Instrucciones de Conexión para la OPCIÓN 1 - Conexión

Directa con el alambre VERDE

1. Conecte el alambre VERDE al lado negativo de la bobina de ignición, o a un

puerto de señales de tacómetro apropiado según se indica a continuación

(véase la Figura 3):

A. Enchufe el conector hembra de 4 clavijas del alambre VERDE de señales del

tacómetro en el conector de 4 clavijas #1 en la parte posterior del tacómetro.

B. Utilice un ojal existente en el mámparo cortafuegos, o taladre un orificio de 3/8

pulgada (9,5 mm) a través del mámparo cortafuegos.Instale un ojal en el orificio y pase el alambre conductor VERDE del tacómetro a través del ojal hacia

el compartimiento del motor.

C. Para los sistemas de ignición convencionales de 4 ciclos y de Bobina-con-Bujía

(Coil on Plug), conecte el alambre VERDE al lado negativo de la bobina de

ignición (en los sistemas de Bobina-Con-Bujía (Coil-On-Plug), cerciórese de

hacer la conexión al lado negativo de una de las bobinas solamente).

D. Para los sistemas de ignición sin Distribuidor será necesario efectuar la

conexión a un puerto de señales de tacómetro adecuado.

2. Proceda a la sección "INSTRUCCIONES DE AJUSTES SEGÚN EL NÚMERO

DE CILINDROS" para ajustar el tacómetro según los parámetros apropiados de

Cilindro / RPM para la opción "Conexión Directa con el alambre VERDE".

Instrucciones de Conexión para la Opción 2 - Captador

Inductivo en el Cable de la Bobina de Ignición

1. Conecte el Captador Inductivo al Cable de la Bobina de Ignición de la manera

descrita a continuación (véase la Figura 3):

A. Utilice un ojal existente en el mámparo cortafuegos, o taladre un orificio de

3/8 pulgada (9,5 mm) a través del mámparo cortafuegos. Instale un ojal en

el orificio y pase el conector hembra de 4 clavijas del Captador Inductivo del

lado del compartimiento del motor a través del ojal, hacia el tacómetro.

NOTA: El alambre conductor del Captador Inductivo es un alambre con

blindaje especial. NO corte el alambre.

B. Enchufe el conector de 4 clavijas del Captador Inductivo en el conector de

4 clavijas #1 en la parte posterior del tacómetro.

C. Retire el tor nillo y la tuerca de la abrazadera del Captador Inductivo.

D. Localice el cable de la bobina de ignición, y con la abrazadera instale el

Captador Inductivo alrededor del cable.Cerciórese de que la flecha estampada en la abrazadera del Captador Inductivo apunte hacia el distribuidor.

E. Vuelva a instalar el tornillo y la tuerca para fijar la abrazadera del captador

inductivo en el cable de la bobina de ignición.

2. Proceda a la sección "INSTRUCCIONES DE AJUSTE SEGÚN EL NÚMERO DE

CILINDROS" para ajustar el tacómetro según los parámetros apropiados de Cilindro/

RPM para la opción "Captador Inductivo en el Cable de la Bobina de Ignición".

Instrucciones de Conexión para la Opción 3 - Captador

Inductivo en el Cable de la Bujía

1. Conecte el Captador Inductivo a uno de los cables de bujía y de la manera descri-

ta a continuación (véase la Figura 3):

© 2004 IEC - All Rights Reserved MRP #93-0012 Rev. B

Figura 3

Opción de montaje en el tablero de instrumentos

1. Determine un lugar en el tablero de instru-

mentos en que se pueda hacer un corte sin

tocar ninguno de los objetos detrás del

tablero.

2. Con ayuda de una plantilla de orificios, corte

un orificio de 1-1/2" (3,8 cm), 2" (5,1 cm) ó 25/8" (6,7 cm), según sea necesario, a través

del tablero.

3. Con una lima circular, alise los bordes ásper-

os alrededor del orificio taladrado.

4. Introduzca el indicador en el hueco en el tablero.

5. Sujete la caja del indicador y gírela según sea necesario, hasta que el dial del cuad-

rante del indicador quede debidamente colocado al frente del tablero.

6. Apriete el anillo de sujeción en el indicador en sentido horario hasta que el indi-

cador esté apretado en el tablero. Apriete el anillo de sujeción SÓLO CON LA

FUERZA DE LA MANO (véase la Figura 2).

Figura 2

1.0

1.0

Tacómetro

Montaje tipo abrazadera

de anillo

Espaciador

roscado

Base del

soporte

Apertura para el montaje

a columna del volante

Captador Inductivo en el Cable de

la Bobina de Ignición - Opción #2

(Conector 1)

Captador Inductivo en el Cable

Modelos con luz de

cambios solamente

Suministro conmutado

de +12 volts

(caja de fusibles)

Tacómetro

A circuito de

iluminación del tablero

Rojo

Tierra del

chasis

Blanco

de la Bujía - Opción #3

(Conector 1)

Conexión Directa con el

alambre VERDE - Opción #1

(Conector 1)

Verde

Café

Ojete de la pared

del compartimiento

del motor

Sonda de

Negro

inducción

Bobina de encendido estándar

--o--

Cable de bujía

ANILLO DE

SUJECIÓN

Al interruptor

del encendido

Bujía

Motor

Page 6

CONEXIONES AL TACÓMETRO (Cont)

3

A. Utilice un ojal existente en el mámparo cortafuegos, o taladre un orificio de 3/8

pulgada (9,5 mm) a través del mámparo cortafuegos.Instale un ojal en el orificio y pase el conector hembra de 4 clavijas del Captador Inductivo del lado del

compartimiento del motor a través del ojal, y hacia el indicador del tacómetro.

NOTA: El alambre conductor del Captador Inductivo es un alambre con

blindaje especial. NO corte el alambre..

B. Enchufe el conector de 4 clavijas del Captador Inductivo en el conector de

4 clavijas #1 en la parte posterior del tacómetro.

C. Retire el tor nillo y la tuerca de la abrazadera del Captador Inductivo.

D. Localice un cable de bujía, y con la abrazadera instale el Captador Inductivo

alrededor de dicho cable. Cerciórese de que la flecha estampada en la

abrazadera del Captador Inductivo apunte hacia la bujía.

E. Vuelva a instalar el tornillo y la tuerca para fijar la abrazadera del captador

inductivo en el cable de la bujía.

2. Proceda a la sección "INSTRUCCIONES DE AJUSTE SEGÚN EL NÚMERO DE

CILINDROS" para ajustar el tacómetro según los parámetros apropiados de

Cilindro / RPM para la opción "Captador Inductivo en el Cable de la Bujía."

Operación y ajuste de la luz de

cambios

La luz de cambios puede usarse para proporcionar una indicación visual del límite máximo

de revoluciones del motor (la velocidad de

giro máxima segura) o el punto óptimo de

cambio (para optimizar el rendimiento del

vehículo).VÉASE LA FIGURA 5.

Ajuste de las rpm de la luz de

cambio

1. Con el interruptor del encendido en posi-

ción "ON" y el motor parado (no en marcha) presione y mantenga presionado el

botón de ajuste de la luz de cambio. Después de transcurridos unos 4 a 5

segundos, el puntero comenzará a avanzar sobre la escala. Continúe presionando el botón y proceda al paso 2.

2. Cuando el puntero del tacómetro indique las rpm deseadas para la luz de cambio, suelte el botón. La memoria electrónica del tacómetro ahora contiene las

rpm a que se desea opere la luz de cambio, y ésta se iluminará cada vez que el

puntero alcance o rebase el valor fijado.

3. Para devolver el tacómetro a su modo normal de operación, después que se

fijen las rpm deseadas para la luz de cambio, presione y suelte el botón de

ajuste de la luz de cambio.

4. Para verificar el ajuste de rpm de la luz de cambios, presione y suelte el botón

de ajuste de la luz de cambio.Presionar de nuevo y soltar el botón de ajuste de

LUZ DE CAMBIOS/MEMORIA DE RPM (sólo para tacómetros con estas características)

5

la luz de cambio para devolver el tacómetro a su modo normal de operación. Si

se desea cambiar el valor, repetir los pasos 1 al 3.

Función de despliegue de la memoria de rpm pico

Esta función almacena en memoria la lectura de rpm más alta (pico) que se alcanzó

durante un viaje en una localidad de memoria dedicada en el tacómetro y le permite

al operador desplegar en cualquier momento la lectura almacenada.

Para desplegar la lectura de rpm almacenada en la memoria del tacómetro, presione y suelte el botón de la memoria. Presiónelo y suéltelo de nuevo para regresar

al modo normal de operación.

NOTA: Las rpm pico (el valor máximo de rpm) alcanzadas durante un viaje

quedarán almacenadas en la memoria del tacómetro hasta que las sobrepase un

valor mayor, o hasta que el operador borre la memoria.

Para borrar la lectura máxima de rpm almacenada en la

memoria del tacómetro

1. Presione y suelte el botón de la memoria del tacómetro para colocarlo en el

modo de despliegue. El puntero deberá desplazarse y permanecer indicando el

valor contenido en la memoria de rpm máxima.

2. Estando el tacómetro en modo de despliegue, presione y mantenga presionado

el botón de la memoria. Dentro de unos 3 a 4 segundos, el puntero del

tacómetro deberá comenzar a desplazarse hasta llegar a cero.Espere a que el

puntero llegue a cero y suelte el botón. Con esto se ha borrado el contenido de

la memoria y el tacómetro almacenará en la memoria el nuevo valor máximo

(pico de rpm alcanzado durante el próximo viaje).

Figura 5

Si el tacómetro no funciona, o si funciona de forma errática, proceda como sigue:

■ Asegúrese de que el sistema de encendido esté en buenas condiciones de

operación y cumpla con las especificaciones de su fabricante. Si el sistema de

encendido está funcionando bien y aún se obtienen lecturas erráticas, el

tacómetro puede estar recibiendo Interferencia electromagnética (EMI por sus

siglas en inglés).Trate de cambiar la ruta del cable de la Sonda de inducción o

el conductor VERDE (según sea el caso) para alejarlo de otros cables de bujía,

bobinas de encendido y el alternador.

LOCALIZACIÓN DE PROBLEMAS

6

■ Si se está usando la opción de Sonda de inducción, invierta la dirección de la

abrazadera de la Sonda de inducción sobre el cable de la bujía de manera que

la flecha apunte en sentido opuesto a la bujía. Si esto no tiene éxito, desplace

la abrazadera de la Sonda de inducción a otra posición sobre el cable de la

bujía, o a otro cable de bujía.

Para ayuda adicional, comuníquese con el centro de servicio técnico.

El fabricante garantiza al comprador original que esta unidad está exenta de def ectos en materiales y mano de obra por un período de un (1) año a partir de la fecha de compra original. Si

la unidad falla en un período de un (1) año, se reemplazará o se reparará, a opción del

Fabricante, sin cargo adicional alguno, cuando se devuelva con porte prepagado al Centro de

Servicio Técnico acompañada del comprobante de pago.El recibo de compra puede usarse

para este propósito.La mano de obra no tiene cobertura en virtud de esta garantía.

Todas las partes de repuesto, sean nuevas o reconstruidas, asumirán como su período de

garantía sólo el plazo restante de esta garantía. Esta garantía no cubre daños causados

por uso indebido, accidental, abusivo, o si el producto fue modificado o reparado por

alguien ajeno al Centro de Servicio Técnico del Fabricante. Los daños consecuentes o

incidentes no son recuperables en virtud de esta garantía. Algunos estados no permiten

la exclusión o la limitación de los daños incidentes o consecuentes, así que la limitación

o exclusión anterior quizá no sea aplicable a su caso.

Esta garantía le otorga derechos legales específicos, y usted quizá pueda tener otros

derechos, los cuales varían de estado a estado.No se permite copiar ni duplicar porción

alguna de esta garantía sin el consentimiento expreso y escrito del Fabricante.

Asistencia técnica y Servicio de garantía

Los productos que requieran servicio deberán devolverse de la manera siguiente:

1. Llame al Centro Servicio Técnico para obtener un Número de Referencia de

Devolución.

2. Embale cuidadosamente el producto para evitar daños durante el envío.

3. Incluya su nombre, el remitente y un teléfono disponible en horas hábiles.

4. Adjunte una copia del recibo de compra fechado.

5. Describa el problema.

6. Envíe el producto con porte pagado a:Technical Service Center, 17291 Mt.Herrmann

Street, Fountain Valley, CA 92708 U.S.A.

Para recibir Asistencia técnica y/o Servicio de garantía, sírvase dirigirse a:

Teléfono: EE.UU. y Canadá 1-800-544-4124; otros países: 714-241-6805 (E.U.A.); Fax

714-432-7910 (E.U.A.); Internet: www.iEQUUS.com; correo electrónico:

service@iEQUUS.com

Para garantía en México ver con distribuidor.

GARANTÍA LIMITADA Y PROCEDIMIENTOS PARA OBTENER SERVICIO

© 2004 IEC - All Rights Reserved

4

El parámetro CYL del tacómetro deberá

ajustarse de manera que coincida con los

valores internos del tacómetro respecto a la

señal de rpm que se reciba del sistema de

ignición del vehículo.

Ajuste los parámetros según se indica a

continuación:

1. Cerciórese que los alambres de alimentación eléctrica y de conexión a tierra del tacómetro estén conectados al

vehículo, y que el conector de 3 clavijas

esté enchufado en el conector #2 en la

parte posterior del tacómetro.

2. Desconecte la alimentación eléctrica del tacómetro (coloque la llave de la ignición

en la posición de apagado). Presione y mantenga oprimido el botón CYL (botón

ROJO pequeño en la parte posterior del tacómetro, véase la Figura 4), después

aplique energía eléctrica al tacómetro (coloque la llave de la ignición en la posición de encendido).

3. Presione y libere el botón CYL tantas veces como sea necesario hasta que la

aguja del tacómetro apunte al valor correcto de rpm según la opción de conexión

de señal utilizada.

■ Utilice los valores que se indican en la Tabla 1 si utiliza la "OPCIÓN 1-

Conexión Directa con el Cable VERDE" o la "OPCIÓN 2 - Captador

Inductivo en el Cable de la Bobina".

■ Aplique los valores indicados en la Tabla 2 si utiliza la "OPCIÓN 3 -

Captador Inductivo en el Cable de la Bujía".

4. Al obtener el ajuste correcto de cilindros, apague la ignición. El valor según el

número de cilindros ya está guardado en la memoria del tacómetro, y permanecerá sin cambios. Para cambiar este ajuste, repita los pasos A hasta el D.

5. Proceda a la "Comprobación Operacional del Tacómetro" para terminar la

instalación.

Comprobación Operacional del Tacómetro

1. Encienda la ignición. NO PONGA EN MARCHA EL MOTOR. La aguja del

tacómetro deberá girar a la posición "0" al encender la ignición.

NOTA: Este tacómetro utiliza tecnología de "Movimiento de núcleo de aire". Con

este tipo de movimiento, la aguja permanecerá (apuntando) en cualquier posición en que se encuentre (no necesariamente en cero) al momento de interrumpir la alimentación eléctrica al tacómetro. Este comportamiento es nor mal

para este tipo de mecanismo de aguja. La aguja deberá volver a cero cuando

se vuelva a aplicar la energía eléctrica al tacómetro.

2. Arranque y deje en marcha el motor. Aumente varias veces las revoluciones del

motor y verifique que cambie la indicación del tacómetro cuando aumenten o disminuyan las rpm. Si no funciona el tacómetro, o si éste funciona erráticamente,

consulte la sección de Localización de Problemas para obtener detalles de resolución de problemas.

INSTRUCCIONES DE AJUSTE SEGÚN EL NÚMERO DE CILINDROS

Figura 4

Tabla 1.Tabla de ajuste del tacómetro según el número

de cilindros (OPCIONES 1 y 2)

Número de cilindros Ajuste la aguja del Número de cilindros Ajuste la aguja del

en el vehículo tacómetro en el en el vehículo tacómetro en el

valor (rpm) valor (rpm)

1 500 6 3000

2 1000 8 4000

3 1500 10 5000

4 2000 12 6000

5 2500

Tabla 2.Tabla de ajuste del tacómetro según el número de cilindros (OPCIÓN 3)

Núm. de cilindros Ajuste la aguja del tacómetro

Tipo de Ignición en el vehículo en el valor (rpm)

Convencional Todos 500

DIS Todos 1000

BOTÓN

CYL

Botón para fijar

la luz de cambio

Luz de cambio

Botón para

desplegar

memoria de rpm

Loading...

Loading...