Page 1

INSTALLATION INSTRUCTIONS

SPEEDOMETER / HOURMETER / CLOCK

PREPARATION FOR INSTALLATION

1

Copyright © 2012 IEC. All Rights Reserved. MRP 93-0034 Rev C

1. Read these instructions completely before installing the gauge, and

seek the advice of a professional if you are not familiar with the installation of vehicle instrumentation or the functions of the related vehicle

systems.

2. Always read the vehicle's service manual and follow its safety pre-

cautions before any test or service procedure is performed.

3. Install gauges only when engine is cool and ignition is off.

4. Disconnect negative (-) battery cable before installing gauges. (Do

not forget to reconnect battery after installation is complete).

NOTE: It may be necessary to reprogram your radio, clock, etc. after

reconnecting the battery.

5. Determine a mounting location for the gauge. Choose a location that

does not impair visibility, or interfere with driving. Check behind the

mounting location for any wiring or components before drilling.

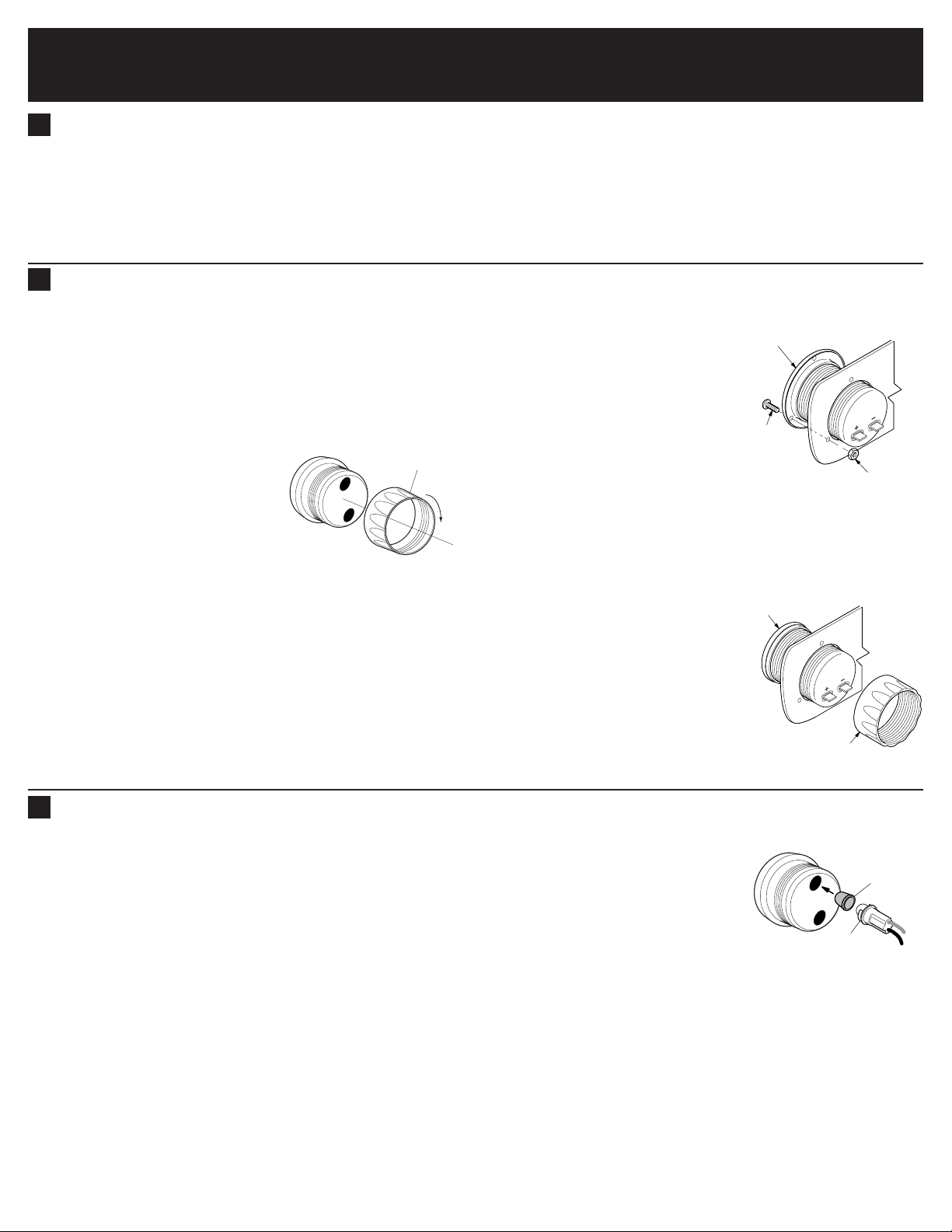

A. SPEEDOMETER / CLOCK (Figure 1)

1. Determine a location on the dashboard that can be cut out without

striking any objects from behind the dash. If an existing hole is already

available for use, proceed to step 3.

2. Using a template, cut out a 3 3/8" (85.7 mm) (or as needed) hole

through the dashboard.

3. Using a round file, smooth out any rough edges around the hole.

4. Insert gauge through front of the hole in dashboard.

5. Hold gauge case and rotate gauge,

as needed, until gauge dial face is

properly positioned in front of dashboard.

6. Tighten locking ring onto gauge in a

clockwise direction until gauge is

tight against dashboard. Tighten

locking ring HAND TIGHT ONLY.

B. HOURMETER

The hourmeter will use one of two types of mounting options; "In-Dash

Mount" (using a mounting cup) or "Flange Mount." Be sure to use the

installation instructions appropriate to your hourmeter.

Flange Mount (Figure 2)

1. Determine a location on the dashboard that can be cut out without

striking any objects from behind the dash. If an existing hole is already

available for use, proceed to step 3.

2. Using a template, cut out a 2" (50.8 mm) hole through the dashboard.

3. Using a round file, smooth out any rough edges around the hole.

4. Insert gauge through front of the hole in dashboard.

GAUGE INSTALLATION

2

5. Hold gauge case and rotate gauge, as needed, until gauge dial face

is properly positioned in front of dashboard.

6. Using the gauge flange as a template, mark the location for three

mounting screws.

7. Using a 1/8" (3.18 mm) drill bit, drill

three holes through the dashboard.

8. Insert gauge through front of the

hole in dashboard, and secure with

three screws, lock washers and nuts

provided. Tighten nuts to 5 inchpounds (0.57 Newton-meters).

In-Dash Mount (Figure 3)

1. Determine a location on the dashboard that can be cut out without

striking any objects from behind the dash. If an existing hole is already

available for use, proceed to step 3.

2. Using a template, cut out a 2" (50.8 mm) hole through the dashboard.

3. Using a round file, smooth out any

rough edges around the hole.

4. Insert gauge through front of the hole

in dashboard.

5. Hold gauge case and rotate gauge, as

needed, until gauge dial face is properly positioned in front of dashboard.

6. Tighten locking ring onto gauge in a

clockwise direction until gauge is tight

against dashboard. Tighten locking

ring HAND TIGHT ONLY

NOTE: Depending on the model of gauge, backlighting color may be

changed to either red, green or blue by installing the optional color filter

over the bulb (not available for all gauge kits).

1. Insert the light bulb and socket assemblies into the light receptacles

on the back of the gauge and press firmly to snap/lock into place.

NOTE: Wire for gauge lights must be purchased separately. Use size 1820 AWG stranded copper wire.

2. Splice the RED or WHITE wire from the gauge light(s) into the vehi-

cle's lighting circuit, between the dimmer control switch and the dash

lights (consult the vehicle's service manual for proper wire).

GAUGE LIGHT INSTALLATION AND CONNECTION - Speedometer

3

3. Connect light socket BLACK wire to a

good chassis ground.

4. Insulate all splices and connections with

shrink tubing to prevent shorting.

WARNING: For bulb replacement use only

part # 161 Instrument/Indicator wedge

type bulbs available at most auto parts

stores. DO NOT USE ANY OTHER PART

NUMBER SINCE THE HEAT PRODUCED

BY A HIGHER WATTAGE BULB WILL

MELT THE GAUGE CASE AND CREATE

A FIRE HAZARD.

Figure 4

4.0

4.0

Figure 1

Figure 2

Figure 3

LOCKING RING

HOURMETER

SCREW

NUT

HOURMETER

LOCKING RING

BULB AND

SOCKET ASSEMBLY

OPTIONAL COLOR

FILTER

Page 2

Copyright © 2012 IEC. All Rights Reserved.

The Manufacturer warrants to the original purchaser that this unit is free of defects

in materials and workmanship under normal use and maintenance for a period of

one (1) year from the date of original purchase. If the unit fails within the one (1) year

period, it will be repaired or replaced, at the Manufacturer’s option, at no charge,

when returned prepaid to the Service Center with Proof of Purchase. The sales

receipt may be used for this purpose. Installation labor is not covered under this warranty. All replacement parts, whether new or remanufactured, assume as their warranty period only the remaining time of this warranty. This warranty does not apply

to damage caused by improper use, accident, abuse, improper voltage, service, fire,

flood, lightning, or other acts of God, or if the product was altered or repaired by anyone other than the Manufacturer’s Service Center. The Manufacturer, under no circumstances shall be liable for any consequential damages for breach of any written

warranty of this unit. This warranty gives you specific legal rights, and you may also

have rights, which vary from state to state.This manual is copyrighted with all rights

reserved. No portion of this document may be copied or reproduced by any means

without the express written permission of the Manufacturer. THIS WARRANTY IS

NOT TRANSFERABLE. For service, send via U.P.S. (if possible) prepaid to

Manufacturer. Allow 3-4 weeks for service/repair.

LIMITED ONE YEAR WARRANTY AND SERVICE PROCEDURES

GAUGE CONNECTION

4

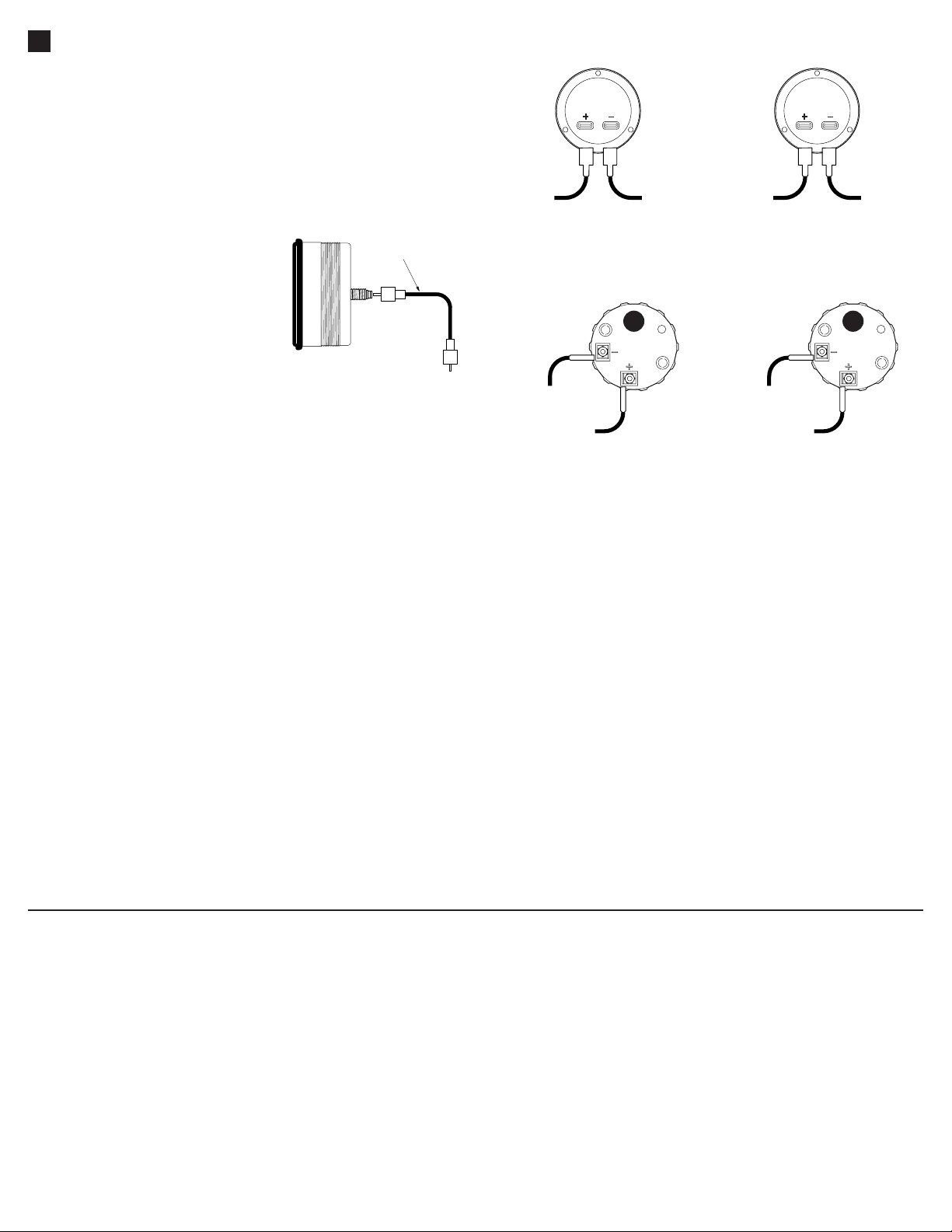

A. SPEEDOMETER (Figure 4)

Connection of the speedometer requires using the vehicle's existing

speedometer cable. Route existing speedometer cable to rear of speedometer and connect cable to 5/8"–18 male connector on rear of speedometer.If the cable drive and/or the female threaded connector from the vehicle's

speedometer cable does not fit, you must buy an adapter and/or replace the

speedo-meter cable. See IMPORTANT note below. Connection adapters

and cables are available from most speedometer shops.

IMPORTANT: The speedometer is designed for a 1:1 drive ratio (60 mph or

96,5 km/h at 1000 RPM) using a 5/8"-18

cable thread shaft. This shaft requires a

0.104” (2,64 mm) square female cable

drive. If the vehicle’s tire size or differential ARE NOT stock (original), speedometer accuracy will be affected. It may be

necessary to change to a different pinion

gear to achieve the required 60 MPH at

1,000 RPM.

TRIPMETER OPERATION

The speedometer is equipped with a foursegment resetable Tripmeter. To reset the

Tripmeter, rotate the Tripmeter reset knob

counterclockwise until the Tripmeter shows "0000".

B. HOURMETER / CLOCK (Figure 5)

NOTE: Hourmeter / clock operating voltage is 10 VDC minimum to 80 VDC

maximum (polarity-sensitive).

NOTE: Lead wires must be purchased separately. Use 16 - 18 AWG wire

minimum.

1. Determine routing for gauge lead wires. Use an existing firewall grom-

met, or drill a 3/8" (9.5 mm) hole through firewall to accommodate lead

wires. Install a rubber grommet (purchased separately) in hole, and

use shrink tubing to protect lead wires from chaffing or other damage.

2. Install and crimp or solder 1/4" female spade connectors (purchased

separately) on gauge positive (+) and negative (-) lead wires.

3. Connect lead wires to hourmeter or clock positive (+) and negative (-)

spade posts. Route lead wires through grommet in firewall.

4. Connect free ends of hourmeter or clock lead wires to vehicle electri-

cal system:

HOURMETER

For Negative Ground Systems

■ Connect hourmeter positive lead wire to a switched voltage source

in the vehicle electrical system.

■ Connect hourmeter negative lead wire to a good bare metal chas-

sis ground.

For Positive Ground Systems

■ Connect hourmeter negative lead wire to a switched voltage

source in the vehicle electrical system.

■ Connect hourmeter positive lead wire to a good bare metal chas-

sis ground.

CLOCK

For Negative Ground Systems

■ Connect clock positive lead wire to an unswitched (constant) volt-

age source in the vehicle electrical system.

■ Connect clock negative lead wire to a good bare metal chassis

ground.

For Positive Ground Systems

■ Connect clock negative lead wire to an unswitched (constant) volt-

age source in the vehicle electrical system.

■ Connect clock positive lead wire to a good bare metal chassis

ground.

5. Secure lead wires along their route to prevent damage from sharp

edges, moving parts or hot engine components.

6. Reconnect negative (-) battery cable.

■ For Hourmeter: Start and run engine for several minutes and ver-

ify hourmeter accumulates operating time.

■ For Clock: Observe clock for several minutes and verify time

advances.

Figure 4

Figure 5

EXISTING

SPEEDOMETER

CABLE

TO

VO LTAGE

SOURCE

NEGATIVE GROUND SYSTEM

TO

CHASSIS

GROUND

TO

CHASSIS

GROUND

POSITIVE GROUND SYSTEM

TO

VO LTAGE

SOURCE

HOURMETER CONNECTION

TO CHASSIS

GROUND

TO VOLTA GE

SOURCE

NEGATIVE GROUND SYSTEM POSITIVE GROUND SYSTEM

TO VOLTA GE

SOURCE

TO CHASSIS

GROUND

CLOCK CONNECTION

If you have any questions, require technical support or information on UPDATES and

OPTIONAL ACCESSORIES, please contact your local store, distributor or the

Service Center.

USA & Canada:

(800) 544-4124 (6am - 6pm, 7 days a week PST)

All others: (714) 241-6802 (6am - 6pm, 7 days a week PST)

FAX: (714) 432-3979 (24 hr.)

Web: www.equus.com

Technical Service Center

17352 Von Karman Ave.

Irvine, CA 92614

Page 3

INSTRUCTIONS DE MONTAGE

INDICATEUR DE VITESSE / HOROMÈTRE / HORLOGE

PRÉPARATION ANTÉRIEURE À L'INSTALLATION

1

Copyright © 2012 IEC. All Rights Reserved. MRP 93-0034 Rev C

1. Lisez ces instructions en entier avant d'installer cette jauge, et con-

sultez un mécanicien professionnel si vous n'êtes pas familier avec

l'installation des instruments du véhicule ou le fonctionnement des

systèmes connexes du véhicule.

2. Lisez toujours le manuel de service du véhicule et observez les

mesures de sécurité qui y sont énoncées avant de faire des vérifications ou des travaux de service.

3. Installez les jauges uniquement lorsque le moteur est froid et que l'al-

lumage est en positon «OFF».

4. Débranchez le câble de la borne négative (-) de la batterie avant d'installer les jauges. (N'oubliez pas de rebrancher la batterie une fois

que vous avez terminé votre installation.)

REMARQUE : Vous devrez peut-être reprogrammer votre radio, votre

horloge, etc. après avoir rebranché votre batterie.

5. Déterminez l'endroit où installer la jauge. Choisissez un endroit qui ne

nuise pas à la visibilité et à la conduite. Vérifiez derrière l'endroit que

vous avez choisi pour déterminer si vous y trouvez du câblage électrique ou d'autres composants avant de perforer des orifices.

A. INDICATEUR DE VITESSE / HORLOGE (Figure 1)

1. Déterminez l'emplacement qui peut être découpé dans le tableau de

bord sans nuire à rien derrière le tableau. S'il y a déjà une ouverture,

passez à l'étape 3.

2. Avec le garabit, découpez un trou de 3 3/8 po (85,7 mm) dans le

tableau de bord.

3. Utilisez une lime ronde et éliminez les aspérités des bordures du trou.

4. Insérez l'arrière de la jauge dans le trou découpé dans le tableau de bord.

5. Tenez la jauge et tournez-la jusqu'à

ce que le devant soit bien placé dans

le tableau de bord.

6. Serrez l’anneau de verrouillage sur

la jauge en le tournant en sens

horaire jusqu'à ce que la jauge soit

serrée sur le tableau de bord/panneau. Serrez l’anneau de verrouillage À LA MAIN SEULEMENT.

B. HOROMÈTRE

L'horomètre utilisera l'une des deux méthodes d'installation suivantes :

«tableau de bord» (avec cuvette d'installation) ou «montage à bride».

Utilisez les instructions s'appliquant à votre horomètre.

Montage à bride (Figure 2)

1. Déterminez l'emplacement sur le tableau de bord où l'ouverture

puisse être découpée sans nuire à rien derrière le tableau. S'il y a

déjà une ouverture, passez à l'étape 3.

2. Avec le garabit, découpez un trou de 2 po (50,8 mm) dans le tableau

de bord.

3. Utilisez une lime ronde et éliminez les aspérités des bordures du trou.

4. Insérez l'arrière de la jauge dans le trou découpé dans le tableau de bord.

INSTALLATION DE LA JAUGE

2

5. Tenez la jauge et tournez-la jusqu'à

ce que le devant soit bien placé

dans le tableau de bord.

6. Utilisez la bride comme gabarit pour

marquer l'emplacement des 3 vis de

montage.

7. Avec une mèche de 1/8 po (3,18

mm), percez 3 trous dans le tableau

de bord.

8. Insérez l'arrière de la jauge dans le

trou découpé dans le tableau de

bord et fixez-la avec les 3 vis, les rondelles et les écrous fournis.

Serrez à 5 po/lb (0,57 Newton-mètre).

Installation dans le tableau de bord (Figure 3)

1. Déterminez l'emplacement qui peut être découpé dans le tableau de

bord sans nuire à rien derrière le tableau. S'il y a déjà une ouverture,

passez à l'étape 3.

2. Avec le garabit, découpez un trou de 2 po (50,8 mm) dans le tableau

de bord.

3. Utilisez une lime ronde et éliminez les

aspérités des bordures du trou.

4. Insérez l'arrière de la jauge dans le

trou découpé dans le tableau de bord.

5. Tenez la jauge et tournez-la jusqu'à ce

que le devant soit bien placé dans le

tableau de bord.

6. Serrez l’anneau de verrouillage sur la

jauge en le tournant en sens horaire

jusqu'à ce que la jauge soit serrée sur

le tableau de bord/panneau. Serrez

l’anneau de verrouillage À LA MAIN

SEULEMENT.

REMARQUE :Selon le modèle de jauge, il est possible de changer la

couleur de l'éclairage par l'arrière des jauges pour passer du rouge, au

vert et au bleu en installant un filtre facultatif de la couleur sur l'ampoule

(non disponible pour toutes les trousses de jauges).

1. Insérez l'assemblage de l'ampoule et la douille dans le logement à l'ar-

rière de la jauge, et pressez fermement jusqu'à qu'il s'emboîte en

place.

REMARQUE : Le fil électrique alimentant l'éclairage de la jauge doit

être acheté à part. Utilisez un fil électrique de jauge 18-20 AWG à

brins toronnés en cuivre.

2. Connectez le fil ROUGE ou BLANC de la jauge au circuit d'éclairage

du tableau de bord du véhicule, entre le gradateur et l'éclairage (consultez le manuel de service de la véhicule pour plus d'informations sur

le fil correcte.)

INSTALLATION ET RACCORDEMENT DE L'ÉCLAIRAGE DE LA JAUGE - Indicateur de vitesse

3

3. Raccordez le fil électrique NOIR de la douille d'éclairage sur une

bonne mise à la masse du châssis.

4. Isolez les connexions à l'aide de gaine

thermorétrécissable pour prévenir les

court-circuits.

AVERTISSEMENT : Utilisez uniquement

l'ampoule de rechange #161 (instruments /

indicateurs) fournie par les vendeurs de

pièces d'auto. LA CHALEUR PLUS

INTENSE DES AMPOULES PLUS FORTES

FERA FONDRE L'EXTÉRIEUR DE LA

JAUGE; ELLE PRÉSENTE UN RISQUE

D'INCENDIE.

Figure 4

4.0

4.0

Figure 1

Figure 2

Figure 3

ANNEAU DE

VERROUILLAGE

HOROMÈTRE

VIS

HOROMÈTRE

ANNEAU DE

VERROUILLAGE

ÉCROU

Ampoule

et douille

Filtre facultatif

de la couleur

Page 4

Copyright © 2012 IEC. All Rights Reserved.

Le fabricant garantit à l'acheteur original que cet appareil ne présentera aucun défaut

de matériau ou de fabrication pendant une année à compter de la date d'achat original. Si l'appareil s'avère défectueux pendant cette période d'une année, il sera réparé

ou remplacé, à la discrétion du fabricant, sans frais pour l'acheteur, à la condition que

ce dernier envoie l'appareil défectueux en port payé au Centre de service, accompagné d'une preuve d'achat acceptable, notamment un reçu de caisse.Cette garantie ne

couvre pas les frais de main d'œuvre pour l'installation des pièces. Toutes les pièces

de rechange, qu'elles soient neuves ou remises à neuf, seront garanties pour la durée

restante de la garantie originale. Cette garantie ne s'applique pas aux dommages

causés par une mauvaise utilisation, un accident, un usage abusif, une tension électrique inappropriée, une mauvaise réparation, un incendie, une inondation, la foudre

ou une autre catastrophe naturelle. Cette garantie ne s'applique pas non plus aux produits ayant été modifiés ou réparés hors d'un centre de service agréé par le fabricant.

Le fabricant ne peut sous aucune circonstance être tenu responsable de quelque

dommage accessoire que ce soit associé au non-respect d'une garantie écrite relative

à ce produit. Cette garantie vous accorde des droits juridiques spécifiques, mais il est

possible que vous ayez également d'autres droits selon votre lieu de résidence. Ce

manuel est protégé par des droits d'auteurs (tous droits réservés). Aucune partie de

GARANTIE LIMITÉE D’UNE ANNÉE ET PROCÉDURE DE SERVICE

RACCORDEMENT DE LA JUAGE

4

A. INDICATEUR DE VITESSE (Figure 4)

Pour connecter l'indicateur de vitesse, il est nécessaire d'utiliser le câble

de tachymètre existant du véhicule. Amener le câble de tachymètre existant jusqu'à l'arrière de l'indicateur de vitesse et l'y raccorder au connecteur mâle 5/8"-18. Si l'entraînement du câble et (ou) le connecteur

femelle fileté en provenance du câble de l'indicateur de vitesse ne convient

pas, vous devez acheter un adaptateur et (ou) remplacer le câble de l'indicateur de vitesse Consultez la note IMPORTANT ci-dessous. Les adaptateurs et câbles de raccordement sont vendus dans la plupart des magasins spécialisés.

IMPORTANT : Cet indicateur de vitesse a

été conçu pour un rapport de transmission de 1:1 (60 mph ou 96,5 km/h à 1000

tr/mn) avec un arbre de câble à filetage

5/8"-18. Cet arbre s'insère dans un connecteur femelle de section carrée de

0,104” (2,64 mm). Si la dimension des

pneus ou le différentiel NE SONT PAS

d'origine, la précision de l'indicateur de

vitesse peut se trouver affectée.Il se peut

qu'il soit nécessaire de changer de

pignon pour obtenir la vitesse de 60 mph

(96,5 km/h) à 1000 tr/min.

FONCTIONNEMENT DU COMPTEUR JOURNALIER

L'indicateur de vitesse est équipé d'un compteur journalier à quatre

chiffres. Pour remettre le compteur journalier à zéro, faire tourner le bouton du compteur dans le sens inverse des aiguilles d'une montre jusqu'à

ce que le compteur affiche «0000».

B. HOROMÈTRE / HORLOGE (Figure 5)

REMARQUE : La tension d'utilisation de de l'horomètre / horloge est de

10-80 V c.c. (respectez la polarité).

REMARQUE : Les câbles ne sont pas fournis. Utiliser des fils de calibre

A.W.G. 16 à 18 au minimum.

1. Déterminer les endroits de passage des fils du horomètre. Pour tra-

verser la paroi ignifuge du moteur, passer par un oeillet existant ou

percer un trou de 3/8" 9,5 mm). Insérer un oeillet en caoutchouc

(vendu séparément) dans le trou ou entourer les fils de ruban adhésif

isolant pour éviter qu'ils s'abîment.

2. Sertir ou souder des cosses plates femelles de 1/4" (6 mm) (vendues

séparément) sur les files positif (+) et négatif (-) du horomètre.

3. Raccorder les fils aux bornes positive (+) et négative (-) du horomètre

ou horloge. Faire passer les câbles à travers l'oeillet de la paroi ignifuge.

4. Raccorder les extrémetiés libres des fils du horomètre ou horloge au

circuit électrique du véhicule :

HOROMÈTRE

Circuits à masse négative

■ Raccorder le fil positif du horomètre à une source de tension com-

mutée sur le circuit électrique du véhicule.

■ Raccorder le fil négatif du horomètre à une bonne masse du véhicule.

Circuits à masse positive

■ Raccorder le fil négatif du horomètre à une source de tnesion

commutée sur le circuit électrique du véhicule.

■ Raccorder le fil positif du horomètre à une bonne masse du véhicule.

HORLOGE

Circuits à masse négative

■ Raccorder le fil positif du horloge à une source de tension directe

sur le circuit électrique du véhicule.

■ Raccorder le fil négatif du horloge à une bonne masse du véhicule.

Circuits à masse positive

■ Raccorder le fil négatif du horloge à une source de tension directe

sur le circuit électrique du véhicule.

■ Raccorder le fil positif du horloge à une bonne masse du véhicule.

■ Raccorder le fil négatif du horomètre à une source de tnesion

commutée sur le circuit électrique du véhicule.

5. Bien attacher les fils le long de leur passage pour éviter qu'ils soient

endommagés par des arêtes coupantes, des organes en mouvement

ou par la température de certains éléments du moteur.

6. Rebrancher le câble négatif (-) de la batterie.

■ Horomètre: Démarrer et faire tourner le moteur pendant

quelques minutes pour s'assurer que le moromètre enregistre la

durée de fonctionnement.

■ Horloge: Observez l'horloge pendant plusieurs minutes et vérifiez

les avances de temps.

Figure 4

Figure 5

CÂBLE D’INDICATEUR

DE VITESSE EXISTANT

VERS LA

SOURCE DE

TENSION

CIRCUIT À MASSE NÉGATIVE

VERS

LA

MASSE

VERS

LA

MASSE

CIRCUIT À MASSE POSITIVE

VERS LA

SOURCE DE

TENSION

RACCORDEMENT DE LA HOROMÈTRE

VERS LA

MASSE

VERS LA SOURCE

DE TENSION

CIRCUIT À MASSE NÉGATIVE

VERS LA SOURCE

DE TENSION

VERS LA

MASSE

CIRCUIT À MASSE POSITIVE

RACCORDEMENT DE LA HORLOGE

ce document ne peut être copiée ou reproduite par quelque procédé que ce soit sans

une autorisation expresse et écrite du fabricant. CETTE GARANTIE N'EST PAS

TRANSFÉRABLE. Pour obtenir une réparation sous garantie, envoyer l'appareil au

fabricant en port payé, via UPS (si possible). Prévoir 3-4 semaines pour la réparation.

Si vous avez des questions, si vous avez besoin d'assistance technique ou si vous

désirez des informations supplémentaires, notamment sur les MISE À JOUR et les

ACCESSOIRES OPTIONNELS, veuillez contacter votre détaillant, un distributeur ou

le Centre de service.

États-Unis et Canada :

(800) 544-4124 (6am à 6pm, heure du Pacifique, sept jours par semaine))

Autres pays: (714) 241-6802 (6am à 6pm, heure du Pacifique, sept jours par semaine)

Télécopieur: (714) 432-3979 (24h/24)

Internet : www.equus.com

Tecnhical Service Center

17352 Von Karman Ave.

Irvine, CA 92614

Page 5

INSTRUCCIONES DE INSTALACIÓN

VELOCÍMETRO / MEDIDOR DE HORAS / RELOJ

PREPARACIÓN PARA LA INSTALACIÓN

1

Copyright © 2012 IEC. All Rights Reserved. MRP 93-0034 Rev C

1. Lea todas las instrucciones antes de instalar el indicador, y solicite la

asesoría de un profesional si usted no está familiarizado con la instalación de instrumentos en vehículos o con las funciones de los diferentes sistemas relacionados con el vehículo.

2. Siempre lea el manual de servicio del vehículo y siga sus precau-

ciones de seguridad antes de realizar cualquier procedimiento de

prueba o de servicio.

3. Instale indicadores sólo cuando el motor esté frío y la ignición esté

apagada.

4. Desconecte el cable negativo (-) de la batería antes de instalar los

indicadores. (No olvide de conectar la batería después de ter-

minar la instalación.).

NOTA: Después de conectar la batería quizá sea necesario volver a

programar el radio, el reloj, etc.

5. Determine una ubicación de montaje para el indicador. Elija una ubicación que no afecte la visibilidad ni interfiera con la conducción del

vehículo. Antes de taladrar, inspeccione detrás de la ubicación de

montaje para comprobar que no haya cableados ni componentes.

A. VELOCÍMETRO / RELOJ (Figura 1)

1. Determine una ubicación en el tablero que se puede cortar sin dañar

a los componentes que hay detrás.(Para usar un agujero ya existente,

consulte el paso 3.)

2. Con un patrón, corte un agujero de 86 mm (o según necesario) en el

tablero.

3. Con una lima redonda,

alise los bordes ásperos

alrededor del orificio

perforado.

4. Introduzca el indicador en el agujero del tablero.

5. Sujete la caja del indicador y gire el

indicador según sea necesario,

hasta que el marcador quede

debidamente colocado al frente del

tablero.

6. Apriete el anillo de sujeción en el

indicador hacia la derecha hasta que

el indicador esté apretado en el

tablero. Apriete el anillo de sujeción

SÓLO CON LA FUERZA DE LA

MANO.

B. MEDIDOR DE HORAS

El medidor de horas utilizará una de dos opciones de montaje "Montaje en

el panel de instrumentos" (usando una base de montaje) o "Montaje en

brida". Utilice las instrucciones de instalación apropiadas para su medidor

de horas.

Montaje en brida (Figura 2)

1. Determine una ubicación en el tablero que se pueda cortar sin dañar

los componentes que hay detrás. (Para usar un agujero ya existente,

consulte el paso 3.)

2. Con un patrón, corte un agujero de 2" (50,8 mm) en el tablero.

3. Con una lima redonda, alise los bordes ásperos alrededor del orificio

perforado.

4. Introduzca el indicador en el agujero del tablero.

INSTALACIÓN DEL INDICADOR

2

5. Sujete la caja del indicador y gire el indicador según sea necesario,

hasta que el marcador quede debidamente colocado al frente del

tablero.

6. Utilizando la brida del medidor como

plantilla, marque los lugares de los

tres tornillos de montaje.

7. Usando una broca de taladro de

1/8" (3,18 mm), perfore tres agujeros a través del panel de instrumentos.

8. Introduzca el medidor a través del

agujero en el panel de instrumentos

y asegúrelo con los tres tornillos, las

arandelas y las tuercas provistas.

Apriete las tuercas hasta 5 pulgadas-libra (0,57 N m).

Montaje en el panel de instrumentos (Figura 3)

1. Determine una ubicación en el tablero que se pueda cortar sin dañar

los componentes que hay detrás. (Para usar un agujero ya existente,

consulte el paso 3.)

2. Con un patrón, corte un agujero de 2"

(50,8 mm) en el tablero.

3. Con una lima redonda, alise los bordes ásperos alrededor del orificio perforado.

4. Introduzca el indicador en el agujero

del tablero.

5. Sujete la caje del indicador y gire el

indicador según sea necesario, hasta

que el marcador quede debidamente

colocado al frente del tablero.

6. Apriete el anillo de sujeción en el indicador hacia la derecha hasta

que el indicador esté apretado en el tablero. Apriete el anillo de sujeción SÓLO CON LA FUERZA DE LA MANO.

NOTA: Dependiendo del modelo, la iluminación de fondo del indicador

puede cambiar a rojo, verde o azul mediante la instalación del filtro de

color opcional sobre la bombilla (no está disponible para todos los juegos

de indicadores).

1. Inserte el foco y receptor en el agujero detrás del indicador y presione

hasta que trabe en su lugar.

NOTA: Es necesario comprar por separado el cable para las luces del

indicador. Use cable de cobre entorchado de calibre AWG 18-20.

2. Empalme el cable ROJO o BLANCO del indicador al circuito de ilumi-

nación del vehículo, entre el control de graduación y las luces.

(Consulte el manual de servicio para el cable correcto.)

3. Conecte el cable NEGRO del receptor de la luz a una conexión a tie-

rra apropiada en el chasis.

INSTALACIÓN Y CONEXIÓN DE LA LUZ DEL INDICADOR - Velocímetro

3

4. Aísle las conexiones con tubería termo encogible para prevenir los cortocir-

cuitos.

ADVERTENCIA: Para lámparas de

reemplazo sólo utilice el tipo instrumento/indicador modelo # 161

disponibles en la mayoría de los

almacenes de auto partes. NO UTILICE NINGÚN OTRO NÚMERO DE

PIEZA PUESTO QUE EL CALOR PRODUCIDO POR UNA LÁMPARA DE

MAYOR POTENCIA DERRETIRÁ LA

CAJA DEL INDICADOR Y CAUSARÁ

UN PELIGRO DE FUEGO.

Figura 4

4.0

4.0

Figura 1

Figura 2

Figura 3

ANILLO DE

SUJECIÓN

MEDIDOR

DE HORAS

TORNILLO

DE MONTAJE

MEDIDOR DE

HORAS

ANILLO DE

SUJECIÓN

BOMBILLA Y RECEPTÁCULO

COLOR OPCIONAL

CONJUNTO DE

FILTRO DE

Page 6

GARANTÍA LIMITADA POR UN AÑO: El fabricante garantiza al comprador original que esta unidad carece de defectos a nivel de materiales y manufactura bajo

el uso y mantenimiento normales, por un período de un (1) año contado a partir

de la fecha de compra original. Si la unidad falla dentro del período de un (1) año,

será reparada o reemplazada, a criterio del fabricante, sin ningún cargo, cuando

sea devuelta prepagada al centro de servicio, junto con el comprobante de compra. El recibo de venta puede utilizarse con ese fin. La mano de obra de instalación no está cubierta bajo esta garantía. Todas las piezas de repuesto, tanto si

son nuevas como remanufacturadas, asumen como período de garantía solamente el período restante de esta garantía. Esta garantía no se aplica a los daños

causados por el uso inapropiado, accidentes, abusos, voltaje incorrecto, servicio,

incendio, inundación, rayos u otros fenómenos de la naturaleza, o si el producto

fue alterado o reparado por alguien ajeno al centro de servicio del fabricante. El

fabricante en ningún caso será responsable de daños consecuentes por

incumplimiento de una garantía escrita de esta unidad. Esta garantía le otorga a

usted derechos legales específicos, y puede también tener derechos que varían

según el estado. Este manual tiene derechos de propiedad intelectual, con todos

GARANTÍA Y SERVICIO (GARANTÍA Y SERVICIO VÁLIDOS SÓLO EN E.U.A Y CANADÁ)

CONEXIÓN DE INDICADOR

4

A. VELOCÍMETRO (Figura 4)

La conexión del velocímetro requiere el uso del cable del velocímetro original del vehículo. Cambie la ruta del cable del velocímetro existente a la

parte trasera del velocímetro y conéctelo a la rosca macho de 5/8" (1,5

mm) calibre 18 en la parte trasera del velocímetro. Si el impulsor cuadrado y/o el conector roscado hembra del cable del velocímetro del vehículo

no ajustan, usted debe comprar un adaptador y/o sustituir el cable del

velocímetro. Vea la nota IMPORTANTE abajo. Hay adaptadores y cables

disponibles en la mayoría de los talleres de velocímetros.

IMPORTANTE: El velocímetro está diseñado para una relación de accionamiento de

1:1 (60 mph o 96,5 km/h [26,8 m/s] a 1 000

r/min) utilizando un cable roscado 5/8" (1,5

mm) calibre 18. Este cable requiere un

receptáculo impulsor cuadrado hembra de

0.104" (2,64 mm). Si el tamaño de las llantas o el diferencial del vehículo no son

estándar (originales de fábrica), la exactitud

del velocímetro resultará afectada. Puede

ser necesario cambiar el engrane impulsor

para obtener la velocidad requerida de 60

MPH (96,5 km/h [26,8 m/s]) a 1 000 r/min.

OPERACIÓN DEL ODÓMETRO DE VIAJE

El velocímetro está equipado con un odómetro de viaje de cuatro cifras

con regreso rápido a cero. Para poner en cero el odómetro, gire la perilla

correspondiente a la izquierda hasta que indique "0 000".

B. MEDIDOR DE HORAS / RELOJ (Figura 5)

NOTA: El voltaje de operación del medidor de horas / reloj es de 10 V c.c.

a 80 V c.c. como máximo (sensible a la polaridad).

NOTA: Los cables de entrada deben comprarse por separado. Use cable

AWG 16 - 18 como mínimo.

1. Determine la dirección de los cables de entrada del indicador. Use un

ojal existente en el mamparo contrafuegos, o taladre un agujero de

3/8" (9,5 mm) de diámetro a través del mamparo contra-fuegos para

acomodar los cables de entrada. Instale un ojal de goma (se vende por

separado) en el agujero, o enrolle cinta aislante alrededor de los cables

de entrada para protegerlos contra el rozamiento u otros daños.

2. Instale y engarce o suelde los conectores hembra de espada de 1/4"

(0,6 mm) (se venden por separado) en los cables positivo (+) y negativo (-) del indicador.

3. Conecte los cables de entrada a los terminales de espada positivo (+)

y negativo (-) del contador de horas o reloj. Encamine los cables de

entrada a través del ojal en el mamparo contrafuegos.

4. Conecte los extremos sueltos de los cables de entrada del conta-dor

de horas o reloj al sistema eléctrico del vehículo:

MEDIDOR DE HORAS

Para los sistemas de polo negativo a tierra

■ Conecte el cable positivo de entrada del contador de horas a la

fuente de voltaje con interruptor en el sistema eléctrico del vehículo.

■ Conecte el cable negativo de entrada del contador de horas a un

buen contacto de tierra en el chasis.

Para sistemas de polo positivo a tierra

■ Conecte el cable negativo de entrada del contador de horas a una

fuente de voltaje con interruptor en el sistema eléctrico del vehículo.

■ Conecte el cable positivo de entrada del contador de horas a un

buen contacto de tierra en el metal desnudo del chasis.

HORLOGE

Circuits à masse négative

■ Raccorder le fil positif du horloge à une source de tension directe

sur le circuit électrique du véhicule.

■ Raccorder le fil négatif du horloge à une bonne masse du véhicule.

Circuits à masse positivo

■ Raccorder le fil négatif du horloge à une source de tension directe

sur le circuit électrique du véhicule.

■ Raccorder le fil positif du horloge à une bonne masse du véhicule.

5. Sujete los cables de entrada a lo largo de su ruta de instalación a fin

de evitar daños causados por bordes filosos, piezas en movimiento o

por el contacto con componentes calientes del motor.

6. Conecte nuevamente el cable negativo (-) de la batería.

■ Horomètre: Démarrer et faire tourner le moteur pendant

quelques minutes pour s'assurer que le moromètre enregistre la

durée de fonctionnement.

■ Horloge: Observez l'horloge pendant plusieurs minutes et vérifiez

les avances de temps.

Figura 4

Figura 5

CABLE DEL

VELOCÍMETRO

EXISTENTE

A LA

FUENTE DE

VOLTAJE

SISTEMA DE POLO NEGATIVO A TIERRA SISTEMA DE POLO POSITIVO A TIERRA

A LA CONEXIÓN

DE TIERRA EN

EL CHASIS

A LA CONEXIÓN

DE TIERRA EN

EL CHASIS

A LA

FUENTE DE

VOLTAJE

CONEXIÓN DE MEDIDOR DE HORAS

A LA CONEXIÓN DE

TIERRA EN EL CHASIS

A LA FUENTE

DE VOLTAJE

NEGATIVE GROUND SYSTEM POSITIVE GROUND SYSTEM

A LA FUENTE

DE VOLTAJE

A LA CONEXIÓN DE

TIERRA EN EL CHASIS

CONEXIÓN DE RELOJ

Copyright © 2012 IEC. All Rights Reserved.

los derechos reservados. Ninguna parte de este documento podrá ser copiada o

reproducida por medio alguno sin el consentimiento expreso por escrito del fabricante. ESTA GARANTÍA NO ES TRANSFERIBLE. Para obtener servicio, envíe el

producto por U.P.S. (si es posible) prepagado al fabricante. El servicio o

reparación tardará de 3 semanas a 4 semanas.

PROCEDIMIENTOS DE SERVICIO: Si tiene alguna pregunta, o necesita

apoyo técnico o información sobre ACTUALIZACIONES y ACCESORIOS

OPCIONALES, por favor póngase en contacto con su tienda o distribuidor

local, o con el centro de servicio. Estados Unidos y Canadá (800) 544-4124 (de

siete días a la semana 6am a 6pm, hora del Pacífico). Todos los demás

Paises:(714) 241-6802 (de siete dias a la semana, de 6am a 6pm, hora del

Pacífico). FAX:(714) 432-3979 (las 24 horas) Web: www.equus.com

LA GARANTÍA VÁLIDA EN MÉXICO ES LA QUE OFRECE EL IMPORTADOR

(VER DOCUMENTO ANEXO).

Tecnhical Service Center

17352 Von Karman Ave.

Irvine, CA 92614

Loading...

Loading...