Page 1

3660 © Innova 2001

FRONT

COVER

3660

HAND PUMP

Page 2

i 3660

Paragraph Title Page No.

I INTRODUCTION............................................................ 1

II SAFETY PRECAUTIONS .............................................. 1

III VEHICLE SERVICE MANUALS................................... 2

IV UNDERSTANDING VACUUM SYSTEMS................... 2

V AUTOMOTIVE VACUUM SYSTEMS ........................... 4

VI VACUUM MOTOR/ACTUATOR OPERATION

AND TESTING................................................................ 7

VII TESTING THE PCV SYSTEM....................................... 8

VIII TESTING THE EGR SYSTEM....................................... 10

IX DIAGNOSING MECHANICAL

ENGINE CONDITIONS ................................................. 13

X EXHAUST SYSTEM RESTRICTION TEST ................. 15

XI FLUID EVACUATION ................................................... 16

XII BLEEDING BRAKES ..................................................... 18

XIII REPLACEMENT PARTS .............................................. 20

XIV SERVICE PROCEDURES ............................................. 21

WARNING:

This manual includes WARNINGS and CAUTIONS

identifying procedures and practices which, if not performed

properly, may result in personal injury or equipment damage.

However, this manual DOES NOT cover all possible uses or

methods of operation for the hand pump. It is the responsibility

of the user to determine that the method of operation and/or

servicing procedure used will not jeopardize personal safety or

vehicle safety. DO NOT USE THE VACUUM PUMP, IN ANY

MANNER, ON THE HUMAN BODY.

Page 3

3660 1

I. INTRODUCTION

Congratulations. You have purchased a precision instrument

manufactured to the highest quality standards. This hand-operated

vacuum pump is a versatile tool that can be used in almost any

application where a vacuum must be generated, an existing vacuum

within a system must be measured or for fluid evacuation.

The vacuum pump is designed to aid in testing automotive vacuum

systems; testing vacuum actuated components and devices, and

bleeding brake systems.

The vacuum pump can also be used (in conjunction with a fluid

evacuation kit) as a fluid evacuation device to evacuate fluids from

various systems or locations.

II. SAFETY PRECAUTIONS

To avoid personal injury, instrument damage and/or damage to

equipment under test, DO NOT operate the hand pump before

reading this manual. ALWAYS use extreme caution when

working on an automobile.

This manual describes common test procedures used by experienced

service personnel and technicians. Many test procedures require

precautions to avoid accidents that can result in personal injury, and/or

vehicle or equipment damage. Always read your vehicle's service

manual and follow its safety precautions before any test or service

procedure is performed.

a. When an engine is running, it produces carbon monoxide )a toxic

and poisonous gas). To prevent serious injury or death from carbon

monoxide poisoning, operate a vehicle ONLY in a well-ventilated

area.

b. To protect your eyes from propelled objects as well as hot or caustic

liquids, always wear approved safety eye protection.

c. When an engine is running, several engine components rotate at a

very high rate of speed (coolant fan, pulleys, fan belt etc.). To avoid

serious injury, always be conscious of moving parts and keep a safe

distance from all these items as well as other potentially moving

objects.

d. Engine parts become extremely hot when the engine is running. To

prevent severe burns, avoid contact with hot engine parts.

e. Before starting an engine for troubleshooting, make sure the

parking brake is engaged. Put the transmission in "park" )for

automatic transmission) or "neutral" (for manual transmission).

Block the drive wheels with a suitable blocking device.

Page 4

2 3660

f. To prevent damage to the on-board computer when taking vehicle

electrical measurements, always use a digital multimeter with at

least 10 Megohms of impedance.

g. The vehicle's battery produces highly flammable hydrogen gas. To

prevent an explosion, keep all sparks, high temperature items and

open flames away from the battery.

h. Don't wear loose clothing or jewelry when working on an engine.

Loose clothing can get caught on the fan, pulleys, belts, etc.

Jewelry is highly conductive to electricity, and can cause a severe

burn if it makes contact between a power source and ground.

III. VEHICLE SERVICE MANUALS

It is recommended that you consult the manufacturer’s service manual

for your vehicle before any test or repair procedures are performed.

Contact your local car dealership or auto parts store for availability of

these manuals. The following companies publish valuable repair

manuals.

Haynes Publications, 861 Lawrence Drive, Newbury Park, CA

91320, Phone: CA (800) 442-9637, TN (800) 242-4637

Motor Publications, 5600 Crooks Road, Suite 200, Troy, Michigan

48098, Phone (800) 426-6867

Mitchell International, 14145 Danielson Street, Poway, CA 92064,

Phone (888) 724-6742

FACTORY SOURCE (Ford, GM, Chrysler, Honda, Isuzu, Hyundai

and Subaru Service Manuals

Helm Inc., 14310 Hamilton Avenue, Highland Park, Michigan 48203,

Phone (800) 782-4356

IV. UNDERSTANDING VACUUM SYSTEMS

In order to properly test and diagnose faults in automotive vacuum

systems, it is important to understand what vacuum is, how it is

measured, and how engines create, distribute and use vacuum.

A. WHAT IS VACUUM?

The earth’s atmosphere (the air that we breathe) is not really empty

space, but is filled with air molecules. Vacuum is the partial or

complete absence of atmosphere (an empty space where no molecules of

any sort exist). Interstellar space is an almost a perfect vacuum.

Page 5

3660 3

B. HOW IS VACUUM MEASURED?

The earth’s atmosphere exerts a force on all surfaces it contacts. This

force is called “atmospheric pressure”. There is a direct relationship

between atmospheric pressure and vacuum. In order to understand

vacuum, we need to understand what atmospheric pressure is and how

it's measured.

Air is composed of tiny particles called molecules. Air molecules have

weight. Atmospheric pressure is defined as the force exerted by the

total weight of the air above a specific area at any elevation. At sea

level, the total weight of a column of air (air molecules) above an area

of one square inch equals 14.7 pounds (1030g/cm2). At higher

elevations there are fewer air molecules, and the weight of the air

above a comparable surface area is lower than at sea level. This is why

the air pressure at higher elevations is lower than at sea level.

Atmospheric pressure is measured using an instrument called a

Manometer/Barometer. A Manometer/Barometer is a hollow glass tube

with one end sealed and the other end immersed in a container of

mercury.

At sea level, the force of the surrounding air pressure (atmospheric

pressure) of 14.7 psi (1030g/cm2) acting on the mercury in the

container forces the mercury up the glass tube to a measured height of

30 inches (76 cm).

Vacuum can be defined as a pressure that is less than the surrounding

air pressure (atmospheric pressure). Vacuum gauges base their

readings on atmospheric pressure as indicated on a Manometer/

Barometer. The “0” indication on a vacuum gauge is calibrated to

represent "atmospheric pressure"; the “30” indication represents "zero

pressure" or a "perfect vacuum". Any reading between these two

indications (“0” and “30”) represents a pressure that is less than the

surrounding air pressure (atmospheric pressure).

C. HOW IS VACUUM CREATED/GENERATED?

Vacuum (a low pressure area) can be created in a sealed container in

one of two ways:

1. If part of the air is removed from a sealed container, there will be

fewer air molecules per square inch inside the sealed container

than in the surrounding outside air. Fewer air molecules within a

constant area equates to a lower air pressure.

2. If the area inside a sealed container is increased but the amount of

air inside the container stays the same. The area inside the

container will have fewer air molecules per square inch than the

surrounding outside air. Increasing area while maintaining a

constant volume of air equates to a lower air pressure.

Page 6

4 3660

V. AUTOMOTIVE VACUUM SYSTEMS

A. HOW AN ENGINE GENERATES VACUUM

Gasoline engines create vacuum as a byproduct of normal operating.

During engine operation, when the pistons inside the cylinders move

down on the intake stroke, the combustion chamber area (volume)

inside the cylinders is greatly increased (see Figure 1). This action

decreases the pressure inside the combustion chamber creating a

partial void or vacuum (an area with fewer air molecules per square

inch than the surrounding outside air.) A mixture of air and fuel from

the carburetor/fuel injectors and intake manifold rushes into the

cylinders through the intake valve to fill this partial void. The

continuous movement of the pistons within the cylinders creates a need

for a constant supply of air and fuel to fill the partial void created

inside the cylinders on the intake strokes. The continuous flow of air

and fuel through the intake manifold creates a low pressure (vacuum)

inside the manifold. The low pressure (vacuum) in the intake manifold

exists as long as the engine is in operation. This is how vacuum is

generated in an internal combustion (gasoline) engine.

In a gasoline-operated engine/vehicle the vacuum that is generated in

the intake manifold is used to operate a number of vacuum-actuated or

vacuum-controlled devices.

NOTE:

Diesel engines, because of their design, produce less vacuum than

gasoline engines. The vacuum produced by a diesel engine is insufficient

to operate vacuum devices. If vacuum devices are added to a diesel

system, an electrical or mechanical vacuum pump is used to operate these

devices. Regardless of how vacuum is generated, the principle of operation

of vacuum devices is the same. The hand vacuum pump can be used to

test vacuum operated devices on both gasoline and Diesel systems.

Figure 1. Piston Intake Stroke

FUEL INJECTOR

VACUUM PORT

EXHAUST

INTAKE MANIFOLD

COMBUSTION

CHAMBER

PISTON

Page 7

3660 5

B. VACUUM DISTRIBUTION SYSTEMS

In order to supply vacuum from the intake manifold to the various

vacuum-operated devices found on an automobile, a vacuum

distribution system is needed. Vehicle manufacturers install vacuum

ports and/or vacuum distribution blocks in the intake manifold. Most

vacuum-operated devices are connected to these vacuum ports/vacuum

distribution blocks using vacuum hoses, lines and fittings.

NOTE:

Some vacuum ports are located above the throttle plates of the

throttle body and only supply vacuum when the throttle plates open.

This type of connection is called "Ported Vacuum". On some vehicles,

emission-related devices such as EGR valves or distributor vacuum

actuators are designed to operate only when the vehicle is driven under

certain conditions. Ported vacuum is used to operate these devices.

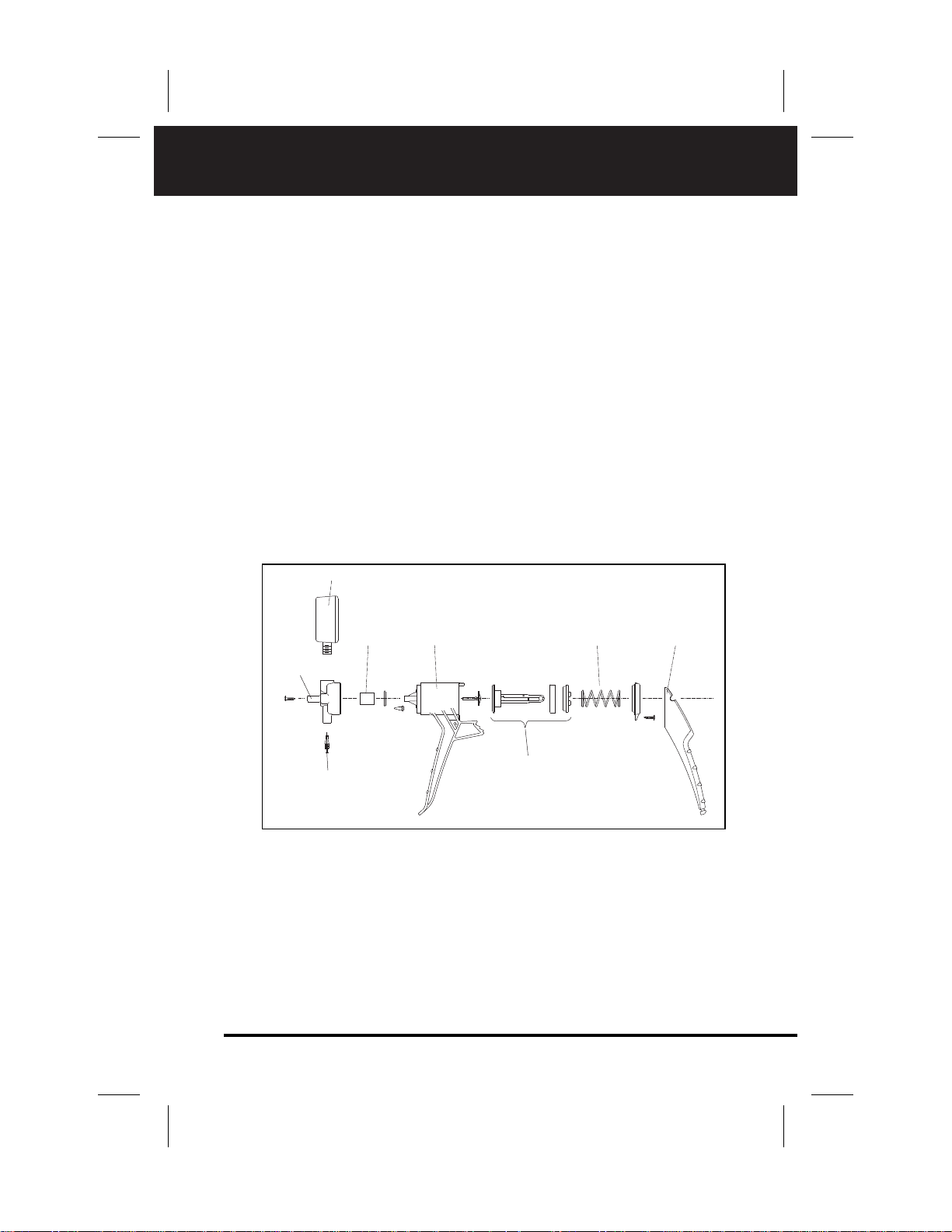

C. USING THE VACUUM PUMP

The vacuum pump consists essentially of a pump body, a moveable

handle, a spring-loaded piston rod, a vacuum gauge, a vacuum fitting

and a vacuum release system (see Figure 2).

The vacuum pump can be used in almost any application where

vacuum must be generated, or where existing vacuum within a system

must be measured. In most cases, the vacuum pump is connected

directly to the vacuum port of a component, or is connected into a

vacuum hose in the system using a tee connector. The following

paragraphs outline the basic modes of operation for the vacuum pump.

Specific uses for the vacuum pump are provided later in this manual.

Figure 2. Hand Vacuum Pump - Exploded View

GAUGE

VACUUM

PORT

VACUUM

RELIEF

VALVE

FILTER

MAIN BODY

PISTON ASSEMBLY

SPRING PUMP HANDLE

Page 8

6 3660

D. APPLYING VACUUM

1. Connect the vacuum pump's vacuum fitting to the component or

system to be tested.

2. Squeeze and release the pump handle, and read the amount of

vacuum indicated on the vacuum gauge.

3. Continue squeezing and releasing the pump handle until the

desired amount of vacuum is shown on the vacuum gauge.

E. TROUBLESHOOTING VACUUM SYSTEMS

NOTE:

This manual describes common general test procedures used by

service personnel and technicians. Use the test procedures described in

this manual only as a guide. Always consult the vehicle's service

manual for more detailed testing instructions and specifications before

any diagnostic test or procedure is performed.

The intake manifold is a sealed system, and the air that enters the

system must be metered to maintain a balanced air/fuel mixture. On a

gasoline engine, this metering is controlled by the throttle plates. A

leak in any part of the vacuum system, including the intake manifold,

introduces unmetered air into the intake manifold, resulting in a

leaner air/fuel mixture (too much air/not enough fuel). A lean air/fuel

mixture can result in higher combustion temperature and engine

misfires. A vacuum leak will also reduce the total amount of vacuum

available to all vacuum-operated devices, and may severely effect their

operation.

The following are some possible symptoms/results of a vacuum leak:

• Rough or uneven idle

• Stalling

• Pinging or knocking

• Burned spark plugs

• Burned exhaust valves

• Faulty operation of vacuum-operated devices

F. TESTING AND CHECKING VACUUM DEVICES AND COMPONENTS

Most problems in automobile vacuum systems result from disconnected

or leaking hoses, bad connectors, defective motor diaphragms or valves.

Pinched vacuum hoses or clogged valves may also restrict vacuum flow.

The first step in checking a vacuum system is to visually check all

vacuum hoses, lines and connectors for cuts, cracks and splits. Check for

collapsed or pinched vacuum hoses. Vacuum hoses have a tendency to

deteriorate because of harsh conditions within the engine compartment.

Page 9

3660 7

VI. VACUUM MOTOR/ACTUATOR OPERATION AND TESTING

A. VACUUM MOTOR/ACTUATOR DESCRIPTION AND OPERATION

A vacuum motor/actuator is a device that uses vacuum to perform a

mechanical function. An automobile engine uses vacuum motors/

actuators to perform many functions. Typical functions performed by

vacuum motors/actuators are:

• Opening and closing the heater and air conditioning duct doors

• Raising the EGR valve pintle off it’s seat to recirculate exhaust gas

back into the system

• Activating the vacuum advance unit to advance distributor spark

advance timing

A vacuum motor/actuator is a

partially sealed container (on

most vehicles container is

cylindrical in shape). One side

of the container is sealed, and

is equipped with a vacuum

port. The other side of the

container is covered by a

rubber diaphragm, or a piston

a spring, with an attached

shaft or a lever. When engine

vacuum is applied to the

container's vacuum port, a

partial vacuum (lower than

atmospheric pressure) is

created in the sealed section of

the container. As a result,

atmospheric pressure exerts a

force on the side of the piston

or diaphragm that is open to

the atmosphere, causing it to move in the direction of the applied

vacuum. This mechanical action is is utilized to activate whatever is

attached to the shaft or lever on the diaphragm (see Figure 3).

The amount of force applied by atmospheric pressure to the diaphragm

is calculated by multiplying the pressure difference between

atmospheric pressure and the pressure within the container times the

surface area of the diaphragm or piston: Atmospheric Pressure Container Pressure X Surface area = Force

The hand vacuum pump can be used to perform a wide range of tests

such as measuring the amount of vacuum in a system or device,

detecting a leak in a system or a fluctuating vacuum supply. The pump

can also be used for testing the function of a variety of vacuumoperated devices.

Figure 3. Typical Vacuum

Motor/Actuator

VACUUM PORT

SPRING

DIAPHRAM

LEVER

Page 10

8 3660

B. VACUUM MOTOR/ACTUATOR TESTING PROCEDURES

The following procedure shows how the vacuum pump might be used to

check a vacuum motor/actuator for a leaking diaphragm:

1. Connect the vacuum pump's vacuum hose to the vacuum port of

the motor/actuator.

2. Operate the handle to apply 8-10 inches (20-25 cm) Hg of vacuum

to the motor/actuator, as shown on the vacuum gauge.

NOTE:

Consult the vehicle’s service manual for specifications.

3. Observe the vacuum gauge for approximately one minute.

•

If the vacuum gauge reading remains steady for one minute,

the diaphragm is not leaking.

•

If the vacuum gauge reading falls, a leaking diaphragm is

indicated.

VII. TESTING THE PCV SYSTEM

A. SYSTEM DESCRIPTION AND OPERATION

The Positive Crankcase Ventilation (PCV) system helps reduce air

pollution by aiding in the scavenging and burning of harmful engine

crankcase vapors and gases before they can enter the atmosphere. The

PCV system consists essentially of an intake filter, PCV valve and

interconnecting hoses (see Figure 4).

Fresh air is drawn through the intake filter (located in the air cleaner),

through the valve cover, and into the crankcase to be mixed with the

crankcase gases. From the crankcase the gases are drawn to the

opposite valve cover, through the PCV valve, and into the intake

manifold. The intake manifold vacuum draws these crankcase gases

where they are mixed with incoming intake air to be burned during

engine combustion.

Airflow through the PCV system adds to the airflow through the

carburetor or throttle body during engine operation. During cruising

and light acceleration, intake manifold vacuum and the pressure inside

the crankcase are relatively high. The strong manifold vacuum draws

the PCV valve plunger into the narrow end of the valve, restricting

most of the flow of gases into the intake manifold. During hard

acceleration or high speed operation (heavy load condition), low intake

manifold vacuum allows the PCV valve spring to overcome the high

crankcase pressure, pushing the plunger out of the narrow end of the

PCV valve and increasing the flow of crankcase gases into the engine

for combustion.

Page 11

3660 9

B. TEST PROCEDURES

As a result of normal engine operation, the PCV valve may become

clogged and reduce the amount of crankcase ventilation. Reduced

ventilation can cause the formation of acids in the crankcase, and a

buildup of pressure which could force engine oil out past the engine

seals. To prevent these problems, the PCV valve should be replaced

periodically.

NOTE:

A slow or rough idle can be caused by a clogged PCV valve.

Check the PCV system BEFORE adjusting engine idle.

OIL FILLER

Figure 4. Typical PCV System / PCV Valve Operation

CAP

TYPICAL PCV SYSTEM / PCV VALVE OPERATION

FRESH AIR

(CLOSURE)

TUBE

AIR CLEANER

CARB.

INT. MAN.

ROCKER COVER

CRANK CASE

3

PCV VALVE

CONTROLS

FLOW RATE

1

FRESH AIR

FLOW

AIR AND

CRANKCASE

VAPOR FLOW

2

OIL SEPARATOR

PCV VALVE OPERATING CONDITIONS

NORMAL HIGH SPEED OR LOAD BACKFIRE DURING CRANKING

HIGH VACUUM

PULLS VALVE

TOWARD TOP SEAT

CRANKCASE PRESSURE

TENDS TO CLOSE VALVE

FLOW

RATE

IS

LOW

VACUUM

IS LOW

SPRING

OPENS

VALVE

FARTHER

FLOW RATE

INCREASES

BACKFIRE CAUSES

HIGH PRESSURE

IN MANIFOLD

PLUNGER

SEATS TO

SEAL OFF

FROM

CRANKCASE

Page 12

10 3660

1. Inspect the PCV system for worn, kinked or plugged hoses. Make

sure all hoses are properly and securely connected.

2. Connect the hand vacuum pump to an intake manifold vacuum

port. (use the hose and a suitable adapter from the accessory kit,

as needed).

3. Start and run the engine until it reaches normal operating

temperature.

4. Run the engine at idle and observe the vacuum gauge.

•

The vacuum gauge should indicate between 16 ~ 22 in. (41 ~

56 cm) Hg.

•

The gauge needle should remain steady (little or no movement).

•

Note the engine speed (RPM) and vacuum at idle.

5. Clamp the vacuum supply hose to the PCV valve.

•

Engine speed should decrease by approximately 100 RPM (as a

result of loss of air flow from the PCV system).

•

Vacuum should increase slightly (indicating vacuum flow

through the PCV system has been plugged).

•

If BOTH a decrease in engine RPM and an increase in vacuum

are not observed, replace the PCV valve and/or any damaged

or plugged hoses.

NOTE:

Be sure to install the correct PCV valve for your vehicle.

Installing the wrong PCV valve can result in either excessive or

insufficient air flow through the PCV system.

5. After replacing the PCV valve, ALWAYS readjust the engine's idle

speed and, if possible, the idle air/fuel mixture. Refer to your

vehicle's service manual for procedures.

NOTE:

On some vehicles idle speed and air/fuel mixture are not

adjustable. The on-board computer makes adjustments based on

sensor inputs and engine operating conditions. ALWAYS consult

the vehicle's service manual before making any adjustments.

VIII. TESTING THE EGR SYSTEM

A. SYSTEM OPERATION

The Exhaust Gas Recirculation (EGR) system is used to reduce Oxides

of Nitrogen (NOx) emissions. NOx is created when nitrogen and oxygen

in the atmosphere mix at temperatures above 2,500F° (1371° C).

During combustion, temperatures in the cylinders can exceed 3,500 F°

(1927° C), providing ideal conditions for the formation of NOx.

The EGR system reduces the formation of NOx by lowering the

combustion temperature. This is accomplished by recirculating exhaust

gases through an EGR valve back into the combustion chambers.

Page 13

3660 11

Depending on the make, model and year of your vehicle, the EGR valve

may be controlled by one of two methods (see Figure 5):

• Ported Vacuum - The EGR valve is actuated by ported vacuum

from above the carburetor's throttle plates. The amount of exhaust

gas that is recirculated back into the combustion chamber depends

on the amount of vacuum that reaches the EGR valve. At idle and

at wide open throttle a negligible amount of vacuum reaches the

valve and the valve stays closed. As the throttle plates gradually

open, vacuum reaches the valve and the valve starts to open. A low

vacuum to the EGR valve will cause the valve to open slightly. As

the vacuum to the valve increases, the EGR valve continues to

open until it is fully opened.

• EGR Control System - The control system monitors engine

operation and modulates the amount of EGR based on engine

operating conditions such as coolant temperature, ambient air

temperature, exhaust back pressure and engine speed or load.

To improve drivability before the engine has reached normal operating

temperature, most vehicles use a thermal switching device, which

shuts off the EGR system while the engine is cold.

Figure 5. Typical EGR System Operation

VACUUM

PORT

SEALED

HOUSING

DIAPHRAGM

SPRING

ACTUATING ROD

EGR

FLOW

EXAUST

FLOW

INTAKE

FLOW

THROTTLE

PLATE

Page 14

12 3660

B. TROUBLESHOOTING

NOTE:

EGR systems vary greatly between vehicle makes and models.

The following paragraphs provide general testing and troubleshooting

procedures for EGR systems. For specific tests for your vehicle, refer to

the manufacturer's service manual.

A defective EGR valve generally remains either fully closed or fully

open. An EGR valve which remains closed will increase NOx emissions.

An EGR valve which remains open will cause the engine to stall at idle,

to idle roughly, to lose power, or to run rough at full throttle.

An EGR valve may fail as a result of one or more of the following

causes:

• Loss of vacuum or control vacuum

• Mechanical defect (such as a ruptured diaphragm)

• Contamination of or damage to the valve seat (restricted by carbon

buildup)

• Restrictions in the exhaust tube

C. TESTING EGR VACUUM/ EGR CONTROL SYSTEM

1. Connect the vacuum pump's vacuum port to the EGR valve's

vacuum supply line (use the vacuum tee included in the accessory

kit, if necessary).

2. Start and run the engine until it reaches normal operating

temperature.

3. Increase engine speed to approximately 2000 ~ 2500 RPM and

observe the vacuum gauge.

•

The EGR valve vacuum supply should be at least 4 ~ 6 in. (10

~ 15 cm) Hg of vacuum.

•

If no vacuum is present, check the vacuum hoses and

connections that supply vacuum to the EGR valve for any

abnormality or defect. Repair as necessary.

•

If vacuum hoses are in good condition, test the control system

that modulates and controls the vacuum to the EGR valve .

(Control systems and testing procedures vary widely

depending on the make, year and model of the vehicle. Consult

the manufacturer's service manual for testing procedures.)

Page 15

3660 13

D. TESTING THE EGR VALVE DIAPHRAGM

1. Turn the engine "off"

2. Disconnect the vacuum hose at the EGR valve.

3. Connect the vacuum pump to the EGR valve (use the clear hose

and adapter included in the accessory kit, as necessary).

4. Squeeze and release the pump handle until 10 ~ 12 in. (26 ~ 30 cm)

Hg of vacuum is indicated on the gauge. Observe the vacuum

gauge for one minute minimum.

•

Verify the vacuum gauge reading of 10 ~ 12 in. (26 ~ 30 cm)

Hg remains steady for at least one minute. If the vacuum

drops, the diaphragm is defective.

E. CHECKING EGR VALVE SEAT/RESTRICTIONS IN EXHAUST

TUBE

The only way to accurately check the EGR valve seat for contamination

or damage and the exhaust tube for restrictions is to remove the EGR

valve. Consult the manufacturer's service manual for procedures.

The EGR valve may also operate properly with the engine at normal

operating temperature, but remain open when the engine is cold. This

usually occurs when a faulty thermal switching device fails to shut off

the vacuum supply when the engine is cold.

IX. DIAGNOSING MECHANICAL ENGINE CONDITIONS

When used properly, a vacuum gauge can provide a considerable

amount of information about the internal condition of an engine.

However, it is easy to misinterpret the readings of the instrument and

thereby reach false conclusions. When using a vacuum gauge on an

engine, it is far more important to note the action and the general

location of the needle rather than the actual vacuum reading.

NOTE:

Vacuum leaks or improper operation of any of the external

vacuum-operated devices (EGR valve, vacuum-operated solenoids, EVAP

system, vacuum valves, etc.) and hoses may interfere with proper engine

diagnosis by giving a false indication of current engine condition. Always

perform a preliminary check for proper operation and sealing integrity of

these devices before an engine vacuum test is performed.

1. Start and run the engine until it reaches operating temperature.

2. Connect the vacuum gauge to the intake manifold. Whenever

possible, connect the gauge hose directly to a vacuum port on the

intake manifold in order to avoid any leaks that might exist in

other connections.

3. Evaluate the test results.

Page 16

14 3660

NOTE:

Use the following illustrations only as a guide. These drawings

are examples based on manufacturer's specifications of 18 in. (51 cm)

Hg of vacuum at idle at sea level. The idle specifications for your vehicle

may be higher or lower (as specified by the vehicle's manufacturer) than

the ones shown. The purpose of these examples is to show the action

or

fluctuations of the needle, which are indicative of engine condition

1. Normal engine (Figure 6)

An engine at idle at sea level

should show a steady needle, and a

vacuum of 15 ~ 22 in. (38 ~ 56 cm)

Hg depending on manufacturer's

specifications. Quickly opening and

closing the throttle should cause

the vacuum to momentarily drop to

below 5 in. (12 cm) Hg, followed by

a momentary rebound to approximately 25 in. (64 cm) Hg, before

returning to normal 15 ~ 22 in.

(38 ~ 56 cm) Hg.

2. Intake system leak, late

ignition/valve timing, or low

compression (Figure 7)

If the gauge reading at idle is

steady but much lower than normal

(5 ~ 13 in./12 ~ 25 cm Hg), this may

be an indication of intake manifold

system leak (intake gasket, carburetor base gasket, vacuum devices

or hoses, etc.). Readings of 3 ~ 8 in.

(8 ~ 20cm) Hg below normal may be

an indication of late ignition/valve

timing or worn piston rings.

3. Ignition system problems or

burned, leaky and sticking

valves (Figure 8)

If the gauge needle fluctuates very

slowly over a range of approximately 2 in. (3 cm) Hg, this may be

an indication of an ignition

problem (spark plug gap, ignition

coil/cables/cap/circuit). If the

valves are burned or leaking, the

vacuum reading will drop every

time the defective valve or valves

are inoperative. An intermittent

drop indicates sticking valves.

Figure 6

Figure 7

Figure 8

20

25

30

20

25

30

20

25

30

15

15

15

10

5

0

10

5

0

10

5

0

Page 17

3660 15

4. Leaking head gasket, worn

valve guides or weak/broken

valve springs (Figure 9)

If the gauge needle fluctuates

regularly between a high and a

low reading, the cylinder head

gasket may have a leak between

two adjacent cylinders. If the

needle vibrates rapidly at idle

speed, the intake valve guides are

probably worn.If the needle

vibrates rapidly when the engine

is accelerated, the valve springs

are weak.

X. EXHAUST SYSTEM RESTRICTION TEST

The vacuum gauge is also a valuable tool to help in the troubleshooting

of a restricted exhaust system. An exhaust restriction usually allows

normal engine performance at idle, but causes poor performance at

higher engine speed or with the engine under load.

Use the following procedure to test for a restricted exhaust system:

NOTE:

In order for this test to be accurate, make sure other engine

problems (as described in “DIAGNOSING MECHANICAL ENGINE

CONDITIONS") are repaired first, before the Exhaust System

Restriction Test is performed.

1. Connect the vacuum pump to an intake port and start the engine.

2. With the engine at idle, note the vacuum reading on the vacuum

gauge.

•

The vacuum reading should be within manufacturer's

specifications.

3. While observing the vacuum gauge, slowly increase engine speed to

2500 ~ 3000 RPM. At high RPM, engine vacuum should be equal to

the vacuum reading at idle ± 3 in./8 cm Hg.

•

If the vacuum decreases to zero or close to zero at high RPM

there is probably a restriction on the exhaust system.

The most probable cause of a restricted exhaust system is a defective

Catalytic Converter or muffler. Consult the vehicle's service manual for

further testing instructions.

Figure 9

20

25

30

15

10

5

0

Page 18

16 3660

XI. FLUID EVACUATION

WARNING:

DO NOT USE THE HAND VACUUM PUMP TO

EVACUATE GASOLINE OR ANY OTHER HIGHLY FLAMMABLE

OR TOXIC FLUIDS.

CAUTION:

Some fluids (brake fluid, oils, power steering fluid,

etc.), are very caustic (corrosive) and may damage painted

surfaces. Take precautions not to get them in contact with

painted surfaces. If you accidentally get them on a painted

surface wash them off immediately.

The hand vacuum pump is an excellent tool to evacuate almost any

type of fluid. The following are typical areas where the hand vacuum

pump can be very useful for evacuating fluids:

• Automatic transmissions/transaxle: If the transmission is

accidentally overfilled with transmission fluid. Most vehicles are

not equipped with a drain plug, and the only way to drain excess

fluid is to remove the pan. A more effective and easier method is to

use the vacuum pump (with the fluid evacuation kit) to siphon the

extra fluid out through the filler tube.

NOTE:

On some transmissions/transaxles the distance from the

top of the filler tube to the transmission oil pan is quite long. A

longer tubing (sold separately) than the one supplied with the fluid

evacuation kit may be needed to evacuate transmission fluid from

these units.

• Power steering pump fluid: to correct an overfilled condition, to

replace the pump reservoir fluid with new power steering fluid.

• Master cylinder: to correct an overfill condition, to replace the

master cylinder brake fluid with new fluid.

• Differential (4WD and rear wheel drive vehicles): some 4WD

and rear wheel drive vehicles need to be serviced periodically by

changing the differential fluid, but are not equipped with a drain

plug. With the vacuum pump and the fluid evacuation kit, the fluid

can be siphoned out through the fill hole without removing the

differential cover.

• Coolant overflow reservoir: remove coolant from overflow

reservoir, to correct an overflow condition or to change reservoir

coolant.

A. ASSEMBLING THE FLUID EVACUATION/BRAKE BLEEDING KIT

Use the following procedure to connect the fluid evacuation/brake

bleeding kit to the vacuum pump (see Figure 10).

Page 19

3660 17

1. Attach the 3-1/2" (9 cm) length of tubing to the bottom fitting of

the reservoir jar lid.

2. Tighten the reservoir jar lid onto the reservoir jar securely.

3. Connect the 1-1/2" (4cm) or the 24 inch (61cm) length of tubing,

whichever is better suited for your application, between the

vacuum pump and the reservoir jar lid at the fitting marked

"PUMP".

NOTE:

To reduce the possibility of drawing fluid into the vacuum

pump body, make sure that the vacuum pump is only connected to

the tubing that goes to the jar lid fitting marked "PUMP".

4. Attach a 24 inch (61cm) length of tubing to the remaining fitting

on the reservoir jar lid.

JAR LID

Figure 10. Vacuum Pump Brake Bleeding

and Fluid Evacuation Accessories

24 in (21cm) TUBING

8oz ( 240ml)

RESERVOIR

JAR CAP

11/2 in (4cm)

tubing

3.5" (9cm) TUBING

GAUGE HEAD

PUMP

HOSE ADAPTERS

PLUG

TEE FITTING

Page 20

18 3660

B. FLUID EVACUATION PROCEDURES

1. Assemble the fluid evacuation/brake bleeding kit as described on

page 16.

NOTE:

If a large quantity of fluid is to be evacuated, it is advised

that a larger fluid reservoir jar be used. A fluid evacuation kit that

includes a 24-ounce (720 ml) reservoir jar and longer tubing is

available as an option. See page “REPLACEMENT PARTS” on

page 20 for more information.

2. Insert the open end of the clear tubing into the item from which

fluid is going to be evacuated. (Make sure the evacuation kit is

assembled properly and the jar lid is properly tightened).

3. Squeeze and release the pump handle, as needed, until the desired

amount of fluid is evacuated.

CAUTION:

To prevent fluid from being drawn into the pump

body, only evacuate fluid until the reservoir container is

half full. When the container is half full, use the relief valve

on the pump to release the vacuum, then empty the container

and repeat the procedure until the desired amount of fluid

is evacuated.

XII. BLEEDING BRAKES

WARNING:

Most Anti-Lock brake systems use a high-pressure

pump to maintain system pressure. ALWAYS observe the

following precautions when servicing Anti-Lock brake systems:

• ALWAYS refer to the manufacturer's service manual for service

and repair procedures for your vehicle's Anti-Lock brake system.

• ALWAYS wear safety goggles when performing servicing

procedures.

• ALWAYS depressurize the system before adding brake fluid or

performing servicing procedures.

• ALWAYS use manufacturer-recommended brake fluids ONLY.

• Unless directed to by the manufacturer's service procedure,

NEVER open a bleeder valve or loosen a hydraulic line while the

system is pressurized.

A. BLEEDING AUTOMOBILE BRAKES

CAUTION:

Brake fluid is very caustic (corrosive) and will

damage painted surfaces. Take precautions to prevent brake

fluid from contacting these surfaces. If brake fluid contacts a

painted surface, wash it off immediately.

Page 21

3660 19

Air in the brake system hydraulic lines can result in a "low" or "soft"

brake pedal. To remedy this problem, the air must be bled from the

hydraulic lines. The vacuum pump provides a simple and effective

method of bleeding air from the brake system.

Use the following procedure to bleed air from automobile brake lines.

NOTES:

• Make sure all brake-bleeding nuts are clean prior to beginning the

brake bleeding procedure.

• Bleed the brake system in the following order (for most vehicles):

a) Master cylinder: If the master cylinder needs to be bled, consult

the vehicle’s service manual and follow the manufacturer’s

instructions for procedures.

b) Combination valve bleeder screws: (if equipped);

c) Wheel cylinders and calipers: Procedures and sequences for

bleeding wheel cylinders and calipers very widely from one

manufacturer to the next. Always consult the vehicle's service

manual and follow the manufacturer's recommendations for

the proper procedure or sequence to follow when bleeding wheel

cylinders and calipers.

• Check the fluid level in the master cylinder frequently during brake

system bleeding, and top off as needed with fresh, clean brake fluid.

1. Assemble the fluid evacuation/brake bleeding kit as described on

page 16.

2. Select the appropriate bleed screw tapered adapter:

•

Tapered adapters fit inside the brake-bleeder screw, and

should be inserted tightly into the bleeder screw with a

pushing, twisting motion.

NOTE:

On some bleeder screws, the clear tubing can be used

directly on the bleeder screw without an adapter. Push the tube over

the top portion of the bleeder screw, ensuring that a sealed condition

exists. If unable to achieve a sealed condition, use a tapered adapter

as described above.

3. Attach the selected adapter (if used) to the open end of the 24-inch

(61cm) piece of tubing.

4. Remove the bleeder screw. Temporarily plug the bleeder screw hole

(use the plug supplied with the accessory kit, or similar) to prevent

the leaking of brake fluid onto the brake assembly.

5. Wrap teflon tape on bleeder screw threads, re-install and tighten

bleeder screw on brake assembly. Take precaution not to cover the

bleed hole on the side of the bleeder screw when wrapping it with

Teflon tape.

Page 22

20 3660

NOTE:

It is possible to bleed the brake system without using teflon

tape on the bleed screw threads, but, air will be drawn from around

the bleed screw threads, and it may be difficult to tell if the air is

coming from the brake system or from around the bleed screw

threads.

6. Squeeze and release the pump handle as necessary (usually 8 ~ 12

times) to create sufficient vacuum in the reservoir jar. If the

vacuum is not holding, retighten the lid on the jar.

7. Open the brake bleeder screw slightly (1/4 - 1/2 turn) to allow

brake fluid to enter the reservoir jar. The air that is bled from the

brake lines will appear as large, uneven bubbles in the 24-inch

(61cm) clear tubing.

8. When the level of fluid in the reservoir jar reaches approximately

1 ~ 2 inches (2.5 ~ 5 cm), tighten the brake bleeder screw.

DISPOSE OF THE USED BRAKE FLUID PROPERLY.

9. Repeat steps I through 8 for all remaining wheels.

XIII. REPLACEMENT PARTS

The following items are available as replacement parts or as optional

accessories:

1. Maintenance kit

2. Replacement gauge

3. Replacement handle

4. Replacement reservoir 8 oz (240 ml))

5. Optional fluid evacuation kit (Includes a 24oz (720ml) reservoir jar

+ accessories).

6. Replacement hose and fitting kit

For ordering information and updates visit us on the web at

www.iequus.com. See SERVICE PROCEDURES on page 21 for more

information.

Page 23

3660 21

XIV. SERVICE PROCEDURES

If you have any questions, please contact your local store, distributor or

Manufacturer Department.

USA & Canada: (800) 544-4124 (7:00-4:00, Monday-Friday PST)

All others: (714) 241-6802 (7:00-4:00, Monday-Friday PST)

FAX: (714) 432-7511 (24 hr.)

THE MANUFACTURER'S ONE YEAR LIMITED WARRANTY

The Manufacturer warrants to the original purchaser that this unit is

free of defects in materials and workmanship under normal use and

maintenance for a period of one (1) year from the date of original

purchase, whether or not actual use begins on that date. User,

however, is responsible for packaging, and transportation of product to

the service center.

If the unit fails within the one (1) year period, it will be repaired or

replaced during normal working hours, at the Manufacturer's option, at

no charge, when returned prepaid to the Service Center with Proof of

Purchase. The sales receipt may be used for this purpose. All

replacement parts, whether new or re-manufactured, assume as their

warranty period only the remaining time or this warranty.

This warranty does not apply to damage caused by improper use,

accident, abuse, improper voltage, service, fire, flood, lightning, or

other acts of God, or if the product was altered or repaired by anyone

other than the Manufacturer's Service Center.

The Manufacturer, under no circumstances shall be liable for any

consequential damages for breach of any written warranty of this unit.

This warranty gives you specific rights, which vary, from state to state.

This manual is copyrighted with all rights reserved. No portion of this

document may be copied or reproduced by any means without the

express written permission of the Manufacturer. THIS WARRANTY IS

NOT TRANSFERABLE.

For Warranty service (please call before sending item in for service),

send via U.P.S. or US mail with a copy of sales receipt prepaid to:

TECHNICAL SERVICE

17291 Mt Herrmann St.

Fountain Valley, CA 92708

Attn: Service Department

NOTE: If sent by US mail, be sure to insure the shipment.

Allow 3-4 weeks service time.

Page 24

© Innova 2001 3660

FRONT

COVER

3660

HAND PUMP

Loading...

Loading...