Page 1

The Current Clamp aids in measuring AC or DC current flow through

a wire or cable.

Safety Precautions

Do not

operate this tool before reading these instructions in their

entirety. The following guidelines must be followed to avoid accidents

that can result in electric shock or personal injury.

■ Pay close attention to WARNING stamped on the tool’s case.

This warning, as well as all warnings and precautions used through

out these instructions, must be followed to avoid electric shock

and/or personal injury.

■ The RESPONSIBLE PARTY shall be made aware that, if the equip-

ment is used in a manner not specified by the manufacturer , the protection provided by the equipment may be impaired.

■ Before using this tool, verify its proper operation on a known similar

function source where the unit value is also known.Take corrective

action based on the indicated results.

To prev ent electrical shock and/or damage to the tool or the equipment

under test, observe the following safety precautions:

■ DO NOT apply more than the rated voltage , as marked on the tool and

tester, between terminals or between any terminal and earth ground.

■ Use caution when working above 30V AC rms, 42 V peak, or 60 V

DC. Such voltages pose a shock hazard.

■ To avoid false readings that could lead to possible electric shock or

personal injury, replace the batteries as soon as the low battery indicator lights.

■ Always inspect the test leads prior to every use. If any damage is

found, do not use the tool.

■ Always consider electrical and electronic equipment to be ener-

gized (live).Never assume any equipment is de-energized.

■ Never ground yourself when taking electrical measurements. Isolate

yourself from ground by using dry rubber insulating mats to cover all

exposed/grounded metal.Stand on rubber mats and wear dry clothing.

■ Use one hand, instead of two, whenever possible to take measure-

ments. If two hands must be used, use extreme caution not to contact any energized conductors with your hands. Be certain test

leads are dry and clean.

■ Do not hold the tool beyond the hand grip when taking measure-

ments.

■ Don't become part of the circuit. Think safety.Act safely.

If working on a vehicle, take the following added precautions:

■ Only work on vehicle in a well ventilated area.

■ Always wear safety eye protection.

■ Avoid moving fan blades or any potentially moving parts.

■ Avoid hot engine parts.

■ Put transmission in "park" (automatic transmission vehicles) or

"neutral" (manual transmission vehicles).Set the parking brake.

■ Turn the ignition "off" before connecting or disconnecting any test-

ing equipment.

■ Put blocks on drive wheels.

■ Avoid wearing loose clothing or jewelry when working on a vehicle.

■ Read your vehicle's service manual and follow it's safety proce-

dures.

Operating Instructions

CURRENT CLAMP

INTRODUCTION

1

SPECIFICATIONS

2

© 2006 Innova Electronics Corp. All rights reserved MRP #93-0191

General

■ Captured Conductor Size: 0.75 in.(19mm) maximum

■ Power Indicator: Green LED

■ Low Battery Indicator: Red LED

■ Operating Temperature: 32 F to 122 F (0C to 50C), 70% relative

humidity

■ Storage Temperature: -4 F to 158 F (-20C to 70C), 80% relative

humidity

■ Battery Type: 9V DC, NEDA 1604, 6F22, 006P

■ Dimensions:

Height: 10.25 in. (260mm)

Width: 2.25 in. (57mm)

Depth: 1.25 in. (32mm)

■ Lead: Coil cable with straight banana plug or 36-inch (91cm) test

lead clipped together

Electrical [at 73±9 F (23±5 C) 70% relative humidity maximum]

■ Effective Measurement Range:

10mV/1A: 100mA to 20A DC or RMS AC for 200mV range of the

tester.

1mV/1A: 1A to 200A DC or RMS AC for 200mV range of the multimeter.

200A to 600A DC or RMS AC for 2V range of the multimeter.

■ Accuracy

System accuracy: Current clamp accuracy + tester accuracy

For example, if the measured conductor carries a 1A current, set

the Current Clamp to 10mV/1A range to get an output signal of

10mV. Suppose the accuracy of the units is 1.5%, the tolerance

limit should be between 10.15mV maximum and 9.85mV minimum.

When the unit is connected to a tester with an accuracy of 0.5% in

200mV range, the reading displayed on the tester will be 10.20mV

max. (10.15mV × (1+0.5%) = 10.20mV) and 9.80mV min.(9.85mV

× (1-0.5%) = 9.80mV)

■ Current Clamp Accuracy

DCA range = 10mV/1A: ±(1.5%+50mA) 100mA~20A

DCA range = 1mV/1A: ±(2.0%+0.5A) 1A~200A;±(2.5%+5A)

200A~600A

ACA range = 10mV/1A: ±(2.0%+50mA) 100mA~20A

(40Hz~400Hz)

ACA range = 1mV/1A: ±(2.5%+0.5A) 1A~200A (40Hz~400Hz);

±(3.0%+5A) 200A~600A (40Hz~400Hz)

■ Load Resistance: 10KΩ typical

■ Temperature Coefficient: 0.1×(specified accuracy) Per degree C.

(0 to 18, 28 to 50)

Page 2

CONTROLS AND INDICATORS

3

CLAMP CURRENT MEASUREMENT

4

REPLACING THE BA TTER Y

5

WARRANTY AND SERVICING

LIMITED ONE YEAR WARRANTY

The Manufacturer warrants to the original purchaser that this unit is free of defects in materials and workmanship under normal use and maintenance for a period of one (1) year from the date of original purchase.

If the unit fails within the one (1) year period, it will be repaired or replaced, at the Manufacturer’s option, at no charge, when returned prepaid to

the Service Center with Proof of Purchase. The sales receipt may be used for this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or remanufactured, assume as their warranty period only the remaining time of this warranty.

This warranty does not apply to damage caused by improper use, accident, abuse, improper voltage, service, fire, flood, lightning, or other acts

of God, or if the product was altered or repaired by anyone other than the Manufacturer’s Service Center.

The Manufacturer, under no circumstances shall be liable for any consequential damages for breach of any written warranty of this unit.This warranty gives you specific legal rights, and you may also have rights, which vary from state to state. This manual is copyrighted with all rights

reserved. No portion of this document may be copied or reproduced by any means without the express written permission of the Manufacturer.

THIS W ARRANTY IS NO T TRANSFERABLE. For service, send via U.P.S .(if possible) prepaid to Manufacturer.Allow 3-4 weeks for service/repair.

SERVICE PROCEDURES

If you have an y questions, require technical support or information on UPDATES and OPTIONAL ACCESSORIES, please contact y our local store,

distributor or the Service Center.

USA & Canada:

(800) 544-4124 (6:00 AM-6:00 PM, Monday-Friday PST)

All others: (714) 241-6802 (6:00 AM-6:00 PM, Monday-Friday PST)

FAX: (714) 432-7511 (24 hr.)

Web: www

.iEQUUS.com

© 2006 Innova Electronics Corp. All rights reserved

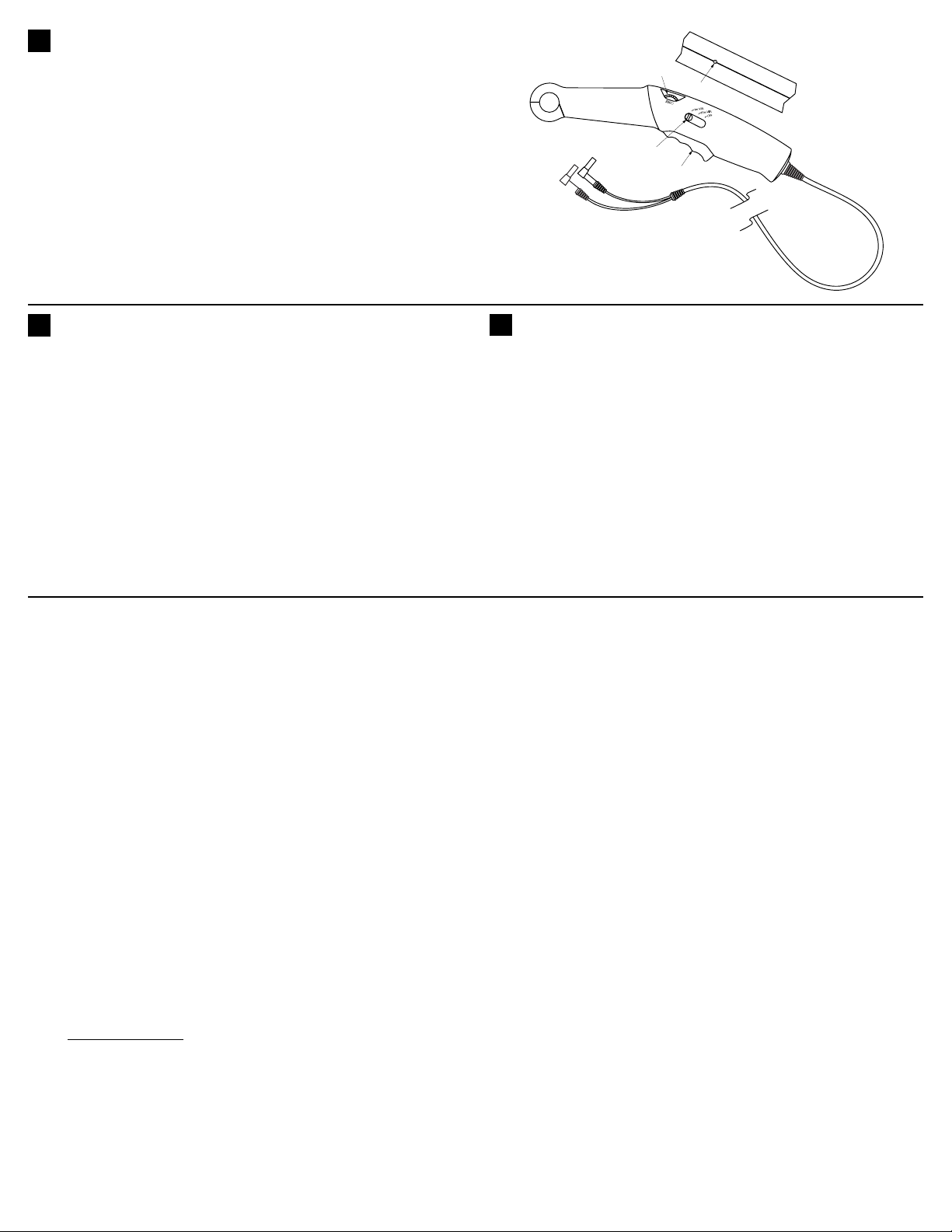

1. Trigger - Opens and closes the Current Clamp jaws.

2. OFF - 10m V/A - 1m V/A Switch - Turns the Current Clamp power

ON and OFF; sets the Current Clamp to the appropriate scale.

3. ZERO Adjustment Thumbwheel - Adjusts the Automotive Tester

reading to "zero" prior to making DC current measurements.

4. Power - Low Battery Indicator

■ Lights GREEN when the Current Clamp is turned ON to indi-

cate the unit is ready for use.

■ Lights RED when the Current Clamp is turned ON to indicate a

low battery condition.

3

4

2

1

1. Plug the BLACK test lead into the ‘COM’ jack; plug the RED test

lead into the appropriate channel.

2. Set the tester's Function/Range Selector switch to the appropriate

position for clamp current measurements.

3. Set the Current Clamp’s OFF - 10m V/A - 1m V/A switch to the

desired range.Verify the Power indicator lights GREEN.

4. If necessary, use the ZERO Adjustment Thumbwheel to "zero" the

tester reading.

5. Squeeze the trigger to open the clamp jaws. Place the clamp jaws

around the wire or cable from the source or load under measurement; release the trigger.

6. Read the results on the tester's display.

NOTE: A 9-volt battery is required for operation of the Current

Clamp.

1. Set the Current Clamp’s OFF - 10m V/A - 1m V/A switch to the

OFF position. Disconnect the Current Clamp from the Automotive

Tester.

2. Remove the screw from the battery compartment cover.Use your

finger or a small coin to remove the cover.

3. If necessary, remove the old battery from the batter y connector.

4. Match the battery ter minals with the batter y connector contacts,

and snap the battery connector securely onto the battery.

5. Place the battery in the batter y compar tment.

6. Reinstall the battery compar tment cover.

Loading...

Loading...