Page 1

E

315mA FUSED

CATII 600V

Page 2

Title Page No.

1

E

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY PRECAUTIONS/WARNINGS . . . . . . . . . . . . . . . . .1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . . . . .5

TESTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . .6

BATTERY AND FUSE REPLACEMENT . . . . . . . . . . . . . . .10

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SERVICE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . .11

INTRODUCTION

Congratulations.You have purchased a precision instrument

•

manufactured to the highest quality standards. This Digital

Multimeter is a general-purpose instrument designed for use

in general electronics, home electrical applications, and automotive electrical/electronic systems.

This meter is designed to test or measure AC voltage, DC

•

voltage, batteries, DC current, resistance, diodes and contin-

uity.

Please take the time to read these operating instructions thor-

•

oughly and completely .Failure to f ollow these instructions ma y

result in electrical shock, instrument damage and/or damage

to the equipment under test. Always use extreme caution

when working on or around electrically operated equipment.

SAFETY PRECAUTIONS/ WARNINGS

Do not operate this multimeter before reading this manual in its

entirety.The following guidelines must be followed to avoid accidents that can result in electric shock or personal injury.

Pay close attention to WARNINGS stamped on the front

•

and rear of the meter's case.These warnings, as well as all

warnings and precautions used through out this manual, must

be followed to avoid electric shock and/or personal injury.

The RESPONSIBLE PARTY shall be made aware that, if the

•

equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

Before using any of the functions on this meter, verify its

•

proper operation on a known similar function source where

the unit value is also known.Take corrective action based on

the indicated results.

To prevent electrical shock and/or damage to the tester or the

equipment under test, observe the following safety precautions:

Page 3

•

DO NOT apply more than the rated voltage, as marked on

the meter, between terminals or between any terminal and

earth ground.

•

Use caution when working above 30V AC rms, 42 V peak, or

60 V DC.Such voltages pose a shock hazard.

•

To avoid false readings that could lead to possible electric

shock or personal injury , replace the batteries as soon as the

low battery indicator displays.

•

Always inspect the multimeter, test leads and any other

accessories for damage prior to every use. If any damage is

found, do not use tester until repairs are done.

•

Always consider electrical and electronic equipment to be energized (live).Never assume any equipment is de-energized.

•

Never ground yourself when taking electrical measurements.

Isolate yourself from ground by using dry rubber insulating

mats to cover all exposed/grounded metal. Stand on rubber

mats and wear dry clothing.

•

Never take resistance measurements on energized (live)

electrical or electronic equipment.

•

Use one hand, instead of two, whenever possible to take

measurements.If two hands must be used, use extreme caution not to contact any energized conductors with your hands.

Be certain test leads are dry and clean.

•

Do not hold the instrument when taking measurements. Place

the instrument on a clean, insulating surface prior to taking

any measurement.

•

Don't become part of the circuit. Think safety.Act safely.

If working on a vehicle, take the following added precautions:

•

Only work on vehicle in a well ventilated area.

•

Always wear safety eye protection.

•

Avoid moving fan blades or any potentially moving parts.

•

Avoid hot engine parts.

•

Put transmission in "park" (automatic transmission vehicles) or

"neutral" (manual transmission vehicles).Set the parking brake.

•

Turn the ignition "off" before connecting or disconnecting any

testing equipment.

•

Put blocks on drive wheels.

•

Avoid wearing loose clothing or jewelry when working on a

vehicle.

•

Read your vehicle's service manual and follow it's safety procedures.

2

E

Page 4

SPECIFICATIONS

3

E

GENERAL SPECIFICATIONS AND FEATURES

3-½ digit LCD display (maximum reading of 2000)

•

Manual range control

•

Automatic negative (-) polarity indication

•

Automatic zero adjustment

•

Over range indicator (except 10 A function). Displays "1" on

•

LCD

Low battery indicator.Displays battery symbol on LCD

•

Automatic power shut off (after 15 idle minutes)

•

Safety standard: CE EMC/LVD. The meter is up to the stan-

•

dards of IEC1010 Pollution Degree 2, over voltage Category

2.

Operating environment:

•

Temperature - 32° to 104° F.(0° C to 40° C)

Humidity - Less than 80% relative humidity (non-condensing)

Altitude - up to 6562 ft (2000 meters)

Storage environment:

•

Temperature - 4° to 140° F (- 20° to 60° C)

Humidity - Less than 90% relative humidity (non-condensing)

Power Supply:Two 1.5V AAA batteries

•

Fuse: 315mA/250V 5X20 mm (Radio Shack, GMA/217

•

series; #270-1046) fuse

Dimensions:

•

Height - 5.50 in. (139 mm)

Width - 3.50 in. (89 mm)

Depth - 1.25 in. (32 mm)

Weight (including batteries): approximately 5.7 oz (170 g)

•

ELECTRICAL SPECIFICATIONS

Accuracy of specifications in the following tables are based on

an operating temperature of 64°F to 82°F (18°C to 28°C) and a

relative humidity of less than 75%.

Maximum voltage from V ma socket to COM socket is 500V

AC/DC; from COM socket to ground is 300V AC/DC.

Page 5

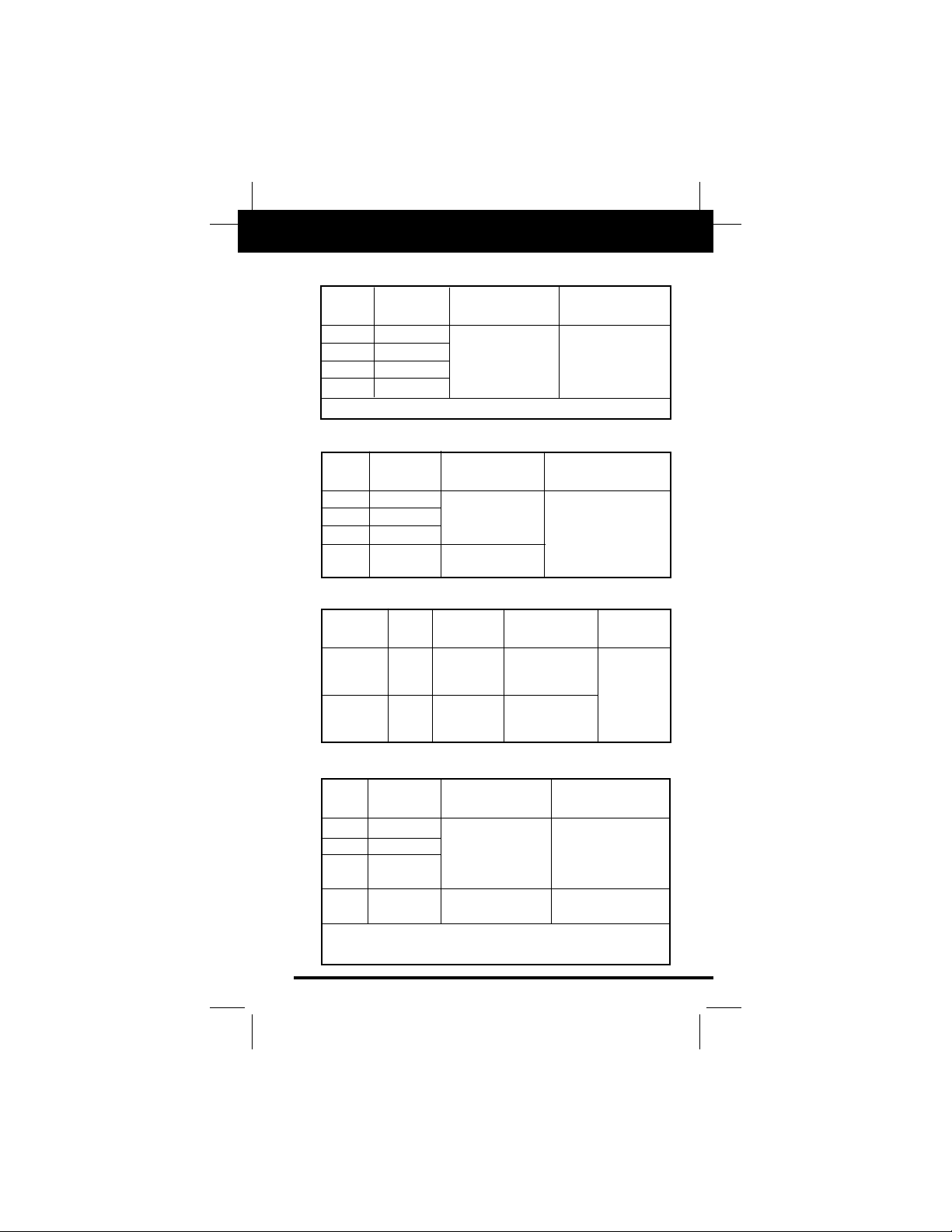

DC VOLTS

RESISTANCE (OHMS)

DIODE/CONTINUITY TEST

DC AMPS

4

E

Range Resolution Accuracy Overload

Protection

200mV 100µV

500V DC

2V 1mV ±(0.8% of reading or AC

20V 10mV

+ 5 digits)

500V RMS

500V 1V

Input impedance: 10MΩ for all ranges.

Range Resolution Accuracy Overload

Protection

200Ω 0.1Ω

±(1% of reading

2KΩ 1Ω

+ 5 digits)

250V DC/AC RMS

200KΩ 10Ω

20M Ω 10K Ω ±(2% of reading

+ 5 digits)

Function Range Resolution Accuracy Overload

Protection

Diode test 1mV Displays,

voltage drop

250V

approximation

DC/AC

Continuity 1Ω 50Ω or less, RMS

test buzzer (beeper)

will sound

Range Resolution Accuracy Overload

Protection

2mA

1µA

20mA

10µA

±(1.5% of reading

0.315A/250V fuse

200mA

100µA

+ 5 digits)

10A 10µA ±(2% of reading Non-Protected

+ 5 digits)

Measuring time is equal to or less than 15 seconds and time

interval is equal to or over 15 minutes.

Page 6

BA TTER Y TEST

AC VOLTS

CONTROLS AND INDICATORS

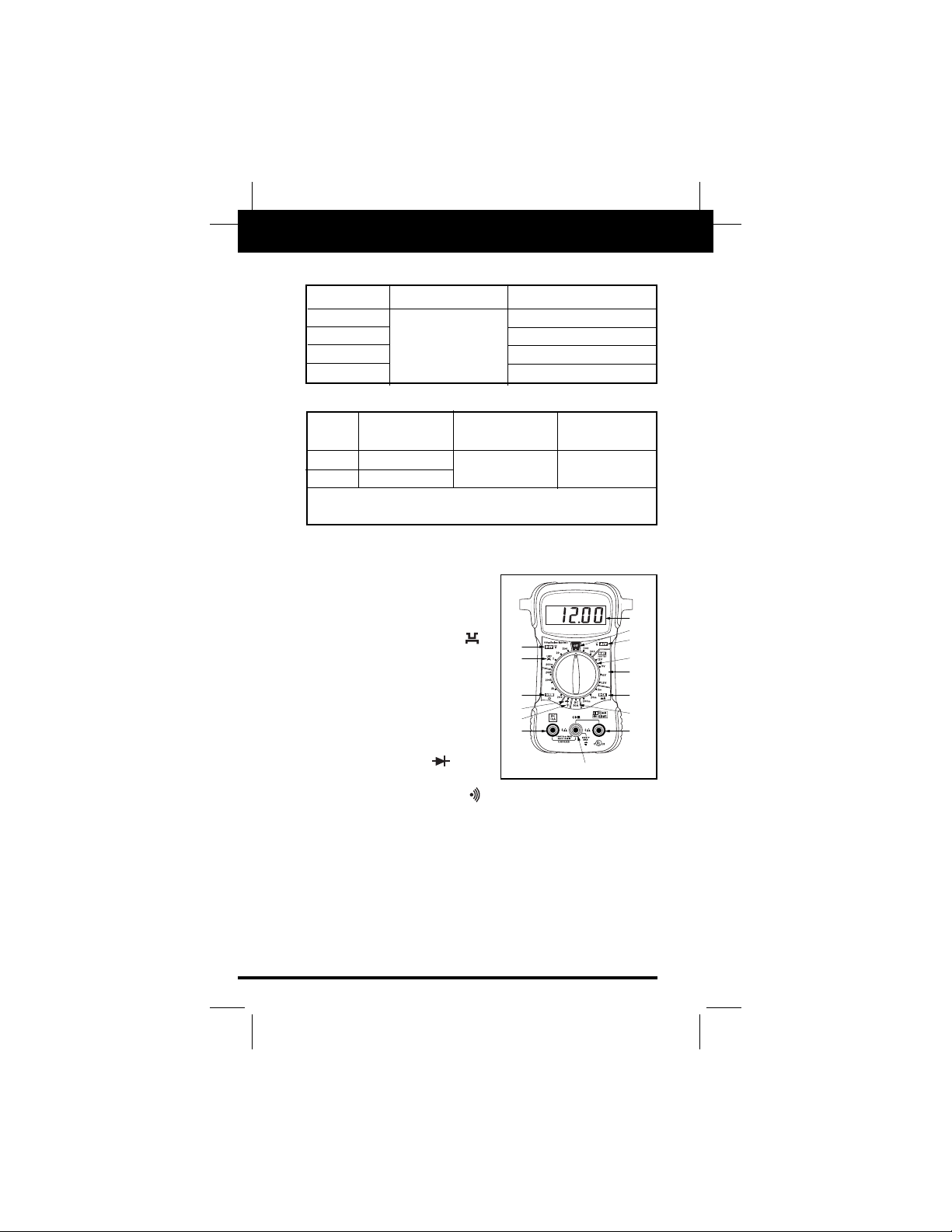

1. DCV Function: Measures

DC volts. Four (4) ranges:

200 millivolts (mV), 2, 20,

and 500 volts.

2. POINTS Function :

Measures voltage drop

across ignition points.

3. OHM (ΩΩ) Function:

Measures resistance. Four

(4) ranges: 200, 2k (2000),

200k (200,000) and 20M

(20,000,000) ohms.

4. DIODE Function : For

testing diodes.

5. CONTINUITY Function : Tests for continuity between

two points.

6. 10A Input Jack.

7. COM Input Jack: Common Input Jack.

8. Volts, mA, OHMS, BAT, DIODE and CONTINUITY Input

Jack.

9. DCA Function: Measures direct current. One (1) range:

10AMPS DC from 0 to 10 amperes.

10. mA Function. Measures current in milliamps. Three

ranges: 2, 20 and 200 milliamps.

5

E

Range Resolution DC Current Load

1.5V 10mA

6V

0.01V

100mA

9V 10mA

12V 100mA

Overload

Range Resolution Accuracy Protection

200V 100mV ±(1.2% of reading 500V DC or AC

500V 1V

+ 10 digits) 500V RMS

Input Impedance: Approximately 5MΩ

Frequency: 40-400Hz

1

2

3

4

5

68

315mA FUSED

CATII 600V

7

15

14

13

12

11

10

9

Page 7

11. BAT. LOAD TEST Function: To test small batteries. Four

(4) ranges: 1.5, 6, 9 and 12 volts.

12. Function/Range Selector Switch: Selects desired function or range.

13. ACV Function: Measures AC voltages. Two ranges: 200

and 500 volts.

14. OFF Function: Turns unit "off" when function is selected.

15. Liquid Crystal Display (LCD): Displays results of tests or

measurements.

Preparation and Caution Before Use

•

Inspect the digital multimeter for damage to the case.Do not

use if cracked, distorted, excessively dirty or any abnormal

condition exists.

•

Inspect the test leads for damage. Check for cracked insulation, broken or damaged probes, loose or bent probe pins. Do

not use if any abnormal condition exists.

•

Set the Function/Range Selector Switch to the proper range

BEFORE taking measurements. If the range/function must

be switched during a test, ALWAYS remove the test leads

from the circuit being measured before switching settings.

•

To avoid possible electric shock, instrument damage, and/or

equipment damage when taking voltage or current measurements, DO NOT exceed the maximum value of the selected

range.

•

If the unit is used near high noise Radio Frequency (RF) generating equipment (spark plug wires, ignition coils or alternator), the display may become unstable or indicate large errors.

If you obtain erratic readings during use, isolate the Multimeter

as far away as possible from these components.

TESTING PROCEDURES

A. AC/DC VOLTA GE MEASUREMENT

6

E

WARNING

To avoid possible electric shock, instrument damage

and/or equipment damage, DO NOT attempt to measure

voltages ABOVE 500V AC/DC or take measurements if

the voltage is unknown. 500V AC/DC between the COM

and V jacks is the maximum voltage that this instrument

is designed to measure. The "COM" terminal potential

should not exceed 300V AC/DC measured to ground.

Page 8

1. Plug the BLACK test lead into "COM" jack of the multimeter;

plug the RED test lead into the "V" jack.

2. Set the meter’s Function/Range Selector Switch to the

appropriate ACV or DCV position as desired (see Controls

and Indicators, Items 1 and 13).

3. Place the RED test lead onto the positive (+) side of the item

being tested and the BLACK test lead onto the negative (-)

(across the source/load) side of the item.BE CAREFUL not to

touch any energized conductors with any part of your body.

4. Read the results on the display.

B. RESISTANCE MEASUREMENT ΩΩ(OHMS)

1. Plug the RED test lead into the "ΩΩ" jack of the multimeter;

plug the BLACK test lead into the "COM" jack.

2. Set the meter’s Function/Range Selector Switch to the OHM

"ΩΩ" range function (see Controls and Indicators, Item 3).

NOTE:T o obtain accurate readings , disconnect at least

one side of the item under test from the circuit or circuit

board before measuring resistance.

3. Place the RED test lead onto one side of the item being tested and the BLACK test lead onto the other side of the item.

(Polarity does not matter when checking resistance).

4. Read the results on the display.

C. DIODE TEST

7

WARNING

Resistance measurements must be made on "de-energized" (dead) circuits ONLY.Impressing a voltage across

the multimeter's terminals while set to any resistance

range may result in electric shock, instrument damage

and/or damage to equipment under test. MAKE SURE

equipment is completely de-energized before taking any

resistance measurements.

E

WARNING

To avoid electrical shock and/or damage to the multimeter,

ensure the power is removed from the circuit before any

DIODE testing procedure is conducted.Test diodes on deenergized (dead) circuits only, never on live circuits.

Page 9

NOTE: A diode is a semiconductor device that lets cur-

rent flow in one direction only .If the diode to be tested is

part of a circuit (with other electronic components), you

must isolate it from the other components by disconnecting at least one side of it from the circuit before

testing. A good diode will show a low voltage drop

across its junction (0.5-0.8 volts for a silicon diode or

about 0.3V for a germanium diode) when the leads are

connected in one polarity and a very high resistance

(or open circuit) when the leads are reversed (connected in the opposite polarity).

1. Plug the RED test lead into the jack of the multimeter;

plug the BLACK test lead into the "COM" jack.

2. Set the meter’s Function/Range Selector Switch to the

position (see Controls and Indicators, Item 4).

3. Place the RED test lead onto one side of the diode being

tested and the BLACK test lead onto the other side.

4. Read the results on the display.

5. Reverse the test leads and again read the results on the dis-

play. Compare the two readings. One reading should indicate a voltage drop value;the other reading should indicate

an overrange (1) condition.

See note above

.

D. CONTINUITY TEST

1. Plug the RED test lead into the jack of the multimeter;

plug the BLACK test lead into the "COM" jack.

2. Set the meter’s Function/Range Selector Switch to the

position (see Controls and Indicators, Item 5).

3. Place the RED Test Lead to one end of the wire or device

being tested for continuity and the BLACK Test Lead to the

opposite end.

4. Listen to the sound of the beeper and confirm the results by

reading the display.

NOTE: The beeper will sound only if the continuity of

the item under test (resistance between the two test

leads) measures less than approximately 50 ohms.

8

E

WARNING

To avoid electric shock, shut off the power to the test article before testing it for continuity.

Page 10

E. DC CURRENT MEASUREMENT (AMPS)

1. Plug the RED test lead into the "mA" or the "DC10A" jack of

the multimeter, as applicable; plug the BLACK test lead to

the "COM" jack.

2. Set the meter's Function/Range Selector Switch to the

appropriate Amps range position as desired (see Controls

and Indicators, Items 9 and 10).

•

To measure from 0 to 200mA, set the Selector Switch to

the desired "DCmA" position.

•

To measure from 200mA to 10 Amps DC, set the

Selector Switch to the "DC10A" position.

3. Disconnect the battery, or shut off the power to the circuit

being tested.

NOTE: To measure current on a particular circuit, you

must open up the circuit and connect the test leads in

series with the circuit before a reading can be obtained.

4. Disconnect one end of the wire or device, from the circuit

where current will be measured.

5. Place the RED test lead on the disconnected wire and place

the BLACK test lead at the location from which the wire was

disconnected (series connection).

6. Reconnect the battery, or apply power to the circuit being

tested.

7. Read the results on the display.

CAUTION: After the test is completed, shut the

power off to the circuit before removing the test

leads and before reconnecting any disconnected

wires or devices.

NOTE: If the reading obtained is a negative number,

reverse the test leads.

9

WARNING

To prevent electrical shock when performing current

measurements, follow all steps as indicated below DO

NOT skip any steps or take any short cuts.

The DC10A range is not fused. To avoid current hazard

and/or damage to the tester, DO NOT try to take measurements on circuits that have more than 10 amps. DO

NOT take more than 15 seconds to take the reading. A

waiting period of AT LEAST 15 MINUTES is necessary

between every 15 second testing period.

E

Page 11

F . BATTER Y TEST

1. Plug the RED test lead into the "BAT." jack of the multime-

ter; plug the BLACK test lead into the "COM" jack.

2. Determine the voltage rating of the battery to be tested.

3. Set the meter’s Function/Range Selector Switch to the

desired "Battery Test" range (see Controls and Indicators,

Item 12).

4. Place the RED test lead on the positive post of the battery

under test; place the BLACK lead on the negative post.

5. Read the results on the display.

NOTE: Battery life is directly proportional to the current

draw (load) of the device that the battery is powering.To

determine battery condition, consult the manufacturer of

the device for minimum operating Voltage requirements.

BATTERY AND FUSE REPLACEMENT

1. Turn the Digital Multimeter “ OFF”and remove the test leads.

2. Remove the two screws on the back of the meter and sep-

arate the case.

3. Replace the fuse or batteries as necessar y:

•

For battery replacement: Remove the batteries from

the battery compartment and replace only with two AAA

(1-½ volt) alkaline batteries.

•

For fuse replacement: Remove the fuse from

the fuse holder and replace with a 0.315A/250V - UL

Listed Bussmann, GMA Type (Radio Shack

GMA/270 series; #270-1046 ) fuse.

NOTE: Use a 0.315A/250V, 5x20mm type fuse ONLY -

Bussmann, GMA Type (Radio Shack #270-1046 or similar).

Using an incorrect fuse may result in serious injury and/or damage

to the unit.

4. Reassemble the case and secure with the two screws.

10

E

WARNING

When replacing the battery or the fuse, remove only the

rear panel. Do not remove or disassemble the circuit

board or the front panel, these items are not serviceable

and if disassembled there is the possibility of loose metal

parts shorting the circuit board and causing an electrocution danger to the user.

Page 12

MAINTENANCE

1. No periodic maintenance is required other than the replace-

ment of the battery, the fuse , and visual inspection of the meter.

2. Keep the meter clean and dry.DO NOT use solv ent to clean,

use a damp (not wet) cloth and fully dry after cleaning.

3. The only replaceable parts are the 1.5 AAA batteries,

0.315A/250V fuse (see page 10 for battery and fuse

replacement) and the Test Leads (for Test Leads call service department).

SERVICE PROCEDURES

The Manufacturer warrants to the original purchaser that this unit

is free of defects in materials and workmanship under normal use

and maintenance for a period of one (1) year from the date of original purchase. If the unit fails within the one (1) year period, it will

be repaired or replaced, at the Manufacturer's option, at no

charge, when returned prepaid to the Technical Service Center

with Proof of Purchase.The sales receipt may be used f or this purpose. Installation labor is not covered under this warranty.

All replacement parts, whether new or re-manufactured, assume

as their warranty period for only the remaining time of this warranty .This warranty does not apply to damage caused by improper use, accident, abuse, improper voltage, service, fire, flood,

lightning, or other acts of God, or if the product was altered or

repaired by anyone other than the Manufacturer's Technical

Service Center. Consequential and incidental damages are not

recoverable under this warranty. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights, which vary from state to state. No portion of

this warranty may be copied or duplicated without the e xpressed

written permission from the Manufacturer.

Obtaining Warranty Service:

Products requiring service should be returned as follows:

1. Call the Technical Service Center to obtain a Return

Reference Number:

USA & Canada = 1-800-544-4124

Other = 714-241-6805

2. Package the product carefully to prevent shipping damage

3. Include your name, return address, and a day contact phone

4. Enclose a copy of the dated sales receipt

5. Describe the problem

11

E

Page 13

6. Ship prepaid to: Technical Service Center, 17291 Mt.

Herrmann Street, Fountain Valley, CA 92708 U.S.A.

Phone:1-800-544-4124 or 714-241-6805 Fax:714-432-7910

Fax:714-432-7910

Web: www

.iEQUUS.com

Email: service@iEQUUS.com

12

E

Page 14

13

Page 15

14

Page 16

E

Page 17

F

315mA FUSED

CATII 600V

Page 18

Titre Page

1

F

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

MESURES DE SÉCURITÉ/AVERTISSEMENTS . . . . . .1

FICHE TECHNIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . .3

COMMANDES ET INDICATEURS . . . . . . . . . . . . . . . . .6

MÉTHODOLOGIE DE VÉRIFICATION . . . . . . . . . . . . . .7

REMPLACEMENT DE LA PILE ET DU FUSIBLE . . . .11

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

INTRODUCTION

Félicitations. Vous avez acheté un instrument de précision

•

fabriqué en respectant les normes de fabrication les plus

élevées. Ce multimètre numérique est un instrument d’utilisation générale conçu pour les applications en électronique,

pour les applications électriques domestiques et pour les

systèmes électriques et électroniques des automobiles.

Ce multimètre a été conçu pour vérifier ou mesurer la ten-

•

sion c.a., la tension c.c., les piles/batteries, le courant c.c., la

résistance, les diodes et la continuité.

Nous vous invitons à prendre le temps de lire les instructions

•

d’utilisation à fond et complètement. Autrement, vous pourriez

provoquer un choc électrique, endommager l’instrument et (ou)

endommager l’équipement que vous voulez vérifier. Il faut toujours prendre des précautions extrêmes lorsqu’on fait des

travaux sur l’équipement électrique.

MESURES DE SÉCURITÉ/ AVERTISSEMENTS

Il ne faut pas utiliser le multimètre avant d'av oir lu ce manuel en

entier. Les directives ci-dessous doivent être observées pour

éviter les accidents qui pourraient découler d'un choc électrique

ou les blessures.

Il faut observer tous les AVER TISSEMENTSestampillés

•

sur l'avant et l'arrière du boîtier du multimètre.Ces avertissements, tous les autres avertissements et toutes les précautions utilisées dans ce manuel, doivent être observés pour

éviter les chocs électriques et (ou) les blessures personnelles.

La PARTIE RESPONSABLE doit être mise au courant de ce

•

qui suit : si l'équipement est utilisé autrement que de la

manière décrite par le fabricant, la protection fournie par

l'équipement pourrait ne pas s'appliquer.

Avant d'utiliser les fonctions de cet appareil, vérifiez son bon

•

fonctionnement sur une source de fonction similaire connue

où la valeur de l'unité est également connue. Prenez les

mesures correctives nécessaires en vous basant sur les

résultats obtenus.

Page 19

Pour prévenir les chocs électriques et (ou) pour ne pas endommager le multimètre ou l’équipement vérifié, observez les

mesures de sécurité ci-dessous.

•

Il NE FAUT PAS utiliser une tension supérieure à ce qui est

indiqué sur le multimètre, entre les bornes ou entre les

bornes et la mise à la masse.

•

Il faut apporter une attention spéciale lorsqu'on utilise une

tension supérieure à 30 V c.a. efficaces, à 42 V en période

de pointe ou à 60 V c.c. Ces tensions présentent un danger

en cas de choc.

•

Pour éviter les fausses lectures qui pourraient mener à des

chocs électriques possibles ou à des blessures, remplacez

les piles dès que le voyant de pile faible («low battery»)

s'affiche.

•

Avant chaque application, inspectez toujours le multimètre,

les conducteurs de vérification et tous les autres accessoires

pour y découvrir toute trace de dommages. Si vous y découvrez des dommages, n’utilisez pas le multimètre avant

d’avoir fait les réparations.

•

Tenez toujours compte de l’équipement électronique et électrique qui sera mis sous tension. Il ne faut jamais prendre

pour acquis que l’équipement n’est pas sous tension.

•

Ne faites jamais en sorte que votre corps serve de mise à la

terre lorsque vous prenez des mesures sur l’équipement

électrique. Isolez-vous du sol en utilisant un tapis isolant en

caoutchouc sec pour couvrir toutes les pièces de métal

exposées/mises à la terre.Tenez-vous debout sur des tapis

en caoutchouc et portez des vêtements secs.

•

Ne prenez jamais des mesures de la résistance sur des circuits électriques ou électroniques sous tension.

•

Lorsque c’est possible, n’utilisez qu’une seule main, et non

les deux, pour faire les mesures.Si vous dev ez utiliser les deux

mains, apportez une attention extrême pour ne pas toucher à

des conducteurs sous tension avec vos mains.Assurez-vous

que les conducteurs de vérification sont secs et propres.

•

Ne tenez pas l’appareil lorsque vous faites vos mesures.

Placez l’instrument sur une surface propre et isolez la surface avant de faire les mesures.

•

Ne devenez pas l’un des composants du circuit.Pensez toujours à votre sécurité et agissez en conséquence.

Si vous travaillez sur un véhicule, prenez les mesures de sécurité additionnelles suivantes.

•

Ne travaillez sur un véhicule que dans un endroit bien ventilé.

•

Portez toujours des lunettes de sécurité.

•

Évitez les pales de ventilateur en mouvement ou toute autre

pièce mobile dangereuse.

2

F

Page 20

Évitez les pièces chaudes du moteur.

3

F

•

Placez le levier de changement des vitesses à « P » (P ark),

•

pour les boîtes de vitesses automatiques, ou au « neutre »

pour les boîtes de vitesses manuelles.Serrez le frein de stationnement.

Placez la clé d’allumage en position « OFF » avant de

•

brancher ou de débrancher tout appareil de vérification.

Placez des cales sous les roues motrices du véhicule.

•

Ne portez pas de vêtements amples ni de bijoux lorsque vous

•

faites des travaux sur un véhicule.

Lisez le manuel de service du véhicule et observez les pré-

•

cautions de sécurité qui s’y trouvent.

FICHE TECHNIQUE

FICHE TECHNIQUE GÉNÉRALE ET CARACTÉRISTIQUES

Affichage numérique à 3 DEL de ½ po (lecture maximale de

•

2000)

Sélection manuel de gamme (tension c.a., tension c.c., ohm,

•

mA c.a. et mA c.c.)

Indication automatique de polarité négative (-).

•

Réglage automatique du zéro.

•

Indicateur de dépassement de gamme (sauf la fonction de

•

10 A). Affiche «1» sur l'écran d'affichage à cristaux liquides.

Indicateur de pile faible.Le symbole de la batterie appa-

•

raît à l'écran d'affichage à cristaux liquides.

Mise hors tension automatique (après 15 minutes d'inutilisa-

•

tion).

Norme de sécurité : CE EMC/LVD. L'appareil respecte les

•

normes de l'IEC1010 du 2e degré de pollution; surtension de

catégorie 2.

Conditions d'utilisation :

•

Température : -32 ° à 104 °F (0 ° à 40 °C).

Humidité : Moins de 80 % d'humidité relative (sans condensation)

Altitude : jusqu'à 6562 pi (2000 mètres)

Entreposage :

•

Température : -4 ° à 140 °F (-20 ° à 60 °C).

Humidité : Moins de 90 % d'humidité relative (sans condensation)

Alimentation électrique : deux piles AAA de 1,5 V.

•

Fusible : fusible de 315 mA/250V 5x20 mm. (Radio Shack,

•

série GMA/217; #270-1046)

Page 21

•

Dimensions :

Hauteur : 5,50 po (139 mm)

Largeur : 3,50 po (89 mm)

Profondeur : 1,25 po (32 mm)

•

Poids (avec les piles) : environ 5,7 onces (170 g)

FICHE TECHNIQUE CONCERNANT L'ÉLECTRICITÉ

La précision des fiches techniques qui suivent est basée sur

une température d’utilisation de 64 °F à 82 °F (18 °C à 28 °C)

et une humidité relative inférieure à 75 %.

La tension maximale entre la douille V ma et la douille COM est

de 500 V c.a./c.c.; la tension entre la douille COM et la masse

est de 300 V c.a./c.c.

TENSION C.C.

RÉSISTANCE (OHM)

4

F

Protection

contre les

Gamme Résolution Précision surcharges

200mV 100µV

2V 1mV

500V c.c.

±0,8 % de la lecture

ou c.a.

20V 10mV + 5 chiffres)

500V

500V 1V efficace

Impédance d’entrée : 10 MΩpour toutes les gammes.

Gamme Résolution Précision Protection contre

les surcharges

200Ω 0,1Ω

±(1 % de la

2KΩ 1Ω

lecture+ 5

200KΩ 10Ω chiffres) 250V c.a./c.a.

20M Ω 10K Ω ±(2 % de la

efficace

lecture+ 5

chiffres)

Page 22

VÉRIFICATION DES DIODES/CONTINUITÉ

AMPÈRES C.C.

AMPÈRES C.C.

VÉRIFICATION DE LA BATTERIE

5

F

Gamme Résolution Précision Protection

contre les

surcharges

2mA 1µA Fusible de

0,315A/250V

20mA 10µA ±(1,5 % de la lecture

200mA 100µA

+ 5 chiffres)

10A 10mA ±(2 % de la lecture Aucune -

+ 5 chiffres) Protégé

Le temps de prise de la mesure est de 15 secondes ou moins

et l’intervalle entre les mesures est d’au moins 15 minutes.

Gamme Résolution Charge du courant c.c.

1,5V 10mA

6V

0,01V

100mA

9V 10mA

12V 100mA

Protection

contre les

Fonctions Gamme Résolution Précision surcharges

Vérification 1mV Affiche la chute

de de tension

diode approximative

250V c.c/

Vérification 1Ω 50Ω ou

c.a.

de la moins,

efficace

continuité l’alarme

sonore

retentit

Page 23

TENSION C.A.

COMMANDES ET INDICATEURS

1. Fonction DCV : Mesure la

tension c.c. Quatre (4)

gammes : 200 millivolts (mV),

2, 20 et 500 volts.

2. Fonction des POINTS :

Mesure la chute de tension

entre les points d’allumage.

3. Fonction OHM (ΩΩ) : Mesure la

résistance. Quatre (4) gammes :

200, 2 k (2000), 200 k (200 000)

et 20 M (20 000 000) ohms.

4. Fonction DIODE : Ser t

à vérifier les diodes.

5. Fonction CONTINUITY :

Vérifie la continuité entre deux

points.

6. Jack d’entrée de 10A.

7. Jack d’entrée COM. jack d'entrée commun.

8. Jack d’entrée des Volts, mA, OHMS, BAT,DIODE et CONTINUITY.

9. Fonction DCA : Mesure le courant continu. Une (1)

gamme : 10 A c.c. entre 0 et 10 ampères.

10. Fonction mA. Mesure le courant en milliampères. Trois

gammes : 2, 20 et 200 milliampères.

11. Fonction BAT. LOAD TEST : Sert à vérifier les petites

piles. Quatre (4) gammes : 1,5, 6, 9 et 12 volts.

12. Sélecteur de fonction/gamme : Ser t à choisir la fonction

ou la gamme désirée.

13. Fonction ACV : Mesure la tension c.a. Deux gammes : 200

et 500 volts.

14. Fonction OFF : Ferme l’appareil lorsqu’on choisit cette

fonction.

6

Protection

Gamme Résolution Précision contre les

surcharges

200V 100mV ±(1,2 % de la lecture 500V c.a.

500V 1V

+ 10 chiffres)

c.c ou c.a

Impédance d’entrée : environ 5 MΩ

εφφιχαχε

Fréquence : 40-400 Hz

1

2

3

4

5

68

315mA FUSED

CATII 600V

7

15

14

13

12

11

10

9

Page 24

15. Affichage à cristaux liquides : Affiche les résultats des

vérifications ou des mesures.

Préparation et précautions à prendre avant d’utiliser

l’appareil

•

Inspectez le multimètre numérique pour voir si le coffret a été

endommagé. N’utilisez pas l’appareil si le coffret est fissuré,

déformé ou très sale ou si vous y constatez d’autres conditions anormales.

•

Inspectez les fils conducteurs pour y découvrir tout signe de

dommage. Voyez si l’isolant est fissuré, si les sondes sont

desserrées ou courbées. N’utilisez pas l’appareil si vous y

constatez des conditions anormales.

•

Placez le sélecteur de fonction/gamme sur la bonne gamme

AVANT de prendre la mesure. Si la gamme/fonction doit être

changée pendant une vérification, retirez TOUJOURS les

conducteurs de vérification du circuit mesuré avant de

changer les réglages.

•

Pour éviter les chocs électriques possibles, les dommages à

l’appareil et (ou) les dommages à l’équipement lorsque vous

mesurez la tension ou le courant, NE DÉPASSEZ PAS les

valeurs maximales mesurées sur la gamme en question.

•

Si l’appareil est utilisé à proximité d’un équipement qui produit de grandes quantités de fréquences radio productrices

de parasites (fil de bougie, bobine d’allumage ou alternateur), l’affichage pourrait devenir instable et comporter une

marge d’erreur importante. Si l’appareil vous donne des lectures fautives pendant que vous l’utilisez, éloignez le multimètre le plus possible de ces composants.

MÉTHODOLOGIE DE VÉRIFICATION

A. MESURE DE LA TENSION C.A./C.C.

7

AVERTISSEMENT

Pour ne pas être victime d'un choc électrique, pour ne

pas endommager l'appareil et (ou) l'équipement, N'ESSAYEZ PAS de mesurer des tensions SUPÉRIEURES à

500 V c.a./c.c.ou de prendre des mesures si vous ne savez

pas quelle est l'ampleur de la tension. Une tension de

500 V c.a./c.c. entre les jacks COM et V est le maximum

que cet appareil peut mesurer. Le potentiel à la borne

«COM» ne devrait pas dépasser 300 V c.a./c.c. lorsque la

mesure est prise par rapport à la mise à la terre.

Page 25

1. Branchez le conducteur de vérification NOIR dans le jack

«COM» du multimètre; branchez le conducteur de vérification ROUGE dans le jack «V».

2. Réglez le sélecteur de fonction/gamme à la position V c.a.

ou V c.c., selon le cas (voir la rubrique Commandes et

Indicateurs, points 1 et 13).

3. Placez le conducteur de vérification ROUGE sur le côté

positif (+) du point à vérifier et le conducteur de vérification

NOIR du côté négatif (-) (par rapport à la source/charge) du

point à vérifier. ATTENTION de ne pas toucher à des con-

ducteurs sous tension avec une partie de votre corps.

4. Les résultats sont affichés sur le multimètre.

B. MESURE DE LA RÉSISTANCE (OHMS)

1. Branchez le fil conducteur de vérification ROUGE dans le

jack «ΩΩ» du multimètre et branchez le fil conducteur de

vérification NOIR dans le jack « COM ».

2. Réglez le sélecteur de fonction/gamme du multimètre à la

gamme de résistance «

ΩΩ

» (voir la rubrique Commandes et

Indicateurs, point 3).

REMARQUE : Pour obtenir des lectures précises,

débranchez au moins un côté du point à vérifier du circuit ou de la plaquette de circuits avant de mesurer la

résistance.

3. Placez le fil conducteur de vérification ROUGE sur un côté du

point à vérifier et le fil conducteur de vérification NOIR de

l’autre côté du point. (La polarité n’a aucune incidence

lorsque vous mesurez la résistance).

4. Les résultats sont affichés à l’écran d’affichage.

8

AVERTISSEMENT

La résistance doit être mesurée UNIQUEMENT lorsque

les circuits ne sont pas sous tension. L'application d'une

tension au niveau des bornes du multimètre, alors que

ce dernier est réglé en fonction d'une gamme particulière,pourrait provoquer des chocs électriques,des dommages à l'appareil et (ou) des dommages à l'équipement

vérifié. ASSUREZ-VOUS que l'équipement est complètement hors tension avant de mesurer la résistance.

Page 26

C. VÉRIFICATION DES DIODES

REMARQUE : Une diode est un semi-conducteur qui

laisse circuler le courant dans une seule direction.Si la

diode à vérifier fait partie d’un circuit (avec d’autres

composants électroniques), vous devez l’isoler des

autres composants en débranchant au moins un côté

de la diode de son circuit avant de faire la vérification.

Une bonne diode aura une faible chute de tension à sa

jonction (0,5-0,8 volts pour une diode au silicium ou

environ 0,3 V pour une diode au germanium) lorsque

les conducteurs sont raccordés dans une polarité; la

résistance sera très grande (voire un circuit ouvert),

lorsque les conducteurs de vérification sont inversés

(raccordés sur la polarité opposée).

1. Branchez le fil conducteur de vérification ROUGE dans le

jack du multimètre; branchez le fil conducteur de vérification NOIR dans le jack COM.

2. Réglez le sélecteur de fonction/gamme à la position

(voir la rubrique Commandes et Indicateurs, point 4).

3. Placez le fil conducteur de vérification ROUGE sur le côté

de la diode à vérifier et le fil conducteur de vérification NOIR

de l’autre côté.

4. Les résultats sont affichés sur le multimètre.

5. Inversez les conducteurs de vérification et voyez les résul-

tats affichés à l'écran du multimètre.Comparez les deux lectures.L'une des lectures devrait donner la valeur de la chute

de tension; l'autre lecture devrait indiquer s'il y a dépassement de la gamme («1»).Voir la note ci-dessus.

D. VÉRIFICATION DE LA CONTINUITÉ

1. Branchez le fil conducteur de vérification ROUGE dans le

jack du multimètre; branchez le fil conducteur de vér ification NOIR dans le jack COM.

9

AVERTISSEMENT

Pour éviter les chocs électriques, coupez l'alimentation

électrique avant de faire la vérification de la continuité.

AVERTISSEMENT

Pour éviter les chocs électriques et (ou) les dommages au

multimètre, assurez-vous que l'alimentation électrique du

circuit est coupée avant de vérifier une DIODE quelconque.

Vérifiez les diodes alors que le circuit n'est pas sous tension; il ne faut jamais vérifier les circuits sous tension.

Page 27

2. Réglez le sélecteur de fonction/gamme à la position

(voir la rubrique Commandes et Indicateurs, point 5).

3. Placez le conducteur de vérification ROUGE sur l'une des

extrémités du fil conducteur ou du dispositif dont vous vérifiez la continuité et le conducteur de vérification NOIR sur

l'autre extrémité.

4. Écoutez pour voir si vous entendez des bips et confirmez

les résultats en faisant la lecture de l'affichage.

REMARQUE : L’alar me retentit uniquement si la con-

tinuité du point à vérifier (résistance entre les deux fils

conducteurs de vérification) mesure moins de environ

50 ohms.

E. MESURE DU COURANT C.C. (AMPÈRES)

1. Branchez le conducteur de vérification ROUGE dans le jack

«mA» ou le jack «DC10A» du multimètre, selon le cas;

branchez le conducteur de vérification NOIR dans le jack

«COM».

2. Réglez le sélecteur de fonction/gamme à la gamme appropriée (A) (voir la rubrique Commandes et Indicateurs, points

9 et 10).

•

Pour mesurer de 0 à 200 mA, réglez le sélecteur à

«DCmA» désirée.

•

Pour mesurer de 200 mA à 10 A c.c., réglez le sélecteur

à «DC10A».

3. Débranchez la batterie ou coupez l'alimentation électrique

du circuit à vérifier.

REMARQUE : Pour mesurer le courant d'un circuit particulier, vous devez ouvrir le circuit et raccorder les conducteurs de vérification en série avec le circuit avant

d'obtenir une lecture.

10

AVERTISSEMENT

Pour éviter les chocs électriques lors de la mesure d'un

courant, suivez toutes les étapes indiquées ci-dessous; il

NE FAUT PAS oublier une étape ni prendre des raccourcis.

La gamme DC10A ne comporte pas de fusible. Pour éviter

les dangers et (ou) pour éviter d'endommager le multimètre, N'ESSAYEZ PAS de prendre des mesures alors

que les circuits sont soumis à un courant de plus de 10

A. NE PRENEZ PAS plus de 15 secondes pour prendre la

mesure. Laissez écouler AU MOINS 15 MINUTES entre

chaque période de vérification der 15 secondes.

Page 28

4. Débranchez l'une des extrémités du conducteur ou du disposi-

tif à l'endroit où vous mesurez le courant du circuit à vérifier.

5. Branchez le conducteur de vérification ROUGE sur le fil

conducteur débranché et placez le conducteur de vérification NOIR à l'endroit d'où le fil conducteur a été débranché

(raccordement en série).

6. Rebranchez la batterie ou appliquez une tension au circuit

à vérifier.

7. Les résultats sont affichés sur le multimètre.

MISE EN GARDE : Une fois que la vérification est

terminée, coupez l'alimentation électrique du circuit

avant de retirer les conducteurs et avant de

rebrancher les fils électriques ou les dispositifs

débranchés.

REMARQUE : Si la lecture obtenue est une valeur

négative, inversez les conducteurs de vérification.

F. VÉRIFICATION DE LA BATTERIE

1. Branchez le fil conducteur de vérification ROUGE dans le jack

« BAT. » du multimètre; branchez le fil conducteur de vérification NOIR dans le jack COM.

2. Déterminez la gamme de tensions de la batter ie à vérifier.

3. Réglez le sélecteur de fonction/gamme à la gamme de

«Battery Test» désirée (voir la rubrique Commandes et

Indicateurs, point 12).

4. Placez le fil conducteur de vérification ROUGE sur la borne

positive de la batterie à vérifier;placez le fil conducteur NOIR

sur la borne négative.

5. Les résultats sont affichés sur le multimètre.

REMARQUE : La durée de vie d'une pile est directe-

ment proportionnelle à la quantité d'énergie soutirée

(charge) par l'appareil alimenté par le pile. Pour déterminer l'état de la pile, consultez le fabricant de l'appareil

pour avoir la plus faible tension d'utilisation.

11

Page 29

REMPLACEMENT DE LA PILE ET DU FUSIBLE

1. Fermez le multimètre numérique et retirez les conducteurs de

vérification.

2. Retirez les deux vis qui se trouvent à l'arrière du multimètre

et ouvrez le coffret.

3. Remplacez le fusible ou les piles, selon le cas.

•

Remplacement de la pile : Retirez les piles et remplacez-les uniquement par deux piles AAA (1,5 V).

•

Remplacement du fusible : Retirez le fusible du portefusible et remplacez-le par un autre fusible de 0,315

A/250 V. - Fusible Bussmann de la liste UL, type GMA

(Radio Shack, GMA/série 270; #270-1046).

REMARQUE : Utilisez UNIQUEMENT un fusible de

0,315 A/250 V de 5x20 mm - Type GMA Bussmann

(Radio Shack #270-1046 ou un autre fusible similaire).

L'utilisation d'un fusible incorrect pourrait entraîner des

blessures graves et (ou) des dommages à l'appareil.

4. Refermez le coffret et serrez les deux vis.

ENTRETIEN

1. Il n'est pas nécessaire de faire un entretien périodique autre

que de remplacer la pile, le fusible et faire une inspection

visuelle de l'appareil.

2. Conservez l'appareil propre et sec. IL NE FAUT PAS utiliser

de solvant pour nettoyer l'appareil;utilisez un chiffon humide

(pas imbibé) et séchez complètement l'appareil une fois

qu'il est nettoyé.

3. Les seules pièces remplaçables sont la pile (1,5 AA), le

fusible (0,315 A/250 V) (voir page 11 pour savoir quelle pile

et quel fusible de rechange utiliser) et les conducteurs de

vérification (pour savoir quels conducteurs de vérification

utiliser, consultez notre département de service).

12

AVERTISSEMENT

Lorsque vous remplacez la pile ou le fusible, retirez

uniquement le panneau arrière. Ne retirez pas et ne

démontez pas le circuit imprimé ni le panneau avant.

Ces articles ne nécessitent aucun service; s'ils sont

démontés, il se peut que des pièces métalliques libres

créent un court-circuit sur le circuit imprimé et que cela

présente des risques d'électrocution pour l'utilisateur.

Page 30

SERVICE

Le fabricant garantit à l'acheteur d'origine que cet appareil ne

comporte aucun défaut, ni au niveau des matériaux ni de l'exécution; cette garantie vaut pendant un (1) an à partir de la date

d'achat d'origine et à condition que l'appareil fasse l'objet de

conditions normales d'utilisation et d'entretien. Si l'appareil connaît des problèmes au cours de la première (1) année, il sera

réparé ou remplacé, au choix du fabricant, sans frais, à condition d'être renvoyé en port payé au Centre de service technique

avec la preuve d'achat.Le reçu de caisse peut être utilisé à cette

fin.Les frais de main-d'œuvre pour l'installation ne sont pas couverts par la présente garantie. Toutes les pièces de rechange,

qu'il s'agisse de pièces neuves ou refaites, ne sont garanties

que pendant la période de garantie résiduelle de la présente

garantie.La présente garantie ne s'applique pas aux dommages

découlant d'une mauvaise utilisation, d'un accident, d'un usage

abusif, d'une tension anormale, de problèmes de service, d'un

incendie, d'une inondation, de la foudre ou d'autres cas de force

majeure ou si le produit est modifié ou réparé par une autre personne que le Centre de service technique du fabricant. On ne

peut pas réclamer de dommages indirects et consécutifs en

vertu de la présente garantie. Certains états ne permettent pas

l'exclusion ou la limitation des dommages indirects ou consécutifs; par conséquent, les limites ou les exclusions ci-dessus

pourraient ne pas s'appliquer dans votre cas. Cette garantie

vous confère des droits légaux spécifiques et vous pourriez

également avoir d'autres droits qui peuvent varier d'un état à

l'autre. Aucune partie de ce document ne peut être copiée ou

reproduite sans l'autorisation écrite expresse du fabricant.

Obtention du service sous garantie:

Pour obtenir le service, envoyez le produit en procédant comme

suit :

1. Téléphonez au Centre de service technique pour obtenir un

numéro de référence pour le renvoi.

États-Unis et Canada : 1-800-544-4124

Ailleurs : (714) 241-6805

2. Emballez le produit avec soin pour éviter les dommages

pendant le transport.

3. Indiquez votre nom, votre adresse et un numéro de téléphone où l'on peut vous rejoindre le jour.

4. Annexez une copie du reçu de vente montrant la date

d'achat.

5. Décrivez le problème.

13

Page 31

6. Expédiez le produit en port payé à l'adresse suivante :

Centre de service technique, 17291 Mt. Herrmann Street,

Fountain Valley, CA 92708 U.S.A.

Tél : 1-800-544-4124 or 714-241-6805

Télécopieur : 714-432-7910

Internet : www

.iEQUUS.com

Courriel : service@iEQUUS.com

14

Page 32

F

Page 33

S

315mA FUSED

CATII 600V

Page 34

Título Pagina

INTRODUCCIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

PRECAUCIONES DE SEGURIDAD/ADVERTENCIAS . . . . .1

ESPECIFICACIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CONTROLES E INDICADORES . . . . . . . . . . . . . . . . . . . . . .6

PROCEDIMIENTOS DE PRUEBA . . . . . . . . . . . . . . . . . . . .7

REEMPLAZO DE BATERÍA Y FUSIBLE . . . . . . . . . . . . . . .11

MANTENIMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PROCEDIMIENTOS DE SERVICIO . . . . . . . . . . . . . . . . . .12

INTRODUCCIÓN

•

¡Felicidades! Ha comprado un instrumento de precisión fabricado con las más altas normas de calidad. Este Multímetro

Digital es un instrumento de uso general diseñado para uso en

electrónica en general, aplicaciones en efectos electrodomésticos y sistemas eléctricos/electrónicos automotrices.

•

Este medidor está diseñado para probar o medir voltaje de

CA, voltaje de CD , baterías, corriente de CD, resistencia, diodos y continuidad.

•

Por favor tome el tiempo necesario para leer estas instrucciones de operación a fondo y por completo. El no seguir

estas instrucciones puede resultar en choque eléctrico,

daños al instrumento y/o daños al equipo bajo prueba.

Siempre tenga mucho cuidado al trabajar en equipos eléctricos o en su cercanía.

PRECAUCIONES DE SEGURIDAD/

ADVERTENCIAS

NO opere este multímetro antes de leer este manual en su total-

idad. Es necesario seguir las siguientes instrucciones para evitar accidentes que pueden causar choques eléctricos o lesiones

personales.

•

Preste especial atención a las ADVERTENCIAS estampadas en las partes delantera y trasera de la caja del

multímetro. Deben cumplirse estas advertencias, así como

todas las advertencias y precauciones utilizadas en este manual, a fin de evitar choques eléctricos y lesiones personales.

•

La PERSONA RESPONSABLE deberá saber que, si el equipo

se usa de una forma no especificada por el fabricante, la protección provista por el equipo puede verse disminuida.

•

Antes de utilizar cualquiera de las funciones de este instrumento, verifique su operación probándolo en una fuente con

una función similar y que tenga un valor conocido. Tome

acción correctiva basado en los resultados indicados.

1

S

Page 35

Para evitar choque eléctrico, daños al instrumento y/o daños al

equipo bajo prueba, observe las siguientes precauciones de

seguridad:

•

NO aplique un voltaje superior al nominal, marcado en el

multímetro, entre los terminales o entre un terminal y tierra.

•

Sea cauto al trabajar por encima de 30V CA rms, 42 V pico,

o 60 V CD. Dichos voltajes conllevan riesgos de choques

eléctricos.

•

Para evitar falsos resultados de mediciones que podrían

causar choques eléctricos o lesiones personales, reemplace

las baterías inmediatamente cuando aparezca el indicador

de bajo nivel de batería .

•

Siempre inspeccione el multímetro, las puntas de prueba y

todos los accesorios antes de usarlos para asegurarse de

que no estén dañados. Si existe algún daño, no use el

multímetro hasta que se haya reparado.

•

Siempre considere que los equipos eléctricos y electrónicos

estén energizados (vivos). Nunca proceda asumiendo que

los equipos están apagados.

•

Nunca conecte su persona a tierra mientras toma medidas

eléctricas. Aíslese de la tierra usando una esterilla seca aisladora de goma para cubrir todo el metal expuesto o conectado a tierra. Párese sobre la esterilla y use ropa seca.

•

Nunca efectúe mediciones de resistencia en equipos eléctricos o electrónicos energizados (vivos).

•

Use una mano, en vez de dos, siempre que sea posible al

efectuar las mediciones.Si es necesario usar ambas manos,

tenga mucho cuidado que las manos no entren en contacto

con conductores energizados. Asegúrese de que las puntas

de prueba estén secas y limpias.

•

No sostenga el instrumento mientras efectúa las mediciones.

Coloque el instrumento sobre una superficie limpia y aisladora antes de efectuar cualquier medición.

•

No forme parte del circuito. Piense en la segur idad. Actúe de

forma segura.

Si trabaja en un vehículo, tome las siguientes precauciones de

seguridad adicionales:

•

Trabaje en el vehículo sólo en un área bien ventilada.

•

Siempre use gafas de protección para los ojos.

•

Manténgase alejado de las aspas del ventilador y cualquier

otra parte que pueda entrar en movimiento.

•

Manténgase alejado de las partes calientes del motor.

•

Coloque la transmisión en la posición de estacionamiento

(Park) si el vehículo es automático, o en neutral si es de

cambios. Fije el freno de estacionamiento.

2

S

Page 36

Apague el encendido (off) antes de conectar o desconectar

3

S

•

cualquier equipo de prueba.

Bloquee las ruedas propulsoras.

•

Evite vestir ropas sueltas o artículos de joyería mientras tra-

•

baja en el vehículo.

Lea el manual de servicio del vehículo y observe sus instruc-

•

ciones de seguridad.

ESPECIFICACIONES

ESPECIFICACIONES Y CARACTERÍSTICAS GENERALES

Pantalla LCD de 3 1/2 dígitos (con máxima lectura de 2000)

•

Selección manual de rango

•

Indicación automática de negativo (-) y polaridad

•

Ajuste automático de cero

•

Indicador de exceso de rango (excepto la función 10 A).

•

Aparece "1" en la pantalla LCD

Indicador de batería agotada:Presenta el símbolo de batería

•

en la pantalla LCD

Apagado automático (después de 15 minutos de inactividad)

•

Normas de seguridad: CE EMC/LVD. Este medidor cumple

•

con la norma IEC1010 Pollution Degree 2 (grado de corrupción 2), Overvoltage Category 2 (sobrevoltaje categoría 2)

Ambiente de funcionamiento:

•

Temperatura 0 °C a 40 °C (- 32° a 104 °F)

Humedad - menos del 80% de humedad relativa (sin condensación)

Altitud - hasta 6562 pies (2000 metros)

Ambiente de almacenamiento:

•

Temperatura - 20° a 60 °C (- 4° a 140 °F)

Humedad - menor que el 90% de humedad relativa (sin condensación)

Fuente de alimentación: dos baterías AAA de 1.5 V

•

Fusible: 315 mA/250 V 5X20 mm (Radio Shack, GMA/217

•

serie; #270-1046)

Dimensiones:

•

Altura - 5.50 pulg. (139 mm)

Anchura - 3.50 Pulg. (89 mm)

Profundidad - 1.25 pulg. (32 mm)

Peso (con baterías):aproximadamente 5.7 onzas (170 g)

•

Page 37

ESPECIFICACIONES ELÉCTRICAS

La exactitud de las especificaciones en las tablas siguientes

está basada en una temperatura de operación de 64°F a 82°F

(18°C a 28°C) y una humedad relativa menor al 75%.

El voltaje máximo entre los enchufes Vma y COM es de 500

VCA/VCD. Entre el enchufe COM y la tierra, es de 300

VCA/VCD.

VOLTIOS CD

RESISTENCIA (OHMIOS)

4

S

Protección

Rango Resolución Exactitud contra

sobrecarga

200mV 100µV

2V 1mV

±(0.8% de la lectura

500V CD

20V 10mV

+ 5 dígitos)

o CA

500V 1V

500V RMS

Impedancia de entrada: 10 MΩ para todos los rangos.

Protección

Rango Resolución Exactitud contra sobrecarga

200Ω 0.1Ω ±(1% de la lectura

+ 5 dígitos)

2KΩ 1Ω 250V CD/CA RMS

200KΩ 10Ω

20M Ω 10K Ω ±(2% de la lectura

+ 5 dígitos)

Page 38

PRUEBA DE DIODOS/CONTINUIDAD

AMPERIOS CD

PRUEBA DE BATERÍAS (INDICADORES LED)

5

S

Protección

contra

Rango Resolución Exactitud sobrecarga

2mA 1µA Fusible 0.315A/

20mA 10µA

±(1.5% de la lectura

250V

200mA 100µA

+ 5 dígitos)

10A 10mA ±(2% de la lectura No tiene

+ 5 dígitos) protección

Tiempo de medición es igual a, o menor de, 15 segundos y

el intervalo de tiempo es igual a, o más de, 15 minutos.

Rango Resolución Corriente de carga, CD

1.5V 10mA

6V

0.01V

100mA

9V 10mA

12V 100mA

Protección

contra

Función Rango Resolución Exactitud sobrecarga

Prueba de 1mV Presenta

diodos en pantalla

lectura

aproximada

de la

caída 250V CD/CA

de voltaje RMS

Prueba de 1Ω 50Ω o

continuidad menos, el

zumbador

suena

Page 39

VOLTIOS CA

CONTROLES E INDICADORES

1. Función de voltios en CD

(DCV): Mide voltios en CD.

Cuatro (4) rangos: 200 milivoltios (mV), 2, 20 y 500

voltios.

2. Función de platinos :

Mide la caída de voltaje en

los platinos del encendido.

3. Función de Ohmios (ΩΩ):

Mide resistencia. Cuatro (4)

rangos: 200, 2K (2000), 200K

(200,000) y 20M (20,000,000)

ohmios.

4. Función de DIODOS :

Prueba diodos.

5. Función de continuidad : Prueba de continuidad entre

dos puntos.

6. Enchufes de 10A

7. Enchufe del común (COM).

8. Enchufes para voltios, mA, OHMIOS, BAT, DIODO y

CONTINUIDAD

9. Función de amperios en CD (DCA): Mide corriente direc-

ta. Un (1) rango: 10 amperios CD, de 0 a 10 amperios.

10. Función de mA: Mide corriente en miliamper ios. Tres (3)

rangos: 2, 20 y 200 miliamperios.

11. Función de prueba de baterías bajo carga: Prueba

baterías pequeñas.Cuatro (4) rangos: 1.5, 6, 9 y 12 voltios.

12. Interruptor selector de Función/Rango: Selecciona la

función o rango deseado.

13. Función de voltios en CA (ACV):Mide voltajes en CA.Dos

rangos: 200 y 500 voltios.

6

S

Protección

contra

Rango Resolución Exactitud sobrecarga

200V 100mV ±(1.2% de la lectura 500V CD o CA

500V 1V

+ 10 dígitos) RMS

Impedancia de entrada: Aproximadamente 5MΩ

Frecuencia: 40 a 400 Hz

Dato en pantalla: RMS del valor de la onda sinusoidal

(valor promedio)

1

2

3

4

5

68

315mA FUSED

CATII 600V

7

15

14

13

12

11

10

9

Page 40

14. Función de apagar (OFF): Apaga la unidad (posición

“OFF”) cuando se selecciona esta posición.

15. Pantalla LCD (pantalla de cristal líquido): Presenta los

resultados de las pruebas o mediciones.

Preparación y precaución antes de usarse

•

Inspeccione el Multímetro en busca de daños en la caja. No

lo use si existen grietas, distorsión, exceso de suciedad o

alguna otra condición anormal.

•

Inspeccione las puntas de prueba en busca de daños.Revise

que no tengan grietas en el aislamiento, puntas rotas o

dañadas, clavijas flojas o dobladas.No las use si existe alguna condición anormal.

•

Coloque el interruptor de selección de Función/Rango en el

rango apropiado ANTES de efectuar la medición.Si es necesario cambiar la posición del interruptor de selección de

Función/Rango durante una prueba, SIEMPRE desconecte

las puntas de prueba del circuito a medir antes de cambiar

la posición del interruptor.

•

Para evitar un posible choque eléctrico, daños al instrumento, y/o daños al equipo bajo prueba al efectuar mediciones

de voltaje o corriente, NO EXCEDA el valor máximo del

rango seleccionado.

•

Si la unidad se usa cerca de equipo que genera ruidos altos

de radiofrecuencia (cables de bujías, bobinas de encendido)

la pantalla puede volverse inestable o indicar errores

grandes. Si se presenta esta condición en uso, coloque el

Multímetro lo más alejado posible de las fuentes de ruido.

PROCEDIMIENTOS DE PRUEBA

A. MEDICIÓN DE VOLTAJE DE CA/CD

1. Conecte la punta NEGRA de prueba en el enchufe marca-

do "COM" en el multímetro; conecte la punta ROJA de

prueba en el enchufe marcado "V".

7

S

ADVERTENCIA

Para evitar un posible choque eléctrico, daños al instrumento o daños al equipo, NO TRATE de efectuar

mediciones de voltajes SUPERIORES a los 500 V de

CA/CD ni efectuar mediciones de voltajes desconocidos.

500 VCD es el voltaje máximo entre los conectores COM

y V que este instrumento está diseñado para medir. El

potencial en el terminal "COM" no debe exceder 300 V de

CA/CD medidos con respecto a tierra.

Page 41

2. Coloque el interruptor de selección de Función/Rango del

medidor en la posición de voltaje de CA (ACV) o de CD

(DCV) deseada. Véase la Sección V, Controles e

Indicadores, numerales 1 y 13.

3. Coloque la punta ROJA de prueba en contacto con el lado positivo (+) del elemento a medir y la punta NEGRA de prueba en

contacto con el lado negativo (-) (a través de la fuente/carga)

del elemento a medir. TENGA CUIDADO de no tocar ningún

conductor energizado con ninguna parte de su cuerpo.

4. Lea los resultados en la pantalla.

B. MEDICIÓN DE RESISTENCIA ΩΩ( OHMS)

1. Conecte la punta de prueba ROJA en el enchufe marcado

“ΩΩ”en el Multímetro; conecte la punta de prueba NEGRA en

el enchufe marcado “COM”.

2. Coloque el interruptor de selección de Función/Rango en el

rango de OHM "ΩΩ" (ohms de resistencia) deseado.Véase la

sección Controles e Indicadores, Renglón 3.

NOTA: Para obtener lecturas exactas, desconecte al

menos uno de los lados del dispositivo a medir del circuito en que se encuentra instalado antes de efectuar la

medición de resistencia.

3. Coloque la punta de prueba ROJA en contacto con un lado

del elemento a medir y la punta de prueba NEGRA en

contacto con el otro lado del elemento a medir. (La polaridad no tiene efecto en las mediciones de resistencia.)

4. Lea los resultados de la lectura en la pantalla.

C. PRUEBA DE DIODOS

8

ADVERTENCIA

Las mediciones de resistencia pueden hacerse SÓLO en

circuitos desenergizados (apagados). El aplicar cualquier

voltaje a los terminales del multímetro cuando éste se

encuentra en uno de los rangos de resistencia puede

resultar en choque eléctrico,daños al instrumento o daños

al equipo bajo prueba. ASEGÚRESE de que el equipo esté

totalmente apagado antes de efectuar cualquier medición.

S

ADVERTENCIA

Para evitar choque eléctrico y/o daño al multímetro,

asegúrese de que la energía eléctrica esté apagada antes

de conduzcir cualquier método de prueba del DIODO.

Pruebe los diodos en los circuitos desenergizados (muertos) solamente, nunca en los circuitos con corriente.

Page 42

NOTA: Los diodos son dispositivos semiconductores

que dejan pasar corriente en un sentido y la bloquean

en el opuesto. Si el diodo a probar forma parte de un

circuito (con otros componentes electrónicos), es

necesario aislarlo de los demás elementos del circuito

(desconectando uno de sus conductores) antes de

efectuar la prueba. Un diodo bueno indica un voltaje

bajo a través de su junta (entre 0.5 y 0.8 volts en diodos de silicio o aproximadamente 0.3 volts en diodos

de germanio) cuando se conectan las puntas de prueba con una polaridad; y una resistencia muy alta (o circuito abierto) cuando se invierten las puntas de prueba (conectadas con la polaridad opuesta).

1. Conecte la punta de prueba ROJA en el enchufe marcado

en el Multímetro; conecte la punta de prueba NEGRA

en el enchufe marcado “COM”.

2. Coloque el interruptor de selección de Función/Rango en la

posición . Véase la sección Controles e Indicadores,

numero 4.

3. Coloque la punta de prueba ROJA en contacto con un lado

del diodo a medir y la punta de prueba NEGRA en contacto con el otro lado del diodo a medir.

4. Lea los resultados en la pantalla.

5. Invierta las puntas de prueba y lea el nuevo resultado en la

pantalla.Compare las dos lecturas.Una lectura debe indicar

un valor de caída de voltaje;la otra lectura debe indicar una

condición de exceso de rango (OL).

Véase la nota ante-

dicha

.

D. PRUEBA DE CONTINUIDAD

1. Conecte la punta de prueba ROJA en el enchufe marcado

en el Multímetro;conecte la punta de prueba NEGRA en

el enchufe marcado “COM”.

2. Coloque el interruptor de selección de Función/Rango en la

posición . Véase la sección Controles e Indicadores,

numeral 5.

3. Coloque la punta de prueba ROJA a un extremo del cable o

el dispositivo que va a ser probado para la continuidad y la

punta de prueba NEGRA al extremo opuesto.

4. Escuche el sonido del beeper y confirme los resultados en

la pantalla.

9

S

ADVERTENCIA

Para evitar choque eléctrico apagele la energía al artículo

de la prueba antes de iniciarle la prueba de continuidad.

Page 43

NOTA: El zumbador sonará sólo si existe continuidad

en el elemento medido (o sea que existe un circuito

entre las dos puntas de prueba) con una resistencia

inferior a los 50 ohms aproximadamente.

E. MEDICIÓN DE CORRIENTE CD (AMPERES)

1. Conecte la punta ROJA de prueba en el enchufe marcado

"mA" o en el enchufe "DC10A" en el multímetro según corresponda; conecte la punta de prueba NEGRA en el

enchufe marcado "COM".

2. Coloque el interruptor de selección de Función/Rango en el

rango "DCA" (amperes de corriente directa) deseado.(Véase

la sección Controles e Indicadores, numerales 9 y 10).

•

Para medir de 0 a 200 mA coloque el selector en la posición "CDmA" deseado.

•

Para medir desde 200mA hasta 10 A de CD, coloque el

interruptor de selección en la posición "DC10A".

3. Desconecte la batería o apague el circuito a medir.

NOTA: Para medir corriente en un circuito particular, es

necesario abrir el circuito y conectar las puntas de

prueba en serie con el circuito antes de poder obtener

una lectura.

4. Desconecte un extremo del cable o dispositivo, del circuito

en que se desea medir la corriente.

5. Coloque la punta ROJA de prueba en contacto con el conductor desconectado y la punta NEGRA de prueba en contacto con el punto desde donde se desconectó el conductor

(conexión en serie).

6. Reconecte la batería o aplíquele alimentación al circuito a

medir.

7. Lea los resultados de la lectura en la pantalla.

10

S

ADVERTENCIA

Para prevenir choque eléctrico al realizar medidas de corriente eléctrica,siga todos los pasos según lo indicado abajo.

No salte ninguno de los pasos ni tome ninguna via corta.

El rango de 10A no tiene fusible. Para evitar el peligro de

la corriente o daños al multímetro, NO TRATE de efectuar mediciones en circuitos con corrientes superiores a

10 amperes. NO SE DEMORE más de 15 segundos para

efectuar la medición. Es necesario tener un período de

espera de AL MENOS 15 MINUTOS entre cada período de

prueba de 15 segundos.

Page 44

PRECAUCIÓN: Después que termine la prueba

apage la energia electrica del circuito antes de

quitar las puntas de prueba y antes de volver a

conectar cualquier cable o dispositivos desconectados.

NOTA: Si la lectura obtenida es negativa, invierta las

puntas de prueba.

F. PRUEBA DE BATERÍAS

1. Conecte la punta de prueba ROJA en el enchufe marcado

“BAT .”en el Multímetro;conecte la punta de prueba NEGRA

en el enchufe marcado “COM”.

2. Determine el voltaje de la batería a medir.

3. Coloque el interruptor de selección de Función/Rango en el

rango de "Battery Test" (prueba de baterías) deseado.

Véase la sección, Controles e Indicadores, numeral 12.

4. Coloque la punta de prueba ROJA en contacto con el borne

positivo (+) de la batería a medir y la punta de prueba

NEGRA en contacto con el lado negativo (–) de la batería a

medir.

5. Lea los resultados de la lectura en la pantalla.

NOTA: La vida de una batería es directamente propor-

cional a la corriente extraída (carga) por el dispositivo

que la batería está accionando. Para determinar la

condición de una batería, consulte al fabricante del dispositivo para determinar el requisito de voltaje mínimo

de su funcionamiento.

REEMPLAZO DE BATERÍA Y FUSIBLE

1. Apague el Multímetro (OFF) y desconecte las puntas de

prueba.

2. Extraiga los dos tornillos de la parte posterior del medidor y

separe la caja.

11

S

ADVERTENCIA

Al reemplazar la batería o el fusible, quite solamente el

panel trasero. No quite ni desmonte el tablero de circuito

o el panel delantero, estos artículos no contienen par tes

reemplazables y si se desmontan ai la posabilidad que las

piezas flojas de metal pongan en cortocircuito el tablero

de circuito y que causen un peligro de electrocucion al

usuario.

Page 45

3. Reemplace el fusible o las baterías según sea necesario:

•

Para reemplazo de las baterías: Saque las baterías

del compartimiento de baterías y reemplácelas únicamente con dos baterías AAA de 1.5 volts.

•

Para reemplazo del fusible: Extraiga el fusible del

porta fusible y reemplácelo con un fusible de Bussmann

0.315 A/250 V, Typo GMA - con aprobación de UL

(Radio Shack GMA/270; Serie #270-1046)

NOTA: Use SÓLO fusibles de - Bussmann, Typo

GMA 0.315 A/250 V, 5x20 mm (Radio Shack #

270-1046 o similar). El uso de un fusible erróneo

puede resultar en lesiones graves o daños a la

unidad.

4. Ensamble de nuevo la caja y sujétela con los dos tornillos.

MANTENIMIENTO

1. No se requiere ningún mantenimiento periódico con excep-

ción del reemplazo de la batería, del fusible, y de la inspección visual del medidor.

2. Mantenga el medidor limpio y seco. No utilice solventes

para limpiarlo, utilize un paño húmedo (no mojado) sece

completamente después de limpiar.

3. Las únicas piezas reemplazables son las baterías 1.5 AAA,

el fusible 0.315A/250V (véase pagina 11 para el reemplazo

de la batería y del fusible) y las puntas de prueba (para las

puntas de prueba llame el departamento de ser vicio).

PROCEDIMIENTOS DE SERVICIO

El fabricante garantiza al comprador original que esta unidad

está exenta de def ectos en materiales y mano de obra en condiciones normales de uso y mantenimiento por un período de un

(1) año a partir de la fecha de compra original. Si la unidad falla

en un período de un (1) año, se reemplazará o se reparará, a

opción del Fabricante, sin cargo adicional alguno, cuando se

devuelva con porte prepagado al Centro de Servicio Técnico

acompañada del comprobante de pago. El recibo de compra

puede usarse para este propósito. La mano de obra no tiene

cobertura en virtud de esta garantía.

Todas las partes de repuesto, sean nuevas o reconstruidas,

asumirán como su período de garantía sólo el plazo restante de

esta garantía. Esta garantía no cubre daños causados por uso

indebido, accidental, abusiv o , v oltaje erróneo , servicio , incendio ,

inundación, rayo u otros actos de fuerza mayor, o si el producto

fue modificado o reparado por alguien ajeno al Centro de

Servicio Técnico del Fabricante.Los daños consecuentes o inci-

12

S

Page 46

dentes no son recuperables en virtud de esta garantía. Algunos

estados no permiten la exclusión o la limitación de los daños

incidentes o consecuentes, así que la limitación o exclusión

anterior quizá no sea aplicable a su caso.

Esta garantía le otorga derechos legales específicos, y usted

quizá pueda tener otros derechos, los cuales varían de estado a

estado. No se permite copiar ni duplicar porción alguna de esta

garantía sin el consentimiento expreso y escrito del Fabricante.

Cómo obtener servicio en virtud de la garantía:

Los productos que requieran servicio deberán devolverse de la

manera siguiente:

1. Llame al Centro Servicio Técnico para obtener un Número

de Referencia de Devolución:

EE.UU.y Canadá = 1-800-544-4124

Desde otro país = 714-241-6805 (E.U.A.)

2. Embale cuidadosamente el producto para evitar daños

durante el envío

3. Incluya su nombre, el remitente y un teléfono disponible en

horas hábiles

4. Adjunte una copia del recibo de compra fechado

5. Describa el problema

6. Envíe el producto con porte pagado a: Technical Service

Center, 17291 Mt. Herrmann Street, Fountain Valley, CA

92708 U.S.A.

Teléfono: 1-800-544-4124 ó 714-241-6805 (E.U.A) Fax: 714-

432-7910 (E.U.A)

Web: www

.iEQUUS.com

Correo electrónico: ser vice@iEQUUS.com

Para garantía en México ver con distribuidor.

13

SSS

Page 47

Page 48

Loading...

Loading...