Page 1

#3173

IMPORT COMPUTER

CODE READER

(FRONT COVER)

Page 2

Table of Contents

Chapter Title Page No.

YOU CAN DO IT! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1 GENERAL INFORMATION

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . 2

VEHICLES COVERED . . . . . . . . . . . . . . . . . . . . . . . . . 3

BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . 4

VEHICLE SERVICE MANUALS . . . . . . . . . . . . . . . . . 5

PRELIMINARY VEHICLE DIAGNOSIS

WORKSHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 ABOUT IMPORT VEHICLE DIAGNOSTIC SYSTEMS

AUTOMOTIVE COMPUTER CONTROL SYSTEMS . . 9

ON-BOARD VEHICLE DIAGNOSTICS - (OBD I) . . . . 10

DIAGNOSTIC TROUBLE CODES . . . . . . . . . . . . . . . . 10

3 HONDA/ACURA

OVERVIEW OF HONDA/ACURA DIAGNOSTIC

SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CODE RETRIEVAL PROCEDURE . . . . . . . . . . . . . . . 14

ERASING CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

HONDA/ACURA FAULT CODE DEFINITIONS . . . . . 21

4 NISSAN/INFINITI

OVERVIEW OF NISSAN/INFINITI DIAGNOSTIC

SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CODE RETRIEVAL PROCEDURE . . . . . . . . . . . . . . . 24

ERASING CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

NISSAN/INFINITI FAULT CODE DEFINITIONS . . . 34

5 TOYOTA/LEXUS

OVERVIEW OF TOYOTA/LEXUS DIAGNOSTIC

SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CODE RETRIEVAL PROCEDURE . . . . . . . . . . . . . . . 38

ERASING CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TOYOTA/LEXUS FAULT CODE DEFINITIONS . . . . 45

6 GLOSSARY

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

GLOSSARY OF TERMS AND ABBREVIATIONS . . . 49

7 WARRANTY AND SERVICE

LIMITED ONE YEAR WARRANTY . . . . . . . . . . . . . . . 51

TECHNICAL ASSISTANCE AND WARRANTY

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

i

Page 3

You Can Do It!

ii

1

Look up the Code Retrieval information for

your vehicle

•

Follow the step-by-step instructions.

2

Read Diagnostic Trouble

Codes

•

The codes are displayed by

either the “Check Engine” light

or at the vehicles computer.

3

Locate Problem Areas

•

Look up fault code descriptions

in the Fault Code Definition

list.

1

ri

lt

6

or

M

or

s

EV

iri

W

it

ui

CHECK ENGINE

Possible Cause

11)

Open or shorted signal circuit,

high O2 signal

Open signal in trans. Control unit

ECM

ght side

s / no malfunctions

cylinder misfire Wiring, fuel or ignition system,

No. 5 cylinder misfire Wiring, fuel or ignition system,

65 No. 4 cylinder misfire Wiring, fuel or ignition system,

ECM

ECM

ECM

ECM

66 No. 3 cylinder misfire Wiring, fuel or ignition system,

67 No. 2 cylinder misfire Wiring, fuel or ignition system,

68 No. 1 cylinder misfire Wiring, fuel or ignition system,

71 Random misfire Wiring, fuel or ignition system,

72 TWC function RH bank Catalytic converter, wiring, ECM

73 TWC function LH bank Catalytic converter, wiring, ECM

bank

76 Fuel injection system function RH Wiring, injector, oxygen sensor

77 Rear HO2S circuit Wiring, injector, oxygen sens

82 CKP sensor Wiring, CKP sensor, EC

84 A/T diagnosis communication line Wiring, ECM

85 CMP actuator - circuit malfunction Wiring, CMP sens

ECM

ECM

bank

86 Fuel injection system function LH Wiring, oxygen

circuit

87 Canister control solenoid valve Wiring,

91 Front HO2S heater circuit RH bank W

CKP sensor

T sensor

or circuit

4 TCC solenoid valve

HO2S heater circu

circ

Page 4

General Information

SAFETY PRECAUTIONS

1 Chapter 1

SAFETY PRECAUTIONS

To avoid personal injury, instrument damage and/or

damage to equipment under test; do not operate the

Import Code Reader before reading this manual.

This manual describes common test procedures used by

experienced service personnel and technicians. Many test

procedures require precautions to avoid accidents that can

result in personal injury, and/or vehicle or equipment damage.

Always read your vehicle’s service manual and follow it’s safety

precautions before any test or service procedure is performed.

a. When an engine is running, it produces carbon monoxide

(a toxic and poisonous gas). To prevent serious injury or

death from carbon monoxide poisoning, operate a vehicle

ONLY in a well-ventilated area.

b. To protect your eyes from propelled objects as well as hot

or caustic liquids, always wear approved safety eye

protection.

c. When an engine is running, several objects rotate at a

very high rate of speed (electric cooling fans, pulleys,

serpentine and fan drive belts, etc.). To avoid serious

injury, always be conscious of moving parts, and keep a

safe distance from all these items as well as other

potentially moving objects.

d. Engine parts become extremely hot when the engine is

running. To prevent severe burns, avoid contact with hot

engine parts.

e. Before starting an engine for troubleshooting, make sure

the parking brake is engaged. Put the transmission in

“park” (for automatic transmission) or “neutral” (for

manual transmission). Block the drive wheels with a

suitable blocking device.

f. Connecting or disconnecting test equipment when the

ignition is “on” can cause a spark. This spark is

potentially damaging to the test equipment and to the

vehicle’s electronic components. Always turn the ignition

“off” before connecting or disconnecting any test

equipment.

g. To prevent damage to the on-board computer when taking

vehicle electrical measurements, always use a digital

multimeter with at least 10 Megohms of impedance.

Page 5

General Information

GENERAL INFORMATION

Chapter 1 2

h. The vehicle’s battery produces highly flammable hydrogen

gas. To prevent an explosion, keep all sparks, high

temperature items or open flames away from the battery.

i. Do not wear loose clothing or jewelry when working on an

engine. Loose clothing can get caught on the fan, pulleys,

belts, etc. Jewelry is highly conductive, and can cause a

severe burn if it makes contact between a power source

and ground.

GENERAL INFORMATION

This Code Reader and manual are designed for use both by

consumers with little or no experience in retrieving codes, or

by experienced technicians. If you are having problems with

your vehicle and only want to know if any Diagnostic Trouble

Codes are present in the vehicle’s computer system, go directly

to Chapter 3 (for Honda/Acura), Chapter 4 (for Nissan/Infiniti)

or Chapter 5 (for Toyota/Lexus), and follow the simple

directions to retrieve the codes. The codes retrieved, and their

definitions, will give you valuable information and a starting

point from which to proceed to the next step.

Once the codes have been retrieved, you can choose to:

•

Take your vehicle to an Automotive Service Center

for repair: Take your vehicle, a copy of the completed

Preliminary Vehicle Diagnosis Worksheet (see page 6) and

diagnostic trouble codes retrieved to your technician for

evaluation. This will demonstrate to your technician that

you are an informed motorist and will also assist him in

pinpointing the location of the problem.

•

Attempt to fix the problem yourself: If you choose to fix

the problem yourself, read and follow all of the recommendations and procedures stated in the factory service

manual for your application.

Page 6

General Information

VEHICLES COVERED

3 Chapter 1

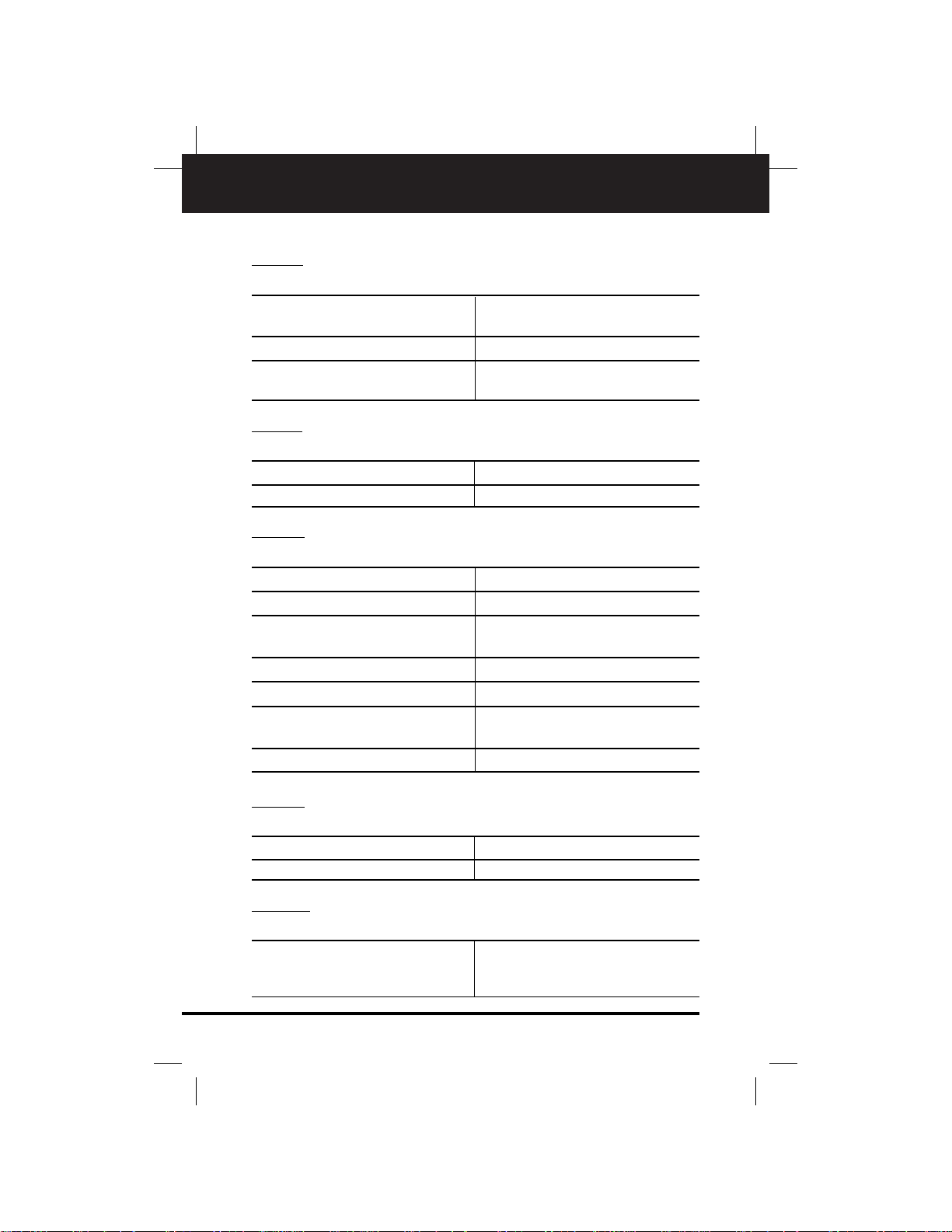

VEHICLES COVERED

HONDA

Model Years Engine Model Years Engine

Accord 84-95 1.8, 2.0, Civic/CRX 87-95 1.5, 1.6

2.2, 2.7

Del Sol 93-95 1.5, 1.6 Odyssey 95 2.2, 2.3

Prelude 85-95 1.8, 2.0, 2.1

2.2, 2.3

ACURA

Model Years Engine Model Years Engine

Integra 86-95 1.6, 1.7, 1.8 Legend 86-95 2.5, 2.7, 3.2

NSX 91-95 3.0, 3.2 Vigor 92-94 2.5

NISSAN

Model Years Engine Model Years Engine

Altima 93-95 2.4 Axxess 90 2.4

Maxima 86-95 3.0 NX 91-94 1.6, 2.0

Pathfinder 87-95 2.4, 3.0 Hardbody 87-95 2.4, 3.0

Pickup

Pulsar 87-90 1.6, 1.8 Quest 93-95 3.0

Sentra 87-95 1.6, 2.0 Stanza 86-92 2.0, 2.4

Van 87-90 2.4 200SX 84-95 1.6, 1.8,

2.0, 3.0

240SX 89-95 2.4 300ZX 86-95 3.0

INFINITI

Model Years Engine Model Years Engine

G20 91-95 2.0 J30 93-95 3.0

M30 90-92 3.0 Q45 90-95 4.5

TOYOTA

Model Years Engine Model Years Engine

4 Runner 84-95 2.4, 3.0 Camry 84-93 2.0 (exc.

Diesel), 2.2,

2.5, 3.0

Page 7

General Information

BEFORE YOU BEGIN

Chapter 1 4

BEFORE YOU BEGIN

•

Fix any known mechanical problems before performing

any test.

Complete a thorough vehicle inspection before starting any

diagnostic procedure. Loose or damaged hoses, wiring, or

electrical connectors are often responsible for poor engine

performance, and in some cases these items may cause a

“false” fault code. Check the following areas:

•

All fluid levels

•

Belts

•

Vacuum Hoses

•

Wiring and Connectors

Please read your vehicle’s service manual and perform all

required preliminary checks BEFORE retrieving fault codes.

TOYOTA (cont)

Model Years Engine Model Years Engine

Celica 86-95 1.6, 1.8, Corolla 86-95 1.6, 1.8

2.0, 2.2

Cressida 83-89 2.8 w/Super Cressida 86-92 2.8, 3.0

Monitor

Display

Land 88-94 4.0, 4.5 MR2 85-95 1.6, 2.0,

Cruiser 2.2

Paseo 92-95 1.5 Pickup 83-94 2.4 (exc.

Diesel), 3.0

Previa 91-95 2.4 (exc. SC) Supra 84-95 2.8, 3.0

T100 93-94 3.0 Tercel 89-94 1.5

Van 84-89 2.0,2.2

LEXUS

Model Years Engine Model Years Engine

ES250 90-91 2.5 ES300 92-93 3.0

GS300 93-95 3.0 LS400 90-94 4.0

SC300 92-95 3.0 SC400 92-95 4.0

Page 8

General Information

VEHICLE SERVICE MANUALS

5 Chapter 1

VEHICLE SERVICE MANUALS

It is recommended that you consult the manufacturer’s service

manual for your vehicle before any test or repair procedures

are performed.

Contact your local car dealership, auto parts store or bookstore

for availability of these manuals. The following companies

publish valuable repair manuals and information:

■ ALLDATA, LLC

9412 Big Horn Blvd.

Elk Grove, California 95758

Phone: 1-916-684-5200

www.alldata.com

■ Haynes Publications

861 Lawrence Drive

Newbury Park, California 91320

Phone: 800-442-9637

www.haynes.com

■ Mitchell International

14145 Danielson Street

Poway, California 92064

Phone: 888-724-6742

www.mitchell.com

■ Motor Publications

5600 Crooks Road, Suite 200

Troy, Michigan 48098

Phone: 800-426-6867

www.motor.com

FACTORY SOURCES

Visit your local Acura, Honda, Infiniti, Lexus, Nissan and

Toyota dealerships to purchase a factory service manual, or

visit:

■ Helm Inc.

14310 Hamilton Avenue

Highland Park, Michigan 48203

Phone: 800-782-4356

www.helminc.com

Page 9

General Information

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

Chapter 1 6

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

The purpose of this form is to help you gather preliminary information

on your vehicle before you retrieve codes. By having a complete

account of your vehicle's current problem(s), you will be able to

systematically pinpoint the problem(s) by comparing your answers to

the fault codes you retrieve. You can also provide this information to

your mechanic to assist in diagnosis and help avoid costly and

unnecessary repairs. It is important for you to complete this form to help

you and/or your mechanic have a clear understanding of your vehicle's

problems.

NAME:

DATE:

VIN*:

YEAR:

MAKE:

MODEL:

ENGINE SIZE:

VEHICLE MILEAGE:

*VIN: Vehicle Identification Number, found at the base of the

windshield on a metallic plate, or at the driver door latch area (consult

your vehicle owner's manual for location).

TRANSMISSION:

❑

Automatic

❑ Manual

Please check all applicable items in each category.

DESCRIBE THE PROBLEM:

Page 10

General Information

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

7 Chapter 1

WHEN DID YOU FIRST NOTICE THE PROBLEM:

❑ Just Started

❑ Started Last Week

❑ Started Last Month

❑ Other:

LIST ANY REPAIRS DONE IN THE PAST SIX MONTHS:

PROBLEMS STARTING

ENGINE QUITS OR STALLS

IDLING CONDITIONS

RUNNING CONDITIONS

❑ No symptoms

❑ Will not crank

❑ Cranks, but will not start

❑ Starts, but takes a long time

❑ No symptoms

❑ Right after starting

❑ When shifting into gear

❑ During steady-speed driving

❑ Right after vehicle comes to a stop

❑ While idling

❑ During acceleration

❑ When parking

❑ No symptoms

❑ Is too slow at all times

❑ Is too fast

❑ Is sometimes too fast or too slow

❑ Is rough or uneven

❑ Fluctuates up and down

❑ No symptoms

❑ Runs rough

❑ Lacks power

❑ Bucks and jerks

❑ Poor fuel economy

❑ Hesitates or stumbles on

accelerations

❑ Backfires

❑ Misfires or cuts out

❑ Engine knocks, pings or rattles

❑ Surges

❑ Dieseling or run-on

Page 11

General Information

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

Chapter 1 8

AUTOMATIC TRANSMISSION PROBLEMS (if applicable)

PROBLEM OCCURS

❑ Morning ❑ Afternoon ❑ Anytime

ENGINE TEMPERATURE WHEN PROBLEM OCCURS

❑ Cold ❑ Warm ❑ Hot

DRIVING CONDITIONS WHEN PROBLEM OCCURS

DRIVING HABITS

GASOLINE USED

WEATHER CONDITIONS WHEN PROBLEM OCCURS

CHECK ENGINE LIGHT / DASH WARNING LIGHT

❑

Sometimes ON ❑ Always ON ❑ Never ON

PECULIAR SMELLS

STRANGE NOISES

❑ Short - less than 2 miles

❑ 2 - 10 miles

❑ Long - more than 10 miles

❑ Stop and go

❑ While turning

❑ While braking

❑ At gear engagement

❑ With A/C operating

❑ With headlights on

❑ During acceleration

❑ Mostly driving downhill

❑ Mostly driving uphill

❑ Mostly driving level

❑ Mostly driving curvy roads

❑ Mostly driving rough roads

❑ Mostly city driving

❑ Highway

❑ Park vehicle inside

❑ Park vehicle outside

❑ Drive less than 10 miles per day

❑ Drive 10 to 50 miles per day

❑ Drive more than 50 miles per day

❑ 87 Octane

❑ 89 Octane

❑ 91 Octane

❑ More than 91 Octane

❑ 32 - 55° F (0 - 13° C)

❑ Below freezing (32° F / 0° C)

❑ Above 55° F (13° C)

❑ "Hot"

❑ Sulfur ("rotten egg")

❑ Burning rubber

❑ Gasoline

❑ Burning oil

❑ Electrical

❑ Rattle

❑ Knock

❑ Squeak

❑ Other

❑ No symptoms

❑ Shifts too early or too late

❑ Changes gear incorrectly

❑ Vehicle does not move when in

gear

❑ Jerks or bucks

Page 12

About Import Vehicle Diagnostic Systems

AUTOMOTIVE COMPUTER CONTROL SYSTEMS

9 Chapter 2

AUTOMOTIVE COMPUTER CONTROL SYSTEMS

The main purpose of the vehicle’s Computer Control System is

to provide maximum engine performance with the least

amount of air pollution and the best fuel efficiency possible.

The Computer Control System consists of the on-board

computer, and several related control devices (sensors,

switches, and actuators). Most on-board computers are located

inside the vehicle behind the dashboard, under the passenger’s

or driver’s seat, or behind the passenger side kick panel. Some

manufacturers may still position it in the engine compartment.

The sensors, switches, and actuators are devices such as

oxygen sensors, coolant temperature sensors, throttle position

sensors, fuel injectors, etc., that are located throughout the

engine, and are connected by electrical wiring to the on-board

computer.

The on-board computer is the heart of the Computer Control

System. The computer software contains several preprogrammed reference values that represent the ideal air/fuel

mixture, spark timing, transmission gear selection, etc., for

any driving condition. These values are programmed at the

factory and are specific to each vehicle model.

The on-board computer receives information (inputs) from

sensors and switches located throughout the engine. These

devices monitor critical engine conditions (coolant

temperature, engine speed, engine load, throttle position,

air/fuel ratio, etc.). The computer compares the actual values

received from these sensors with the reference values that are

programmed in it’s memory. The computer commands the

necessary corrections through operating output actuators as

needed so that the incoming sensor values match the preprogrammed reference values for that particular driving

condition.

Since vehicle operating conditions are constantly changing, the

computer continuously makes adjustments or corrections

(especially to the air/fuel mixture and spark timing) to keep all

the engine systems operating within the pre-programmed

reference values.

Page 13

About Import Vehicle Diagnostic Systems

ON-BOARD VEHICLE DIAGNOSTICS (OBD I)

Chapter 2 10

NOTE:

The computer does not make the adjustments or

corrections directly. It commands other devices such as the fuel

injectors, idle air control, EGR valve or Ignition Module to

perform these functions. These devices are called Actuators

because they initiate an action in response to the commands of

the computer.

ON-BOARD VEHICLE DIAGNOSTICS (OBD I)

•

Beginning in 1988, California’s Air Resources Board

(CARB), and later, the Federal Government's

Environmental Protection Agency (EPA), required

vehicle manufacturers to include a self diagnostic program

capable of identifying an emissions-related fault via the

vehicles On-Board Computers (some manufacturers used

OBD before it was required). The first generation of

Onboard Diagnostics came to be known as OBD I.

•

OBD I is a set of self-testing or self-diagnosing instructions

that are programmed into the vehicle’s on-board computer.

•

The program is specifically designed to detect failures in

the sensors, actuators, switches and wiring of the various

vehicle emissions-related systems (fuel injection system,

ignition system, EGR system, catalytic converter, etc.). If

the computer detects a failure in any one of these

components or systems, it alerts the driver by

illuminating the “Check Engine” light on the dash.

•

The computer also assigns a numeric code (OBD I systems

utilized a 2 or 3 digit code) for each specific problem that it

detects, and stores these codes in it’s memory for later

retrieval. The codes can be retrieved from the computer’s

memory with the use of a device called a “Code Reader” or

a “Scan Tool”.

NOTE:

With the exception of some 1994 and 1995 vehicles,

most vehicles from about 1982 to 1995 are equipped with

OBD I systems.

DIAGNOSTIC TROUBLE CODES

Diagnostic Trouble Codes, or Fault Codes, can be used to

identify engine systems or components that are malfunctioning.

The computer records codes for the following two types of

engine problems:

Page 14

About Import Vehicle Diagnostic Systems

DIAGNOSTIC TROUBLE CODES

11 Chapter 2

•

“Hard” Codes. “Hard” codes are stored for problems

which are happening now. “Hard” codes cause the “Check

Engine” light to turn on. The light remains on as long as

the “hard” code is present.

•

“Intermittent” Codes. “Intermittent” codes are stored

for problems, which happened in the past but, are not

currently present or detected by the vehicle’s computer.

Intermittent problems may cause the “Check Engine”

light to flicker by briefly turning on and turning off when

the problem goes away. “Intermittent” codes stay in the

computer’s memory even when the problem is no longer

present. These intermittent problems may be caused by

faulty wiring, vehicle operating conditions, etc.

NOTE:

Not all vehicles store “Intermittent” codes.

Page 15

About Import Vehicle Diagnostic Systems

Chapter 2 12

Page 16

Honda/Acura

OVERVIEW OF HONDA/ACURA DIAGNOTIC SYSTEMS

13 Chapter 3

OVERVIEW OF HONDA/ACURA DIAGNOSTIC SYSTEMS

•

Retrieving codes from

Honda/Acura vehicles

requires the use of the two

terminal connector of code

retrieval tool as shown in Figure H1.

•

Honda/Acura vehicles use a variety of diagnostic systems

which use either the “Check Engine” light or LEDs (Light

Emitting Diodes) on the ECM (Engine Control Module) to

display diagnostic trouble codes.

•

To retrieve codes you will need to

access your vehicle’s computer test

connector or ECM.

•

Honda/Acura vehicles use a rectangular two-socket plastic connector,

usually light blue in color (H2).

NOTE:

Some Honda/Acura models do not require a tool to

retrieve codes. The “Tool Req?” column in the “Code Retrieval

Procedures Tables” on pages 14 through 17 will let you know if

a tool is required. If no tool is required, just follow the

procedures as indicated to retrieve codes.

“Check Engine” Light

•

The “Check Engine” light does more than alert you to a

potential problem. It also transmits the fault codes in the

computer’s memory through a series of blinks and pauses

when the vehicle is in diagnostic mode.

•

Your “Check Engine” light is located on your vehicle’s

instrument cluster, and may be labeled “PGM-FI”, “PGMCARB”, “CHECK”, or with a picture of an engine (Figure

H3).

NOTE:

If your “Check Engine” light does not come on when you

turn on the ignition, please refer to your vehicle’s service

manual. You may have a problem with the vehicle that is

preventing it from illuminating. You must fix this problem

before you can retrieve fault codes from the vehicle’s computer.

H1

H2

H3

HONDA

CONNECTOR

CHECK

CHECK ENGINE

Page 17

Honda/Acura

CODE RETRIEVAL PROCEDURE

Chapter 3 14

CODE RETRIEVAL PROCEDURE

•

Always observe safety precautions whenever working on a

vehicle.

•

Fix any known mechanical problems before this test.

•

Warm up engine before this test.

•

Have a pencil and paper handy.

1. Locate your vehicle in the appropriate table (see below for

“Honda Code Retrieval Procedures”; see page 16 for

“Acura Code Retrieval Procedures”).

2. Follow the procedures applicable to your vehicle.

■ Refer to page 18 for “ECU/Test Connector Locations”,

(Figures H4 through H9).

■ Refer to page 19 for “Code Examples” (Figures H10

through H17).

3. Refer to pages 21 and 22 for “Honda/Acura Fault Code

Definitions”. Match the retrieved Diagnostic Trouble Codes

with those listed, read the associated definition(s), and

consult the vehicle’s service manual for further evaluation.

4. Refer to page 20 for the “Erasing Codes” procedure.

Consult the appropriate table for your vehicle (“Honda

Erasing Procedure” or “Acura Erasing Procedure”) and

follow the procedure listed.

Honda Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

Accord 84-85 1.8 (F.I. N Procedure: Access ECU (located

only) under driver’s seat) (H4). Turn ignition

on and observe LEDs on ECU for

codes.

Codes: Codes are displayed using 4

LEDs labeled 8, 4, 2, 1 (H10).

Determine codes by adding LED values.

Examples: LED 8 and LED 1 on =

code 9 (8 + 1 = 9) (H11)

LED 4 on = code 4 (4 + 0 = 4)

(H12)

No LEDs = code 0

(H13)

When more than one code is present,

codes are separated by a 2 second pause.

Page 18

Honda/Acura

CODE RETRIEVAL PROCEDURE

15 Chapter 3

Honda Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Accord 86-89 2.0 (F.I. N Procedure: Access ECU (located under

only) front driver’s seat) (H4) by moving seat

all the way back. Turn ignition on and

observe LED on ECU for codes.

Codes: Codes blinked out by LED are

separated by two second pause, then

repeated. For example: 2 blinks - two

second pause - 2 blinks = code 2 (H14)

Accord 90 2.2 N Procedure: Access ECU (located on

Prelude 88-91 2.0, 2.1 passenger side floor board) (H6) by

pulling back the carpet. Turn ignition

on and observe LED on ECU for codes.

Codes: Codes 1 ~ 10 are displayed

using a series of short blinks (H15),

codes 11 & up use a combination of

long and short blinks (H16). The number of long blinks equals the first digit

and the number of short blinks equals

the second (H17).

Accord 91-95 2.2 (incl. Y Procedure: Access service check con-

V-TEC), nector (located under dashboard on

2.7 (incl. passenger side) (H7). Plug Code Reader

V-TEC) into service check connector and turn

Civic 92-95 1.5, 1.6 ignition on and observe “Check Engine”

Del Sol 94-95 1.5, 1.6 light for codes.

Odyssey 95 2.2, 2.3

Codes: Codes blink out one after the

other. “Check Engine” light will stop

blinking after all codes have been displayed. Trouble codes 1 - 10 are displayed using a series of short blinks

(H15); codes 11 & up use a combination of long and short blinks (H16).

The number of long blinks equals the

first digit and the number of short

blinks indicates the second (H17).

Civic/ 87-91 1.5, 1.6 N Procedure: Access ECU (located on

CRX passenger side floor board) (H6) by

pulling back the carpet. Turn ignition

on and observe LED on ECU for codes.

Codes: Codes blinked out by LED are

separated by two second pause, then

repeated. For example: 2 blinks - two

second pause - 2 blinks = code 2 (H14).

Page 19

Honda/Acura

CODE RETRIEVAL PROCEDURE

Chapter 3 16

Honda Code Retrieval Procedures (Cont)

Acura Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

Prelude 85-87 1.8, 2.0 N Procedure: Access ECU (located be-

hind driver’s seat within door pillar assembly) (H8). Turn ignition on and

observe LED on ECU for codes.

Codes: Codes blinked out by LED are

separated by two second pause, then

repeated. For example: 2 blinks - two

second pause - 2 blinks = code 2 (H14)

Prelude 92-95 2.2, 2.3 Y Procedure: Access service check con-

nector (located behind center console on

driver’s side) (H9). Plug Code Reader

into service check connector and turn

ignition on. Observe “Check Engine”

light for codes.

Codes: Codes 1 - 10 are displayed

using a series of short blinks (H15),

codes 11 & up use a combination of

long and short blinks (H16). The number of long blinks equals the first digit

and the number of short blinks equals

the second (H17).

Tool

Model Years Eng. Req? Perform the following:

Integra 86-91 1.6, 1.8 N Procedure:

• All except 90, 91 models: Access

ECU (located under front passenger

seat) (H5) by moving seat all the

way back.

• 90, 91 models only: Access ECU

(located on passenger side floor board)

(H6) by pulling back the carpet.

• Turn ignition on and observe LED

on ECU for codes.

Codes: Codes blink out one after the

other. Trouble codes 1 - 10 are displayed using a series of short blinks

(H15), codes 11 and up use a combination of long and short blinks (H16).

The number of long blinks equals the

first digit and the number of short

equals the second (H17).

Page 20

Honda/Acura

CODE RETRIEVAL PROCEDURE

17 Chapter 3

Acura Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Integra 92-95 1.7, 1.8 Y Procedure: Access service check conIntegra 94-95 1.8 nector (located under dashboard on pasV-TEC senger side) (H7). Plug Code Reader

Legend 91-95 2.5, 2.7, 3.2 into service check connector and turn

NSX 91-95 3.0, 3.2 ignition on. Observe “Check Engine”

Vigor 91-95 2.5 light for codes.

Codes: Codes blink out one after the

other. Trouble codes 1 - 10 are displayed using a series of short blinks

(H15), codes 11 and up use a combination of long and short blinks (H16).

The number of long blinks equals the

first digit and the number of short

equals the second (H17).

Legend 86-90 2.5, 2.7 N Procedure:

• 1986 models only: Access ECU

(located under front passenger seat

(H5) by moving seat all the way

back.

• 1987~89 models only: Access ECU

(located on passenger side floor

board) (H6) by pulling back carpet.

• Turn ignition on and observe LED

on ECU for codes.

Codes: Codes blink out in single

flashes followed by a two second pause

(For example, 2 blinks, then two second pause equals code 2 (H14). LED

will stop flashing after all codes have

been displayed.

Page 21

Honda/Acura

CODE RETRIEVAL PROCEDURE

Chapter 3 18

ECU/Test Connector Locations

The physical locations of the ECU or test connector for

Honda/Acura vehicles are shown in Figures H4 through H9.

Refer to the code retrieval instructions in Table H1 (Honda) or

Table H2 (Acura) to determine the correct location for your

vehicle.

H4

H5

H6

H7

H8

H9

Page 22

Honda/Acura

CODE RETRIEVAL PROCEDURE

19 Chapter 3

Code Examples

Examples of Honda/Acura fault codes are shown in Figures

H10 through H17. Refer to the code retrieval instructions in

Table H1 (Honda) or Table H2 (Acura) to determine the code

display for your vehicle.

H10

H12

H11

H13

H14

H15

H16

H17

8421

8421

LED 4

ON

BLINKBLINK

LONG BLINK

= Code 4

SHORT

BLINK BLINKBLINKBLINKBLINK

BLINK BLINK

BLINK

SHORT BLINK

SHORT

BLINKBLINK

LED 8

ON

PAUSE

2 SECONDS

PAUSE

3 - 4 SECONDS

8421

LED 1

ON

8421

ALL LEDs OFF

= CODE 2

= CODE 10

= Code 9

= Code 0

0.6 SEC.

LONG BLINK

LONG BLINK LONG BLINK

0.3 SEC.

SHORT

PAUSE

0.9 SECONDS

BLINKBLINK

SHORT

PAUSE

0.9 SECONDS

BLINK

LONG

PAUSE

2 SECONDS

LONG

PAUSE

2 SECONDS

= CODE 12 & 21

Page 23

Honda/Acura

ERASING CODES

Chapter 3 20

ERASING CODES

•

Always observe safety precautions whenever working on a

vehicle.

•

Remove Code Reader from vehicle’s test connector before

erasing codes.

•

Erase codes only when all repairs have been completed.

Refer to “Honda Erasing Procedures” or “Acura Erasing

Procedures” for specific instructions for your year, make

and model.

•

After erasing codes, verify that repairs were successfully

completed. Start the engine and warm to normal

operating temperature. After normal operating

temperature is reached, turn off the ignition and repeat

the code retrieval procedure for your vehicle. If no codes

are retrieved, the repair(s) was successful.

NOTE:

Removing fuses or battery cables may clear the memory

on the radio, clock, etc., or may enable the “Theftlock” feature

on the radio.

Honda Erasing Procedures

Acura Erasing Procedures

Model Years Procedure

Accord 84-85 Remove fuse No. 10 for 10 seconds

87-89 Remove fuse No. 11 for 10 seconds

90-93 Remove fuse No. 24 for 10 seconds

Civic / 94 Remove “Radio” fuse for 10 seconds

CRX

87-91 Remove fuse No. 30 for 10 seconds

Del Sol 92-95 Remove fuse No. 32 for 10 seconds

Odyssey 93-95 Remove “Radio” fuse for 10 seconds

Prelude 90 Remove “Radio” fuse for 10 seconds

89-91 Remove fuse No. 35 for 10 seconds

92-95 Remove fuse No. 43 for 10 seconds

Model Years Procedure

Integra 86-91 Remove “Hazard” fuse for 10 seconds

92-95 Remove “Back Up” fuse for 10 seconds

Legend 90 Remove “Alternator Sense” fuse for 10 seconds

91-95 Remove fuse No. 15 for 10 seconds

NSX 91-95 Remove “Clock” fuse for 10 seconds

Vigor 92-94 Remove “Back Up” fuse for 10 seconds

Page 24

Honda/Acura

FAULT CODE DEFINITIONS (0 - 20)

21 Chapter 3

HONDA/ACURA FAULT CODE DEFINITIONS

IMPORTANT:

Retrieving and utilizing Diagnostic Trouble

Codes (DTCs) for troubleshooting vehicle operation problems is

only one part of an overall diagnostic strategy. Never replace a

part based solely on the DTC definition. Always consult the

vehicle’s service manual for more detailed testing instructions.

Each DTC has a set of testing procedures, instructions and flow

charts that must be followed to confirm the exact location of the

problem. This type of information is found in the vehicle’s

service manual.

Code Description Possible Cause

0 ECU / ECU signal No signal to ECU

1 Oxygen sensor circuit Oxygen sensor or circuit, ECU

2 Oxygen sensor circuit Oxygen sensor or circuit, ECU

3 MAP sensor circuit Map sensor circuit

4 CKP sensor / engine speed (RPM) Crank angle sensor or circuit, ECU

sensor

5 MAP sensor circuit MAP sensor or circuit, mechanical

problem

6 ECT sensor circuit ECT sensor or circuit, automatic

transaxle control unit

7 TPS / Angle Sensor TPS sensor or circuit, automatic

transaxle control unit

8 CKP sensor / engine speed (RPM) Crank angle sensor or circuit, ECU

sensor

9 CMP sensor CMP sensor or circuit

10 IAT sensor IAT sensor or circuit

11 Idle Mixture Adjuster Sensor Idle mixture adjuster sensor or

circuit

12 EGR system fault No EGR action, faulty EGR valve

13 BARO sensor circuit BARO sensor or circuit

14 Idle Air Control valve circuit / ECU Open or shorted out ignition sig-

nal circuit / No signal to ECU

15 Ignition Output signal Open or shorted ignition output

signal circuit

16 Fuel Injector Circuit Open or shorted fuel injector

circuit

17 VSS circuit VSS sensor or circuit

18 Ignition Timing Adjuster Open or shorted signal circuit

19 A/T Lock-up control solenoid Open or shorted signal circuit,

Lock-up control solenoid lock-up solenoid

20 Electrical Load Detector / Sensor Electrical load detector or circuit

Page 25

Honda/Acura

Fault Code Definitions (21 - 59)

Chapter 3 22

Code Description Possible Cause

21 Spool Solenoid Valve Open or shorted signal circuit,

spool solenoid valve

22 Valve Timing Electronic Oil Open or shorted signal circuit,

pressure switch valve timing oil pressure switch

23 Knock sensor circuit Knock sensor or circuit

30 AT / ECU communication signal A AT control unit, ECU

31 AT / ECU communication signal B AT control unit, ECU

35 Traction control / ECU / signal Traction control module, ECU

36 Traction control / ECU / signal Traction control module, ECU

41 Oxygen sensor heater - left side Oxygen sensor / heater or circuit

42 Oxygen sensor heater - right side Oxygen sensor / heater or circuit

43 Fuel Supply system - left side Oxygen sensor or circuit, fuel

system

44 Fuel Supply system - right side Oxygen sensor or circuit, fuel

system

45 Fuel metering - left side Injector control circuit, incorrect

fuel metering

46 Fuel metering - right side Injector control circuit, incorrect

fuel metering

48 Heated oxygen sensor Oxygen sensor or circuit

53 Right Knock Sensor Right knock sensor or circuit

54 CKP sensor 2 CKP sensor 2 or circuit

59 CMP sensor 2 CMP sensor 2 or circuit

Page 26

Nissan/Infiniti

OVERVIEW OF NISSAN/INFINITI DIAGNOSTIC SYSTEMS

23 Chapter 4

OVERVIEW OF NISSAN/INFINITI DIAGNOSTIC SYSTEMS

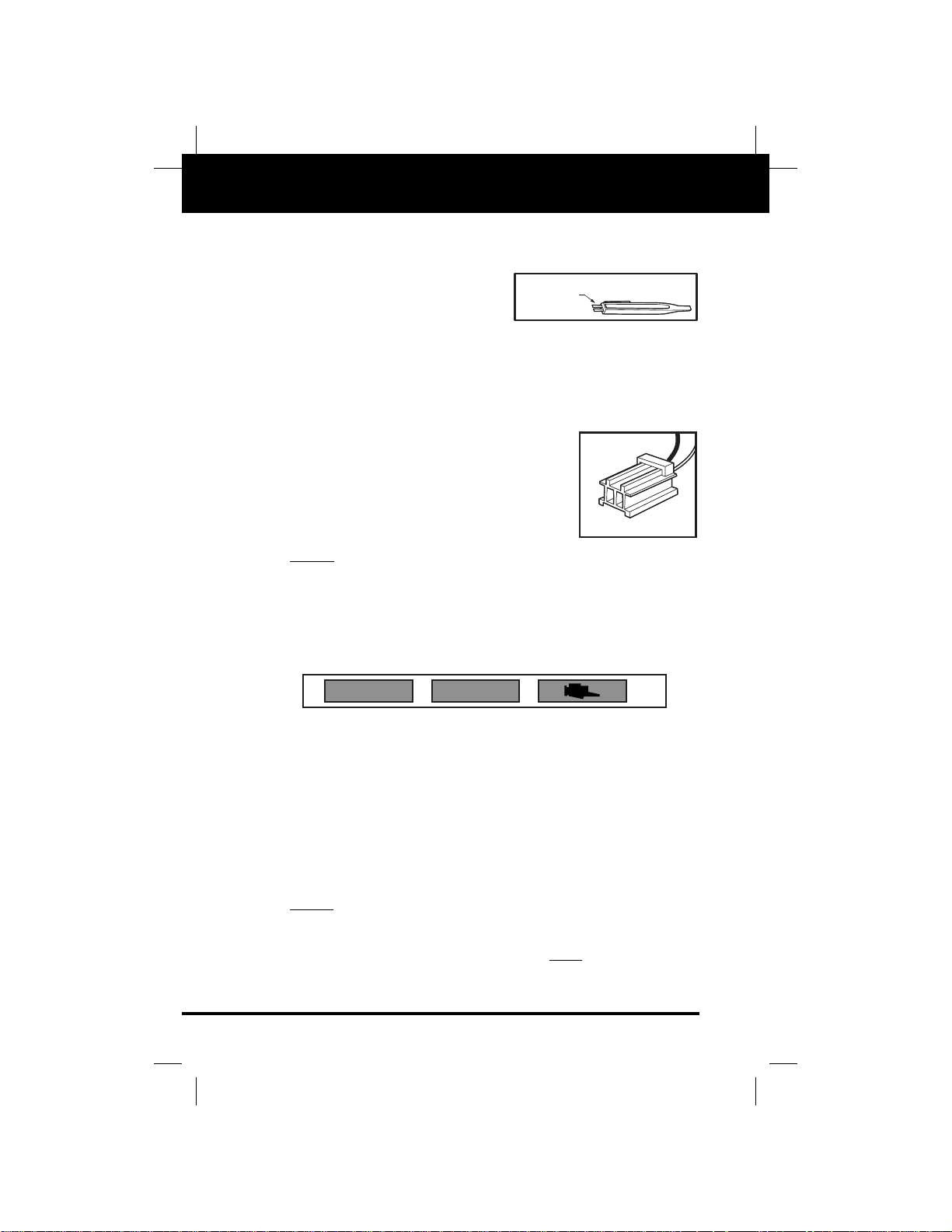

•

Retrieving codes from

Nissan/Infiniti vehicles

requires the use of the flat

end of the code retrieval

tool shown in Figure N1.

•

Nissan/Infiniti vehicles use a variety of computer systems

which are equipped with either a single-LED (Light

Emitting Diode) or a dual-LED display.

•

To retrieve codes, you need to first locate the LED display on

the vehicle’s computer. The LED(s) are mounted inside the

computer, but may be seen by looking through an opening in

the top of or on the side of the computer housing. In some

cases you may have to remove the computer from its mount.

NOTE:

Refer to the vehicle’s service manual when removing the

computer from it’s mount, as it is easily damaged.

All Nissan/Infiniti vehicles

covered in this manual are

equipped with a screw-type

diagnostic mode selector on

the vehicle’s computer. The

diagnostic mode selector is

accessed through a cutout in

the computer housing. Two

marks show the operating

limits of the diagnostic mode

selector. The Code Reader is

used to adjust the position of

the diagnostic mode selector

(N2).

NOTE:

Some Nissan/Infiniti models do not require a tool to

retrieve codes. The “Tool Req?” column in the “Code Retrieval

Procedures Tables” on pages 24 through 29 will let you know if

a tool is required. If no tool is required, just follow the

procedures as indicated to retrieve codes.

N1

N2

NISSAN

TOOL

Page 27

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

Chapter 4 24

CODE RETRIEVAL PROCEDURE

•

Always observe safety precautions whenever working on a

vehicle.

•

Fix any known mechanical problems before this test.

•

Warm up engine before this test.

•

Have a pencil and paper handy.

1. Locate your vehicle in the appropriate table (see below for

“Nissan Code Retrieval Procedures”; see page 29 for

“Infiniti Code Retrieval Procedures”).

2. Follow the procedures applicable to your vehicle.

■ Refer to page 30 for “ECU Locations”, (Figures N3

through N7).

■ Refer to page 31 for “Code Examples” (Figures N8

through N11).

3. Refer to pages 34-36 for “Nissan/Infiniti Fault Code

Definitions”. Match the retrieved Diagnostic Trouble Codes

with those listed, read the associated definition(s), and

consult the vehicle’s service manual for further evaluation.

4. Refer to page 32 for the “Erasing Codes” procedure.

Consult the appropriate table for your vehicle (“Nissan

Erasing Procedure” or “Infiniti Erasing Procedure”) and

follow the procedure listed.

Nissan Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

Altima 93-95 2.4 Y Procedure: Access ECU (located beMaxima 92-94 3.0 (DOHC) hind center console) (N3). Turn ignition

Sentra 91-95 2.0 on. Using Nissan tool, turn diagnostic

Stanza 90-92 2.4 mode selector fully clockwise; wait two

200SX 95 1.6, 2.0 seconds, then turn selector fully coun-

terclockwise. Observe red LED on

ECU for codes.

Codes: Codes are displayed using a

combination of long and short blinks.

Codes are determined by the number

and duration of blinks. A long blink indicates the first digit (ten); a short

blink indicates the second digit (ones)

(N8). Example: long blink-pause short

blink short blink = code 12 (N9). If

Page 28

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

25 Chapter 4

Nissan Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Altima 93-95 2.4 Y more than one code is stored, the ECU

Maxima 92-94 3.0 (DOHC) will blink the lowest number code first,

Sentra 91-95 2.0 pause for two seconds, then display the

Stanza 90-92 2.4 next highest number code. This con200SX 95 1.6, 2.0 tinues until all stored codes have been

(cont) displayed; the cycle then repeats.

Stanza 86 2.0 Y Procedure: Access ECU (from driver’s

200SX 84-86 1.8, 2.0 side kick panel) (N6) (except Stanza

Wagon, which is located under driver’s

seat). Make sure diagnostic mode selector is turned fully counterclockwise.

Turn ignition on. Using Nissan tool,

turn selector fully clockwise. Observe

both red and green LEDs on ECU for

codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

Pulsar 88-90 1.6, 1.8 Y Procedure:

Sentra 88-90 1.6 • All except 200 SX: Access ECU (loStanza 87-90 2.0, 2.4 cated under passenger seat) (N5)

200SX 87-88 2.0, 3.0 (except Stanza Wagon, which is lo-

cated under driver’s seat).

• 200 SX only: Access ECU (located

behind driver side kick panel) (N6).

• Turn ignition on. Using Nissan tool,

turn diagnostic mode selector fully

clockwise and observe LEDs on ECU.

When LEDs have flashed three times,

turn selector fully counterclockwise.

Observe both red and green LEDs

on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

Page 29

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

Chapter 4 26

Nissan Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Maxima 86-94 3.0 (SOHC) Y Procedure:

• All except 87, 88 Maxima: Access

ECU (located under passenger seat)

(N5).

• 87, 88 Maxima only: Access ECU

(located behind center console) (N3).

• Turn ignition on. Using Nissan tool,

turn diagnostic mode selector fully

clockwise, wait at least two seconds,

then turn selector fully counterclockwise. Observe both red and green

LEDs on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

NX 91-93 1.6, 2.0 Y Procedure: Access ECU (located be240SX 91-95 2.4 hind center console) (N3) (except 300ZX,

300ZX 90-95 3.0 (incl. which is located in passenger side foot-

Turbo) well under carpet (N5)). Turn ignition

on. Using Nissan tool, turn diagnostic

mode selector fully clockwise; wait two

seconds, then turn selector fully counterclockwise. Observe red LED on ECU

for codes.

Codes: Codes are displayed using a

combination of long and short blinks.

Codes are determined by the number

and duration of LED blinks. A long

blink indicates the first digit (tens); a

short pause indicates the second digit

(ones) (N8). Example: long blink-pauseshort blink short blink = code 12 (N9).

If more than one code is stored, the

ECU will blink the lowest number code

lowest number code first, pause for two

seconds, then display the next highest

number code. This continues until all

stored codes have been displayed; the

cycle then repeats.

Page 30

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

27 Chapter 4

Nissan Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Van 87-88, 2.4 Y Procedure: Access ECU (located under

90 passenger seat) (N5). Using Nissan tool,

Pathfin- 87-95 2.4, 3.0 turn diagnostic mode selector fully

der clockwise and observe LEDs on ECU.

Hard- 87-95 2.4, 3.0 When LEDs have blinked three times,

body turn selector fully counterclockwise.

Pickup Observe both red and green LEDs on

ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

240SX 89-90 2.4 Y Procedure: Access ECU (from passen-

ger side front kick panel) (N4), and position it so LEDs can be observed. Using

Nissan tool, turn diagnostic mode selector fully clockwise and observe LEDs on

ECU. When LEDs have blinked three

times, turn selector fully counterclockwise. Observe both red and green LEDs

on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates

the first digit (tens); the Green LED indicates the second digit (ones).

Example: one Red flash and two Green

flashes = code 12 (N11).

300ZX 86 3.0 (incl. Y Procedure: Access ECU (from passen-

Turbo) ger side front kick panel) (N4). Make

sure diagnostic mode selector is turned

fully counterclockwise. Turn ignition on.

Using Nissan tool, turn selector fully

clockwise. Observe both red and green

LEDs on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates

Page 31

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

Chapter 4 28

Nissan Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

300ZX 86 3.0 Y the second digit (ones). Example: one

(cont) Red flash and two Green flashes = code

12 (N11).

300ZX 87-89 3.0 (incl. Y Procedure: Access ECU (from passen-

Turbo) ger side front kick panel) (N4). Turn ig-

nition on. Using Nissan tool, turn diagnostic mode selector fully clockwise and

observe LEDs on ECU. When LEDs

have blinked three times, turn selector

fully counterclockwise. Observe both

red and green LEDs on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

Axxess 90 2.4 Y Procedure: Access ECU (located be-

hind center console) (N3). Turn ignition

on. Using Nissan tool, turn diagnostic

mode selector fully clockwise and observe LEDs on ECU. When LEDs have

blinked three times, turn selector fully

counterclockwise. Observe both red

and green LEDs on ECU for codes.

Codes: Codes are displayed by blinking

of both Red and Green LEDs (N10). The

Red LED blinks first, followed by the

Green LED. The Red LED indicates the

first digit (tens); the Green LED indicates the second digit (ones). Example:

one Red flash and two Green flashes =

code 12 (N11).

Page 32

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

29 Chapter 4

Infiniti Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

G20 91-95 2.0 Y Procedure: Access ECU (from pas-

senger side kick panel) (N4). Turn ignition on. Using Nissan tool, turn diagnostic mode selector fully clockwise;

wait for two seconds, then turn selector

fully counterclockwise. Observe LED on

ECU (or vehicle’s “Check Engine” light)

for codes.

Codes: Codes are displayed using both

long and short blinks (N8). The long

blinks represent the first digit, the

short blinks represent the second digit

(N9). Codes are displayed in numeric

order, beginning with the lowest number code and ending with the highest

number code.

J30 93-95 3.0 Y Procedure: Access ECU (from pasM30 90-92 3.0 senger side kick panel) (N4) and posiQ45 90-95 4.5 tion it to observe LED. Turn ignition

on. Using Nissan tool, turn diagnostic

mode selector fully clockwise, wait for

two seconds, then turn selector fully

counterclockwise. Observe LED on ECU

(or vehicle’s “Check Engine” light) for

codes.

Codes: Codes are displayed using both

long and short blinks (N8). The long

blinks represent the first digit, the

short blinks represent the second digit

(N9). Codes are displayed in numeric

order, beginning with the lowest number code and ending with the highest

number code.

Page 33

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

Chapter 4 30

ECU Locations

The physical locations of the ECU for Nissan/Infiniti vehicles

are shown in Figures N3 through N7. Refer to the code

retrieval instructions in Table N1 (Nissan) or Table N2 (Infiniti)

to determine the correct location for your vehicle.

N3

N4

N5 N6

N7

ECU may need to be

accessed from driver or

passenger side, depending

on model.

Page 34

Nissan/Infiniti

CODE RETRIEVAL PROCEDURE

31 Chapter 4

Code Examples

Examples of Nissan/Infiniti fault codes are shown in Figures

N8 through N11. Refer to the code retrieval instructions in

Table N1 (Nissan) or Table N2 (Infiniti) to determine the code

display for your vehicle.

N8

N9

N10

N11

GREEN

LED

SHORT BLINK

0.3 SEC.

SHORT

PAUSE

0.9 SECONDS

PAUSEPAUSE

RED

BLINK

LONG BLINK

0.6 SEC.

LONG BLINK

LONG BLINK LONG BLINK

RED

LED

RED

BLINK

RED

BLINK

GREEN

BLINK

PAUSE

BLINKBLINK

SHORT

PAUSE

0.9 SECONDS

GREEN

BLINK

GREEN

BLINK

BLINK

LONG

PAUSE

2 SECONDS

2 SECONDS

PAUSE

PAUSE

LONG

PAUSE

= CODE 12 & 21

= CODE 12 & 21

Page 35

Nissan/Infiniti

ERASING CODES

Chapter 4 32

ERASING CODES

•

Always observe safety precautions whenever working on a

vehicle.

•

Erase codes only when all repairs have been completed.

Refer to “Nissan Erasing Procedures” or “Infiniti Erasing

Procedures” for specific instructions for your year, make

and model.

•

After erasing codes, verify that repairs were successfully

completed. Start the engine and warm to normal

operating temperature. After normal operating

temperature is reached, turn off the ignition and repeat

the code retrieval procedure for your vehicle. If no codes

are retrieved, the repair(s) was successful.

Nissan Erasing Procedures

Model Years Procedure

Altima 93-95 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

Axxess 90 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

Maxima 87-92 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

93-94 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

NX 91-93 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

Path- 87-95 After codes have been retrieved turn selector fully clockwise.

finder After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

Hard- 87-95 After codes have been retrieved turn selector fully clockwise.

body After the LED’s have blinked four times turn the selector

Pickup fully counterclockwise. ECU code memory is now erased.

Pulsar 88-90 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

Sentra 88-90 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

91-95 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

Page 36

Nissan/Infiniti

ERASING CODES

33 Chapter 4

Nissan Erasing Procedures (Cont)

Infiniti Erasing Procedures

Model Years Procedure

Stanza 86 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

87-89 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

91-92 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

Van 87-90 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

200SX 84-86 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

87-88 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

90 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

240SX 89-90 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

91-95 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

300ZX 86 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

87-89 After codes have been retrieved turn selector fully clockwise.

After the LED’s have blinked four times turn the selector

fully counterclockwise. ECU code memory is now erased.

90-95 After codes have been retrieved turn selector fully clockwise

and wait for two seconds. ECU code memory is now erased.

Model Years Procedure

All All After you have finished retrieving codes turn the selector

back fully clockwise to erase the ECU code memory.

Page 37

Nissan/Infiniti

FAULT CODE DEFINITIONS (11 - 51)

Chapter 4 34

NISSAN/INFINITI FAULT CODE DEFINITIONS

IMPORTANT:

Retrieving and utilizing Diagnostic Trouble

Codes (DTCs) for troubleshooting vehicle operation problems is

only one part of an overall diagnostic strategy. Never replace a

part based solely on the DTC definition. Always consult the

vehicle’s service manual for more detailed testing instructions.

Each DTC has a set of testing procedures, instructions and flow

charts that must be followed to confirm the exact location of the

problem. This type of information is found in the vehicle’s

service manual.

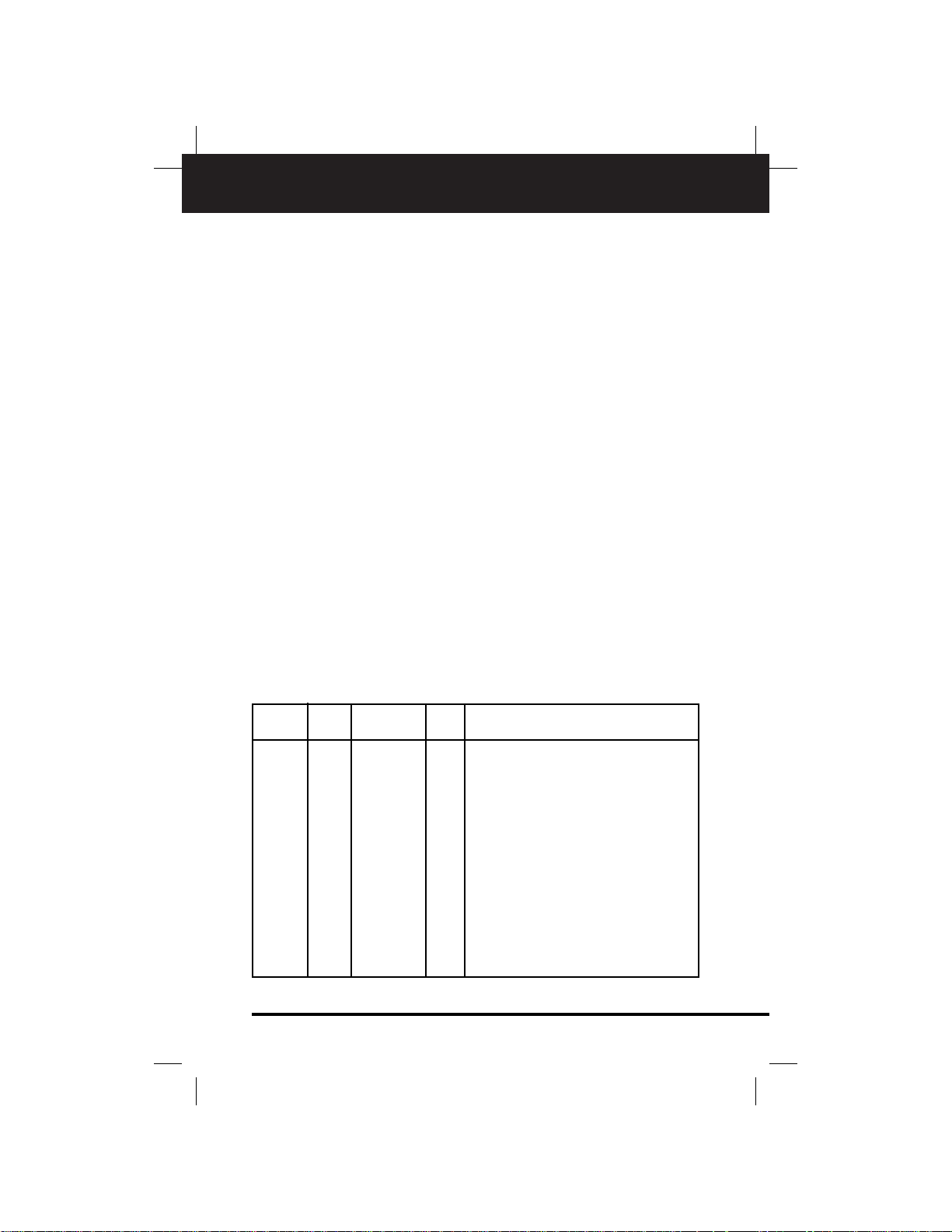

Code Description Possible Cause

11 CKP sensor circuit CKP sensor or circuit

12 MAF sensor circuit MAF sensor or circuit, MAF signal

too high

13 ECT sensor circuit ECT sensor or circuit

14 VSS circuit VSS or circuit

16 Traction Control System Open or shorted signal circuit

21 No ignition reference pulse Loss of primary signal

22 Fuel Pump / Idle speed control valve Open or shorted signal circuit

23 Idle switch / throttle valve switch Open or shorted signal circuit /

defective idle speed valve

24 Idle switch / Trans. switch / Open or shorted signal circuit

Neutral/Park switch

25 Idle Speed control Open or shorted AAC circuit

31 ECU circuit Abnormal input signals

32 EGR sensor circuit No EGR operation

33 HO2S fault Open or shorted signal circuit,

high HO2S signal

34 Knock Sensor circuit Knock sensor or circuit

35 EGR temperature sensor EGR temperature sensor or circuit

36 EGR valve / system EGR / EVAP valve or circuit

37 Closed loop control HO2S, intake/fuel system

41 Air temperature sensor Air temperature sensor or circuit

42 Fuel temperature sensor Fuel temperature sensor or circuit

43 TPS circuit TPS or circuit

44 No faults / no malfunctions

45 Injector leak Leak at injector

46 Secondary TPS circuit Secondary TPS or circuit

51 Injector circuit Defective injector

Page 38

Nissan/Infiniti

FAULT CODE DEFINITIONS (53 - 111)

35 Chapter 4

Code Description Possible Cause

53 Oxygen sensor - right side Open or shorted signal circuit,

high O2 signal

54 A/T signal Open signal in trans. Control unit

55 No faults / no malfunctions

63 No. 6 cylinder misfire Wiring, fuel or ignition system,

ECM

64 No. 5 cylinder misfire Wiring, fuel or ignition system,

ECM

65 No. 4 cylinder misfire Wiring, fuel or ignition system,

ECM

66 No. 3 cylinder misfire Wiring, fuel or ignition system,

ECM

67 No. 2 cylinder misfire Wiring, fuel or ignition system,

ECM

68 No. 1 cylinder misfire Wiring, fuel or ignition system,

ECM

71 Random misfire Wiring, fuel or ignition system,

ECM

72 TWC function RH bank Catalytic converter, wiring, ECM

73 TWC function LH bank Catalytic converter, wiring, ECM

76 Fuel injection system function RH Wiring, injector, oxygen sensor

bank

77 Rear HO2S circuit Wiring, injector, oxygen sensor

82 CKP sensor Wiring, CKP sensor, ECM

84 A/T diagnosis communication line Wiring, ECM

85 CMP actuator - circuit malfunction Wiring, CMP sensor, ECM

86 Fuel injection system function LH Wiring, oxygen sensor, MAF, ECM

bank

87 Canister control solenoid valve Wiring, EVAP valve, ECM

circuit

91 Front HO2S heater circuit RH bank Wiring, HO2S, ECM

94 TCC solenoid valve Wiring, clutch solenoid, ECM

95 CKP sensor Wiring, CKP sensor, ECM

98 ECT sensor Wiring, ECT sensor, ECM

101 Front HO2S heater circuit LH bank Wiring HO2S, ECM

101 CMP sensor circuit CMP sensor or circuit

102 MAF sensor circuit MAF sensor or circuit

103 ECT sensor circuit ECT sensor or circuit

104 VSS circuit malfunction VSS or circuit

111 EVAP canister purge control system EVAP valve

Page 39

Nissan/Infiniti

FAULT CODE DEFINITIONS (113 - 115)

Chapter 4 36

Code Description Possible Cause

113 EVAP canister purge control system EVAP valve

114 Fuel trim - right side - fuel too rich Oxygen sensor or circuit, fuel

pressure

115 Fuel trim - right side - fuel too rich Oxygen sensor or circuit, fuel

pressure

Page 40

Toyota/Lexus

OVERVIEW OF TOYOTA/LEXUS DIAGNOSTIC SYSTEMS

37 Chapter 5

OVERVIEW OF TOYOTA/LEXUS DIAGNOSTIC SYSTEMS

•

Retrieving codes from Toyota/Lexus

vehicles requires connecting either the

round or square end of code retrieval

tool (Figure T1) to vehicle’s test

connector.

•

To retrieve codes, you will need to access

your vehicle’s computer test connector.

Round Connector (T2): Used on older model

cars and vans. Yellow or green in color,

located under the hood.

•

Front corner (right or left)

•

Fender well (right or left)

•

Fire wall (right or left)

It may have a protective cap or may be plugged into a

protective cap mounted on the side wall. Use round head of

Code Reader on vehicles with this type of connector.

Square Connector (T3): Used on newer

model cars and vans. Black or grey in color

located under the hood near either:

•

Front corner (right or left)

•

Fender well (right or left)

•

Fire wall (right or left)

It has a cover labeled “DIAGNOSTIC”, “DIAGNOSIS”, or

“CHECK CONN”. Use square head of Code Reader on vehicles

with this type of connector.

NOTE:

Some Toyota/Lexus models do not require a tool to

retrieve codes. The “Tool Req?” column in the “Code Retrieval

Procedures Tables” on pages 38 through 41 will let you know if

a tool is required. If no tool is required, just follow the

procedures as indicated to retrieve codes.

“Check Engine” Light

•

Transmits the fault codes in the computer’s memory to

you.

T1

T3

T2

Page 41

Toyota/Lexus

CODE RETRIEVAL PROCEDURE

Chapter 5 38

CODE RETRIEVAL PROCEDURE

•

Always observe safety precautions whenever working on a

vehicle.

•

Fix any known mechanical problems before this test.

•

Warm up engine before this test.

•

Have a pencil and paper handy.

1. Locate your vehicle in the appropriate table (see below for

“Toyota Code Retrieval Procedures”; see page 40 for

“Lexus Code Retrieval Procedures”).

2. Follow the procedures applicable to your vehicle.

■ Refer to page 41 for “Diagnostic Connector Locatons”,

(Figures T6 and T7).

■ Refer to page 42 for “Code Examples” (Figures T8

through T10).

3. Refer to pages 45-47 for “Toyota/Lexus Fault Code

Definitions”. Match the retrieved Diagnostic Trouble Codes

with those listed, read the associated definition(s), and

consult the vehicle’s service manual for further evaluation.

4. Refer to page 43 for the “Erasing Codes” procedure.

Consult the appropriate table for your vehicle (“Toyota

Erasing Procedures” or “Lexus Erasing Procedures”) and

follow the procedure listed.

Toyota Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

Corolla 85-86 1.6 Y Procedure: Locate round diagnostic

Pickup 85-86 2.4 connector (under hood) (T6). Plug Code

Supra 84-86 2.8 Reader into diagnostic connector. Turn

4 Runner 84-86 2.4 ignition on. Observe “Check Engine”

Van 84-89 2.0, 2.2 light for codes.

Codes: If there are no codes stored in

memory, the “Check Engine” light will

blink once every three seconds. If codes

are stored, the light will blink a number

of times equal to the code number every

three seconds. Example: Three blinks =

code 3 (T8). If more than one code is

stored, the lowest number code is displayed first, followed by a three second

pause, then the next highest number

code. Codes will continue to cycle (repeat) as long as the ignition is on and

the Code Reader is connected.

Page 42

Toyota/Lexus

CODE RETRIEVAL PROCEDURE

39 Chapter 5

Toyota Code Retrieval Procedures (Cont)

Tool

Model Years Eng. Req? Perform the following:

Camry 85-93 2.0, 2.2, 2.5 Y Procedure: Locate rectangular diag-

Celica 86-95 1.6, 1.8, nostic connector (under hood) (T7). Plug

2.0, 2.2 Code Reader into diagnostic connector.

Corolla 89-95 1.6, 1.8 Turn ignition on. Observe “Check

Engine” light for codes.

Codes: Codes are displayed using a

series of blinks and pauses. Example:

blink-pause-blink, blink, blink = code 13

(T9). If more than one code is stored,

the lowest number code is displayed

first, followed by a 2.5 second pause,

then the next highest number code.

When all codes have been displayed,

there is a 4.5 second pause, then the

codes are repeated. Codes will continue

to cycle as long as the ignition is on

and the Code Reader is connected.

Cressida 83-89 All w/ N Procedure: Locate “Super Monitor Dis-

Supra 87-88 “Super play” on dashboard (T5). Push and hold

Monitor the SELECT and INPUT M keys simulDisplay” taneously for four seconds. DIAG will

appear on the screen. Push and hold

SET key for four seconds. View codes on

LCD display.

Codes: The screen will show OK of no

codes are present (T10). If codes are

present they will appear on the screen

screen (T10). If more than one code is

present, they will be separated by a

three second pause.

Cressida 87-92 2.8, 3.0 Y Procedure: Locate rectangular diagLand 88-94 4.0, 4.5 nostic connector (under hood) (T7). Plug

Cruiser Code Reader into diagnostic connector.

Paseo 92-95 1.5 Turn ignition on. Observe “Check

Pickup 87-95 2.4, 3.0 Engine” light for codes.

(Fl only)

Codes: If there are no codes stored in

Previa 91-95 2.4 (exc. SC)

memory, the “Check Engine” light will

Supra 87-95 3.0

blink about two times per second. If

T100 93-94 3.0

codes are stored, codes are displayed

Tercel 89-94 1.5 using a series of blinks and pauses.

4 Runner 87-95 2.4, 3.0 Example: blink-pause-blink blink

blink = code 13 (T9). If more than one

code is stored, codes are separated by

a 2.5 second pause. When all codes have

been displayed, there is a 4.5 second

pause, then the codes are repeated.

Page 43

Toyota/Lexus

CODE RETRIEVAL PROCEDURE

Chapter 5 40

Toyota Code Retrieval Procedures (Cont)

Lexus Code Retrieval Procedures

Tool

Model Years Eng. Req? Perform the following:

Cressida 87-92 2.8, 3.0 Y Codes will continue to cycle as long as

Land 88-94 4.0, 4.5 the ignition is on and the Code Reader

Cruiser is connected.

Paseo 92-95 1.5

Pickup 87-95 2.4, 3.0

(Fl only)

Previa 91-95 2.4 (exc. SC)

Supra 87-95 3.0

T100 93-94 3.0

Tercel 89-94 1.5

4 Runner 87-95 2.4, 3.0

(cont)

MR2 85-89 1.6 Y Procedure: Locate rectangular diag-

91-95 2.0, 2.2 nostic connector (under hood) (T7). Plug

Code Reader into diagnostic connector.

Turn ignition on. Observe “Check

Engine” light for codes.

Codes: If there are no codes stored in

memory, the “Check Engine” light will

blink once every six seconds on 85-88

models, and about two times per second

on 89-95 models. If codes are stored,

codes are displayed using a series of

blinks and pauses. Example: blinkpause-blink blink blink = code 13 (T9).

If more than one code is stored, codes

are separated by a 2.5 second pause.

When all codes have been displayed,

there is a 4.5 second pause, then the

codes are repeated. Codes will continue

to cycle as long as the ignition is on and

the Code Reader is connected.

Tool

Model Years Eng. Req? Perform the following:

ES350 90-91 2.5 Y Procedure: Locate rectangular diagES300 92-93 3.0 nostic connector (under hood) (T7). Plug

GS300 93-95 3.0 Code Reader into diagnostic connector.

LS400 90-94 4.0 Turn ignition on. Observe “Check

SC300 92-95 3.0 Engine” light for codes.

SC400 92-95 4.0

Page 44

Toyota/Lexus

CODE RETRIEVAL PROCEDURE

41 Chapter 5

Lexus Code Retrieval Procedures (Cont)

Diagnostic Connector Locations

The physical locations of diagnostic connectors for Toyota /

Lexus vehicles are shown in Figures T5 through T7. Refer to

the code retrieval instructions in Table T1 (Toyota) or Table T2

(Lexus) to determine the correct location for your vehicle.

Tool

Model Years Eng. Req? Perform the following:

ES350 90-91 2.5 Y Codes: Codes are displayed using a

ES300 92-93 3.0 series of blinks and pauses. Example:

GS300 93-95 3.0 blink pause blink, blink, blink = code 13

LS400 90-94 4.0 (T9). If more than one code is stored,

SC300 92-95 3.0 codes are separated by a 2.5 second

SC400 92-95 4.0 pause. When all codes have been dis(cont) played, there is a 4.5 second pause, then

the codes are repeated. Codes will continue to cycle as long as the ignition is

on and the Code Reader is connected.

T5

T6

T7

HM

SELECT INPUT SET

SUPER MONITOR

Page 45

Toyota/Lexus

CODE RETRIEVAL PROCEDURE

Chapter 5 42

Code Examples

Examples of Toyota/Lexus fault codes are shown in Figures

T8 through T10. Refer to the code retrieval instructions in

Table T1 (Toyota) or Table T2 (Lexus) to determine the code

display for your vehicle.

T8

T9

T10

BLINKBLINK

BLINK

SHORT

PAUSE

BLINK

BLINK

BLINK

BLINK

SELECT INPUT SET

HM

SUPER MONITOR

PAUSE

3 - 4 SECONDS

PAUSE

3 - 4 SECONDS

or

= CODE 3

= CODE 13

SELECT INPUT SET

HM

SUPER MONITOR

Page 46

Toyota/Lexus

ERASING CODES

43 Chapter 5

ERASING CODES

•

Always observe safety precautions whenever working on a

vehicle.

•

Remove Code Reader from vehicle’s test connector before

erasing codes.

•

Erase codes only when all repairs have been completed.

Refer to “Toyota Erasing Procedures” or “Lexus Erasing

Procedures” for specific instructions for your year, make

and model.

•

After erasing codes, verify that repairs were successfully

completed. Start the engine and warm to normal

operating temperature. After normal operating

temperature is reached, turn off the ignition and repeat

the code retrieval procedure for your vehicle. If no codes

are retrieved, the repair(s) was successful.

NOTE:

Removing fuses or battery cables may clear the memory

on the radio, clock, etc., or may enable the “Theftlock” feature

on the radio.

Toyota Erasing Procedures

Model Years Procedure

4 Runner 85-94 With ignition off, remove 15A “EFI’ fuse for 30 seconds.

Camry 85 With ignition off, remove negative battery cable for 30

conds.

86 With ignition off, remove 15A “ECU-B” fuse for 30 seconds.

87-93 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Celica 86-95 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Corolla 87-91 With ignition off, remove 15A “Stop” fuse for 30 seconds.

92-95 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Cressida 83-89 With Super Monitor Display: With ignition off, remove

15A “EFI” fuse for 30 seconds.

87-88 With ignition off, remove 15A “EFI” fuse for 30 seconds.

89-92 With ignition off, remove 20A “EFI” fuse for 30 seconds.

MR2 85-87 With ignition off, remove 7.5A “AM2” fuse for 30 seconds.

88-95 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Land 88-94 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Cruiser

Paseo 92-95 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Page 47

Toyota/Lexus

ERASING CODES

Chapter 5 44

Toyota Erasing Procedures (Cont)

Lexus Erasing Produres

Model Years Procedure

Pickup 85-88 With ignition off, remove 15A “EFI” fuse for 30 seconds.

89 With ignition off, remove 15A “Haz-Horn” fuse for 30

seconds.

90-94 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Previa 91-95 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Supra 87-88 With Super Monitor Display: With ignition off, remove

15A “EFI” fuse for 30 seconds.

85-86 With ignition off, remove 15A “Stop” fuse for 30 seconds.

87-92 With ignition off, remove 15A “EFI” fuse for 30 seconds.

94-95 With ignition off, remove 30A “EFI” fuse for 30 seconds.

T100 93 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Tercel 89-90 With ignition off, remove 20A “Stop” fuse for 30 seconds.

91-94 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Van 84-89 With ignition off, remove 15A “EFI” fuse for 30 seconds.

Model Years Procedure

ES250 90-91 With ignition off, remove the 20A “EFI” fuse for 10 seconds.

ES300 92-93 With ignition off, remove the 15A “EFI” fuse for 10 seconds.

GS300 93-95 With ignition off, remove the 20A “EFI” fuse for 10 seconds.

LS400 90-94 With ignition off, remove the 20A “EFI” fuse for 10 seconds.

SC300 92-93 With ignition off, remove the 30A “EFI” fuse for 10 seconds.

94-95 With ignition off, remove the 20A “EFI” fuse for 10 seconds.

SC400 92-95 With ignition off, remove the 30A “EFI” fuse for 10 seconds.

Page 48

Toyota/Lexus

FAULT CODE DEFINITIONS (1 - 16)

45 Chapter 5

TOYOTA/LEXUS FAULT CODE DEFINITIONS

IMPORTANT:

Retrieving and utilizing Diagnostic Trouble

Codes (DTCs) for troubleshooting vehicle operation problems is

only one part of an overall diagnostic strategy. Never replace a

part based solely on the DTC definition. Always consult the

vehicle’s service manual for more detailed testing instructions.

Each DTC has a set of testing procedures, instructions and flow

charts that must be followed to confirm the exact location of the

problem. This type of information is found in the vehicle’s

service manual.

Code Description Possible Cause

1 System Normal

2 VAF sensor circuit VAF circuit, ECU

3 No ignition signal Ignition or circuit, coil, ECU

4 ECT sensor circuit ECT sensor or circuit, ECU

5 O2S circuit O2S sensor or circuit, ECU

6 Engine Speed (RPM) sensor circuit Ignitor or circuit, distributor, ECU

7 TPS circuit TPS or circuit, ECU

8 IAT sensor circuit IAT sensor or circuit, ECU

9 VSS circuit VSS sensor or circuit, ECU

10 Starter signal circuit VSS sensor or circuit, main relay

or circuit, ignition circuit, starter

circuit, ECU

11 ECU Power Supply Ignition or circuit, coil, ECU

11 A/C switch ON during code retrieval A/C switch, ECU

11 Closed throttle position switch Throttle position switch or circuit,

OFF during code retrieval ECU

11 Park / Neutral position switch in Park / Neutral switch, start

D during code retrieval switch, ECU

12 Engine Speed (RPM) sensor Distributor or circuit, ignitor or

circuit circuit, starter or circuit, ECU

(non-turbo models); crankshaft

or position sensor / circuit, starter

or circuit, ECU (turbo models)

13 Engine Speed (RPM) sensor above Distributor or circuit, ignitor or

1000 RPM circuit, starter or circuit, ECU

(non-turbo models); crankshaft or

position sensor / circuit, starter or

circuit, ECU (turbo models)