Page 1

E

Can

OBD2 & 1

The Easiest

And Best Way

To Troubleshoot

OBD2 and OBD1

Vehicles!

Page 2

Table of Contents

i OBD2 & 1

E

Title Page No.

INTRODUCTION

What is OBD? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

YOU CAN DO IT! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS

Safety First! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ABOUT THE TOOL

Battery Installation / Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Adjustments/Settings and DTC Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TOOL CONTROLS

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Viewing DTC’s in the Tool’s Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preliminary Vehicle Diagnosis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PREPARATION FOR TESTING

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Vehicle Service Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GENERAL CODE RETRIEVAL PROCEDURES

OBD1 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OBD2 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OBD2 Systems

Vehicles Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Code Retrieval Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Erasing Diagnostic Trouble Codes (DTC’s) . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I/M Readiness Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chrysler/Jeep OBD1 Systems

Chrysler/Jeep OBD1 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Vehicles Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Instrument Panel Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Data Link Connector (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Code Retrieval Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ford OBD1 Systems

Ford Computer System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Vehicles Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Test Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connecting the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Code Retrieval Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Additional Tests for EEC-IV Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

GM OBD1 Systems

Your Vehicle’s Computer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Vehicles Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

About the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Data Link Connector (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Malfunction Indicator Light (MIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Code Retrieval Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Toyota/Lexus OBD1 Systems

On-Board Vehicle Diagnostics (OBD1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Vehicles Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Data Link Connector (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Instrument Panel Malfunction Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . 74

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Code Retrieval Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Servicing DTCs

Servicing DTCs - OBD I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Erasing DTCs (OBD I Systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Glossary

Glossary of Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Warranty and Servicing

Limited One Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Page 3

Introduction

WHAT IS OBD?

OBD2 & 1 1

E

WHAT IS OBD?

The OBD2 & 1 Tool is designed to work on most Chrysler, Ford,

GM and Toyota OBD1 systems and all

OBD2 compliant vehicles.

One of the most exciting improvements

in the automobile industry was the addition

of on-board diagnostics (OBD) on vehicles,

or in more basic terms, the computer that

activates the vehicle’s “CHECK ENGINE”

light. OBD 1 was designed to monitor manufacturer-specific systems on vehicles built

from 1981 to 1995.Then came the development of OBD 2, which is on all

1996 cars and light trucks sold in the

United States. These systems are part of a government mandate to

lower vehicle emissions. The sophisticated programs in the vehicle’s

on-board computer system are designed to detect failures in a range

of vehicle systems.Diagnostic information can be accessed through a

Data Link Connector test port specifically designed for this purpose.

For all OBD systems, if a problem is found, the computer turns on the

“CHECK ENGINE” light to warn the driver, and sets a Diagnostic

Trouble Code (DTC) to identify where the problem occurred.A special

diagnostic tool, such as the OBD2 & 1 Tool, is required to retrieve

these codes, which consumers and professionals use as a starting

point for repairs.

Page 4

You Can Do It!

EASY TO USE - EASY TO VIEW - EASY TO DEFINE

2 OBD2 & 1

E

Easy T o Use ....

■ Connect the Tool to the vehicle’s test

connector.

■ Turn the ignition key "On.”

■ Press the POWER/LINK button.

Easy T o View ....

■ The Tool retrieves stored codes, as well

as Freeze Frame data and I/M

Readiness status (OBD2 systems only).

■ Codes, I/M Readiness status and

Freeze Frame data are displayed on the

Tool’s LCD display screen. System status is indicated by LED indicators.

Easy T o Define ....

■ Read code definitions from the Tool’s

LCD display.

■ View Freeze Frame data (OBD2 sys-

tems only).

Page 5

OBD2 & 1 3

E

Safety Precautions

SAFETY FIRST!

SAFETY FIRST!

This manual describes common test procedures used by

experienced service technicians. Many test procedures

require precautions to avoid accidents that can result in

personal injury, and/or damage to your vehicle or test

equipment.Always read your vehicle's service manual and follow its safety precautions before and during any test or service procedure. ALWAYS observe the following general safety

precautions:

When an engine is running, it produces carbon monoxide, a toxic and poisonous gas.To pre vent serious injury

or death from carbon monoxide poisoning, operate the

vehicle ONLY in a well-ventilated area.

To protect your eyes from propelled objects as well as

hot or caustic liquids, always wear approved safety

eye protection.

When an engine is running, many parts (such as the

coolant fan, pulleys, fan belt etc.) turn at high speed.To

avoid serious injury, always be aware of moving parts.

Keep a safe distance from these parts as well as other

potentially moving objects.

Engine parts become very hot when the engine is running. To prevent severe burns, avoid contact with hot

engine parts.

Before starting an engine for testing or trouble-shooting, make sure the parking brake is engaged. Put the

transmission in park (for automatic transmission) or

neutral (for manual transmission). Block the drive

wheels with suitable blocks.

Connecting or disconnecting test equipment when the

ignition is ON can damage test equipment and the vehicle's electronic components. Turn the ignition OFF

before connecting the Tool to or disconnecting the Tool

from the vehicle’s Data Link Connector (DLC).

To avoid personal injury, instrument damage and/or

damage to your vehicle; do not use the CAN OBD2 Tool

before reading this manual.

N

R

P

D

L

Page 6

4 OBD2 & 1

E

Safety Precautions

SAFETY FIRST!

To prevent damage to the on-board computer when taking vehicle electrical measurements, always use a digital multimeter with at least 10 megOhms of impedance.

Fuel and battery vapors are highly flammable. To prevent an explosion, keep all sparks, heated items and

open flames away from the battery and fuel / fuel

vapors. DO NOT SMOKE NEAR THE VEHICLE DURING TESTING.

Don't wear loose clothing or jewelry when working on an

engine. Loose clothing can become caught in the fan,

pulleys, belts, etc.Jewelry is highly conductive, and can

cause a severe burn if it makes contact between a

power source and ground.

Page 7

OBD2 & 1 5

E

About the Tool

BATTERY INSTALL / REPLA CEMENT / ADJUSTMENTS/SETTINGS & DTC LIBRARY

BATTERY INSTALLATION / REPLACEMENT

Replace batteries when the battery symbol is visible on display

and/or the 3 LEDS are all lit and no other data is visible on screen.

1. Locate the battery cover on the back of the Tool.

2. Slide the battery cover off (use your fingers).

3. Replace batteries with three AA-size batteries (for longer life, use

Alkaline-type batteries).

4. Reinstall the battery cover on the back of the Tool.

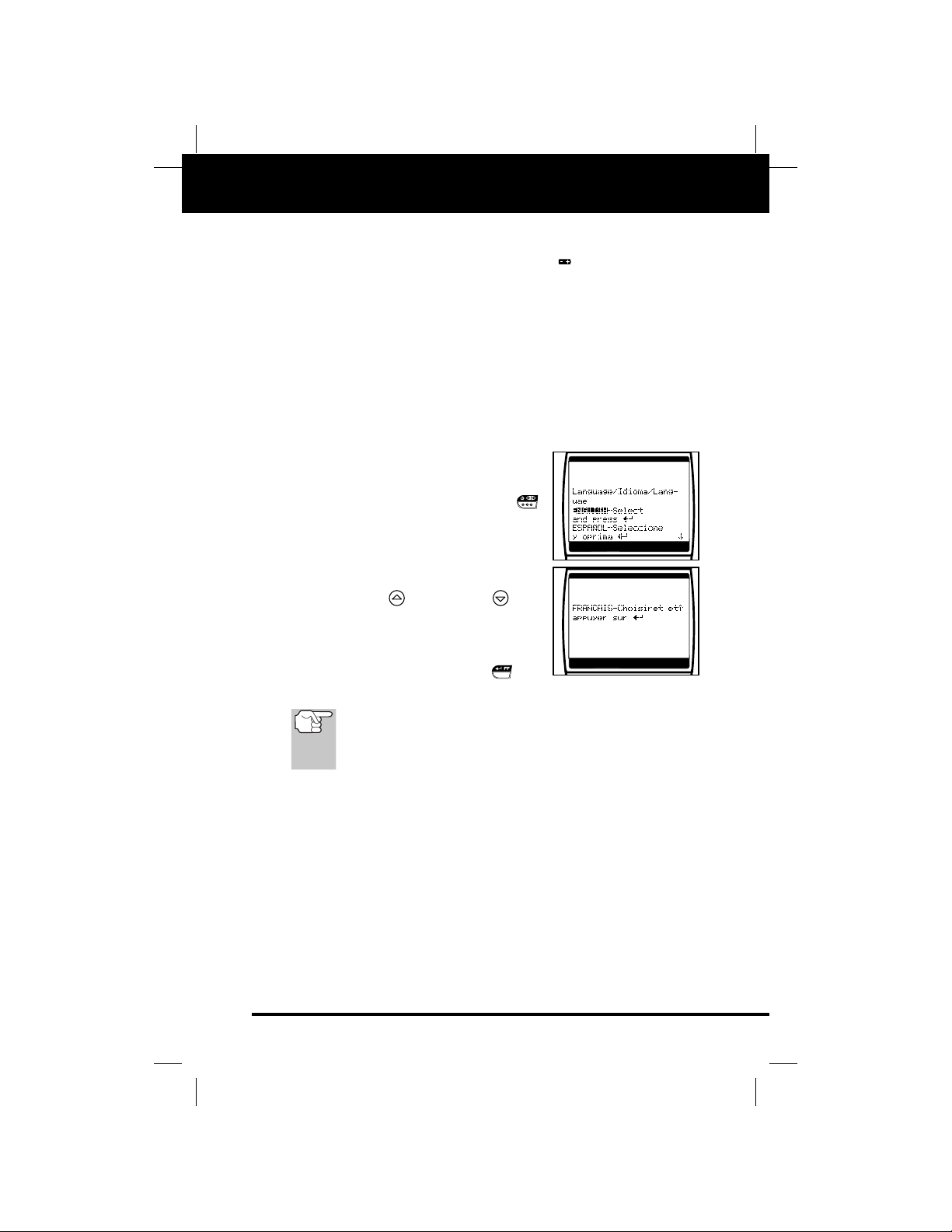

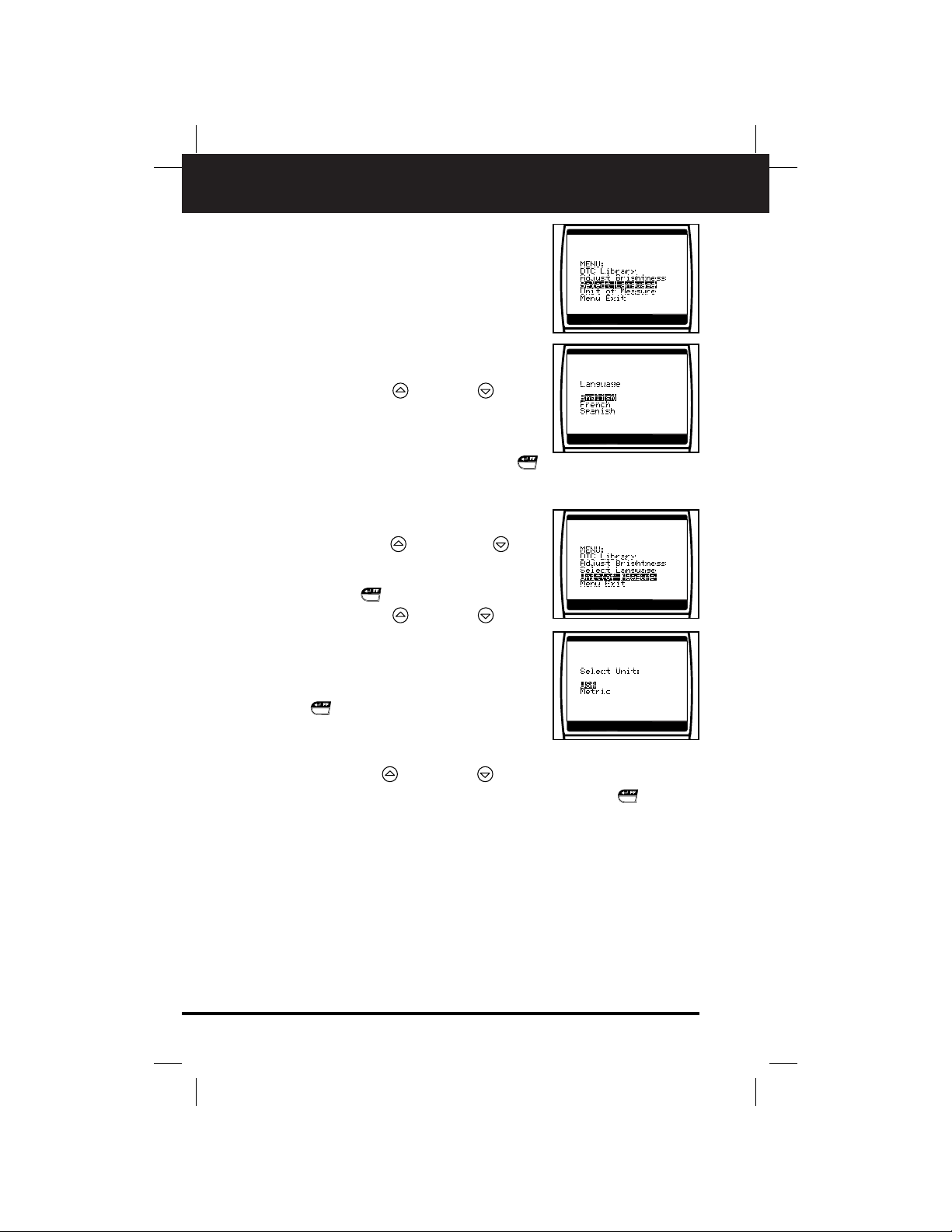

Language Selection After Battery Installation

The first time the unit is turned on , you

must select the desired display language

(English, French or Spanish) as follows:

1. Press and hold the POWER/LINK

button for approximately 3 seconds to

turn the Tool “ON.”

■ The Select Language screen dis-

plays.

2. Use the UP and DOWN but-

tons, as necessary, to highlight the

desired display language.

3.

When the desired display language is

selected, press the ENTER/FF button to confirm your selection.

After the initial language selection is performed, it, as well as

other settings, can be changed as desired. Proceed to

“ADJUSTMENTS/SETTINGS AND DTC LIBRARY”below for

further instructions.

ADJUSTMENTS/SETTINGS AND DTC LIBRARY

The OBD2 & 1 Tool lets you make several adjustments and settings to

configure the tool to your particular needs. It also contains an OBD2

DTC Library that allows you to search for DTC definitions.The following functions, adjustments and settings can be performed when the

OBD2 & 1 Tool is in “MENU Mode”:

■ DTC Library: Lets you search the library of OBD2 DTC definitions.

■ Adjust Brightness: Adjusts the brightness of the LCD display

screen.

■ Select Language: Sets the display language for the Tool to

English, French or Spanish.

Page 8

6 OBD2 & 1

E

About the Tool

ADJUSTMENTS/SETTINGS AND DTC LIBRARY

■ Unit of Measure: Sets the Unit of Measure for the Tool’s display to

USA or metric.

Adjustments and settings can be made only when the Tool is

NOT connected to a vehicle.

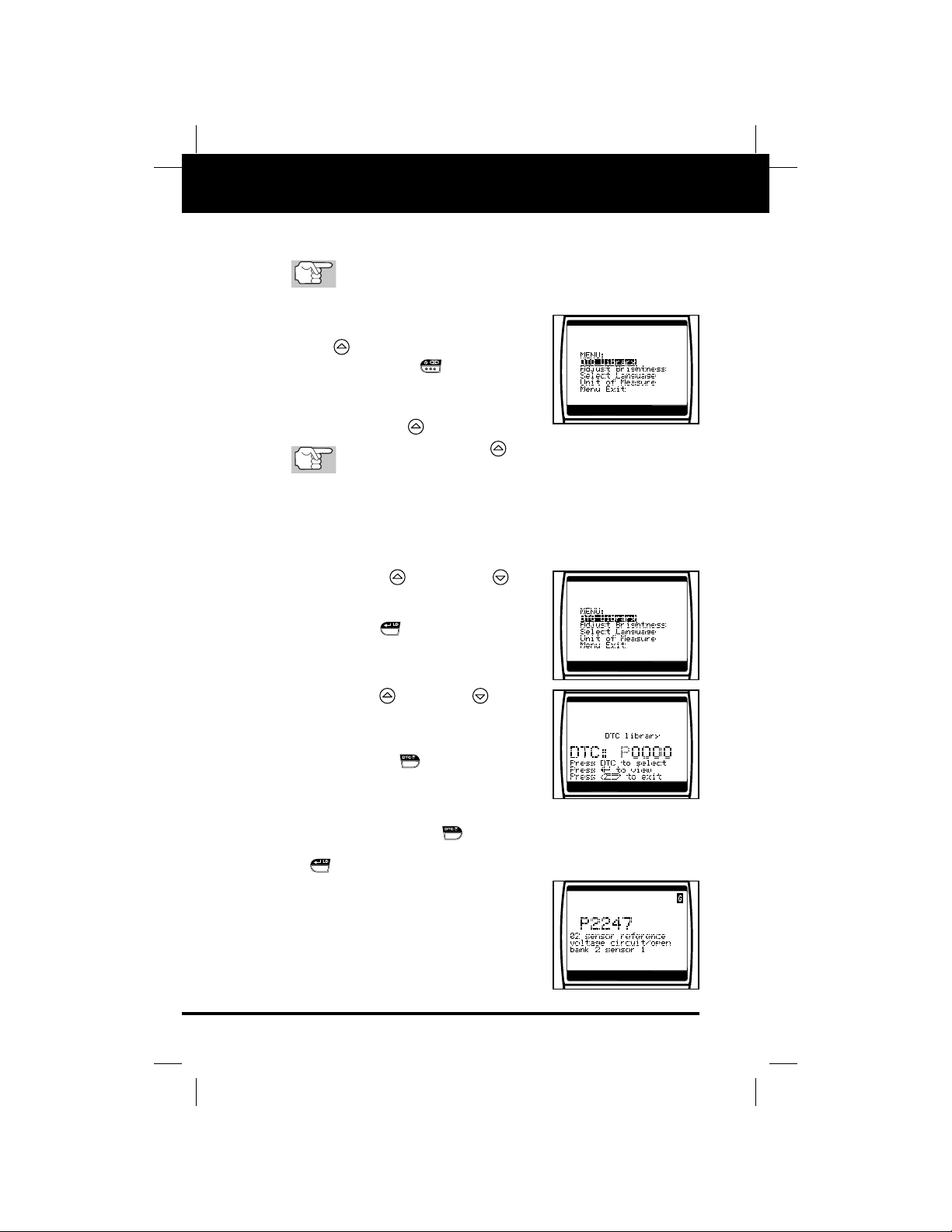

To enter the MENU Mode:

1. With the Tool OFF, press and hold

the

UP button, then press and release

the POWER/LINK button.

■ The adjustments and setting MENU

displays.

2. Release the UP button.

DO NOT release the UP button until the adjustments and

settings MENU is visible on the display.

3. Make adjustments and settings as described in the following paragraphs.

Searching for a DTC Definition Using the DTC Library (applicable

to OBD2 systems only)

1. Use the UP and DOWN but-

tons, as necessary, to highlight DTC

Library in the MENU, then press the

ENTER/LD button.

■ The Enter DTC screen displays.The

screen shows the code “P0000”, with

the “P” flashing.

2. Use the UP and DO WN buttons,

as necessary, to scroll to the desired

DTC type (P=Powertrain, U=Network,

B=Body, C=Chassis), then press the

DTC SCROLL button.

■ The selected character displays “solid”,

and the next character begins flashing.

3. Select the remaining characters in the DTC in the same way, pressing the DTC SCROLL button to confirm each character.When

you have selected all the DTC characters, press the ENTER/LD

button to view the DTC definition.

■ If you entered a “Generic” DTC

(DTCs that start with “P0”, “P2” and

some “P3”):

- The selected DTC and DTC definition (if available), show on the

Scan Tool’s LCD display.

Page 9

OBD2 & 1 7

E

About the Tool

ADJUSTMENTS/SETTINGS AND DTC LIBRARY

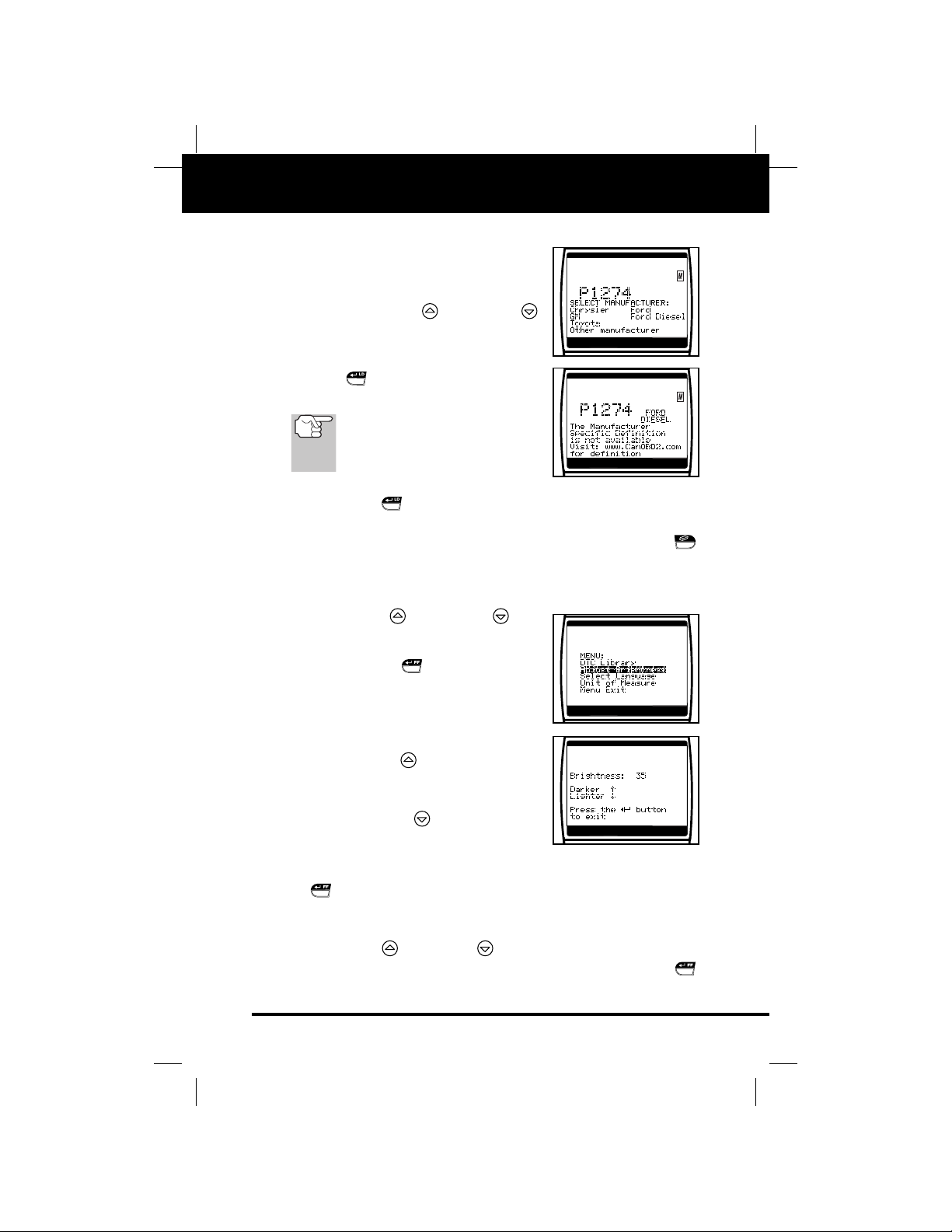

■ If you entered a “Manufacturer-Specific” DTC (DTCs that start

with “P1” and some “P3”):

- The “Select Manufacturer” screen

displays.

- Use the UP and DOWN

buttons, as necessary, to highlight the appropriate manufacturer, then press the

ENTER/LD

button to display the correct

DTC for your vehicle.

If a definition for the DTC you

entered is not available, an advisory message shows on the Scan

Tool’s LCD display.

4. If you wish to view definitions for additional DTCs, press the

ENTER/LD button to return to the DTC Library screen, and

repeat steps 2 and 3.

5. When all desired DTCs have been viewed, press the ERASE

button to exit the DTC Library.

Adjusting Display Brightness

1. Use the UP and DOWN but-

tons, as necessary, to highlight Adjust

Brightness in the MENU, then press

the ENTER/FF button.

■ The Adjust Brightness screen dis-

plays.

■ The Brightness field shows the cur-

rent brightness setting, from 0 to 43.

2. Press the UP button to decrease

the brightness of the LCD display (make

the display darker).

3. Press the DOWN button to increase

the brightness of the LCD display (make

the display lighter).

4. When the desired brightness is obtained, press the ENTER/FF

button to save your changes and return to the MENU.

Selecting the Display Language

1. Use the UP and DOWN buttons, as necessary, to highlight

Select Language in the MENU, then press the ENTER/FF

button.

Page 10

About the Tool

ADJUSTMENTS/SETTINGS AND DTC LIBRARY

8 OBD2 & 1

E

■ The Select Language screen dis-

plays.

■ The currently selected display

Language is highlighted.

2. Press the UP or DOWN button,

as necessary, to highlight the desired

display language.

3. When the desired display language is

highlighted, press the ENTER/FF

button to save your changes and return to the MENU.

Setting the Unit of Measure

1. Use the UP and DOWN but-

tons, as necessary, to highlight Unit of

Measure in the MENU, then press the

ENTER/FF button.

2. Press the UP or DOWN button,

as necessary, to highlight the desired

Unit of Measure.

3. When the desired Unit of Measure

value is selected, press the ENTER/FF

button to save your changes.

Exiting the MENU Mode

1. Use the UP and DOWN buttons, as necessary, to highlight

Menu Exit in the MENU, then press the ENTER/FF button.

■ The LCD display returns to the DTC screen.

Page 11

OBD2 & 1 9

E

Tool Controls

CONTROLS AND INDICATORS

CONTROLS AND INDICATORS

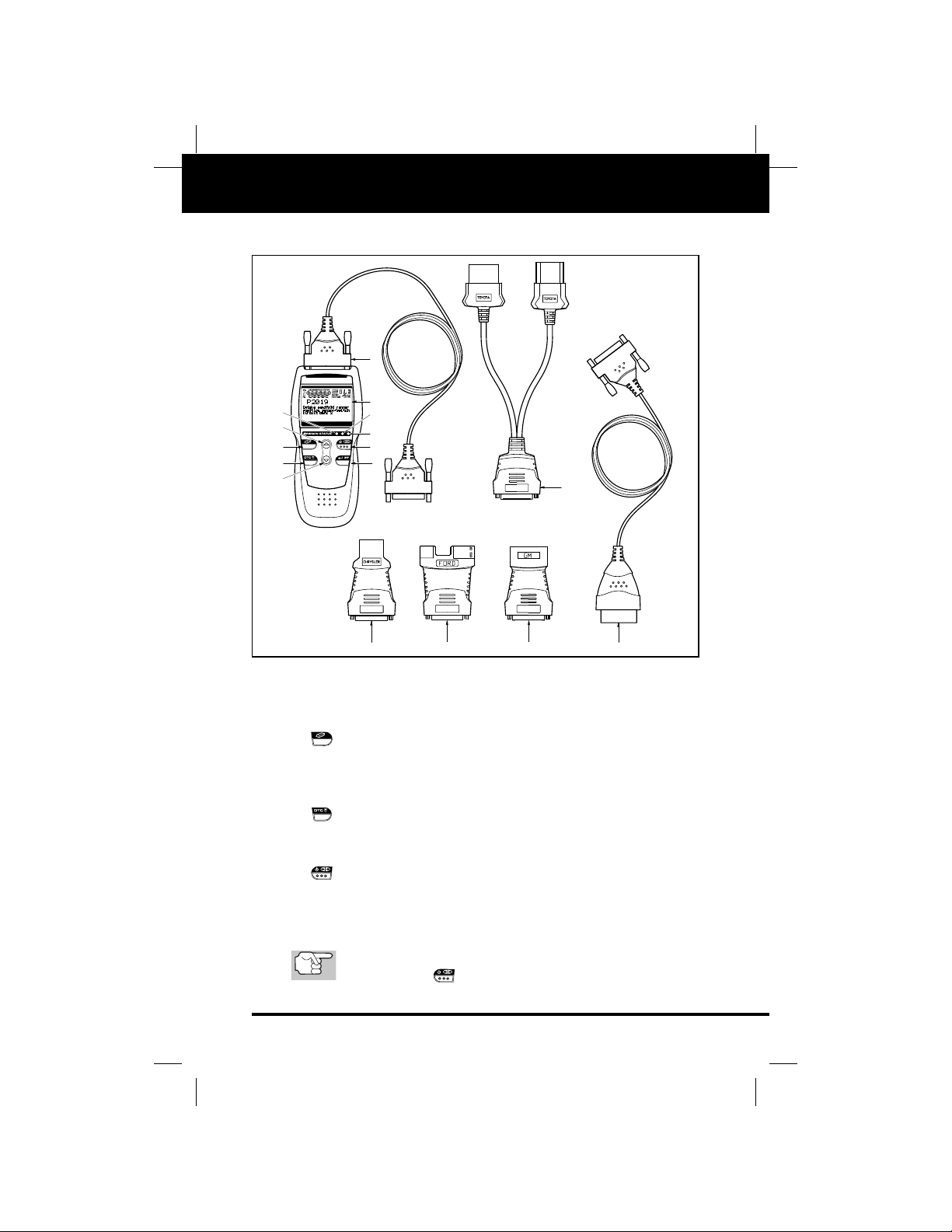

See Figure 1 for the locations of items 1 through 16, below.

1. ERASE button - Erases Diagnostic Trouble Codes (DTCs),

and “Freeze Frame” data from your vehicle’s computer, and resets

Monitor status.(“Freeze F rame”data and Monitor status are applicable

to OBD2 systems only.)

2. DTC SCROLL button - Displays the DTC View screen and/or

scrolls the LCD display to view DTCs when more than one DTC is

present.

3. POWER/LINK button - When the Tool IS NOT

connected to a vehicle, turns the Tool “On” and “Off”. When the Tool is

connected to a vehicle, links the Tool to the vehicle’s PCM to retrieve

diagnostic data from the computer’s memory. (The LINK function is

applicable to OBD2 systems only.)

To turn the Tool "On", you must press and hold the

POWER/LINK button for approximately 3 seconds.

Figure 1. Controls and Indicators

11

7

6

1

2

5

10

8

9

3

4

16

12

13 14

15

Page 12

10 OBD2 & 1

E

Tool Controls

CONTROLS AND INDICATORS

4. ENTER/FREEZE FRAME button - When in MENU mode,

confirms the selected option or value. When retrieving and viewing

DTCs, displays Freeze Frame data for the highest priority code. (The

Freeze Frame function is applicable to OBD2 systems only.)

5. DOWN button - When in MENU mode, scrolls DOWN through

the menu and submenu selection options. When retr ieving and viewing DTCs, scrolls down through the current display screen to display

any additional data.

6. UP button - When in MENU mode, scrolls UP through the

menu and submenu selection options. When retrieving and viewing

DTCs, scrolls ups through the current display screen to display any

additional data.

7. GREEN LED - Indicates that all engine systems are running nor-

mally (all Monitors on the vehicle are active and performing their diagnostic testing, and no DTCs are present). (Monitors are applicable to

OBD2 systems only.)

8. YELLOW LED - Indicates there is a possible problem. A “Pending”

or a history DTC is present and/or some of the vehicle’s emission monitors have not run their diagnostic testing.(Monitors and pending DTCs

are applicable to OBD2 systems only.)

9. RED LED - Indicates there is a problem in one or more of the vehi-

cle’s systems.The red LED is also used to show that DTC(s) are present. DTCs are shown on the Tool’s LCD display. In this case, the

Malfunction Indicator (“Check Engine”) lamp on the vehicle’s instrument panel will light steady on.

10. LCD Display - Displays settings Menu and submenus, test

results, Tool functions and Monitor status information. See DISPLAY

FUNCTIONS, on next page, for more details. (Monitors are applicable

to OBD2 systems only.)

11. Cable - Connects the Tool to the vehicle’s Data Link Connector

(DLC) when retrieving codes from OBD I systems (used with items 12,

13, 14 and 16).

12. CHRYSLER Connector Cable Adaptor - Installs on cable (item

11) when connecting to a Chrysler OBD1 Data Link Connector.

13. FORD Connector Cable Adaptor - Installs on cable (item 11)

when connecting to a Ford OBD1 Data Link Connector.

14. GM Connector Cable Adaptor - Installs on cable (item 11) when

connecting to a GM OBD1 Data Link Connector.

15. OBD II Cable - Connects the Tool to the vehicle's Data Link

Connector (DLC) when retrieving codes from OBD II systems.

16. TOYOTA Connector Cable Adaptor - Installs on cable (item 11)

when connecting to a Toyota OBD1 Data Link Connector.

Page 13

OBD2 & 1 11

E

Tool Controls

DISPLAY FUNCTIONS

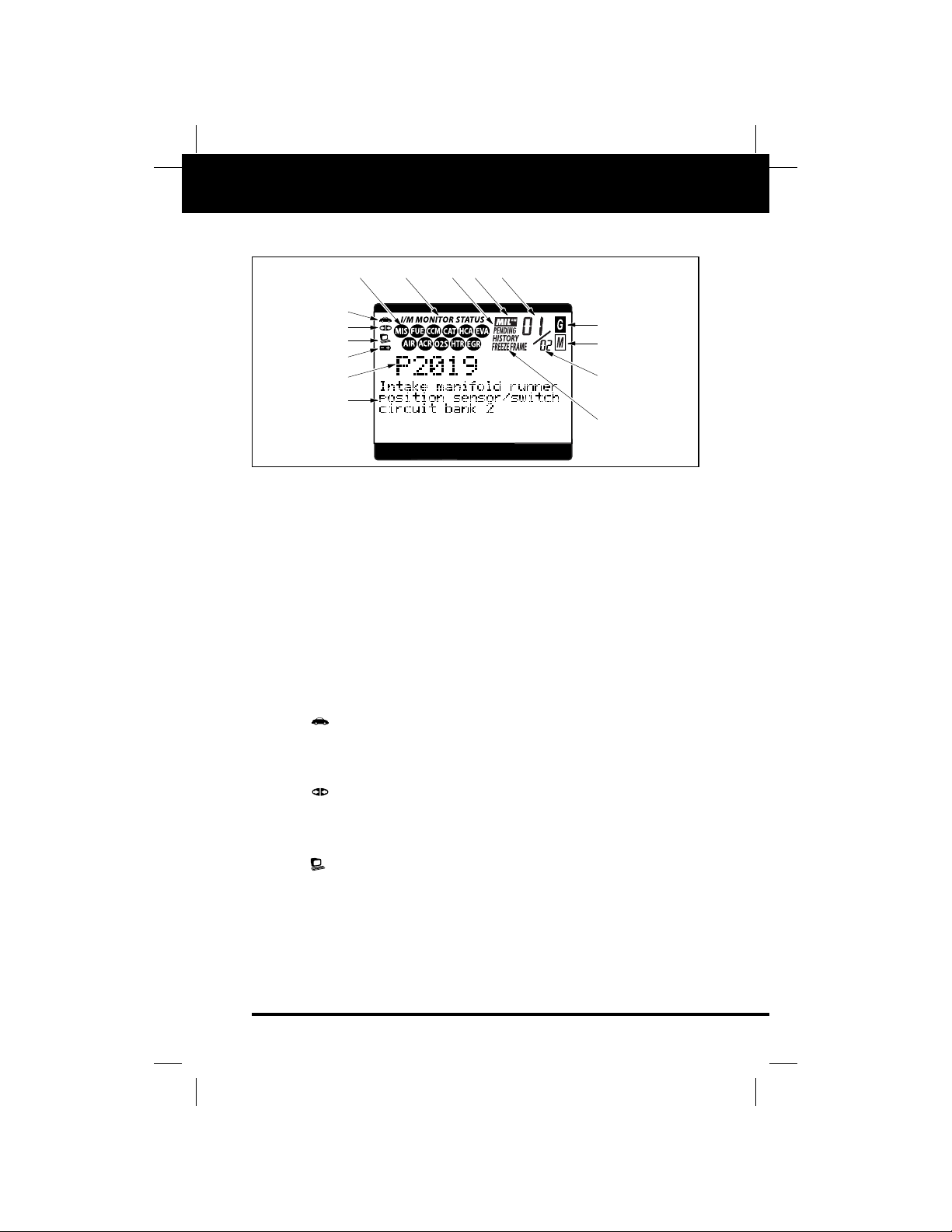

DISPLAY FUNCTIONS

See Figure 2 for the locations of items 1 through 16, below.

1. I/M MONITOR STATUS field - Identifies the I/M Monitor status

area. (This function is applicable to OBD2 systems only.)

2. Monitor icons - Indicate which Monitors are supported by the vehicle under test, and whether or not the associated Monitor has run

its diagnostic testing (Monitor status).When a Monitor icon is solid,

it indicates that the associated Monitor has completed its diagnostic testing.When a Monitor icon is flashing, it indicates that the vehicle supports the associated Monitor, but the Monitor has not yet run

its diagnostic testing. (This function is applicable to OBD2 systems

only.)

3. Vehicle icon - Indicates whether or not the Tool is being properly powered through the vehicle’s Data Link Connector (DLC). A

visible icon indicates that the Tool is being powered through the

vehicle’s DLC connector.

4. Link icon - Indicates whether or not the Tool is communicating (linked) with the vehicle’s on-board computer.When visible, the

Tool is communicating with the computer. If the Link icon is not visible, the Tool is not communicating with the computer.

5. Computer icon - When this icon is visible it indicates that the

Tool is linked to a personal computer. An optional “PC Link Kit” is

available that makes it possible to upload retrieved data to a personal computer.

Figure 2. Display Functions

21

10

11 12

3

4

5

6

7

8

14

15

13

9

Page 14

12 OBD2 & 1

E

Tool Controls

DISPLAY FUNCTIONS

6. Tool Internal Battery icon - When visible, indicates the Tool

batteries are “low” and should be replaced. If the batteries are not

replaced when the battery symbol is "on", all 3 LEDs will light

up as a last resort indicator to warn you that the batteries need

replacement. No data will be displayed on screen when all 3 LEDs

are lit.

7. DTC Display Area - Displays the Diagnostic Trouble Code (DTC)

number. Each fault is assigned a code number that is specific to

that fault.

8. Test Data Display Area - Displays DTC definitions, Freeze Frame

data, and other pertinent test information messages.

9. MIL icon - Indicates the status of the Malfunction Indicator Lamp

(MIL).The MIL icon is visible only when a DTC has commanded the

MIL on the vehicle’s dashboard to light.

10. CODE icon - Identifies the Code Number Sequence display area.

11. PENDING icon - Indicates the currently displayed DTC is a

“Pending” code. (This function is applicable to OBD2 systems

only.)

12. Code Number Sequence - The Tool assigns a sequence number

to each DTC that is present in the computer’s memory, star ting

with “01.” This number indicates which code is currently displayed.

Code number “01”is always the highest priority code, and the one

for which “Freeze Frame” data has been stored. (Freeze Frame

data is applicable to OBD2 systems only.)

If “01” is a “Pending” code, there may or may not be

“Freeze Frame” data stored in memory.

13. Code Enumerator - Indicates the total number of codes retrieved

from the vehicle’s computer.

14. Generic DTC icon - When visible, indicates that the currently

displayed DTC is a “Generic” or “Universal” code. (This function is

applicable to OBD2 systems only.)

15. Enhanced DTC icon - When visible, indicates that the currently

displayed DTC is a Manufacturer Specific Code. (This function is

applicable to OBD2 systems only.)

Page 15

OBD2 & 1 13

E

Tool Controls

VIEWING DTCs IN THE TOOL’S MEMORY

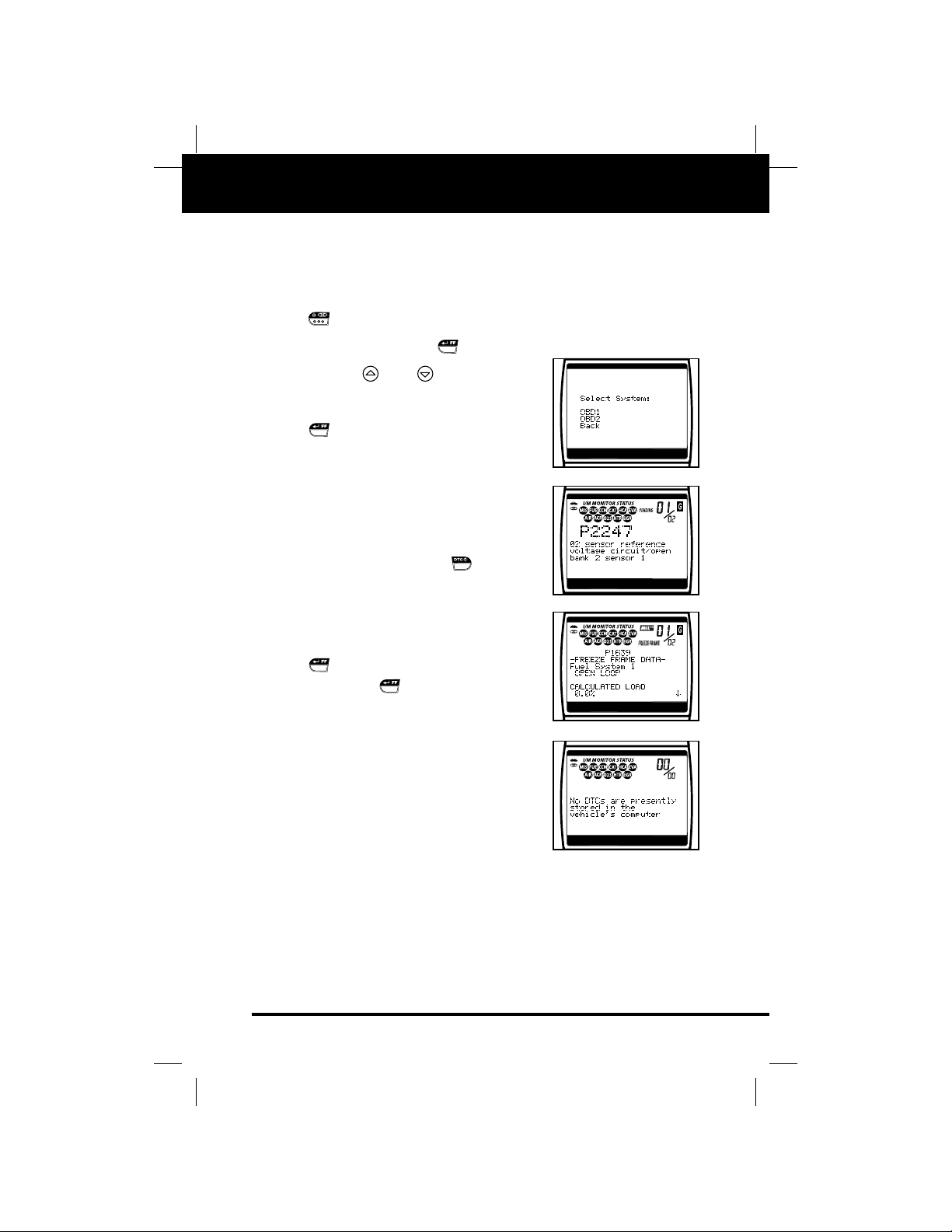

VIEWING DTCs IN THE TOOL’S MEMORY

To view DTC’s and other diagnostic data stored in the Tool’s memory,

do the following:

1. With no DLC cable connected to the Tool, press the POWER/LINK

button to turn the Tool “on”.

2. Press the ENTER/FF button.

3. Use the and keys to highlight

and select your vehicle’s OBD system

(OBD1 or OBD2). Press the ENTER/FF

button to continue.

■ Select “Back” if you wish to return to

the Main Menu.

4. If DTCs are present in the Tool’s memo-

ry, the first stored DTC will display on

the screen.

■ If more than one DTC is present, use

the DTC SCROLL button to

scroll through the DTC’s.

5. “For OBD2 systems only” - Saved

Freeze Frame data and Monitor status

are also available (press the

ENTER/FF button to view Freeze

Frame data).

6. If no DTCs are in the Tool’s memory, a

“No DTC’s are presently stored in the

Tool’s memory” message displays.

Page 16

14 OBD2 & 1

E

Preparation for Testing

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

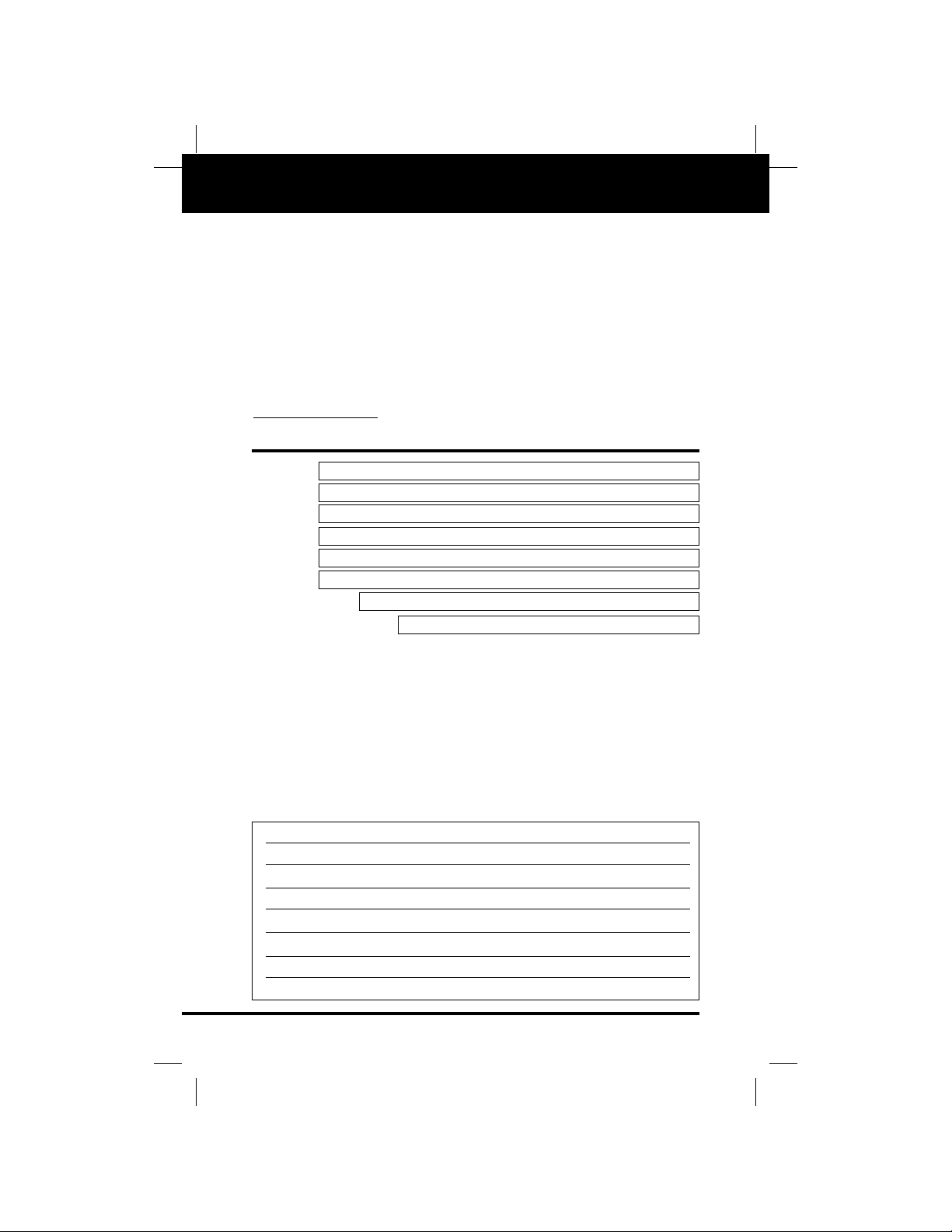

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

The purpose of this form is to help you gather preliminary information on

your vehicle before you retrieve codes.By having a complete account of

your vehicle's current problem(s), you will be able to systematically pinpoint the problem(s) by comparing your answers to the fault codes you

retrieve. You can also provide this information to your mechanic to assist

in diagnosis and help avoid costly and unnecessary repairs. It is important for you to complete this f orm to help you and/or y our mechanic have

a clear understanding of your vehicle's problems. An electronic version

of this Preliminary Vehicle Diagnosis Worksheet is available online at

www

.canOBD2.com.You can complete the form online and print a copy

to take to your mechanic.

NAME:

DATE:

VIN*:

YEAR:

MAKE:

MODEL:

ENGINE SIZE:

VEHICLE MILEAGE:

*VIN: Vehicle Identification Number, found at the base of the windshield

on a metallic plate, or at the driver door latch area (consult your vehicle

owner's manual for location).

TRANSMISSION:

❑

Automatic

❑ Manual

Please check all applicable items in each category.

DESCRIBE THE PROBLEM:

Page 17

OBD2 & 1 15

E

Preparation for Testing

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

WHEN DID YOU FIRST NOTICE THE PROBLEM:

❑ Just Started

❑ Started Last Week

❑ Started Last Month

❑ Other:

LIST ANY REPAIRS DONE IN THE PAST SIX MONTHS:

PROBLEMS STARTING

ENGINE QUITS OR STALLS

IDLING CONDITIONS

RUNNING CONDITIONS

❑ No symptoms

❑ Will not crank

❑ Cranks, but will not start

❑ Starts, but takes a long time

❑ No symptoms

❑ Right after starting

❑ When shifting into gear

❑ During steady-speed driving

❑ Right after vehicle comes to a stop

❑ While idling

❑ During acceleration

❑ When parking

❑ No symptoms

❑ Is too slow at all times

❑ Is too fast

❑ Is sometimes too fast or too slow

❑ Is rough or uneven

❑ Fluctuates up and down

❑ No symptoms

❑ Runs rough

❑ Lacks power

❑ Bucks and jerks

❑ Poor fuel economy

❑ Hesitates or stumbles on

accelerations

❑ Backfires

❑ Misfires or cuts out

❑ Engine knocks, pings or rattles

❑ Surges

❑ Dieseling or run-on

Page 18

16 OBD2 & 1

E

Preparation for Testing

PRELIMINARY VEHICLE DIAGNOSIS WORKSHEET

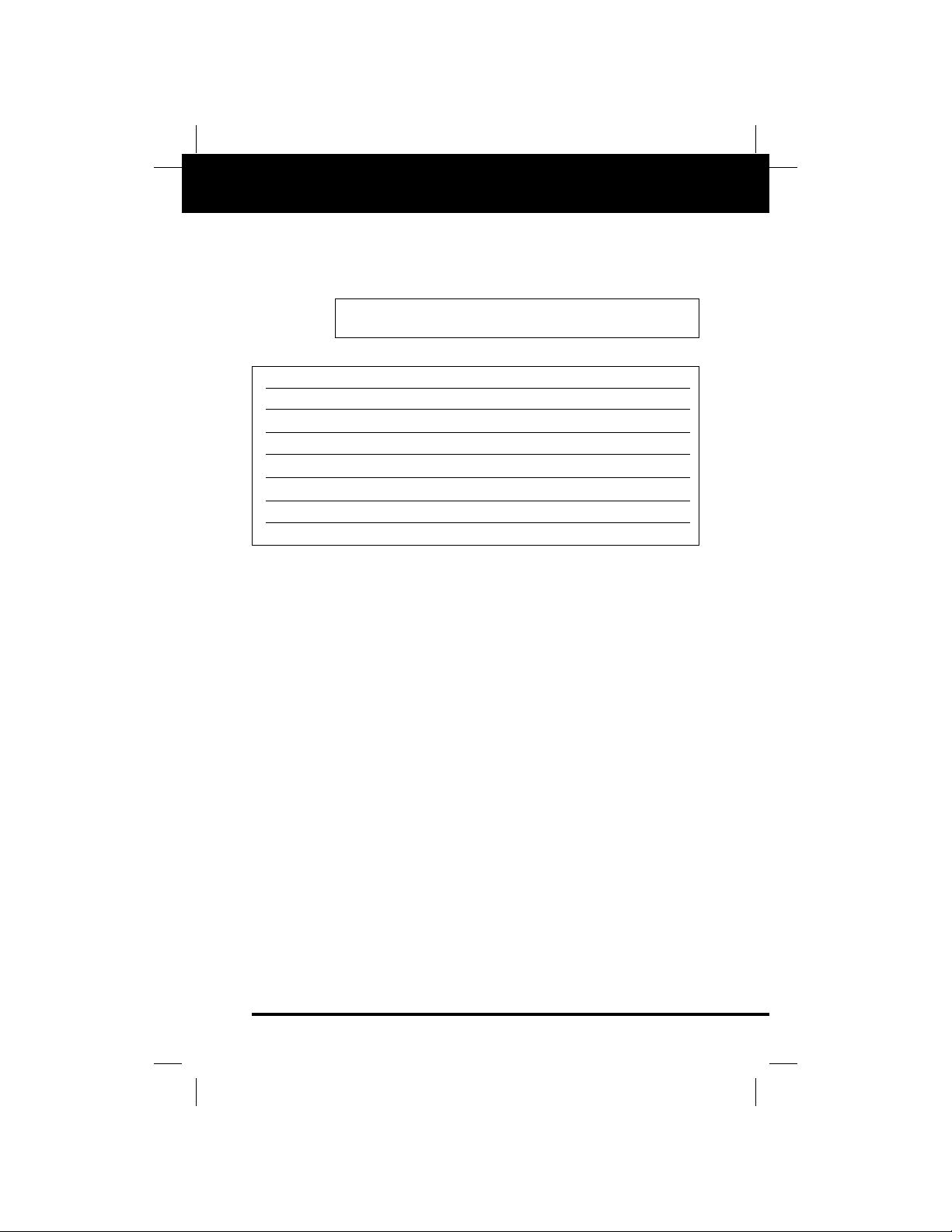

AUTOMATIC TRANSMISSION PROBLEMS (if applicable)

PROBLEM OCCURS

❑ Morning ❑ Afternoon ❑ Anytime

ENGINE TEMPERATURE WHEN PROBLEM OCCURS

❑ Cold ❑ Warm ❑ Hot

DRIVING CONDITIONS WHEN PROBLEM OCCURS

DRIVING HABITS

GASOLINE USED

WEATHER CONDITIONS WHEN PROBLEM OCCURS

CHECK ENGINE LIGHT / DASH WARNING LIGHT

❑

Sometimes ON ❑ Always ON ❑ Never ON

PECULIAR SMELLS

STRANGE NOISES

❑ Short - less than 2 miles

❑ 2 - 10 miles

❑ Long - more than 10 miles

❑ Stop and go

❑ While turning

❑ While braking

❑ At gear engagement

❑ With A/C operating

❑ With headlights on

❑ During acceleration

❑ Mostly driving downhill

❑ Mostly driving uphill

❑ Mostly driving level

❑ Mostly driving curvy roads

❑ Mostly driving rough roads

❑ Mostly city driving

❑ Highway

❑ Park vehicle inside

❑ Park vehicle outside

❑ Drive less than 10 miles per day

❑ Drive 10 to 50 miles per day

❑ Drive more than 50 miles per day

❑ 87 Octane

❑ 89 Octane

❑ 91 Octane

❑ More than 91 Octane

❑ 32 - 55° F (0 - 13° C)

❑ Below freezing (32° F / 0° C)

❑ Above 55° F (13° C)

❑ "Hot"

❑ Sulfur ("rotten egg")

❑ Burning rubber

❑ Gasoline

❑ Burning oil

❑ Electrical

❑ Rattle

❑ Knock

❑ Squeak

❑ Other

❑ No symptoms

❑ Shifts too early or too late

❑ Changes gear incorrectly

❑ Vehicle does not move when in

gear

❑ Jerks or bucks

Page 19

OBD2 & 1 17

E

Preparation for Testing

BEFORE YOU BEGIN

BEFORE Y OU BEGIN

The OBD2 & 1 Tool aids in

monitoring electronic- and

emissions-related faults in

your vehicle and retrieving

fault codes related to malfunctions in these systems.

Mechanical problems such as

low oil level or damaged

hoses, wiring or electrical connectors can cause poor engine performance and may also cause a fault code to set.Fix any known mechanical problems before performing any test. See your vehicle’s service

manual or a mechanic for more information.

Check the following areas before starting any test:

■ Check the engine oil, power steering fluid, transmission fluid (if

applicable), engine coolant and other fluids for proper le v els .Top off

low fluid levels if needed.

■ Make sure the air filter is clean and in good condition.Make sure all

air filter ducts are properly connected. Check the air filter ducts for

holes, rips or cracks.

■ Make sure all engine belts are in good condition.Check for crac ked,

torn, brittle, loose or missing belts.

■ Make sure mechanical linkages to engine sensors (throttle,

gearshift position, transmission, etc.) are secure and properly connected. See your vehicle’s service manual for locations.

■ Check all rubber hoses (radiator) and steel hoses (vacuum/fuel) for

leaks, cracks, blockage or other damage. Make sure all hoses are

routed and connected properly.

■ Make sure all spark plugs are clean and in good condition. Check

for damaged, loose, disconnected or missing spark plug wires.

■ Make sure the battery terminals are clean and tight. Check for cor-

rosion or broken connections. Check for proper battery and charging system voltages.

■ Check all electrical wiring and harnesses for proper connection.

Make sure wire insulation is in good condition, and there are no

bare wires.

■ Make sure the engine is mechanically sound. If needed, perform a

compression check, engine vacuum check, timing chec k (if applicable), etc.

Page 20

18 OBD2 & 1

E

Preparation for Testing

VEHICLE SERVICE MANUALS

VEHICLE SERVICE MANUALS

Always refer to the manufacturer’s service manual for your vehicle

before performing any test or repair procedures.Contact your local car

dealership, auto parts store or bookstore for availability of these manuals.The following companies publish valuable repair manuals:

■ Haynes Publications

861 Lawrence Drive

Newbury Park, California 91320

Phone: 800-442-9637

■ Mitchell International

14145 Danielson Street

Poway, California 92064

Phone: 888-724-6742

■ Motor Publications

5600 Crooks Road, Suite 200

Troy, Michigan 48098

Phone: 800-426-6867

FACTORY SOURCES

Ford, GM, Chrysler, Honda, Isuzu, Hyundai and Subaru Service

Manuals

■ Helm Inc.

14310 Hamilton Avenue

Highland Park, Michigan 48203

Phone: 800-782-4356

Page 21

OBD2 & 1 19

E

General Code Retrieval Procedures

OBD1 SYSTEMS / OBD2 SYSTEMS

Procedures for Retrieving Diagnostic Trouble Codes from OBD1 systems are vehicle manufacturer specific.Each manufacturer uses their

own procedure.

Procedures for retrieving Diagnostic Trouble Codes from OBD2

systems are generic, and apply to all vehicles equipped with OBD2

systems.

From the following list, select the procedure that applies to your vehicle’s OBD system, and proceed to appropriate section for detailed

code retrieval procedures.

OBD1 SYSTEMS

Most cars and light trucks (under 8500 GW) sold in the U.S.from early

1980’s to 1995 are equipped with what is known as the first generation

of On-Board Diagnostics or “OBD1”.

■ If your Chrysler/Jeep, Ford, GM or Toyota vehicle, (1995 and older)

is equipped with an ‘OBD1 System”, proceed to the proper section

as indicated below, for a detailed application list and code retrieval

procedures:

■ CHRYSLER/JEEP . . . . . . . . . . . . . . . .page 36

■ FORD . . . . . . . . . . . . . . . . . . . . . . . . .page 42

■ GM . . . . . . . . . . . . . . . . . . . . . . . . . . .page 65

■ TOYOTA . . . . . . . . . . . . . . . . . . . . . . . .page 71

OBD2 SYSTEMS

ALL 1996 and newer cars and light trucks (under 8500 GW) sold in the

U.S.are equipped with what is known as the second generation of OnBoard Diagnostics or “OBD2”.

■ If your vehicle (1996 and newer) is equipped with an “OBD2

System”, proceed to the “OBD2 SYSTEMS” section on page 20 for

a detailed application list, code retrieval procedures, Monitor status,

and Freeze Frame data information.

Page 22

20 OBD2 & 1

E

OBD2 Systems

VEHICLES COVERED

VEHICLES COVERED

The OBD2 & 1 Tool is designed to work on all OBD 2 compliant vehicles. All 1996 and newer vehicles (cars and light trucks) sold in the

United States are OBD 2 compliant.

Federal law requires that all 1996 and newer cars and light

trucks sold in the United States must be OBD 2 compliant;

this includes all Domestic, Asian and European vehicles.

Some 1994 and 1995 vehicles are OBD 2 compliant. To find out if a

1994 or 1995 vehicle is OBD 2 compliant, check the following:

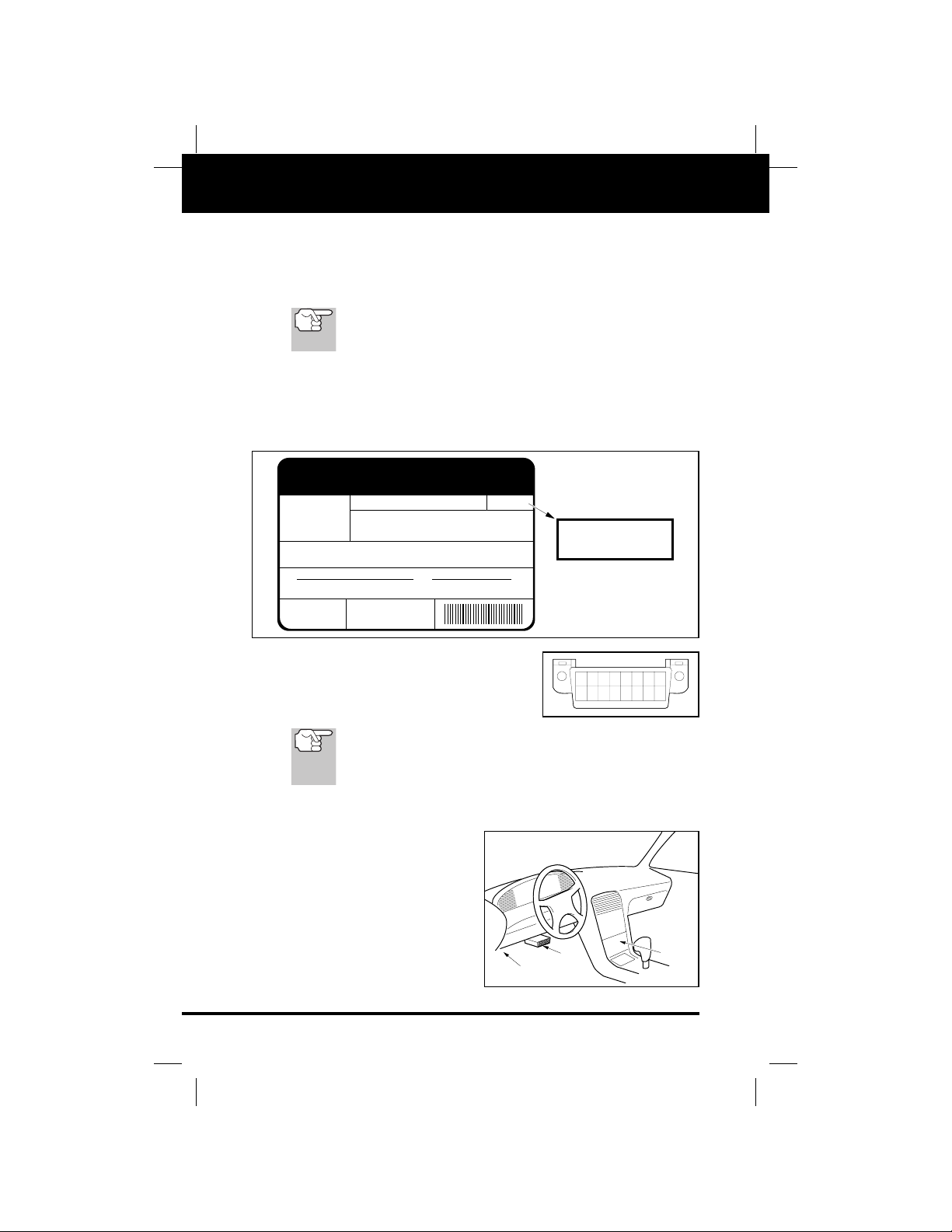

1. The Vehicle Emissions Control Information (VECI) Label. This

label is located under the hood or by the radiator of most vehicles.If

the vehicle is OBD 2 compliant, the label will state “OBD II Certified.”

2. Government Regulations require that

all OBD 2 compliant vehicles must

have a “common” sixteen-pin Data

Link Connector (DLC).

Some 1994 and 1995 vehicles have 16-pin connectors but

are not OBD 2 compliant. Only those vehicles with a Vehicle

Emissions Control Label stating “OBD II Certified” are OBD 2

compliant.

Data Link Connector (DLC) Location

The 16-pin DLC is usually

located under the instrument

panel (dash), within 12 inches

(300 mm) of center of the

panel, on the driver’s side of

most vehicles.It should be easily accessible and visible from

a kneeling position outside the

vehicle with the door open.

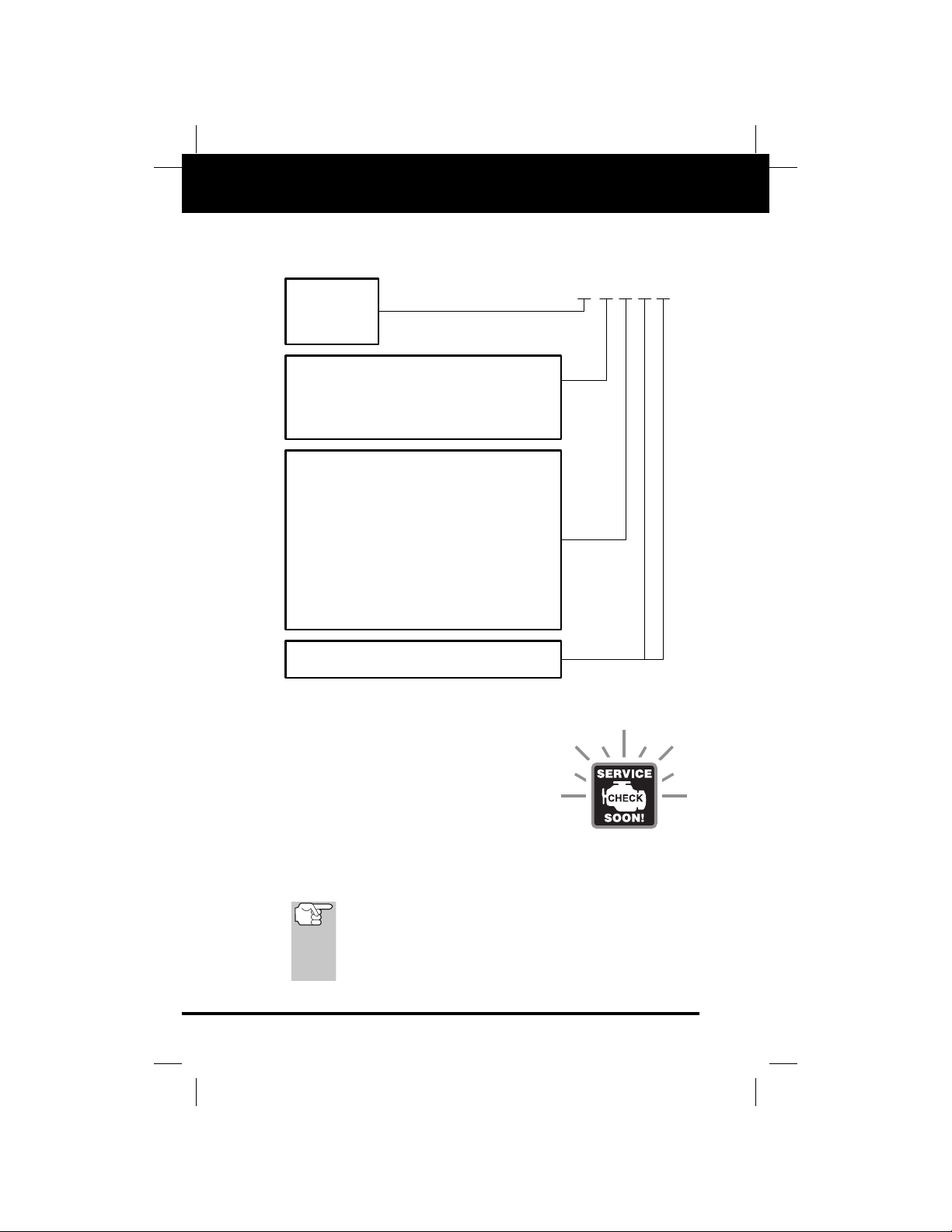

VEHICLE EMISSION CONTROL INFORMATION

ENGINE FAMILY EFN2.6YBT2BA

VEHICLE

MANUFACTURER

REFER TO SERVICE MANUAL FOR ADDITIONAL INFORMATION

TUNE-UP CONDITIONS: NORMAL OPERATING ENGINE TEMPERATURE,

ACCESSORIES OFF, COOLING FAN OFF, TRANSMISSION IN NEUTRAL

EXHAUST EMISSIONS STANDARDS STANDARD CATEGORY

CERTIFICATION

IN-USE

SPARK PLUG

TYPE NGK BPRE-11

GAP: 1.1MM

DISPLACEMENT 2.6L

THIS VEHICLE CONFORMS TO U.S. EPA AND STATE

OF CALIFORNIA REGULATIONS APPLICABLE TO

1999 MODEL YEAR NEW TLEV PASSENGER CARS.

TLEV

TLEV INTERMEDIATE

CATALYST

OBD II

CERTIFIED

OBD II

CERTIFIED

12345678

910111213141516

LEFT CORNER

OF DASH

NEAR

CENTER

OF DASH

BEHIND

ASHTRAY

Page 23

OBD2 & 1 21

E

OBD2 Systems

DIAGNOSTIC TROUBLE CODES (DTCs)

On some Asian and European vehicles the DLC is located

behind the “ashtray”(the ashtray must be removed to access

it) or on the far left corner of the dash. If the DLC cannot be

located, consult the vehicle’s service manual for the location.

DIAGNOSTIC TROUBLE CODES (DTCs)

Diagnostic Trouble Codes (DTCs) are

meant to guide you to the proper service procedure in the vehicle’s service

manual. DO NOT replace parts based

only on DTCs without first consulting

the vehicle’s service manual for proper testing procedures for that particular

system, circuit or component.

DTCs are alphanumeric codes that are used to identify a

problem that is present in any of the systems that are monitored by the on-board computer (PCM). Each trouble code

has an assigned message that identifies the circuit, component or system area where the problem was found.

OBD 2 diagnostic trouble codes are made up of five characters:

■ The 1st character is a letter. It identifies the “main system” where

the fault occurred (Body, Chassis, Powertrain, or Network).

■ The 2nd character is a numeric digit.It identifies the “type”of code

(Generic or Manufacturer-Specific).

Generic DTCs are codes that are used by all vehicle manufacturers. The standards for generic DTCs, as well as their

definitions, are set by the Society of Automotive Engineers

(SAE).

Manufacturer-Specific DTCs are codes that are controlled

by the vehicle manufacturers.The Federal Government does

not require vehicle manufacturers to go beyond the standardized generic DTCs in order to comply with the new

OBD2 emissions standards.However, manufacturers are free

to expand beyond the standardized codes to make their systems easier to diagnose.

■ The 3rd character is a numeric digit. It identifies the specific sys-

tem or sub-system where the problem is located.

■ The 4th and 5th characters are numeric digits. They identify the

section of the system that is malfunctioning.

Diagnostic T rouble

Codes (DTCs) are

codes that identify a

specific problem area.

Page 24

22 OBD2 & 1

E

OBD2 Systems

DIAGNOSTIC TROUBLE CODES (DTCs)

DTCs and MIL Status

When the vehicle’s on-board computer detects

a failure in an emissions-related component

or system, the computer’s internal diagnostic

program assigns a diagnostic trouble code

(DTC) that points to the system (and subsystem) where the fault was found.The diagnostic program saves the code in the computer’s memory. It records a “Freeze Frame” of

conditions present when the fault was found, and lights the Malfunction

Indicator Lamp (MIL). Some faults require detection for two trips in a

row before the MIL is turned on.

The “Malfunction Indicator Lamp” (MIL) is the accepted term

used to describe the lamp on the dashboard that lights to

warn the driver that an emissions-related fault has been

found. Some manufacturers may still call this lamp a “Check

Engine” or “Service Engine Soon” light.

P0201 - Injector Circuit Malfunction, Cylinder 1

OBD 2 DTC EXAMPLE

B

-

Body

C

-

Chassis

P

-

Powertrain

U

-

Network

-

Generic

0

-

Manufacturer Specific

1

-

Generic

2

-

Includes both Generic and Manufacturer

3

Specific Codes

Identifies the system where the

problem is located:

1

-

Fuel and Air Metering

2

-

Fuel and Air Metering (injector circuit

malfunction only)

3

-

Ignition System or Misfire

4

-

Auxiliary Emission Control System

5

-

Vehicle Speed Control and Idle Control

System

6

-

Computer Output Circuits

7

-

Transmission

8

-

Transmission

Identifies what section of the system

is malfunctioning

P 0 2 0 1

Page 25

OBD2 & 1 23

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

CODE RETRIEVAL PROCEDURE

Never replace a part based only on the DTC definition.

Each DTC has a set of testing procedures, instructions

and flow charts that must be followed to confirm the location of the problem.This information is found in the vehicle's

service manual. Always refer to the vehicle's service manual

for detailed testing instructions.

Check your vehicle thoroughly before performing

any test. See Before You Begin on page 17 for

details.

ALWAYS observe safety precautions whenever working on a

vehicle. See Safety Precautions on page 3 for more infor-

mation.

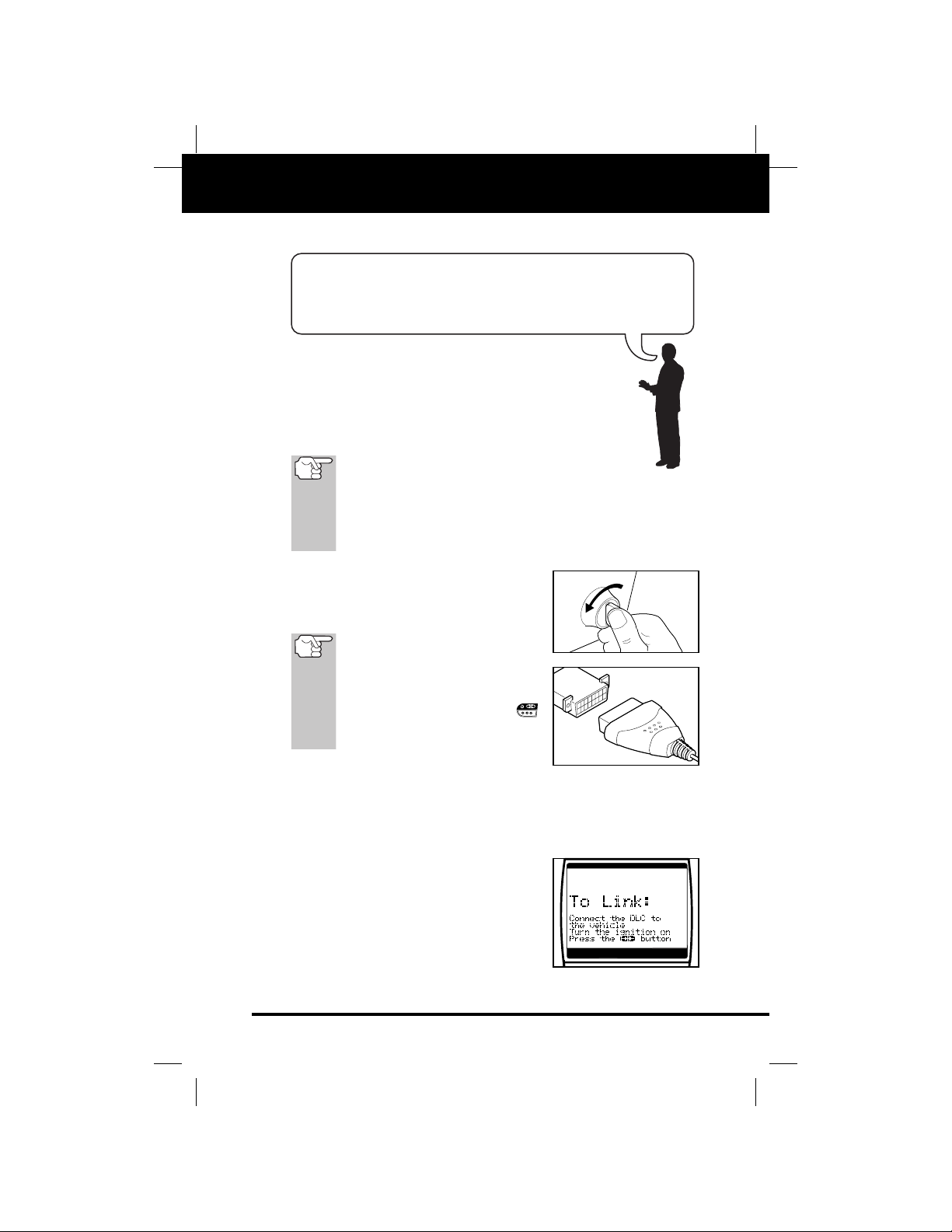

1. Turn the ignition OFF.

2. Locate the vehicle's 16-pin Data Link

Connector (DLC). See page 20 for connector location.

Some DLCs have a plastic cover

that must be removed bef ore connecting the Tool cable connector.

If the Tool is ON, turn it

OFF by

pressing the POWER/LINK

button BEFORE connecting the

Tool to the DLC.

3. Connect the OBD II Cable to the Tool,

then connect to the vehicle’s DLC.

■ If you hav e prob lems connecting the cab le connector to the DLC,

rotate the connector 180° and try again.

■ If you still have problems, check the pins on the Tool’s DLC and

on the vehicle’s DLC.

4. When the Tool’s cable connector is properly connected to the vehicle’s DLC, the

unit automatically turns ON, and the

LCD display shows instructions for linking to the vehicle’s on-board

computer.

Retrieving and using Diagnostic Trouble Codes (DTCs) for

troubleshooting vehicle operation is only one part of an

overall diagnostic strategy.

Page 26

24 OBD2 & 1

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

■ If the unit does not power on automatically when connected to

the vehicle’s DLC connector, it usually indicates there is no

power present at the vehicle’s DLC connector. Check your fuse

panel and replace any burned-out fuses.

■ If replacing the fuse(s) does not correct the problem, consult your

vehicle’s repair man ual to identify the proper computer (PCM) fuse/

circuit, and perform any necessary repairs before proceeding.

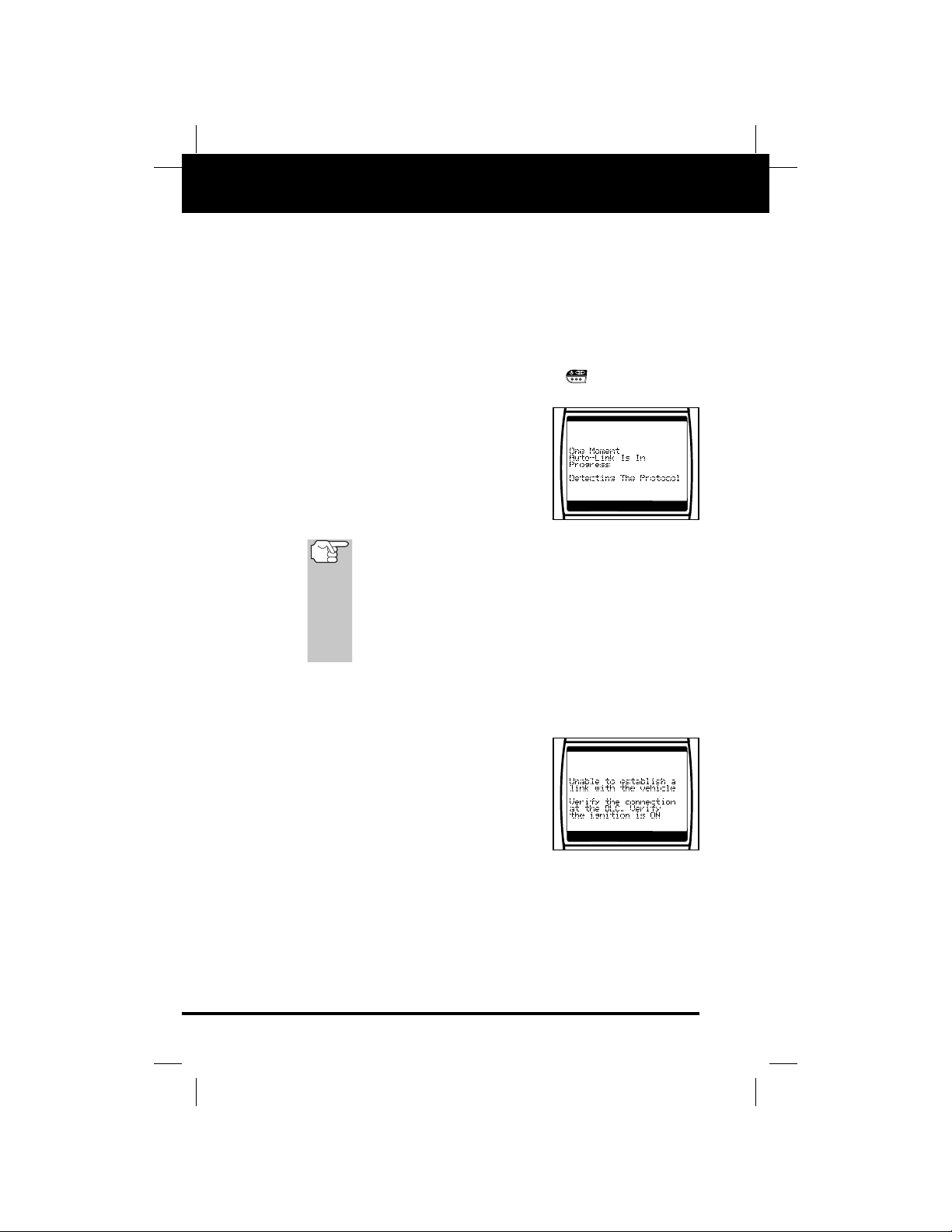

5. Turn the ignition on. DO NOT start the engine.

6. Press and release the Tool’s POWER/LINK button.

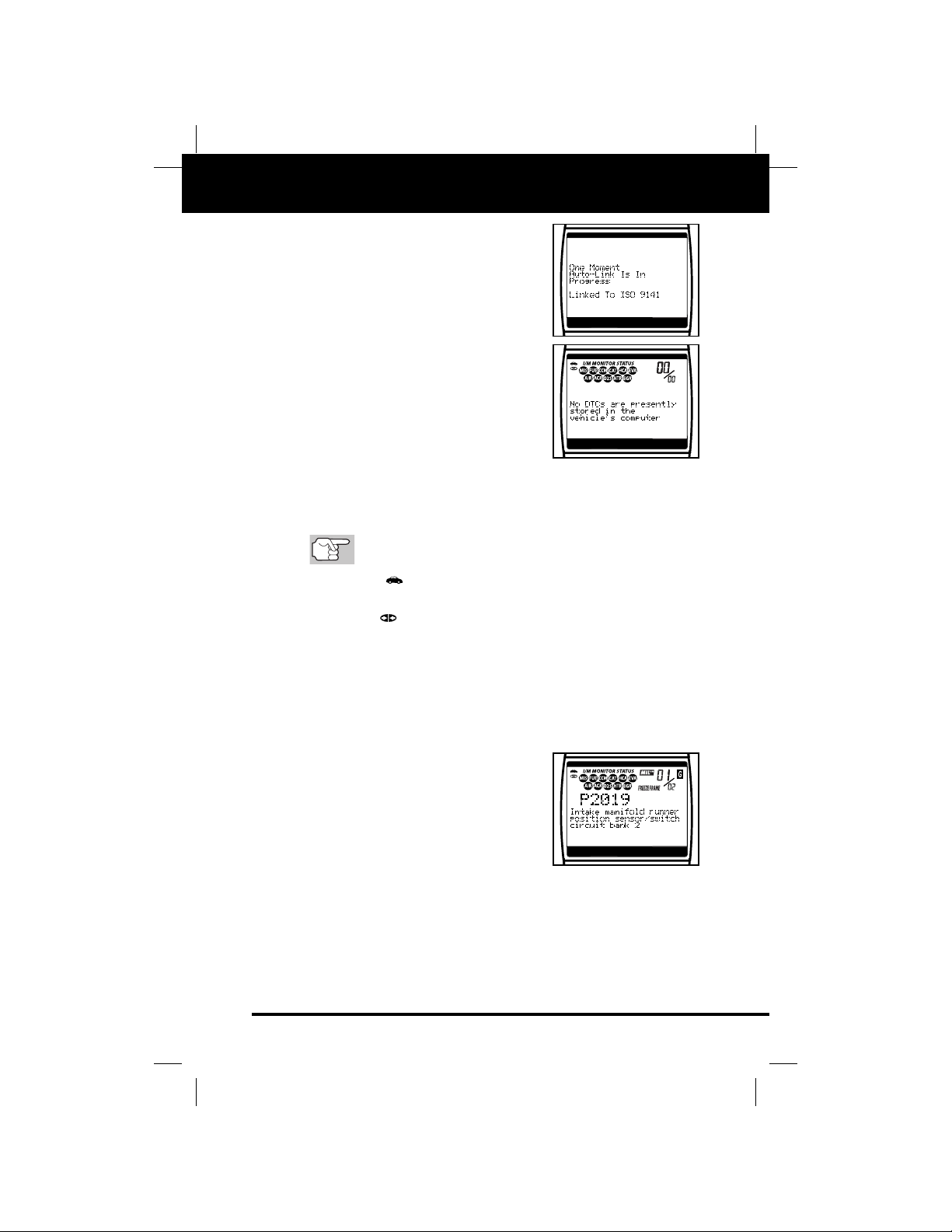

■ The Tool will automatically start a

check of the vehicle’s computer to

determine which type of communication protocol it is using.When the Tool

identifies the computer’s communication protocol, a communication link is

established. The protocol type used

by the vehicle’ s computer is shown on

the LCD display.

A PROTOCOL is a set of rules and procedures for regulating data transmission between computers, and between

testing equipment and computers. As of this writing, five

different types of protocols (ISO 9141, Keyword 2000,

J1850 PWM, J1850 VPW and CAN) are in use by vehicle

manufacturers.The Tool automatically identifies the protocol type and establishes a communication link with the

vehicle’s computer.

7. After approximately 10~60 seconds, the Tool will retrieve and dis-

play any Diagnostic Trouble Codes, Monitor Status and Freeze

Frame Data retrieved from the vehicle’s computer memory.

■ If the Tool fails to link to the vehicle’s

computer a “Linking Failed” message

shows on the Tool’s LCD display.

- Verify the connection at the DLC

and verify the ignition is ON.

- Turn the ignition OFF, wait 5 seconds, then turn back ON to reset

the computer.

- Ensure your vehicle is OBD2 compliant. See Vehicles

Covered on page 20 for vehicle compliance v erification inf ormation.

Page 27

OBD2 & 1 25

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

■ The Tool will automatically re-link to

the vehicle’s computer every 30 seconds to refresh the data being

retrieved. When data is being refreshed, the message “One moment

Auto – link in progress”is shown on the

LCD display. This action repeats as

long as the Tool is communicating

with the vehicle’s computer.

■ The Tool will display a code only if

codes are present in the vehicle’s

computer memory. If no codes are

present, a “No DTC’s are presently

stored in the vehicle’s computer”

message is displayed.

■ The Tool is capable of retrieving and storing up to 32 codes in

memory, for immediate or later viewing.

8. To read the display:

Refer to Display Functions on page 11 for a description

of LCD display elements.

■ A visible icon indicates that the Tool is being powered

through the vehicle’s DLC connector.

■ A visible icon indicates that the Tool is linked to (communi-

cating with) the vehicle’s computer.

■ The I/M Monitor Status icons indicate the type and number of

Monitors the vehicle supports, and provides indications of the

current status of the vehicle’s Monitors .A solid Monitor icon indicates the associated Monitor has run and completed its testing.

A blinking Monitor icon indicates the associated Monitor has

not run and completed its testing.

■ The upper right hand corner of the

display shows the number of the code

currently being displayed, the total

number of codes retrieved, the type

of code (G = Generic; E = Enhanced

or Manufacturer specific), and

whether or not the displayed code

commanded the MIL on. If the code

being displayed is a PENDING code, the PENDING icon is

shown.

■ The Diagnostic Trouble Code (DTC) and related code definition

are shown in the lower section of the LCD display.

Page 28

26 OBD2 & 1

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

In the case of long code definitions, or when viewing

Freeze Frame data, a small arrow is shown in the

upper/lower right-hand corner of the code display area

to indicate the presence of additional information. Use

the

and

buttons, as necessary , to vie w the addi-

tional information.

9. Read and interpret Diagnostic Trouble Codes/system condition

using the LCD display and the green, yellow and red LEDs.

The green, yellow and red LEDs are used (with the LCD

display) as visual aids to make it easier to determine

engine system conditions.

■ Green LED – Indicates that all

engine systems are “OK” and operating normally. All monitors suppor ted

by the vehicle have run and performed their diagnostic testing, and

no trouble codes are present. A zero

will show on the Tool’s LCD display,

and all Monitor icons will be solid.

■ Yellow LED – Indicates one of the

following conditions:

A. A PENDING CODE IS PRESENT – If

the yellow LED is illuminated, it may

indicate a Pending code is present.

Check the Tool’s LCD display for confirmation. A Pending code is confirmed by the presence of a numeric

code and the word PENDING on the

Tool’s LCD display.

B. MONITOR NO T R UN STA TUS – If the

Tool’s LCD display shows a zero

(indicating there are no DTC’s present in the vehicle’s computer memory), but the yellow LED is illuminated,

it may be an indication that some of

the Monitors supported by the vehicle

have not yet run and completed their

diagnostic testing. Check the Tool’s

LCD display for confirmation. All

Monitor icons that are blinking have not yet run and completed

their diagnostic testing; all Monitor icons that are solid have run

and completed their diagnostic testing.

Page 29

OBD2 & 1 27

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

■ Red LED – Indicates there is a prob-

lem with one or more of the vehicle’s

systems.The red LED is also used to

indicate that DTC(s) are present (displayed on the Tool’s screen). In this

case, the Multifunction Indicator

(Check Engine) lamp on the vehicle’s

instrument panel will be illuminated.

■ DTC’s that start with “P0”, “P2” and some “P3” are considered

Generic (Universal).All Generic DTC definitions are the same on

all OBD2 equipped vehicles.The Tool automatically displays the

code definitions for Generic DTC’s.

■

DTC’s that start with “P1” and some

“P3” are Enhanced (Manufacturer specific) codes and their code definitions

vary with each vehicle manufacturer.

When an Enhanced (Manufacturer

specific) DTC is retrieved, the LCD display shows a list of vehicle man ufacturers. Use the UP and DOWN

buttons, as necessary, to highlight the appropriate manufacturer,

then press the ENTER/FF button to display the correct code

definition for your vehicle.

If the manufacturer for your vehicle is not listed, use the

UP and DOWN buttons, as necessary, to select

Other manufacturer and press the ENTER/FF but-

ton for additional DTC information.

If the Manufacturer Specific

definition for the currently displayed code is not av ailab le, an

advisory message shows on

the Tool’s LCD display.

10.If more than one code was retrieved press the DTC SCROLL

button, as necessary, to display additional codes one at a time.

■ Whenever the Scroll function is used to view additional codes,

the Tool’s communication link with the vehicle’s computer disconnects. To re-establish communication, press the LINK

button again.

11.Freeze Frame Data (if available) can be viewed at any time (except

MENU mode) by pressing the ENTER/FF button.

Page 30

28 OBD2 & 1

E

OBD2 Systems

CODE RETRIEVAL PROCEDURE

■ In OBD2 systems, when an emis-

sions-related engine malfunction

occurs that causes a DTC to set, a

record or snapshot of engine conditions at the time that the malfunction

occurred is also saved in the vehicle’s computer memory. The record

saved is called Freeze Frame data.

Saved engine conditions include, but are not limited to: engine

speed, open or closed loop operation, fuel system commands,

coolant temperature, calculated load value, fuel pressure, vehicle speed, air flow rate, and intake manifold pressure.

If more than one malfunction is present that causes more

than one DTC to be set, only the code with the highest priority will contain Freeze Frame data.The code designated

“01” on the Tool display is referred to as the

PRIORITY code, and Freeze Frame data always refers to

this code.The prior ity code is also the one that has commanded the MIL on.

If Freeze Frame data is not

available for the code shown

on the LCD display when the

ENTER/FF button

is

pressed, an advisory message

shows on the LCD display.

Press the DTC SCROLL

button to return to the previous

code display.

Retrieved information can be uploaded to a Personal

Computer (PC) with the use of an optional “PC Link Kit.”

See instructions included with PC-Link program for more

information.

12.Determine engine system(s) condition by viewing the Tool’s LCD

display for any retrieved Diagnostic Trouble Codes, code definitions, Freeze Frame data and inter preting the green, yellow and

red LEDs.

■ If DTC’s were retrieved and you are going to perform the repairs

yourself, proceed by consulting the Vehicle’s Service Repair

Manual for testing instructions, testing procedures, and flow

charts related to retrieved code(s).

■ If you plan to take the v ehicle to a prof essional to ha v e it serviced,

complete the Preliminary Vehicle Diagnosis Worksheet on

page 14 and take it together with the retrieved codes, freez e frame

data and LED information to aid in the troubleshooting procedure.

Page 31

OBD2 & 1 29

E

OBD2 Systems

ERASING DIAGNOSTIC TROUBLE CODES (DTCs)

■ To prolong battery life, the Tool automatically shuts “Off” approx-

imately three minutes after it is disconnected from the vehicle.

The DTCs retrieved, Monitor Status and Freeze Frame data (if

any) will remain in the Tool’s memory, and may be viewed at any

time by turning the unit “On”.If the Tool’s batteries are removed,

or if the Tool is re-linked to a vehicle to retrieve codes/data, any

prior codes/data in its memory are automatically cleared.

ERASING DIAGNOSTIC TROUBLE CODES (DTCs)

When the Tool’s ERASE function is used to erase DTCs

from the vehicle's on-board computer, "Freeze Frame"

data and manufacturer-specific enhanced data are also

erased.

If you plan to take the vehicle to a Service Center for repair, DO NOT

erase the codes from the vehicle's computer. If the codes are erased,

valuable information that might help the technician troubleshoot the

problem will also be erased.

Erase DTCs from the computer's memory as follows:

When DTCs are erased from the vehicle's computer memory, the I/M Readiness Monitor Status program resets the status of all Monitors to a not run "flashing" condition. To set all

of the Monitors to a DONE status, an OBD 2 Drive Cycle

must be performed.Refer to your vehicle's service manual for

information on how to perform an OBD 2 Drive Cycle for the

vehicle under test.

The Tool must be connected to the

vehicle’s DLC to erase the codes

from the computer’s memory. If

you press the ERASE button

when the Tool is not connected to

the vehicle’s DLC, the erase

instruction screen displays.

1. If not connected already, connect the

Tool to the vehicle's DLC, and turn the

ignition "On.” (If the Tool is already connected and linked to the vehicle's computer, proceed directly to step 4. If not,

continue to step 2.)

2. Turn the ignition ON. DO NOT start the

engine. Press and release the

POWER/LINK button to establish

communication with the vehicle's computer.

Page 32

30 OBD2 & 1

E

OBD2 Systems

I/M READINESS TESTING

3. Press and release the ERASE but-

ton. A confirmation message shows on

the LCD display.

- If you are sure you want to proceed

press the ERASE button again to

erase DTCs from the vehicle’s computer.

- If you do not want to continue with the erase process, press the

POWER/LINK button to exit the erase mode.

4. If you chose to erase DTCs, a progress

screen displays while the erase function

is in progress.

■ If the erase was successful, a confir-

mation message shows on the LCD

display. Press the POWER/LINK

button to return to the DTC

screen.

■ If the erase was not successful, an

advisory message shows on the

LCD display. Verify that the Tool is

properly connected to the vehicle’s

DLC and that the ignition is on, then

repeat steps 2 and 3, above.

Erasing DTCs does not fix the problem(s) that caused the

code(s) to be set.If proper repairs to correct the problem that

caused the code(s) to be set are not made, the code(s) will

appear again (and the check engine light will illuminate) as

soon as the vehicle is driven long enough for its Monitors to

complete their testing.

I/M READINESS TESTING

I/M is an Inspection and Maintenance program legislated by the

Government to meet federal clean-air standards.

The program requires that a vehicle be taken periodically to an

Emissions Station for an "Emissions Test" or "Smog Check,” where the

emissions-related components and systems are inspected and tested

for proper operation. Emissions Tests are generally performed once a

year, or once every two years.

On OBD 2 systems, the I/M program is enhanced by requiring vehicles to

meet stricter test standards. One of the tests instituted by the Federal

Government is called I/M 240. On I/M 240, the vehicle under test is driven under different speeds and load conditions on a dynamometer for 240

seconds, while the vehicle's emissions are measured.

Page 33

OBD2 & 1 31

E

OBD2 Systems

I/M READINESS TESTING

Emissions tests vary depending on the geographic or regional area in which the vehicle is registered.If the vehicle is registered in a highly urbanized area, the I/M 240 is probably the

type of test required.If the vehicle is registered in a rural area,

the stricter “dynamometer type” test may not be required.

I/M Readiness Monitors

I/M Readiness shows whether the various emissions-related systems

on the vehicle are operating properly and are ready for Inspection and

Maintenance testing.

State and Federal Gov ernments enacted Regulations, Procedures and

Emission Standards to ensure that all emissions-related components

and systems are continuously or periodically monitored, tested and

diagnosed whenever the vehicle is in operation. It also requires vehicle manufacturers to automatically detect and report any problems or

faults that may increase the v ehicle's emissions to an unacceptable lev el.

The vehicle's emissions control system consists of several components or sub-systems (Oxygen Sensor, Catalytic Conv erter, EGR, Fuel

System, etc.) that aid in reducing vehicle emissions.

To have an efficient Vehicle Emission Control System, all the emissions-related components and systems must work correctly whenever

the vehicle is in operation.

To comply with State and Federal Government regulations, vehicle

manufacturers designed a series of special computer programs called

"Monitors" that are programmed into the vehicle's computer. Each of

these Monitors is specifically designed to run tests and diagnostics on

a specific emissions-related component or system (Oxygen Sensor,

Catalytic Converter, EGR Valve, Fuel System, etc.) to ensure their

proper operation. Currently, there are a maximum of eleven Monitors

available for use.

Each Monitor has a specific function to test and diagnose

only its designated emissions-related component or system.

The names of the Monitors (Oxygen Sensor Monitor, Catalyst

Monitor, EGR Monitor, Misfire Monitor, etc.) describe which

component or system each Monitor is designed to test and

diagnose.

Emissions Inspection and Maintenance (I/M) Readiness

Monitor Status Inf

ormation

I/M Readiness Monitor Status shows which of the vehicle's Monitors

have run and completed their diagnosis and testing, and which ones

have not yet run and completed testing and diagnosis of their designated sections of the vehicle's emissions system.

Page 34

32 OBD2 & 1

E

OBD2 Systems

I/M READINESS TESTING

■ If a Monitor was able to meet all the conditions required to enable it

to perform the self-diagnosis and testing of its assigned engine system, it means the monitor "HAS RUN.”

■ If a Monitor has not yet met all the conditions required for it to per-

form the self-diagnosis and testing of its assigned engine system; it

means the Monitor "HAS NOT RUN.”

The Monitor Run/Not Run status does not show whether

or not a problem exists in a system. Monitor status only

indicates whether a particular Monitor has or has not run

and performed the self-diagnosis and testing of its associated system.

Performing I/M Readiness Quick Check

When a vehicle first comes from the factory, all Monitors indicate a “HAVE RUN” status. This indicates that all Monitors

have run and completed their diagnostic testing.The “HAVE

RUN” status remains in the computer's memor y, unless the

Diagnostic Trouble Codes are erased or the vehicle's computer memory is cleared.

The Tool allows you to retrieve Monitor/System Status Infor-mation to

help you determine if the vehicle is ready for an Emissions Test (Smog

Check).In addition to retrieving Diagnostic Trouble Codes, the Tool also

retrieves Monitor Run/Not Run status.This inf ormation is very important

since different areas of the state/country have different emissions laws

and regulations concerning Monitor Run/Not Run status.

Before an Emissions Test (Smog Check) can be performed, your vehicle must meet certain rules, requirements and procedures legislated

by the Federal and state (country) governments where you live.

1. In most areas, one of the requirements that must be met before a

vehicle is allowed to be Emissions Tested (Smog Checked) is that

the vehicle does not have any Diagnostic Trouble Codes present

(with the exception of PENDING Diagnostic Trouble Codes).

2. In addition to the requirement that no Diagnostic Trouble Codes be

present, some areas also require that all the Monitors that a particular vehicle supports indicate a "Has Run" status condition before

an Emissions Check may be performed.

3. Other areas may only require that some (but not all) Monitors indicate a "Has Run" status before an Emissions Test (Smog Check)

may be performed.

Page 35

OBD2 & 1 33

E

OBD2 Systems

I/M READINESS TESTING

Monitors with a "Has Run" status indicate that all the

required conditions they needed to perform diagnosis

and testing of their assigned engine area (system) have

been met, and all diagnostic testing has completed successfully.

Monitors with a "Has Not Run" status have not yet met

the conditions they need to perform diagnosis and testing of their assigned engine area (system), and have not

been able to perform diagnostic testing on that system.

The green, yellow and red LEDs provide a quic k wa y to help y ou determine if a vehicle is ready for an Emissions Test (Smog Check). Follow

the instructions below to perform the Quick Check.

Perform the Code Retrieval Procedure as described on page 23,

then interpret the LED indications as follows:

Interpreting I/M Readiness Test Results

1. GREEN LED - Indicates that all engine

systems are "OK" and operating normally (all Monitors supported by the

vehicle have run and performed their

self-diagnostic testing). The vehicle is

ready for an Emissions Test (Smog

Check), and there is a good possibility

that it can be certified.

2. YELLOW LED - Determine from the Code Retrieval Procedure

(page 23) which of the two possible conditions is causing the yellow

LED to light.

■ If a "PENDING" Diagnostic Trouble

Code is causing the yellow LED to

light, it is possible that the vehicle will

be allowed to be tested for emissions

and certified. Currently, most areas

(states) will allow an Emissions Test

(Smog Check) to be performed if the

only code in the vehicle's computer is

a "PENDING" Diagnostic Trouble

Code.

■ If the illumination of the Yellow LED is

being caused by monitors that “have

not run” their diagnostic testing, then

the issue of the vehicle being ready

for an Emissions Test (Smog Check)

depends on the emissions regulations and laws of your local area.

Page 36

34 OBD2 & 1

E

OBD2 Systems

I/M READINESS TESTING

- Some areas require that all Monitors indicate a "Has Run" sta-

tus before they allow an Emissions Test (Smog Check) to be

performed. Other areas only require that some, but not all,

Monitors have run their self-diagnostic testing before an

Emissions Test (Smog Check) may be performed.

From the code retrieval procedure, determine the status of

each Monitor (a solid Monitor icon shows Monitor "Has Run"

status, a flashing Monitor icon indicates "Has Not Run" status). Take this information to an emissions professional to

determine (based on your test results) if your vehicle is ready

for an Emissions Test (Smog Check).

3. RED LED - Indicates there is a problem

with one or more of the vehicle's systems. A vehicle displaying a red LED is

definitely not ready for an Emissions

Test (Smog Check). The red LED is also

an indication that there are Diagnostic

Trouble Code(s) present (displayed on

the Tool's screen). The Multifunction

Indicator (Check Engine) Lamp on the

vehicle's instrument panel will light steady. The problem that is

causing the red LED to light must be repaired before an Emissions

Test (Smog Check) can be performed. It is also suggested that the

vehicle be inspected/repaired before driving the vehicle further.

If the Red LED was obtained, there is a definite problem present in

the system(s). In these cases, you have the following options.

■ Repair the vehicle yourself. If you are going to perform the

repairs yourself, proceed by reading the vehicle service manual

and following all its procedures and recommendations.

■ Take the vehicle to a professional to have it serviced.The prob-

lem(s) causing the red LED to light must be repaired before the

vehicle is ready for an Emissions Test (Smog Check).

Using the I/M Readiness Monitor Status to Confirm a Repair

The I/M Readiness Monitor Status function can be used (after repair of

a fault has been performed) to confirm that the repair has been performed correctly, and/or to check for Monitor Run Status. Use the following procedure to determine I/M Readiness Monitor Status:

1. Using retrieved Diagnostic Trouble Codes (DTCs) and code definitions as a guide, and following manufacturer's repair procedures,

repair the fault or faults as instructed.

2. After the fault or faults have been repaired, connect the Tool to the

vehicle's DLC and erase the code or codes from the vehicle's computer memory.

Page 37

OBD2 & 1 35

E

OBD2 Systems

I/M READINESS TESTING

■ See page 29 for procedures to erase DTCs from the v ehicle's on-

board computer.

■ Write the codes down on a piece of paper for reference before

erasing.

3. After the erase procedure is performed, most of the Monitor icons

on the Tool’s LCD display will be flashing.Leave the Tool connected

to the vehicle, and perform a Trip Drive Cycle for each "flashing"

Monitor:

Misfire, Fuel and Comprehensive Component Monitors run

continuously and their icons will always be on solid, even

after the erase function is performed.

■ Each DTC is associated with a specific Monitor.Consult the vehi-

cle's service manual to identify the Monitor (or Monitors) associated with the faults that were repaired.Follow the manufacturer's

procedures to perform a Trip Drive Cycle for the appropriate

Monitors.

■ While observing the Monitor icons on the Tool’s LCD display, per-

form a Trip Drive Cycle for the appropriate Monitor or Monitors.

WARNING: If the vehicle needs to be driven in order to perform a

Trip Drive Cycle, ALWAYS have a second person help you. One

person should drive the vehicle while the other person observes

the Monitor icons on the Tool for Monitor RUN status. Trying to

drive and observe the Tool at the same time is dangerous, and

could cause a serious traffic accident.

4. When a Monitor's Trip Drive Cycle is performed properly, the

Monitor icon on the Tool’s LCD display changes from "flashing" to

"solid,” indicating that the Monitor has run and finished its diagnostic testing.

■ If, after the Monitor has run, the MIL on the vehicle's dash is not

lit, and no stored or pending codes associated with that particular Monitor are present in the vehicle's computer, the repair was

successful.

■ If, after the Monitor has run, the MIL on the vehicle's dash lights

and/or a DTC associated with that Monitor is present in the vehicle's computer, the repair was unsuccessful. Refer to the vehicle's service manual and recheck repair procedures.

Page 38

36 OBD2 & 1

E

Chrysler/Jeep OBD1 Systems

CHRYSLER/JEEP OBD1 SYSTEMS

CHRYSLER/JEEP OBD1 SYSTEMS

Chrysler Motors On-Board Computer Systems

Chrysler Motors introduced its first electronic fuel injected vehicle in

late 1983. The on-board computer management systems used on

Chrysler vehicles have evolved over the years, and their names have

changed accordingly.

1983-87: The on-board computer used in these vehicles is a splitsystem, composed of two separate units: the Logic Module and the

Power Module. The Logic Module contains a microprocessor which

processes data received from sensors located throughout the vehicle

and makes decisions (based on these inputs) which effect engine

operation.The Logic Module is usually located on the right-hand side,

behind the kick panel.The Power Module supplies operating power to

the Logic Module, and contains the circuits which control the highcurrent devices. Power Module operation is controlled by the Logic

Module.The P ower Module is located in the engine compartment, near

the vehicle’s battery.

1987-90: This system is called a Single Module Engine Controller

(SMEC). This system still uses two separate circuit boards (Logic

Module and Power Module).However, both circuit boards are located

in a common enclosure.

1989-95: This system is called a Single Board Engine Controller

(SBEC). On this system, the Logic Module and Power Module circuit

boards are integrated on a single circuit board.

1993-97: Beginning in 1993, the computer was renamed the

Powertrain Control Module (PCM).In addition to controlling the engine

management system and emission system, the computer also takes an

active role in controlling powertrain (transmission system) operation.

Unless otherwise specified, all references to “computer”within

this manual also apply to “Logic Module/ Power Module”,

“SMEC”, “SBEC” or “PCM”.

Jeep On-Board Computer Systems

1993-95: In 1993, Jeep on-board computer systems (fuel injected

vehicles only) were converted to the Chrysler on-board computer systems. All 1993 through 1995 fuel injected Jeep and Chrysler vehicles

are equipped with similar on-board computer systems.

Page 39

OBD2 & 1 37

E

Chrysler/Jeep OBD1 Systems

VEHICLES COVERED / PANEL INDICATOR LIGHTS / DLC

VEHICLES COVERED

This section covers Chrysler fuel injected vehicles from 1983-1995.

INSTRUMENT PANEL INDICATOR LIGHTS

Your vehicle’s instrument panel has either a “Power Loss”, “Check

Engine” or “Malfunction Indicator Lamp”, depending on the year of the

vehicle.These lights are designed to warn you of component malfunctions.

If your instrument panel indicator lights do not come on when

you turn on the ignition, please refer to your vehicle’s service

manual.You may hav e prob lems in the car’s circuitry. It is recommended that you fix these problems before retrieving

DTC’s from your vehicle’s computer.

DATA LINK CONNECTOR (DLC)

Chrysler vehicles are equipped with special test connectors that make it possible to

connect specialized testing equipment that

communicates with the vehicle’s on-board

computer. Chrysler’s vehicle test connectors are usually dark in color (BLACK or

GREY) and are located under the hood.

Model

Type Year Model

Passenger 1983-1995 Chrysler, Dodge and Plymouth Fuel

Cars Injected Models Only (Excluding

Lasor/Talon 1.8L, 2.0L (ALL YEARS),

1990 Monaco/Premier)

Light Truck 1987-1995 Chrysler, Dodge and Plymouth Fuel

and Vans Injected Models Only

1992-1995 Diesel Models

Jeep 1993-1995 Jeep Fuel Injected Models Only

POWER

LOSS

CHECK

ENGINE

MALFUNCTION

INDICATOR

LAMP

Page 40

38 OBD2 & 1

E

Chrysler/Jeep OBD1 Systems

CODE RETRIEVAL PROCEDURE

CODE RETRIEVAL PROCEDURE

Never replace a part based only on the DTC definition.

Each DTC has a set of testing procedures, instructions and

flow charts that must be followed to confirm the location of

the problem.This information is found in the vehicle’s service

manual. Always refer to the vehicle’s service manual for

detailed testing instructions.

Check your vehicle thoroughly before performing any test.

See Before Y ou Begin on page 17 for details.

ALWAYS observe safety precautions whenever working on a

vehicle.See Safety Precautions on page 3 for more information.

1. Locate the vehicle’s Data Link Connector (DLC). See Data Link

Connector (DLC) on page 37 for connector location.

Some DLCs have a plastic cover that must be removed

before connecting the Tool’s cable connector.

2. Connect the Tool cable (with the

Chrysler Connector Cable Adaptor

attached) to the Tool, then connect the

adaptor to the vehicle’s DLC. Press the

POWER/LINK button to turn the

Tool ON.

■ Set the parking brake, and make sure

all vehicle accessories are turned off.

3. Turn the ignition ON. DO NOT start the

engine. Press the ENTER/FF but-

ton to continue.

4. Select the model year of the vehicle

from which you wish to retrieve codes:

If a previous vehicle selection is currently saved in the Tool's

memory, the "Current Selection/Select New Vehicle" menu

displays.If no previous vehicle selection is stored in the Tool's

memory, "Select New Vehicle" displays.Use the and

buttons, as necessary, to make your selection.

Retrieving and using Diagnostic Trouble Codes (DTCs) for

troubleshooting vehicle operation is only one part

of an overall diagnostic strategy.

Page 41

OBD2 & 1 39

E

Chrysler/Jeep OBD1 Systems

CODE RETRIEVAL PROCEDURE

■ To retrieve DTCs from the vehicle selection currently in the Tool’s

memory:

- From the “Current Selection/

Select New Vehicle” screen, highlight Current Selectionand press

the ENTER/FF button.

- Proceed to step 5 to continue.

■ To retrieve DTCs from a new vehicle:

- From the “Current Selection/

Select New Vehicle” screen, highlight Select New Vehicle and

press the ENTER/FF button;

the “Select V ehicle Year” menu displays.

- Highlight the desired year, then press the ENTER/FF

button. The “Current Selection/Select New Vehicle” screen

displays for your confirmation.

FCC - means 1994 Four Cylinder Control Module for

the 1994 Chrysler vehicles.

- If the year shown in the “Current Selection” field is correct,

highlight Current Selection and press the ENTER/FF

button. Proceed to step 5 to continue.

If the year shown is not correct, highlight Select New

Vehicle and press the ENTER/FF buttonto return

to the “Select Vehicle Year” menu to make your corrections.

5. Prepare the vehicle to retrieve codes:

■ For 1988-1995 Chrysler/Jeep vehicles: The Tool will automati-

cally begin the code retrieval process.Proceed to step 6 to continue.

■ For 1984-1988 Chrysler vehicles ONLY:WITHOUT starting the

engine, turn ignition ON, OFF, ON, OFF and ON again within 5

seconds to activate the code retrieval process. Proceed to step

6 to continue.

6. When the Tool is in the process of

retrieving codes, a “One Moment

Please...” message shows on the Tool’s

LCD display.

Page 42

40 OBD2 & 1

E

Chrysler/Jeep OBD1 Systems

CODE RETRIEVAL PROCEDURE

■ If the Tool fails to link to the vehicle’s

computer, a “Vehicle is not responding” message shows on the Tool’s

LCD display. Do the following:

- Verify the ignition is ON.

- Check the cable connections at

the Tool and at the vehicle’s DLC.