Equator 375 User Manual

SERVICE MANUAL

(TROUBLE SHOOTING AND REPAIRING TIPS)

Fourth Edition – February 2006

CONSERV REFRIGERATOR

MODELS

375 / 1200 SERIES ( OLD & NEW)

WARRANTY INFORMATION

Your Equator appliance is protected by this warranty under normal,

personal, family or household use (1 Year), and limited commercial use

(90 days) in the USA and Canada.

WARRANTY

Equator Corporation undertakes to the consumer-owner

to repair or, at Equator Corporation’s option, to replace

any part of this product which proves to be defective in

workmanship or material under normal personal, family

or household use, in the USA and Canada, for a period of

one year from the date of original purchase.

For commercial use, the product is warranteed for a

period of 90 days.

During this period, Equator Corporation will provide all

labor and parts necessary to correct such defect, free of

charge, if the appliance has been installed and operated

in accordance with Equator Corporation’s written

instructions with the appliance. Ready access to the

appliance, for service, is the responsibility of the

consumer-owner.

EXCLUSIONS

In no event shall Equator Corporation be liable for

incidental or consequential damages or for damages

resulting from external causes such as abuse, misuse,

incorrect voltage or acts God.

This warranty does not cover service calls which do not

involve defective workmanship or materials covered by

this warranty. Accordingly, diagnosis and repair costs

for a service call which does not involve defective

workmanship or materials will be the responsibility of the

consumer-owner.

Specifically, the following work is not covered under

warranty and does not constitute warranty work:

.

Installation - improper hook-up or leveling

.

Maintenance - cleaning of air and/or water filter

.

Damage - replacing broken door handle

WARRANTYSERVICE

This warranty is given by:

Equator Corporation,

Equator Plaza,

2801 W. Sam Houston Pkwy.N.,

Houston, TX 77043-1611.

Service under this warranty must be obtained by the

following steps, in order:

Call an Equator Corporation Authorized Service Agent

(obtain number of nearest agent from your dealer or by

calling Equator Service at

1-800-776-3538). Under normal circumstances,

Service will be provided during regular business hours

(9:00 a.m. to 5:00 p.m. weekdays).

GENERAL

Since it is responsibility of the consumer-owner to

establish the warranty period by verifying the original

purchase date, Equator Corporation recommends that

a receipt, delivery slip or some other appropriate

payment record be kept for that purpose.

Remember to send in your Warranty Registration Card

so that a proof of your purchase exists with Equator.

This warranty gives you specific legal rights, and

you may also have other rights which vary from State to

State.

Corporate Office

EQUATOR CORPORATION

Equator Plaza

2801 W. Sam Houston Pkwy. N.

Houston, TX 77043-1611

Tel: 713-464-3422 - Fax: 713-464-2151

Tel: 800-935-1955

Most work is covered. The defining factor is, has the

machine malfunctioned (Equator is responsible) or has

the customer omitted or done something to cause

machine to malfunction (customer is responsible).

Some States do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

1.

2.

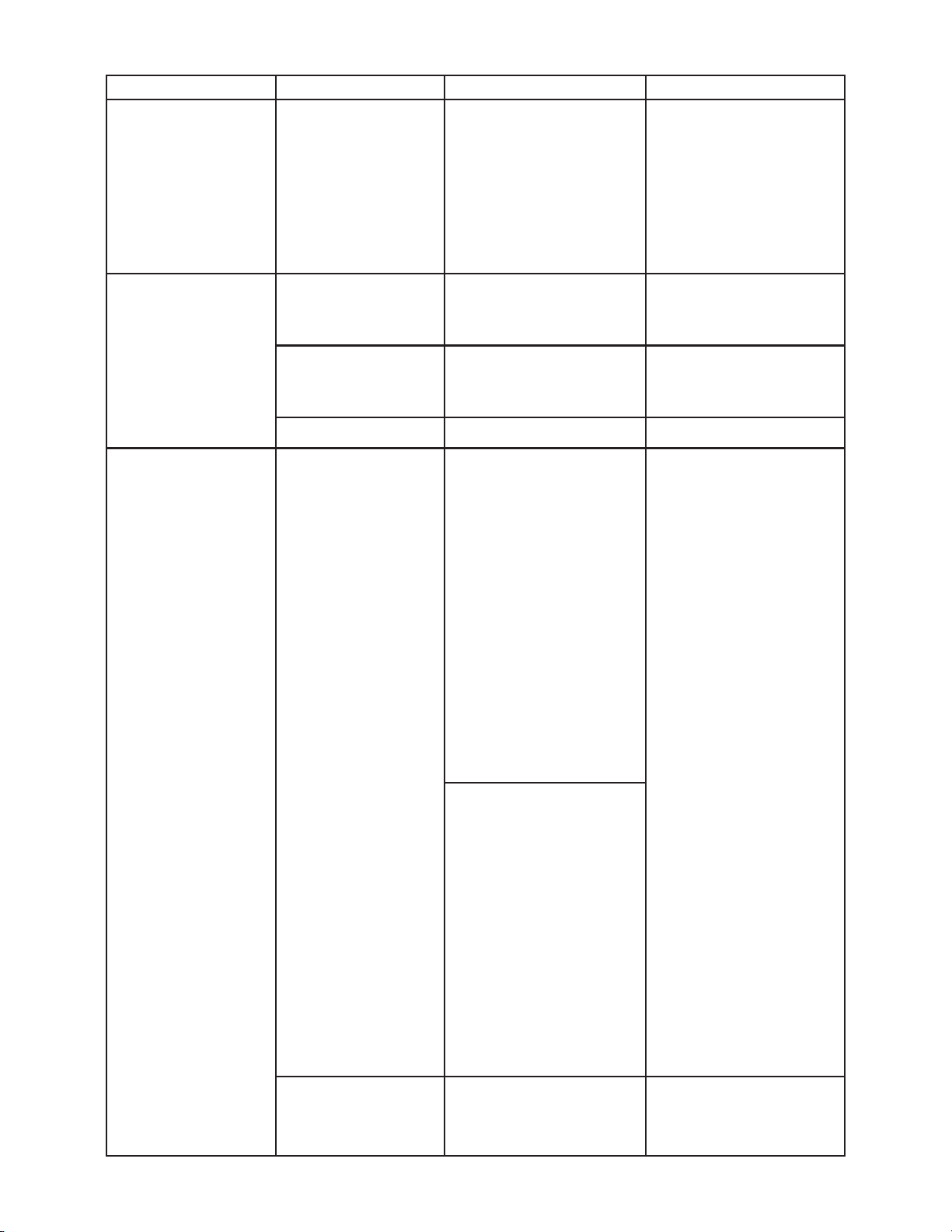

1.1 Trouble-Shooting Chart

Disturbance Cause Trouble-Shooting Remedy

Unit does not

refrigerate or freeze,

compressor does not

operate.

Wall socket is dead. Check installation. Install new fuse if

necessary. Inform user.

Mains cable is

defective.

See section 1.2: Troubleshooting in the electrical

circuit.

Repair or replace socket

or mains cable.

Thermostat is

defective.

Defective winding in

compressor.

Starting device is

defective.

Wiring for starting

device is incorrectly

installed.

No-Frost Timer is set in

defrosting position.

Unit does not

refrigerate or freeze,

compressor tries to

start but fails to

operate.

Insufficient mains

voltage.

Wrong or defective

starting device.

Wiring for starting

device is incorrectly

installed.

Replace thermostat.

See section 1.6: Troubleshooting for Electrical

Faults in the Compressor.

See section 1.2: trouble

shooting in the Electric

circuit.

Check mains voltage. Inform user that

See section 1.2:

Troubleshooting in the

Electric Circuit.

Replace compressor.

Replace starting device.

Correct in accordance

with wiring diagram in

the spare parts list.

Turn timer knob past

defrosting.

installation should be

repaired by an electrician.

Install new starting

device.

Correct according to

wiring diagram in the

spare parts list.

To be continued on

the next page

Winding fault in

compressor.

Condensing pressure

too high (obstruction

capillary tube).

See section 1.5:

Troubleshooting for

Electrical Faults in the

compressor.

Open system and location

obstruction by blowing

N2 through system. See

Section 2.1: Opening the

Refrigerating System with

R600a for Repairs.

Replace compressor.

Remove filter drier and

cut 5 cm of the capillary

tube. Blow through the

system thoroughly before

installing new filter.

3.

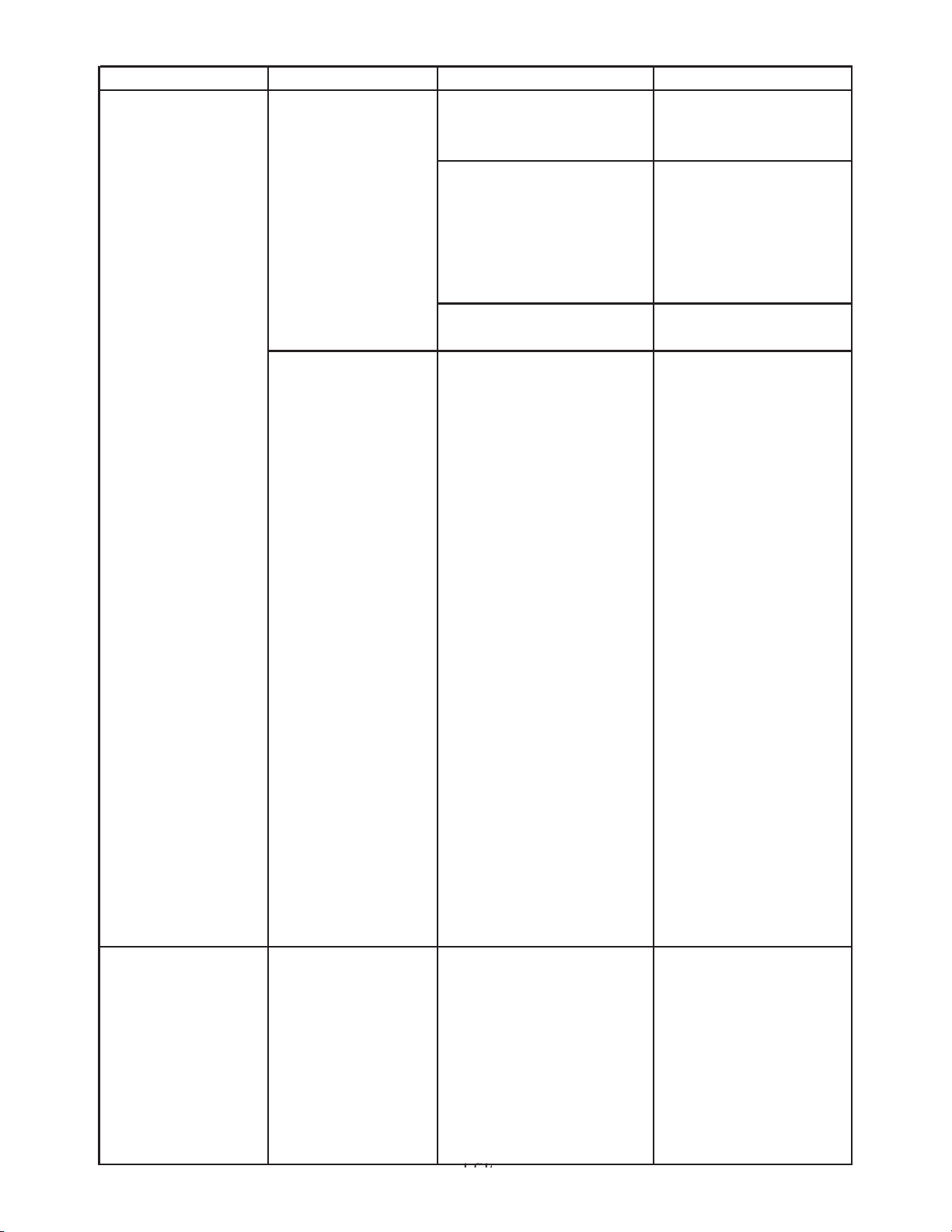

Dis turbance Caus e Trouble -Shooting Re me dy

Oil present in system

after horizontal

transport.

Locked rotor (fault in

compressor).

Ambient temperature

very low. O il in

compressor too cold,

possibly in connection

with undervoltage.

Question user about mode

of transportation and time

interval between

ins ta llatio n a nd s ta rt- up .

Check that compressor

hums and picks up to tal

starting current. Open

system and blow N2

through system.

Measure ambient

temperature. Measure

voltage.

Let unit stand for several

hours at warm

temperature and try to

start again. Ifcompressor

does not start, open the

system and blow through

with N2.

If system (filter) is not

blocked, replace

compressor.

Find a better location for

unit. C ondenser can be

insulated if necessary, but

DON’T FORGET to

remove again if ambient

temperature increases.

Compressor tries to

start but does not

always succeed on

firs t a tte mpt.

Refrigerate and/or

freeze normally.

Compressor tries to

start but does not

succeed on first

attempt.

Compressor runs

co ntinuously. Unit

refrigerates/freezes

normally or to o much.

To be continued on

the next page.

Canbe normal.

Ventilation is perhaps

ins uffic ient.

S ta nd st ill time for

compressor is too

short.

Thermostat phial is

incorrectly installed.

Ice formation around

thermostat phial.

Thermostat set too

lo w.

Ice formation in phial

tube.

Measure the temperature

of compressor housing

(max. 110°C) and filter

(max. 70°C).

Check for snug fit of

doors. Time standstill

period for compressor.

Check location of phial. Correct the fault. Cutout

Check for snug fit of

doors

Turn thermostat knob

counter-clockwise.

Find a better location for

the unit.arrange ways for

a better ventistat.

If standstill time is too

short, replace thermostat.

temperature can be raised

by giving the phial a

greater surface contact

with the evaporator.

Inform user to defrost

unit.

If compressor stops,

inform user about function

of thermostat.

Defrost unit. Remo ve

thermostat phial, dry

thoro ughly and replace.

Repeat until the phial is

dry. Seal with putty.

4.

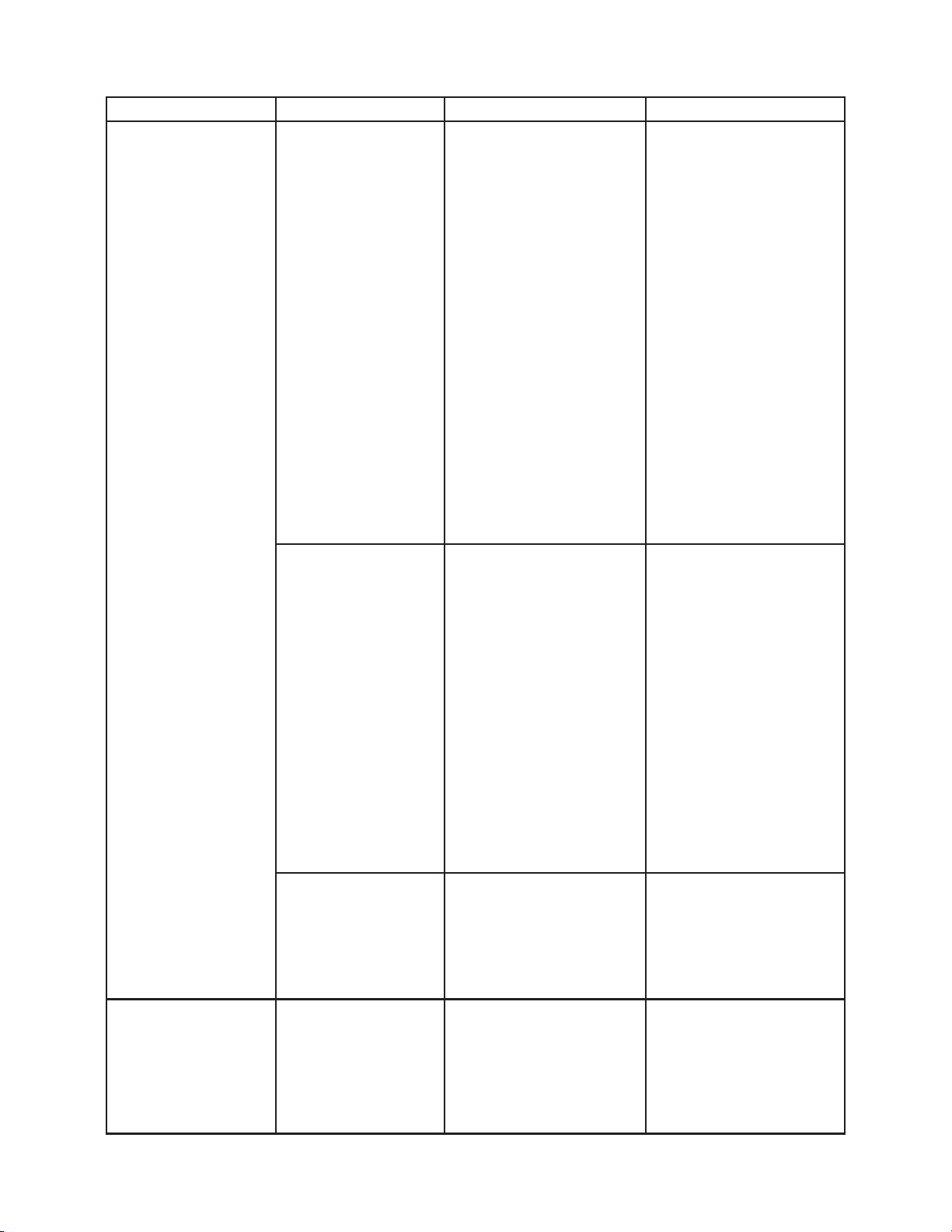

Disturbance Cause Troubleshooting Remedy

Defective thermostat. 1.Turn thermostat knob to

zero. 2.Compressor

continues to run.

Compressor starts

normally but stops

Extremely high

voltage.

3.Dismount brown wire.

4.Compressor continues

to run. 5.Compressor

stops.

Measure voltage. Inform user.

4.Check internal wiring

for short circuit (fastfreeze switch). 5.Replace

thermostat.

again.

Unit

refrigerates/freezes

too much, normally,

too little or not at all.

Compressor may run

continuously.

High ambient

temperature. Poor

ventilation.

Can be normal. Check temperature in

Leakage in system

with resulting loss of

refrigerant.

Measure temperature and

check ventilation around

compressor.

unit.

Symptom: Evaporator not

wholly utilized. Localize

leak with electronic leak

detector-first at soldering

joints, pipes and

compressor in motor

Improve ventilation.

Inform user.

After repairing leakage,

repair system as in the

case of ice blockage in

capillary tube. See

relevant section in chart.

compartment. Next in the

evaporator and condenser.

When leak is localized,

cover area with a layer of

Leak-Tec or liquid soap.

Bubbles will appear at the

exact site of leakage.

Check pressure side with

compressor running and

suction side when

pressure ise equalized. If

refrigerant pressure is

insufficient for leak

detection, install a service

valve on charging pipe

and refrigerant and N

(approximately

10kg/cm

). Repeat leak

2

detection.

No-Frost Fan is not operating. Electric connections.

Check and see if blade is

fixed properly on shaft.

2

Blade is fixed or

replaced.

5.

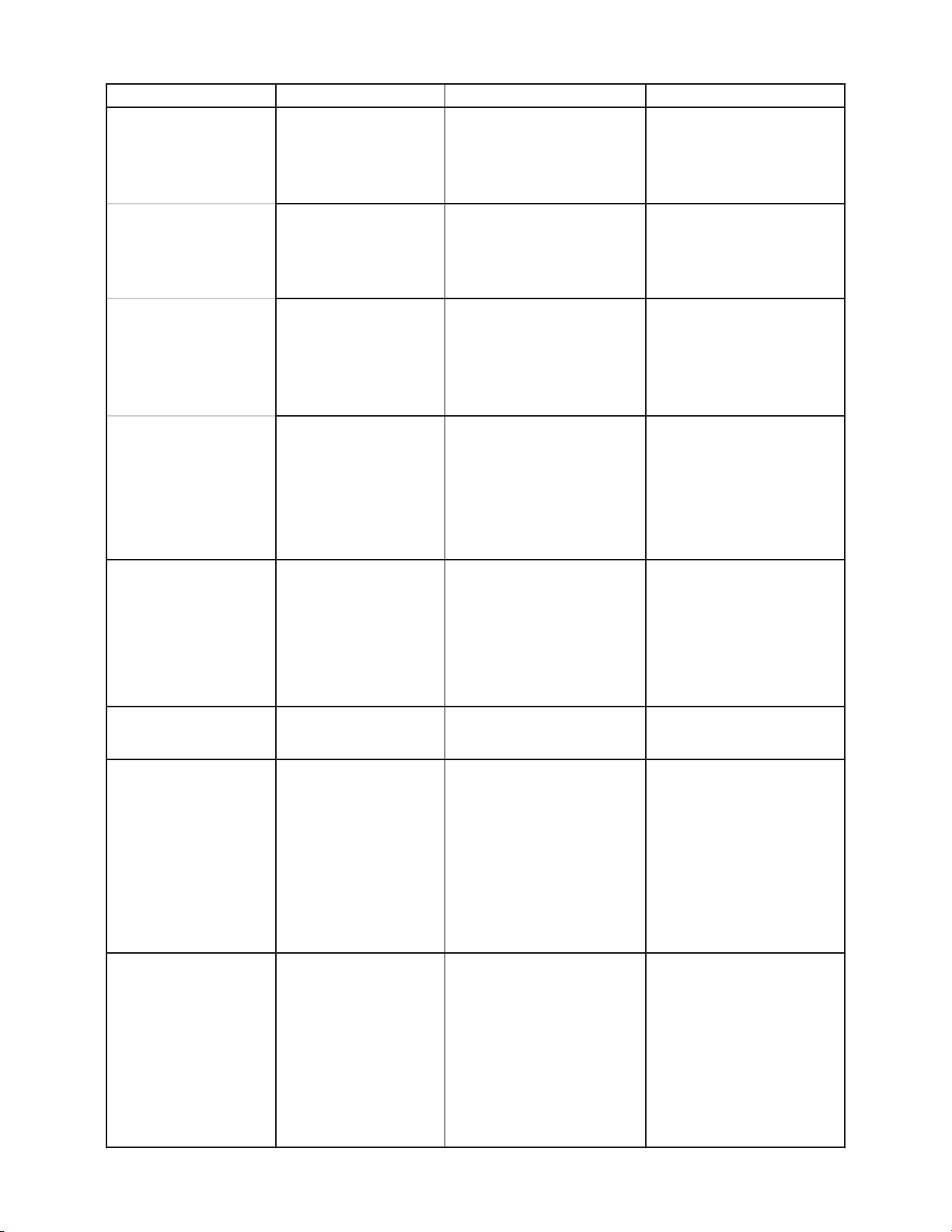

Ditrubance Cause Trouble-shooting Remedy

No-Frost

No-Frost

No-Frost Evaporator blocked

by ice.

Check if blade is locked

mechanically.

Check if blade is fixed

correctly on shaft.

Check id timer is set in

defrosting position.

Check for snug fit of doors,

cable or tube wall ducts.

Check if timer is under

tension when set at

defrosting (remember that

timer is only under is under

tension when freezer

thermostat is cut in). Check

bimetallic thermostat and

thermal fuse. Bimetallic

thermostat can only be

checked when the

evaporator is cold (colder

than 5°C). Check if heating

element is under tension.

Furthermore, when the

doors have been open for a

long time, the evaporator

may be blocked by ice.Even

though the compressor runs

continuously, up to 10

hours will be elapsed before

the next defrosting takes

place. There will be no

cooling in this period.

Fittings for fan or air

guiding duct are adjusted

or replaced.

Blade must turn so that

air flow only can be

sucked in and blown out

in the right places. Blade

must cover 10mm of

shaft end, on two-step fan

14mm.

Turn timer forward.

Repair leakage. Check

electric connections and

contact unit of timer.

Refrigerates/freezes

too little or not at all.

Compressor runs

continuously.

Capillary tube

completely or

partially blocked

(material from filter

in capillary tube

opening). Capillary

tube is inserted so far

up in the filter that it

touches the filter net.

Mount valve on charging

pipe. Measure suction

pressure. Check pressure

equalizing time. Cut

capillary tube

approximately 5cm after

filter. Blow N2 through

charging pipe and check

flow through capillary tube

See section 4.1 and 4.1.1

6.

Disturbance Cause Trouble-shooting Remedy

Ice blockage in

capillary tube.

Heat injection area on

evaporator with cloth

with hot water. If

refrigerant now can be

heardtoflowmore

quickly through the

system, ice blockage in

capillary tube is indicated.

Alternatively, stop

compressor and let

evaporator defrost and

start compressor again. In

case of ice blockage, frost

formation on the

evaporator will increase

initially and then return to

its original level.

Blow N2 through system.

Install outsize service

filter. Ensure careful

evacuation. Start

compressor. Stop when

warm. Evacuate system

again. With heavy

contamination of system

it is necessary to repeat

this process several

times. Filter can be

replaced again.

No or very little

compressor capacity.

Capillary tube

mounted incorrectly

at injection site (rollbond evaporator).

Mount a service valve on

charging pipe and check

suction pressure. Pressure

conditions indicate no or

very little compressor

capacity. Test

compressor.

Symptoms resemble those

of loss of refrigerant.

If volumetric check

indicates insufficient

compressor capacity,

replace compressor. Note

that defects in the

compressor can be caused

by complete or partial

blockage at another point

in the system. This

situation must be

remedied before a new

compressor is installed.

Replace refrigerating

evaporator.

Insufficient

refrigerating/freezing.

Thermostat is set too

high.

Turn thermostat knob

clockwise. Check to

ensure that phial is

correctly installed.

Replace thermostat.

7.

Dis turbance Caus e Trouble -shooting Re me dy

Compressor runs

co ntinuously.

Unit has recently been

fille d wit h la rge

quantities of food.

Built-in thermometer

is defective. User’s

thermometer is

defective.

Ambient temperature

is b elo w 0 °C .

refrigerant has

collected in the

condenser.

Ambient temperature

is to o high, p os sib ly

because unit is too

close to a heat

source, o r ventilation

is ins uffic ient.

Doors do not fit

snugly.

Question user about use

of unit immediately prior

to s ervic e c all.

Check for correct

thermometer readings.

Symptoms resemble those

of partially blocked

ca pilla ry tub e. Re co rd

ambient temperature.

Compare exact

temperature with user’s

observations. Check air

circulation.

Insert paper between

door and frame and

closed door. If paper can

be pulled out without

resistance, the door does

not fit tightly enough.

Inform user about the

problems caused by this.

Instruct user about use of

fast-freeze switch.

Replace built-in

thermometer if necessary.

Findamoresuitable

lo ca tio n fo r the unit, w ith

higher ambient

temperature.

Arrange for better

lo ca tio n o f unit a nd /o r

better ventilation.

Fold double-sided tape to

suita ble thic kne ss a nd

press in between gasket

and door. Pull gently in

gasket at relevant area.

Rapid ice formation

on freezer shelves.

Insufficie nt

refrigeration.

Automatic defrosting

does not function.

Possibly due to ice

forma tio n on

evaporator.

As above. As above. As above.

User wishes to lower

temperature in unit.

The cut-in

temperature of the

thermostat is too low.

The thermostat phial

has insufficient surface

contact with the

evaporator.

Measure the exact

temperature.

Measure temperature at

phial. Temperature here

must not be lower than the

cut-out temperature. See

Section 2.

The cut-o ut temperature

ca n b e lo we re d by giving

the thermostat phial a

reduced surface contact

with the aluminum

evaporator (refer to

automatic defrosting

section).

Increase the cut-in

temperature of the

thermostat b y giving the

phial a greater surface

contact with the

evaporator. If this does

not help, replace the

thermostat.

8.

Loading...

Loading...