Equalizer TFA12TI, TFA15TI, TFA12TIRD37H, TFA15TIRD37H Operator's Instruction Manual

OPERATOR INSTRUCTION MANUAL

TFA12TI

TFA15TI

TFA12TIRD37H

TFA15TIRD37H

EQUALIZER INTERNATIONAL LTD

www.equalizerinternational.com

INTEGRAL

HYDRAULIC

FLANGE

ALIGNMENT

TOOLS

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

2

CONTENTS

1. INTRODUCTION

2. TOOL SAFETY

2.1 GENERAL SAFETY

2.2 PERSONNEL COMPETENCY

2.3 DISCLAIMER

2.4 DEFINITION OF TERMS

2.5 HAZARDS

3. TOOL OPERATION

3.1 GENERAL GUIDANCE

3.2 HANDLING

3.3 TOOL INSTALLATION

3.4 ADJUSTMENT LEG

3.5 WING EXTENSION

3.6 CYLINDER ADJUSTMENT SLEEVE

3.7 TOOL CHECKS

3.8 ALIGNMENT

3.9 SECURING THE FLANGE JOINT

4. TOOL MAINTENANCE

4.1 INSPECTION

4.2 CLEANING

4.3 SERVICING

4.4 LUBRICATION PROCEDURE

4.5 STORAGE & TRANSPORTATION

4.6 OPERATING CONDITIONS

4.7 SUB-SEA USAGE

5.

5.1 TOOL CAPABILITIES

5.2 TOOL FUNCTION

5.3 KIT CONTENTS

5.4 DIMENSIONS

6. TROUBLESHOOTING

7. REGULATORY INFORMATION

7.1 REGISTERED HEAD OFFICE

7.2 APPLICABLE PATENT NUMBERS

8. PARTS LISTS & SERVICE KITS

15/06/17

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

3

2.

TOOL SAFETY

2.1

GENERAL SAFETY

These instructions cover the safe operation and

maintenance of THE EQUALIZER RANGE OF TFA

INTEGRAL HYDRAULIC FLANGE ALIGNMENT tools.

The use of any tools should be as part of a broader taskbased risk assessment, which should be carried out by the

operation supervisor or other competent person.

Failure to comply with the safety information contained

within this manual could result in personal injury or

equipment damage. Read all instructions, warnings and

cautions carefully, and follow all safety precautions.

The safety of the operator, any assisting personnel and

the general public is of paramount importance. Always

work in accordance with applicable national, local, site &

company-wide safety procedures.

2.2

PERSONNEL COMPETENCY

Only personnel deemed competent in the use of mechanical

and hydraulic equipment should use these tools.

2.3

DISCLAIMER

Equalizer cannot be held responsible for injury or damage

resulting from unsafe product use, lack of maintenance

or incorrect product and/or system operation. If in doubt

as to the safety precautions and applications, contact

Equalizer using the contact details at the back of this

manual.

1.

INTRODUCTION

The Equalizer™ range of TFA integral hydraulic ange

alignment tools have been developed to assist in the

aligning of large anges on the inside of large pipes, for

example those which make up the tower sections of a

wind-turbine.

The tools have been designed to cope with the larger

loads and dimensions associated with these ange joints

while remaining relatively lightweight and user-friendly.

It is essential that the users familiarise themselves with

the contents of this manual prior to using the tool.

This manual contains information for the following tools:

• TFA12TI

Integral Hydraulic Flange Alignment Tool

• TFA15TI

Integral Hydraulic Flange Alignment Tool

• TFA12TIRD37H

Integral Hydraulic Flange Alignment Tool

• TFA15TIRD37H

Integral Hydraulic Flange Alignment Tool

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

4

internal damage to hose wire strands. Protect

hoses from crush risks, such as heavy objects

or vehicles; crush damage can cause hose

failure.

WARNING: Applying pressure to a damaged

hose may cause it to rupture.

WARNING: Immediately replace worn or

damaged parts. Use only genuine Equalizer

parts from approved distributors or service

centres. Equalizer parts have been engineered

and manufactured to be t-for-purpose.

DANGER: To minimise risk of personal injury

keep hands and feet away from the tool and

workpiece during operation.

WARNING: Always wear suitable clothing and

Personal Protective Equipment (PPE). Do not

handle pressurised hoses; escaping oil under

pressure can penetrate the skin, causing serious

injury. Seek medical attention immediately if oil

penetration is suspected.

WARNING: Only pressurize complete and fully

connected hydraulic systems. Do not pressurize

systems that containt unconnected couplers.

CAUTION: Do not lift hydraulic equipment by

the hoses or couplers. Use only the designated

carrying handles.

CAUTION: Lubricate tools as directed in this

manual prior to operation. Use only approved

lubricants of high quality, following the lubricant

manufacturers instructions.

2.4

DEFINITION OF TERMS

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage

to, or destruction of equipment or other property.

A WARNING indicates a potential danger that requires

correct procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

DO: an illustration showing how the tool should

be used.

DON’T: an illustration showing an incorrect way

to use a tool.

2.5

HAZARDS

WARNING: ensure all hydraulic components are

rated to a safe working pressure of 700 bar

(10 000 psi).

WARNING: Do not overload equipment. The

risk of hydraulic overloading can be minimised

by using the Equalizer Hand Pump, which has a

factory-set safety valve preventing the safe

working pressure being exceeded.

If alternative hydraulic pumps are used, ensure

that there are adequate systems to limit the

the working pressure to 700 bar (10 000 psi).

CAUTION: ensure components are protected

from external sources of damage, such as

excessive heat, ame, moving machine parts,

sharp edges and corrosive chemicals.

CAUTION: Take care to avoid sharp

bends and kinks in hydraulic hoses.

Bends and kinks can cause severe

back-up pressure and cause hose

failure. Protect hoses from dropped

objects; a sharp impact may cause

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

5

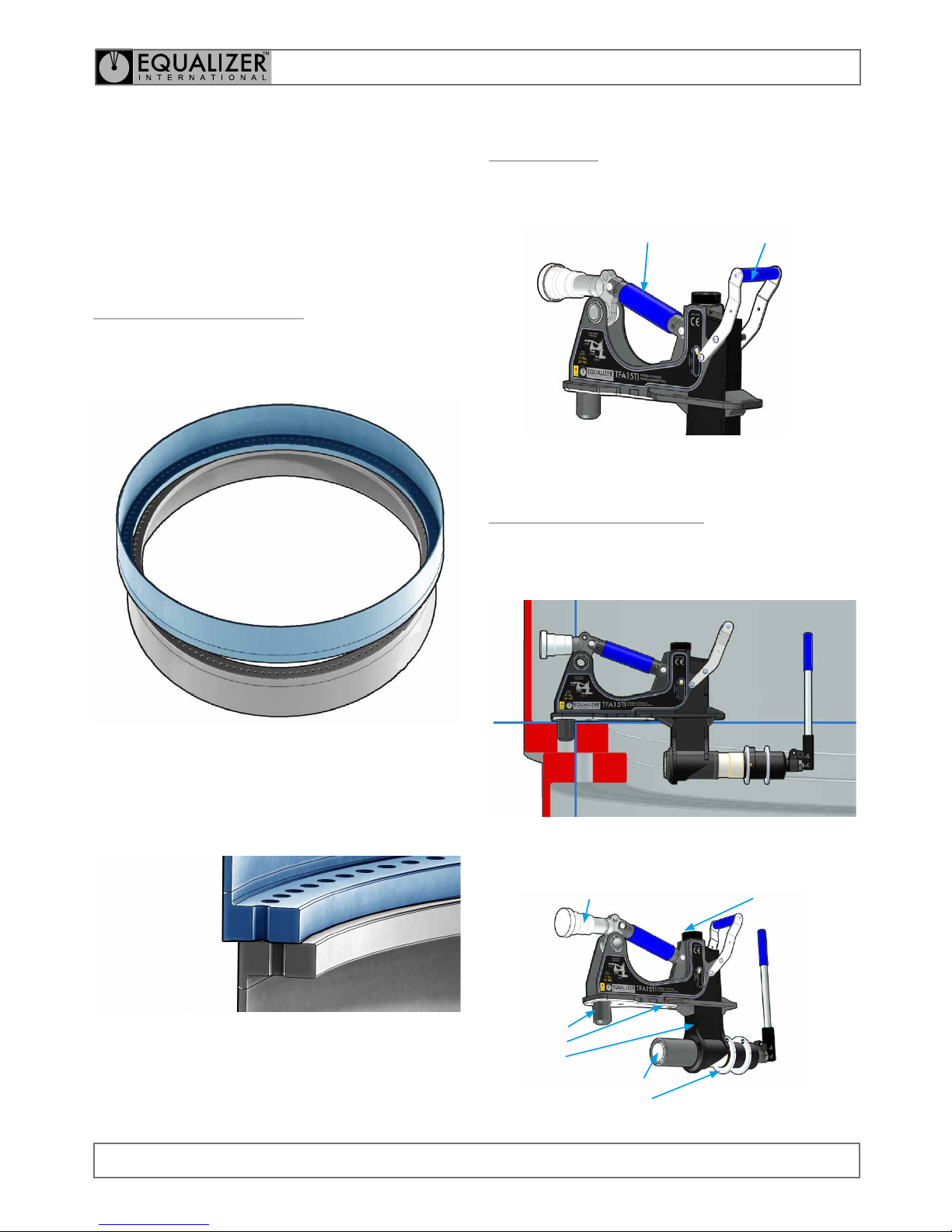

3.2

HANDLING

The tool should be lifted and manouvered using its two

handles.

BACK HANDLE

FRONT HANDLE

3.3

TOOL INSTALLATION

Position the tool into the bolt-hole ensuring that the hook

is fully located into the bolt-hole and the base plate of the

tool is sitting at against the upper ange.

HOOK

BASE PLATE

WING

WING

ADJUSTMENT

ADJUSTMENT LEG

CYLINDER ADJUSTMENT

ALIGNMENT PISTON

3.

TOOL OPERATION

3.1

GENERAL GUIDANCE

Prior to alignment, an assessment should be carried out

to determine the most appropriate positioning of the tool

on the ange joint.

The TFA ange alignment tool should always be installed

in such a way that the lower ange is closer to the user

and the upper ange is further away. The tool is designed

to hook into the bolt-hole of the upper ange and push

the lower ange into alignment.

Prior to installation, ensure the Adjustment Leg and

Cylinder Adjustment Sleeve are fully retracted. Ensure

that the Alignment piston is fully retracted.

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

6

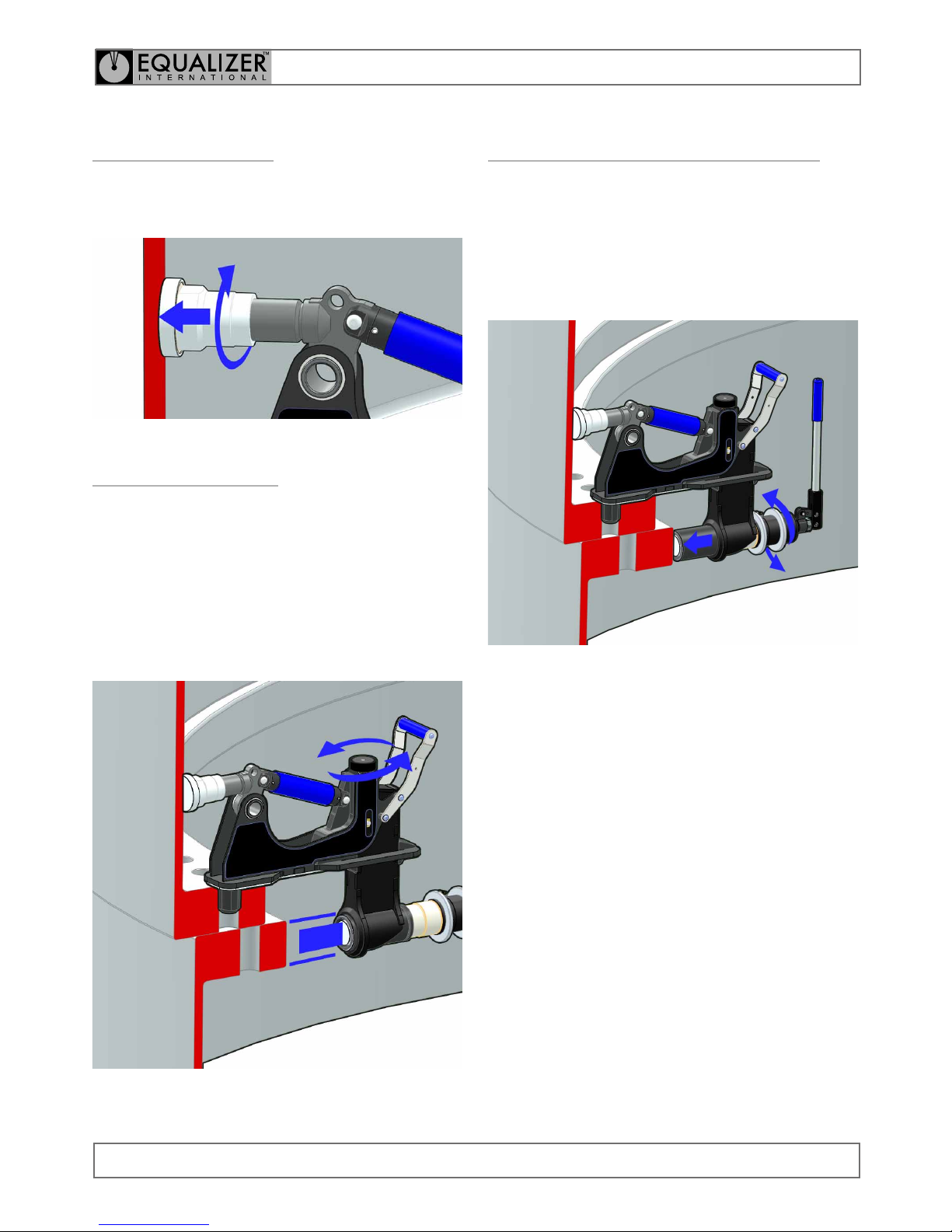

3.6

CYLINDER ADJUSTMENT SLEEVE

The Alignment Piston has a 65 mm stroke. The Cylinder

Adjusment Sleeve extends the reach of the tool to t a

variety of ange sizes, without comprimising its maximum

alignment capacity.

Turn the Cylinder Adjustment Sleeve by the knurled ring

until the Alignment Foot is touching the lower ange.

3.4

ADJUSTMENT LEG

Extend the Adjustment Leg by turning the knurled foot

clockwise until it contacts the pipe wall. Ensure that the

tool is sitting squarely.

3.5

WING EXTENSION

The Alignment Piston is located on an adjustable wing

which can be extended to enable the tool to be used on a

variety of ange sizes.

Use the Wing Extension adjustment knob to lower the

wing until the foot of the Alignment piston is positioned

within the space between the upper and lower faces of

the lower ange.

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

7

3.8

ALIGNMENT

Refer to section 5.2 for tool actuation instructions.

Actuating the tool will extend the Alignment Piston and

align the anges.

3.9

SECURING THE FLANGE JOINT

After the ange joint has been aligned it can be secured

by installing as many bolts as possible into the bolt holes.

It may be necessary to repeat the alignment process

several times while working around the ange joint.

3.7

TOOL CHECKS

Ensure that the tool is sitting square on the

ange, that the wing is parallel to the pipe wall

and that the Adjustment Leg is adjusted prior

to actuating the tool. Actuating the tool when it

is not correctly installed could cause injury or

equipment damage.

Do not allow ngers, hands or other body parts

to come into contact with the ange while

actuating the tool. Only hold the tool by its

designated handles.

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

8

4.3

SERVICING

Replace missing worn or damaged parts. Use only

genuine Equalizer parts from approved distributors or

service centres. Equalizer parts have been engineered and

manufactured to be t-for-purpose.

Grease all moving parts by following the Lubrication

Procedure prior to usage, storage or transportation.

If topping up or replacing hydraulic oil as part of a service,

use only premium quality hydraulic oil of the grade 15 cSt.

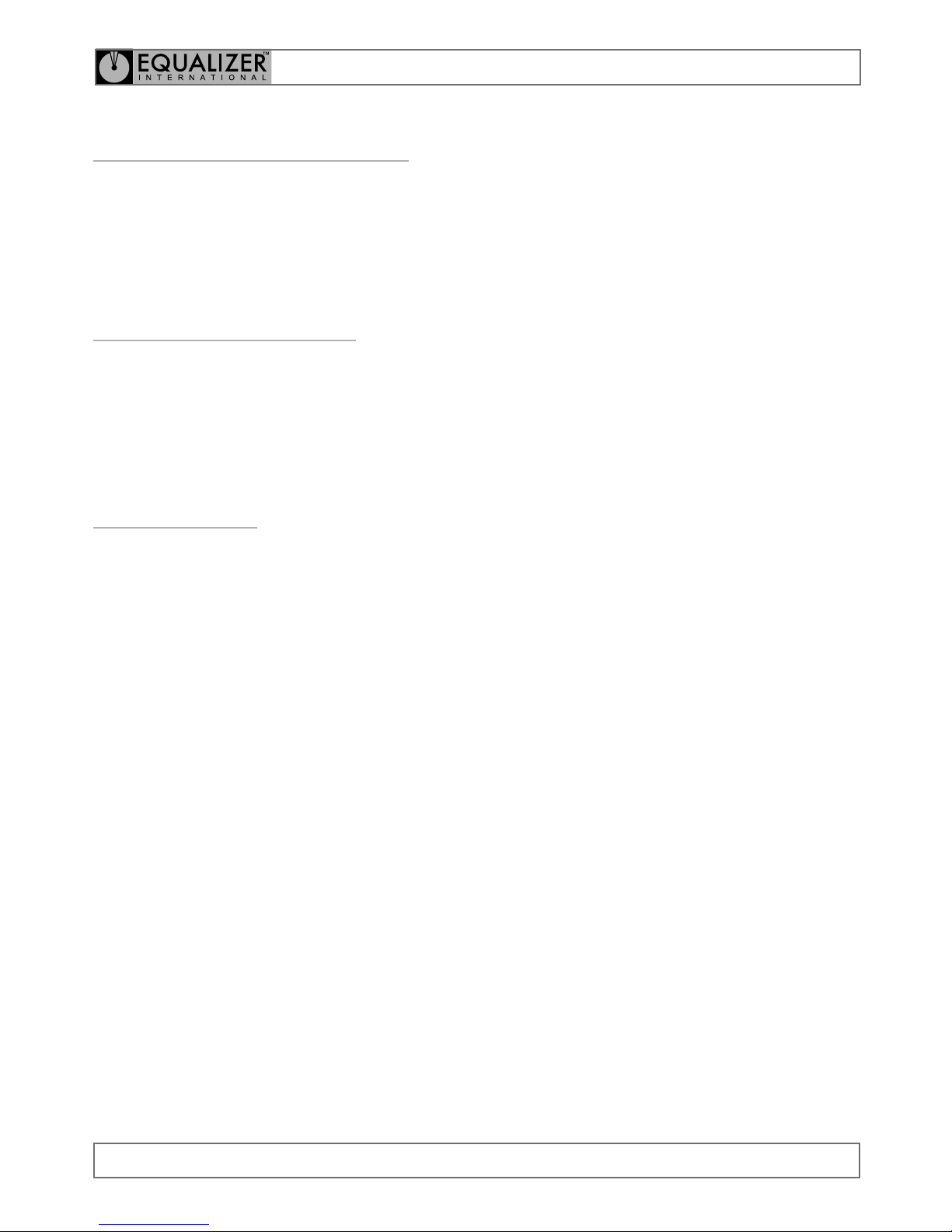

4.4

LUBRICATION PROCEDURE

Apply grease following cleaning and servicing, prior to

usage, storage or transportation. Never assemble and

leave a tool without following the greasing procedure as

degradation or damage may occur.

Use only high pressure molybdenum disulphide grease.

Apply grease liberally to the following areas:

• the Adjustment Leg thread

• the Wing Extension thread

• the Cylinder Adjustment thread

ADJUSTMENT

LEG THREAD

CYLINDER

ADJUSTMENT

THREAD

WING

EXTENSION

THREAD

4.

TOOL MAINTENANCE

4.1

INSPECTION

A thorough inspection should be carried out prior to usage,

storage or transportation to ensure the completeness and

condition of the tool.

Inspection should include:

• visual inspection of the outer parts of the tool,

checking for obvious damage, degradation or missing

parts

• visual inspection of the Alignment Piston (requiring

tool actuation). Damage to the Alignment Piston can

be indicative of tool over-load.

Cleaning and servicing should be undertaken as required

prior to the tool being used, stored or transported.

4.2

CLEANING

To lightly clean the tool, wipe gently with a damp cloth.

If more thorough cleaning is required (for example

following immersion in water) carry out the following

cleaning procedure:

• strip the tool down, observing the schematics in

section 8

• clean the components using detergent, following the

manufacturer’s guidelines

• rinse the components to remove traces of detergent

• dry the components thoroughly

Inspect, service and lubricate the tool immediately after

the cleaning process.

OPERATOR INSTRUCTION MANUAL

IM_TFA_TI_Rev01_A4

TFA INTEGRAL HYDRAULIC TOOLS

FLANGE ALIGNMENT TOOLS

9

4.5

STORAGE & TRANSPORTATION

Equalizer tools should be stored in a cool dry place. Tools

should always be cleaned, serviced and lubricated prior to

storage. Ensure that tools are stored in their designated

packing cases.

4.6

OPERATING CONDITIONS

HYDRAULIC TOOLS:

Minimum Flange Contact Temperature: -30 °C (-22 °F)

Maximum Flange Contact Temperature: 70 °C (158 °F)

4.7

SUB-SEA USAGE

Using TFA integral hydraulic tools Sub-Sea

The TFA integral hydraulic tools are actuated by means of

a single-acting spring-return hydraulic cylinder and can be

used sub-sea providing the following actions are taken:

• The pump release valve is fully opened and remains

open until the tool has descended to the working

depth. This will allow the pressure to equalise.

• The tool is actuated via the hand pump by a diver.

• Upon completion of works the release valve is left in

the fully-open position until the tool has ascended to

the surface.

• The tool and pump are stripped-down, cleaned and

lubricated immediately to minimise corrosion.

Loading...

Loading...