Page 1

SL-D3000

Administrator's Guide

Page 2

Meaning of Symbols

Note: Notes contain important information on the operation of this product.

Tip: Tips contain useful or additional information on the operation of this product.

Operating System Versions

In this manual, the following abbreviations are used.

Windows refers to Windows 7, Vista, XP.

O Windows 7 refers to Windows 7 Home Basic, Windows 7 Home Premium, Windows 7 Professional, and

Windows 7 Ultimate.

O Windows Vista refers to Windows Vista Home Basic Edition, Windows Vista Home Premium Edition,

Windows Vista Business Edition, Windows Vista Enterprise Edition, and Windows Vista Ultimate Edition.

O Windows XP refers to Windows XP Home Edition, Windows XP Professional x64 Edition, and Windows XP

Professional.

Copyrights and Trademarks

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation. The information contained herein is designed only for use with this

EPSON printer. Epson is not responsible for any use of this information as applied to other printers.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of accident, misuse, or abuse

of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure

to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any options or any

consumable products other than those designated as Original EPSON Products or Epson Approved Products by

Seiko Epson Corporation.

Seiko Epson Corporation shall not be held liable for any damage resulting from electromagnetic interference that

occurs from the use of any interface cables other than those designated as Epson Approved Products by Seiko Epson

Corporation.

EPSON is registered trademark, SureLab is a trademark, and EPSON Exceed Your Vision is a registered logomark

of Seiko Epson Corporation.

General Notice: Other product names used herein are for identification purposes only and may be trademarks of

their respective owners. Epson disclaims any and all rights in those marks.

This information is subject to change without notice.

© 2013 Epson America, Inc. 2/13

CPD-38306R1

2

Page 3

Contents

Contents

Setup and Maintenance

Pre-operation Check

Post-operation Check

Printer Information

Checking Printer Information . . . . . . . . . . . . . . . . . . . 10

Changing User Levels

Settings/Maintenance

Performing Maintenance . . . . . . . . . . . . . . . . . . . . . . .15

System Operation Settings/Inspections . . . . . . . . . . .20

Installation Information Settings . . . . . . . . . . . . . . 20

Settings for Optional Equipment . . . . . . . . . . . . . .21

Printer Operation Settings . . . . . . . . . . . . . . . . . . . . 23

Print Condition Settings/Inspections . . . . . . . . . . . . . 24

Image Quality Settings . . . . . . . . . . . . . . . . . . . . . . . 24

Paper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

CR Unit Adjustment/Maintenance . . . . . . . . . . . . . . .27

Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Color Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Gray Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Print Head Maintenance . . . . . . . . . . . . . . . . . . . . . 63

Printer Adjustment/Maintenance . . . . . . . . . . . . . . . . 64

Operation History . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Parts Replacement History. . . . . . . . . . . . . . . . . . . . 65

Paper Feed-Related Adjustment . . . . . . . . . . . . . . . 66

Software Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

System Language Settings. . . . . . . . . . . . . . . . . . . . . 68

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Appendix

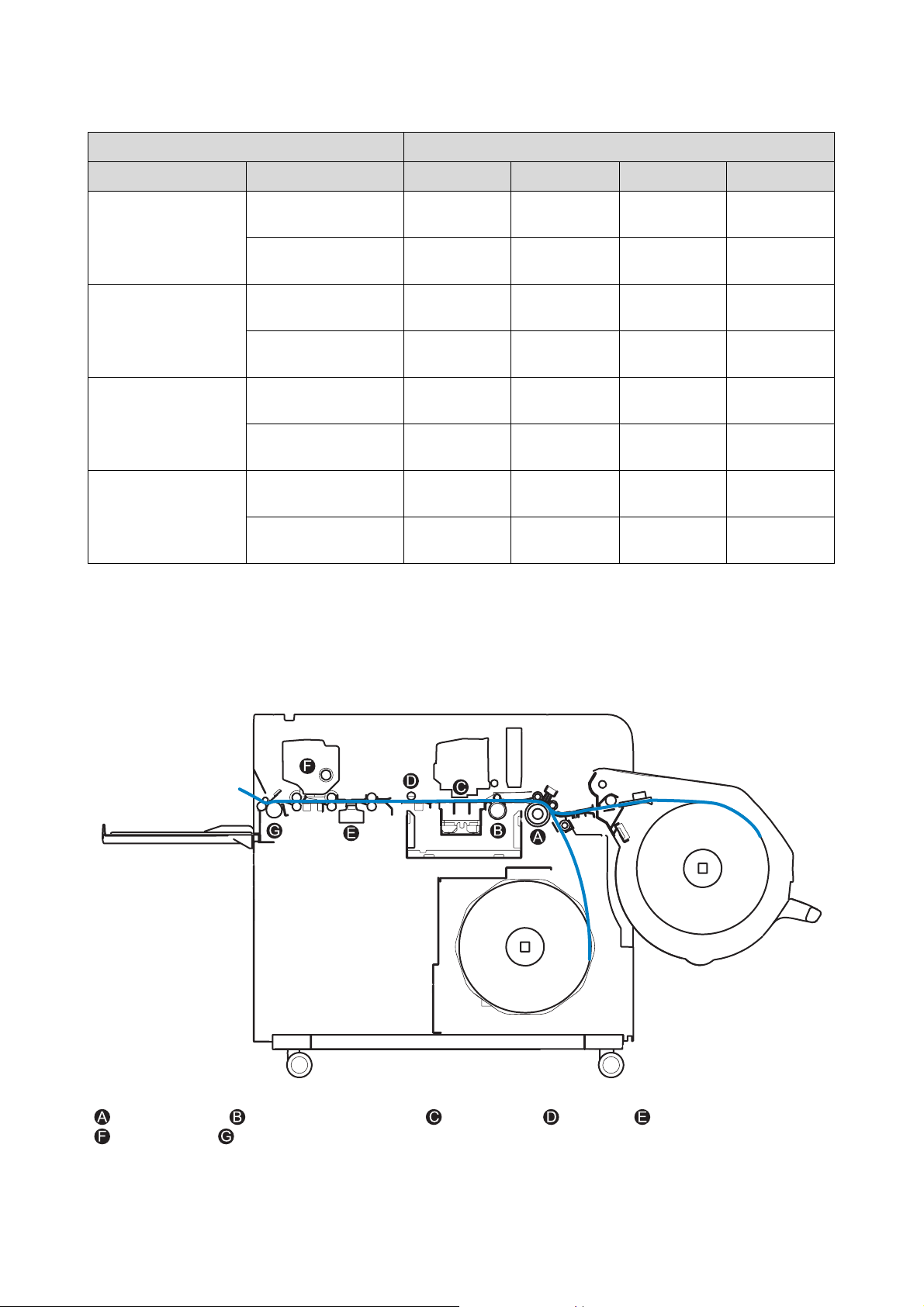

Ejected Paper Path and Supported Paper Sizes . . . . .74

Paper Feed Path Diagram . . . . . . . . . . . . . . . . . . . . . . .75

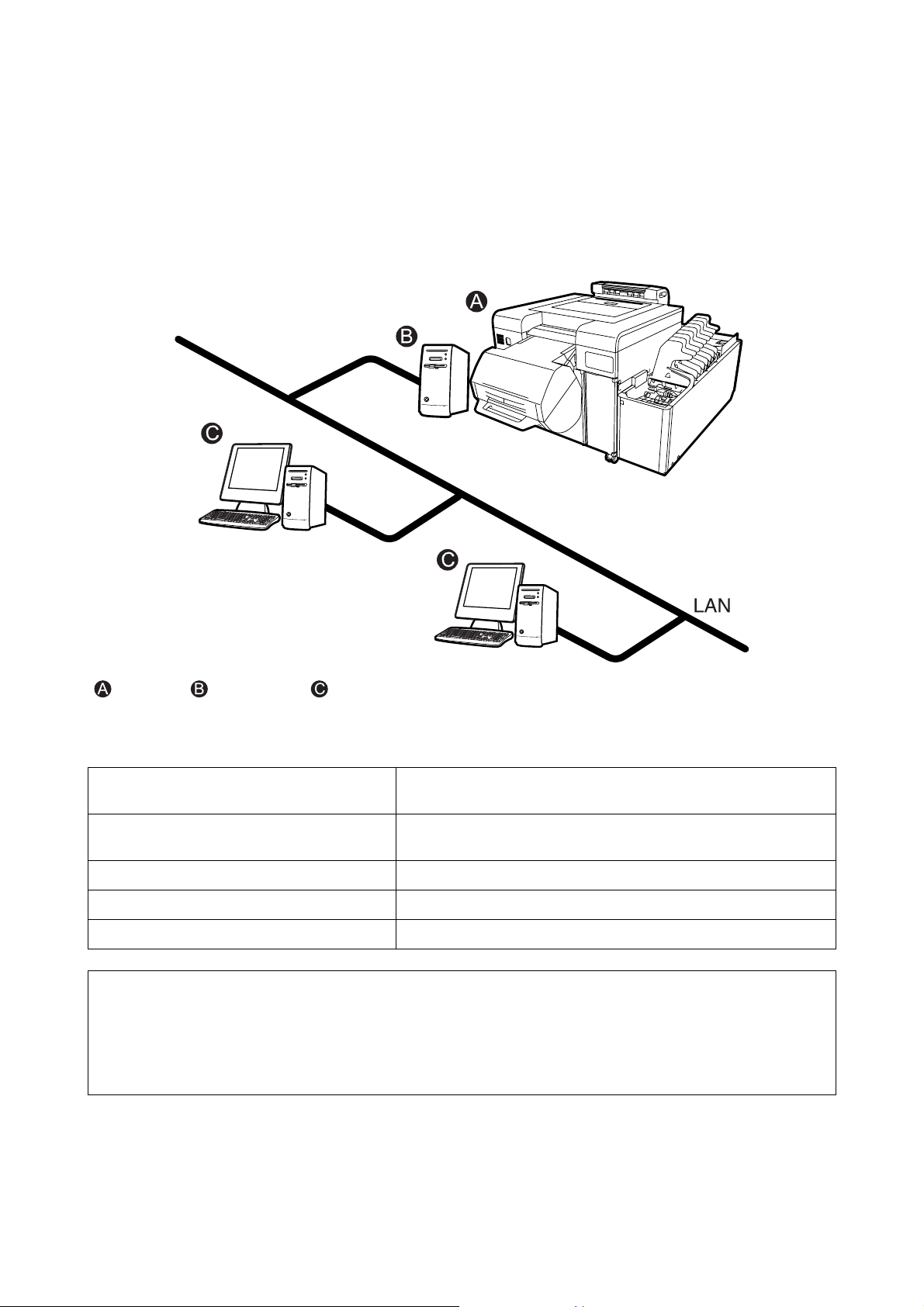

Extending the Client PC . . . . . . . . . . . . . . . . . . . . . . . .77

Preparing to extend the Client PC. . . . . . . . . . . . . .78

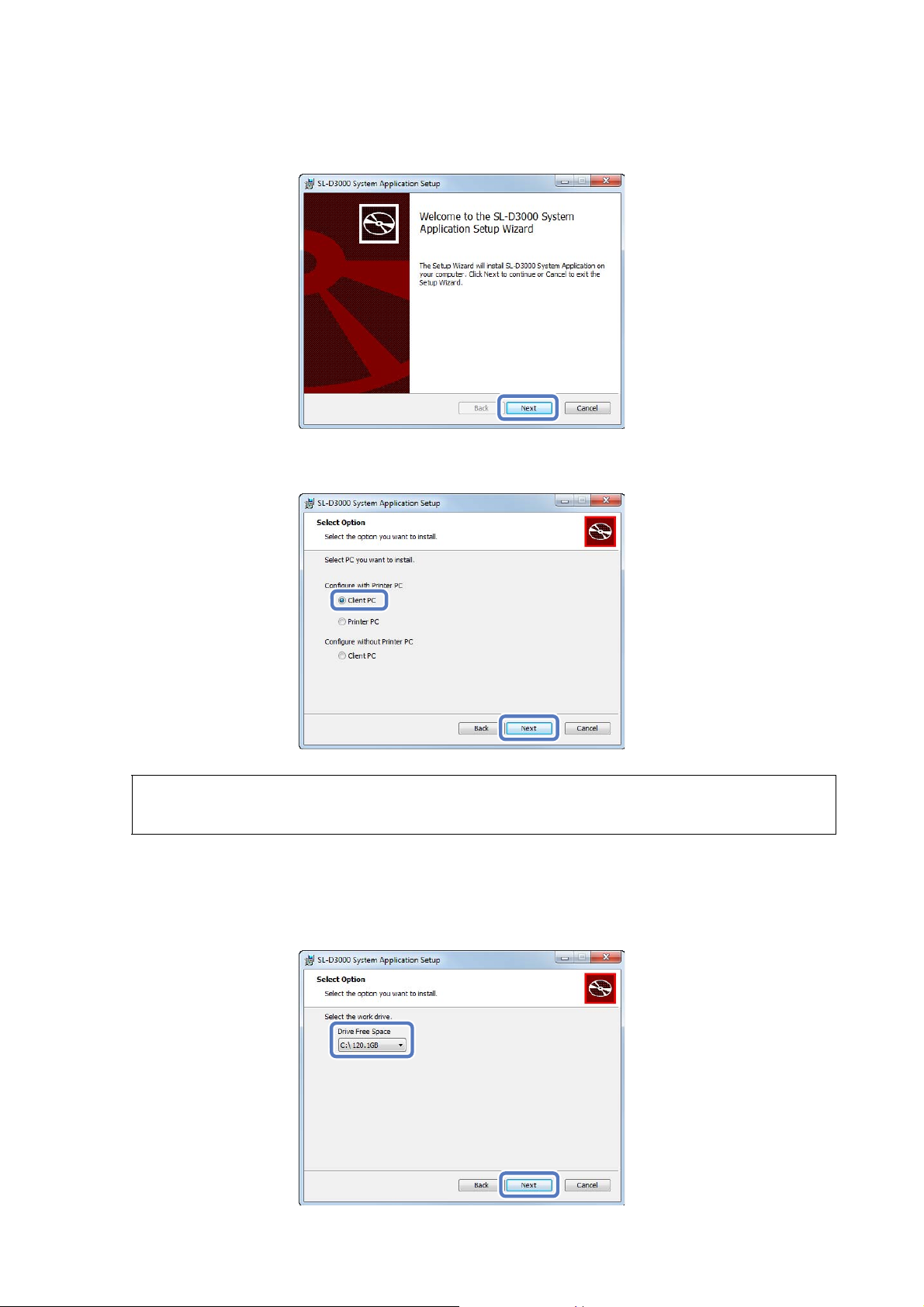

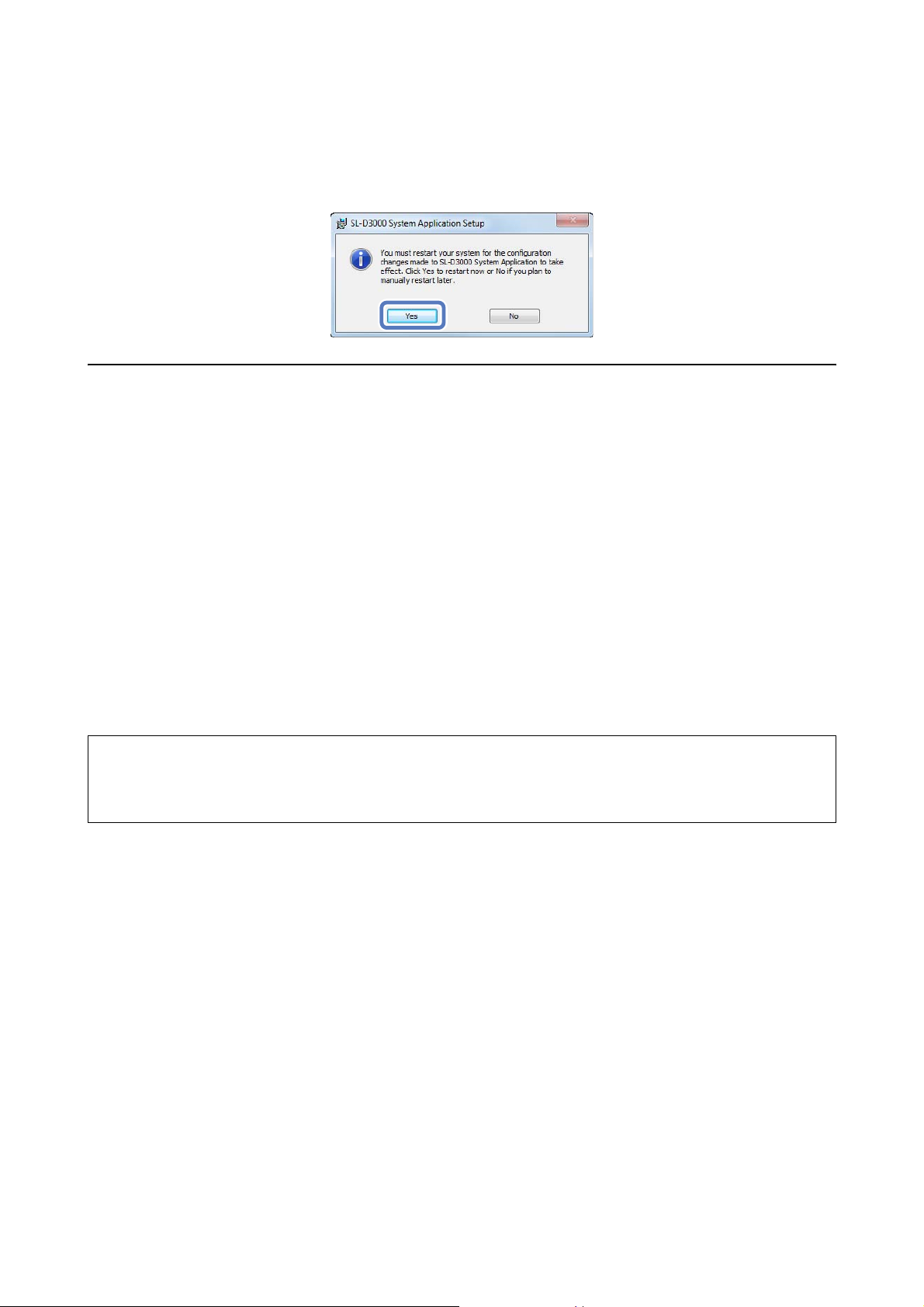

Installing the system application . . . . . . . . . . . . . . .78

Initial settings for the Maintenance Utility . . . . . .80

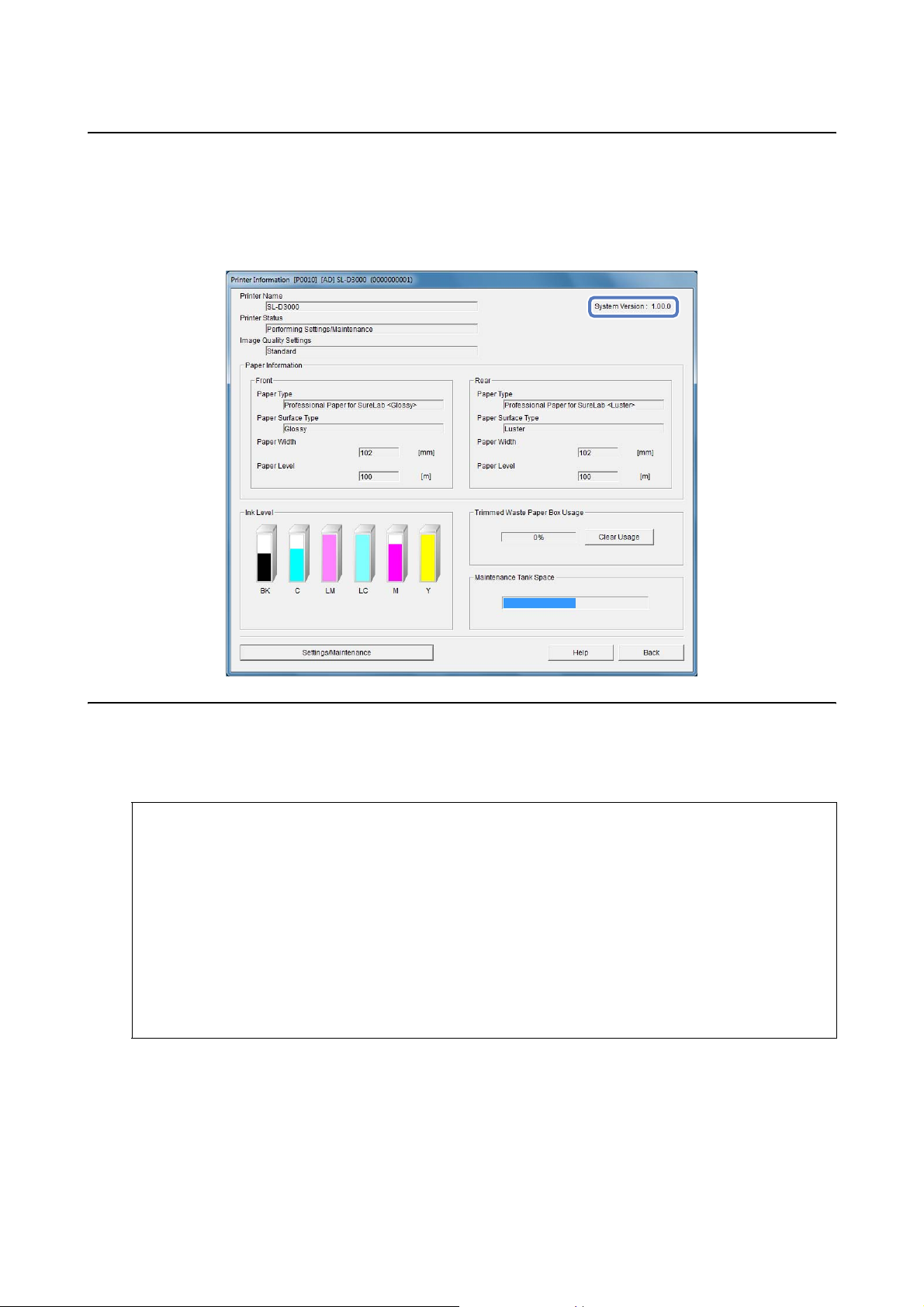

Changing the System Application Version. . . . . . . . .81

Upgrading or Downgrading. . . . . . . . . . . . . . . . . . .81

Checking the System Application Version. . . . . . .82

Changing the System Application Version . . . . . .82

Removing the System Application. . . . . . . . . . . . . . . .85

OPEN SOURCE SOFTWARE LICENSE TERMS. . .86

SEIKO EPSON CORPORATION SOFTWARE

LICENSE AGREEMENT. . . . . . . . . . . . . . . . . . . . . . . .94

Error History

Acquire Log

Add/Delete Printer

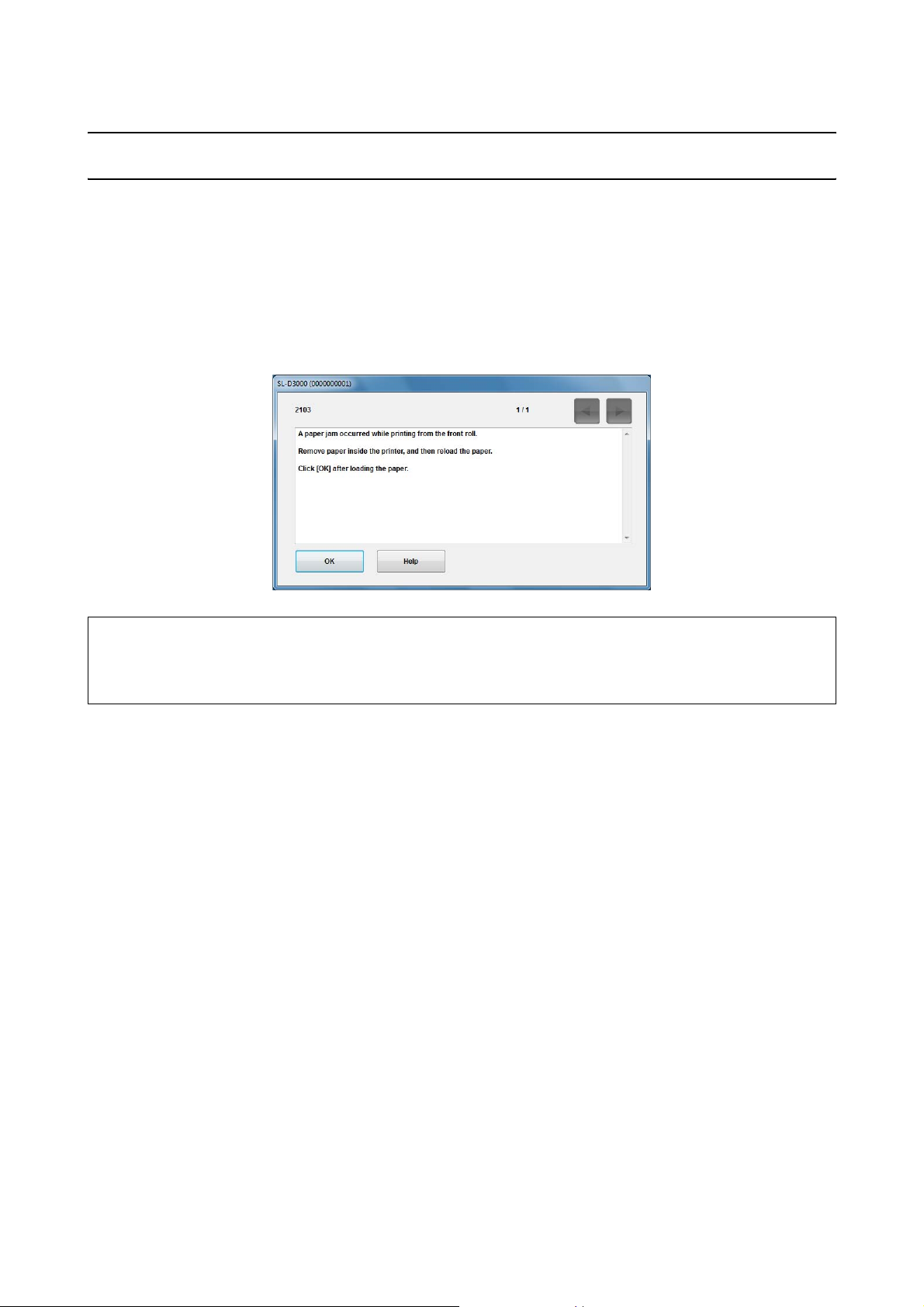

When a Message is Displayed

About Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3

Page 4

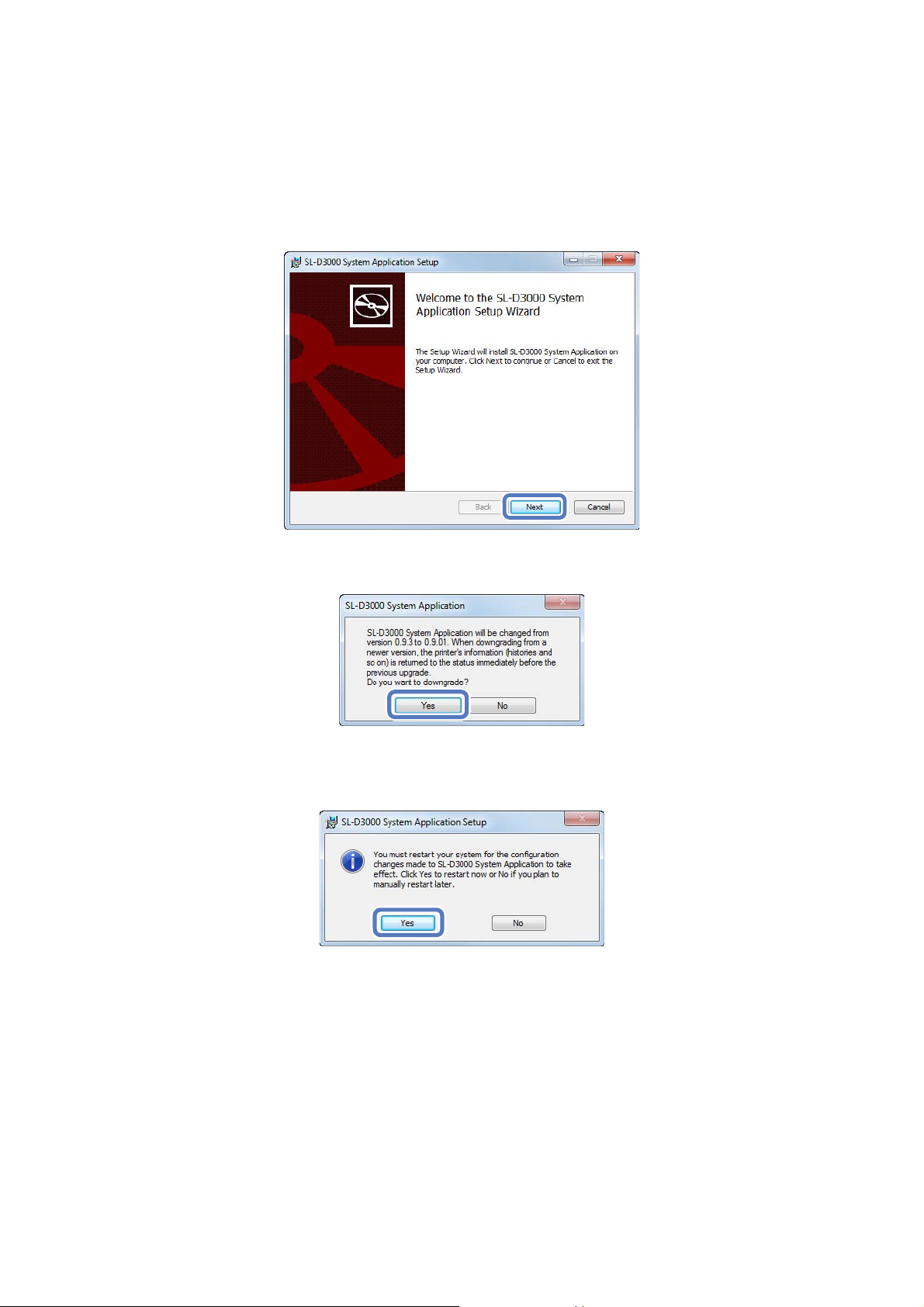

Setup and Maintenance

Setup and Maintenance

You can perform printer maintenance and check printer status from the Client PC.

You can set the user authority to "Operator" or "Administrator". Available functions differ depending on the

authority.

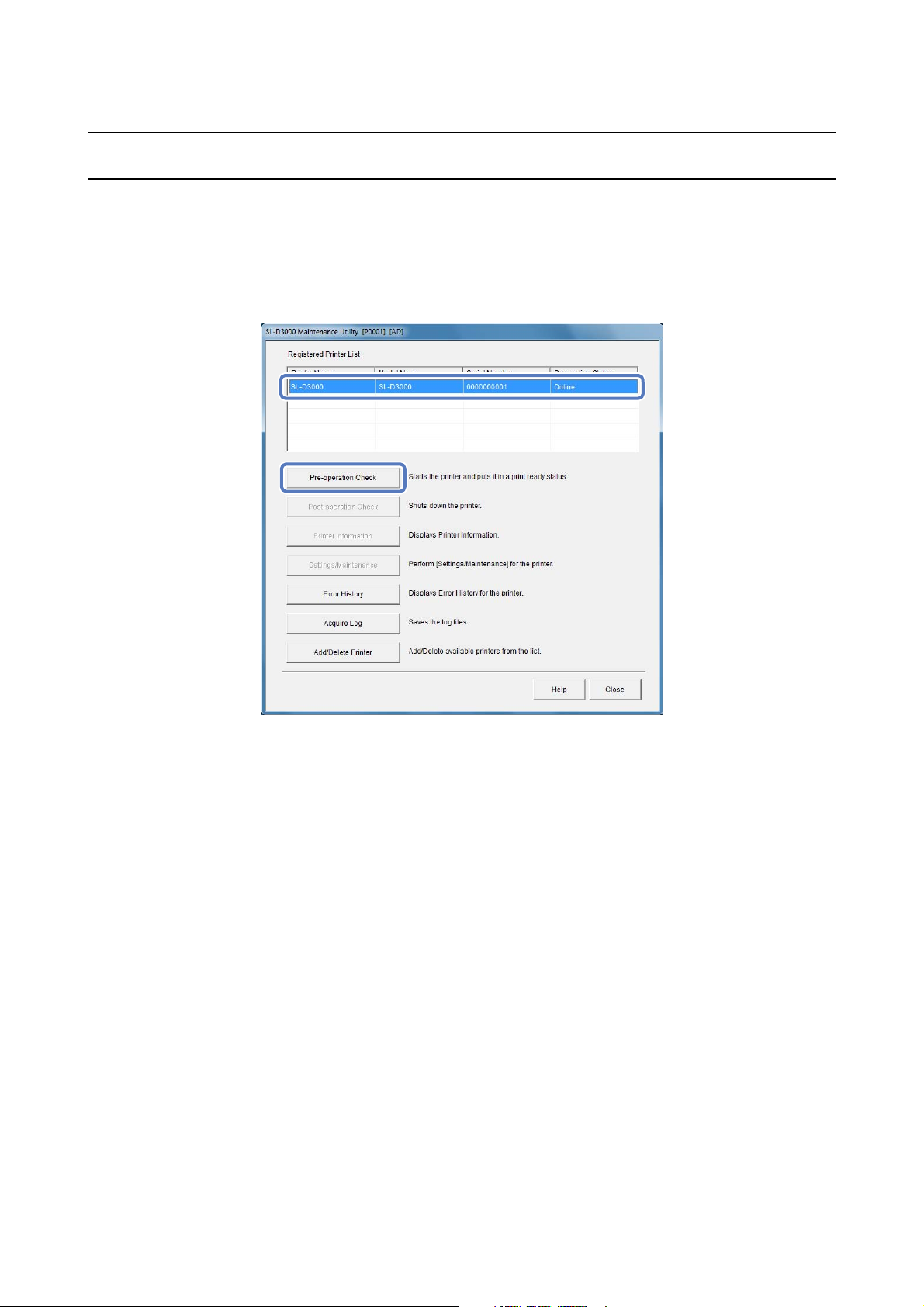

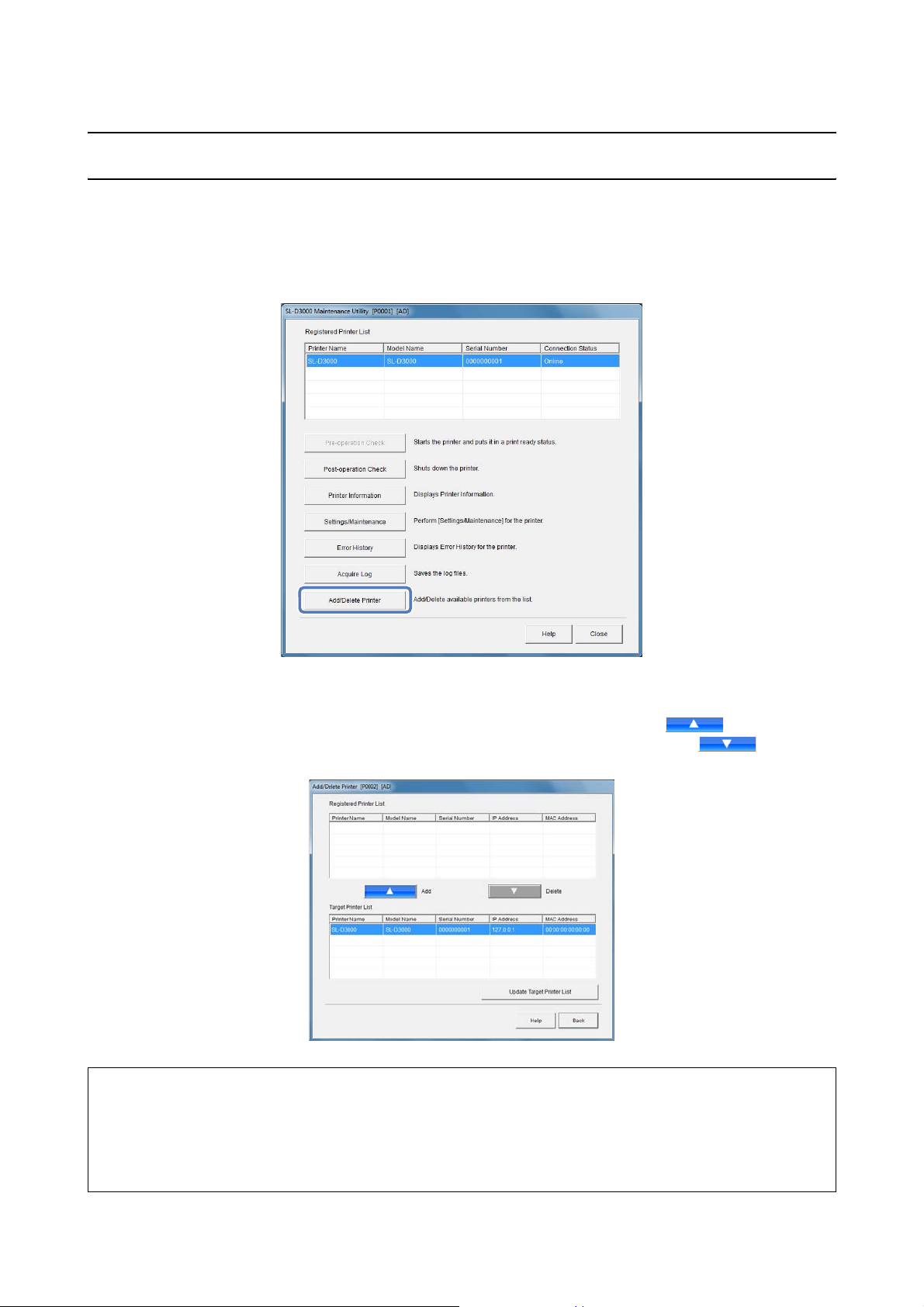

SL-D3000 Maintenance Utility screen (when using as an Operator):

You can perform a Pre-operation Check, Post-operation Check, Printer Information, Settings/Maintenance, ,

and check Error History.

In Printer Information, you can check the printer's status.

In Settings/Maintenance, you can perform adjustment/maintenance operations such as head cleaning.

In Error History, you can check errors that have occurred in the printer, and information.

4

Page 5

Setup and Maintenance

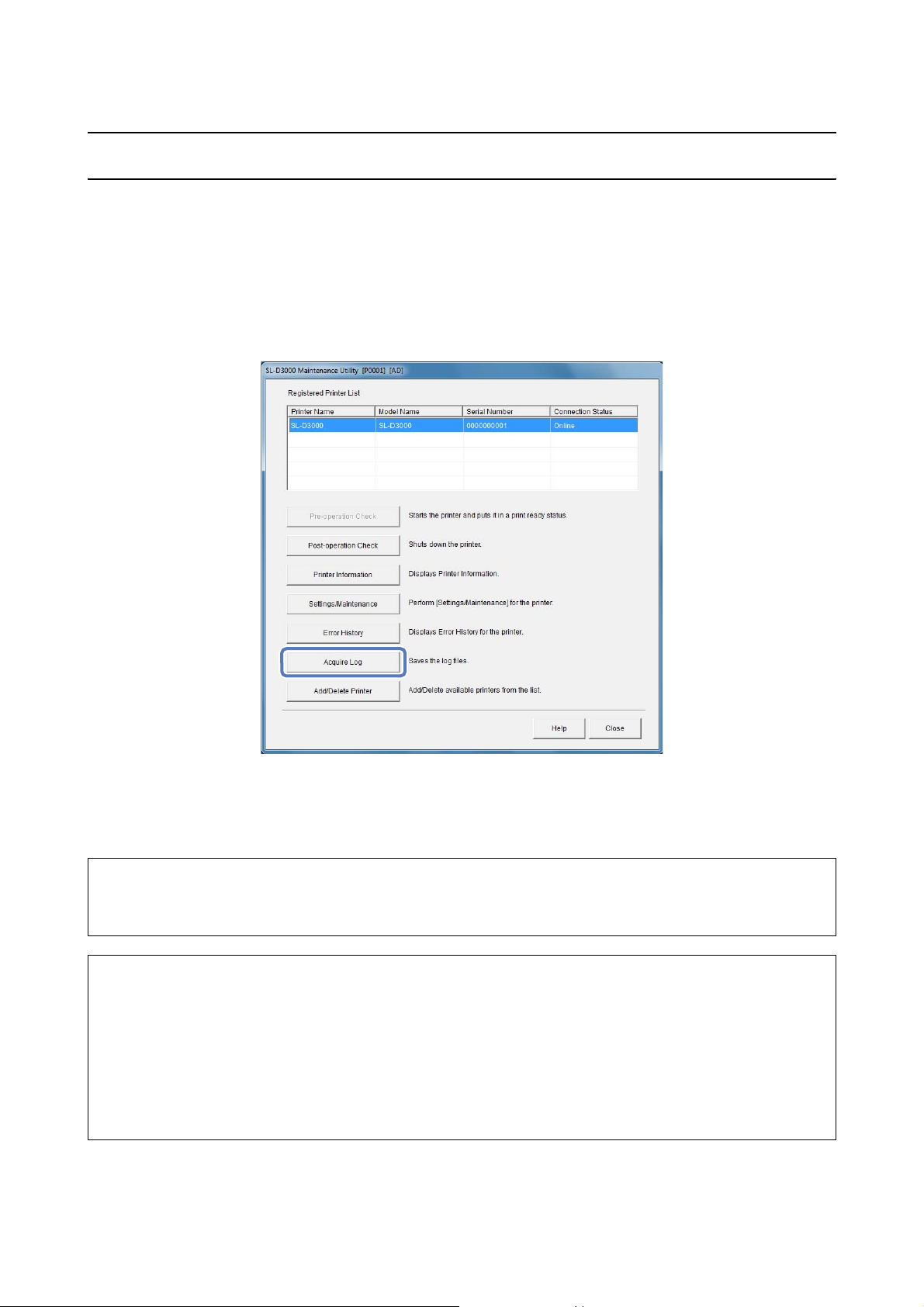

SL-D3000 Maintenance Utility screen (when using as an Administrator):

"...[AD]" is displayed in the title bar on screens in Administrator's mode.

You can perform a Pre-operation Check, Post-operation Check, Printer Information, Settings/Maintenance,

Acquire Log, Add/Delete Printer, and check Error History.

In Printer Information, you can check the printer's status.

In Settings/Maintenance, you can perform adjustment/maintenance operations such as head cleaning and

calibration.

In Error History, you can check errors that have occurred in the printer, and information.

In Acquire Log, you can save log files.

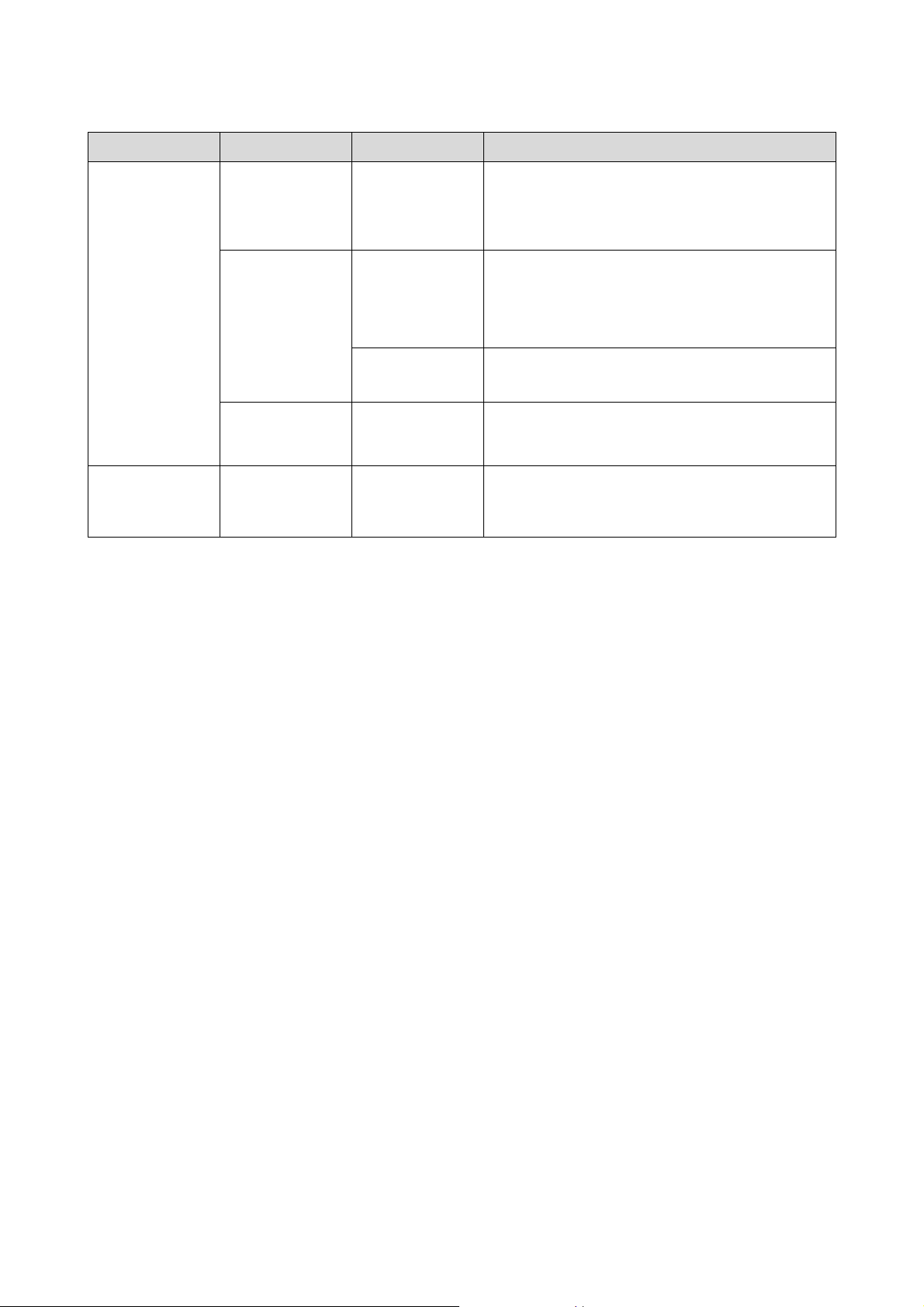

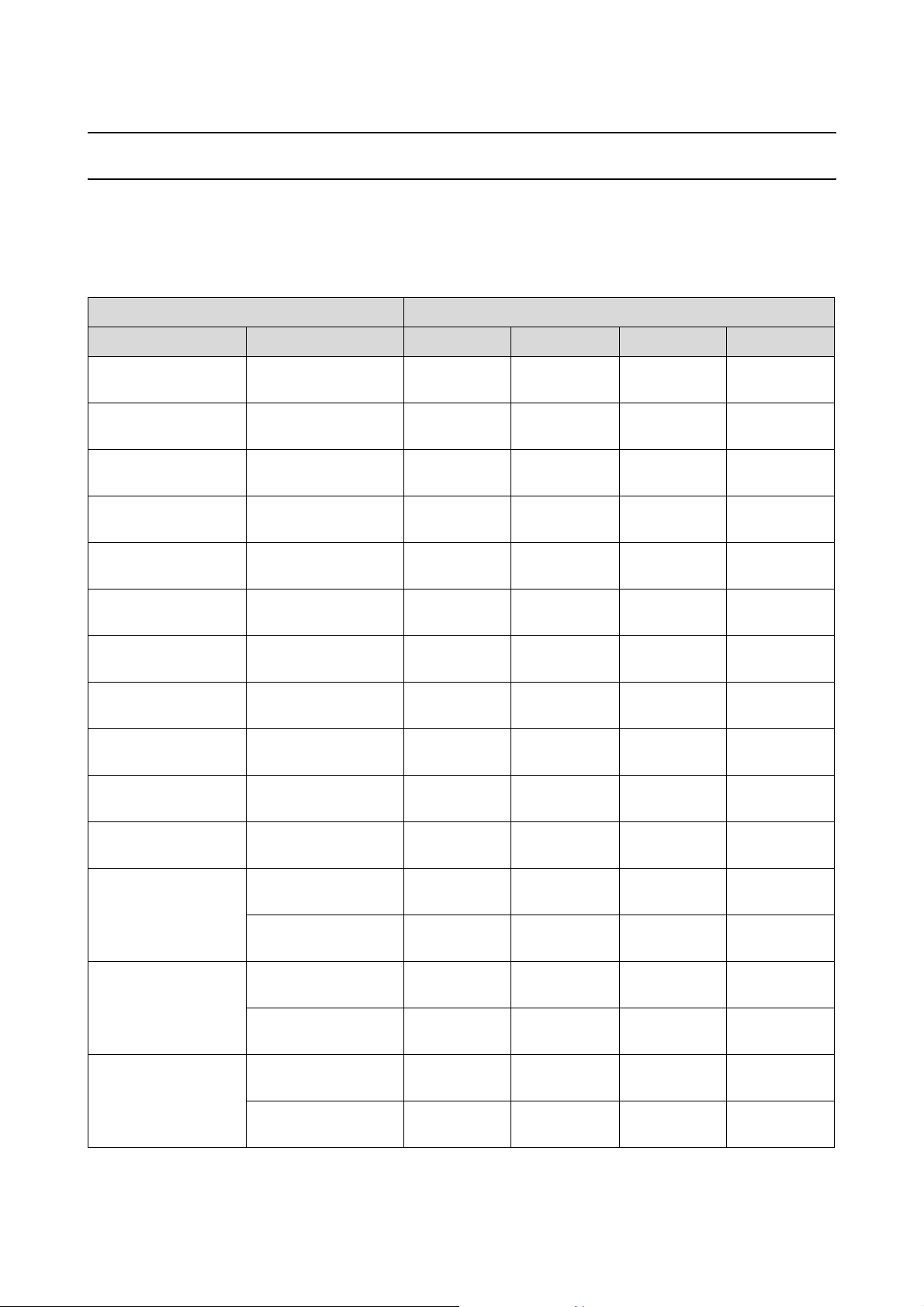

Available functions:

Button Settings/Maintenance Functions Menu Operator Adminis-

Large Items Medium Items Small Items

Pre-operation Check - - - Yes Yes

Post-operation Check - - - Yes Yes

Printer Information - - - Yes Yes

trator

5

Page 6

Setup and Maintenance

Button Settings/Maintenance Functions Menu Operator Adminis-

Large Items Medium Items Small Items

trator

Settings/Maintenance System Operation

Settings/Inspections

(01)

Print Condition

Settings/Inspections

(02)

CR Unit

Adjustment/Mainten

ance (03)

Installation

Information Settings

(011)

Settings for Optional

Equipment (012)

Printer Operation

Settings(013)

Image Quality

Settings (021)

Paper Settings (022) - Yes Yes

Head Cleaning (031) Auto Cleaning (0311) Yes Yes

Nozzle Check (0312) Yes Yes

Periodic Nozzle

Check Settings (0313)

Color Calibration

(034)

Calibration (0341) No Yes

History of Correction

Values (0342)

Create Calibration

(0343)

- No Yes

- No Yes

- No Yes

- No Yes

No Yes

No Yes

No Yes

Gray Adjustment

(035)

Head Maintenance

(036)

Printer

Adjustment/Mainten

ance (04)

Software Settings

(05)

Error History - - - Yes Yes

Acquire Log - - - No Yes

Add/Delete Printer - - - No Yes

Operation History

(044)

Parts Replacement

History (045)

Paper Feed-Related

Adjustment (048)

System Language

Settings (051)

Register

Replacement Date for

Periodically Replaced

Parts (0451)

Clear Counter 1

(0452)

Paper Feed Amount

Durability Correction

(0483)

- No Yes

No Yes

- Yes Yes

No Yes

No Yes

No Yes

- No Yes

6

Page 7

Setup and Maintenance

Tip:

See the "SL-D3000 Operation Guide" for more information on items that are available to operators.

U "SL-D3000 Operation Guide" - "Setup and Maintenance"

7

Page 8

Pre-operation Check

Pre-operation Check

Click Pre-operation Check on the Client PC to start the printer.

In Pre-operation Check, the printer starts after the items that need to be checked manually have been displayed.

Furthermore, when Printer PC is connected to the printer, Printer PC starts automatically.

Tip:

See the "SL-D3000 Operation Guide" for more information on the Pre-operation Check.

U "SL-D3000 Operation Guide" - "Starting the Printer"

8

Page 9

Post-operation Check

Post-operation Check

Click Post-operation Check on the Client PC to shut down the printer.

When the printer is shut down in Post-operation Check, and Printer PC is connected to the printer, Printer PC

closes automatically.

Tip:

See the "SL-D3000 Operation Guide" for more information on the Post-operation Check.

U "SL-D3000 Operation Guide" - "Shutting down the Printer"

9

Page 10

Printer Information

Printer Information

You can confirm various types of printer information.

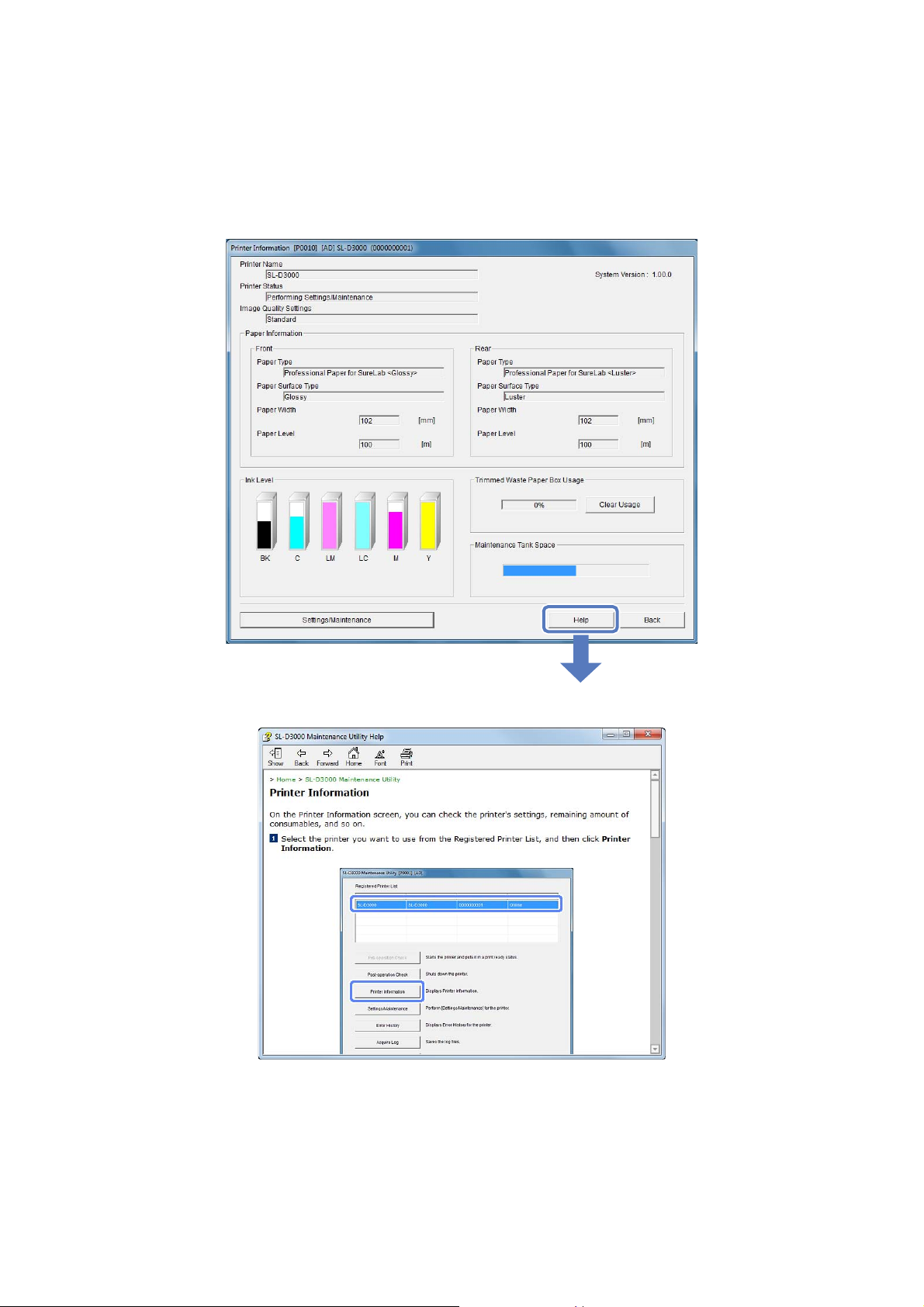

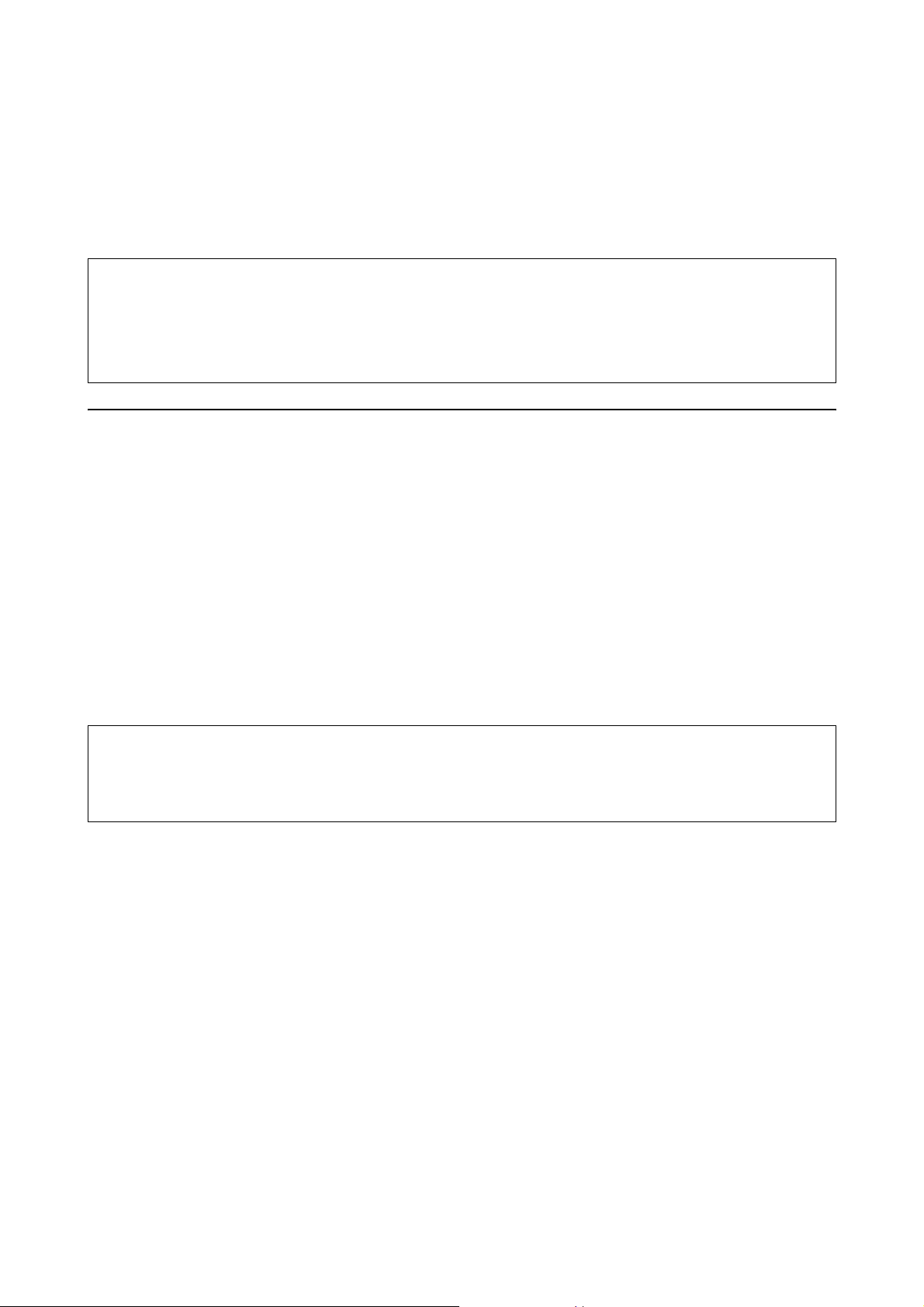

Checking Printer Information

On the Printer Information screen, you can check the printer's settings, remaining amount of consumables, and so

on.

Select the printer you want to use from the Registered Printer List, and then click Printer Information.

A

Tip:

In the following situations, the Printer Information button is unavailable.

O When the printer's Pre-operation Check is not complete

O When the cable to the printer is disconnected

O When the printer's Power switch is off

10

Page 11

Printer Information

On the Printer Information screen, you can check the printer's settings, remaining amount of consumables,

B

and so on.

Item Explanation

Printer Name Displays the printer name.

Printer Status Displays the printer status.

Standby The printer is ready to print.

Printing The printer is printing.

Performing

Settings/Maintena

nce

An error has

occurred

Initializing The printer is initializing.

Shutting down The printer is shutting down.

Offline The printer is not turned on, or is not connected.

Image Quality Settings Displays the image settings.

Standard Prints at standard (720 dpi) quality.

High Image

Quality

The printer is performing maintenance operations such as a

nozzle check.

An error has occurred in the printer.

Prints at high resolution (1440 dpi) quality.

Paper Information

(Front/Rear)

Displays information about the loaded paper.

"-" is displayed when paper is not loaded or information cannot be acquired from the

printer.

11

Page 12

Printer Information

Item Explanation

Ink Level Displays the remaining amount of ink.

"Caution" is displayed when ink is running low. "Error" is displayed when the amount of

ink remaining has fallen below the minimum limit. The ink cartridge is grayed out when

the ink cartridge is not installed, or if there is a problem with the ink cartridge.

If an non-genuine cartridge is installed, a message is displayed indicating that it is not

covered by the warranty.

Trimmed Waste Paper Box

Usage

Clear Usage Click to clear the trimmed waste paper box usage.

Maintenance Tank Space Displays the amount of free space in the maintenance tank as a bar.

Settings/Maintenance Click to open the Settings/Maintenance screen.

Help Click to display the Help.

Close Closes the Printer Information screen.

Displays the usage status of the trimmed waste paper box.

"-" is displayed when information cannot be acquired from the printer.

When you remove the trimmed waste paper from the trimmed waste paper box, click

Clear Usage to reset the usage.

When information cannot be acquired from the printer, the bar is not displayed.

U “System Operation Settings/Inspections” on page 20

U “Print Condition Settings/Inspections” on page 24

U “CR Unit Adjustment/Maintenance” on page 27

U “Printer Adjustment/Maintenance” on page 64

U “Software Settings” on page 68

Note:

This product has been adjusted based on genuine ink cartridges. If you use non-genuine cartridges, the print results may

be faint or the amount of ink remaining may not be detected correctly.

Tip:

Only the Dual Roll Model supports front roll paper. For the Single Roll Model, information is not displayed under the

front paper item. See the information for rear roll paper.

This completes this section.

12

Page 13

Changing User Levels

Changing User Levels

You can change the user level from Operator mode to Administrator mode.

Display the SL-D3000 Maintenance Utility or the Printer Information screen.

A

While holding down the Ctrl and Alt keys on the keyboard, press S (or s).

B

The Enter Password screen is displayed.

13

Page 14

Changing User Levels

Enter the password, and then click OK.

C

The user level is changed to Administrator mode.

Tip:

O The administrator password is "0000".

O Restart this SL-D3000 Maintenance Utility when switching from Administrator mode to Operator mode.

14

Page 15

Settings/Maintenance

Settings/Maintenance

You can perform maintenance operations such as Print Head Unit cleaning and calibration, as well as manage

settings.

Performing Maintenance

You can select each maintenance function on the Settings/Maintenance screen.

When performing maintenance in Settings/Maintenance, make sure that the p light on the printer's Operation

panel is on before starting operations.

Select the printer you want to use from the Registered Printer List, and then click Settings/Maintenance.

A

Tip:

O In the following situations, the Settings/Maintenance button is unavailable.

O When the cable connected to the printer is disconnected

O When the printer's Power switch is off

O When the printer's pre-operation check is not complete

O The Settings/Maintenance screen opens when you click Settings/Maintenance on the Printer Information

screen.

15

Page 16

Settings/Maintenance

Select the function you want to use.

B

You can make settings by selecting a function from the menu on the left.

Click Back to close the Settings/Maintenance screen.

C

16

Page 17

Settings/Maintenance

When the Printer Information screen is displayed, click Back to close the screen.

D

This completes this section.

17

Page 18

Settings/Maintenance

Available functions on the Settings/Maintenance screen:

Large Items Medium Items Small Items Setting Contents

System Operation

Settings/Inspectio

ns (01)

Print Condition

Settings/Inspectio

ns (02)

CR Unit

Adjustment/Maint

enance (03)

Installation

Information

Settings (011)

Settings for

Optional

Equipment (012)

Printer Operation

Settings (013)

Image Quality

Settings (021)

Paper Settings

(022)

Head Cleaning

(031)

- Displays the printer's information.

- Change the settings for the optional equipment.

- Make settings for power saving and the warning buzzer.

- Select the image quality mode.

- Check information about the loaded paper.

Auto Cleaning

(0311)

Nozzle Check

(0312)

Periodic Nozzle

Check Settings

(0313)

U “Installation Information Settings” on page 20

U “Settings for Optional Equipment” on page 21

U “Printer Operation Settings” on page 23

U “Image Quality Settings” on page 24

U “Paper Settings” on page 25

Detect clogged nozzles and clean the Print Head Unit

automatically.

U “Auto Cleaning” on page 29

Check for clogged nozzles and clean the Print Head Unit

manually.

U “Nozzle Check” on page 30

Set whether or not to perform auto nozzle check.

U “Periodic Nozzle Check Settings” on page 34

Color Calibration

(034)

Gray Adjustment

(035)

Head Maintenance

(036)

Calibration (0341) Perform calibration with a color measurement device.

U “Calibration” on page 37

History of

Correction Values

(0342)

Create Calibration

(0343)

- Adjust the Color Balance, Density, and Gradation.

Write the correction value acquired through calibration.

U “History of Correction Values” on page 45

Perform calibration for the standard printer, and then

create the standard value.

U “Create Calibration” on page 46

U “Gray Adjustment” on page 50

Clean the print head unit and the wipers for the print

head.

To perform this type of cleaning, you need the optional

Print Head Maintenance Kit (C12C890991).

For more details, see the User's Guide supplied with the

Print Head Maintenance Kit.

18

Page 19

Settings/Maintenance

Large Items Medium Items Small Items Setting Contents

Printer

Adjustment/Maint

enance (04)

Software Settings

(05)

Operation History

(044)

Parts Replacement

History (045)

Paper

Feed-Related

Adjustment (048)

System Language

Settings (051)

- Check errors that have occurred, the number of prints,

Register

Replacement Date

for Periodically

Replaced Parts

(0451)

Clear Counter 1

(0452)

Paper Feed

Amount Durability

Correction (0483)

- Set the date and time, language, and units for the UI

and the number of head cleaning operations in the

printer.

U “Operation History” on page 64

Check the replacement date for parts that need to be

replaced.

U “Register Replacement Date for Periodically Replaced

Parts” on page 65

Check each counter.

U “Clear Counter 1” on page 65

Adjust the amount of paper feed.

U “Paper Feed-Related Adjustment” on page 66

display.

U “System Language Settings” on page 68

19

Page 20

Settings/Maintenance

System Operation Settings/Inspections

In System Operation Settings/Inspections (01) on the Settings/Maintenance screen, you can check the contents of

the Installation Information Settings (011) and make settings for Settings for Optional Equipment (012) and Printer

Operation Settings (013).

Installation Information Settings

Click Installation Information Settings (011) from System Operation Settings/Inspections (01) to display the

screen. Here you can check the printer's information.

Item Explanation

Printer Name Displays the printer name.

Set by service personnel.

Installation Date Displays the installation date.

Set by service personnel.

Model Name Displays the model name.

Serial Number Displays the printer's serial number.

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

20

Page 21

Settings/Maintenance

Settings for Optional Equipment

Click Settings for Optional Equipment (012) from System Operation Settings/Inspections (01) to display the

screen. Make settings for optional equipment that has been installed.

After changing settings, click Apply to apply the changes.

Item Explanation

Back Printing Unit Attached/Not

Attached

Print Density

Control

(Head 1/Head 2)

Select Roll Paper Select the roll paper feeder you want to use for the test print.

Paper Surface Type Displays the Paper Surface Type of the paper loaded in the roll paper

Test Print Click to perform a test print.

Displays the installation status for the back printing unit.

Adjust the print density for the back printing unit heads in seven levels.

This can be set when the back printing unit is Attached.

This can be selected when the back printing unit is Attached and paper is

loaded.

feeder.

"-" is displayed when roll paper is not loaded.

This can be performed when the back printing unit is Attached and the

roll paper feeder is selected.

This cannot be performed when the Paper Surface Type does not

support back printing.

21

Page 22

Settings/Maintenance

Item Explanation

Sorter/Long Paper

Ejection Unit

Humidity Control Unit Attached/Not

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Date of Adjustment Displays the time when Print Density Control was last performed.

Apply Click to apply any changed settings.

Attached/Not

Attached

Sorter Select Enabled or Disabled for the sorter.

Attached

Displays the installation status for the Sorter/Long Paper Ejection Unit.

This can be set when the Sorter/Long Paper Ejection Unit is Attached.

When changing from Disabled to Enabled, you need to restart the

printer.

Displays the installation status for the humidity control unit.

Set by service personnel.

You can check the changed date settings for each Paper Surface Type.

Tip:

O Only the Dual Roll Model supports front roll paper. For the Single Roll Model, information is not displayed under the

front paper item. See the information for rear roll paper.

22

Page 23

Settings/Maintenance

Printer Operation Settings

Click Printer Operation Settings (013) from System Operation Settings/Inspections (01) to display the screen.

Make settings for the power saving, the warning buzzer and the completion confirmation for long length sheet

printing.

After changing settings, click Apply to apply the changes.

Item Explanation

Power Saving Settings Select the time to enter sleep mode (power saving mode) after this product finishes operations.

Settings: None, 5 Minutes, 10 Minutes, 15 Minutes, 30 Minutes, 1 Hour, 2 Hours

Warning Buzzer Settings Select whether or not to sound the warning buzzer.

Settings: ON/OFF

Completion Confirmation

for Long Length Sheet

Printing

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Apply Click to apply any changed settings.

Select whether or not to display a confirmation message (2190) when completing long length

sheet printing of 12 to 18 inches (305 to 457 mm).

Displays a message when completing long length sheet printing over 18 inches (457 mm).

This is only available when the Sorter/Long Paper Ejection Unit is attached.

Settings: Selected (the message is not displayed) / Not selected (the message is displayed)

23

Page 24

Settings/Maintenance

Print Condition Settings/Inspections

In Print Condition Settings/Inspections (02) on the Settings/Maintenance screen, you can set Image Quality

Settings (021), and check Paper Information (022).

Image Quality Settings

Click Image Quality Settings (021) from Print Condition Settings/Inspections (02) to display the screen. Make

image quality settings.

This is only available when there are no image quality settings in the application used for printing.

After changing settings, click Apply to apply the changes.

Item Explanation

Standard Set the printer's image quality to Standard (720 dpi).

Generally, use Standard settings.

High Image Quality Set the printer's image quality to high resolution (1440 dpi).

When you want to print at a higher resolution than Standard, set to High Image Quality.

Printing takes longer than in Standard mode, as priority is given to image quality.

This is only available when Glossy or Luster is set as the Paper Surface Type.

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Apply Click to apply any changed settings.

24

Page 25

Settings/Maintenance

Paper Settings

Click Paper Settings (022) from Print Condition Settings/Inspections (02) to display the screen.

You can check the paper information loaded in the front roll paper feeder or the rear roll paper feeder, and change

the remaining amount of paper.

Tip:

Only the Dual Roll Model supports front roll paper. For the Single Roll Model, information is not displayed under the

front paper item. See the information for rear roll paper.

Item Explanation

Front Paper Type Displays the type of paper (the paper name) loaded in the front roll paper feeder.

Paper Surface

Type

Paper Width Displays the width of the paper loaded in the front roll paper feeder.

Paper Level Displays the remaining amount of paper loaded in the front roll paper feeder. If the

Rear Paper Type Displays the type of paper (the paper name) loaded in the rear roll paper feeder.

Paper Surface

Type

Paper Width Displays the width of the paper loaded in the rear roll paper feeder.

Paper Level Displays the remaining amount of paper loaded in the rear roll paper feeder. If the displayed

Displays the paper surface type (the processing type for the paper surface) loaded in the

front roll paper feeder.

Displays the width detected by the printer.

displayed amount of paper remaining differs from the actual amount, enter the correct

amount of paper and then click Apply.

Displays the paper surface type (the processing type for the paper surface) loaded in the rear

roll paper feeder.

Displays the width detected by the printer.

amount of paper remaining differs from the actual amount, enter the correct amount of

paper and then click Apply.

25

Page 26

Settings/Maintenance

Item Explanation

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Apply Click to apply any changed settings.

26

Page 27

Settings/Maintenance

CR Unit Adjustment/Maintenance

In CR Unit Adjustment/Maintenance (03) on the Settings/Maintenance screen, you can perform Head Cleaning

(031) and Color Calibration (034).

When performing maintenance in Settings/Maintenance, make sure that the p light on the printer's Operation

panel is on before starting operations.

Head Cleaning

This function allows you to check for clogging in the print head, and to clear any clogged nozzles. If printing is

performed while nozzles are clogged, there may be streaks in the prints or there may be a difference in color. If you

notice any of these problems, follow the instructions on the next page to perform Head Cleaning (031).

The following two menus are available in Head Cleaning (031).

Auto Cleaning (0311) A sensor inside the printer checks

for any clogged nozzles and

performs head cleaning

automatically if clogging is

detected.

Nozzle Check (0312) You can specify the clogging

detection method and the

cleaning method. Perform a

nozzle check if the situation has

not improved after performing

Auto Cleaning (0311).

27

Page 28

Settings/Maintenance

There are streaks in the prints or other problems such as a difference in color

1

<Example>

Perform Auto Cleaning (0311).

2

When all of the Result

icons on the screen are

“green”

-> Operations are

complete.

If the problems in the

prints are not resolved,

perform clogging

detection and head

cleaning as described in

the Notes section.

3

When a Result icon on the screen is

“yellow”

-> Perform Auto Cleaning (0311) again.

Go to the next step if the Result are not

"Good" after repeating the procedure

three times.

Perform Detect Clogging from Nozzle Check (0312), and then click Powerful for

any of the heads that have “red” (or “yellow”) icons.

After cleaning, perform Detect Clogging.

If the Result on the screen are “Good”, and

there are no problems in the prints

When a Result icon on the screen is

“red”

Go to the next step.

If the Result on the screen are “Good”, but

there are still problems in the prints

-> Operations are complete.

-> Contact Service Support.

Notes:

When the Result of Auto Cleaning (0311) are "Good", but nozzles still appear to be clogged

Auto Cleaning (0311) and Detect Clogging search for clogged nozzles using an electronic sensor. Therefore, it is possible

that clogged nozzles were not detected by the sensor. If there is any doubt, perform Print Check Pattern from Nozzle

Check (0312), visually check for clogged nozzles, and then perform cleaning as necessary.

28

Page 29

Settings/Maintenance

Auto Cleaning

From the CR Unit Adjustment/Maintenance (03) menu, click Auto Cleaning (0311) from Head Cleaning (031) to

display the screen.

Click Auto Cleaning.

A

Nozzle check begins, and cleaning is performed as necessary.

This may take some time depending on the status of the nozzles.

Check the status of each head displayed in the Result.

B

When the nozzles are cleared, "Good" is displayed.

If nozzles are clogged, a message is displayed that indicates you need to clean the Print Head Unit again.

Perform necessary cleaning.

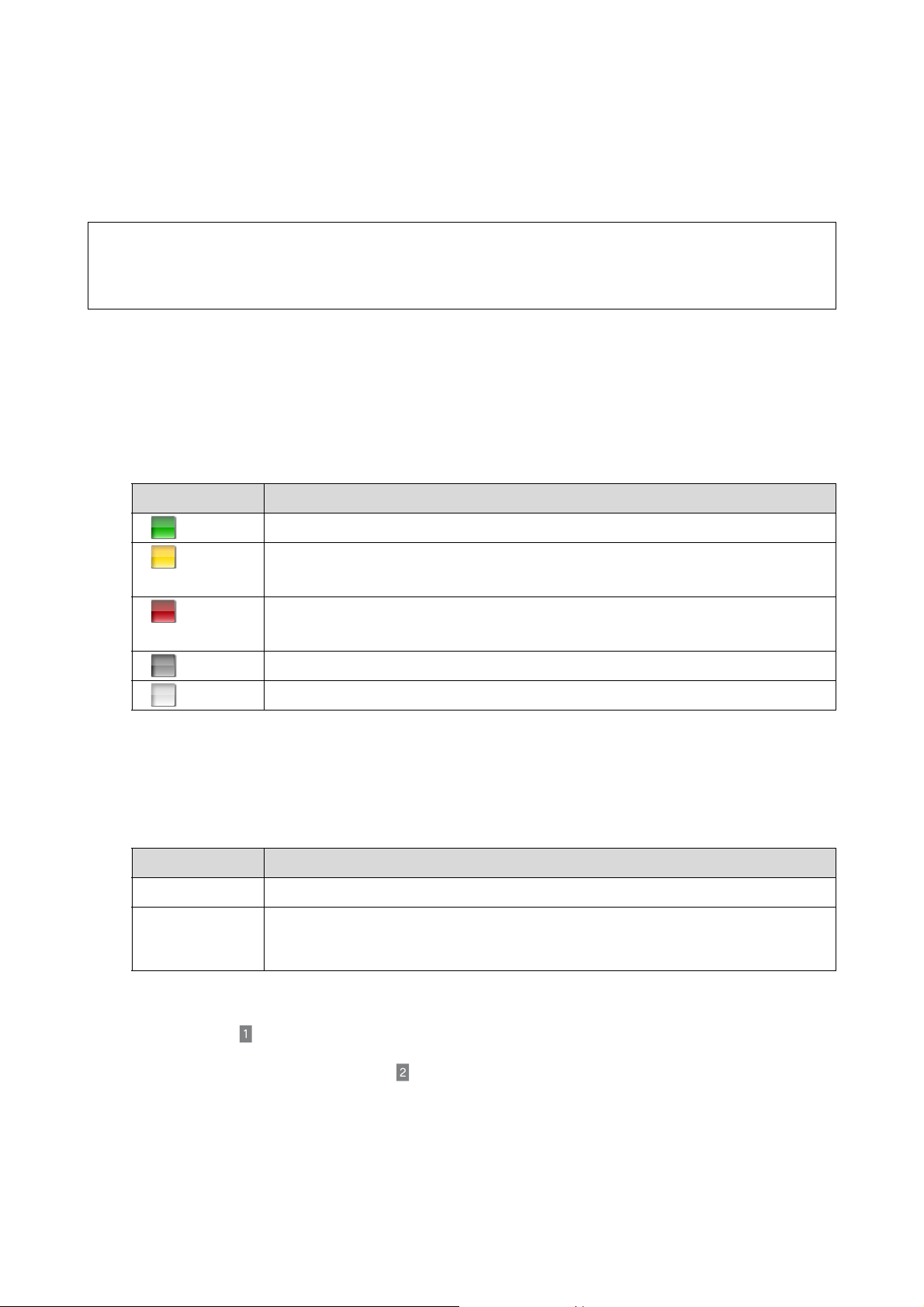

Reading the Results:

Color Explanation

Green The nozzles are not clogged.

Yellow Clogging is detected.

Perform Auto Cleaning (0311) again.

Red Clogging is detected.

Perform Detect Clogging from Nozzle Check (0312), and then perform Powerful cleaning

again for heads indicated by red.

White Auto Cleaning is still in progress.

29

Page 30

Settings/Maintenance

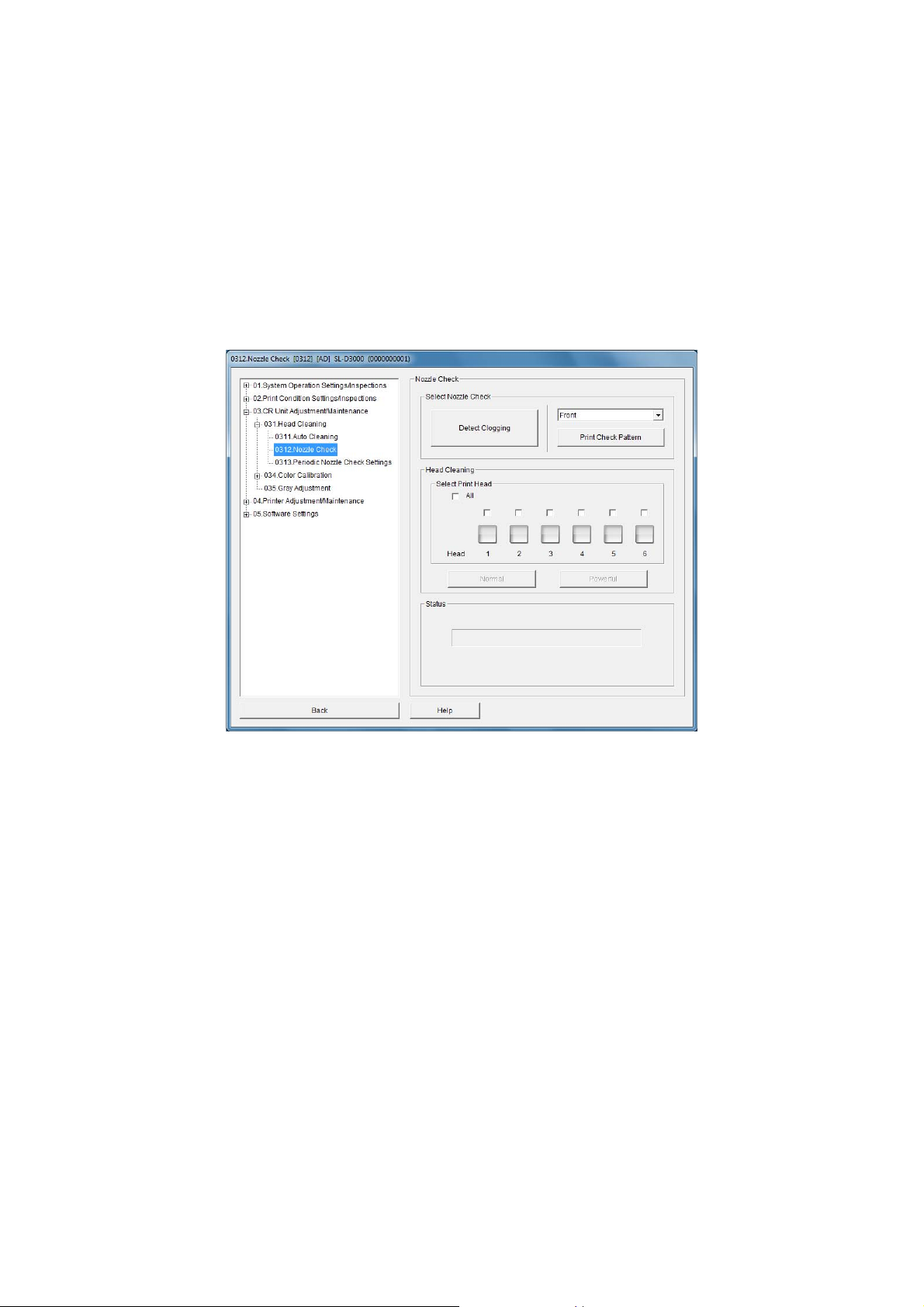

Nozzle Check

From the CR Unit Adjustment/Maintenance (03) menu, click Nozzle Check (0312) from Head Cleaning (031) to

display the screen.

This function allows you to check for clogged nozzles in the Print Head Unit. The printer automatically detects

clogging and displays the information on the screen. You can also print a check pattern for confirmation.

After performing a nozzle check, specify the type on the screen to perform head cleaning if necessary.

30

Page 31

Settings/Maintenance

Checking with Detect Clogging

The printer checks the status of the nozzles, and displays any clogged nozzles on the screen. Perform Print Head

Unit cleaning according to the check results.

Tip:

The method for confirming the status of the nozzles also includes the method for printing a check pattern.

U “Printing the check pattern” on page 32

Click Detect Clogging.

A

Clogging detection starts, and the status of each nozzle is indicated by the colors.

Clogging detection takes about one minute.

Reading the Results:

Color Explanation

Green The nozzles are not clogged.

Yellow Clogging is detected.

Perform Normal cleaning.

Red Clogging is detected.

Perform Powerful cleaning.

Gray Head cleaning is complete.

White Detect Clogging is still in progress.

Select the head where clogged nozzles were detected, and then click Normal or Powerful.

B

To clean all of the print head units, check All.

The color changes to gray for the heads that have been cleaned.

Item Explanation

Normal Cleans the surface of the head, and clears clogged nozzles.

Powerful Cleans more powerfully if the results of Detect Clogging are still red or nozzles are clogged after

repeating head cleaning several times. Because Powerful consumes more ink compared to

Normal, prepare new ink cartridges before performing cleaning if ink levels are low.

Check the results after cleaning.

C

Go back to step , and then use Detect Clogging to check the status of the nozzles.

If any nozzles are clogged, perform step to clean the nozzles.

31

Page 32

Settings/Maintenance

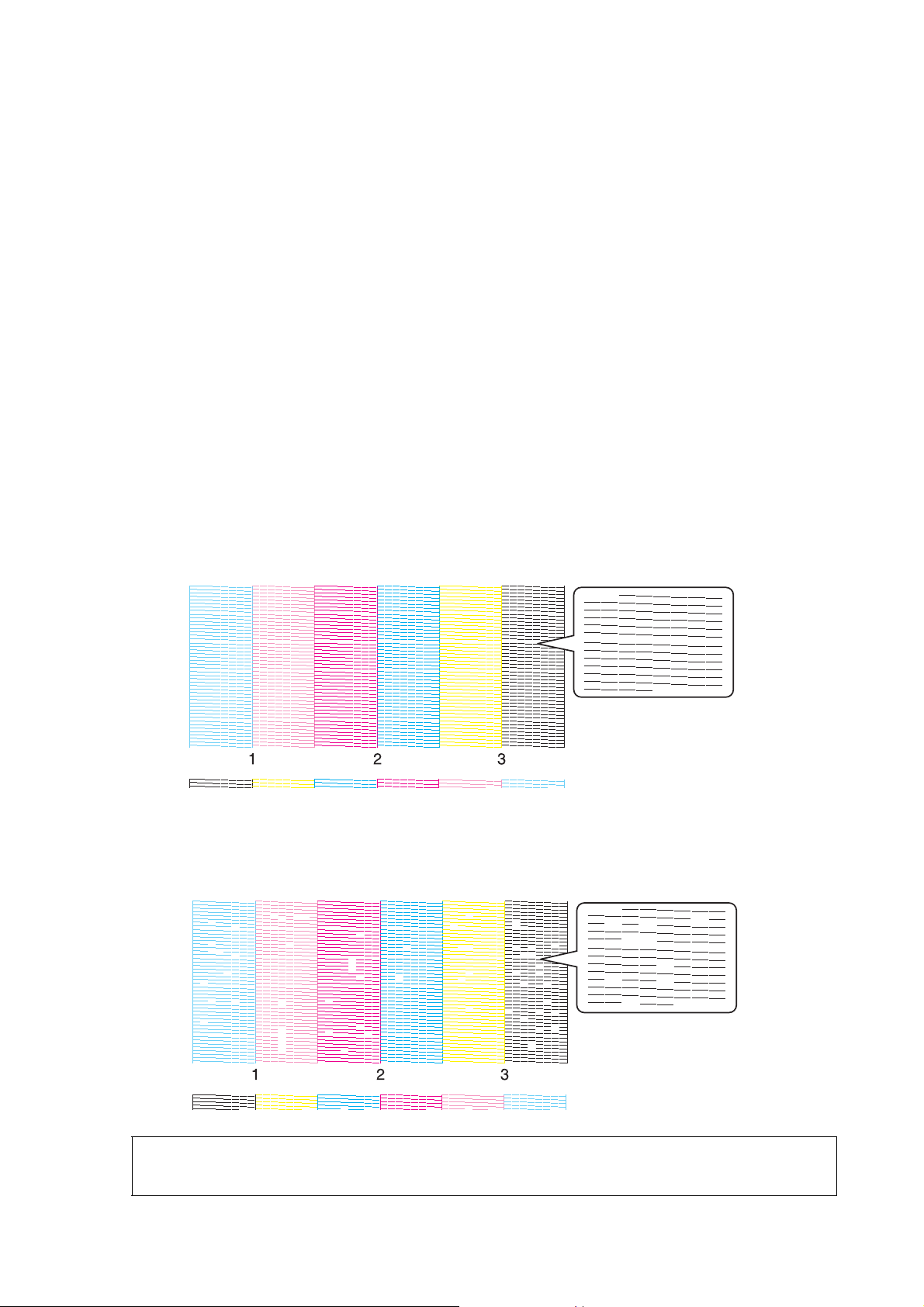

Printing the check pattern

Print a check pattern, and then check for clogged nozzles. Perform Print Head Unit cleaning according to the check

results.

Select the roll paper feeder you want to use for printing.

A

This can be selected when paper is loaded.

Click Print Check Pattern.

B

The check pattern is printed.

Check the print results.

C

See the illustration below for more information on reading the print results.

If there are any gaps in the check pattern, you need to perform head cleaning.

Result: Good

There are no gaps in the check pattern. The nozzles are not clogged.

Result: Nozzles are clogged

There are gaps in the check pattern. Nozzles are clogged. Perform cleaning.

Tip:

The numbers under the check pattern (1, 2, 3, ...) indicate the head number.

32

Page 33

Settings/Maintenance

Select the head that has clogged nozzles, and then click Normal or Powerful.

D

To clean all of the print head units, check All.

Item Explanation

Normal Cleans the surface of the head, and clears clogged nozzles.

Powerful Select if nozzles are still clogged after performing Normal head cleaning several times. Because

Powerful consumes more ink compared to Normal, prepare new ink cartridges before

performing cleaning if ink levels are low.

After cleaning, check the results using nozzle check.

E

Go back to step , and then print a check pattern to check the status of the nozzles.

If any nozzles are clogged, perform step to clean the nozzles.

Tip:

The method for confirming the status of the nozzles also includes Detect Clogging in which the printer

automatically detects clogging.

U “Checking with Detect Clogging” on page 31

33

Page 34

Settings/Maintenance

Periodic Nozzle Check Settings

From the CR Unit Adjustment/Maintenance (03) menu, click Periodic Nozzle Check Settings (0313) from Head

Cleaning (031) to display the screen.

Set whether or not to perform auto nozzle check.

We recommend that this is set to ON, because if it is set to OFF the user needs to manually check for clogging.

After changing settings, click Apply to apply the changes.

Item Explanation

ON Nozzle Check is performed automatically during Pre-operation Check, when a print order starts

and when a print order finishes.

Perform [Auto Cleaning]

during Pre-operation

Check.

OFF Auto nozzle check is not performed.

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Apply Click to apply any changed settings.

Select whether or not to perform cleaning automatically if the nozzle check detects a clog in the

print head during the Pre-operation Check. When selected, cleaning is performed automatically

and a clogging detected message (1501) is only displayed if the clog is not cleared. When

performing cleaning, the time needed for the Pre-operation Check is increased by a few

minutes.

When not selected, a message is displayed without performing cleaning if the nozzle check

detects a clog in the print head during the Pre-operation Check.

34

Page 35

Settings/Maintenance

Color Calibration

Warning:

w

If the Maintenance Utility shuts down abnormally and does not operate while performing color calibration, connect

the printer and the Client PC, and then follow the steps below to restart the Printer PC.

1. Perform a printer emergency stop.

U "SL-D3000 Operation Guide" - "Shutting down the Printer in an Emergency"

2. Restart the Client PC and the Printer PC.

3. Turn on the printer.

U "SL-D3000 Operation Guide" - "What to do after an Emergency Stop"

Colors on different printers may differ depending on environmental changes and time-dependent changes. When

using multiple printers, colors may differ among printers of the same model. The color calibration function

measures the printing results, creates a correction value using the difference from the standard color (standard

calibration value), registers the correction value to the Printer PC, and corrects colors when printing.

The following two methods of color correction use different standard calibration values.

O When reducing the color differences from a standard printer

Uses the calibration file created by the standard printer.

O When reducing the color differences between multiple printers

Use the calibration file created by the main printer. You can select the main printer from your printers.

Procedures for writing a correction value when reducing the color differences from a standard printer

Step Procedure Reference Page

1 Selecting the printer for which you want to correct color differences, and

performing Settings/Maintenance

2 Printing a correction chart with the initial calibration file provided U “Calibration” on page 37

3 Measuring a correction chart with the color measurement device

4 Creating and verifying the correction value

5 Writing the correction value file to the Printer PC

U “Performing Maintenance” on

page 15

35

Page 36

Settings/Maintenance

Procedures for writing a correction value when reducing the color differences between multiple printers

Step Procedure Reference Page

1 Selecting the main printer, and performing Settings/Maintenance U “Performing Maintenance” on

page 15

2 Creating the calibration file with the printer U “Create Calibration” on page

46

3 Selecting the printer for which you want to correct color differences, and

performing Settings/Maintenance (*)

4 Printing a correction chart with the calibration file created by the main

printer

5 Measuring the correction chart with a color measurement device

6 Creating and verifying the correction value

7 Writing the correction value file to the Printer PC

(*) To correct multiple printers, repeat steps 3 to 7.

U “Performing Maintenance” on

page 15

U “Calibration” on page 37

Note:

O You need a color measurement device to perform calibration. The following models are supported.

O The "i1Pro" from X-Rite (with or without a UV filter)

O The "i1iSis" from X-Rite

O When performing calibration, make sure you use paper with a width of 8 inches, 10 inches, 12 inches, or 210 mm.

O When using a color measurement device, install the software for the measurement device in advance on the Client PC

(the PC that will perform the calibration).

O Do not touch the printable side of the correction chart or the verification chart. Moisture and oils from your hands

can affect the color measurement results.

O Consult service personnel for more information on preparing and setting up the color measurement device.

36

Page 37

Settings/Maintenance

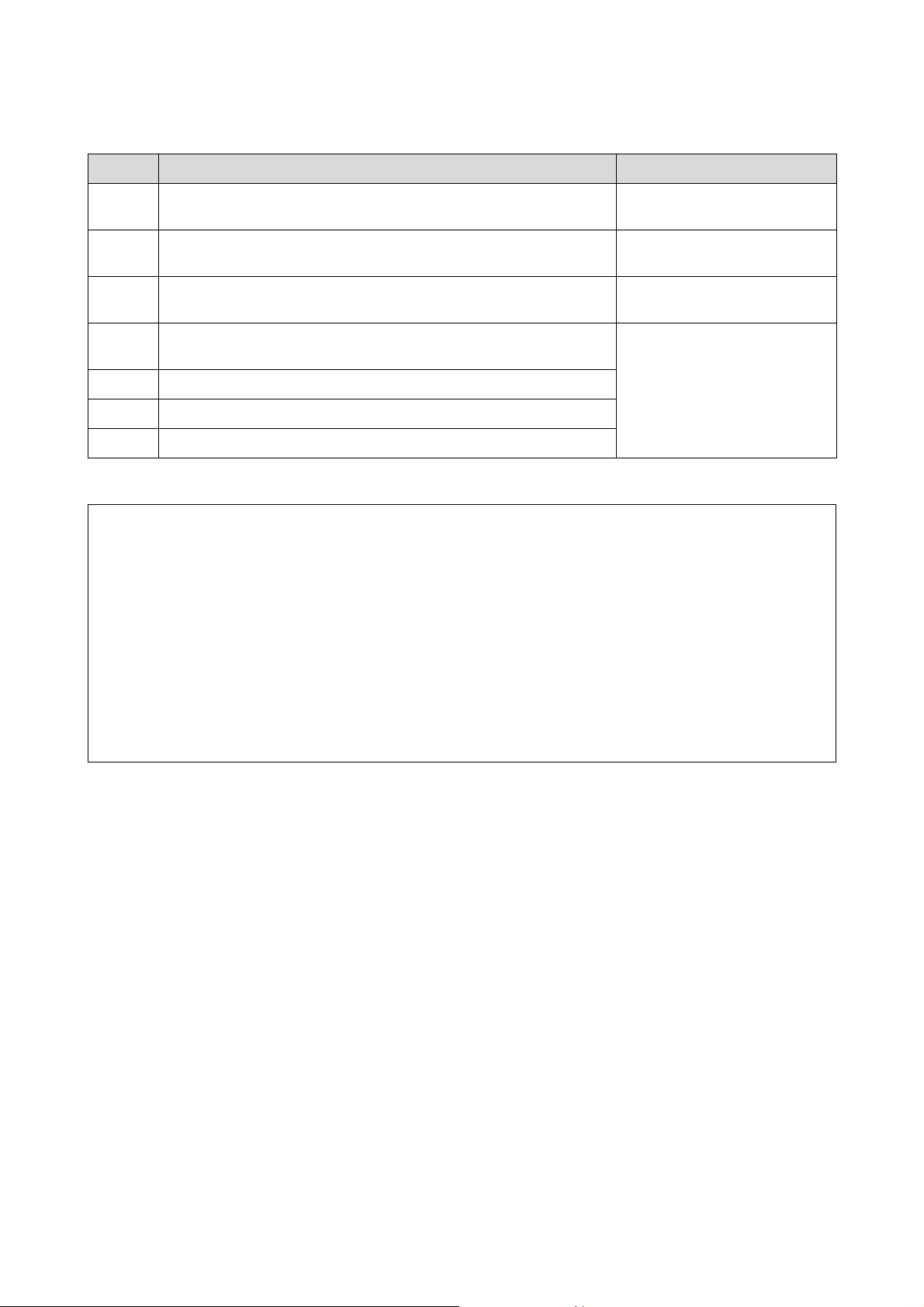

Calibration

Click Calibration (0341) from Color Calibration (034) to display the screen.

You can perform calibration by using the following work flow.

Create Correction

Value

Correction Value

Verification

Print Print a correction chart: Prints a chart for adjustment.

Measure Color Measure color for the correction chart:

Perform color measurement for the printed chart on the Client PC with a

connected color measurement device.

Create Correction Value Creating a correction value: Create a correction value file.

Print Print a verification chart: Prints a verification chart.

Measure Color Measure color for the verification chart:

Perform color measurement for the printed chart on the Client PC with a

connected color measurement device.

Write Verify correction accuracy:

Verify the accuracy of the created correction value to complete the

correction value file creation process.

Tip:

O After adjusting values for Gray Adjustment, perform Color Calibration, and then make the settings again.

U “Gray Adjustment” on page 50

O Click Date of Adjustment to display the time when it was last adjusted. You can check the changed date settings for

each Paper Surface Type.

37

Page 38

Settings/Maintenance

Print a correction chart

Select the roll paper feeder used for printing in

A

Paper.

Displays the Paper Width and Paper Surface

Type for the paper loaded in the selected roll

paper feeder.

Tip:

O Click Applicable Paper Surface Type to

check the relations between the paper used

for creating a correction value and the paper

applied the created correction value.

O Only the Dual Roll Model supports front

roll paper. For the Single Roll Model, see the

information for rear roll paper.

Click Print from Correction Value Creation

D

Phase.

A confirmation screen is displayed.

Click Yes.

E

Click No to cancel printing.

For Use Standard Value for Collective Creation,

a total of three charts are printed. These include

standard and high image quality for

Glossy/Luster, and standard for Matte.

For Specify Standard Value using Glossy/Luster

surface type, a total of two charts are printed.

These include standard and high image quality.

For Specify Standard Value using Matte surface

type, one standard chart is printed.

Select the color measurement device.

B

Select the standard value you want to use.

C

When collectively creating the correction values

that will be compatible with each paper surface

type, check Use Standard Value for Collective

Creation, and then select the standard value

from the list. When using a standard value for

each paper surface type, check Specify Standard

Value, and then select the standard value from

the list.

Note:

When collectively creating the correction values,

make sure you use Glossy paper.

Tip:

The initial calibration file provided contains

standard values for a standard printer. To

minimize the color difference between multiple

printers, check Specify Standard Value, and

then select the standard value file created by the

main printer.

U “Create Calibration” on page 46

Tip:

O Nozzle Check is performed automatically

before printing. If clogging is detected in the

head, Print again after cleaning the head

and clearing the clogged nozzles.

U “Head Cleaning” on page 27

O The number of charts printed varies

depending on the settings and the paper.

38

Page 39

Settings/Maintenance

The following screen is displayed after printing

F

the first sheet. Follow the on-screen

instructions, and then click OK.

The charts the second sheet and after are

printed.

Note:

Do not allow the printed correction charts to

overlap while drying. The color tone of the

overlapped section may differ, leading to

improper calibration.

U “Correction chart color measurement (for

the "i1Pro")” on page 40

U “Correction chart color measurement (for

the "i1iSis")” on page 42

Tip:

If the confirmation message is set not to display

in Completion Confirmation for Long Length

Sheet Printing from Printer Operation Settings,

this message is not displayed.

U “Printer Operation Settings” on page 23

Wait for 30 minutes until drying is complete.

G

Make sure the printed correction charts do not

overlap during the drying process.

Check the the drying time displayed on Status.

When the drying time reaches 0, Drying

complete. is displayed, and the Measure Color

button becomes available.

When the printed chart is dry, perform color

measurement.

Operations may differ depending on the color

measurement device you use.

39

Page 40

Settings/Maintenance

Correction chart color measurement (for the "i1Pro")

Check that the color measurement device you

A

want to use is connected.

Tip:

For more information on color measurement

device, see the document supplied with the

device.

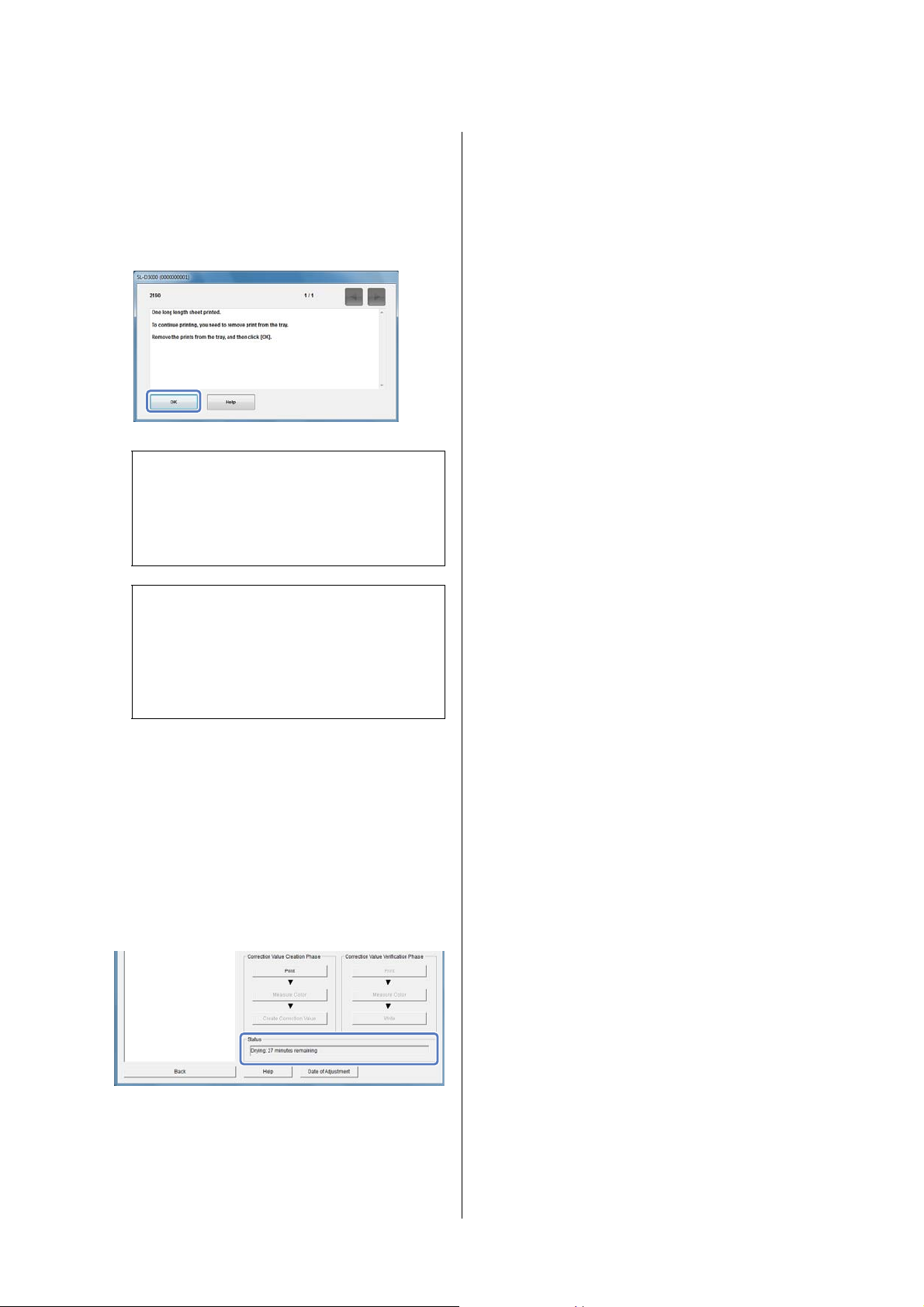

Click Measure Color from Correction Value

B

Creation Phase.

Place the color measurement device on the

C

calibration base plate, and then click OK.

Performs color measurement for the white

calibration tile.

Place the correction chart that matches the color

D

chart ID and preset ID displayed on the screen

on the measurement backup board supplied

with the color measurement device.

Place the chart on white paper if there is no

backup board available for measurement.

Tip:

O The color chart ID and preset ID are printed

at the bottom of the correction chart.

O If a correction chart sticks out beyond the

edge of the measurement backup board, cut

off the margin along the cutoff line on the

chart.

Click OK.

E

Color measurement starts.

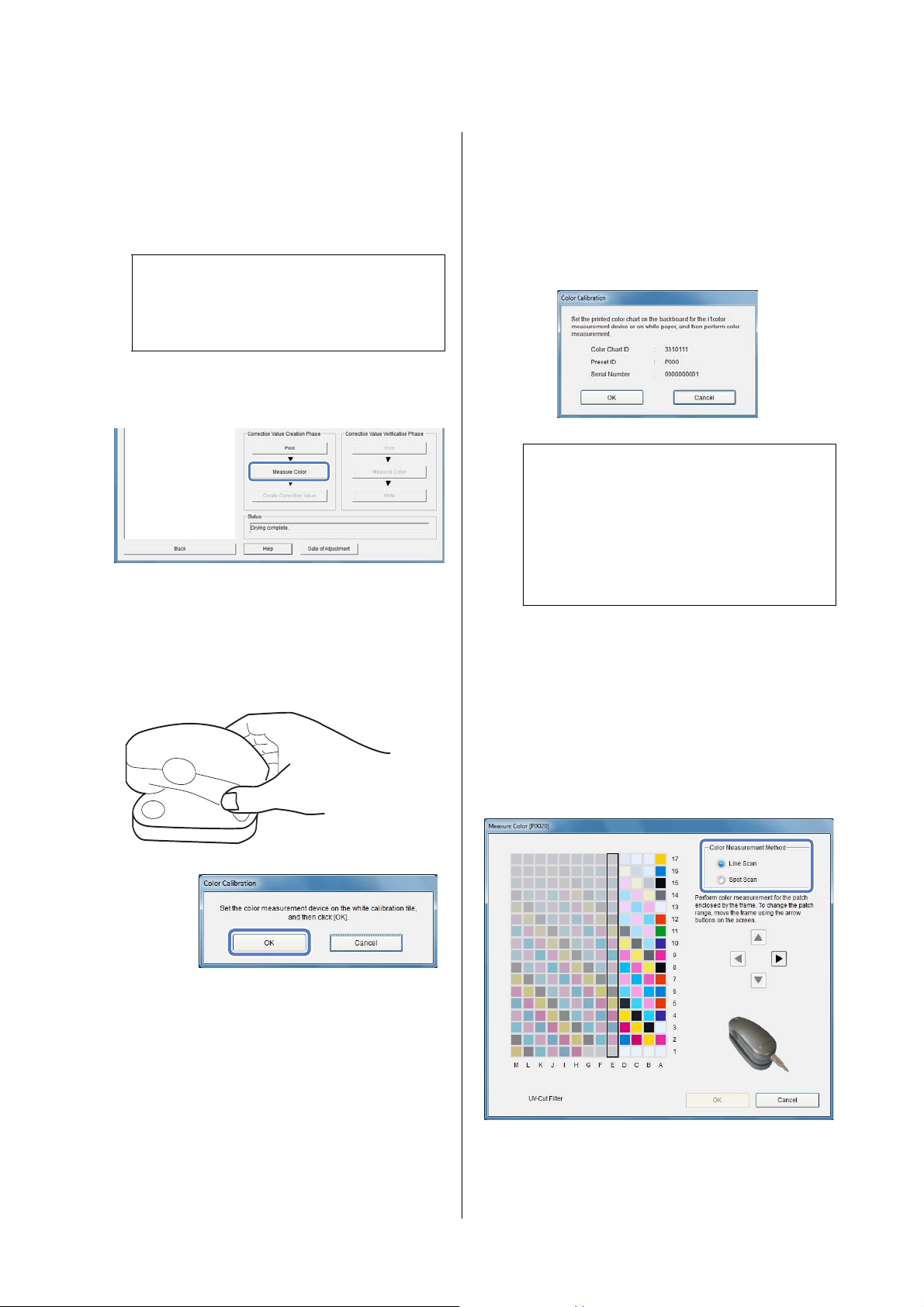

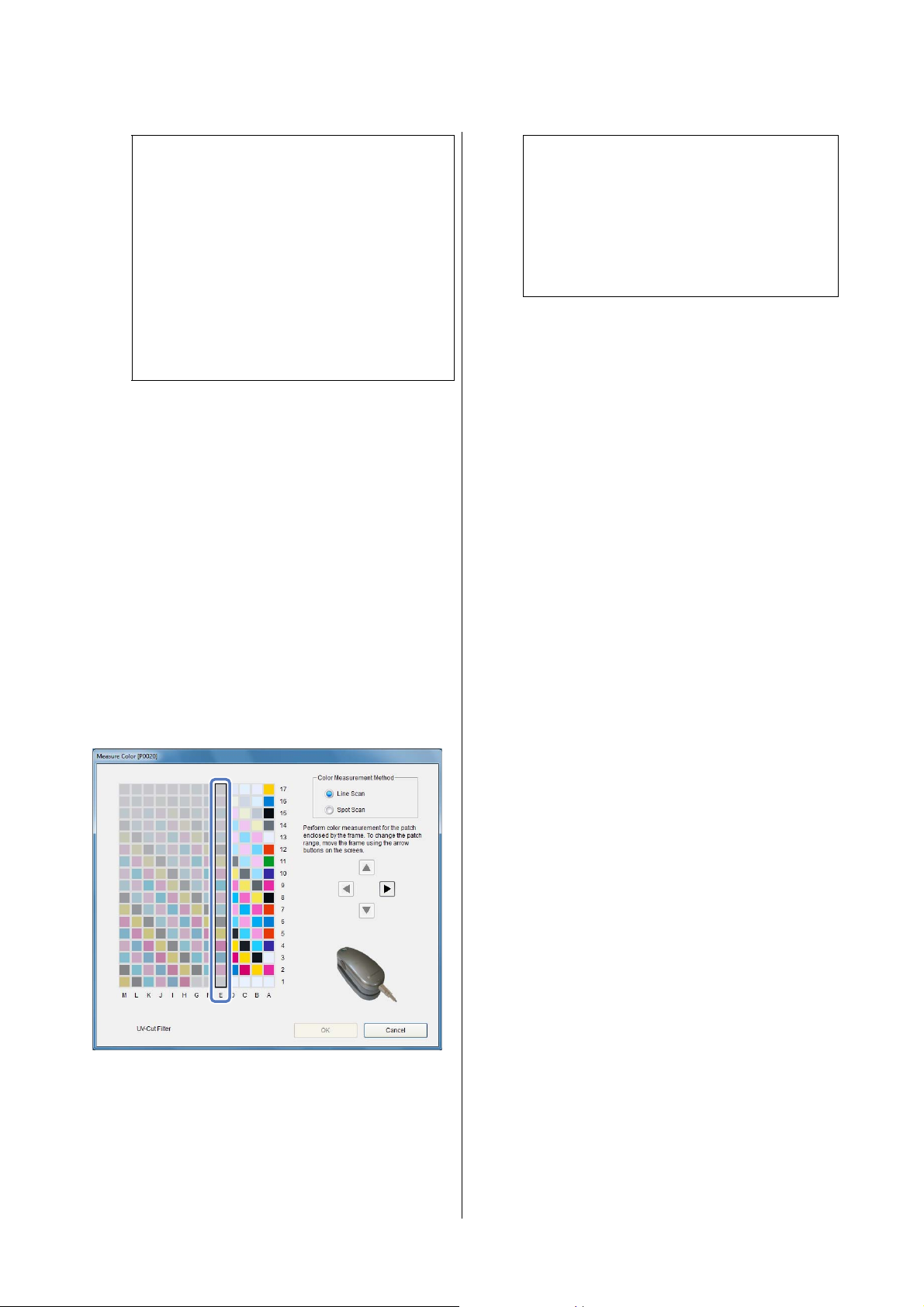

Select Color Measurement Method.

F

Select a Line Scan to perform color

measurement for each line, or select Spot Scan

to perform color measurement for each patch.

40

Page 41

Settings/Maintenance

Tip:

O Select Line Scan to perform color

measurement quickly. If the results of color

measurement using Line Scan are not what

you expected, try Spot Scan.

O When performing color measurement with

Line Scan, use the chart measurement ruler

supplied with the color measurement device.

O When performing color measurement with

Spot Scan, use the spot measurement guide

supplied with the color measurement device.

Perform color measurement in the order of the

G

range displayed on the screen.

To change the scanning range, move by clicking

the arrow buttons on the screen.

When performing color measurement in Line

Scan, match the color measurement device to

the measurement ruler being used, hold down

the button on the side, and slowly move over the

patch to scan.

Tip:

O The color measurement range differs

depending on the Color Measurement

Method selected.

O For more information on color

measurement device, see the document

supplied with the device.

When color measurement is complete, click

H

OK.

Continue to create the correction value.

U “Create, verify, and write the correction value” on

page 43

When performing color measurement with Spot

Scan, adjust the measurement guide so that it is

over the target patch, place the color

measurement device, and then press the button

on the side.

When reading is successful, the data is displayed

on the screen where the correction chart is read.

When reading fails, an "X" is displayed on the

screen where the correction chart is read. In this

case, try reading again.

41

Page 42

Settings/Maintenance

Correction chart color measurement (for the "i1iSis")

Check that the color measurement device you

A

want to use is connected.

Tip:

For more information on color measurement

device, see the document supplied with the

device.

Click Measure Color from Correction Value

B

Creation Phase.

Tip:

O The color chart ID and preset ID are printed

at the bottom of the correction chart.

O If the paper width of the correction chart is

wider than the maximum supported width

of the color measurement device, cut off the

margin along the cutoff line on the chart.

When color measurement is complete, click

D

OK.

When the screen is displayed, check that the

C

light on the right of the color measurement

device is flashing green, and then insert the

correction chart that matches the color chart ID

and preset ID displayed on the screen into the

color measurement device.

Color measurement starts.

Continue to create the correction value.

U “Create, verify, and write the correction value” on

page 43

42

Page 43

Settings/Maintenance

Create, verify, and write the correction value

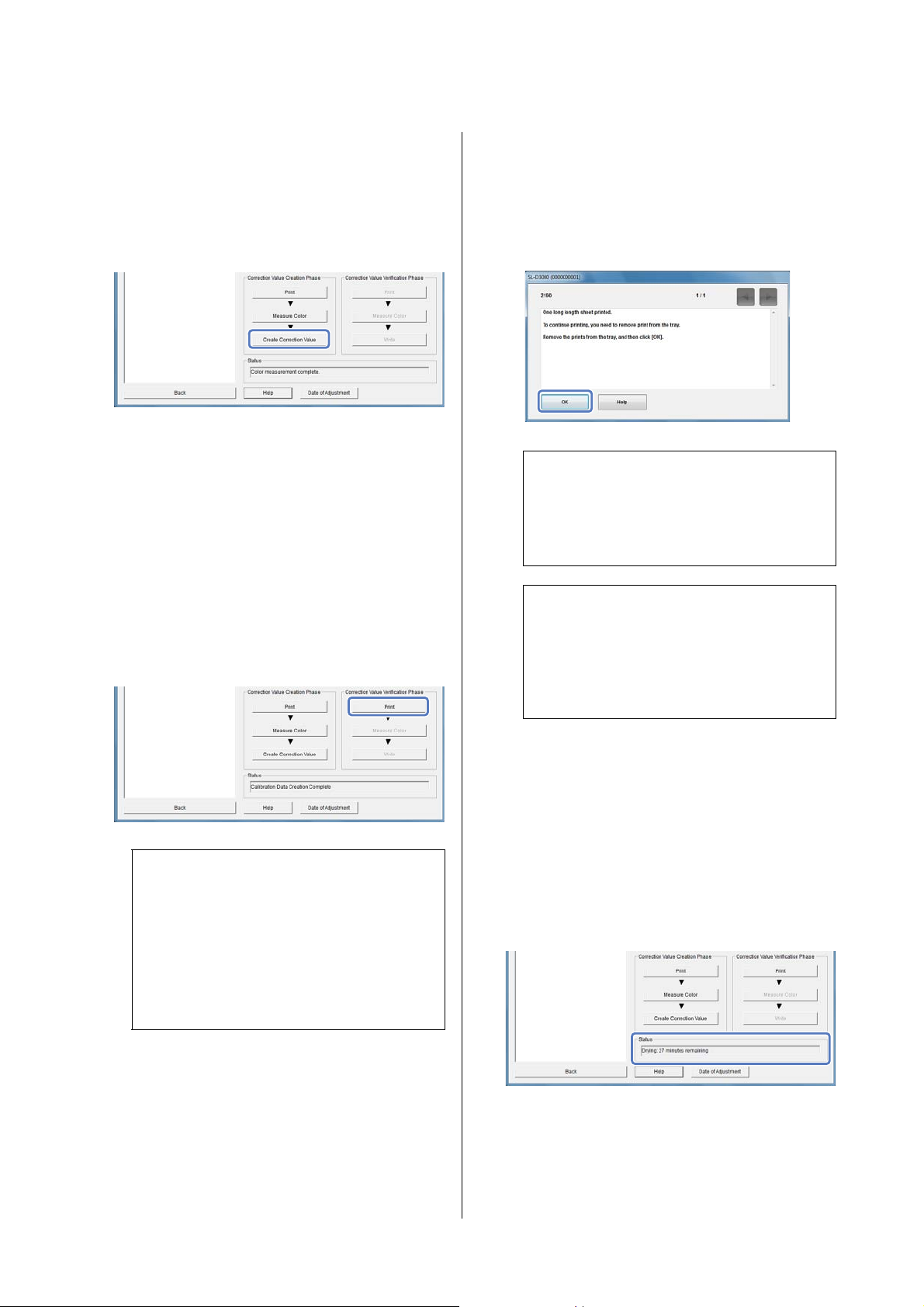

Click Create Correction Value from

A

Correction Value Creation Phase.

The correction value is created.

Click Print from Correction Value Verification

B

Phase.

For Use Standard Value for Collective Creation,

a total of three charts are printed. These include

standard and high image quality for

Glossy/Luster, and standard for Matte.

For Specify Standard Value using Glossy/Luster

surface type, a total of two charts are printed.

These include standard and high image quality.

For Specify Standard Value using Matte surface

type, one standard chart is printed.

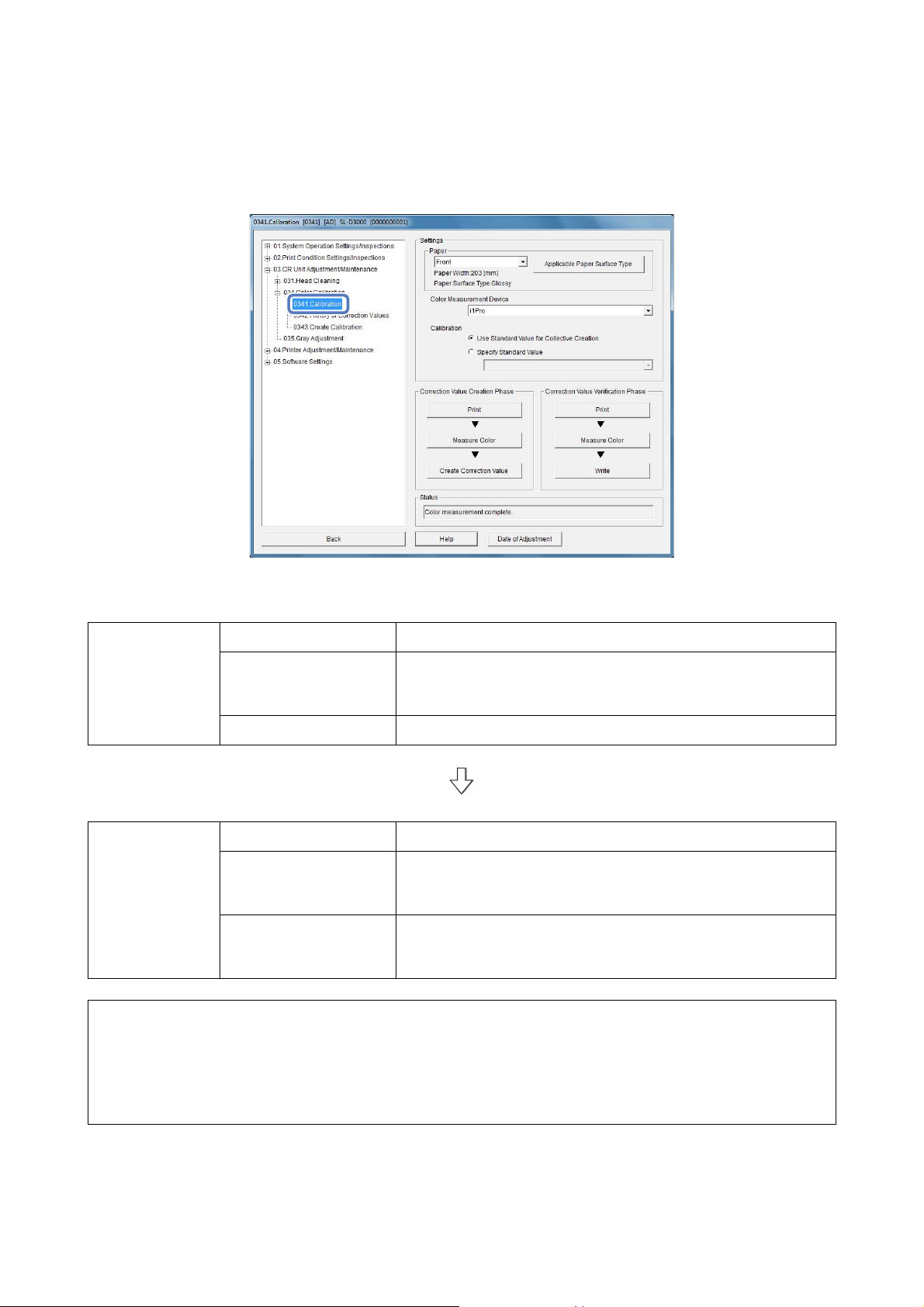

The following screen is displayed after printing

C

the first sheet. Follow the on-screen

instructions, and then click OK.

The charts the second sheet and after are

printed.

Note:

Do not allow the printed correction charts to

overlap while drying. The color tone of the

overlapped section may differ, leading to

improper calibration.

Tip:

If the confirmation message is set not to display

in Completion Confirmation for Long Length

Sheet Printing from Printer Operation Settings,

this message is not displayed.

U “Printer Operation Settings” on page 23

Tip:

O Nozzle Check is performed automatically

before printing. If clogging is detected in the

head, print again after cleaning the head

and clearing the clogged nozzles.

U “Head Cleaning” on page 27

O The number of charts printed varies

depending on the settings and the paper.

Wait for 30 minutes until drying is complete.

D

Make sure the printed correction charts do not

overlap during the drying process.

Check the drying time displayed on Status.

When the drying time reaches 0, Drying

complete. is displayed, and the Measure Color

button becomes available.

43

Page 44

Settings/Maintenance

Click Measure Color from Correction Value

E

Verification Phase.

Perform color measurement in the color

F

measurement device in the same way as color

measurement for the correction chart.

U “Correction chart color measurement (for

the "i1Pro")” on page 40

U “Correction chart color measurement (for

the "i1iSis")” on page 42

Click Write from Correction Value Verification

G

Phase.

The screen where you can enter the name of the

correction value is displayed.

Enter the name of the correction value, and then

H

click OK.

You cannot use the same name for more than

one correction value. If the same name already

exists, enter another name of the correction

value.

Verify correction accuracy.

If the verification results are "OK", write the

created correction value file to the Printer PC.

Subsequent prints are corrected using the

written correction value.

If the results are "NG", you need to create the

correction value again. Perform operations

from Print in the correction value creation

phase.

44

Page 45

Settings/Maintenance

History of Correction Values

Click History of Correction Values (0342) from Color

Calibration (034) to display the screen.

Select the correction values created previously from the

list, and write to the Printer PC.

Select the correction values to write to the

A

Printer PC from the History of Correction

Values list.

Tip:

All correction values created previously are

displayed in the History of Correction Values list.

If you select a correction value created

previously, you can return the correction value to

the previously selected value.

Click Write.

B

The correction value is written to Printer PC.

Subsequent prints are corrected using the

selected correction value.

45

Page 46

Settings/Maintenance

Create Calibration

Click Create Calibration (0343) from Color

Calibration (034) to display the screen.

Create the calibration file to be used in Calibration

(0341).

Tip:

O You can create a standard value for each paper

surface type.

O The initial calibration file provided contains

standard values for a standard printer. When

reducing the color differences between multiple

printers, select the calibration file created by the

main printer.

Note:

O You need a color measurement device to perform

calibration. The following models are supported.

O The "i1Pro" from X-Rite (with or without a UV

filter)

O The "i1iSis" from X-Rite

O When using a color measurement device, install

the software for the measurement device in

advance on the Client PC (the PC that will perform

the calibration).

Select the roll paper feeder used for printing in

A

Paper.

Tip:

Only the Dual Roll Model supports front roll

paper. For the Single Roll Model, see the

information for rear roll paper.

Select the color measurement device.

B

Enter the Calibration File Name.

C

Enter the file name of the calibration.

You can enter a file name that complies with

Windows operating system restrictions.

If the file name already exists, a screen is

displayed asking if you want to overwrite the

file.

Click Print from Calibration Creation Phase.

D

A confirmation screen is displayed.

O Consult service personnel for more information on

preparing and setting up the color measurement

device.

Click Yes.

E

Click No to cancel printing.

For a Glossy or Luster surface type, two charts

are printed. These are standard and high image

quality charts.

For a Matte surface type, one standard chart is

printed.

46

Page 47

Settings/Maintenance

Tip:

O Nozzle Check is performed automatically

before printing. If clogging is detected in the

head, print again after cleaning the head

and clearing the clogged nozzles.

U “Head Cleaning” on page 27

O The number of charts printed varies

depending on the settings and the paper.

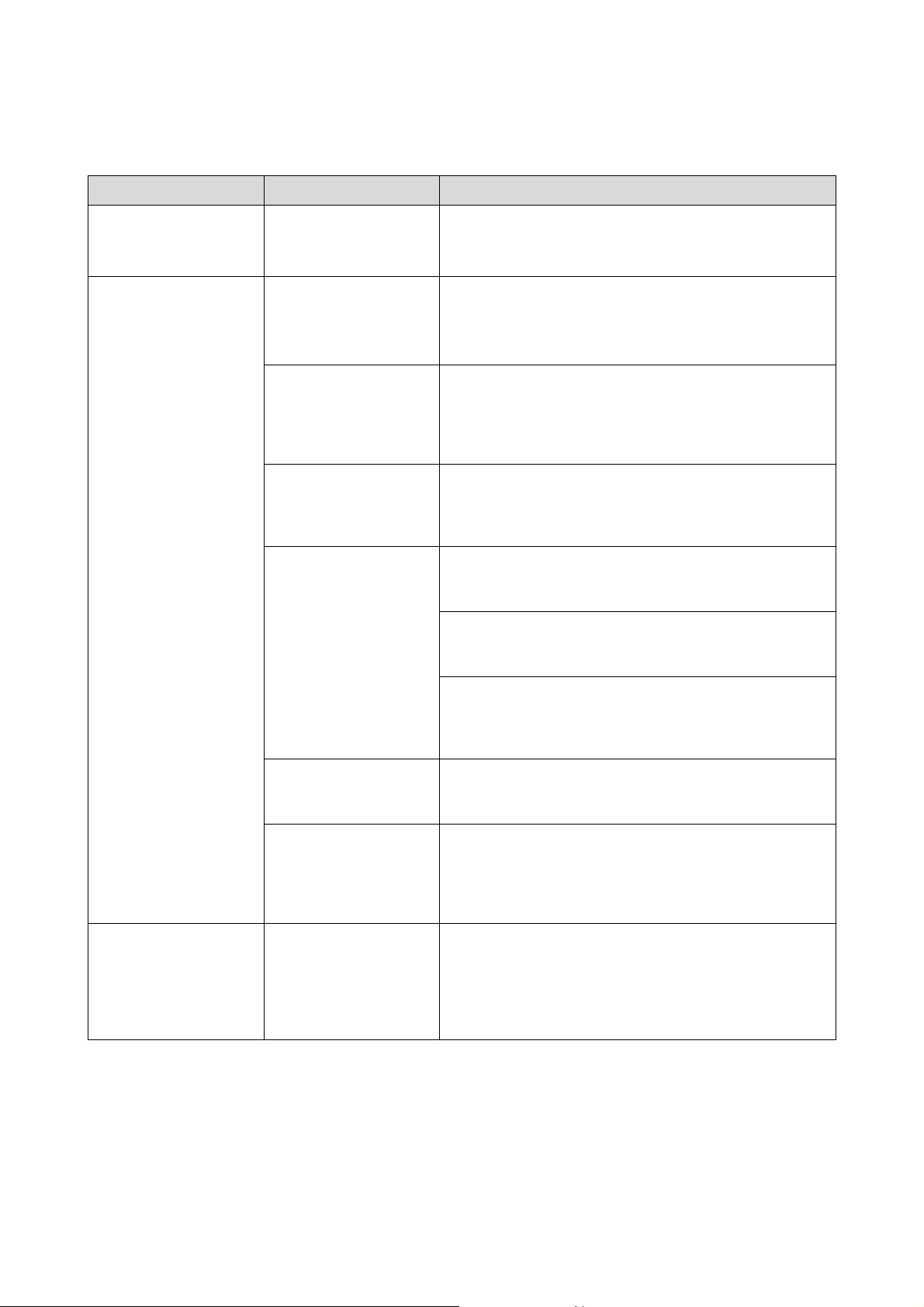

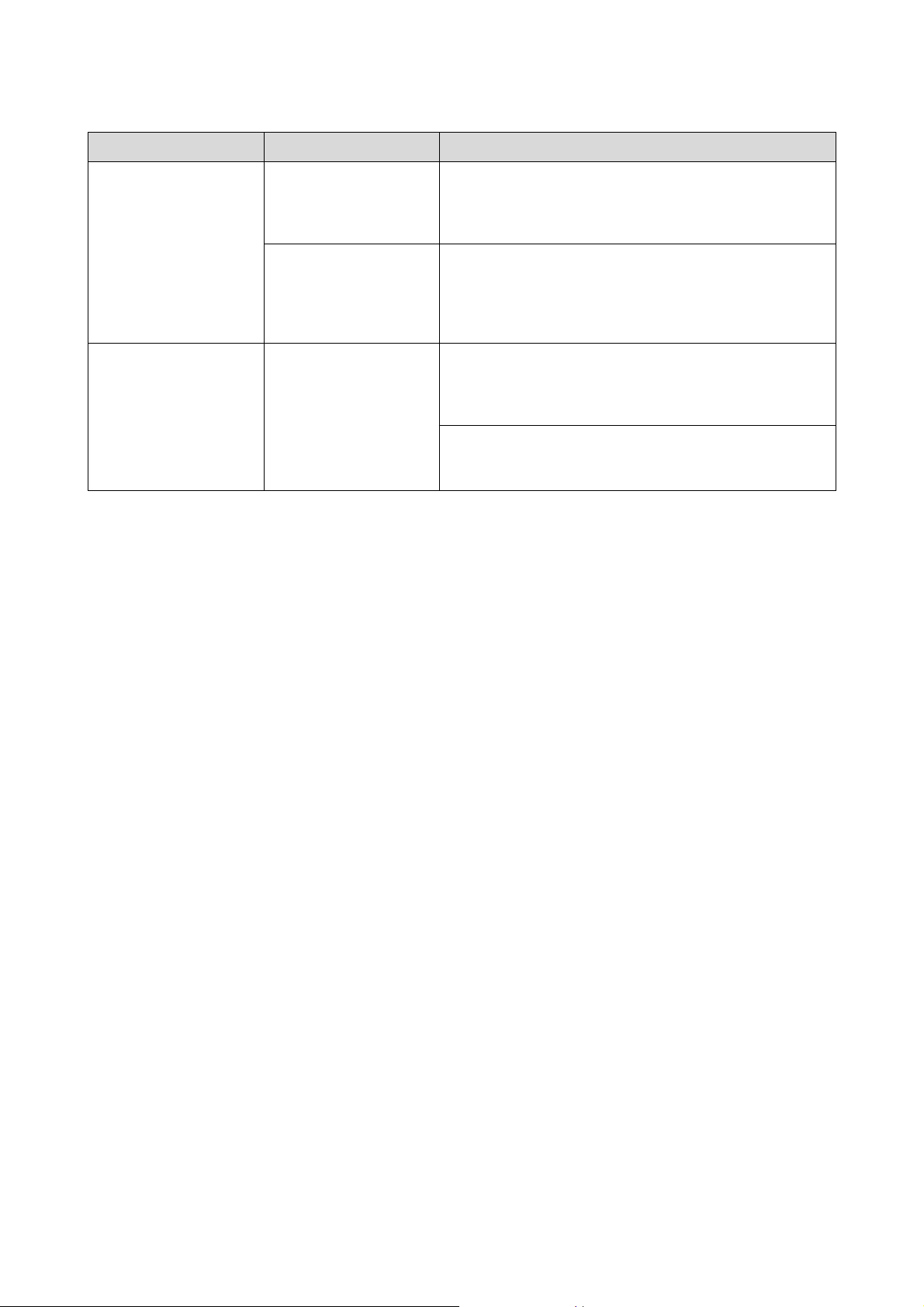

The following screen is displayed after printing

F

the first sheet. Follow the on-screen

instructions, and then click OK.

The charts the second sheet and after are

printed.

When the drying time reaches 0, Drying

complete. is displayed, and the Measure Color

button becomes available.

Check that the color measurement device you

H

want to use is connected.

Click Measure Color from Calibration Creation

I

Phase.

Note:

Do not allow the printed correction charts to

overlap while drying. The color tone of the

overlapped section may differ, leading to

improper calibration.

Tip:

If the confirmation message is set not to display

in Completion Confirmation for Long Length

Sheet Printing from Printer Operation Settings,

this message is not displayed.

U “Printer Operation Settings” on page 23

Wait for 30 minutes until drying is complete.

G

Make sure the printed correction charts do not

overlap during the drying process.

Check the drying time displayed on Status.

Perform color measurement in the color

J

measurement device in the same way as color

measurement for the correction chart.

U “Correction chart color measurement (for

the "i1Pro")” on page 40

U “Correction chart color measurement (for

the "i1iSis")” on page 42

Click Create Calibration from Calibration

K

Creation Phase.

The calibration file is created.

You can select the created calibration file in

Calibration.

47

Page 48

Settings/Maintenance

Problems with Color Calibration

Symptom Error Messages What to do

Cannot print a correction

chart.

Print is not enabled.

A color measurement

error occurs.

-

" Operation failed."

"Failed to calibrate. Color

measurement finished. Do

you want to continue? "

When using [i1Pro]:

"Failed to calibrate. Color

measurement finished. Do

you want to continue? "

When using [i1Pro]:

“×” or “!” is displayed.

When using [i1iSis]:

"Invalid color chart or the

color chart was not

printed correctly."

When using [i1Pro]:

“×” or “!” is displayed.

Has paper with a paper width of less than 8 inches been set?

Set the correct paper type and width.

Does the connected spectrometer match the selected

spectrometer?

Select the correct spectrometer.

When using [i1Pro] and performing color measurement for a

white calibration tile, is the spectrometer installed correctly

on the base plate?

Install the spectrometer correctly on the base plate, and then

perform color measurement for the white calibration tile again.

Did the spectrometer perform a quick, rough scan while

performing color measurement in [i1Pro]?

Make sure the spectrometer performs a slow and thorough scan

when measuring color.

Has a correction chart with a different Color Chart ID been

loaded?

Load the correction chart with the correct Color Chart ID.

Is the correction chart loaded correctly?

Load the correction chart correctly, and then perform color

management again.

Is the print quality of the correction chart too low, or is it

soiled?

Perform Head Cleaning, reprint the correction chart, and then

perform color measuring again.

The maintenance utility

closes during color

measuring due to an error.

“×” or “!” is displayed.

" Operation failed."

-

-

Is the PC connected to the spectrometer correctly?

Check the connection between the spectrometer and the PC, and

then perform color measuring again.

Were the correction charts overlapping during the drying

process?

The color tone for the overlapping sections may change while

drying, and calibration may not be performed correctly.

Print the correction charts again.

Did the spectrometer perform a quick, rough scan while

performing color measurement in [i1Pro]?

Restart the printer and the PC, and then perform color measuring

again.

Make sure the spectrometer performs a slow and thorough scan

when measuring color.

48

Page 49

Settings/Maintenance

Symptom Error Messages What to do

The results of the

Correction Value

Verification Phase are NG.

An error occurred while

generating the correction

value, writing the

correction value, or

writing the standard value.

-

-

"Operation failed."

"Failed to write Correction

Value File. Try again. "

Did a color measurement error occur?

Perform Correction Value Creation Phase and Correction Value

Verification Phase again while referring to the solutions in "A

Color Measurement Error Occurred" from Troubleshooting.

Were the correction charts overlapping during the drying

process?

The color tone for the overlapping sections may change while

drying, and calibration may not be performed correctly.

Print the correction charts again.

Are the PC and the printer connected to the spectrometer

correctly?

Check the connection between the PC and the printer, and then

click Create Correction Value again.

Is there enough free space on the PC's hard disk?

Make sure there is sufficient free space on the PC's hard disk, and

then click Create Correction Value again.

49

Page 50

Settings/Maintenance

Gray Adjustment

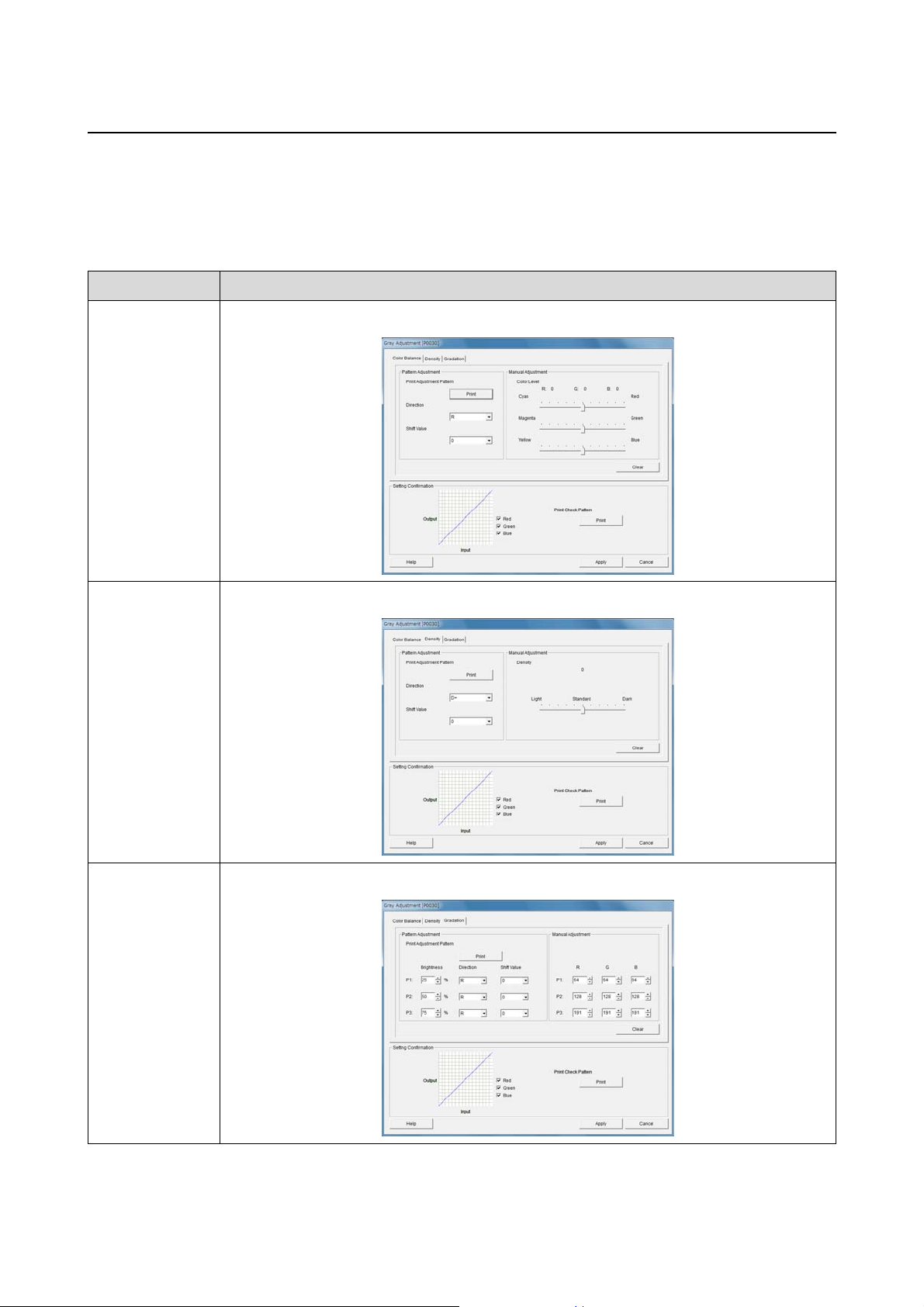

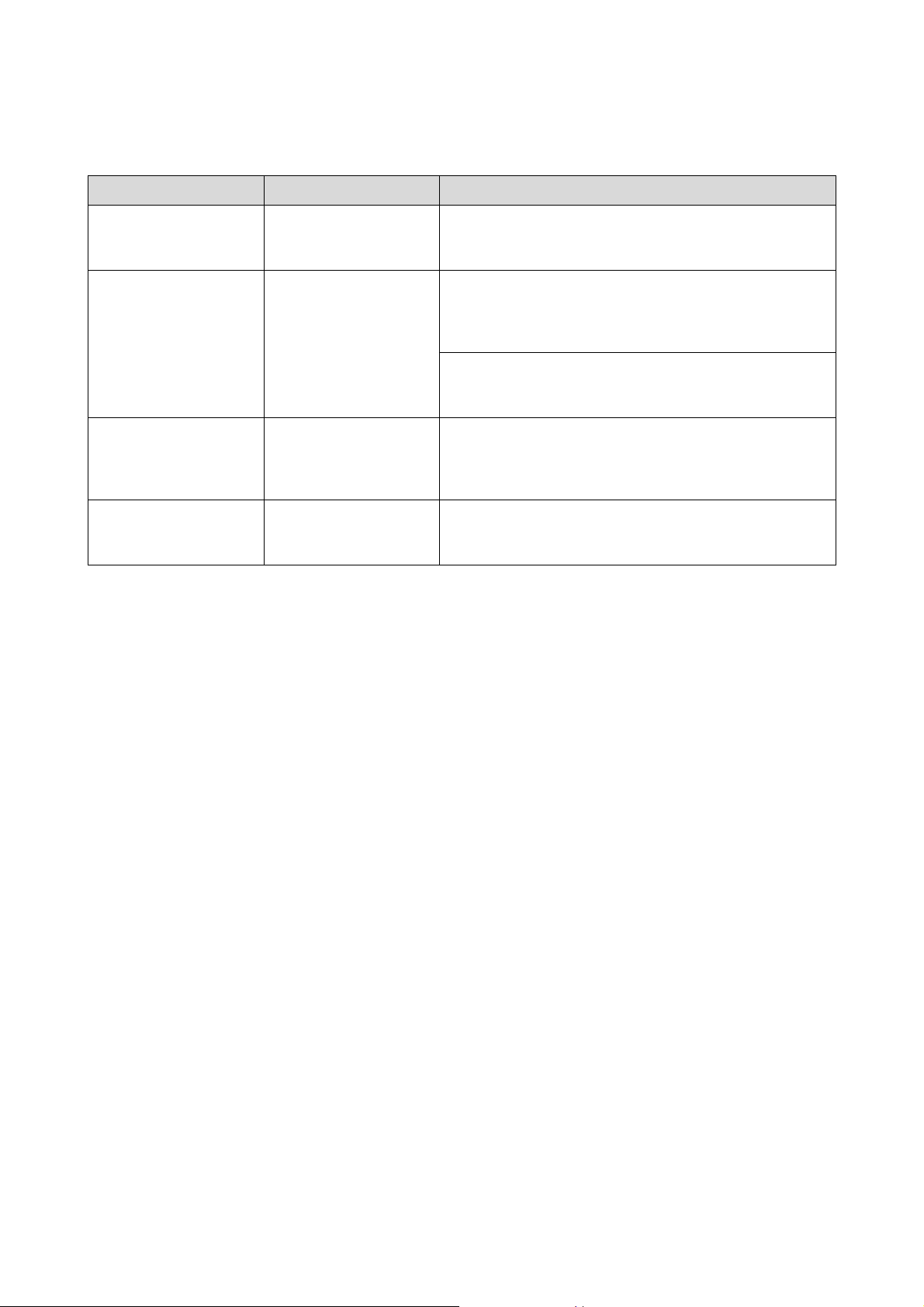

You can adjust each value for Color Balance, Density, and Gradation to correct the tone of the prints.

Adjustment values can be saved for each Standard or High Image Quality of the Image Quality Settings.

Print an adjustment pattern, and then select the optimal values from the adjustment pattern.

Tab Explanation

Color Balance Changes the strength for Cyan (C), Magenta (M), and Yellow (Y) to adjust the color balance.

Density Adjusts the density (Dark/Light).

Gradation Adjusts the overall gradation (the difference between light and shade) of the image.

50

Page 51

Settings/Maintenance

Note:

O You can perform Gray Adjustment for each Paper Surface Type.

O Click Date of Adjustment to display the time when it was last adjusted. You can check the changed date settings for

each Paper Surface Type and the Image Quality Settings.

O Only the Dual Roll Model supports front roll paper. For the Single Roll Model, see the information for rear roll paper.

O After performing Color Calibration, you need to make settings for Gray Adjustment again.

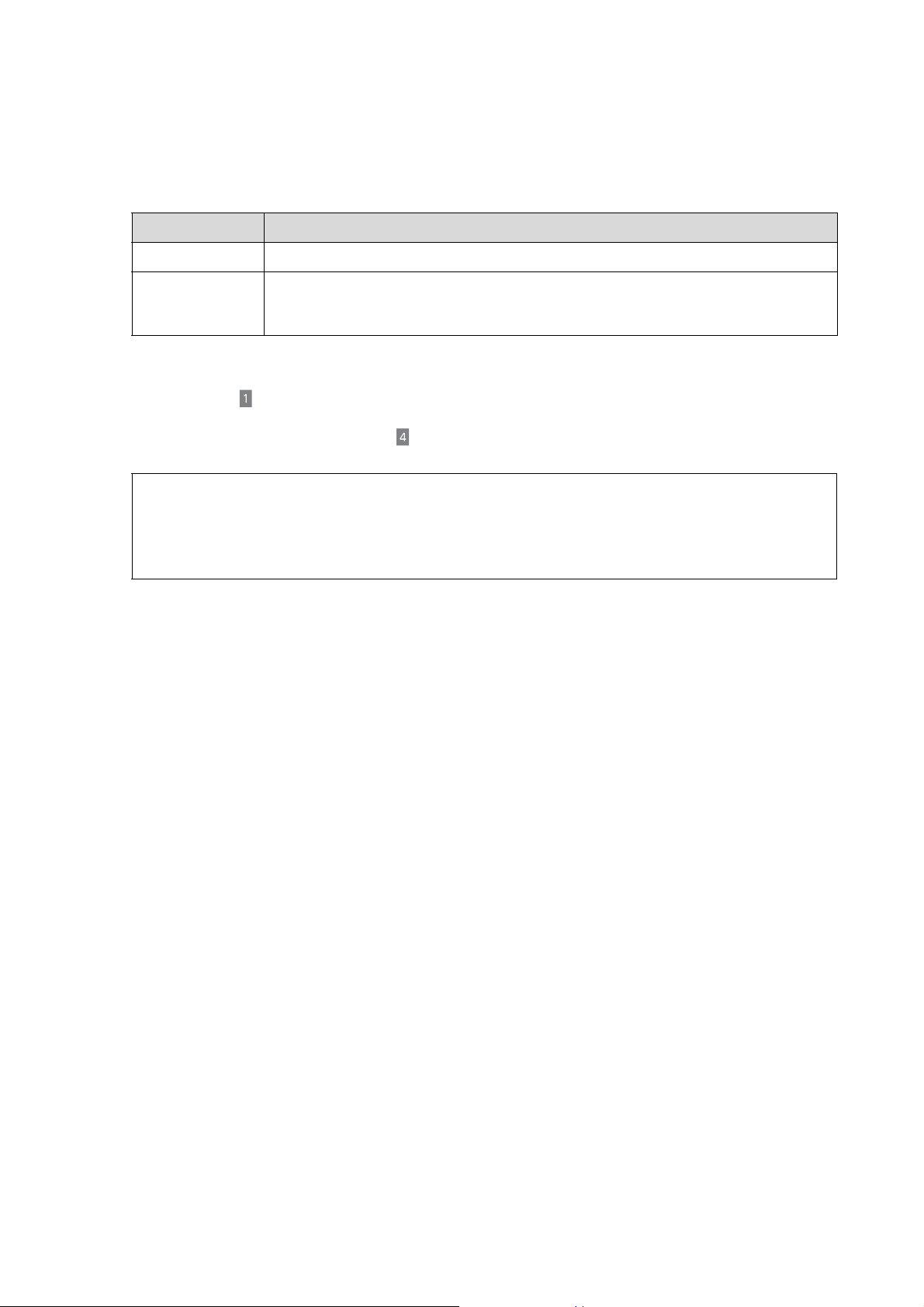

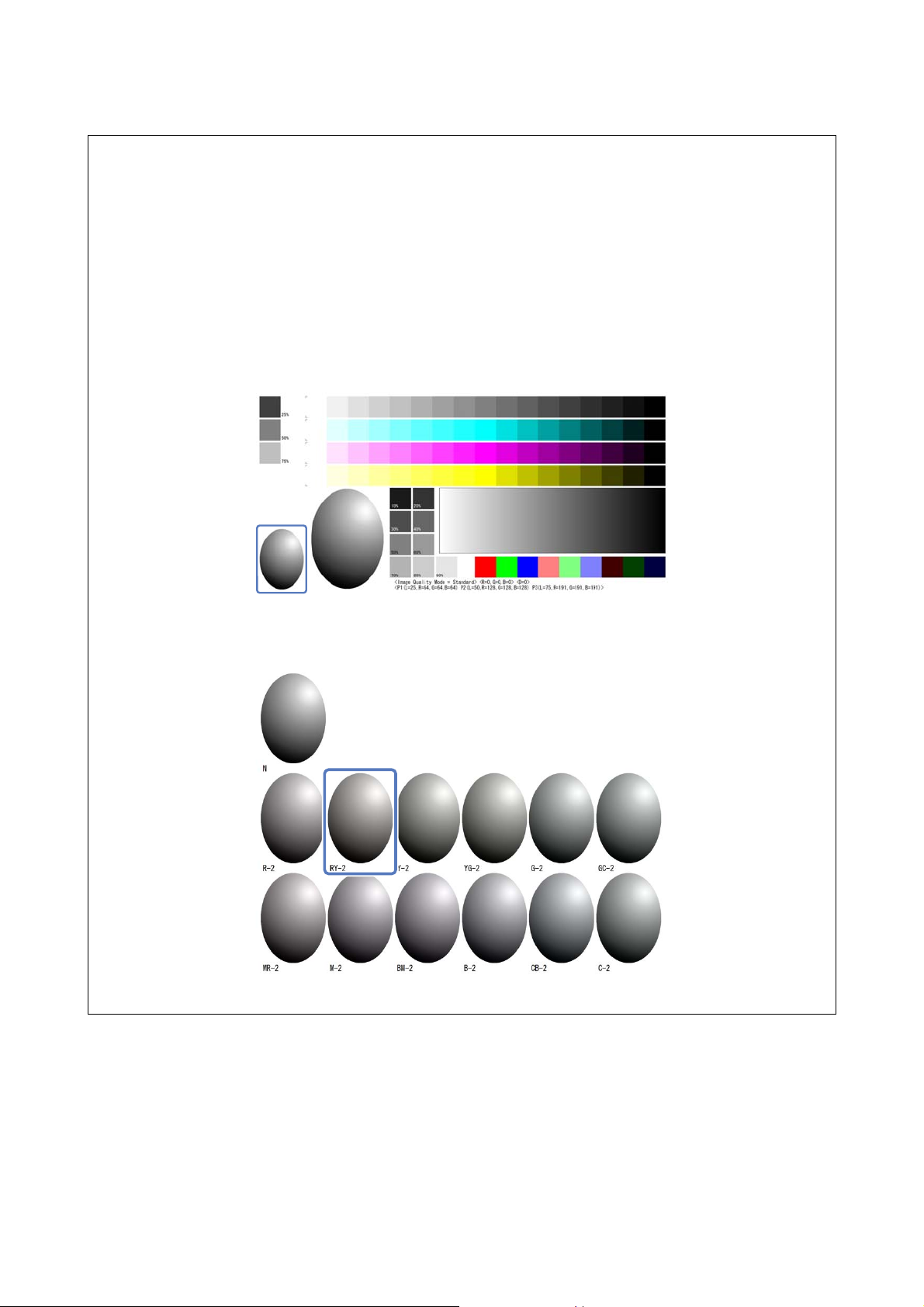

O If you are using multiple printers and you want to match the color balance between the printers, print a check pattern

for your main printer and an adjustment pattern for the printer that you want to match to the main printer. Adjust

the second printer using the setting on the adjustment pattern that is closest to the main printer.

Check pattern for main printer

Adjustment pattern for printer to be matched to the main printer (Select the color tone closest to the main

printer)

51

Page 52

Settings/Maintenance

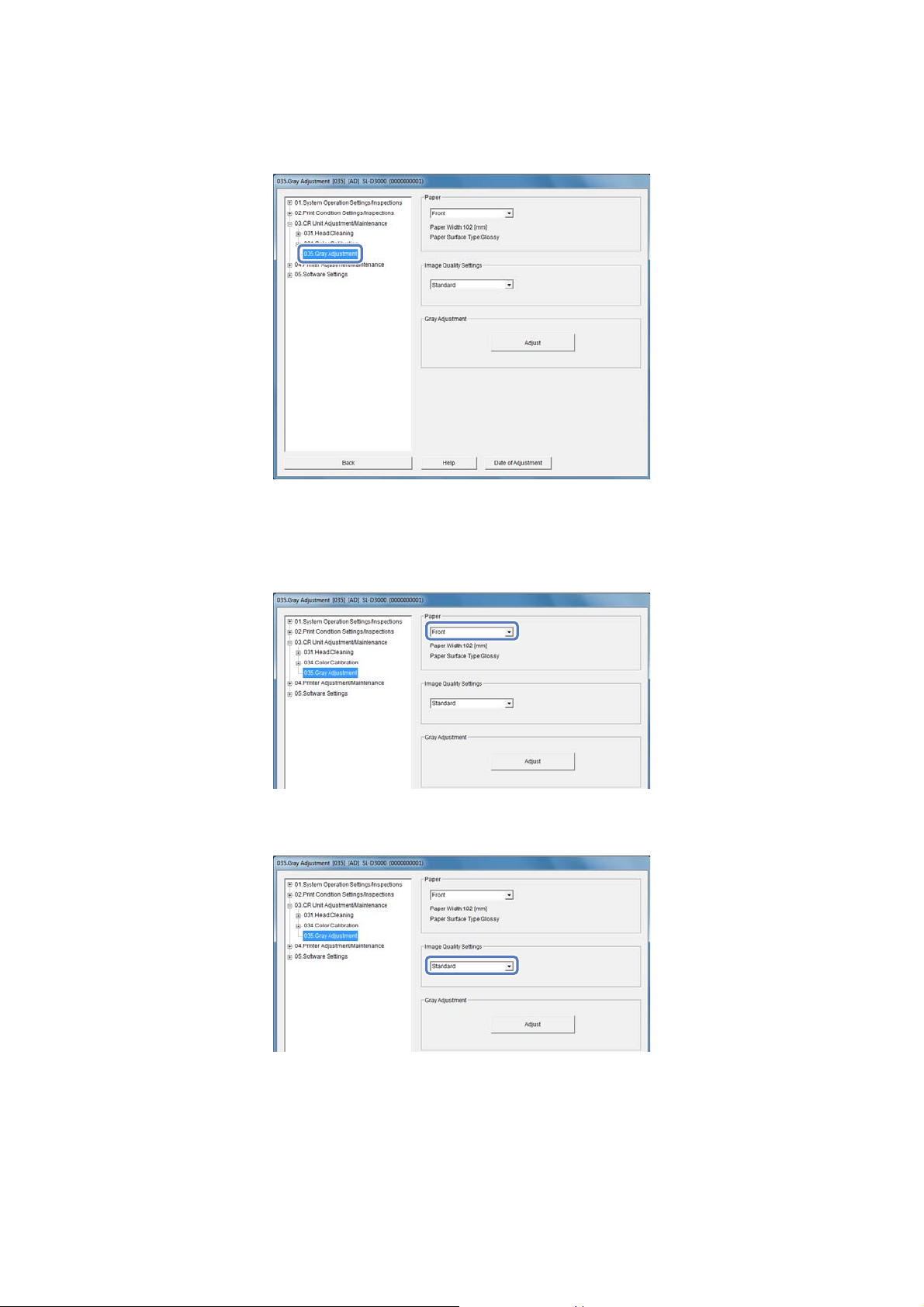

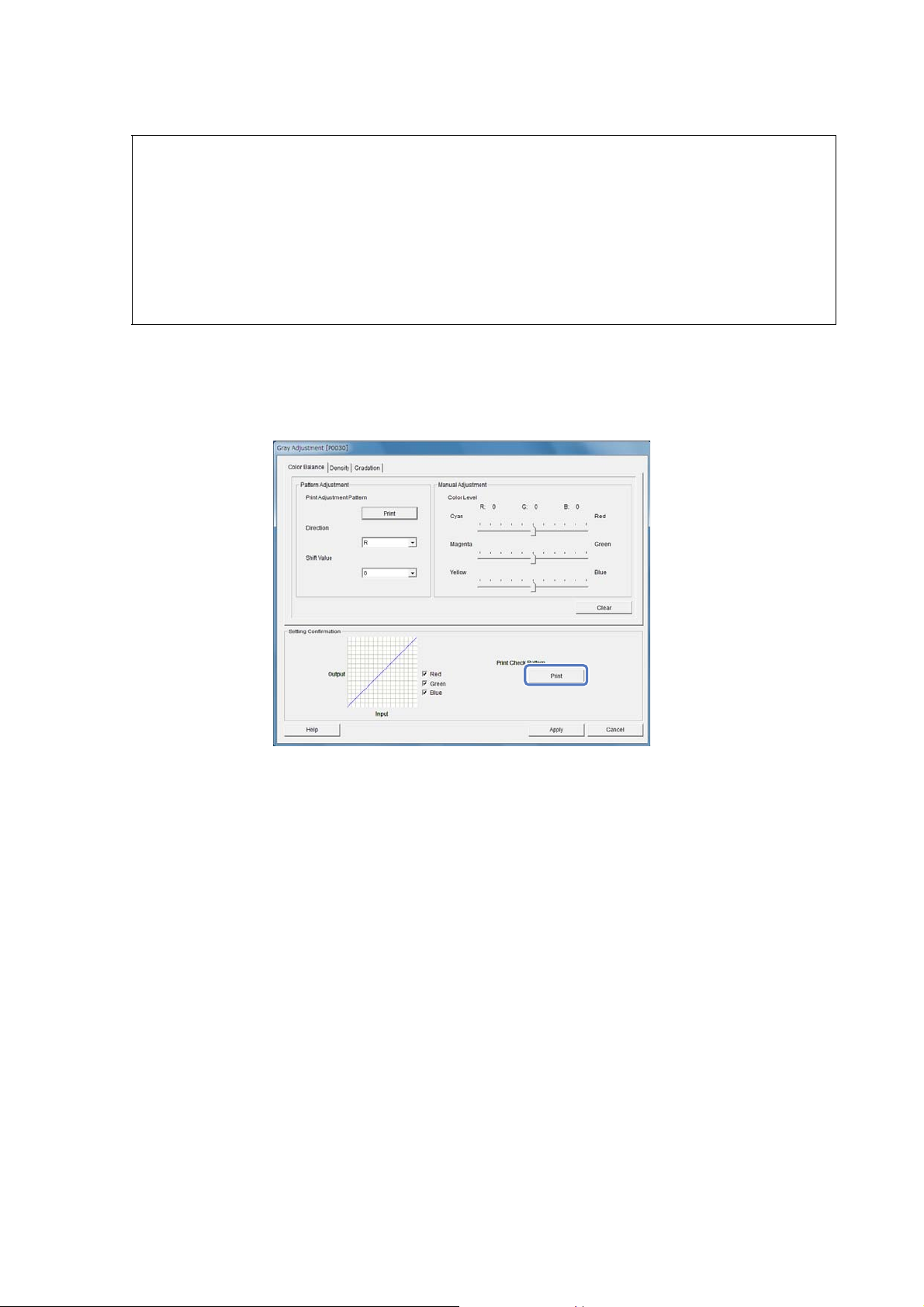

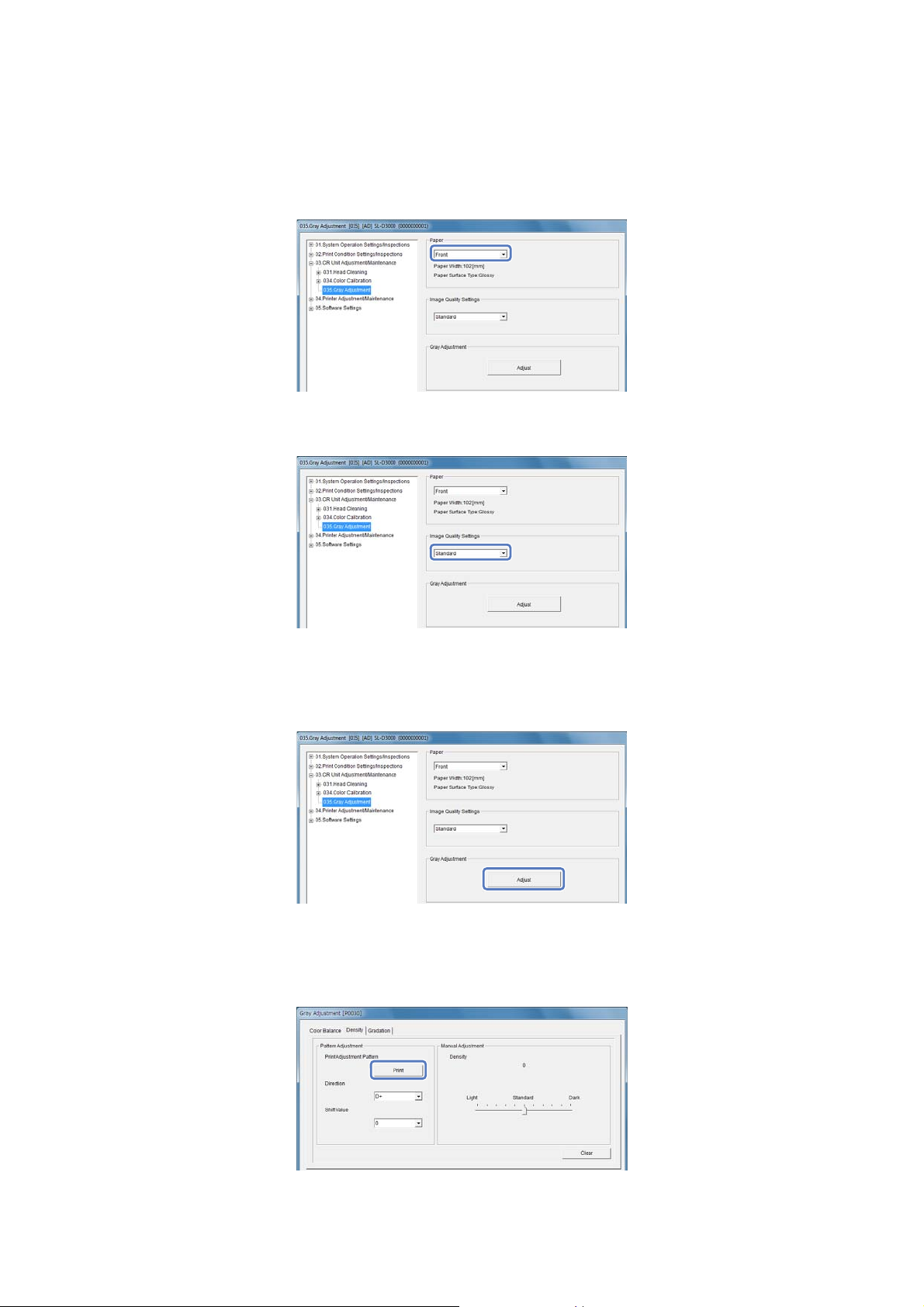

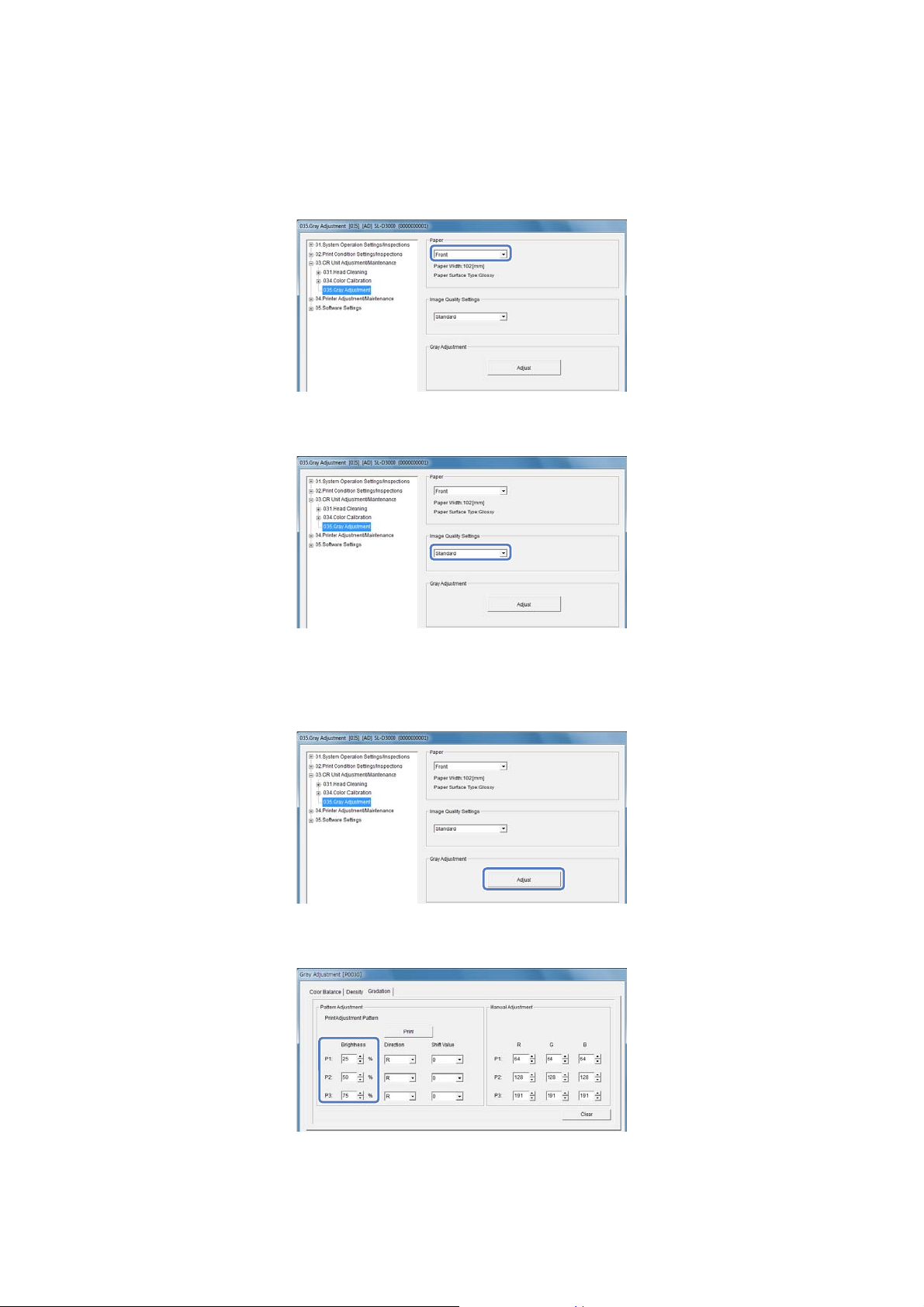

Click Gray Adjustment (035) from the CR Unit Adjustment/Maintenance (03) menu to display the settings.

Color Balance

From Paper, select the roll paper feeder that will be used to print the adjustment pattern.

A

From Image Quality Settings, select the image quality adjustment method.

B

52

Page 53

Settings/Maintenance

Click Adjust.

C

The settings screen is displayed.

Click Print from Print Adjustment Pattern on the Color Balance tab.

D

Select Adjustment Pattern Shift Value, and then click Print.

E

Select the larger value to print the adjustment pattern which indicates large differences between each

adjustment value.

To make fine adjustments, select a lower value.

Print the adjustment pattern.

53

Page 54

Settings/Maintenance

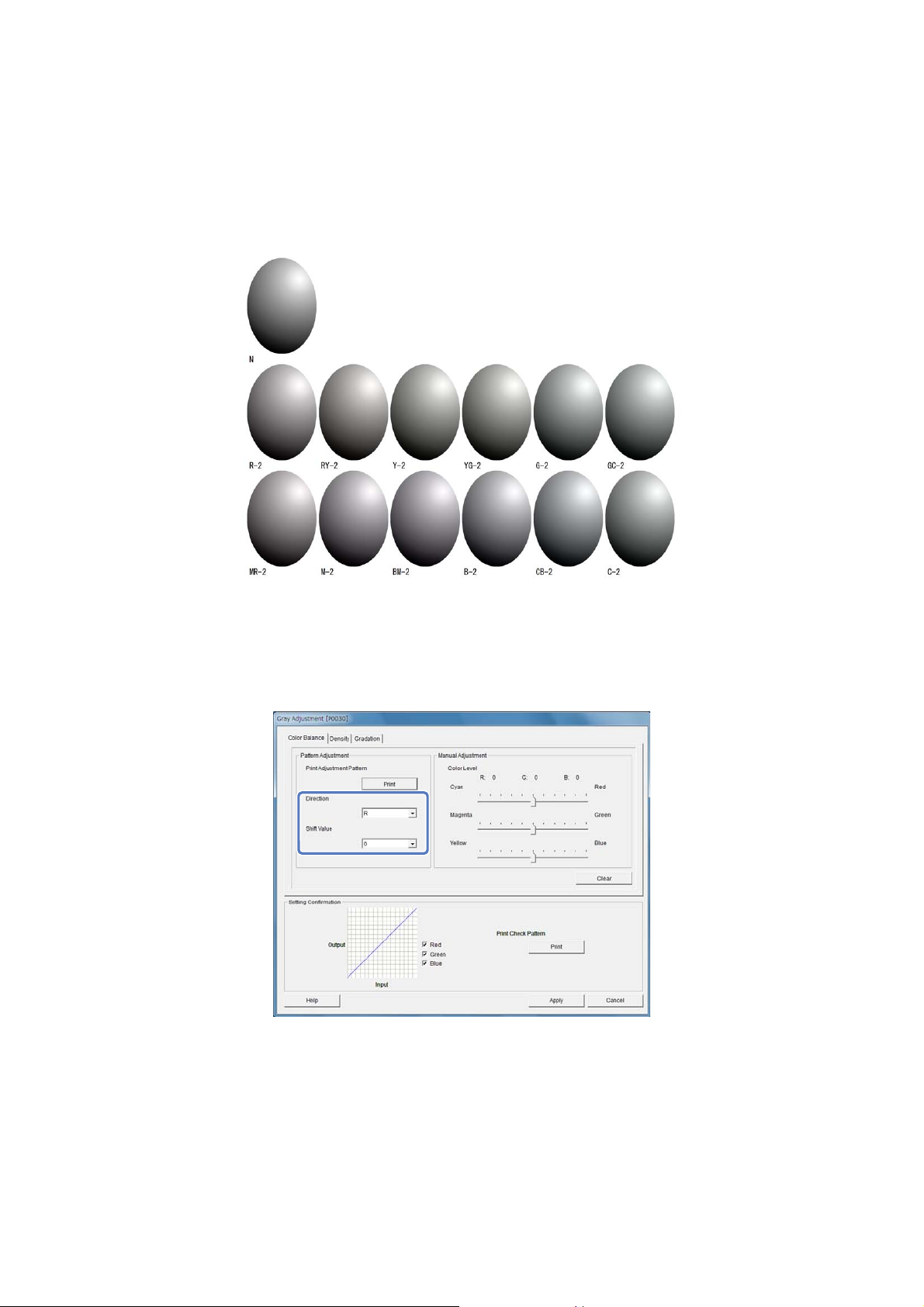

Select the best pattern from the adjustment pattern, and check the adjustment values.

F

The adjustment value is printed in letters and numbers at the bottom left of each pattern. (Example: RY-2)

The letter indicates the direction of the adjustment color. "N" means no correction.

The number shows the amount of changes.

Select the Direction and Shift Value.

G

Specify the adjustment value selected from the adjustment pattern.

When a setting is changed, the settings are reflected in the slide bar on the right of the screen and the graph

(tone curve) at the bottom of the screen.

54

Page 55

Note:

O The tone curve shows the output strength for each input color (R: Red, G: Green, B: Blue). When in an

uncorrected state (a straight line from top right to bottom left), the image darkens (colors become deeper)

when moved down, and the image lightens (the colors become paler) when moved up.

O You can manually adjust the color by using Manual Adjustment on the right of the screen. If you make

manual adjustments, the Pattern Adjustment value becomes unavailable.

O When you click Clear, the Color Balance adjustment values are returned to their default values. The Density

and Gradation values are retained.

Click Print from Print Check Pattern.

H

Prints the check pattern.

Check that the color balance is as intended.

Settings/Maintenance

Click Apply.

I

The settings are applied and the screen is closed.

55

Page 56

Settings/Maintenance

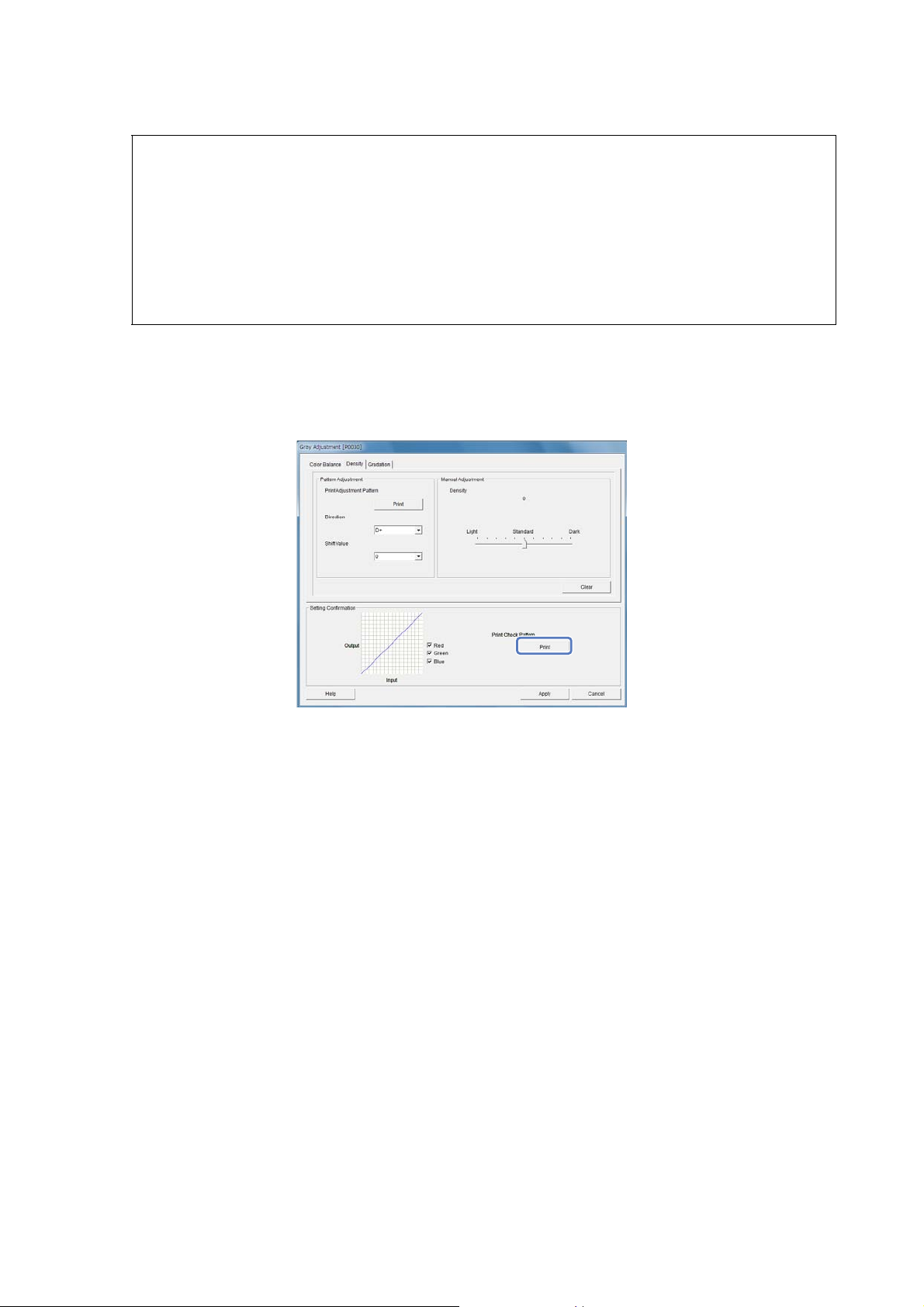

Density Correction

From Paper, select the roll paper feeder that will be used to print the adjustment pattern.

A

From Image Quality Settings, select the image quality adjustment method.

B

Click Adjust.

C

The settings screen is displayed.

Click Print from Print Adjustment Pattern on the Density tab.

D

The adjustment pattern is printed.

56

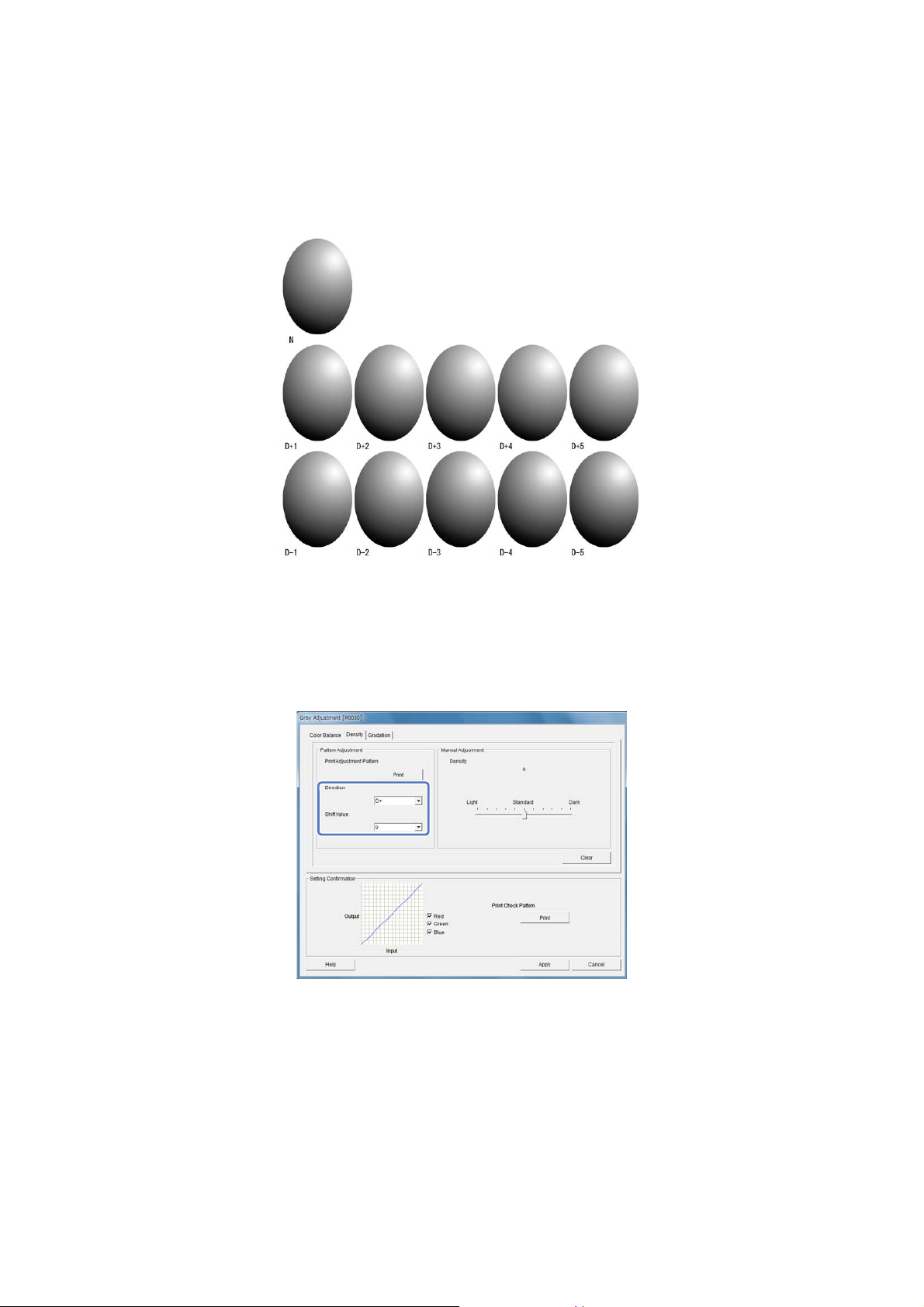

Page 57

Settings/Maintenance

Select the best pattern from the adjustment pattern, and check the adjustment values.

E

The adjustment value is printed in letters and numbers at the bottom left of each pattern. (Example: D-2)

"N" means no correction. The number shows the amount changed.

Select the Direction and Shift Value.

F

Specify the adjustment value selected from the adjustment pattern.

Select the light and shade (D+ and D-) using Direction, and set a numerical value using Shift Value.

When a setting is changed, the settings are reflected in the slide bar on the right of the screen and the graph

(tone curve) at the bottom of the screen.

57

Page 58

Note:

O The tone curve shows the output strength for each input color (R: Red, G: Green, B: Blue). When in an

uncorrected state (a straight line from top right to bottom left), the image darkens (colors become deeper)

when moved down, and the image lightens (the colors become paler) when moved up.

O You can manually adjust the density by using Manual Adjustment on the right of the screen. If you make

manual adjustments, the Pattern Adjustment value becomes unavailable.

O When you click Clear, the Density adjustment values are returned to their default values. The Color Balance

and Gradation values are retained.

Click Print from Print Check Pattern.

G

Prints the check pattern.

Check that the color balance is as intended.

Settings/Maintenance

Click Apply.

H

The settings are applied and the screen is closed.

58

Page 59

Settings/Maintenance

Gradation Correction

From Paper, select the roll paper feeder that will be used to print the adjustment pattern.

A

From Image Quality Settings, select the image quality adjustment method.

B

Click Adjust.

C

The settings screen is displayed.

On the Gradation tab, specify the brightness points as necessary (P1: Shadow, P2: Half-tone, P3: Highlight).

D

59

Page 60

Settings/Maintenance

Click Print from Print Adjustment Pattern.

E

Displays the screen setting the amount of change in the printed adjustment pattern.

Select Adjustment Pattern Shift Value, and then click Print.

F

Select the larger value to print the adjustment pattern which indicates large differences between each

adjustment value.

To make fine adjustments, select a lower value.

Select the amount of change for P1 (Shadow), P2 (Half-tone), and P3 (Highlight) according to the brightness

point.

The adjustment pattern is printed.

Select the best pattern from the adjustment pattern, and check the adjustment values.

G

The adjustment value is printed in letters and numbers at the bottom left of each pattern. (Example: R-2)

The letter indicates the direction of the adjustment color. "N" means no correction.

The number shows the amount changed.

Check P1 (Shadow), P2 (Half-tone), and P3 (Highlight) according to the brightness point.

60

Page 61

Settings/Maintenance

Select the Direction and Shift Value.

H

Specify the adjustment value selected from the adjustment pattern.

When a setting is changed, the settings are reflected in the values for Manual Adjustment on the right of the

screen and the graph (tone curve) at the bottom of the screen.

Note:

O The tone curve shows the output strength for each input color (R: Red, G: Green, B: Blue). When in an

uncorrected state (a straight line from top right to bottom left), the image darkens (colors become deeper)

when moved down, and the image lightens (the colors become paler) when moved up.

O You can manually adjust the gradation by using Manual Adjustment on the right of the screen. If you make

manual adjustments, the Pattern Adjustment value becomes unavailable.

O When you click Clear, the Gradation adjustment values are returned to their default values. The Color

Balance and Density values are retained.

Click Print from Print Check Pattern.

I

Prints the check pattern.

Check that the color balance is as intended.

Click Apply.

J

The settings are applied and the screen is closed.

61

Page 62

Settings/Maintenance

Problems with Gray Adjustment

Symptom Error Messages What to do

The print quality for the

adjustment pattern is too

low.

An error occurred while

applying the parameters.

Errors in the adjustments

have been applied. I want

to make adjustments

again.

The adjustment values

have been initialized.

-

"Try again after closing the

Settings/Maintenance

screen."

"Operation failed."

-

-

Is the print head clogged?

Print an adjustment pattern again after performing head

cleaning.

Are the PC and the printer connected to the spectrometer

correctly?

Check the connection between the PC and the printer, and then

click Apply again.

Is there enough free space on the PC's hard disk?

Make sure there is sufficient free space on the PC's hard disk, and

then click Apply again.

Initialize and then readjust.

Press Clear for the Color Balance, Density Adjustment, and

Gradation Correction to initialize the settings, and then make

adjustments again.

Have adjustment values been initialized after performing

color calibration?

Perform gray adjustment again.

62

Page 63

Settings/Maintenance

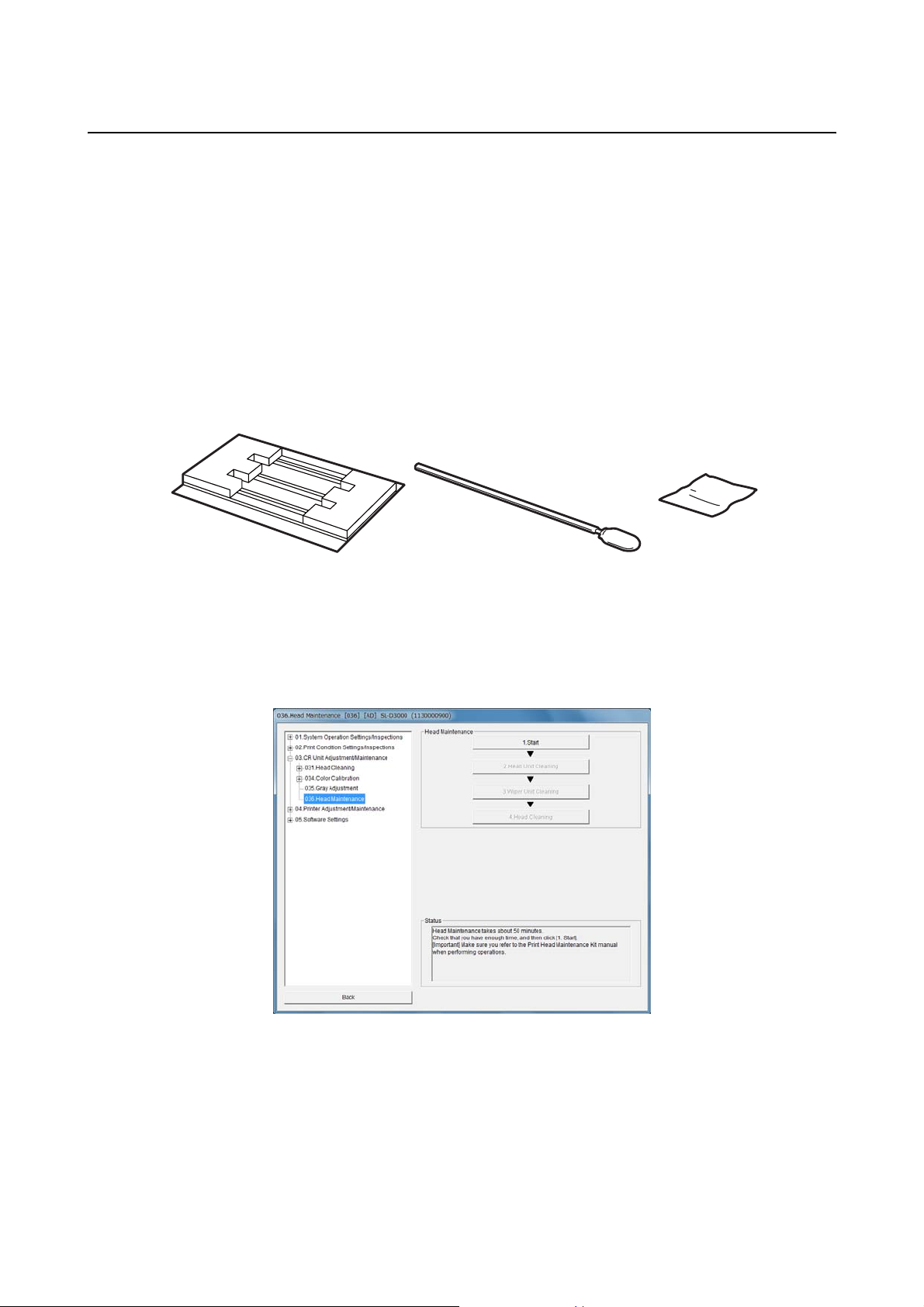

Print Head Maintenance

To prevent print head quality from declining, or to restore print quality, clean the print head unit and the wipers for

the print head.

Perform cleaning in the following situations.

O When streaks or smears caused by drops of ink appear on the surface of the prints

O When you want to avoid streaks or smears caused by drops of ink appearing in the prints

To perform this type of cleaning, you need the optional Print Head Maintenance Kit (C12C890991).

Click Head Maintenance (036) from the CR Unit Adjustment/Maintenance (03) menu.

For more information on performing head maintenance, see the User's Guide supplied with the Print Head

Maintenance Kit.

63

Page 64

Settings/Maintenance

Printer Adjustment/Maintenance

In Printer Adjustment/Maintenance (04) on the Settings/Maintenance screen, you can check Operation History

(044) and Parts Replacement History (045).

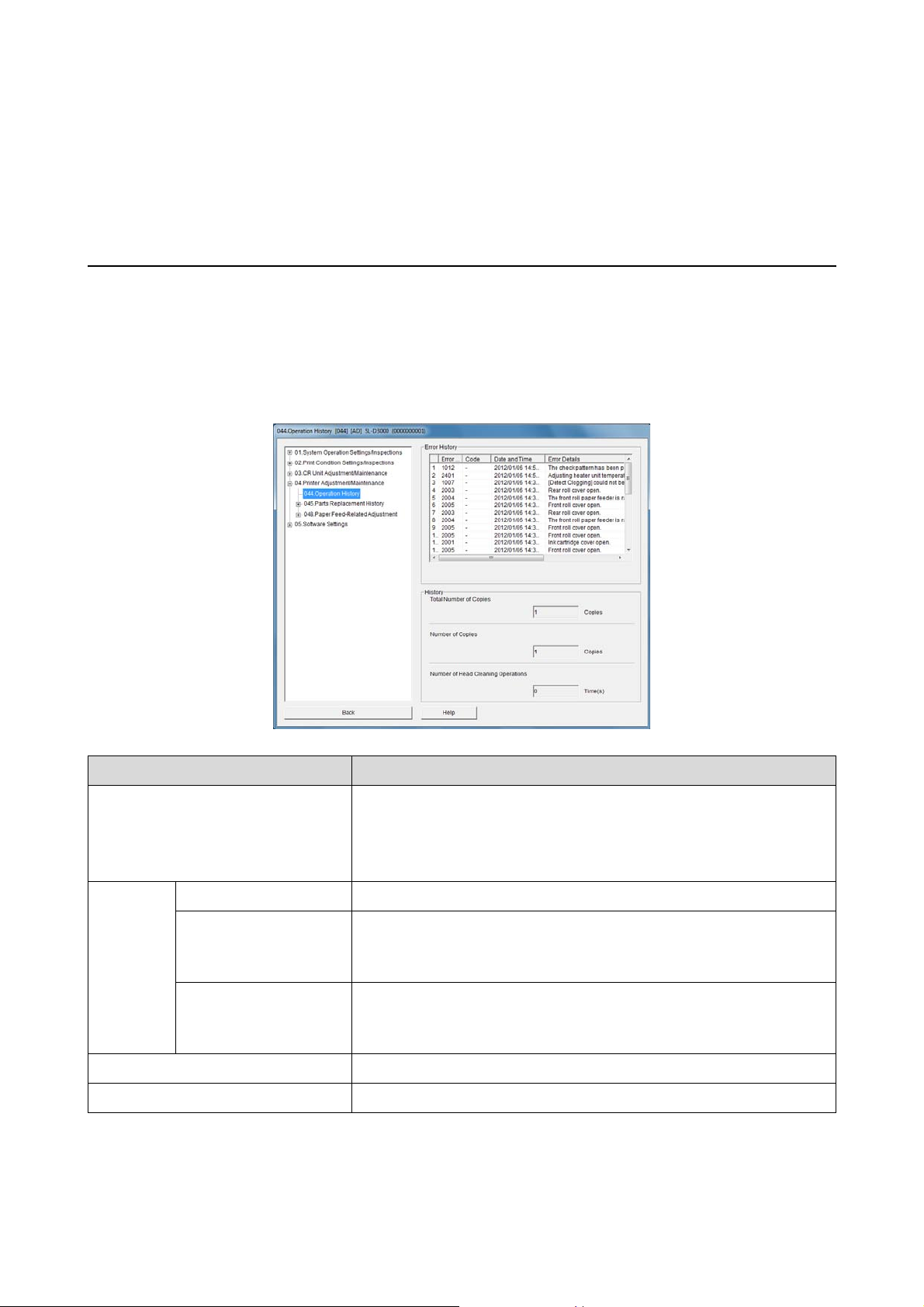

Operation History

Click Operation History (044) from Printer Adjustment/Maintenance (04) to display the screen.

You can check errors that have occurred, the number of prints, and the number of head cleaning operations in the

printer.

Item Explanation

Error History Displays up to 100 errors that have occurred in the printer, and information.

Error ID indicates the error number.

Error History may be cleared by service personnel as it is used for management

information when performing maintenance.

History Total Number of Copies Displays the total number of copies.

Number of Copies Displays the number of copies.

This number may be cleared by service personnel as it is used for management

information when performing maintenance.

Number of Head Cleaning

Operations

Back Click to close the Settings/Maintenance screen.

Help Click to display the Help.

Displays the number of head cleaning operations.

This number may be cleared by service personnel as it is used for management

information when performing maintenance.

64

Page 65

Settings/Maintenance

Parts Replacement History

In Parts Replacement History (045), you can confirm the replacement day for parts that need to be replaced

periodically in Register Replacement Date for Periodically Replaced Parts (0451), and check the amount of usage for

each part in Clear Counter 1 (0452).

Register Replacement Date for Periodically Replaced Parts

From the Printer Adjustment/Maintenance (04) menu, click Register Replacement Date for Periodically Replaced

Parts (0451) from Parts Replacement History (045) to display the screen.

You can check the date that parts that need periodic replacement were replaced.

Service personnel can set the date.

Clear Counter 1

From the Printer Adjustment/Maintenance (04) menu, click Clear Counter 1 (0452) from Parts Replacement

History (045) to display the screen.

You can check the counters for each part.

This number may be cleared by service personnel as it is used for management information when performing

maintenance.

65

Page 66

Settings/Maintenance

Paper Feed-Related Adjustment

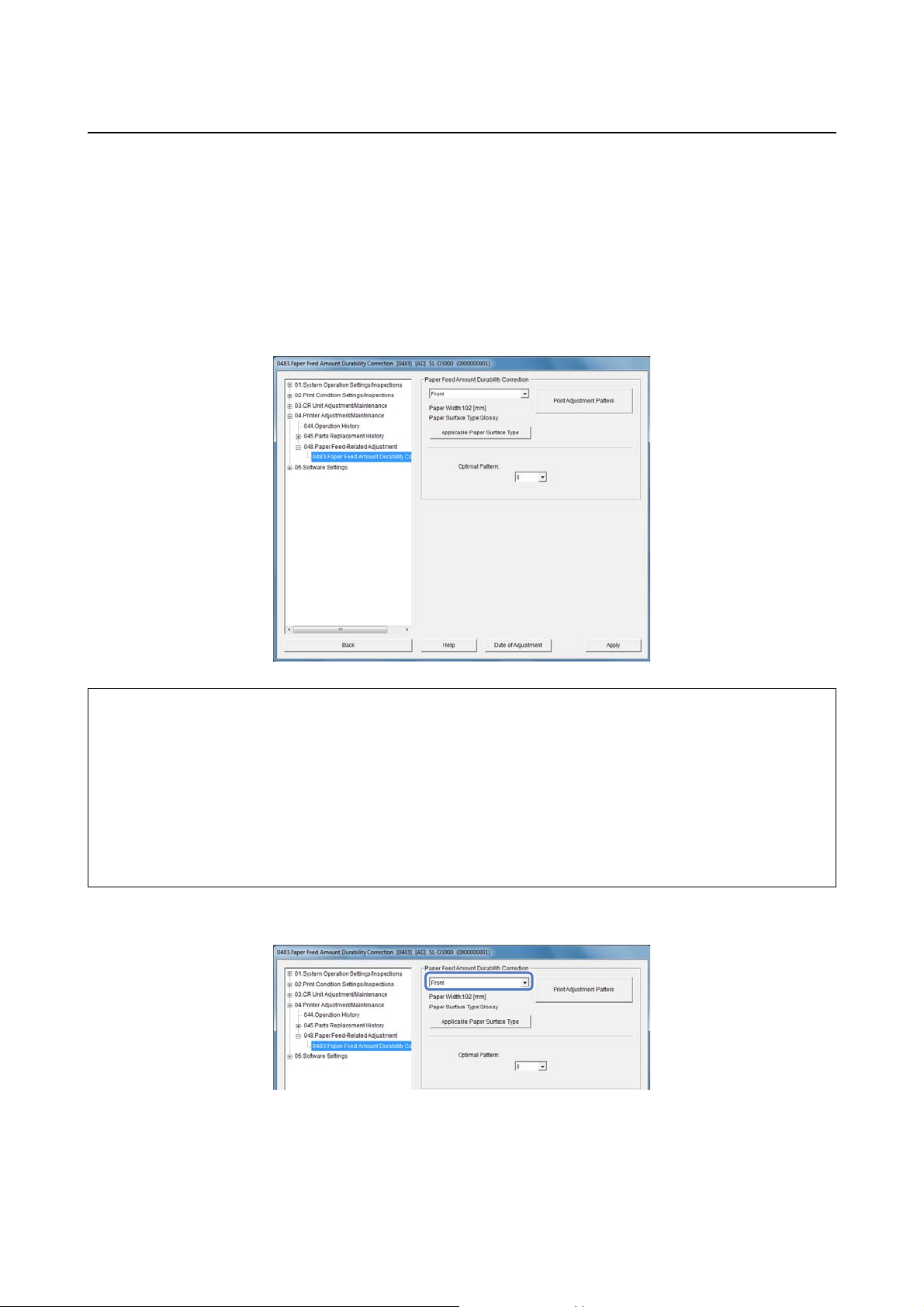

Paper Feed Amount Durability Correction

From the Printer Adjustment/Maintenance (04) menu, click Paper Feed Amount Durability Correction (0483)

from Paper Feed-Related Adjustment (048) to display the screen.

The paper feed amount may change due to environmental changes or time-dependent changes. If the print quality

deteriorates, correcting the paper feed amount may improve the print quality.

Tip:

O Correct for each Paper Width and Paper Surface Type.

O You do not need to adjust paper with a width of 8 inches and A4 size paper separately. These are considered to be the

same width.

O Click Applicable Paper Surface Type to check if the value for the paper surface type used for adjusting can be used

for other paper surface types.

O Click Date of Adjustment to display the time when it was last adjusted. You can check the changed date settings for

each Paper Surface Type.

In Paper, select the roll paper feeder you want to use for printing.

A

66

Page 67

Click Print Adjustment Pattern.

B

The adjustment pattern is printed.

Settings/Maintenance

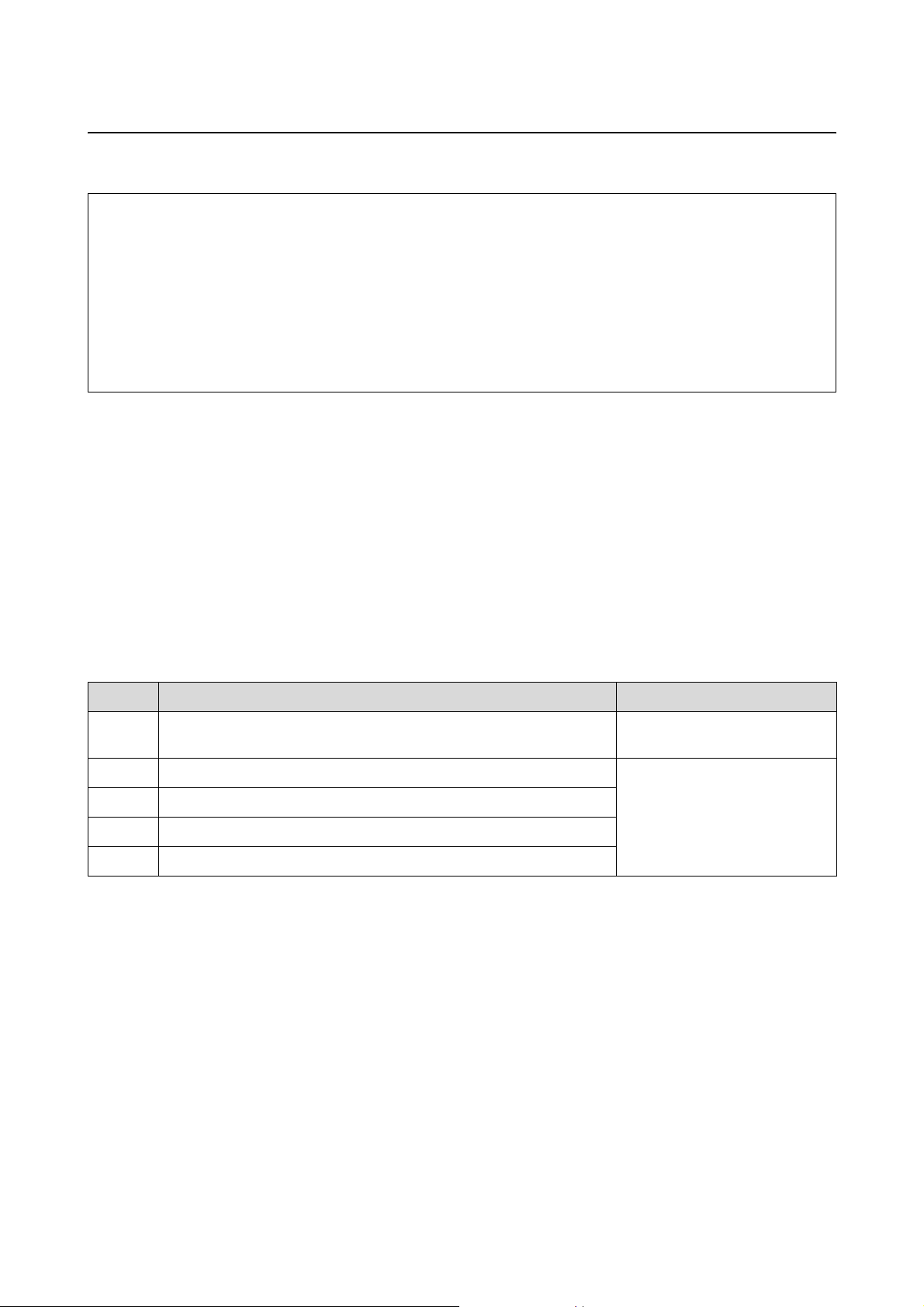

Select the optimal number from the adjustment patterns, and then click Apply.

C

Tip:

O See the following and select the print pattern that has no black or white lines.

O If there are no "good" patterns in the printed adjustment patterns, enter the number that is closest to "good",

and then print the adjustment patterns again.

67

Page 68

Settings/Maintenance

Software Settings

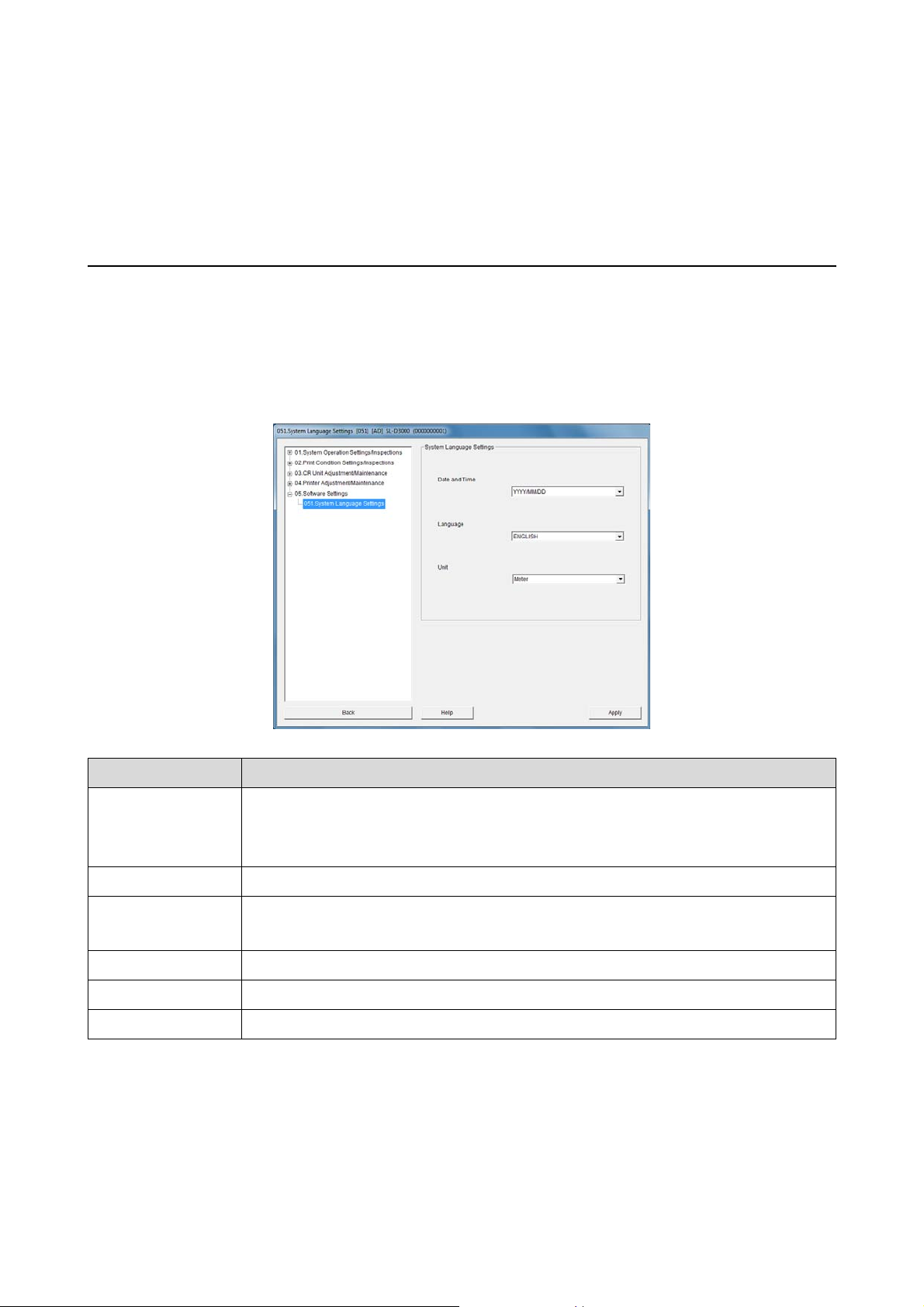

In Software Settings (05) on the Settings/Maintenance screen, you can set the date, language, and units in System

Language Settings (051).

System Language Settings

Click System Language Settings (051) from Software Settings (05) to display the screen. Set the date, language, and

units that are displayed on the screen.